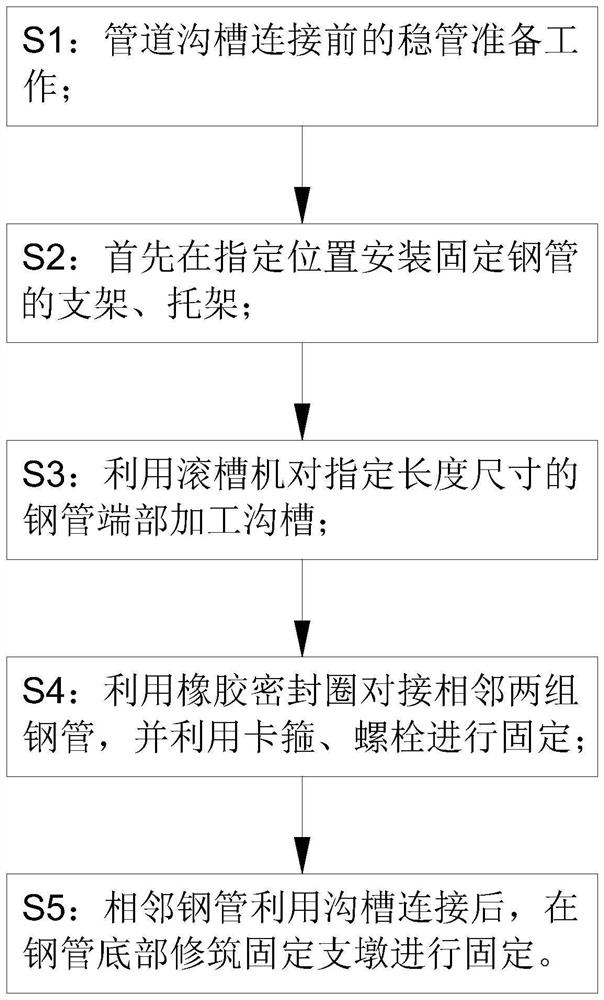

Construction method for pipeline groove connection

A construction method and technology for pipeline trenches, which are applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of water seepage at the joints of pipes, affecting normal use, lack of rigorous construction methods, etc., to avoid the problem of trench deviation. , Improve the effect of groove machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

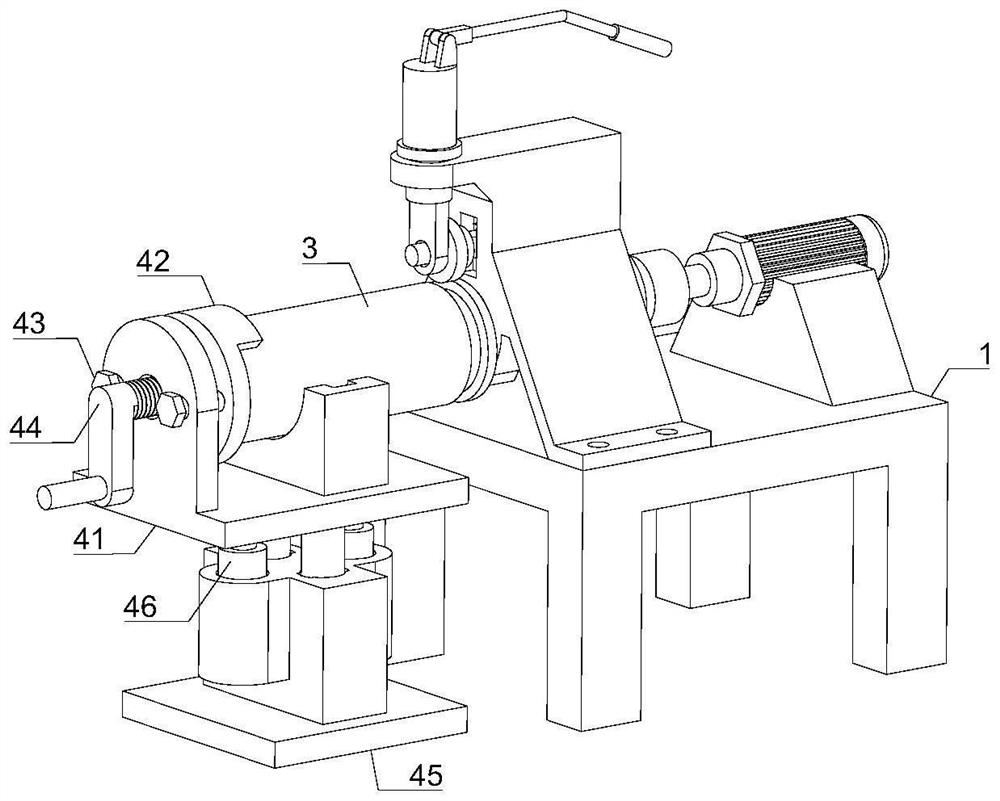

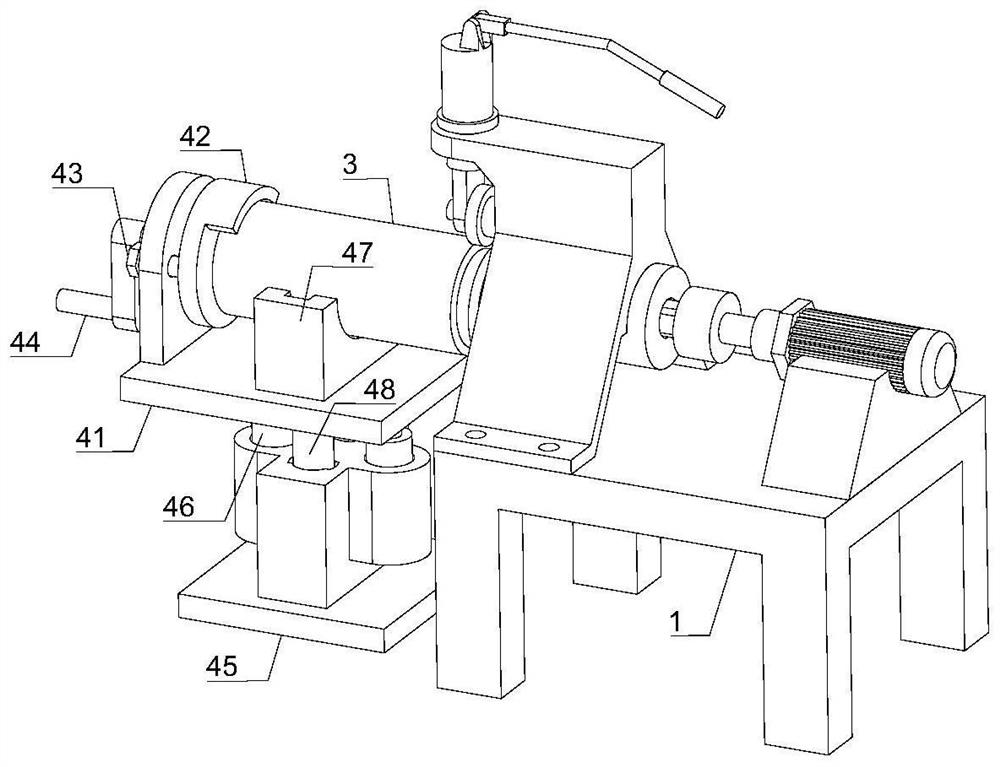

[0058] As an embodiment of the present invention, the inside of the bottom support plate 45 is provided with a movable groove 451 corresponding to the connecting rod 48, and a spring 452 is fixedly connected to the bottom of the movable groove 451; the connecting rod 48 is movably connected to the Inside the active slot 451.

[0059] Specifically, when the top support plate 41 and the bottom support plate 45 are driven away by the cylinder 46, the connecting rod 48 at the bottom of the top support plate 41 will move in the movable groove 451 inside the bottom support plate 45, and at the same time be positioned on the bottom support plate 45. The inner spring 452 will no longer be squeezed by the connecting rod 48, and when the connecting rod 48 returns to the inside of the bottom support plate 45, the connecting rod 48 will squeeze the spring 452 and make the spring 452 generate elastic potential energy.

[0060] As an embodiment of the present invention, the limit seat 47 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com