A particle damping vibration reduction machine tool

A particle damping, machine tool technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of machine tool system oscillation, difficult industrial application, poor vibration damping effect, etc., and achieve short processing and manufacturing cycles. , The manufacturing process is simple, and the effect of reducing the vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

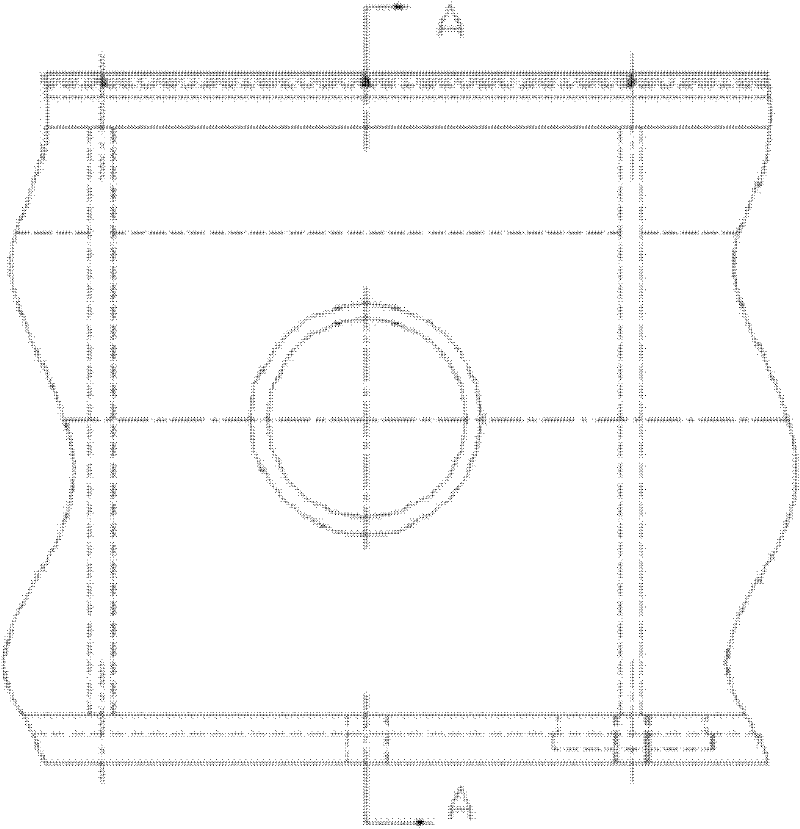

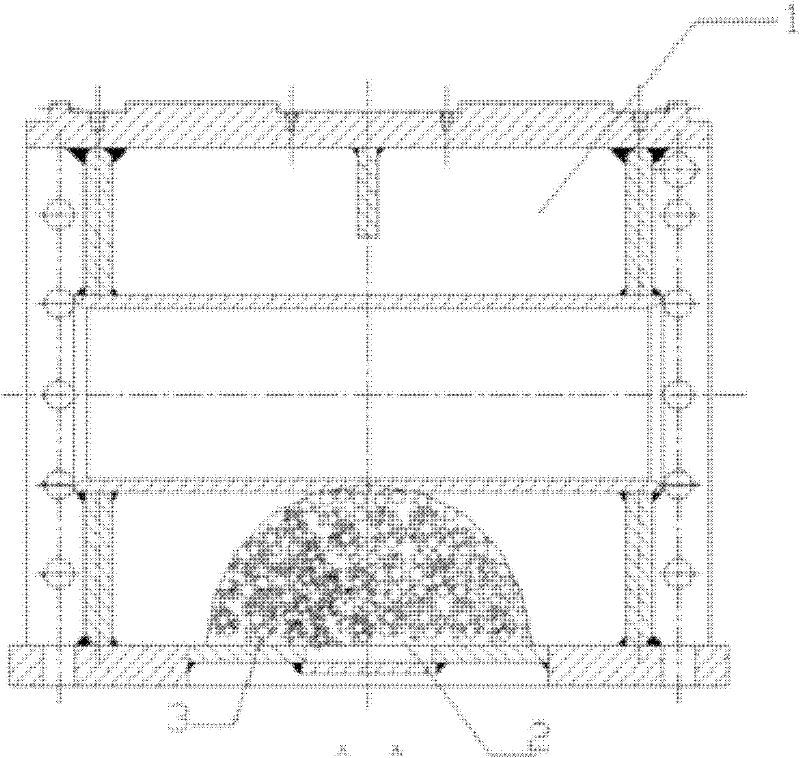

[0038] In the particle damping bed structure of a large moving beam moving column 4×16m gantry milling machine, the particle damping vibration reduction bed 1 is composed of a cavity 2, damping particles 3 and particle sealing elements, etc., and the cavity is a semi-cylindrical cavity. Cavity, because the large-scale gantry milling machine body in the actual working state is in low fundamental frequency vibration, the direction of the vibration source acting on the machine bed is parallel to the direction of particle gravity, and the damping particle 3 is an external high-vibration-absorbing characteristic with a certain shape, the core High toughness composite particle material, the particle size is 0.8M / h 2 mm~3.5M / h 2 mm mixed gradation particles, the filling rate is 90%.

Embodiment 2

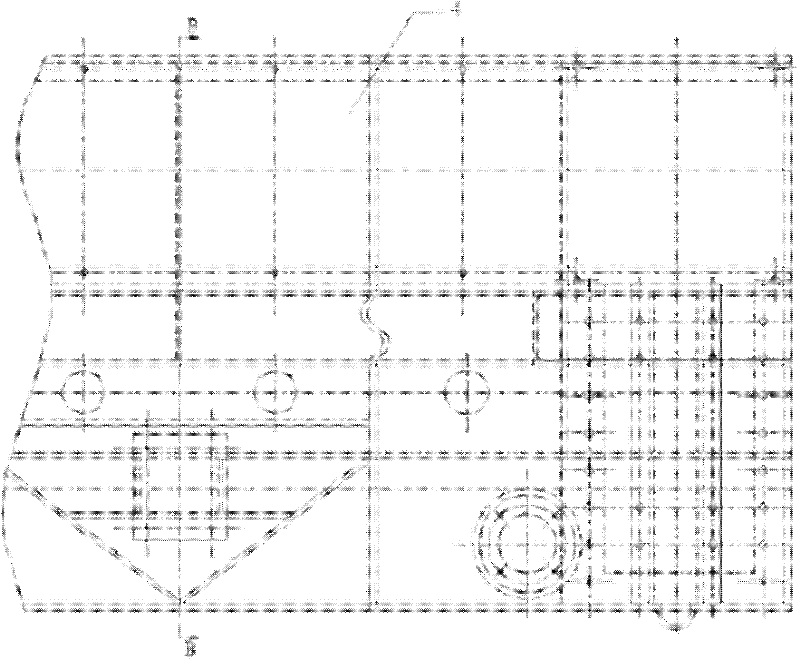

[0039] Example 2 In the particle damping top beam structure of a large-scale moving beam moving column 4×16 meters gantry milling machine, the particle damping vibration-damping top beam 4 is composed of a cavity 2, damping particles 3 and a particle sealing body, and the cavity is the middle For the reinforced cubic cavity, since the large gantry milling roof beam in the actual working state is close to the vibration source, it is in the middle fundamental frequency vibration, the direction of the vibration source acting on the machine bed is perpendicular to the direction of particle gravity, and the damping particles 3 have a certain Composite particle material with high vibration damping characteristics on the outside of the shape and high strength on the core, with a particle size of 4.5M / h 2 mm~7M / h 2 mm mixed gradation particles, the filling rate is 95%.

Embodiment 3

[0041] In the large-scale moving beam moving column 4×16m gantry milling machine particle damping column structure, the particle damping vibration-damping column 5 is composed of a cavity 2, damping particles 3 and a particle sealing body, and the cavity is a middle reinforcement and a transverse cylinder. Because the large gantry milling column in the actual working state is far away from the vibration source and is in low fundamental frequency vibration, the direction of the vibration source acting on the machine bed is perpendicular to the direction of gravity of the particles, and the damping particles 3 have a certain shape Composite particle material with high external vibration damping characteristics and high strength core, the particle size is 0.4M / h 2 mm~3.5M / h 2 mm mixed gradation particles, the filling rate is 90%.

[0042] After particle damping and vibration reduction are applied to the large-scale moving beam and moving column 4×16m gantry milling machine bed 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com