A high-precision circular knitting machine needle cylinder molding method and molding equipment

A large circular knitting machine and forming method technology, applied in knitting, weft knitting, metal processing equipment, etc., can solve the problems of insufficient precision, high scrap rate, low production efficiency of needle cylinders, etc., to improve efficiency, improve production efficiency, Effective use of grooving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

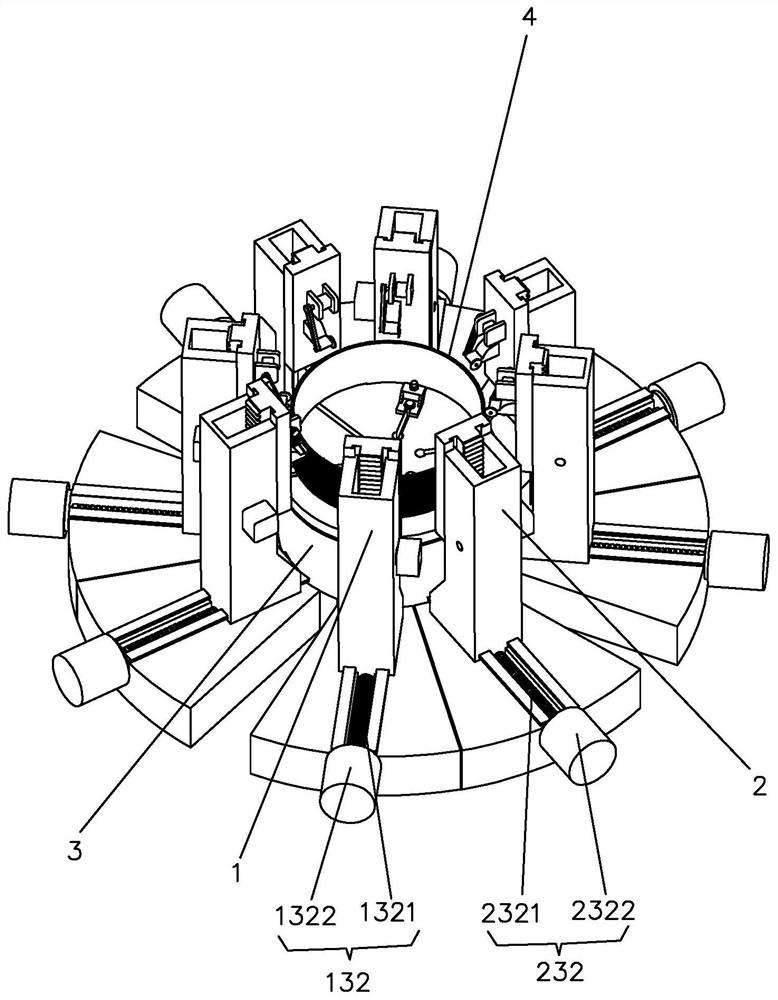

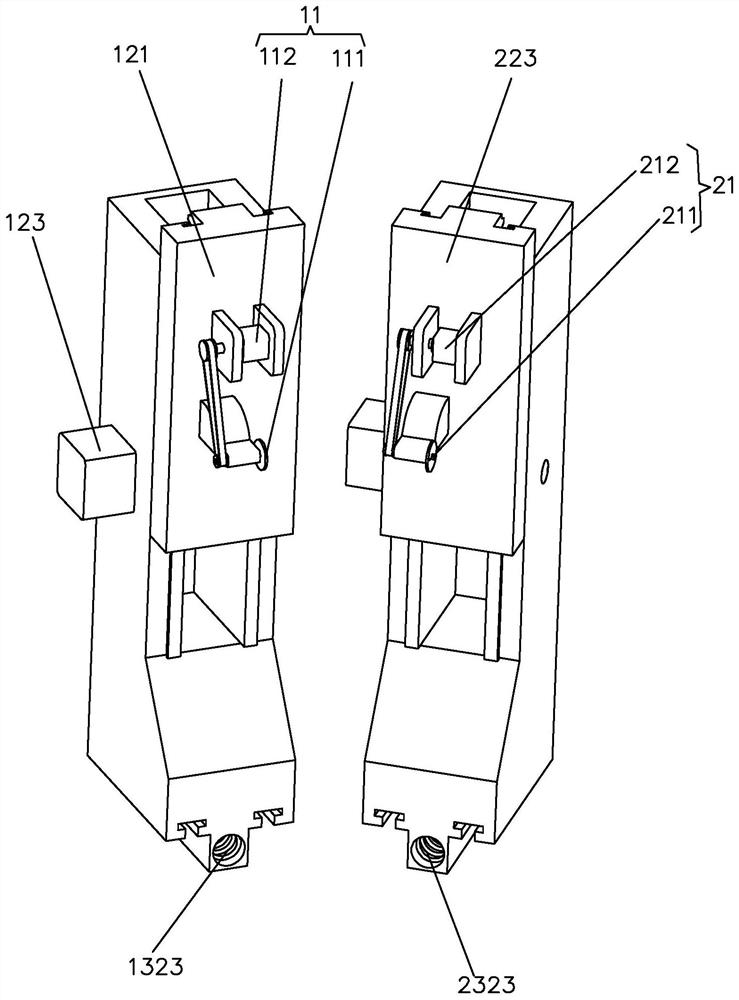

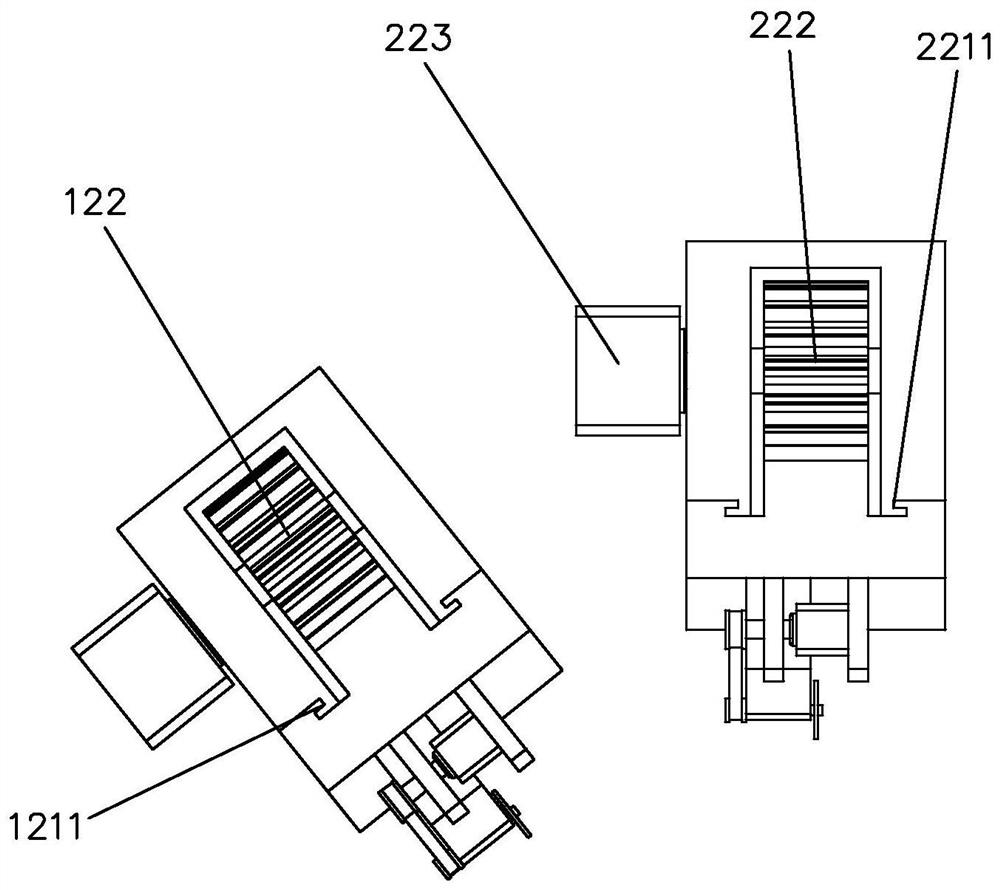

[0058] Such as Figure 1-5 As shown, a high-precision circular knitting machine needle cylinder molding method is characterized in that: comprising the following steps:

[0059] (1) Carry out rough turning on the blank syringe;

[0060] (2) Carry out finish turning on the blank needle cylinder after rough turning to form a needle cylinder without needle groove;

[0061] (3) Milling grooves on the outer surface of the needle cylinder without needle grooves to form needle grooves;

[0062] (4) grinding the needle groove formed in the step (3) to remove burrs;

[0063] (5) Inspect the needle groove of the polished needle cylinder to determine whether it is qualified;

[0064] In steps (3) and (4), the needle cylinder is grooved by using the needle cylinder forming method of a high-precision circular knitting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com