Plate grooving device and plate grooving method

A grooving equipment and plate technology, applied in the field of plate processing, can solve the problems of difficult to control the speed of plate movement, unstable feed per revolution of the tool, unstable surface quality, etc., to achieve stable grooving quality and low labor costs. , Reduce the effect of knife lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following is attached Figure 1-14 The application is described in further detail.

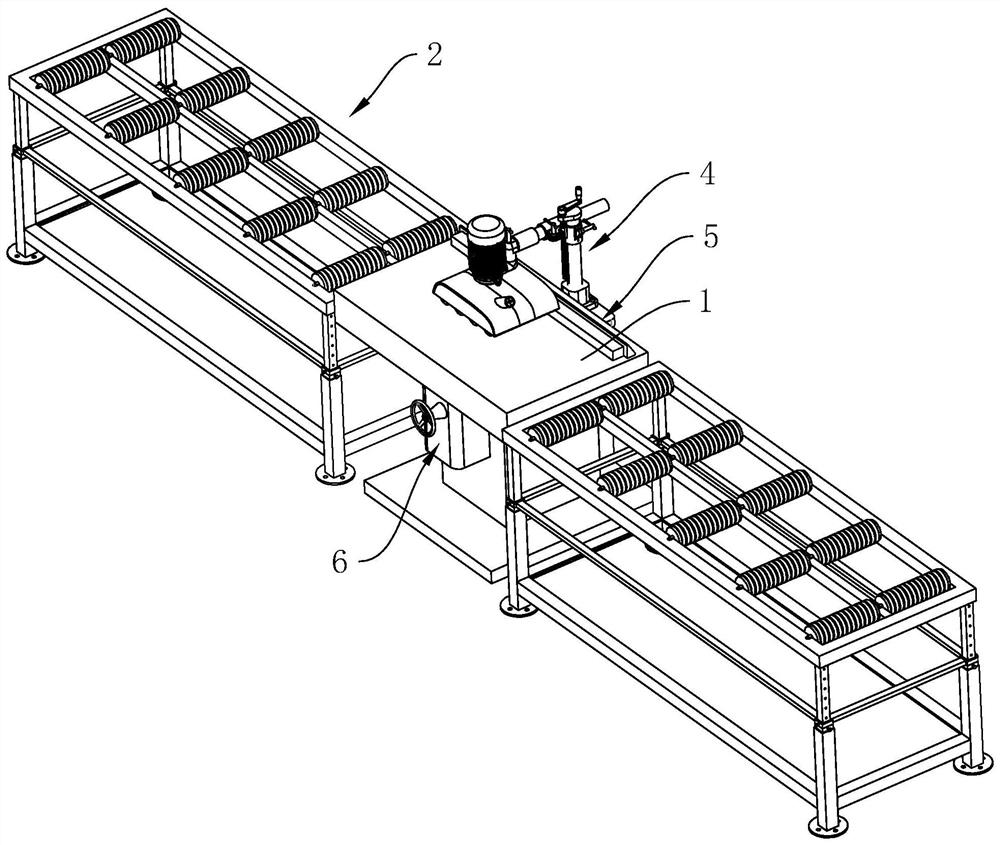

[0054] The embodiment of the present application discloses a plate slotting equipment, refer to figure 1 , including a workbench 1, the workbench 1 is provided with a pressure roller assembly for driving the plate to move, a guide assembly 5 for guiding the plate, a cutting assembly 6 for grooving the plate, the feeding end and the outlet of the workbench 1 The material ends are respectively provided with supporting components 2 .

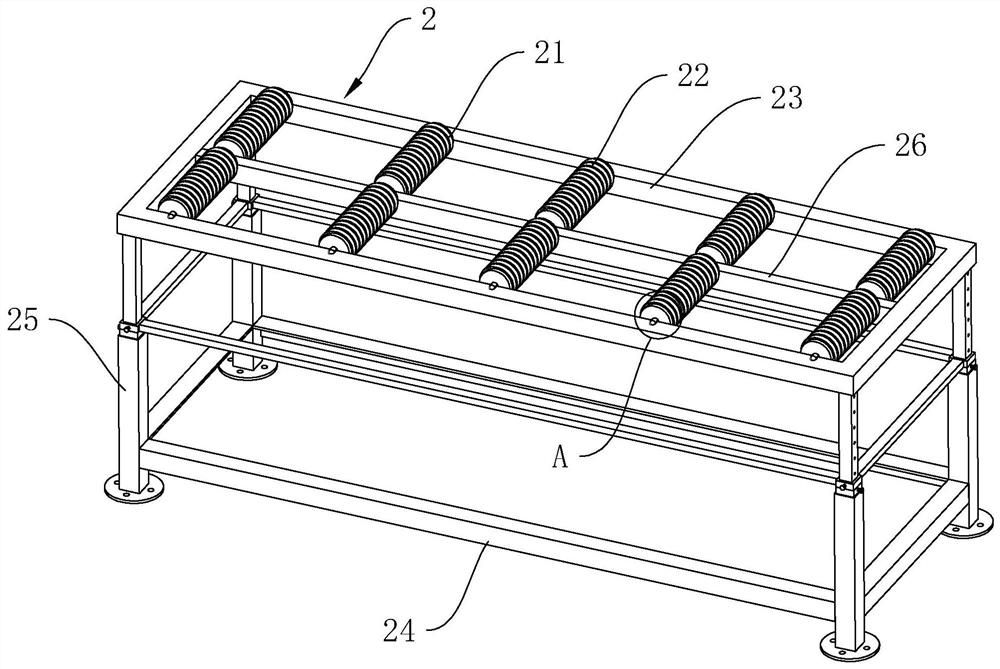

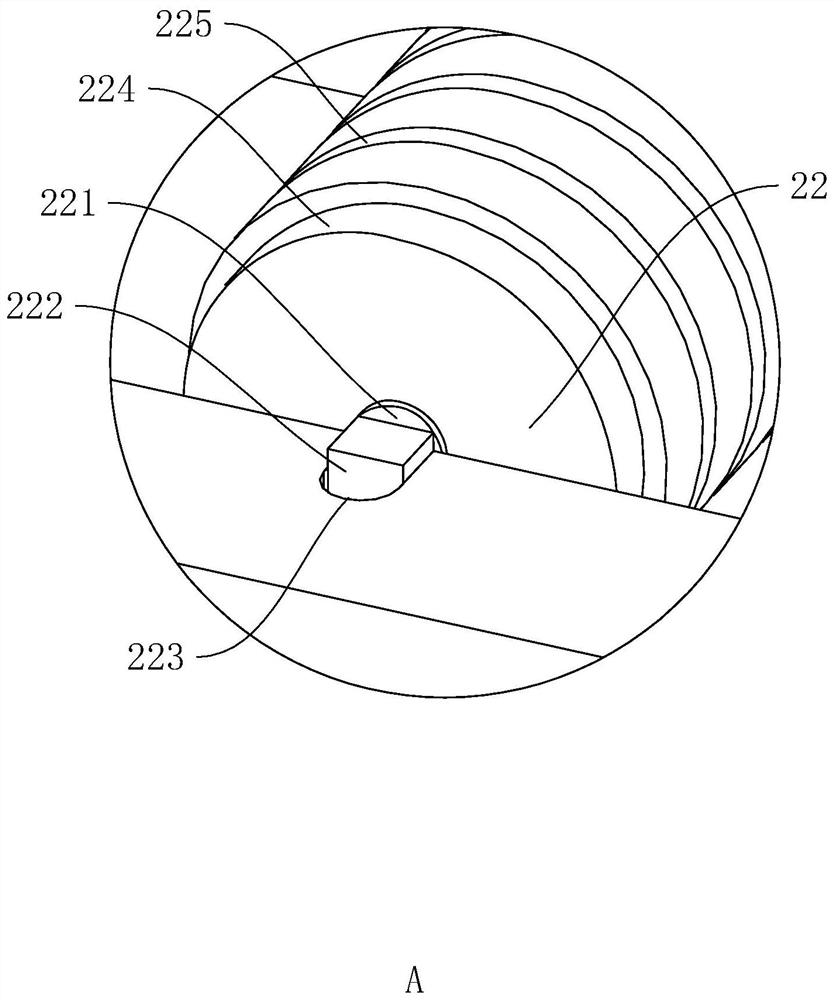

[0055] refer to figure 2 , the support assembly 2 includes a support frame 21, and the support frame 21 is rotatably connected with a transfer roller 22. During the process of slotting the longer plate, it is supported by the transfer roller 22 during loading and unloading, so as to prevent the plate from Bending deformation under the action of gravity.

[0056] refer to figure 2 , the support frame 21 comprises a top frame 23, a bottom frame 24 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com