Deepwater embedded rock bearing platform foundation construction method

A technology for foundation construction and deep water, applied in basic structure engineering, construction, etc., can solve the problems of cofferdam not being able to be implanted to the predetermined position, unsuitable for underwater blasting construction, difficult construction of caps, etc., so as to ensure the effect of retaining water and stopping water. , Small influence, good groove quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

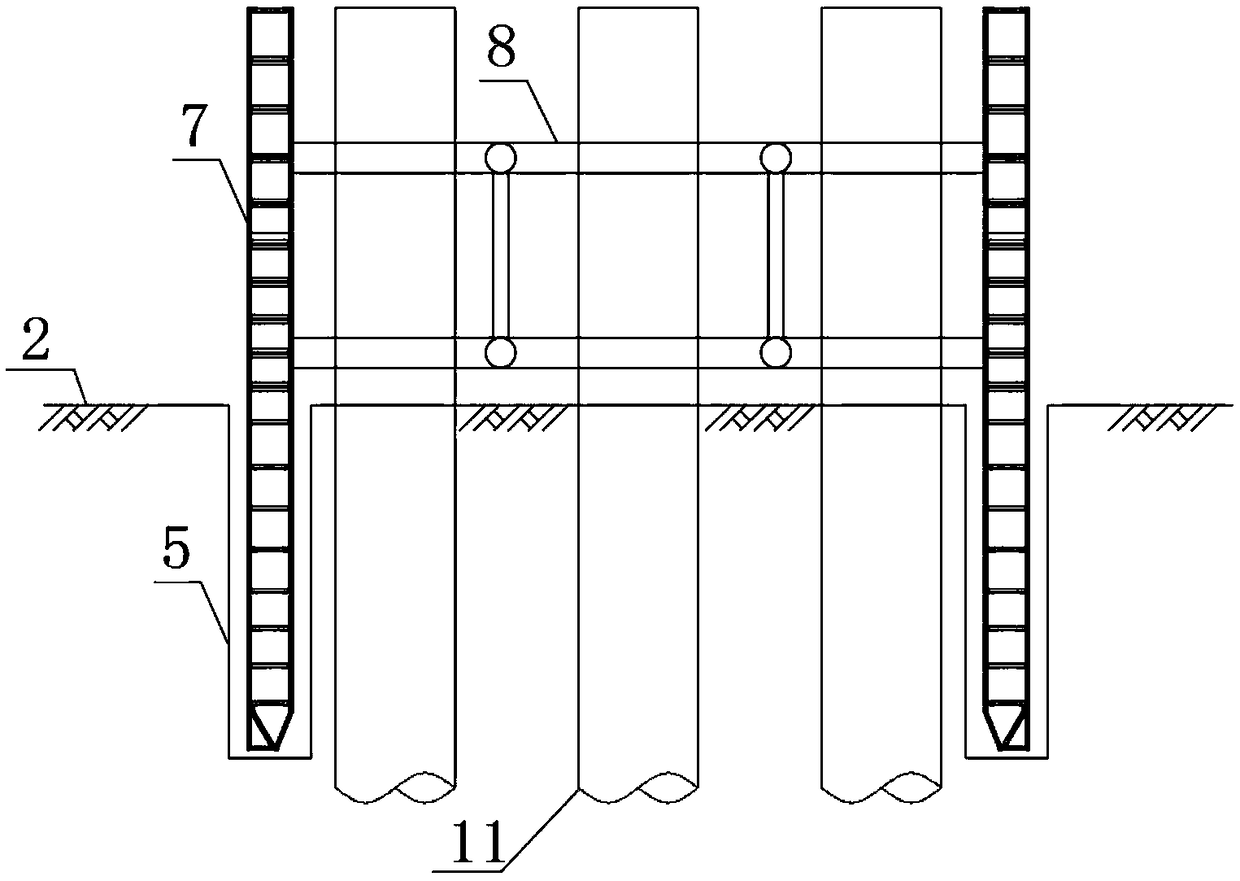

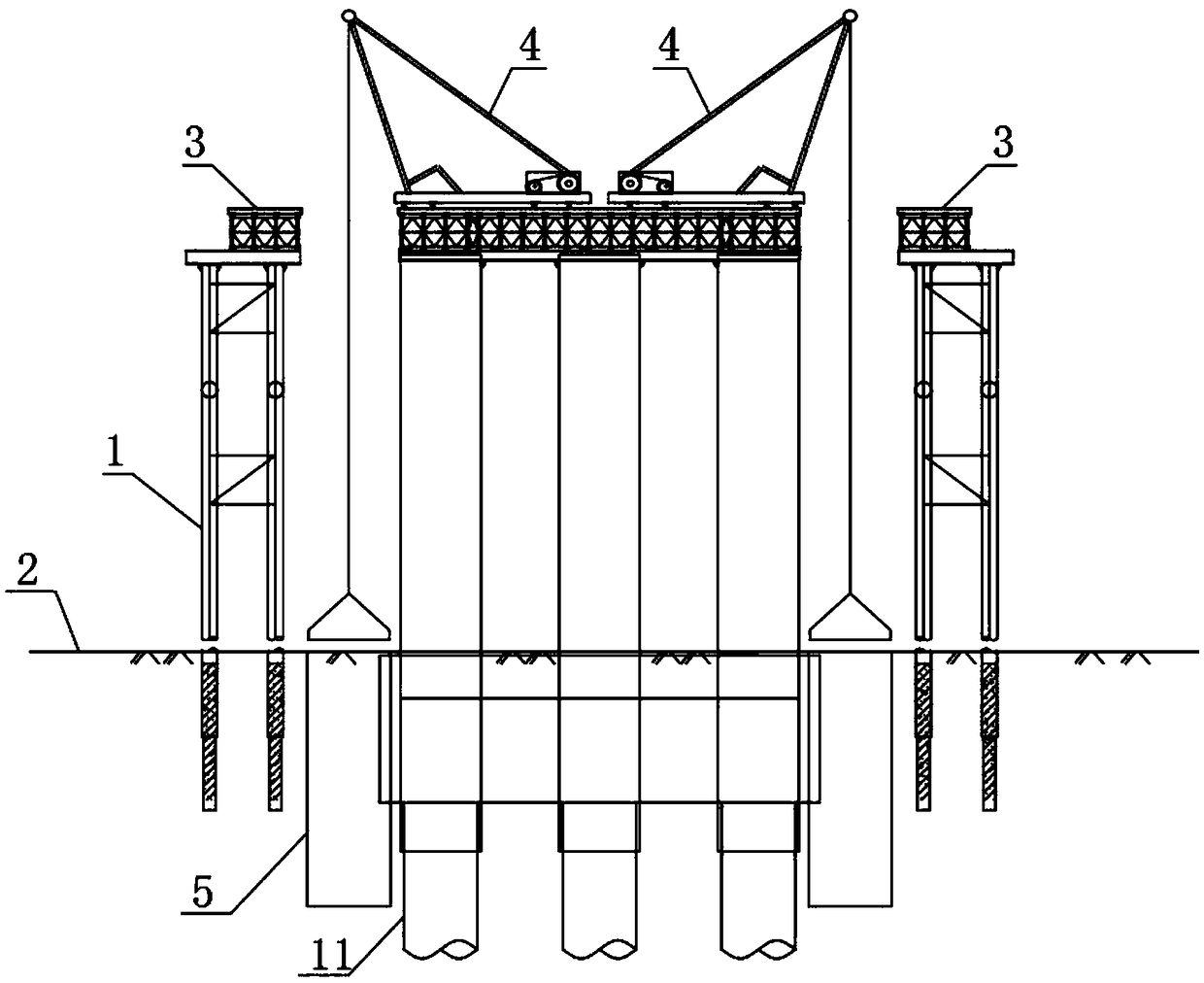

[0037] A deep water rock-socketed platform foundation construction method, such as Figure 1 to Figure 4 shown, including the following steps:

[0038] Step 1, clean up the riverbed 2 cover layer, drive large and small steel pipe piles 1 into the riverbed, and weld and erect Bailey beams, and lay platform panels to form the water construction work platform 3.

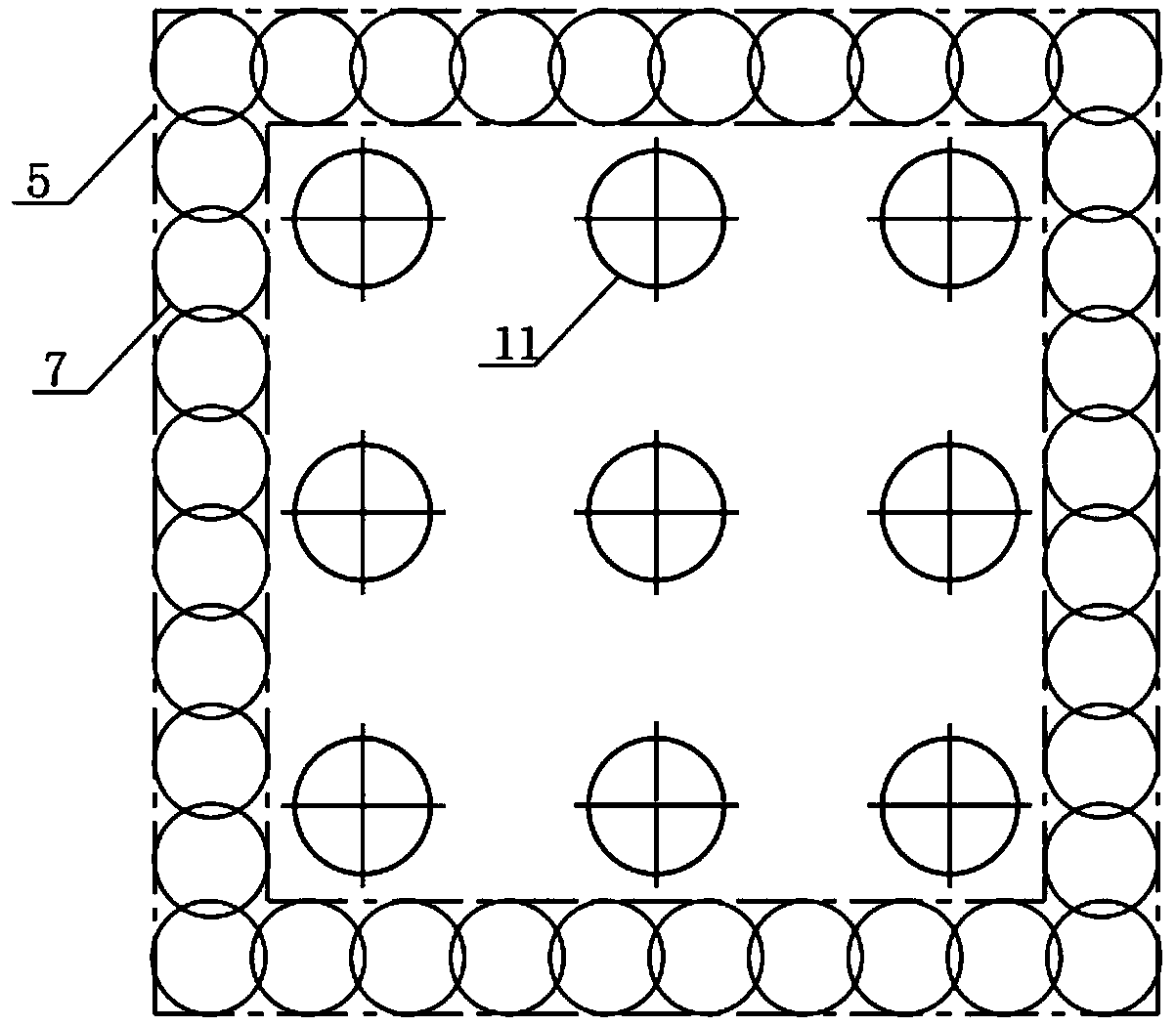

[0039] Step 2. Carry out measurement and lofting according to the design drawings, and arrange the opening range of slots 5.

[0040] Step 3. Arrange the percussion drilling machine 4 on the above-water construction work platform 3, and carry out drilling construction along the opening range 5 of the slot hole.

[0041] Specifically, the slot hole is drilled first, and then the rock formation within the opening range of the slot hole is drilled to form a groove. During the construction of the slot hole, a steel casing 11 is installed at the hole position, and the steel casing 11 is buried in the rock formation 50 ~80c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com