Vibration testing device for hydropower unit in hydropower station and vibration attenuation implementing method of vibration testing device

A technology for hydraulic unit and vibration testing, which is applied to measurement devices, testing of machine/structural components, and static/dynamic balance testing, etc., can solve the problems of reducing the vibration of hydraulic units, not considering units, and crashing the machine. Achieve the effect of reducing vibration amplitude, easy vibration reduction method and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

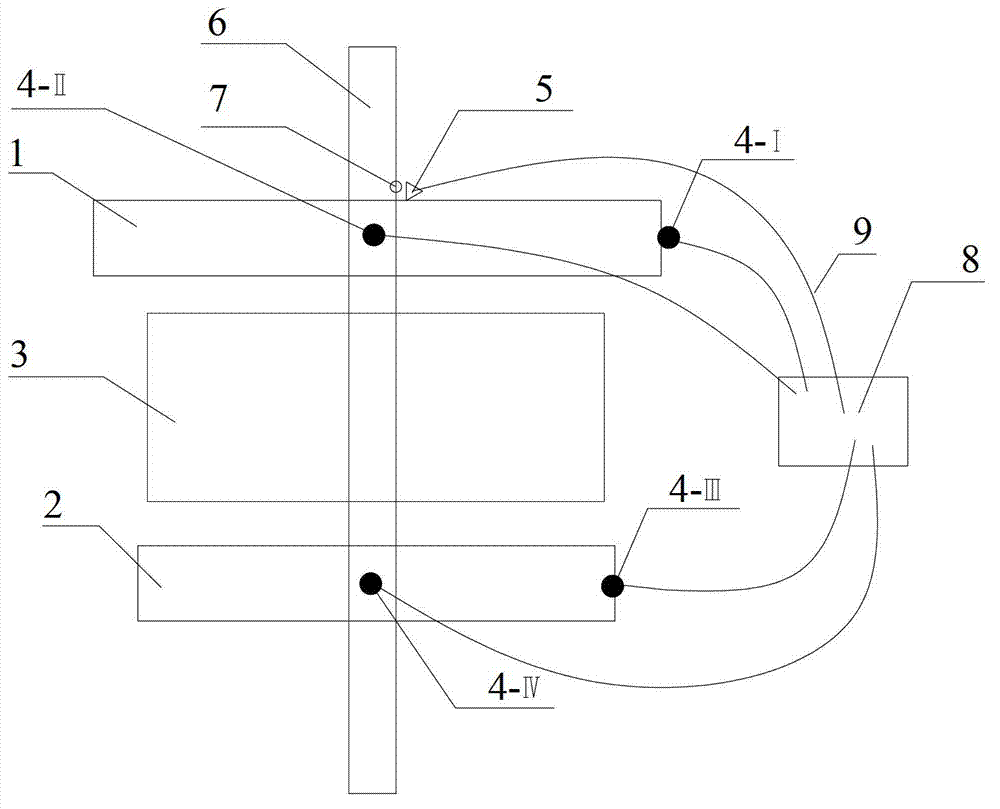

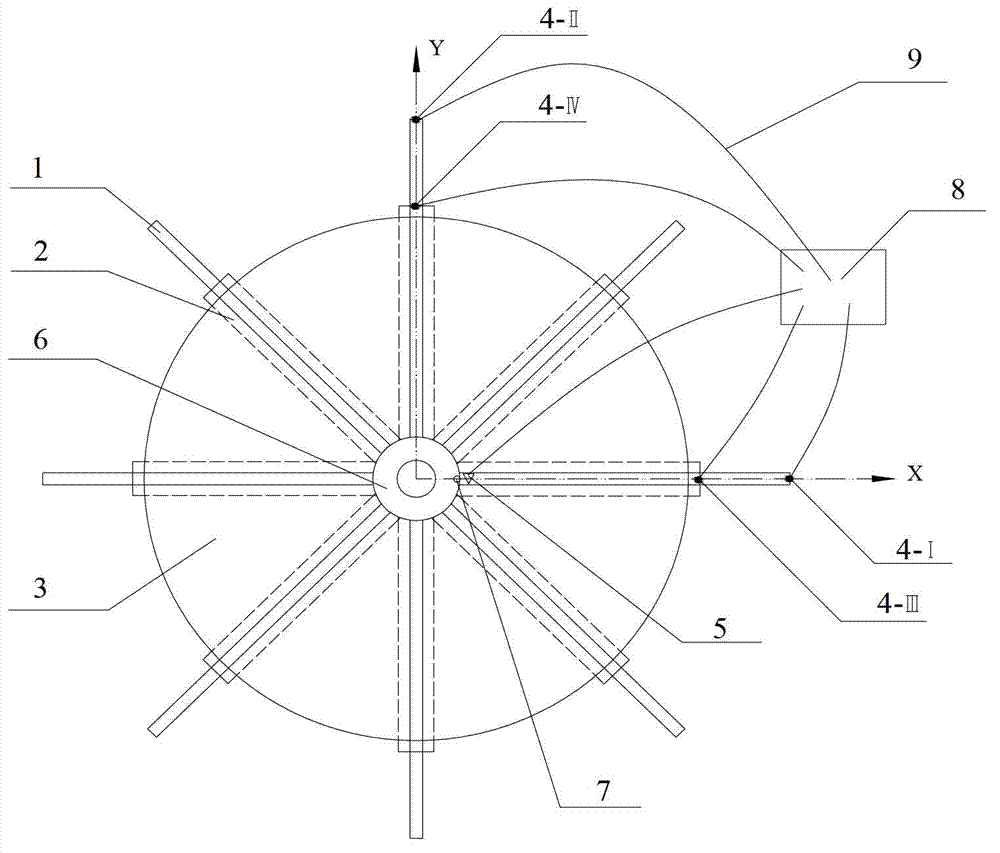

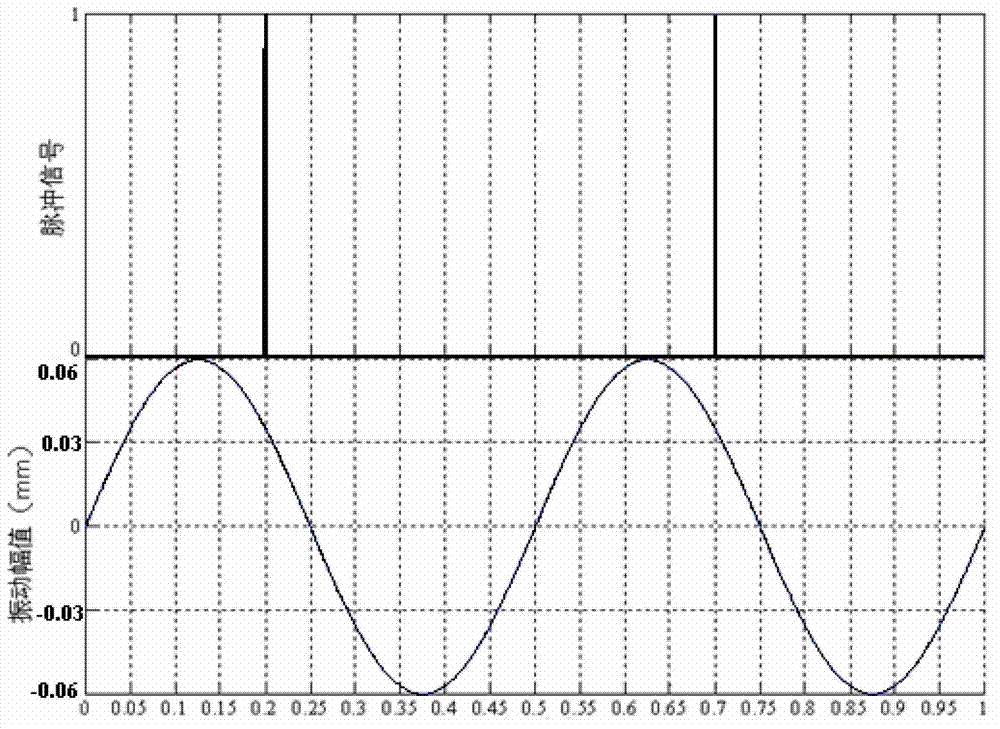

[0021] A vibration testing device for a hydraulic unit of a hydropower station, including horizontal vibration sensors 4-I, 4-II, 4-III, 4-IV, a magnetic proximity switch 5, a magnetic sheet-type fixed reference point 7 and a signal acquisition instrument 8, and a horizontal vibration sensor A total of four 4-I, 4-II, 4-III, and 4-IV are set up and respectively fixed on the upper and lower racks 1 and 2 above and below the rotor 3. Each rack 1, The two horizontal vibration sensors installed on the outside of 2 are 90 degrees to each other and the directions of the horizontal vibration sensors on the upper and lower frames 1 and 2 are correspondingly consistent; the magnetic proximity switch 5 is fixed on the upper frame 1 near the rotating shaft 6, and the magnetic sheet The fixed reference point 7 is fixed on the rotating shaft 6 and is on the same horizontal line as the magnetic proximity switch 5. When the reference point 7 passes the magnetic proximity switch 5, the switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com