Patents

Literature

92results about How to "Improve groove quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

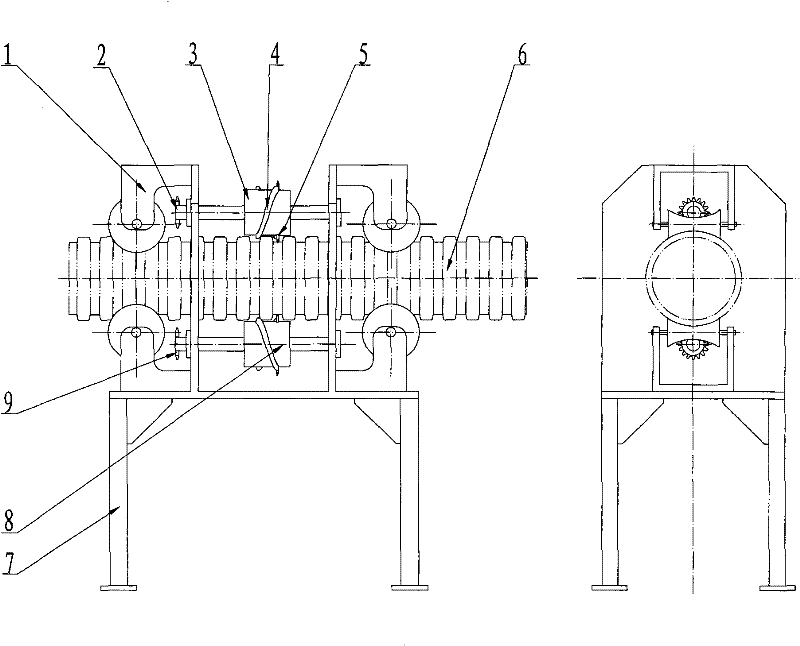

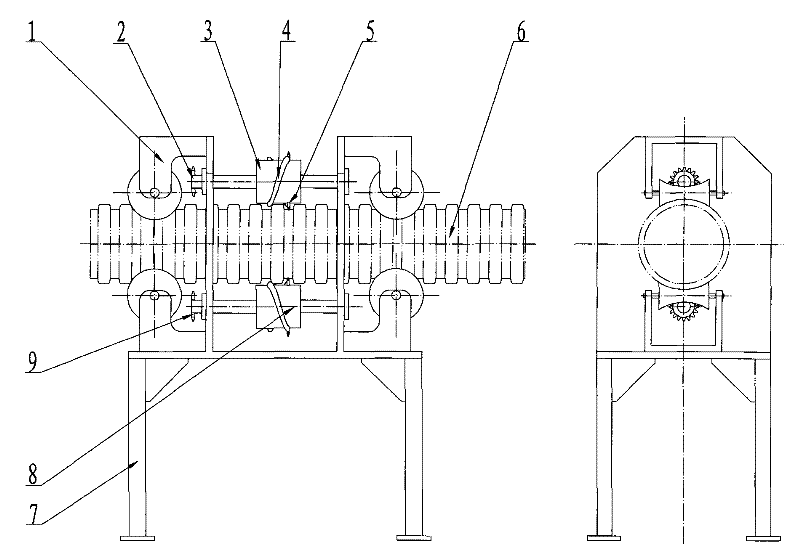

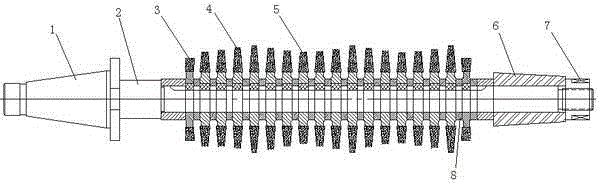

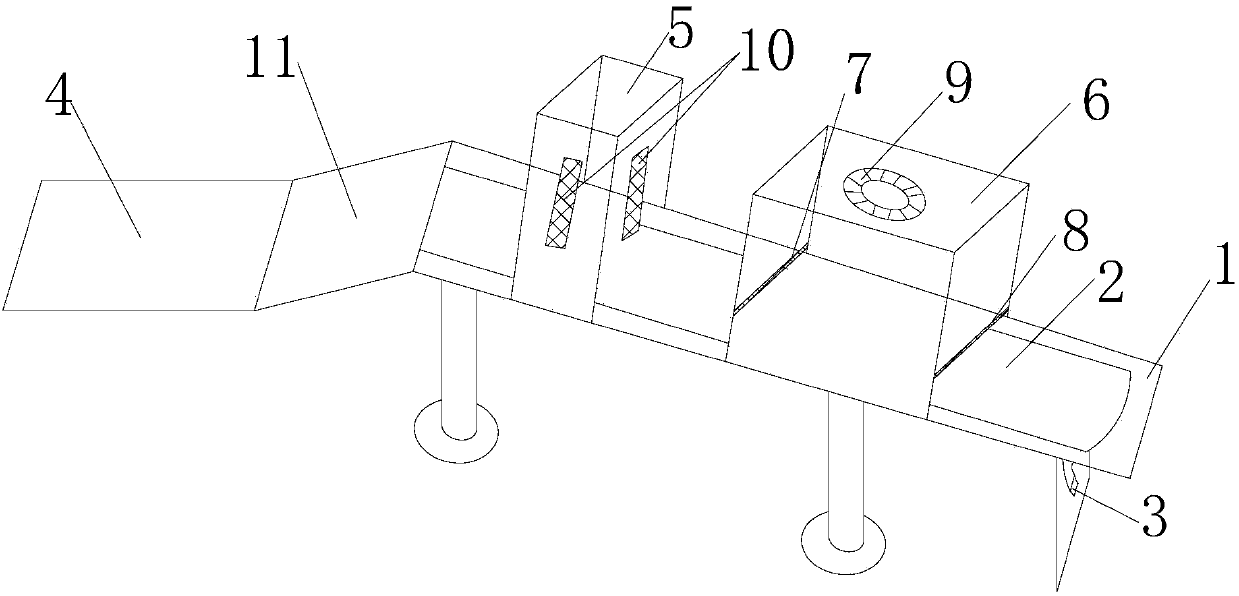

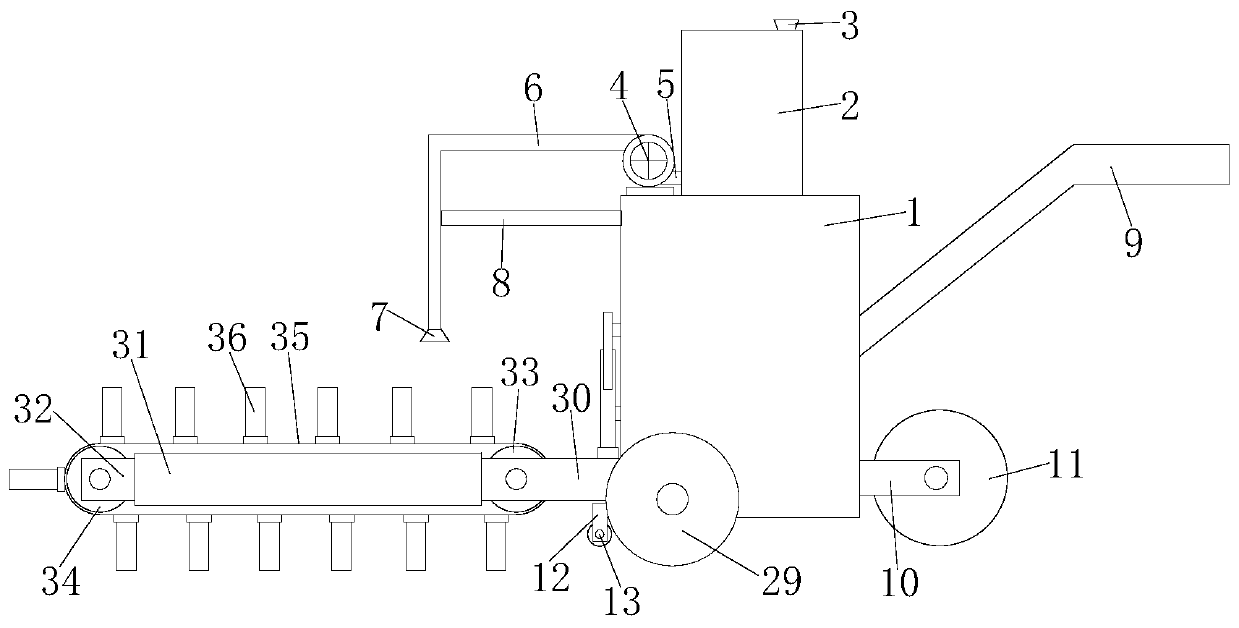

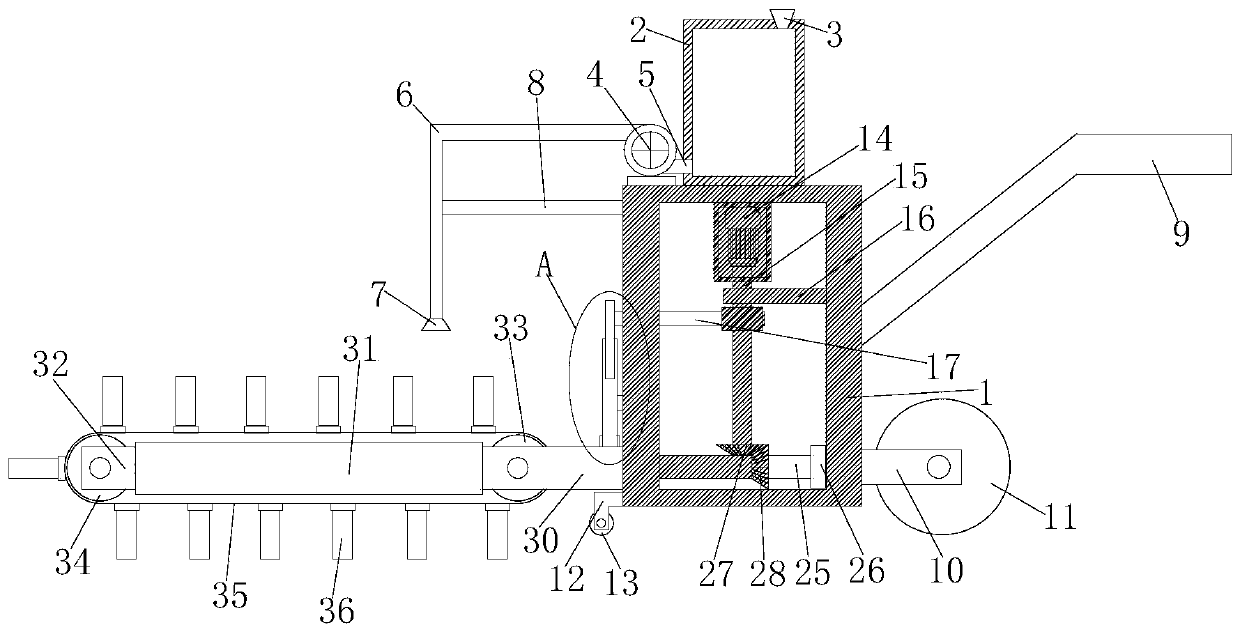

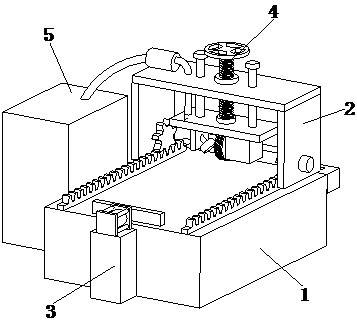

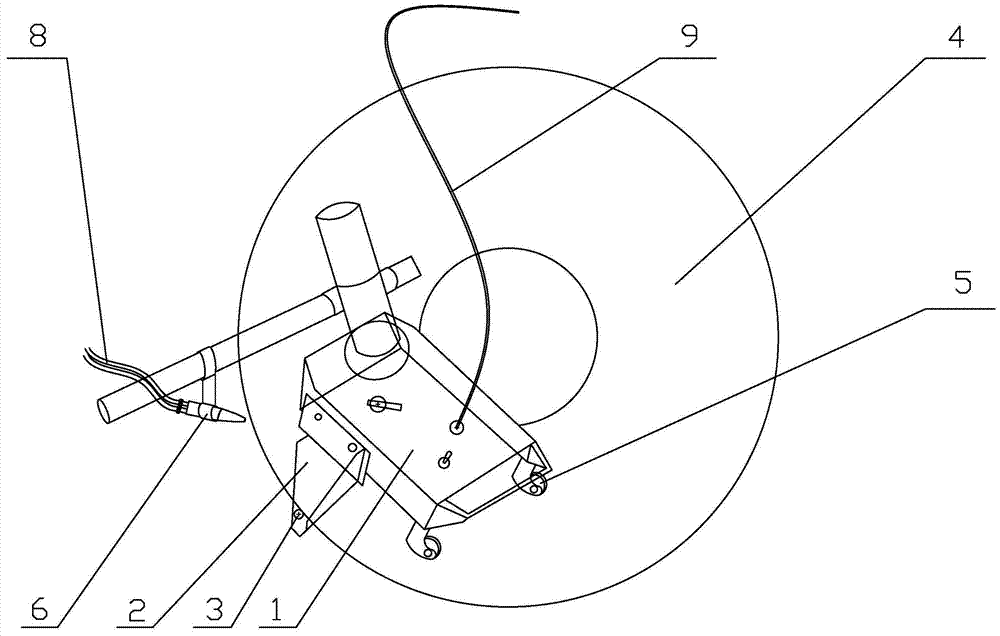

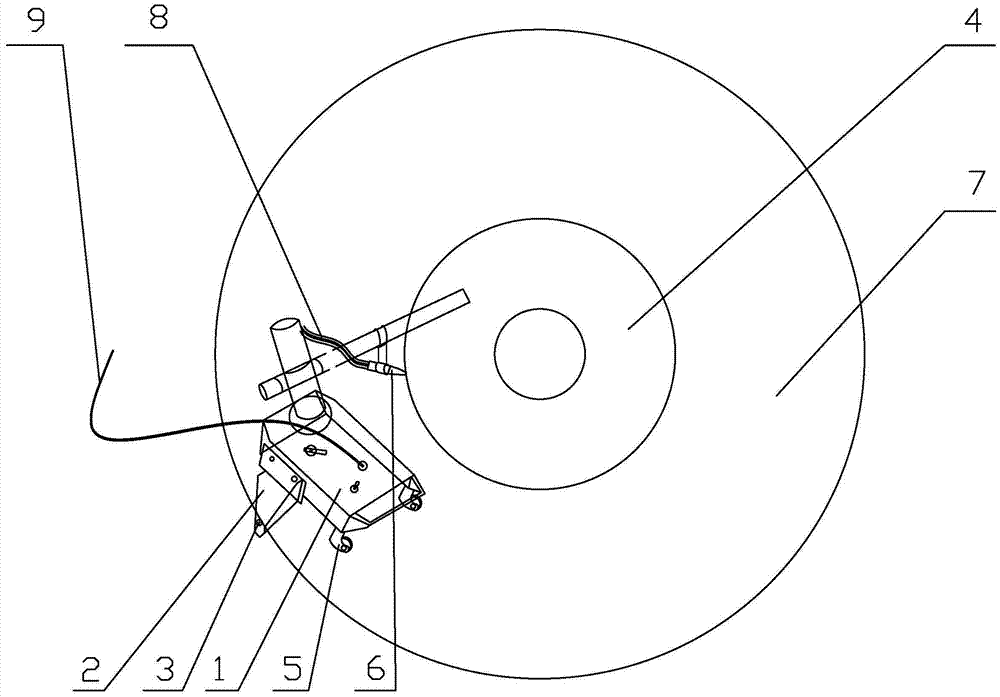

Worm-type plastic corrugated pipe grooving machine

The invention relates to a worm-type plastic corrugated pipe grooving machine. Function of conveying plastic corrugated pipes is completed by a worm curve fixed on a cutter bar of a grooving cutter; the functions of cutting and grooving are realized by one alloy cutter head arranged at the terminal of the worm curve, the worm curve is meshed with wave crests of the plastic corrugated pipes, the plastic corrugated pipes advance for one pitch when being pushed by the worm curve once the cutter bar rotates for a circle, namely the plastic corrugated pipes advance to the next wave crest from the current wave crest, the alloy cutter head arranged at the terminal of the worm curve carries out grooving on the current wave crest for once, the alloy cutter head arranged at the terminal of the worm curve is vertical to axes of the plastic corrugated pipes to ensure that a blade is in a cutting interval while the plastic corrugated pipes do not axially move, the plastic corrugated pipes continuously axially move along with rotation of the cutter bar, and the blade carries out grooving on the wave crest one by one. The grooving machine provided by the invention has simple mechanical structure, no independent pipe conveying device or electronic and electrical inductive control system is required, grooving position is accurate, grooving quality is greatly improved, and rejection rate is greatly reduced while grooving efficiency is greatly improved.

Owner:ZHANGJIAGANG BEIER MACHINERY

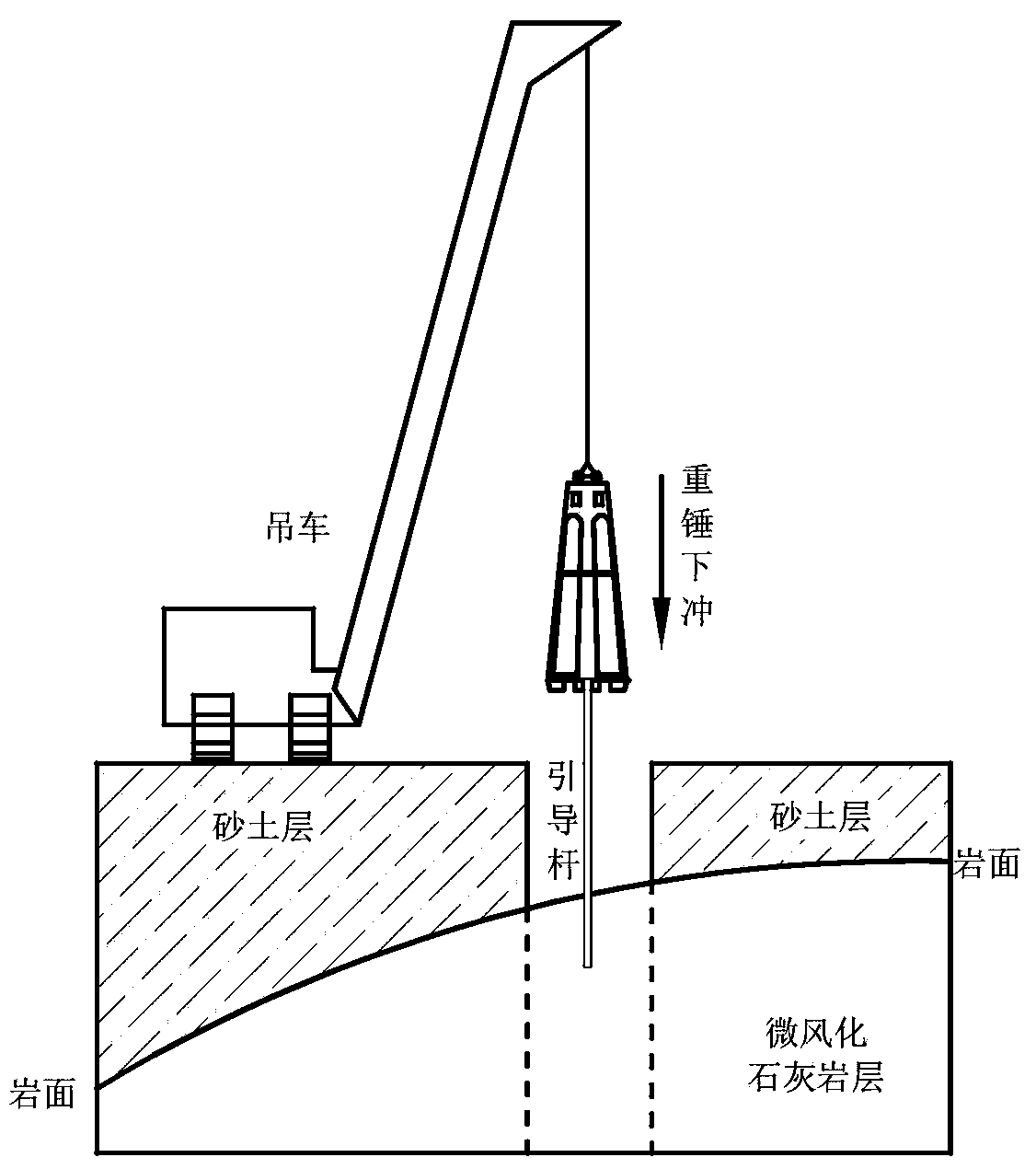

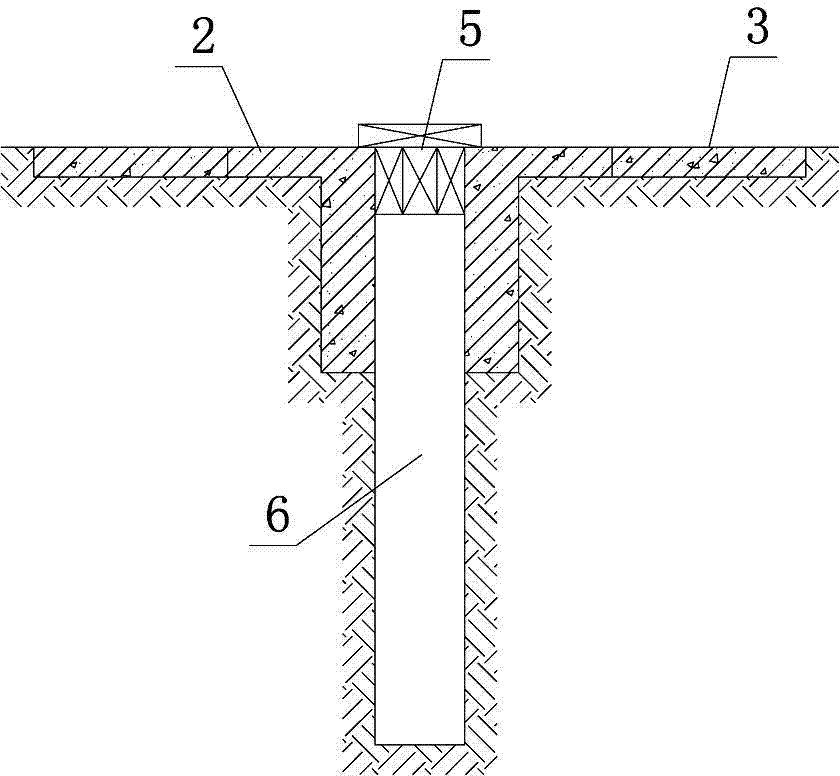

Effective grooving construction method for underground continuous wall in slightly-weathered limestone with overlying sandy soil

ActiveCN103437341AGood hammering effectGood construction performanceArtificial islandsSoil-shifting machines/dredgersSlurry wallEconomic shortage

The invention provides an effective grooving construction method for an underground continuous wall in slightly-weathered limestone with overlying sandy soil. The method specifically comprises the steps of 1) performing core drilling in a grooving area to determine rock characters; 2) measuring the position of a setting-out calibration guide wall; 3) performing guide wall construction and determining the distribution of hole punching positions; 4) drilling guide holes, and installing guide rods; 5) punching a rock layer by using a heavy hammer and grabbing crushed rocks by using a grooving machine; 6) brushing a wall by using a square hammer and connecting the holes to form a groove; 7) cleaning the bottom of the groove to finish the grooving construction. The construction method provided by the invention has the advantages that the defects and the shortages of unsafe and unstable factors, slow construction progress, poor grooving quality and the like are overcome, and the effective, low-cost and high-accuracy grooving construction in the slightly-weathered limestone is realized; the construction effect is good, the grooving speed is fast, the construction process is simple and convenient and the construction period is greatly shortened.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +1

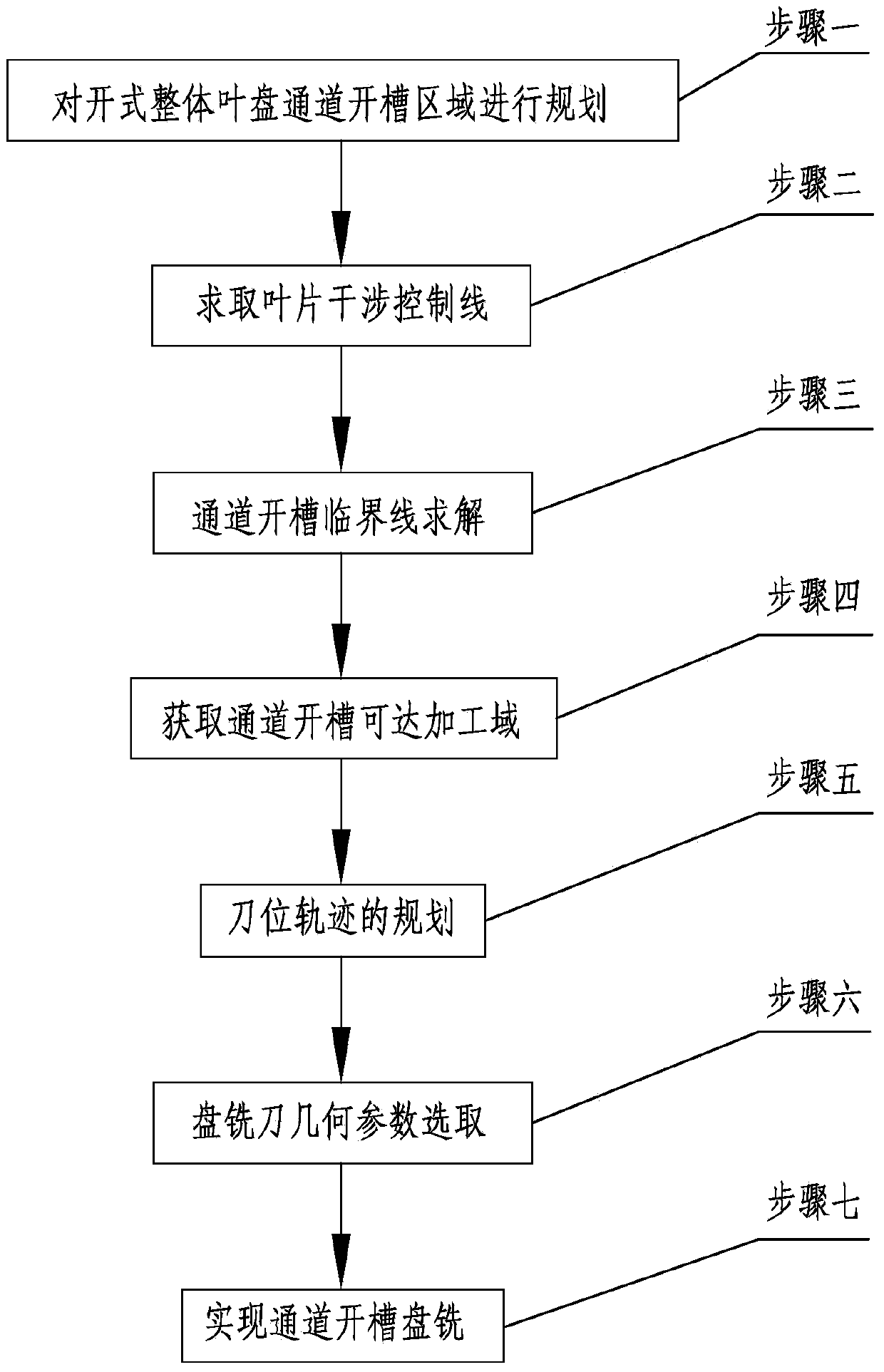

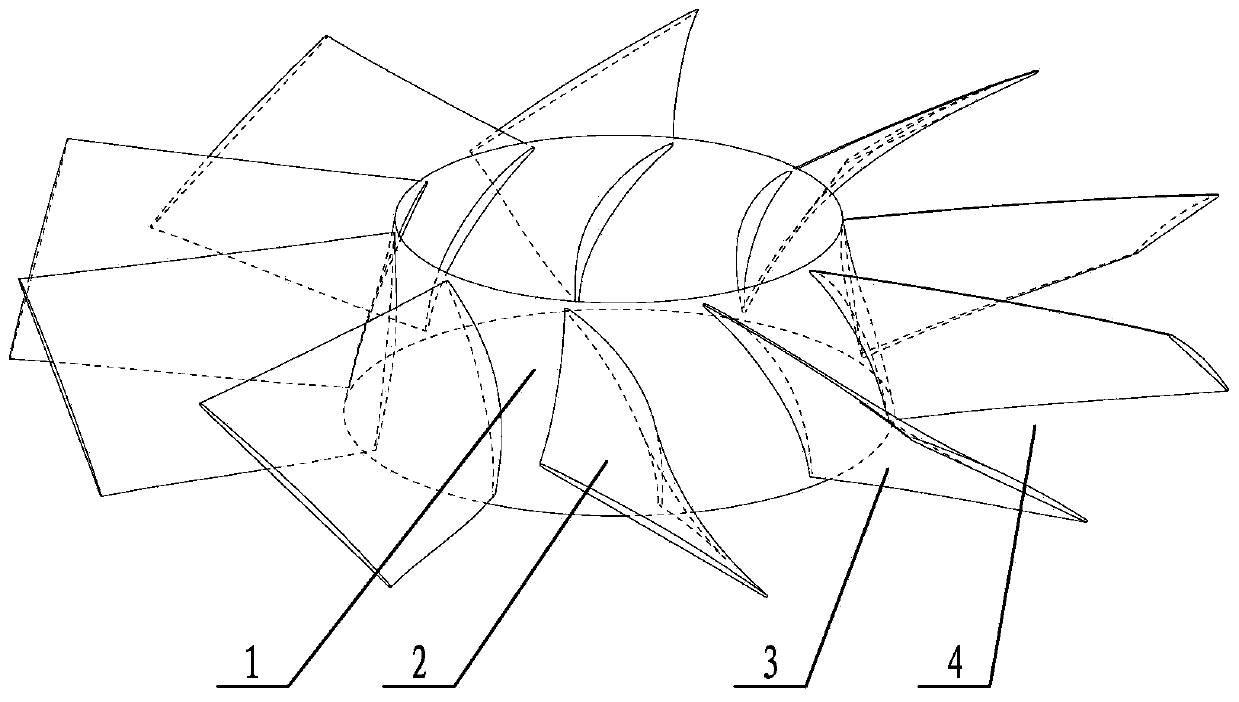

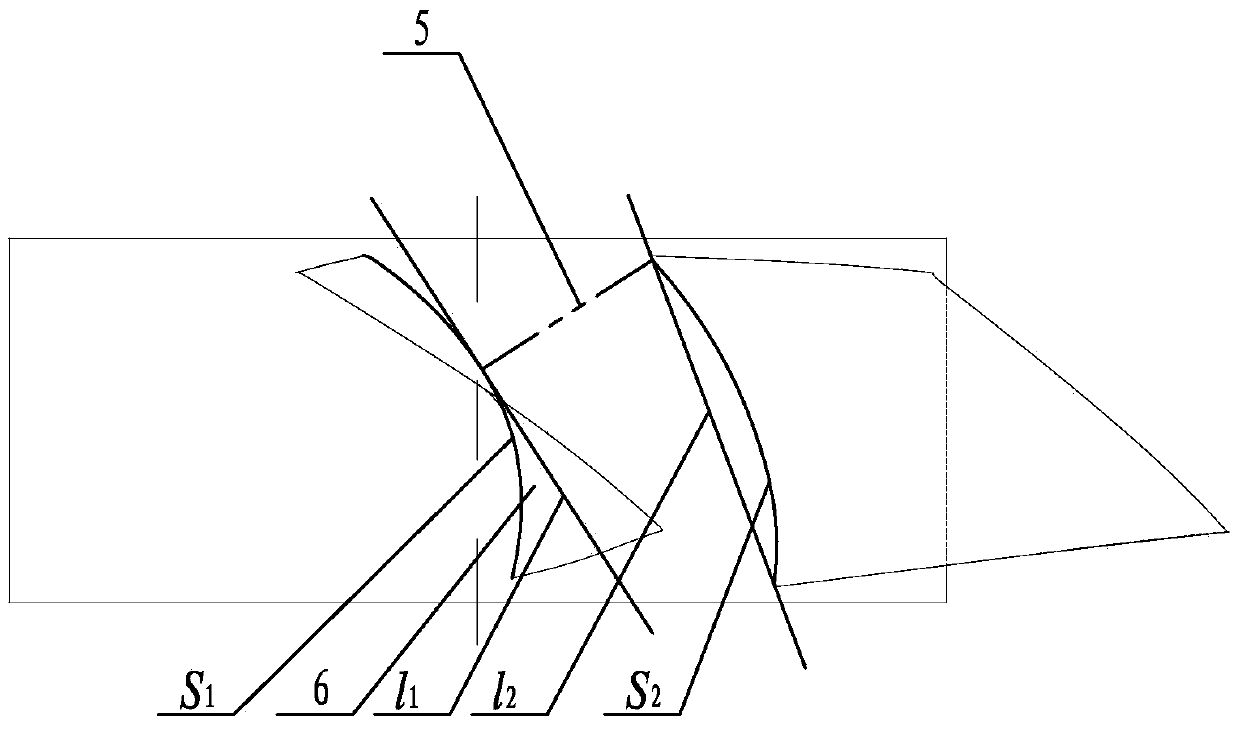

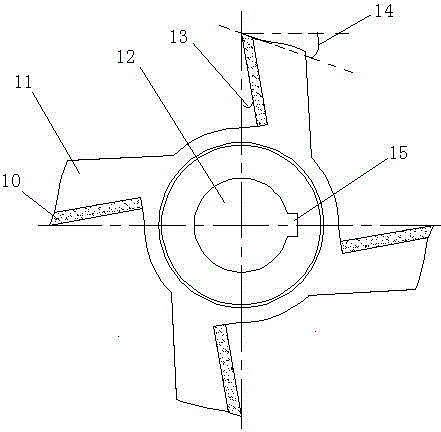

Method for disc-milling grooving processing on open-type blisk

InactiveCN103586518AUniform machining allowanceImprove processing qualityMilling equipment detailsFree formMilling cutter

The invention discloses a method for disc-milling grooving processing on an open-type blisk. The method solves the problem that the existing open-type blisk channel rough grooving process has a large material removal amount and low processing efficiency, and produces interference between a cutter and a free-form surface blade because of narrow and deep grooving channels so that the cutter is worn easily. The method comprises the following steps of planning an open-type blisk channel grooving area, calculating a blade interference control line, calculating a channel grooving critical line, acquiring a channel grooving reachable processing area, planning a cutter position track, selecting disc-milling cutter geometrical parameters, and carrying out channel grooving disc-milling. The method is suitable for open-type blisk grooving disc-milling.

Owner:HARBIN UNIV OF SCI & TECH

Percussive drilling construction process for diaphragm wall passing through rock-filled layer in reclamation area

InactiveCN101892676AReduces chances of intrusion into structural side wallsAvoid Disadvantages of HandlingArtificial islandsUnderwater structuresSlurry wallPunching

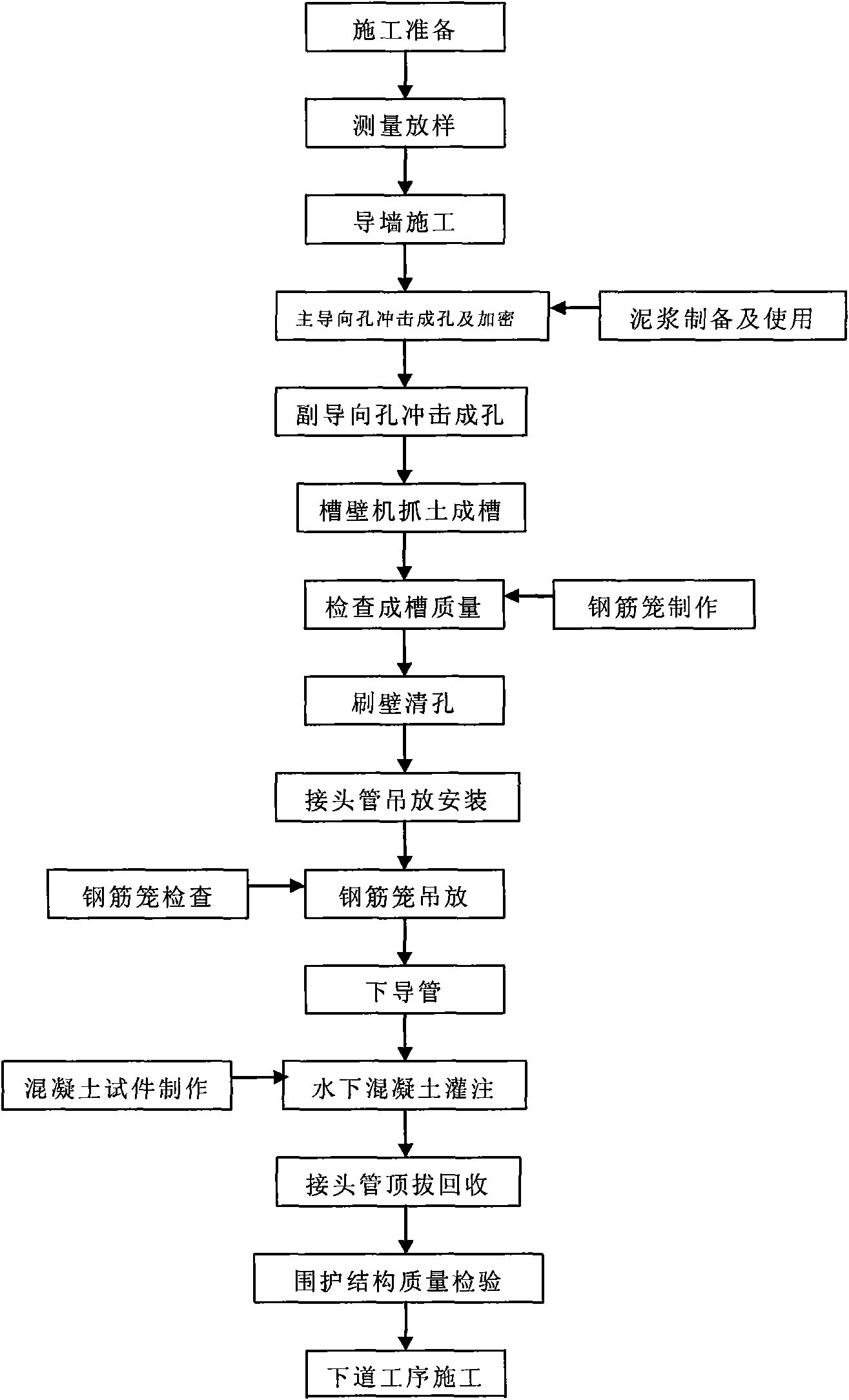

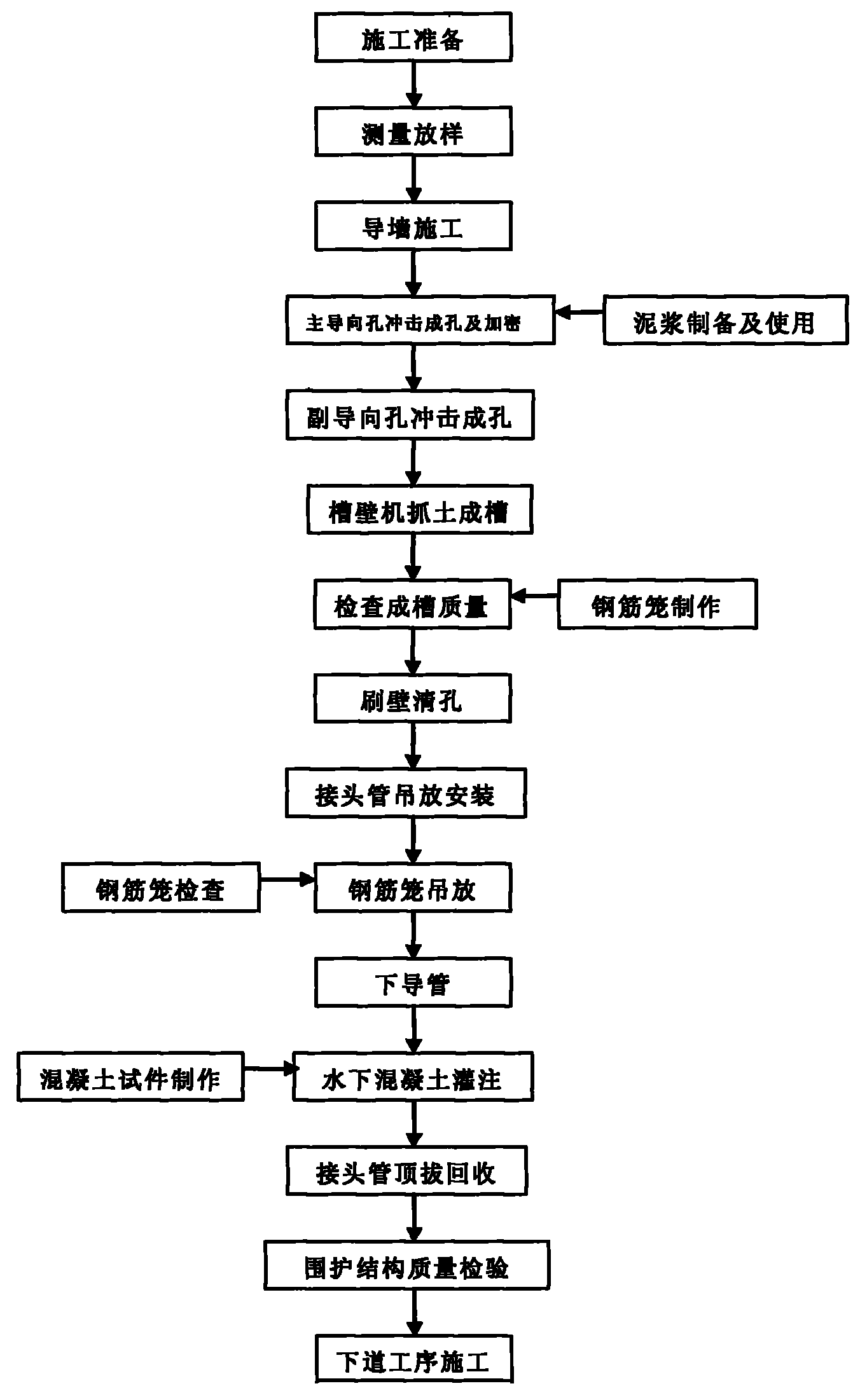

The invention relates to a percussive drilling construction process for a diaphragm wall passing through a rock-filled layer in a reclamation area. The process comprises the following steps of: performing setting-out survey and lead wall construction; after the positions of guide holes are determined, first continuously punching main guide holes accommodating pipe joints, from the top side of the diaphragm wall to a depth which is 0.5m greater than a designed depth by using a punch pile machine, and then forming an encrypted main guide hole at the position which is between the two main guide holes and is 1.5m away from each of the main guide holes; after the position of the encrypted main guide hole is determined, performing continuous punching from the top side of the diaphragm wall by using a punch hammer, moving the punch pile machine to a position above the gap between the two main guide holes, then punching the gap between the two main guide holes by using the punching hammer so as to form an accessory hole, and digging soil by using a grooving machine to form a groove; brushing the wall and cleaning the holes; hoisting and installing the pipe joints; hoisting a steel reinforcement cage; lowering down conduits; filling underwater concrete; pulling and reclaiming the pipe joints; and checking the quality of an enclosure structure. Thus, the construction process solves the problem of low work efficiency during the construction of the diaphragm wall under the geological condition of the rock-filled layer, has the characteristics of high work efficiency and good grooving quality, improves the safety of foundation pit construction, and effectively reduces the comprehensive construction cost.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP

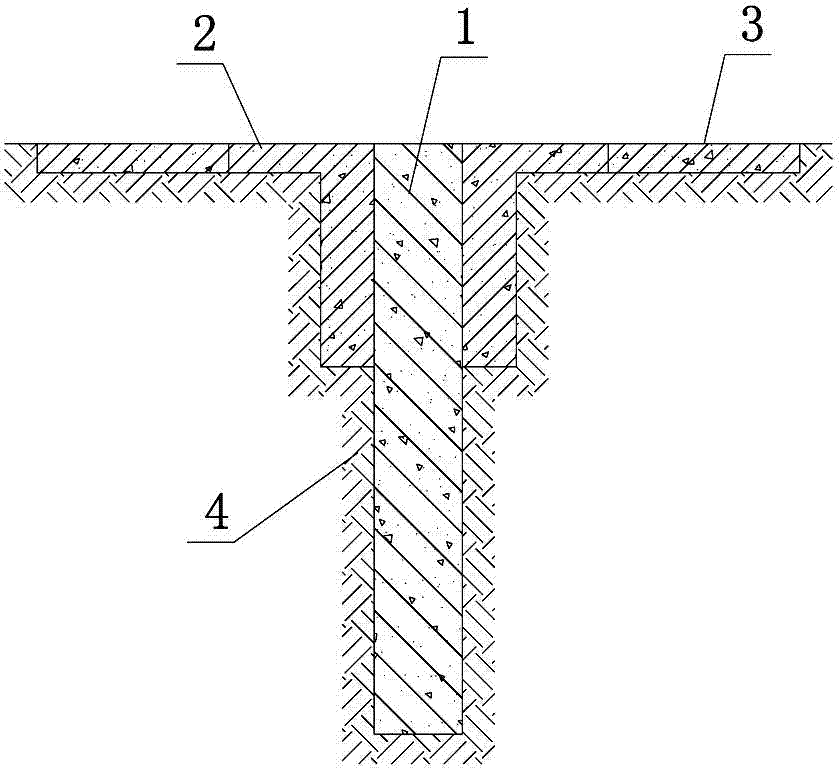

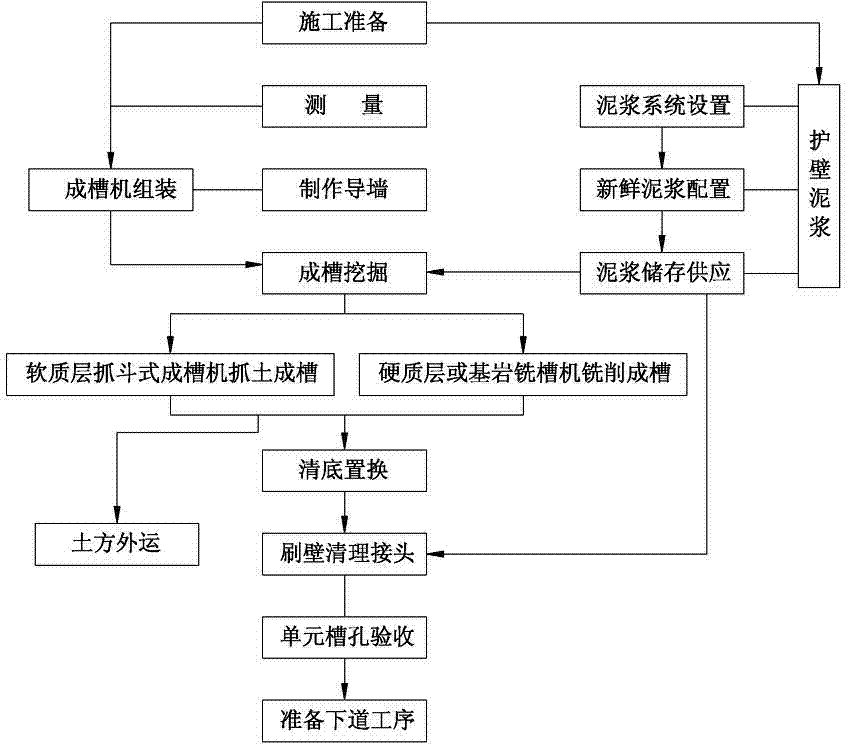

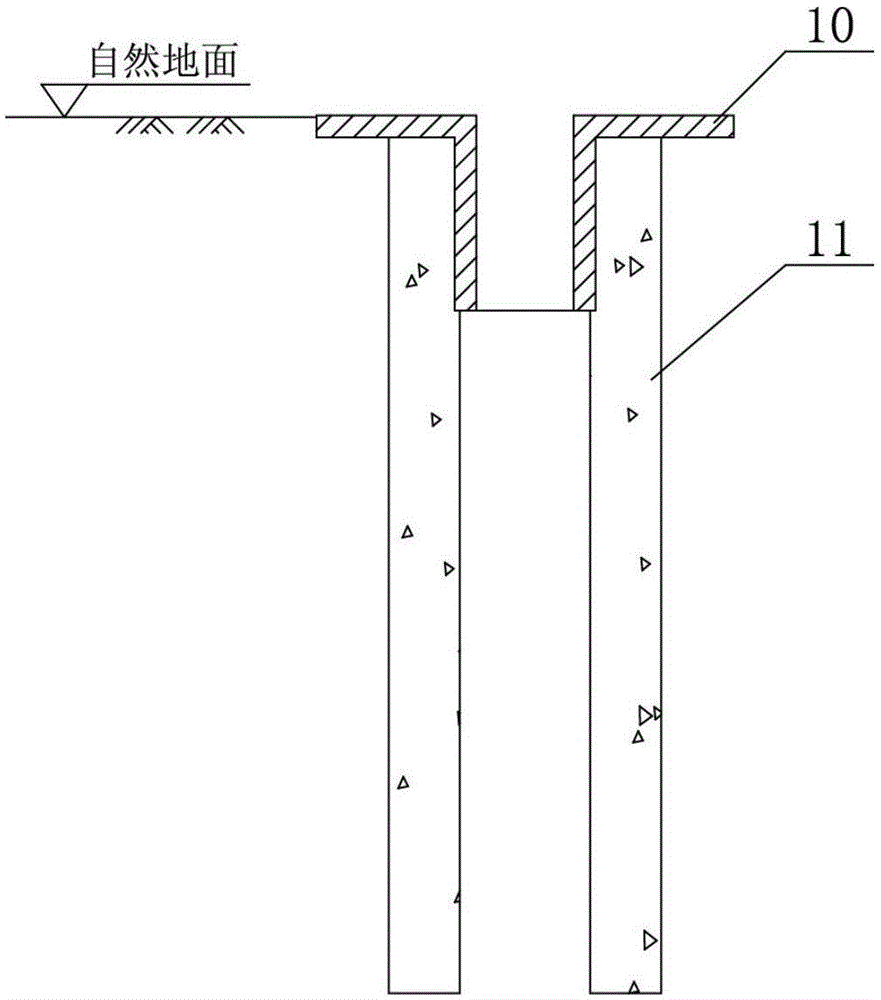

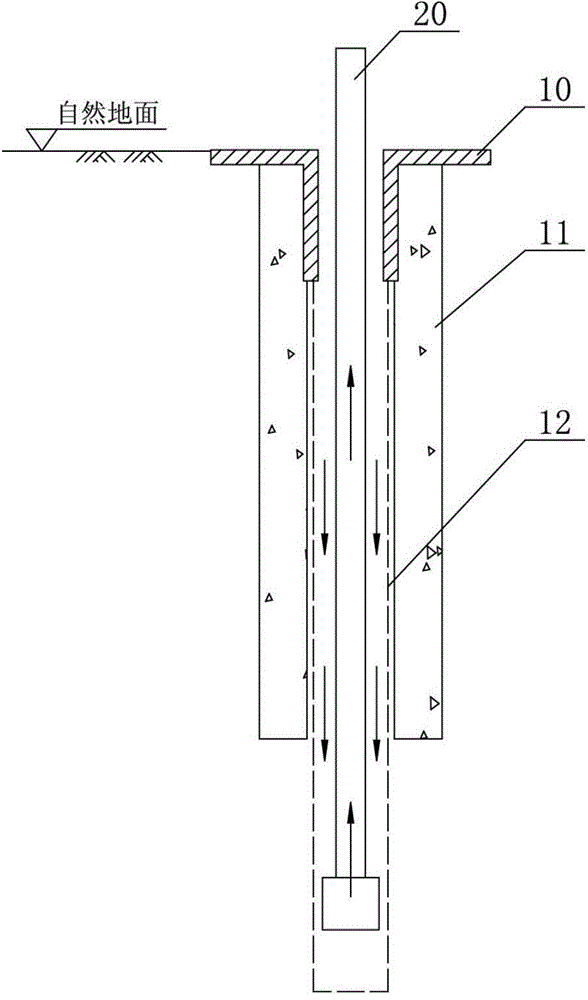

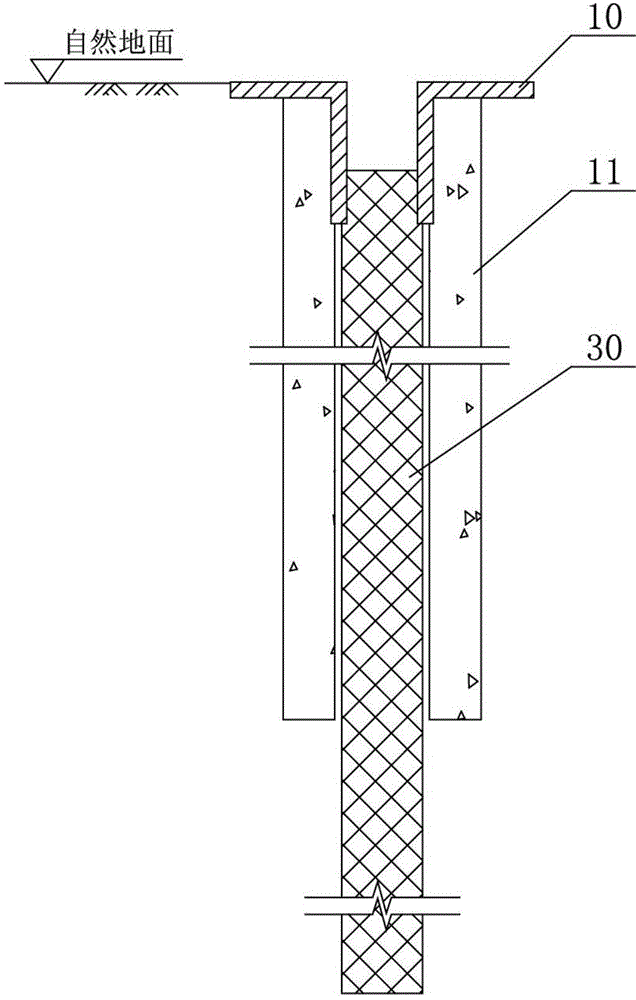

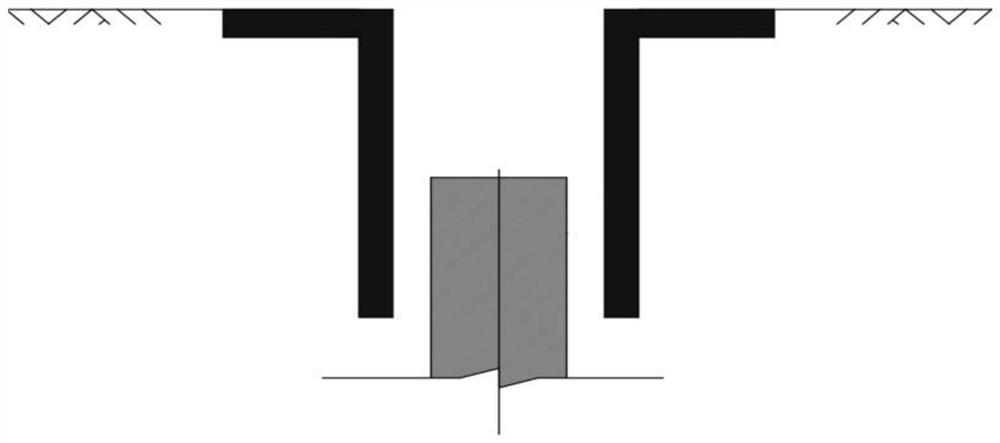

Super-deep underground continuous wall and construction method thereof

The invention relates to a super-deep underground continuous wall which comprises an underground continuous wall body. Guide walls are symmetrically arranged on the two sides of the wall body, the cross sections of the guide walls are in the shape of an L, the lower ends of the guide walls are located on underground rock-soil, and the lug edges of the guide walls are connected with a concrete pavement. The invention further discloses a construction method of the super-deep underground continuous wall. The method includes the following steps of construction preparation, measuring, guide wall manufacturing, wall protection slurry manufacturing, grooving construction, bottom-clearing replacement, connector cleaning through wall brushing and unit slot section inspection, wherein a grabbing-milling integrated grooving method is used in the grooving construction. The method is high in grooving efficiency, short in construction time and short in groove wall soaking time, the grabbing-milling integrated grooving method is used in the grooving construction, technologies can be changed timely according to different stratum hardness situations, the characteristics that a grab bucket is high in digging speed at the soft soil layer and milling wheel can achieve rapid milling and digging footage at a hard soil layer or bed rod with standard penetration test blow count exceeding 45 are fully used, and therefore rapid and efficient grooving of the whole wall can be achieved.

Owner:ZHONGDING INT ENG

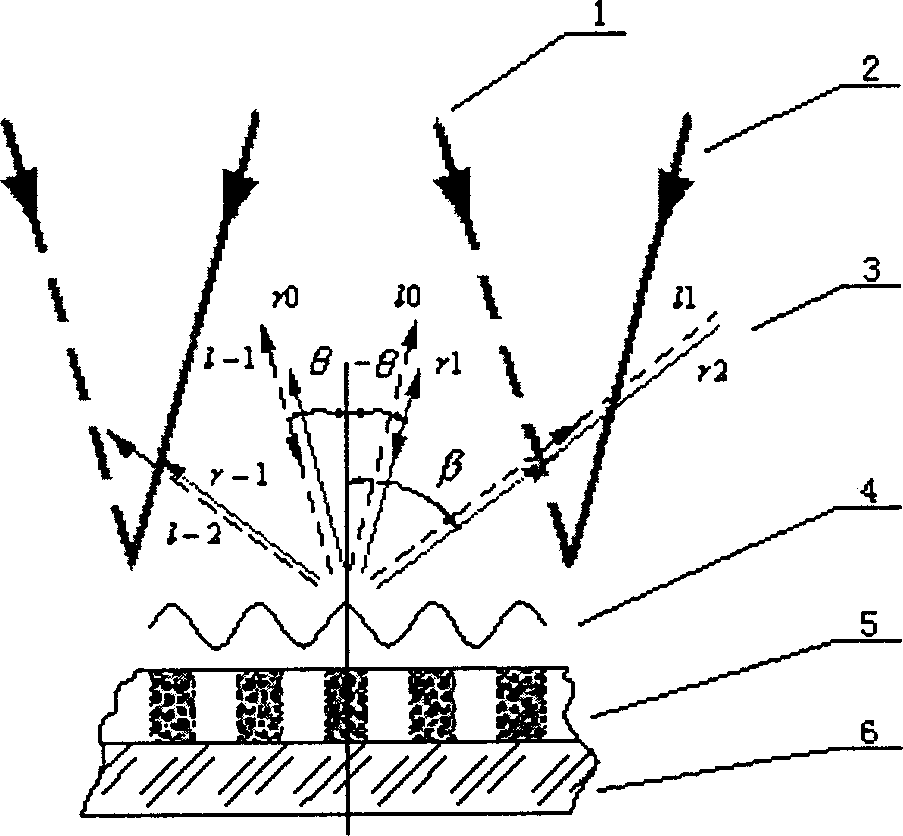

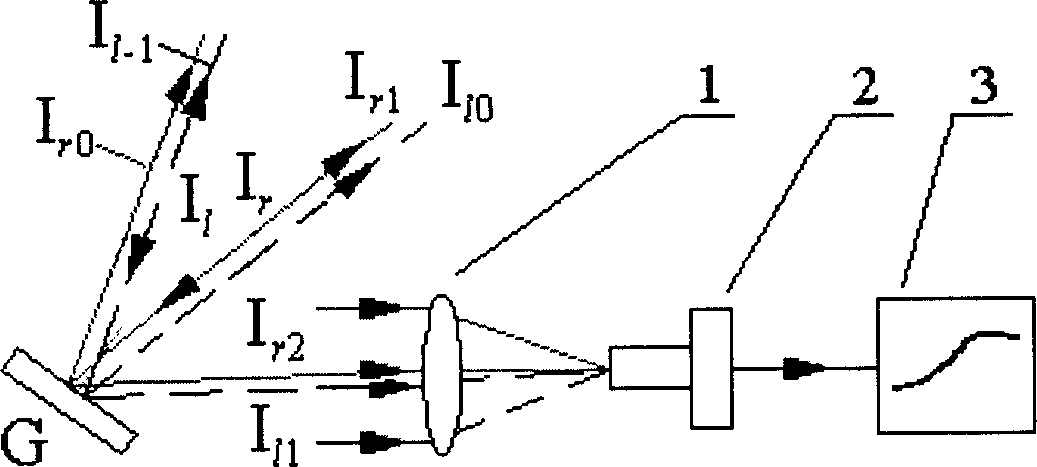

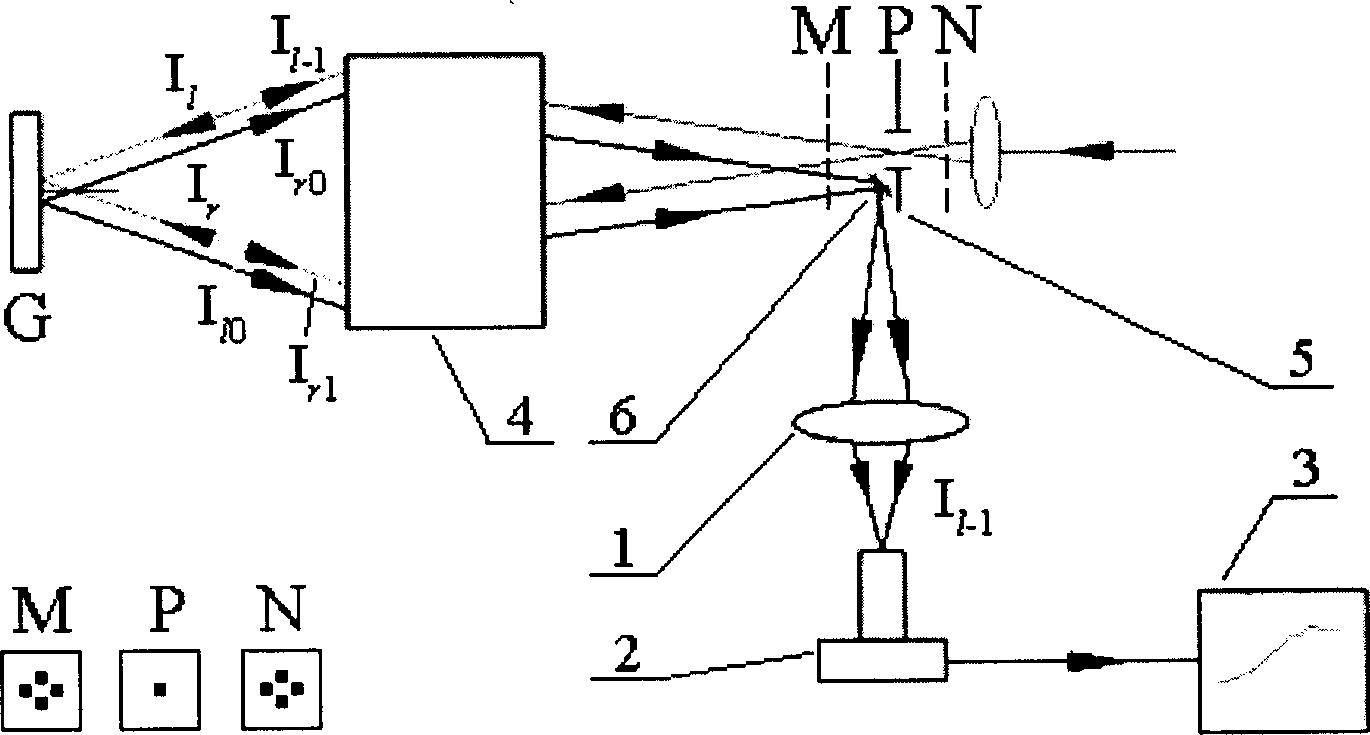

Optical method for real time latent image self-moritoring in holographic raster mfg

The invention refers to a real-time latent-image self-monitoring method in the course of making a holographic grating. It uses arbitrary interference recording light beam of the light intensity acting on the grating as the real-time sub-image self-monotiring incident light beam, and when the ratio of the wavelength of the incident light beam and the period of the grating lambda / d<2 / 3, the gratinghas multiple diffraction levels, it real-time self-monitors the light beam outside the system collimated and photoelectricly multiplied in the transmission direction of self-diffractions Ir2 and Ir1 of arbitrary level sub-image, or real-timely self-monitors the autocollimating level returning according to the original route filtered, collimated and photoelectricaly multiplied.

Owner:TSINGHUA UNIV

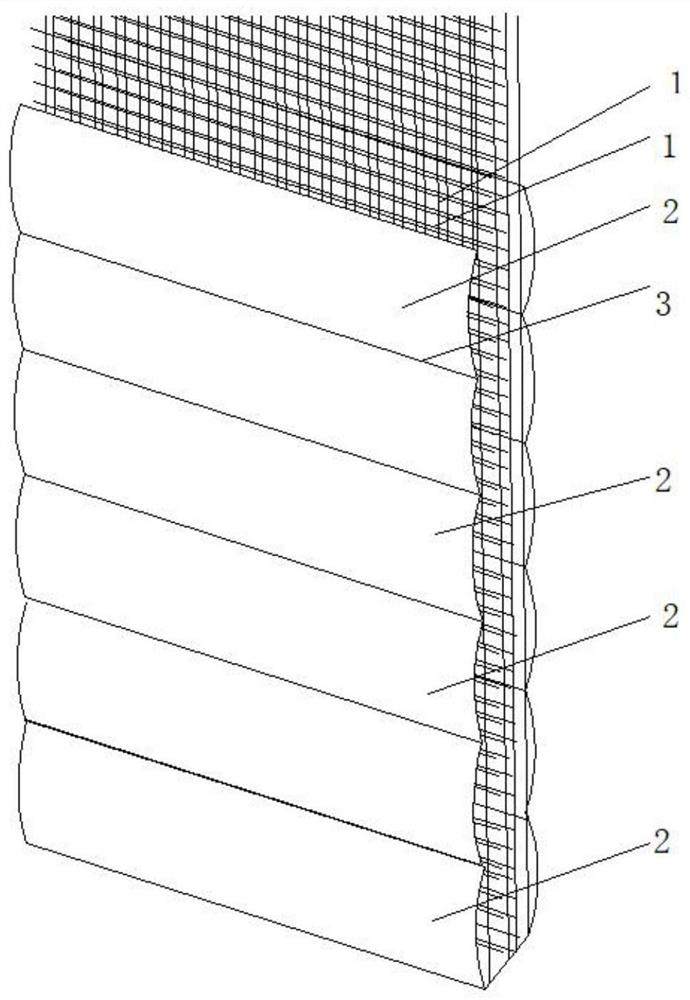

Construction method for underground diaphragm wall penetrating through super-thick silt layer

ActiveCN104612179APrevent collapseImprove construction progressArtificial islandsUnderwater structuresSlurry wallDrill

The invention provides a construction method for an underground diaphragm wall penetrating through a super-thick silt layer, and relates to the technical field of underground project construction. For constructing the underground diaphragm wall on a project field with the stratum of the super-thick silt layer, grooving quality is different to control, and the problems that the construction efficiency is low, a consumed working period is long, and consequently the project cost is increased exist. The construction method comprises the following steps that firstly, paying offing and grooving are conducted along the central line of an underground diaphragm wall to be constructed; secondly, three-axis cement mixing piles are applied and strook into the two sides of the underground diaphragm wall to reinforce the groove walls; thirdly, a guide wall is built on the three-axis cement mixing piles; fourthly, an open groove is partitioned into a plurality of unit groove sections, holes are drilled in the unit groove sections to a intense weathered layer, when excavation is conducted to a medium weathered layer, a rotary excavating drill is replaced to smash and remove the medium weathered layer and the intense weathered layer, and then detritus is grabbed; fifthly, silt at the bottom is brought out of the unit groove sections through a reverse circulation silt removing system, and slurry is poured into the unit groove sections; sixthly, steel bar cages are installed in the unit groove sections, and concrete pouring of the underground diaphragm wall is conducted.

Owner:SHANGHAI MECHANIZED CONSTR GRP

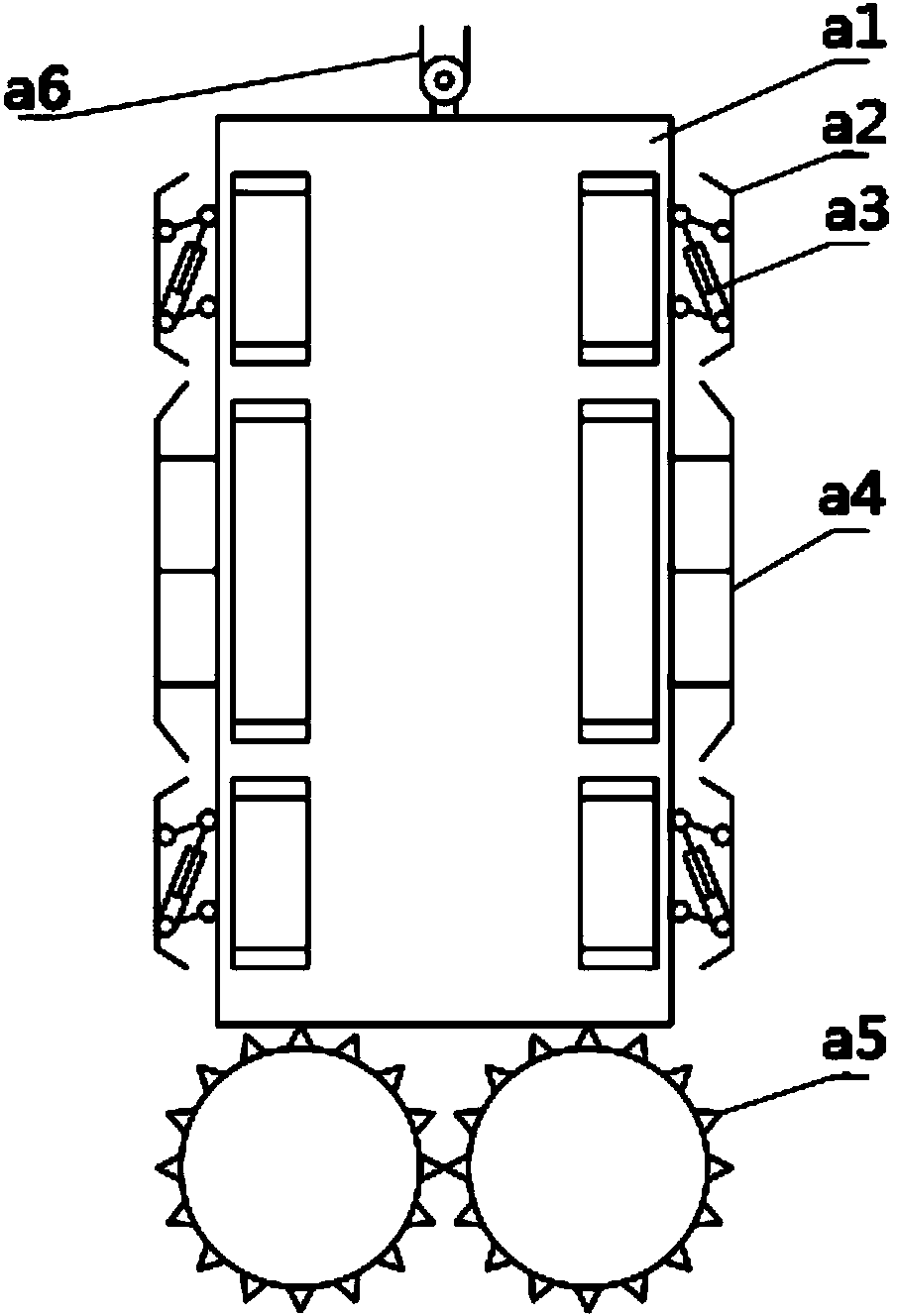

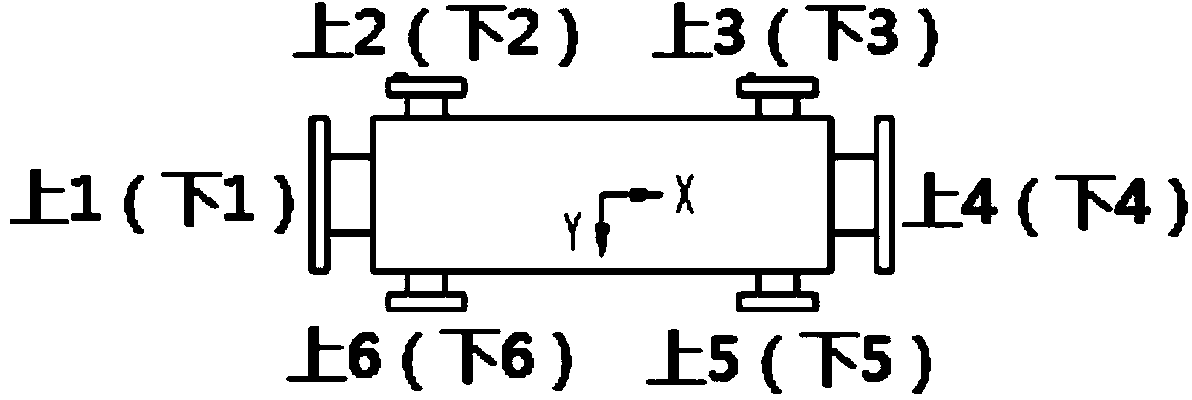

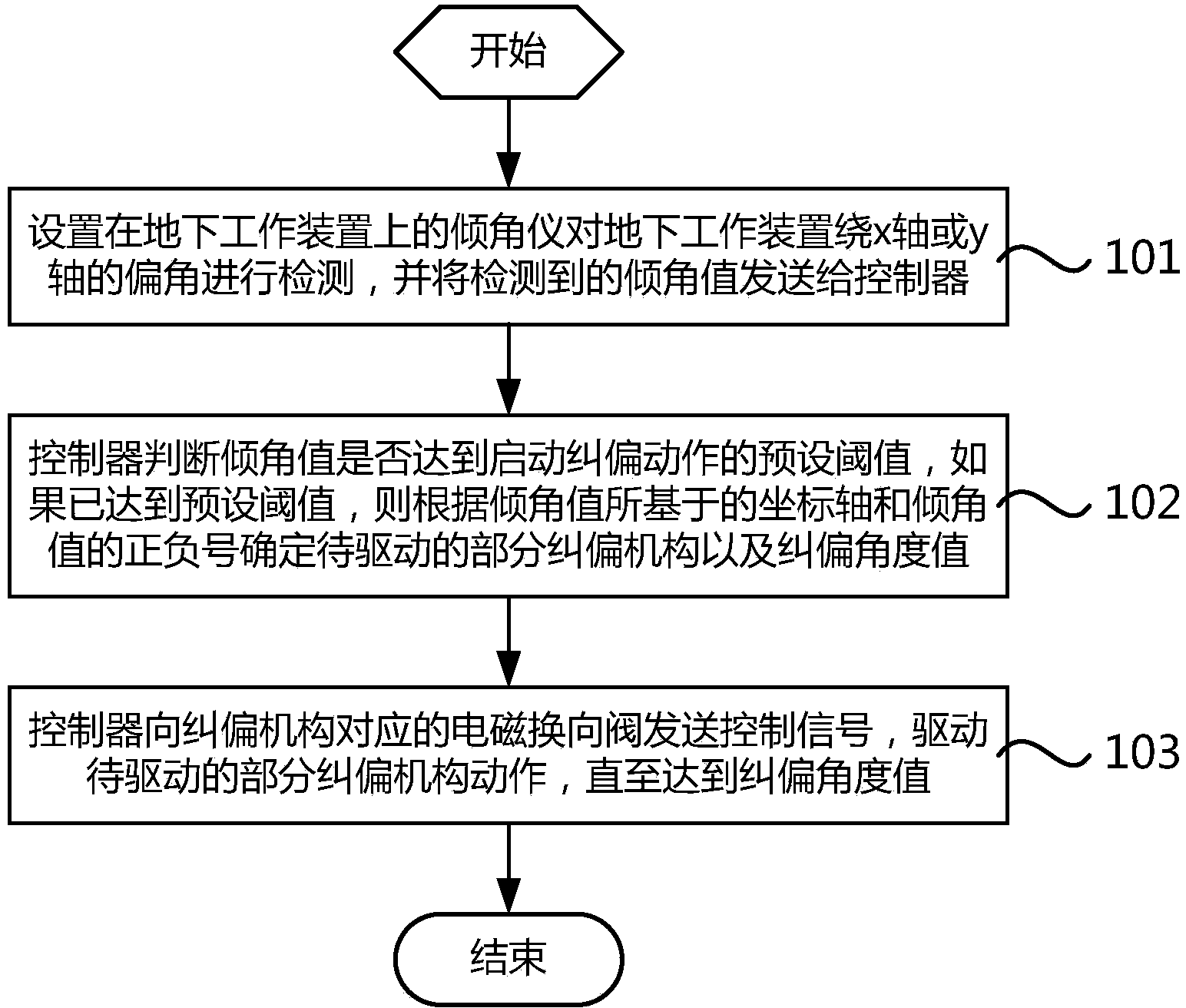

Automatic inclination correcting method and device

ActiveCN103835329AHigh accuracy of deviation correctionImprove groove qualitySoil-shifting machines/dredgersControl signalAngular degrees

The invention relates to an automatic inclination correcting method and device. The method includes the flow of correcting the angle of declination of an underground working device around an x axis or a y axis, and the flow specifically includes the steps that an inclinator is used for detecting the angle of declination of the underground working device around the x axis or the y axis and sending the detected value of the dip angle to a controller; the controller judges whether the value of the dip angle reaches a preset threshold value or not, and if the value of the dip angle reaches the preset threshold value, part of inclination correcting mechanisms to be driven and an inclination correcting angle value are determined according to a coordinate axis on which the value of the dip angle is based and the sign of the value of the dip angle; the controller sends control signals to electromagnetic directional valves corresponding to part of the inclination correcting mechanisms to be driven to drive part of the inclination correcting mechanisms to be driven to move till the inclination correcting angle value is reached. The multiple inclination correcting mechanisms on the underground working device can automatically and properly conduct inclination correcting based on inclination of the underground working device, high inclination correcting accuracy can be achieved without depending on the experience and the state of an operator, and grooving quality is improved.

Owner:XCMG CONSTR MACHINERY

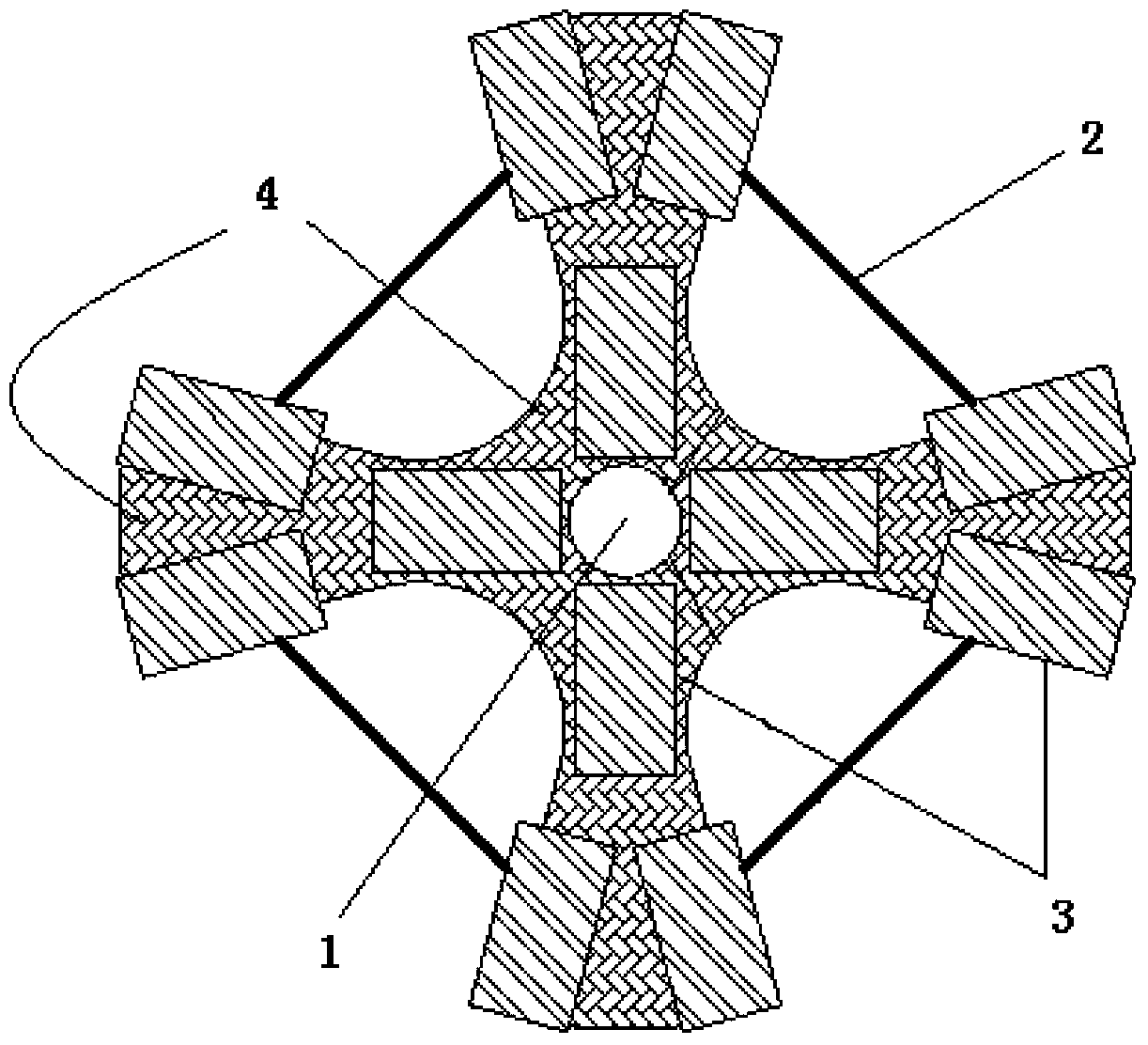

Combined milling cutter used for graphite grooving

InactiveCN105196427AGood slotting qualityBoth quality and efficiencyStone-like material working toolsTool bitMilling cutter

The invention provides a combined milling cutter used for graphite grooving. The combined milling cutter comprises a cutter shaft and 4-20 milling cutter bodies sequentially connected to the cutter shaft in a sleeving mode. Each milling cutter body comprises 4-8 tool bits. One end of the cutter shaft is fixedly connected with a drive rotating plate, and the other end of the cutter shaft is connected with a bearing supporting the cutter shaft. Positioning space rings are arranged between the milling cutter bodies so that the distances between the milling cutter bodies can be regulated. Each milling cutter body has a sleeving rotation angle ranging from 5 degrees to 30 degrees relative to the adjacent corresponding milling cutter bodies. The diameters of part of the milling cutter bodies are different. The front angle of the tool bit of each milling cutter is 8-12 degrees, the rear angle of the tool bit of each milling cutter is 18-22 degrees, and the tool bits are made of hard alloy. The combined milling cutter is rapid in grooving speed and good in grooving quality, and 4-20 grooves can be synchronously formed.

Owner:南通国阳新材料有限公司

Multifunctional groove box cutting machine and using method thereof

PendingCN107877713AGood orientationReduce or avoid harmWorking accessoriesStone-like material working toolsEngineeringMechanical engineering

The invention relates to the field of cutting machine equipment, in particular to a multifunctional groove box cutting machine and a using method thereof. The cutting machine comprises a machine body;a motor is arranged in the machine body, is connected with a cutting saw blade through a transmission mechanism and drives the cutting saw blade to rotate to work through the transmission mechanism;and a protective cover used for wrapping the cutting saw blade is arranged on the machine body and is provided with a guide assembly used for feeding and guiding the cutting machine. According to thecutting machine and the using method thereof, the guide assembly is arranged so that the feeding smoothness of the cutting machine can be guaranteed to a certain degree, meanwhile, the guide assemblyhas a good guiding function so that the grooving efficiency can be improved to a certain degree, by means of the guiding function of a guide mechanism, the grooving straightness can be ensured, and the grooving quality can be improved.

Owner:胡才春

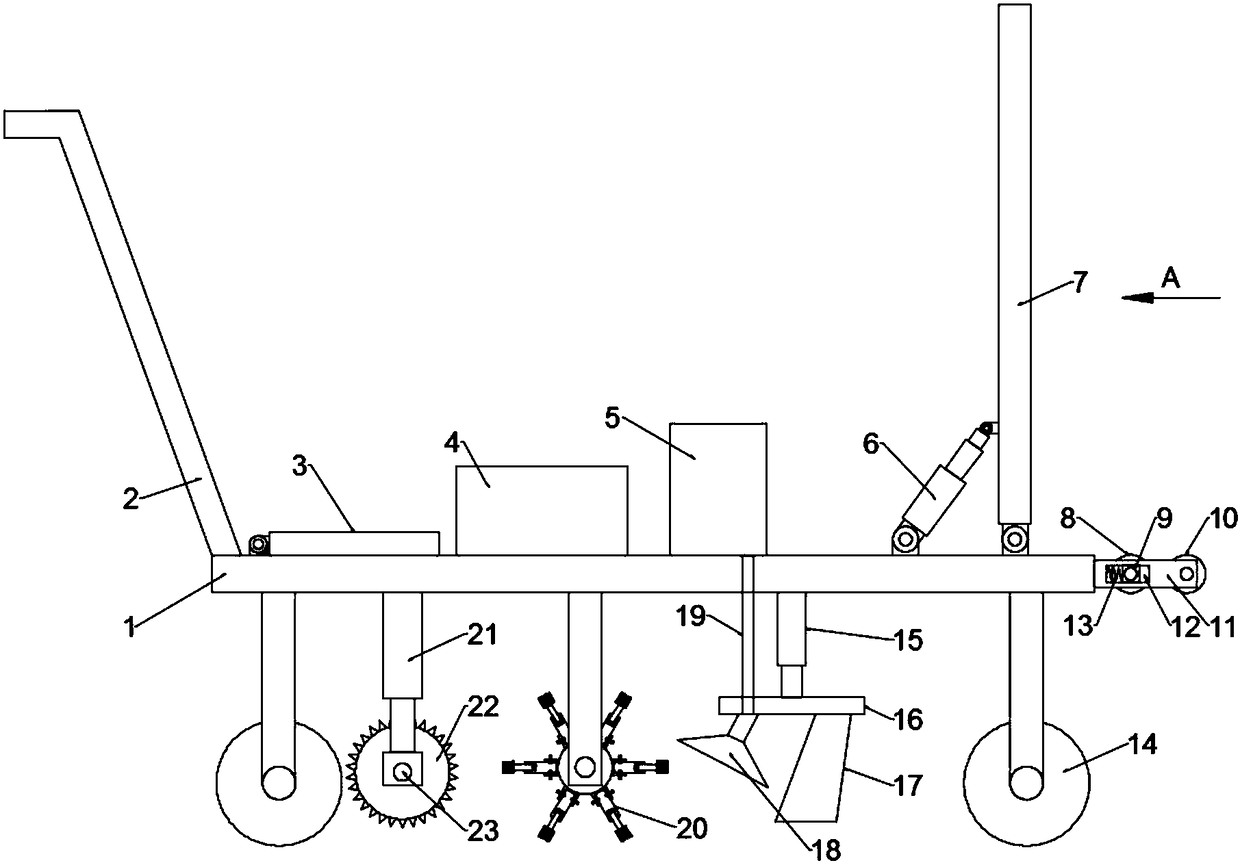

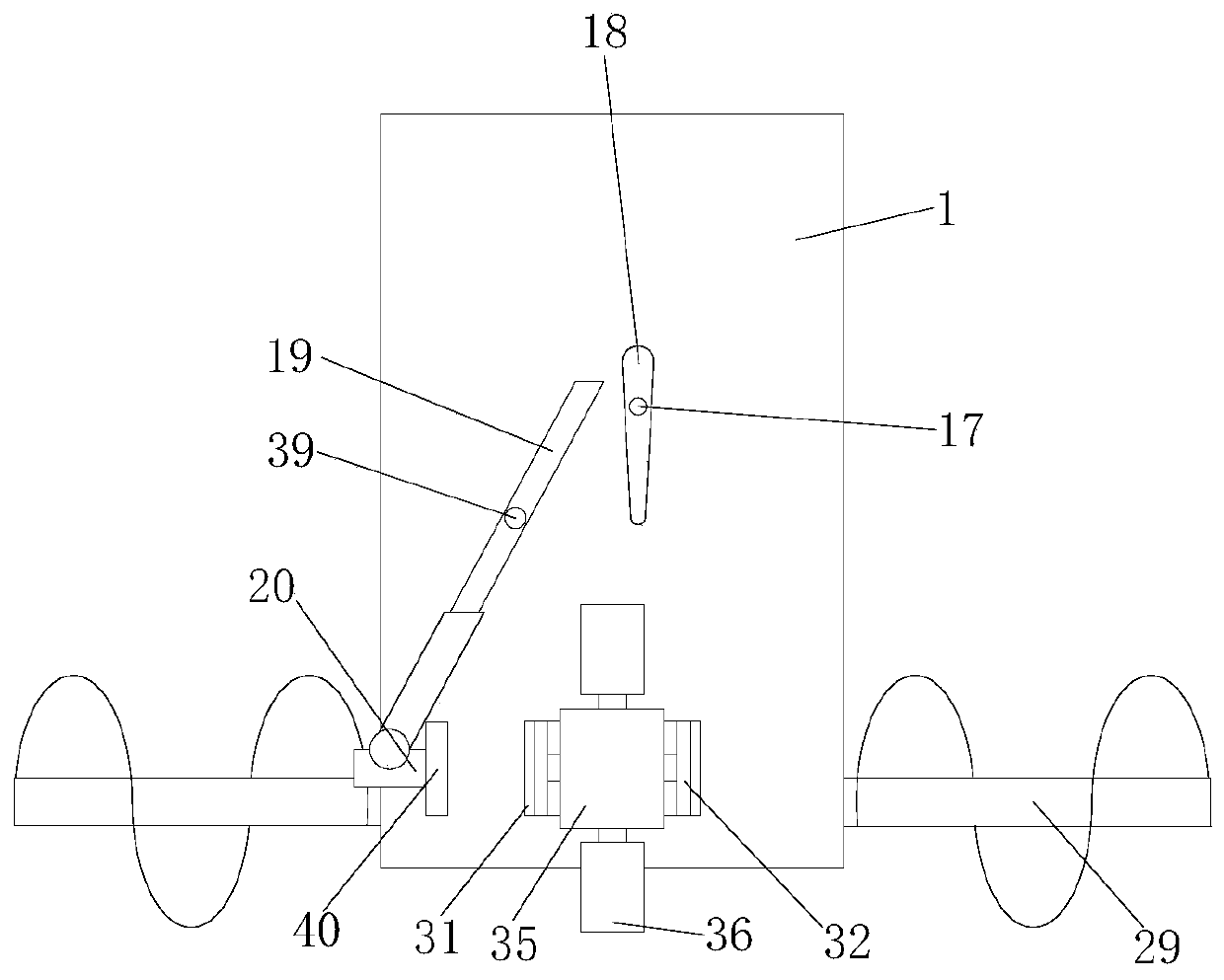

Multifunctional cable laying device for power construction

InactiveCN108599024AAvoid pollutionReduce labor intensityApparatus for laying cablesHydraulic cylinderEngineering

The invention discloses a multifunctional cable laying device for power construction. The device comprises a base plate, a grooving roll, first electrical push rods, a first motor, a brushing device,a second electrical push rod, a funnel type suction nozzle, a dust collector, a support frame, a first hydraulic cylinder, second hydraulic cylinders, support shafts, a first rotation roll, a second rotation roll, and a third spring, wherein the brushing device comprises a mounting roll, sleeves, mounting rods, movable rods and metal brushes. The device provided by the invention has the advantagesthat through the first electrical push rods, the slotting roll, the brushing device, the funnel type suction nozzle, the dust collector and a shovel, grooving can be completed, and the grooving depthcan be adjusted; through the brushing device, dust and stones in a groove can be brushed off, so that the groove can be cleaned, and the grooving quality can be improved; through the support frame, the first hydraulic cylinder, the second hydraulic cylinders and the support shafts, a cable can be directly laid during the grooving, so that the work efficiency can be improved; and the operation issimple, convenient and labor-saving, so that the labor intensity of workers can be reduced.

Owner:单义丹

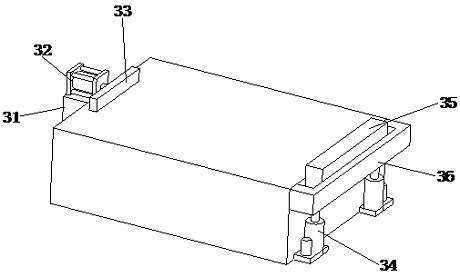

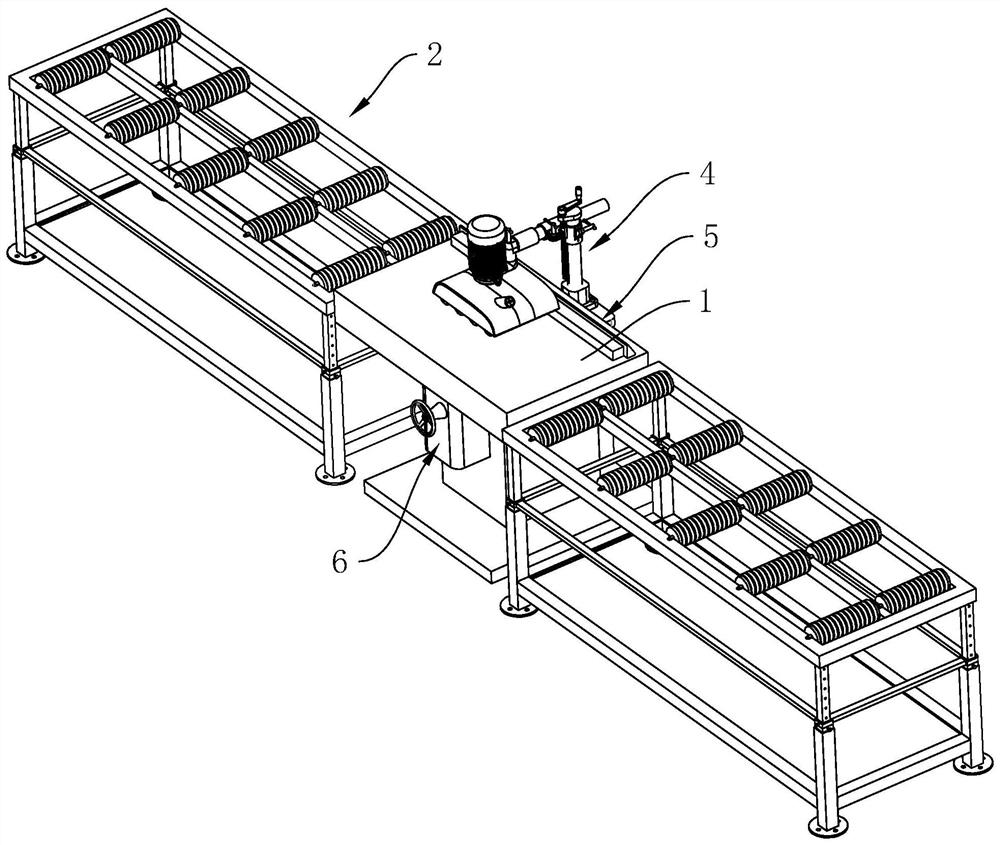

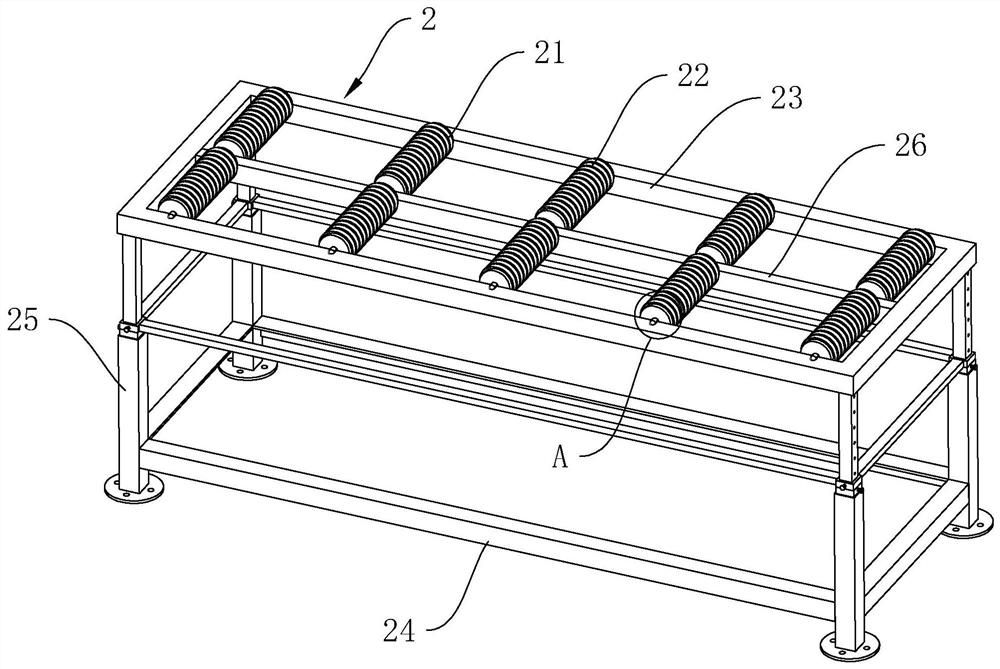

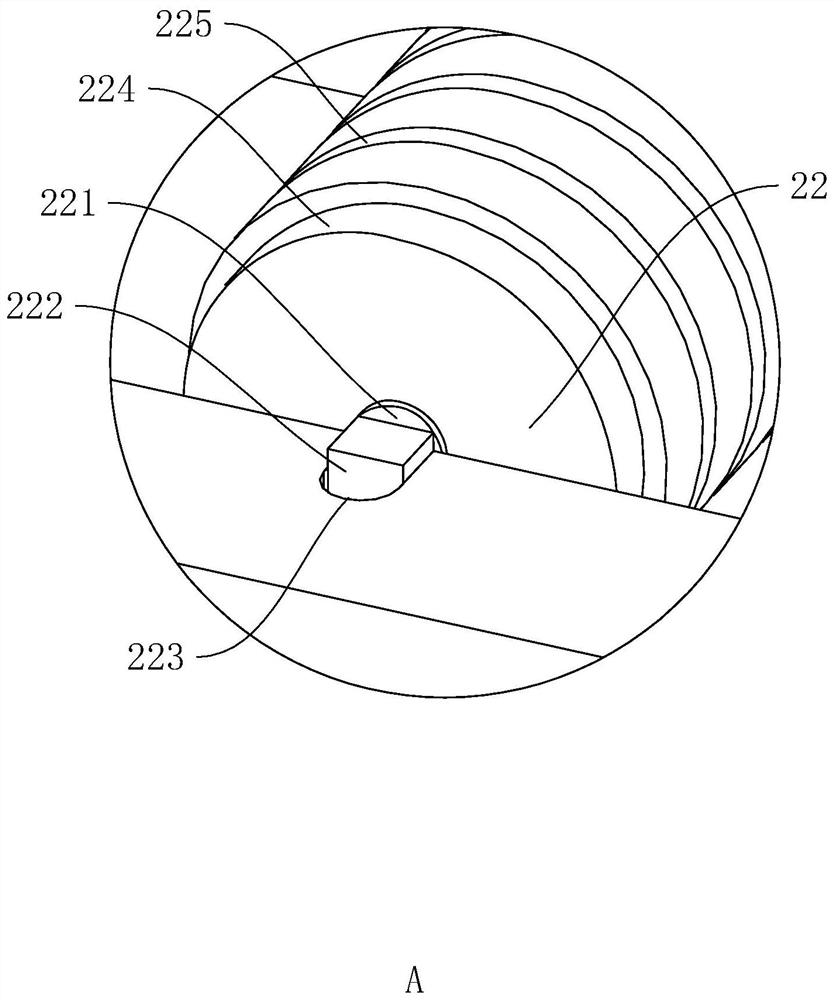

Conveying device of floor grooving machine

InactiveCN104003196AImprove groove qualitySimple structureCharge manipulationWood mortising machinesEngineeringDrive motor

The invention discloses a conveying device of a floor grooving machine. The conveying device comprises a supporting frame, a conveying belt located on the supporting frame and a driving motor used for driving the conveying belt. The driving motor is located below the supporting frame, the tail end of the supporting frame is connected to the input end of a grooving machine working table, the end, close to the grooving machine working table, of the supporting frame is sequentially provided with a drying box and a washing box from left to right, and the conveying belt is covered with the drying box and the washing box, so that floors enter the grooving machine working table after being sequentially conveyed to the washing box and the drying box through the conveying belt. According to the conveying device of the floor grooving machine, the position, close to the abutting joint end of the conveying supporting frame and the grooving machine working table, of the conveying supporting frame is sequentially provided with the washing box and the drying box, the floors are driven by the conveying belt to enter the washing box and the drying box sequentially to be washed, then the floors enter the grooving machine working table to be grooved, and therefore the grooving quality of the floors is improved.

Owner:ANHUI YIJIAXIN WOOD

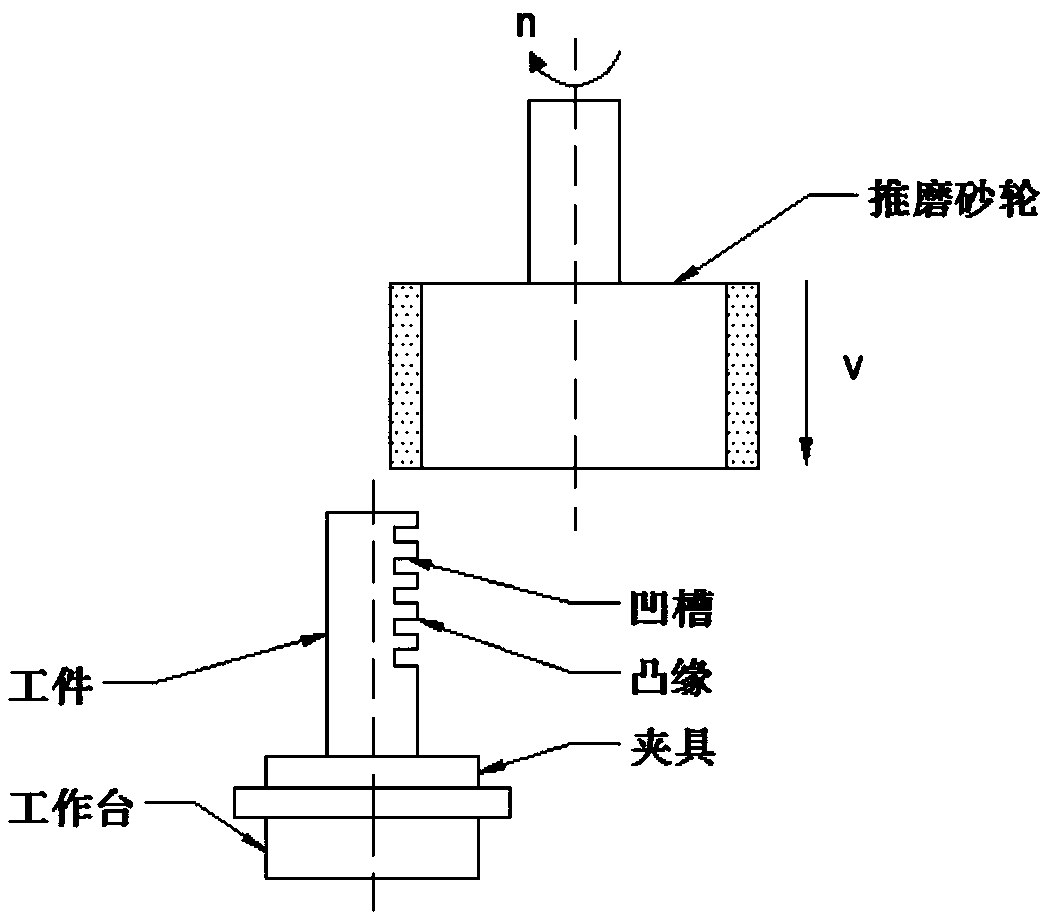

Abrasive water jet grooving-diamond wheel grinding composite ceramic machining method

InactiveCN109465711AAbrasives are inexpensiveReduce processing costsGrinding machinesPropagation effectAbrasive water jet

The invention provides an abrasive water jet grooving-diamond wheel grinding composite ceramic machining method. The method comprises the following steps that S1, grooving machining is carried out ona flat-plate ceramic workpiece by adopting an abrasive water jet machine tool according to machining requirements to form a parallel flange; and S2, the parallel flanges formed in the step S1 is ground by adopting a diamond grinding wheel until the machining needs are met, wherein abrasive water jet cutting machining mainly consumes water and abrasive particles, no tool is worn in the machining process, the used abrasive is low in cost, and the machining cost can be greatly reduced. In conclusion, the crack propagation effect is utilized so that high-removal rate machining of hard brittle materials such as ceramics can be realized on the premise of higher feeding speed and no tool abrasion.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

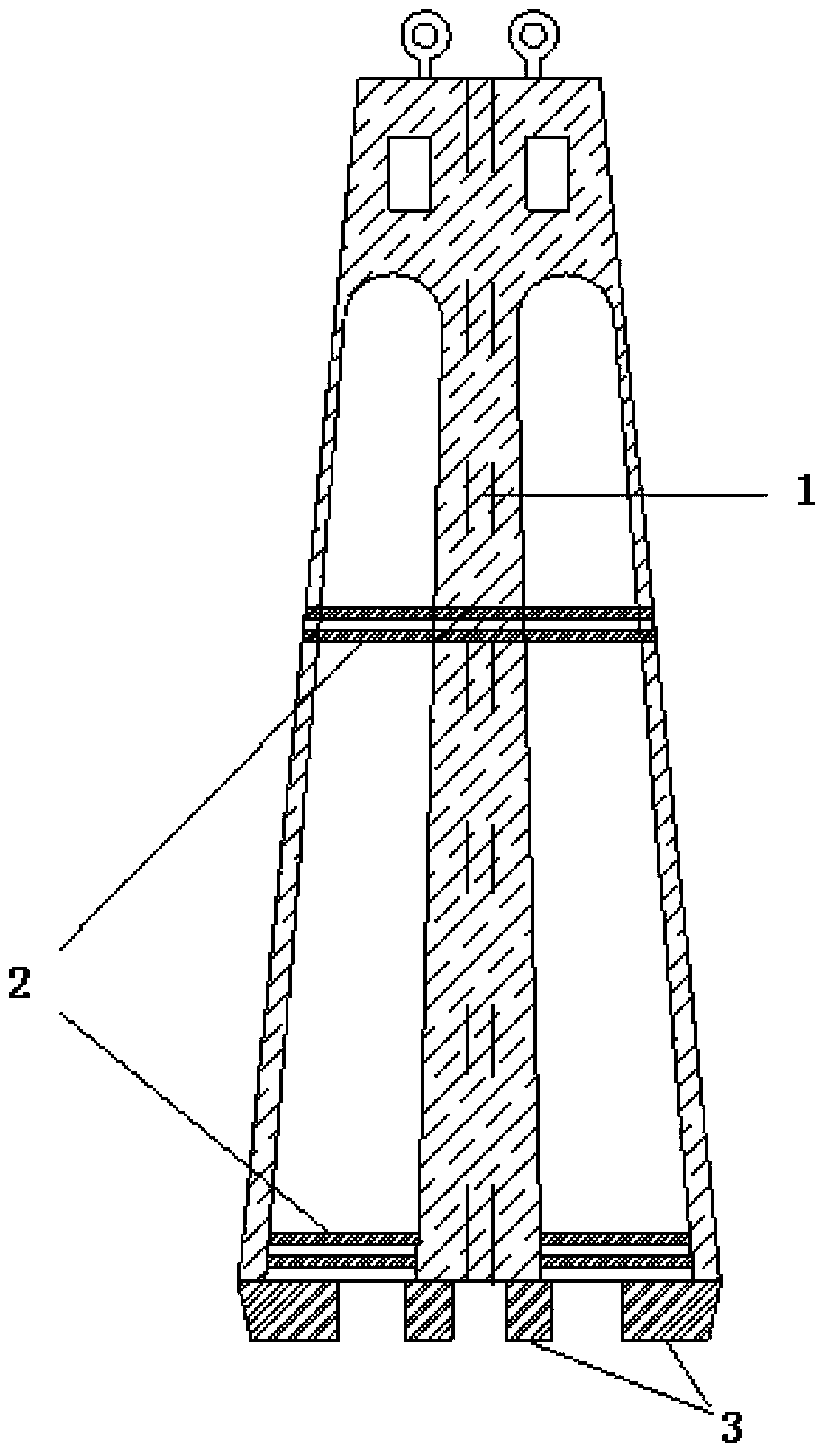

Single-wheel groove milling equipment and construction method thereof for underground diaphragm wall grooving

InactiveCN105220682AEasy accessEasy to cleanSoil-shifting machines/dredgersBulkheads/pilesSlurry wallStructural engineering

The invention discloses single-wheel groove milling equipment and a construction method thereof for underground diaphragm wall grooving. The single-wheel groove milling equipment comprises a groove milling device and a waste soil discharging device; the groove milling device comprises a residue spraying pipe which is vertically arranged in an underground drilled hole, a single-wheel groove milling machine is disposed on one side of the residue spraying pipe, a limiting guide way is disposed on the residue spraying pipe in the length direction, and the single-wheel groove milling machine moves along the limiting guide way; the waste soil discharging device is communicated with the bottom of the residue spraying pipe, and soil layer milling is performed by the single-wheel groove milling machine through repeated translation of the residue spraying pipe in a groove section. Compared with the prior art, the single-wheel groove milling equipment and the construction method thereof for underground diaphragm wall grooving have the advantages that the equipment is suitable for being used in the geologic environment with hard stratums, and underground diaphragm wall grooving operation with a short construction period, good grooving quality and small investment can be achieved.

Owner:南京奔腾建设有限公司

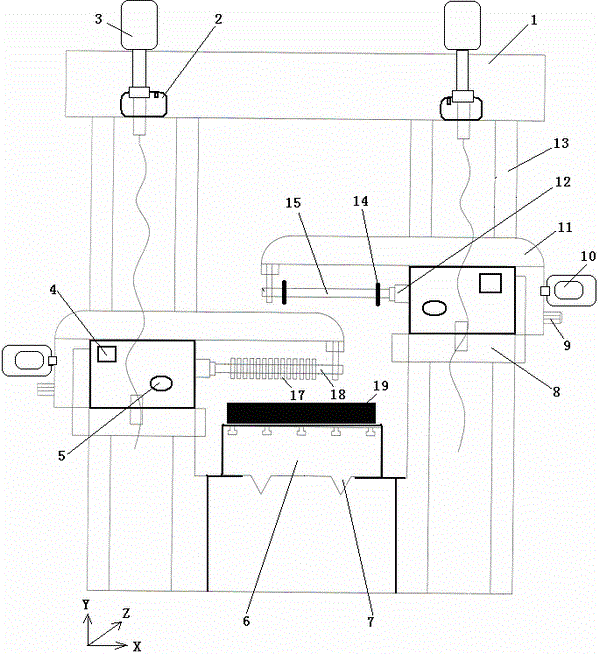

Double-station sheet cutting connecting rod fracture splitting groove device

ActiveCN111992823AAvoid windingImprove processing efficiencyPlastic recyclingElectrical-based machining electrodesReciprocating motionClassical mechanics

The invention discloses a double-station sheet cutting connecting rod fracture splitting groove device which comprises a platform, a left station machining device, a right station machining device, asecondary vertical driving device, a secondary horizontal driving device and a controller. The left station machining device and the right station machining device each comprises a clamp, a main horizontal driving device, a main vertical reciprocating driving device and a machining electrode assembly. Each machining electrode assembly comprises a connecting frame fixedly installed on the main vertical reciprocating driving device, a reel rotatably installed on the connecting frame, a sheet wound on the reel and clamping feet used for clamping the sheet, vertical through holes are formed in theclamping feet, and the sheets are sleeved with the vertical through holes and stretch out of the lower ends of the vertical through holes. The sheets are clamped and tensioned by the clamping feet todo continuous reciprocating motion in the vertical direction, meanwhile, the continuous reciprocating motion in the vertical direction and grooving machining in the horizontal direction form composite machining, continuous reciprocating in the vertical direction is auxiliary motion of grooving machining, and discharging and chip removal are facilitated.

Owner:GUANGDONG UNIV OF TECH

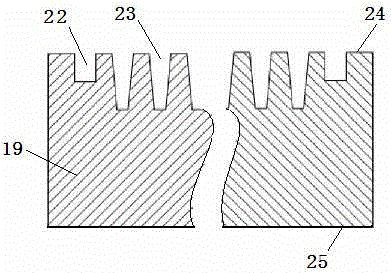

Double-cutter-shaft machine tool for graphite slotting and machining technology of machine tool

ActiveCN105291279ATo overcome the disadvantage of not being able to open multiple parallel grooves on the surface of brittle materials such as graphiteHigh shape accuracyStone-like material working toolsCantilevered beamElectric machinery

The invention discloses a double-cutter-shaft machine tool for graphite slotting. The machine tool is provided with a motor A, a horizontal guide rail and a working platform. Two motors B, a horizontally-arranged cross beam, two stand columns, two cutter shaft assemblies and a stand column lubricating system are included; the two motors B are arranged above the cross beam, motors B penetrate the cross beam to be connected, and each motor B can drive one cutter shaft assembly to vertically move on one stand column in the Z-axis direction; and each cutter shaft assembly comprises a cantilever beam, a cutter shaft, a cutter shaft bearing seat, a bracket and a motor C. During machining, one motor B drives one cutter shaft assembly to achieve slotting of a first set of grooves, and the other motor B drives the other cutter shaft assembly to achieve slotting of a second set of grooves. The production efficiency of forming of a plurality of parallel grooves in graphite is high, the shape and size precision of the grooves is high, and the automation control degree is high.

Owner:南通国阳新材料有限公司 +1

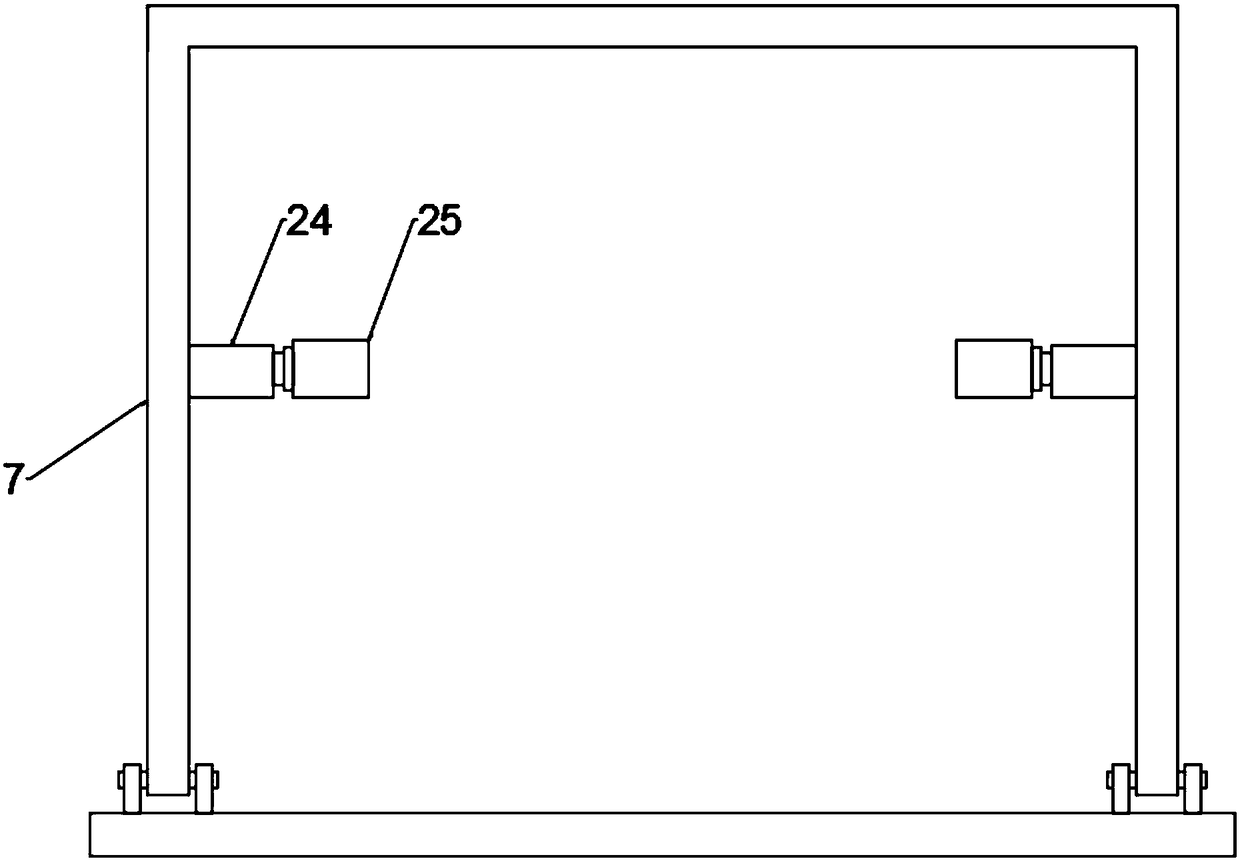

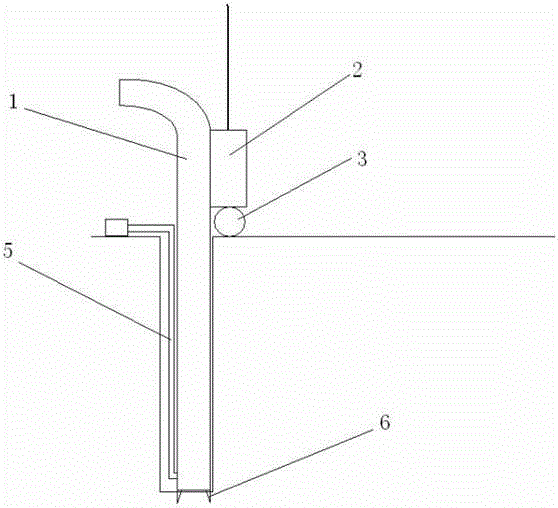

Stereoscopic light-emitting character enclosing machine

The invention discloses a stereoscopic light-emitting character enclosing machine which belongs to the technical field of stereoscopic light-emitting character processing equipment. The stereoscopic light-emitting character enclosing machine comprises a board clamping device and a cutting device, which are mounted on a machine body, wherein the board clamping device is mounted above a mainboard of the machine body, and the cutting device is mounted below the mainboard of the machine body. The stereoscopic light-emitting character enclosing machine is compact in structure, reliable in performances and low in cost and can be widely applied to production and manufacturing of stereoscopic light-emitting characters.

Owner:WEIFANG HANDUN CNC EQUIP

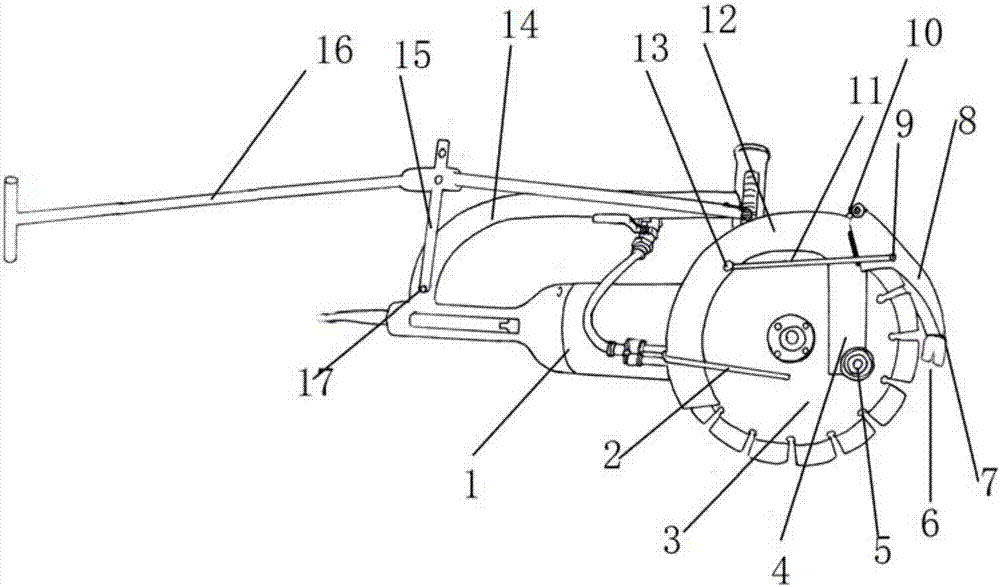

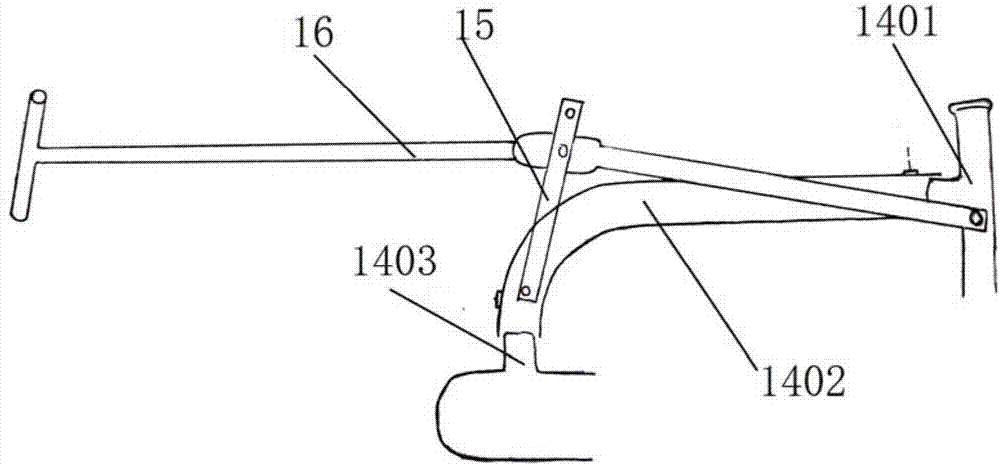

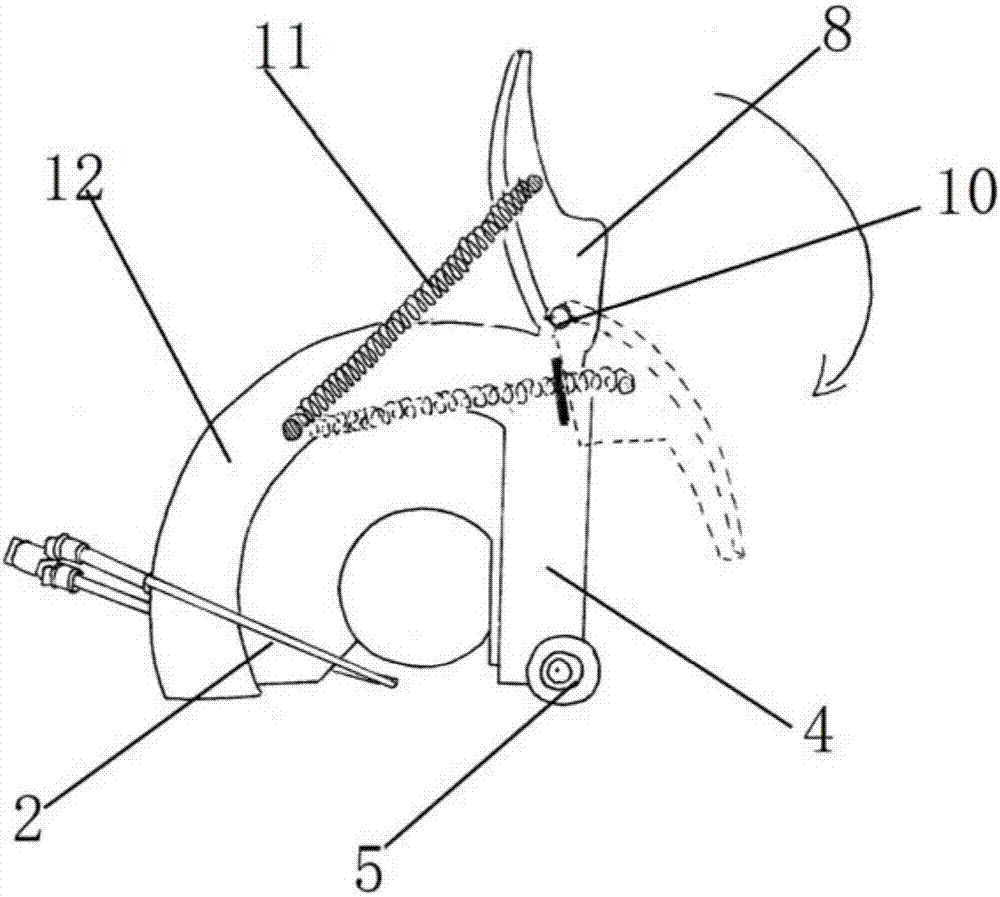

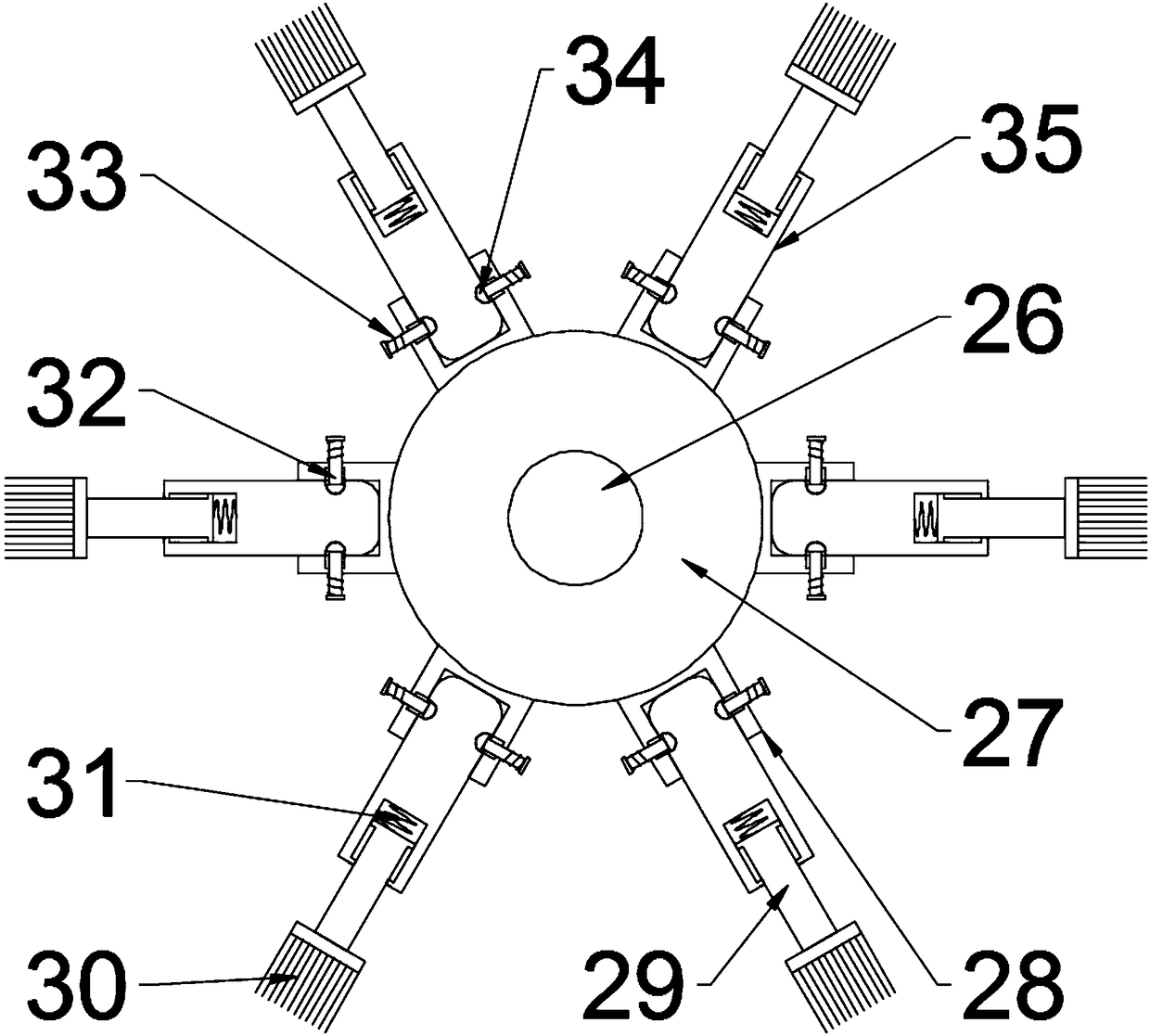

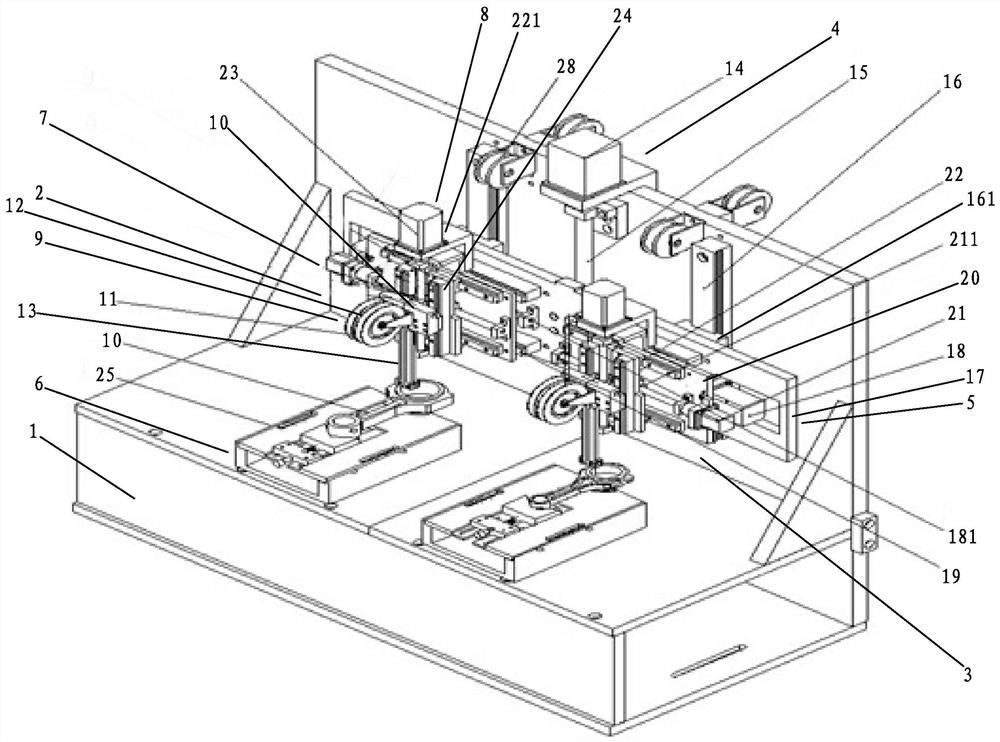

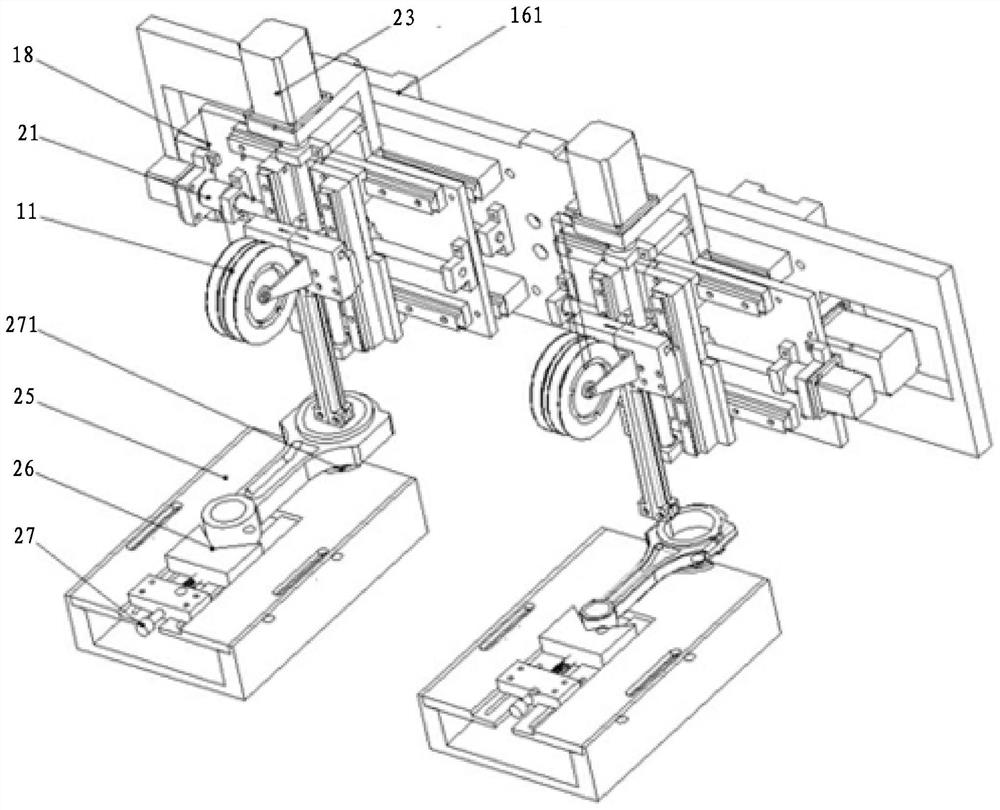

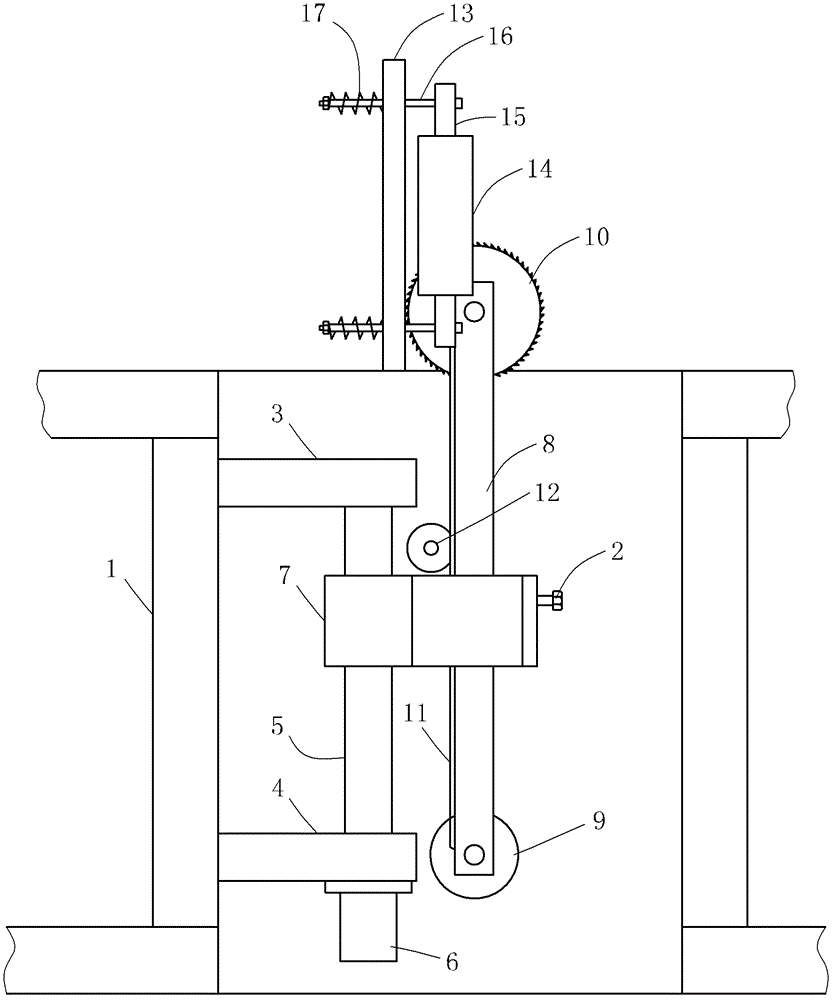

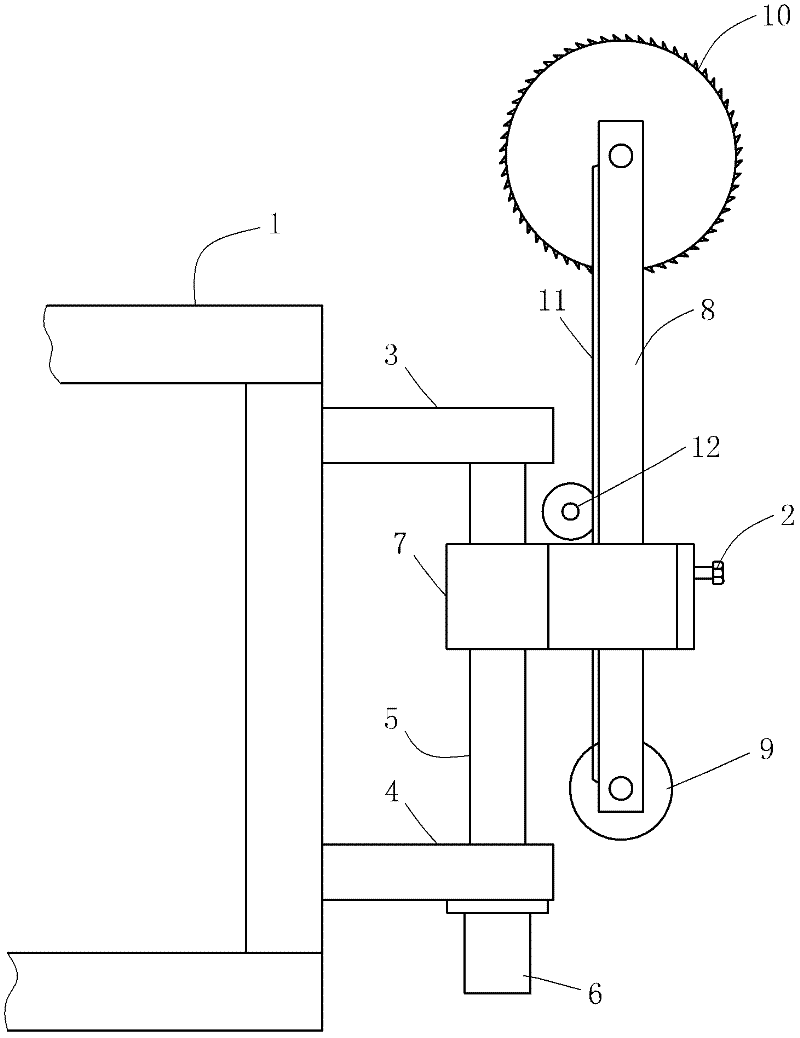

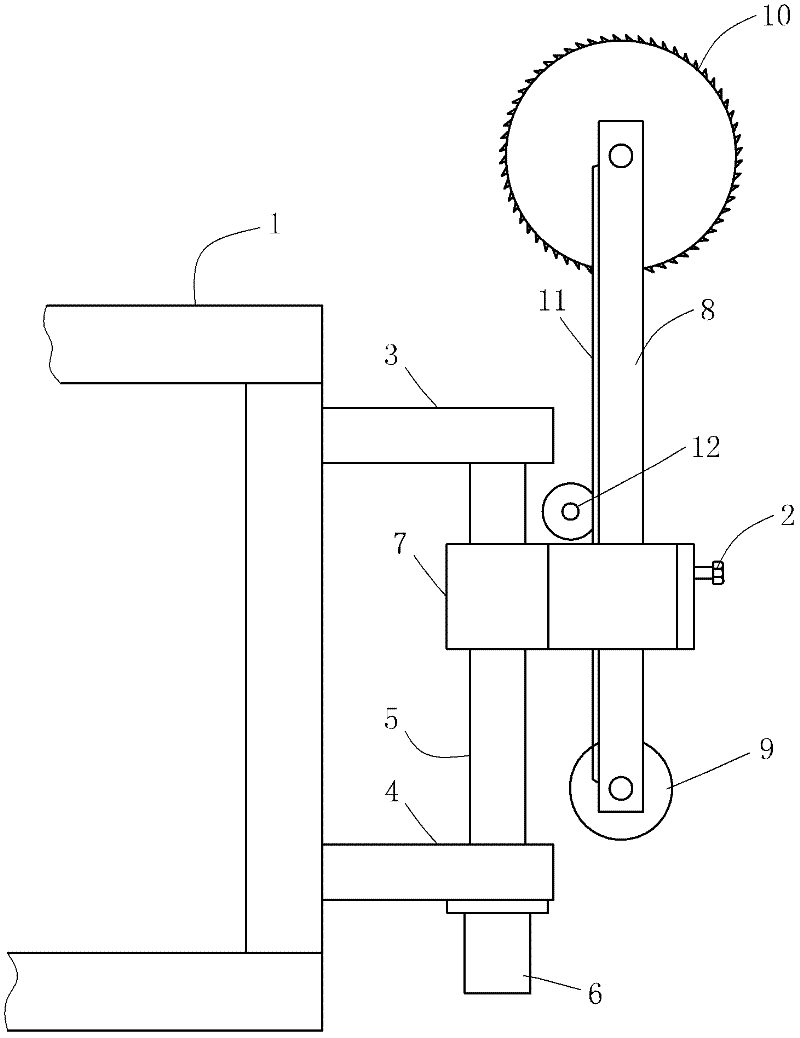

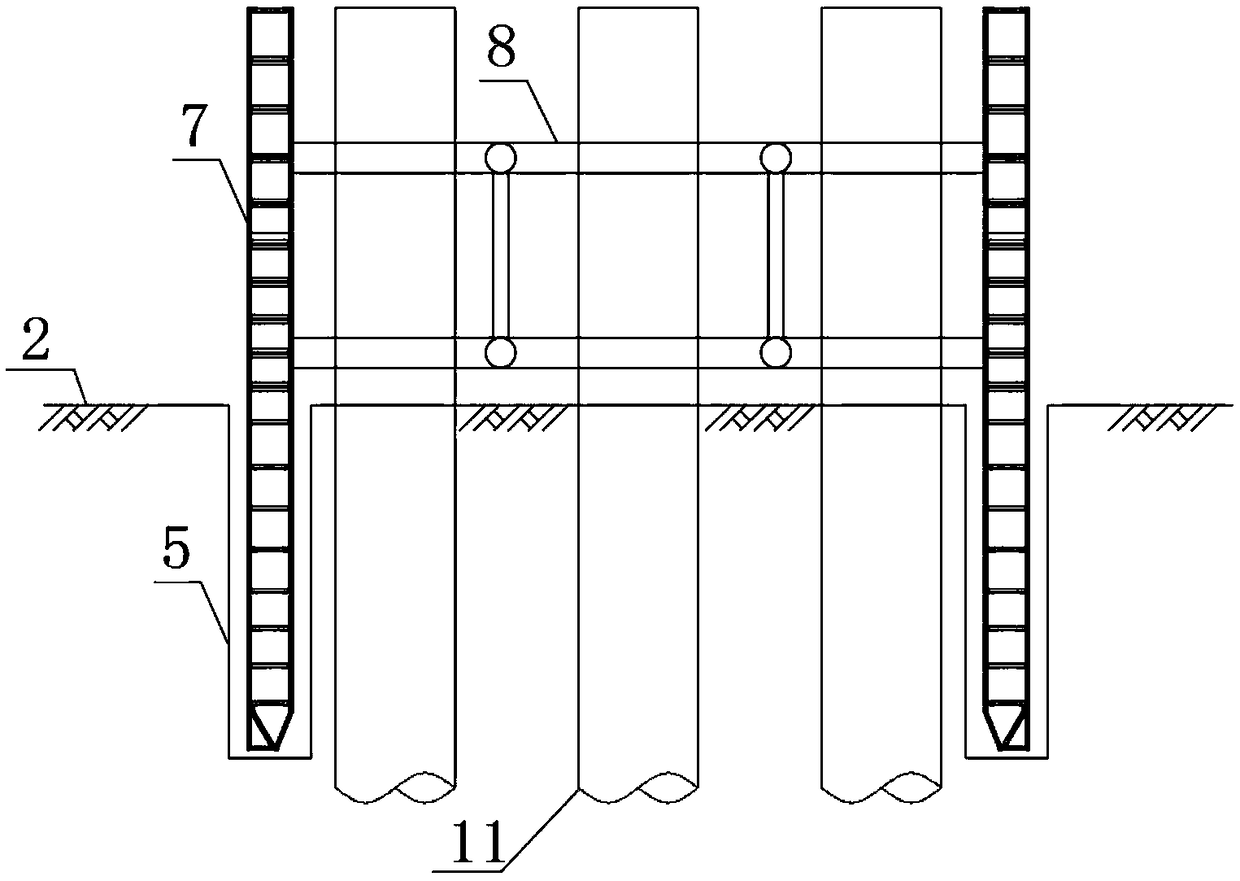

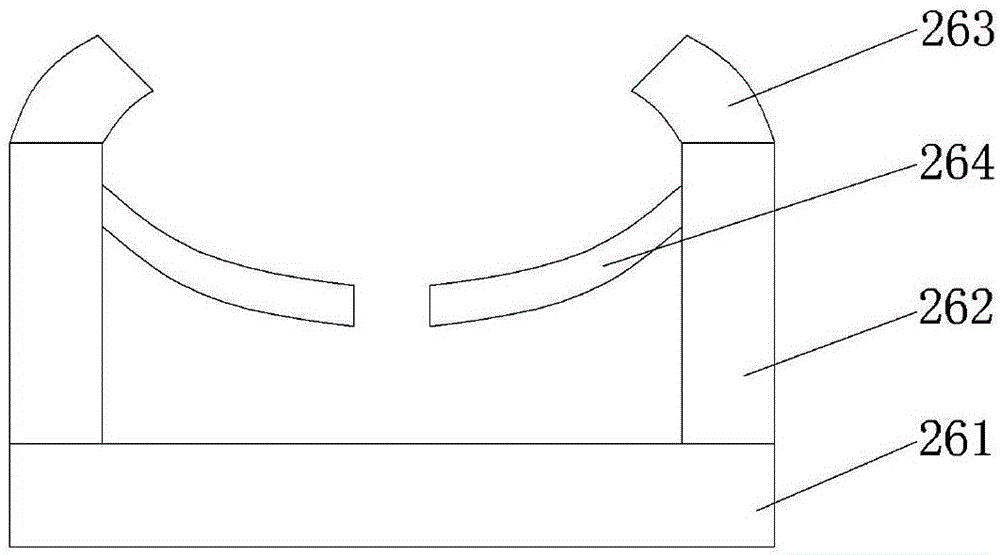

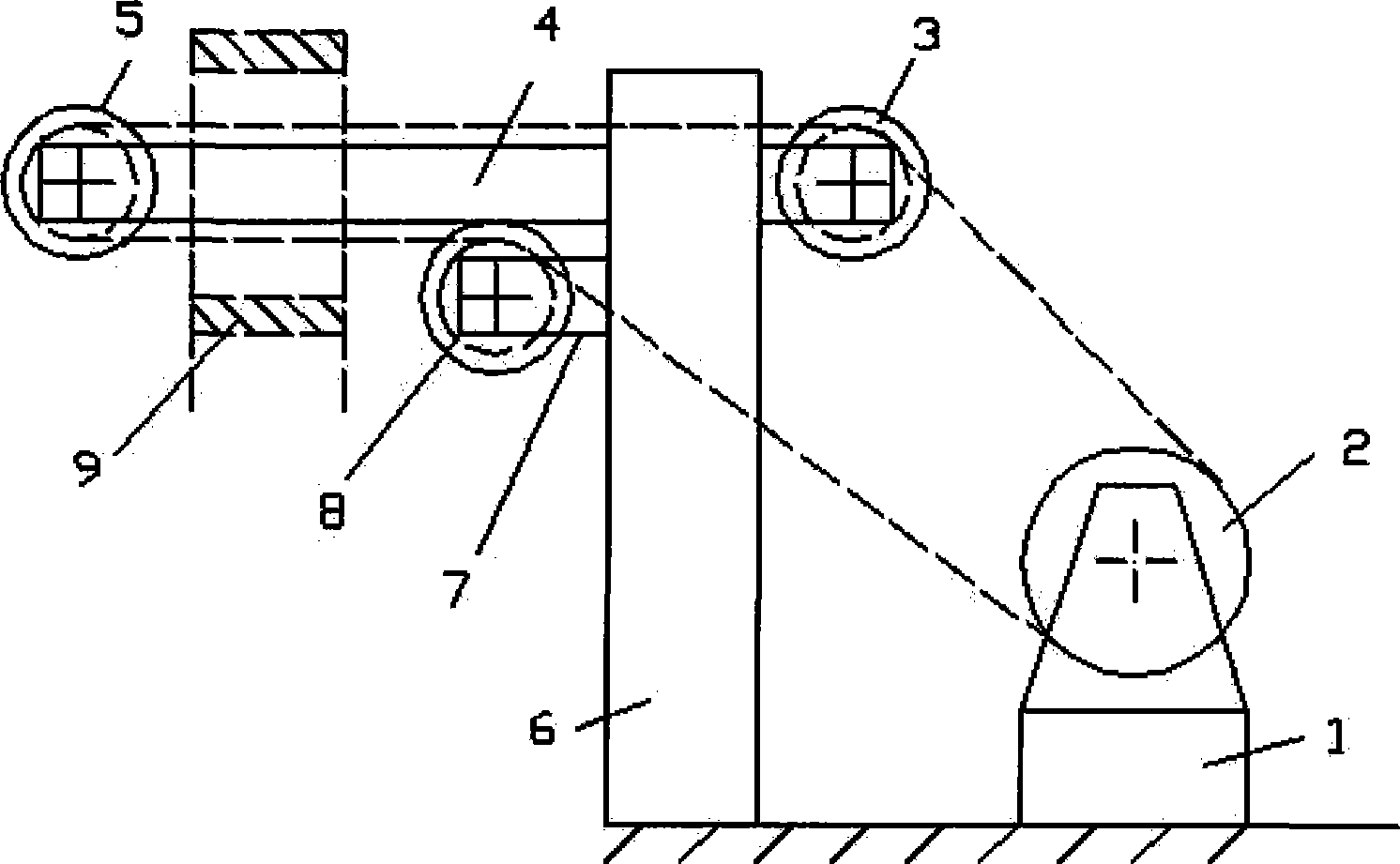

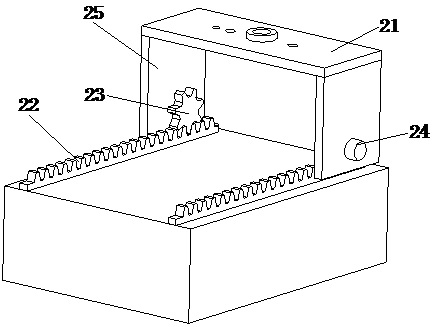

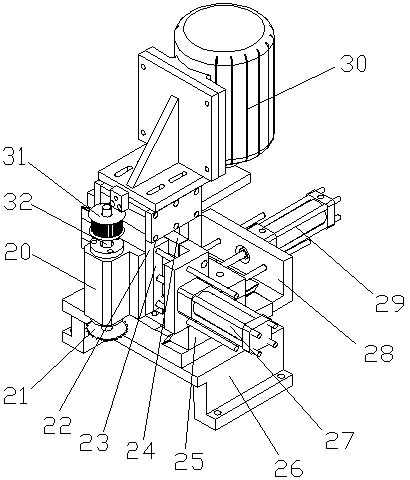

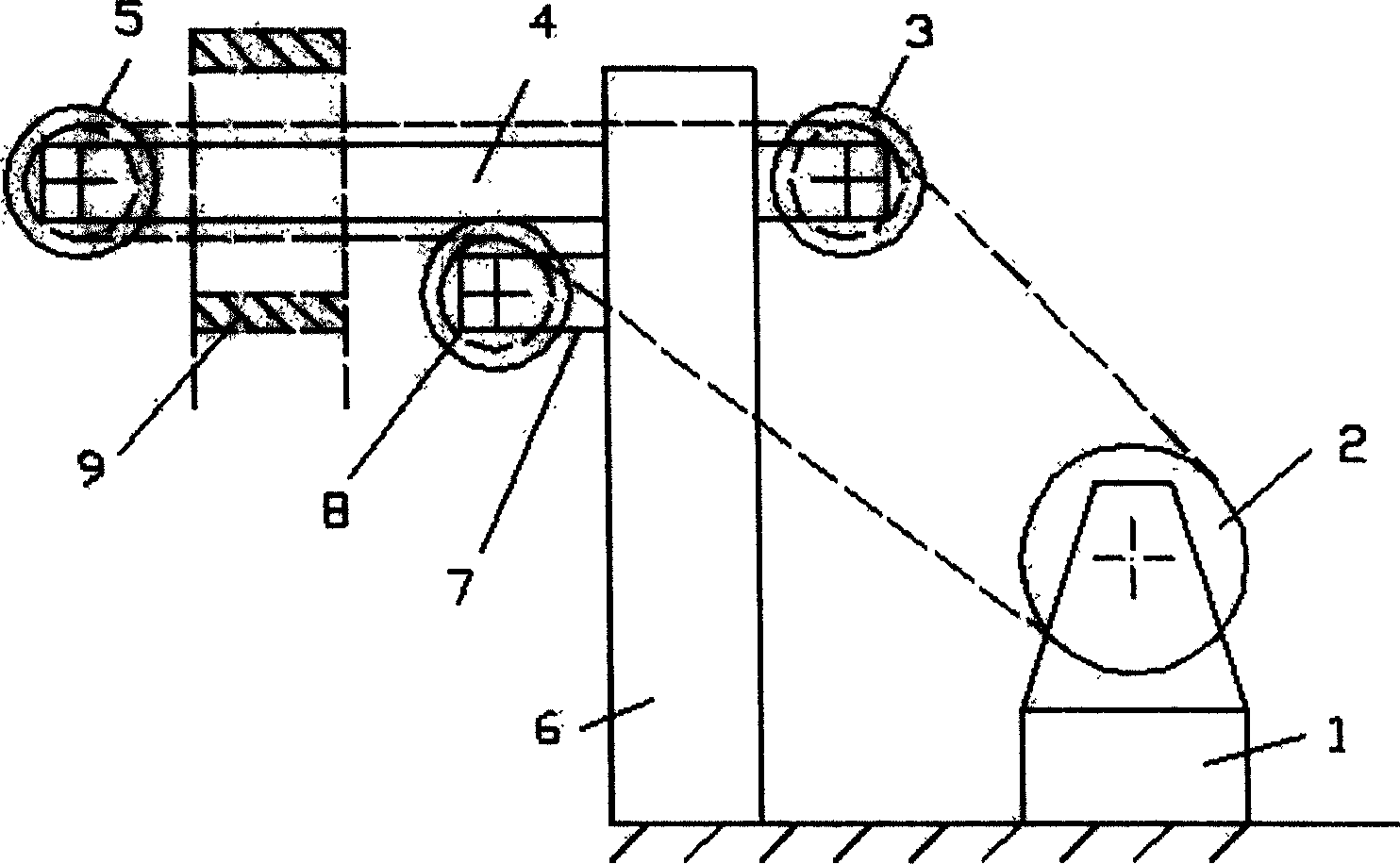

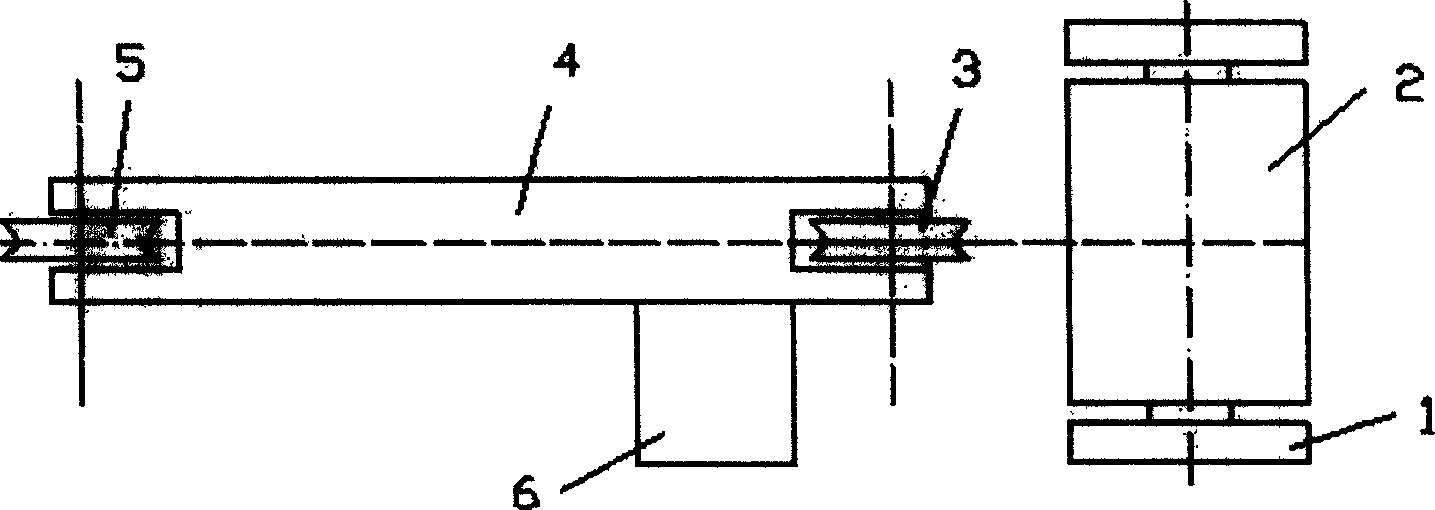

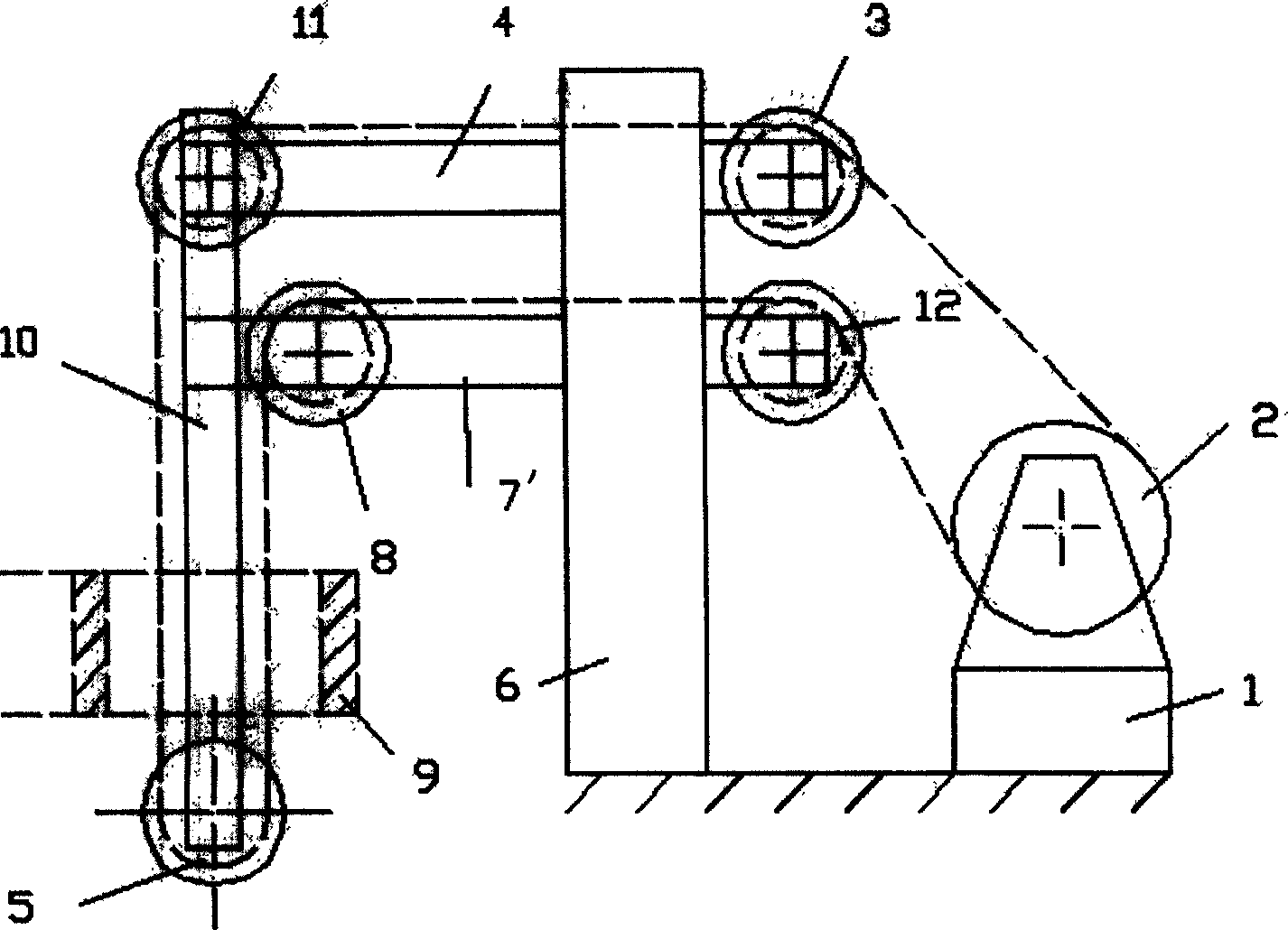

Grooving device of stereo luminous character enclosing machine

InactiveCN102430800AImprove stabilityImprove quality and efficiencyMetal sawing devicesRotational axisLinear motion

The invention discloses a grooving device of a stereo luminous character enclosing machine and belongs to the technical field of stereo luminous character processing equipment. The grooving device comprises a mounting seat for connecting a rack, wherein a rotation shaft driven by a first power device is rotatably mounted on the mounting seat; a sliding seat is fixedly mounted on the rotation shaft; a cutter bar is slidably mounted on the sliding seat; a cutter disk driven by a second power device is arranged on the cutter bar; and a linear driving device enabling the cutter bar to move linearly is arranged between the sliding seat and the cutter bar. The grooving device disclosed by the invention has a simple structure, operates stably, can be used for improving the grooving quality and is widely applied to the stereo luminous character enclosing machine.

Owner:WEIFANG HANDUN CNC EQUIP

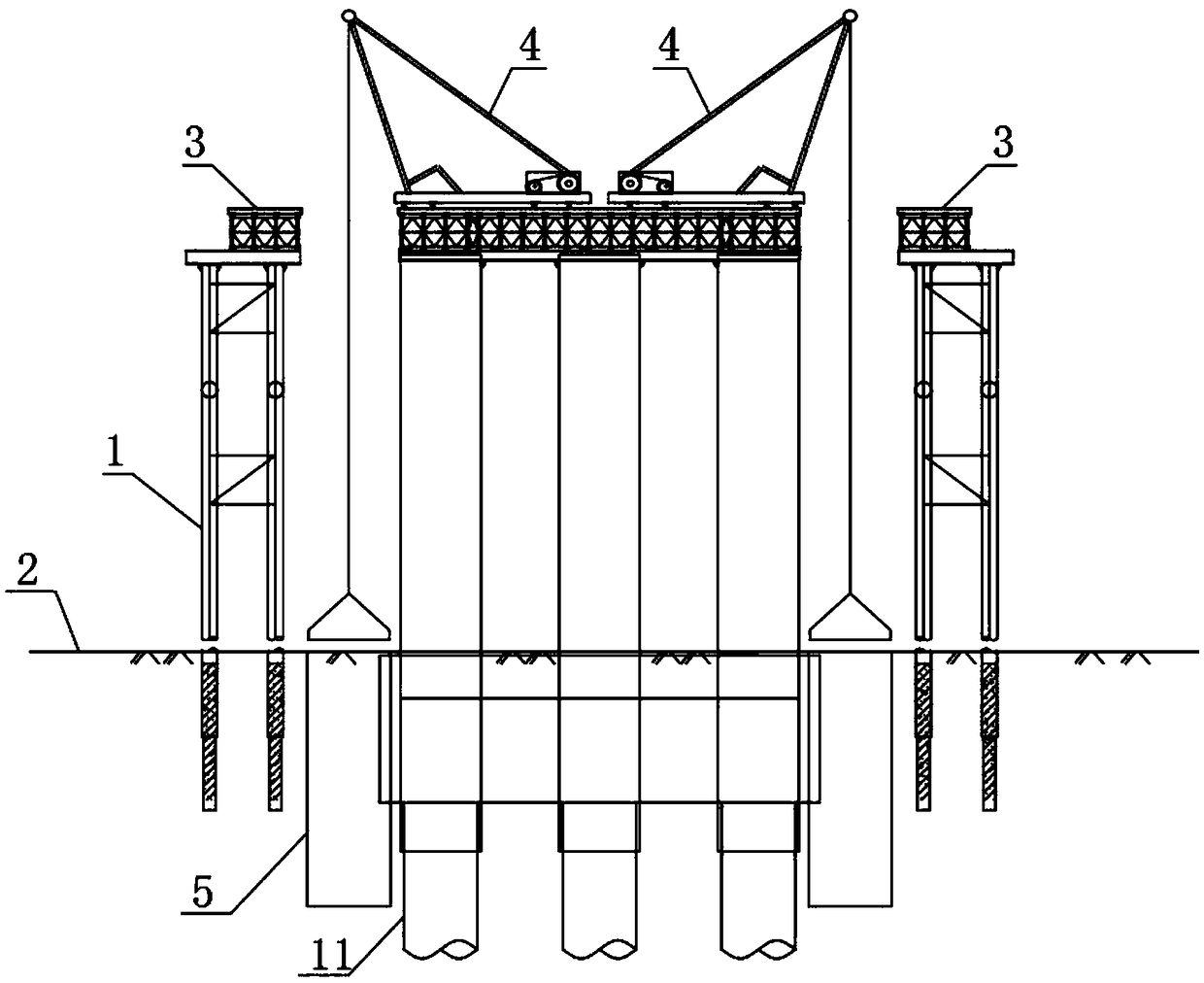

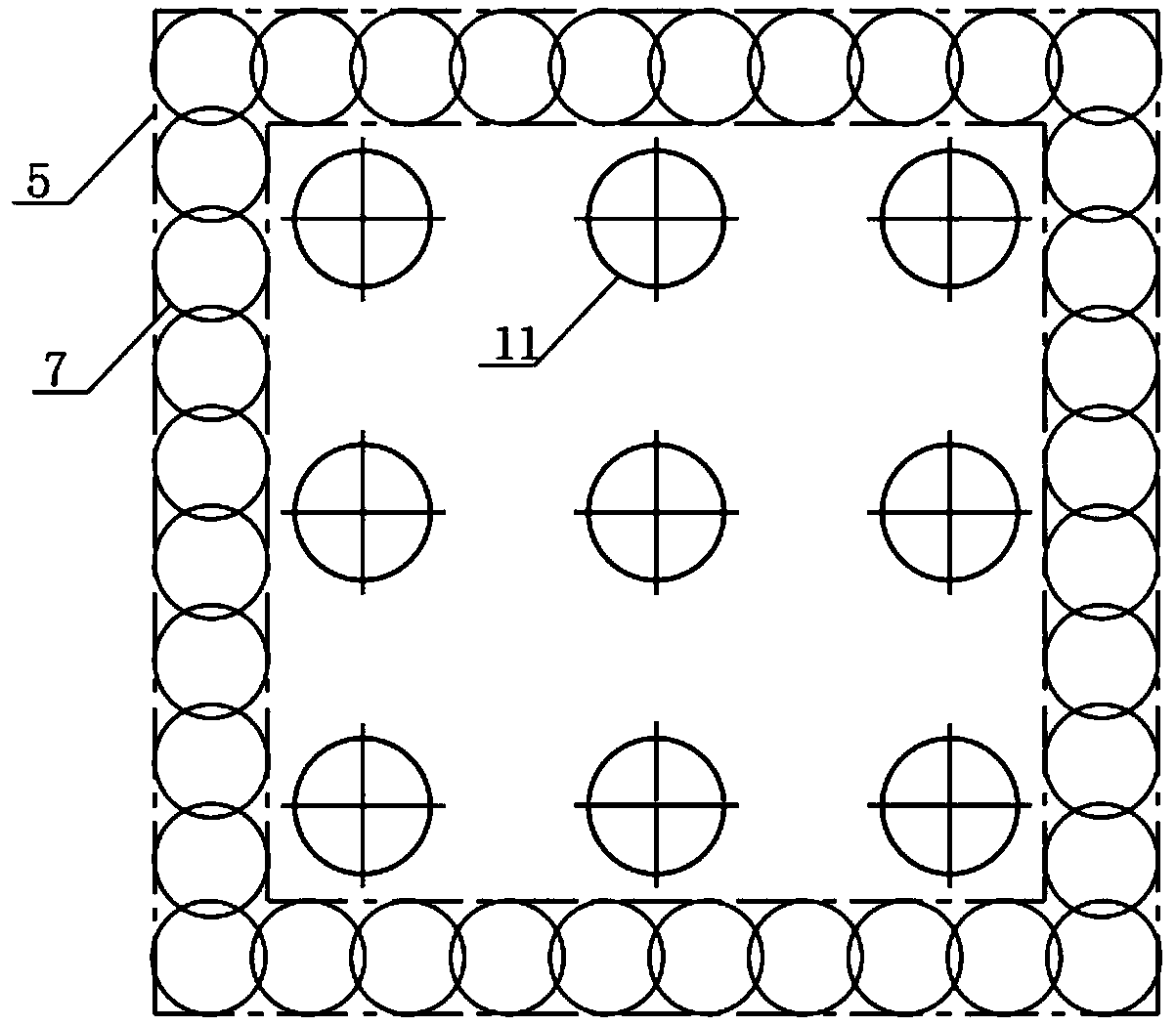

Deepwater embedded rock bearing platform foundation construction method

ActiveCN109469085AImprove groove qualityEnsure water-repelling and water-stopping effectFoundation engineeringSteel jacketCofferdam

The invention is applicable to the technical field of bridge deepwater foundation construction and provides a deepwater embedded rock bearing platform foundation construction method. According to themethod, a percussion drill is arranged by virtue of an over-water construction work platform; a slotted hole and a groove are formed, and no coverage layer is arranged; and the non-explosion construction mode is adopted. The influence on rock stratum disturbance and the surrounding environment is small; an over-water work platform does not need to be built; pile foundation construction equipment is fully utilized; no extra new equipment needs to be invested; a cofferdam foundation groove is good in groove formation quality; and the water stop effect of a steel jacket box cofferdam is guaranteed.

Owner:THE THIRD CONSTR CO LTD OF CHINA CONSTR THIRD ENG BUREAU

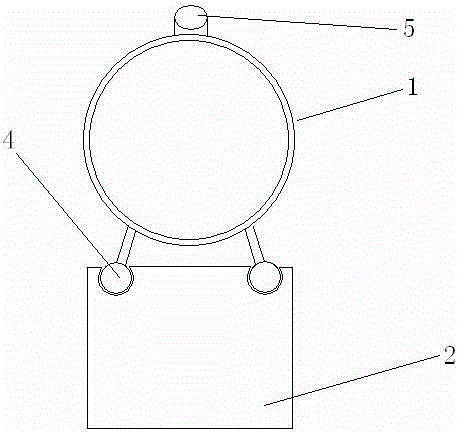

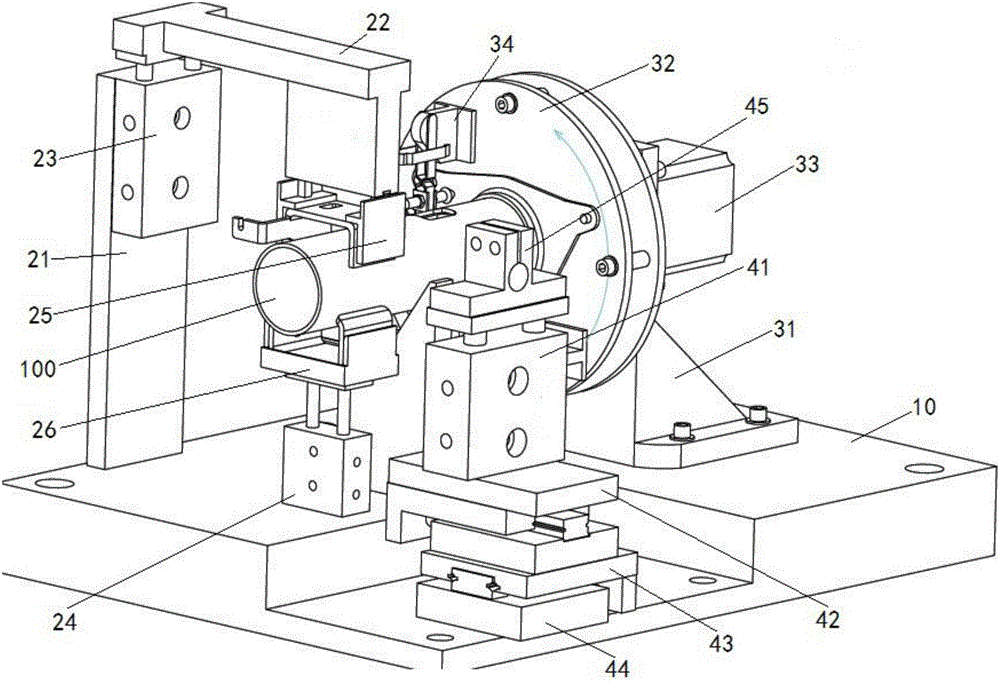

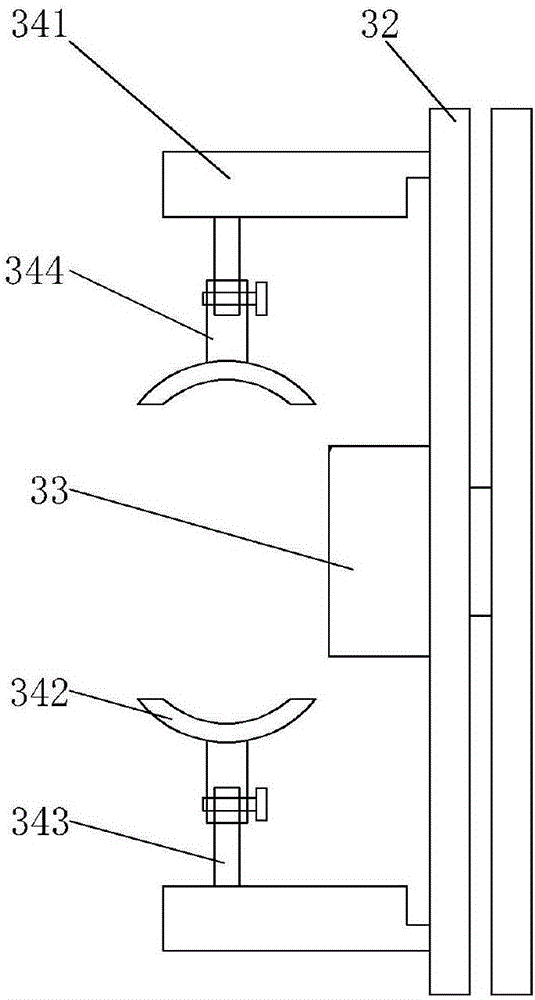

Fixing device for steel pipe grooving

The invention discloses a fixing device for steel pipe grooving. The fixing device comprises a base, a first fixing mechanism, a second fixing mechanism and a guiding mechanism. The first fixing mechanism comprises a stand column, a beam, a first lifting air cylinder, a second lifting air cylinder, a first clamp head and a second clamp head. The second fixing mechanism comprises a fixing base, a rotating disc and a rotating motor. An annular positioning protrusion and three annular positioning clamps are arranged on the rotating disc. The three annular positioning clamps are arranged on the outer side of the annular positioning protrusion and uniformly distributed around the axis of the rotating disc. The guiding mechanism comprises a third lifting air cylinder, a Y-axis sliding block, an X-axis sliding block and a bottom block which are sequentially arranged from top to bottom, and the movable end of the third lifting air cylinder is provided with a placement base for positioning a grooving machine. The fixing device is compact in structure, convenient to use and capable of effectively fixing a steel pipe, rapidly and accurately performing grooving in the axial direction and the radial direction of the steel pipe conveniently, and greatly improving the grooving efficiency and the grooving quality.

Owner:ZHEJIANG CHANKONG STEEL PIPE

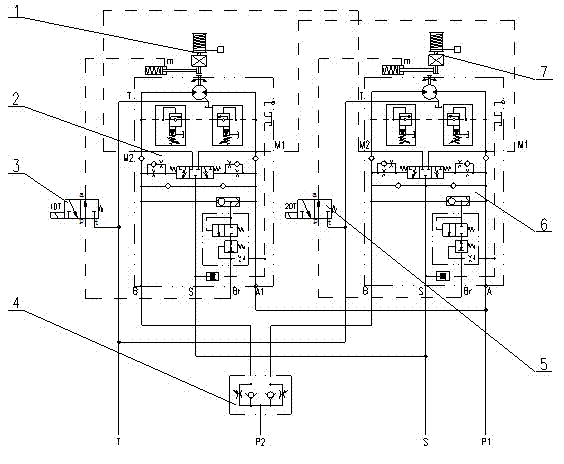

Double-winch synchronous control system

The invention relates to a double-winch control system, particularly to a double-winch synchronous control system. The double-winch synchronous control system comprises a front winch, a back winch, a front balance valve, a back balance valve, a front two-position three-way magnetic valve, a back two-position three-way magnetic valve and a one-way speed regulation valve group, wherein balance valves are mounted on the front winch and the back winch, the one-way speed regulation valve group is connected onto lifting oil ways of the front winch and the back winch, the front two-position three-way magnetic valve is connected between a Br port and a reducer brake port m of a front winch motor, the back two-position three-way magnetic valve is connected between a Br port and a reducer brake port m of a back winch motor, two M2 ports of the front winch and the back winch are connected, and two M1 ports of the front winch and the back winch are connected. According to the double-winch synchronous control system, synchronous speed regulation performance is stable and reliable when two winches place grab buckets down, loads of the two winches can be balanced when the grab buckets are lifted, unbalance loading cannot be caused, pipeline connection is simple, the cost is low, and the system is convenient to operate.

Owner:玉柴桩工(常州)有限公司

Irrigation and water conservancy construction slotting equipment

InactiveCN111364542AReduce hardnessAvoid damageSoil-shifting machines/dredgersIrrigation ditchesSprayerWater spray

The invention belongs to the technical field of irrigation and water conservancy equipment, and particularly relates to irrigation and water conservancy construction slotting equipment. The irrigationand water conservancy construction slotting equipment comprises a box body. A water tank is fixedly installed on the top of the box body. A water inlet is formed in the top of the water tank. A waterpump is fixedly installed on the top of the box body. A water pumping pipe and one end of a water outlet pipe are fixedly installed on the water pump. The water outlet pipe is fixedly installed on one side of the box body, and a sprayer is fixedly installed at the other end of the water outlet pipe. A handle is fixedly installed on one side of the box body. A first mounting plate is fixedly installed on one side of the box body, and a first guide pulley is installed on the first mounting plate in a rotating mode. A second mounting plate is fixedly installed on the other side of the box body,and a second guide pulley is fixedly installed on the second mounting plate. According to the irrigation and water conservancy construction slotting equipment, manual slotting is avoided, and time andlabor are saved; moreover, a vibration device is arranged, soil bonding is effectively prevented, and slotting efficiency and quality are greatly improved; and a water spraying device is further arranged, soil is made humid and softened, the phenomenon that the soil is too hard to damage a slotting rod is prevented and the service life of the slotting equipment is prolonged.

Owner:王小珍

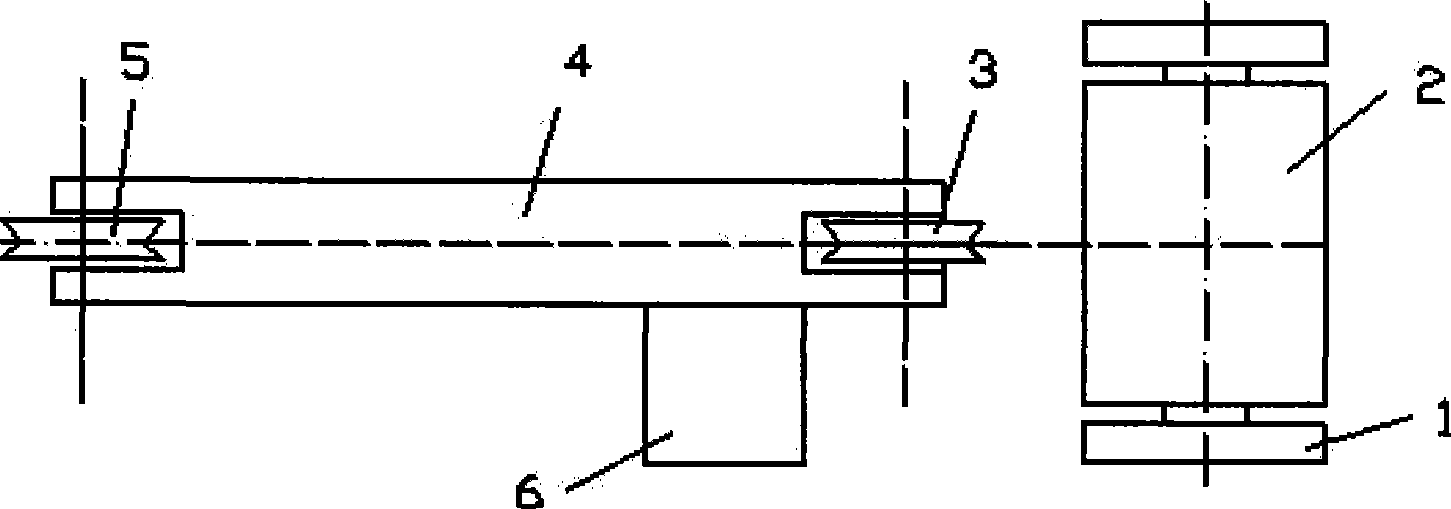

Wire-electrode cutting electromachining machine tool for asymmetrical guide frame notch cutting in series

InactiveCN101428366AImprove productivityReduce operation time and difficultyElectrical-based machining electrodesWire frameWire cutting

The invention discloses a wire-cutting electric machining machine tool for series-type asymmetrical wire frame grooving, the machine tool is characterized in that a thread rolling cylinder base and a supporting pole are fixed on the machine tool bed, a thread rolling cylinder is fixed on the thread rolling cylinder base, a main wire frame is fixed on the supporting pole, and a rear guide wheel is fixed at the rear end of the main wire frame; and a front guide wheel is fixed at the front end thereof; a perforation wire frame is fixed at a certain angle at the front end of the main wire frame from one end thereof, and a rewinding guide wheel is fixed at the front end of the perforation wire frame; an auxiliary wire frame is fixed on the supporting pole and positioned at the lower part of the main wire frame, a transitional guide wheel is fixed at the rear end of the auxiliary wire frame, and a directional guide wheel is fixed at the front end thereof; a metal wire from the thread rolling cylinder perforates a work piece through the rear guide wheel and the front guide wheel and returns to the thread rolling cylinder around the rewinding guide wheel through the directional guide wheel and the transitional guide wheel; therefore, when the components are cut from inside to outside through the wire-cutting electric machining machine tool for grooving, the perforating wire is not required for each time, the production rate can be obviously enhanced, and the operation time and the operating difficulty are reduced.

Owner:GUANGDONG UNIV OF TECH

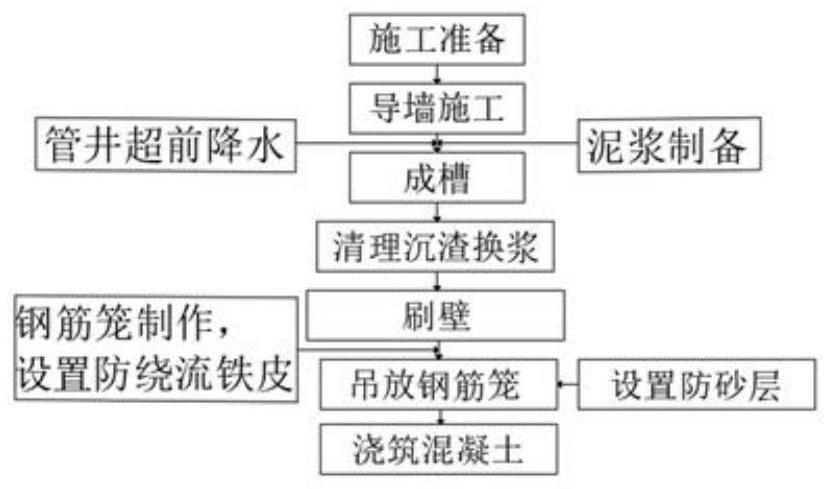

Construction method of underground diaphragm wall in water-rich silty-fine sand layer

InactiveCN112281810AReduce side pressureImprove stabilityExcavationsBulkheads/pilesSlurry wallSodium Bentonite

The invention discloses a construction method of an underground diaphragm wall in a water-rich silty-fine sand layer. The construction method comprises the following steps of guide wall construction,tube well advanced precipitation, slurry preparation, grooving, groove cleaning and slurry replacement, wall brushing, reinforcement cage manufacturing, reinforcement cage hoisting, sand prevention layer arrangement and concrete pouring. According to the construction method of the underground diaphragm wall in the water-rich silty-fine sand layer, firstly, the self-stability of groove walls is improved through advanced precipitation of tube wells in a foundation pit which are constructed in advance; and during grooving, sodium bentonite is adopted for slurry manufacturing, and thin and tough slurry cakes are formed on the groove walls, so that the collapse resistance is improved.

Owner:江苏旭辰交通科技发展有限公司

Wood board slotting processing device

InactiveCN112277099AControl depthDepth is easy to controlWood mortising machinesBark-zones/chip/dust/waste removalGear wheelWood machining

The invention discloses a wood board slotting processing device, and belongs to the technical field of wood processing. The wood board slotting processing device comprises a workbench, a moving assembly, a fixing assembly, a slotting assembly and a dust suction assembly, wherein the workbench is horizontally arranged; the moving assembly is arranged on the workbench and is in sliding fit with theworkbench; the fixing assembly is arranged beside the workbench and is in sliding fit with the top of the workbench; the slotting assembly is arranged on the moving assembly; and one end of the dust suction assembly is arranged beside the workbench, and the other end of the dust suction assembly is arranged on the slotting assembly. According to the wood board slotting processing device, a movingmotor works to drive two gears to rotate on two racks in a meshed mode, so that two moving side plates are driven to slide on the workbench, the length of a wood board slot can be controlled, the holesize is accurate, and the working efficiency is high.

Owner:CHANGDE FEIERMEI CHEM TECH CO LTD

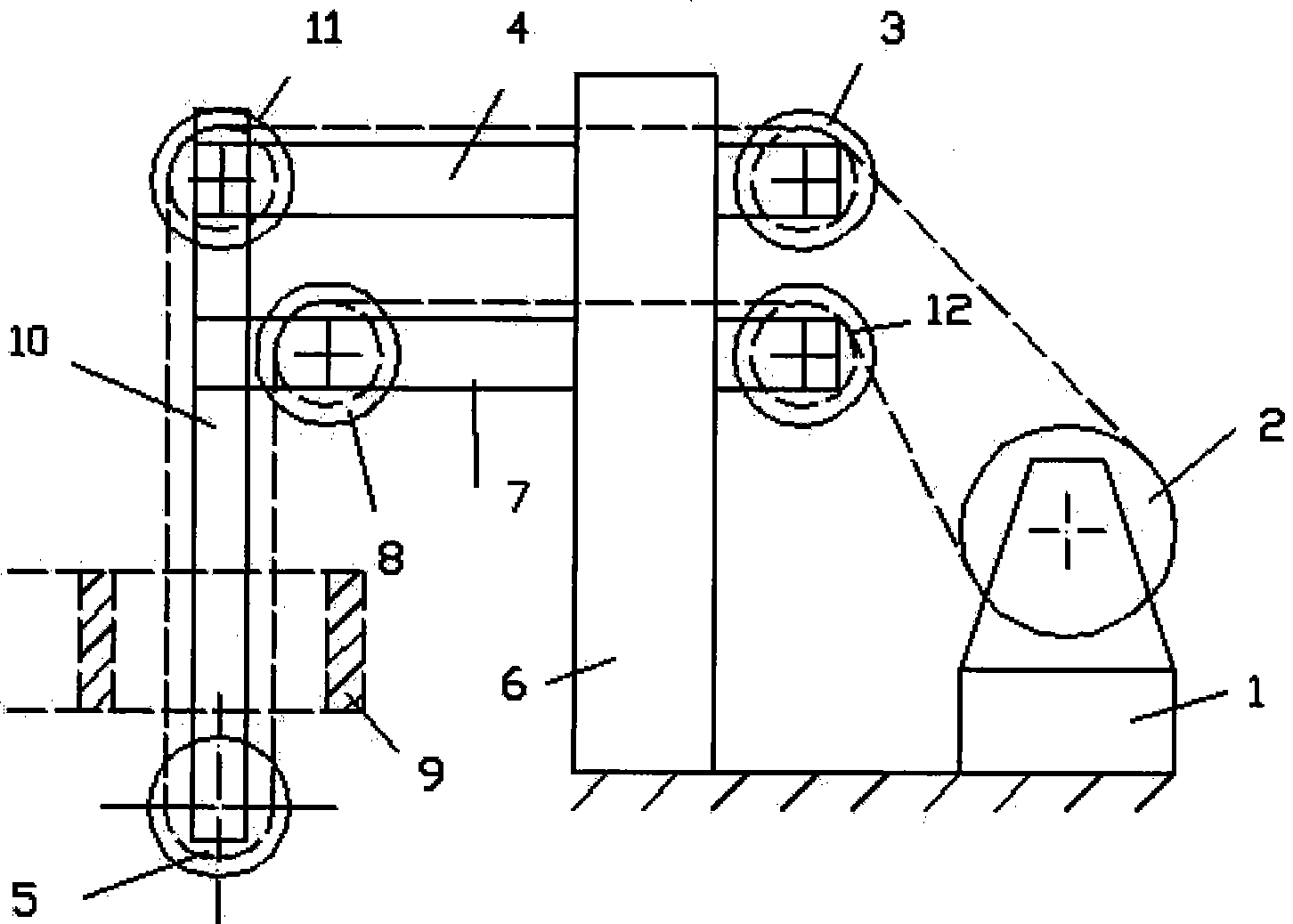

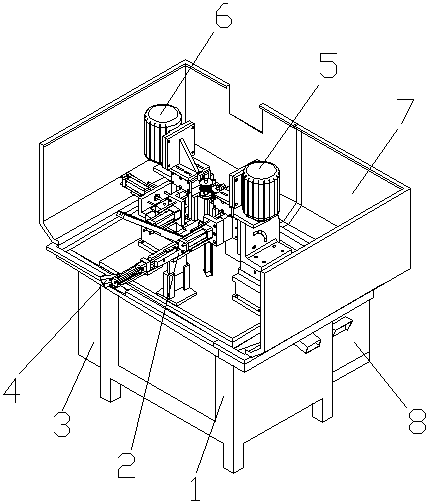

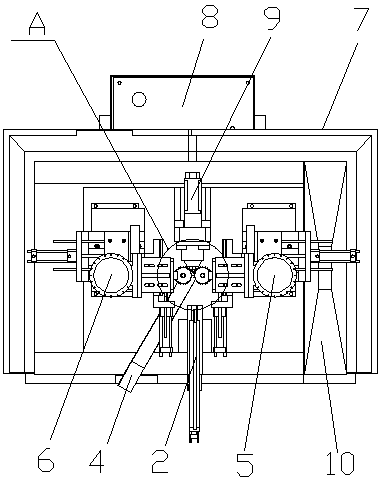

Indexing rotation type automatic slotting machine

ActiveCN108326608ACompact structureHigh degree of automationMetal sawing devicesPrecision positioning equipmentDistribution controlFuel tank

The invention relates to a slotting technology in machining, in particular to an indexing rotation type automatic slotting machine. The indexing rotation type automatic slotting machine comprises a rack as well as a power distribution control box, a feeding device, a left slotting device, a right slotting device and an indexing rotation device which are arranged on the rack, wherein the left slotting device and the right slotting device are symmetrically arranged on two sides of the indexing rotation device; the feeding device is arranged in front of the indexing rotation device; a dischargingtrack is arranged below the indexing rotation device; a scrap hopper is arranged in the position, below the right slotting device, on the rack; a protective plate is arranged in the position, locatedaround the left slotting device and the right slotting device, on the rack; a power oil tank cooperating with the left slotting device and the right slotting device is arranged on the rear side of the rack. The indexing rotation type automatic slotting machine has the advantages that structure is compact, automation degree is high, slotting efficiency is increased greatly, labor intensity of a worker is reduced greatly, and machining precision is improved.

Owner:SUZHOU YUANLIAN SCI & TECH PIONEER PARK MANAGEMENT CO LTD

Plate grooving device and plate grooving method

PendingCN112265085AReduce vibration amplitudeReduce labor costsProfiling/shaping machinesWood mortising machinesWorkbenchPhysics

The invention relates to a plate grooving device and belongs to the technical field of plate processing. The plate grooving device comprises a workbench; the workbench is provided with a compression roller assembly for driving a plate to move, a guiding assembly for guiding the plate, and a cutting assembly for grooving the plate; the compression roller assembly comprises a base and a compressionroller base arranged on the base; a roller used for abutting against the upper surface of the plate is rotationally connected to the compression roller base; a driving mechanism used for driving the roller to rotate around the axis is arranged on the compression roller base; the guiding assembly comprises an installing base installed on the workbench; a guiding rod is arranged on the installing base; a tool groove used for containing a tool is formed in the guiding rod; and a chip baffle is arranged at one end, far away from the grooving device, of the tool groove. The plate grooving device has the effect of optimizing the plate grooving quality.

Owner:湖南雅居乐家居有限公司

Groove cutting method and cutting equipment for trackless circular part board

InactiveCN103567600AQuality improvementImprove processing speedGas flame welding apparatusSteering angleTorch

The invention discloses a groove cutting method and cutting equipment for a trackless circular part board. A semiautomatic flame cutting machine is used, and a roller is mounted on the side surface of the flame cutting machine through a roller frame; when the diameter of the circular part board is larger than or equal to 1000 mm, the flame cutting machine is arranged on the circular part board, and the roller is in rolling matching with the peripheral end surface of the circular part board; when the diameter of the circular part board is smaller than 1000 mm, the circular part board is coaxially arranged on a circular cutting template, the flame cutting machine is arranged on the circular cutting template, and the roller is in rolling matching with the peripheral end surface of the circular cutting template; and the steering angle of a front guide wheel of the flame cutting machine is adjusted, so that the turning radius of the flame cutting machine is in consistence with the peripheral radian of the circular part board or the circular cutting template, a cutting torch of a cutting gun of the flame cutting machine is adjusted to be aligned to the peripheral end surface of the circular part board, and the groove angle is well adjusted. With the adoption of the groove cutting method and the cutting equipment, the groove quality of the circular part board can be improved, the processing speed can be increased, part deformation is avoided, and guarantee is provided for later welding.

Owner:FANGCHENGGANG ZHONGYI HEAVY IND

Linear cutting electrical process machine for cutting groove

InactiveCN1765554AImprove productivityReduce operation time and difficultyElectrical-based machining electrodesProduction rateEngineering

The invention discloses a wire-electrode cutting electrical machine for cutting groove, wherein, the winding reel base and the support post are mounted on the body of machine, while the winding reel is mounted on the winding reel base; main guide frame is mounted on the support post; a guide wheel is mounted at the back of main guide frame whose front has a spiral guide wheel; the auxiliary guide frame has a orient guide wheel; the metal wire out from the winding reel can pass back guide wheel, work-piece, bypass spiral guide wheel, to the winding reel; said spiral guide wheel has smaller diameter than the hole of work-piece. When the invention cutting work-piece from outer to inner, the through-wire can be avoided in each time to improve the producing efficiency and reduce the operation time and difficulty.

Owner:GUANGDONG UNIV OF TECH

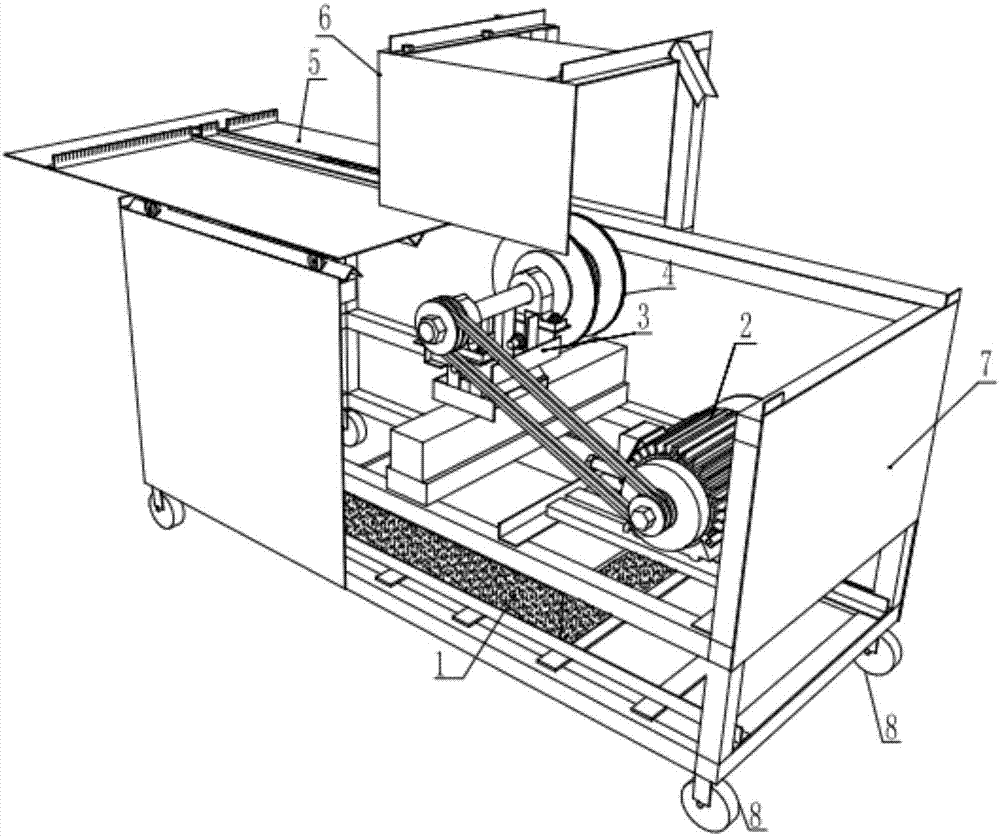

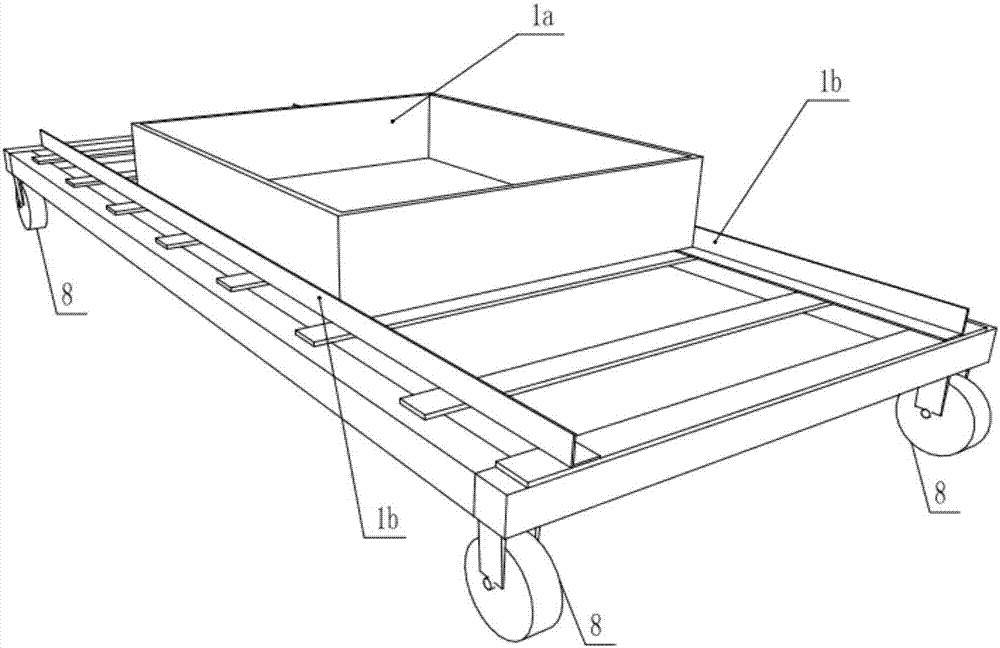

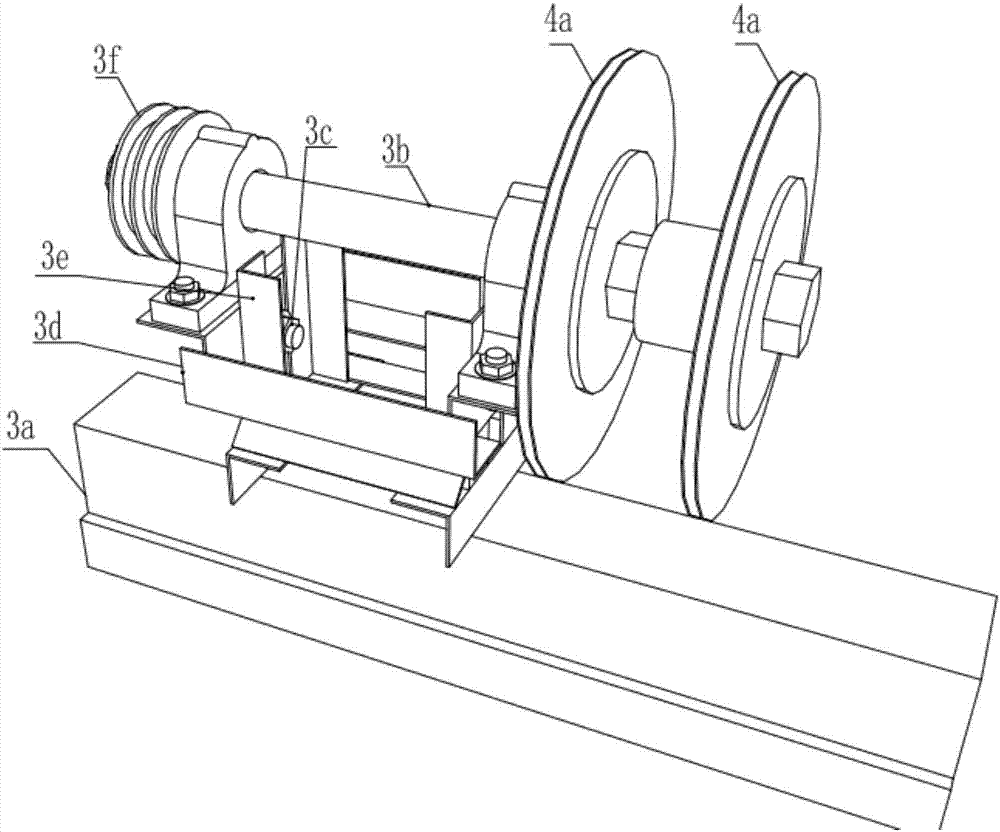

Integrated building block grooving machine

PendingCN107877715ASolve the problem of excessive dustEasy to useWorking accessoriesStone-like material working toolsArchitectural engineeringSlide plate

An integrated building block grooving machine comprises a rectangular crate (7) and a grooving device arranged in the crate, the grooving device comprises a dust falling water trough (1) formed in thelower portion of the crate and a grooving depth adjustment supporting seat (3) arranged above the dust falling water trough, the grooving depth adjustment supporting seat (3) is connected with an adjustable blade combination device (4) and a motor (2), a sliding plate (5) is arranged on the top face of a crate body of the crate (7), and a protective cover (6) is arranged on the position, corresponding to the adjustable blade combination device (4), above the sliding plate (5). According to the integrated building block grooving machine, the grooving depth, width and distance of a building block can be controlled, the grooving efficiency and the grooving quality are effectively improved, the problem that flying dust is over much in the mechanical grooving process is solved, and operation is safe and convenient.

Owner:YUNNAN CONSTR ENG GENERAL CONTRACTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com