Method for reducing welding residual stress of thick plate by utilizing multi-layer and multi-pass welding interlayer welding residual heat to assist vibration

A technology of multi-layer multi-pass welding and residual stress, applied in heat treatment furnaces, heat treatment equipment, process efficiency improvement, etc., can solve problems such as poor adaptability, influence on welding process, poor safety, etc., and achieve efficiency improvement, improve efficiency, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

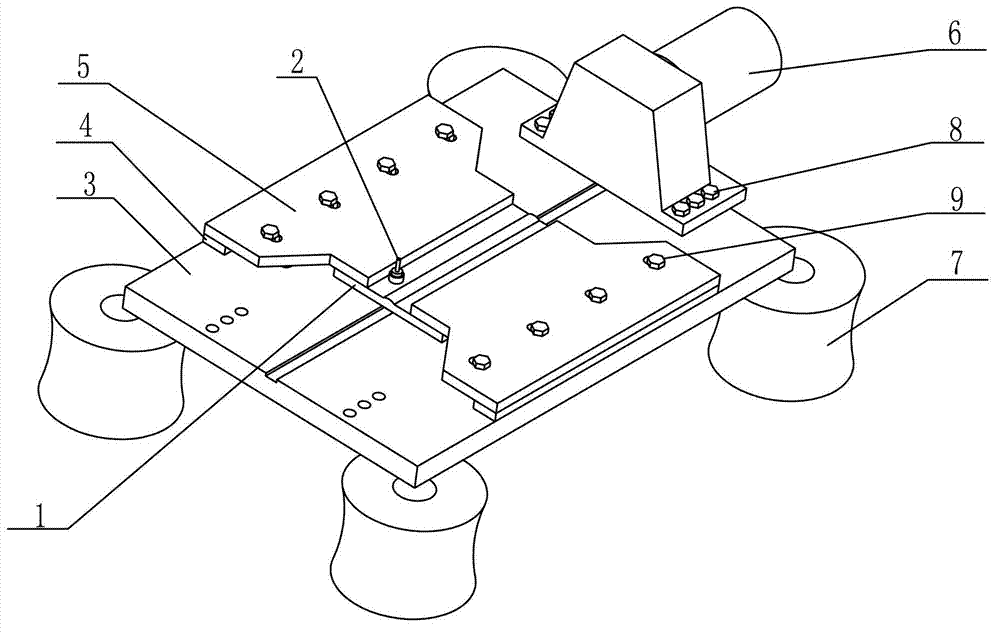

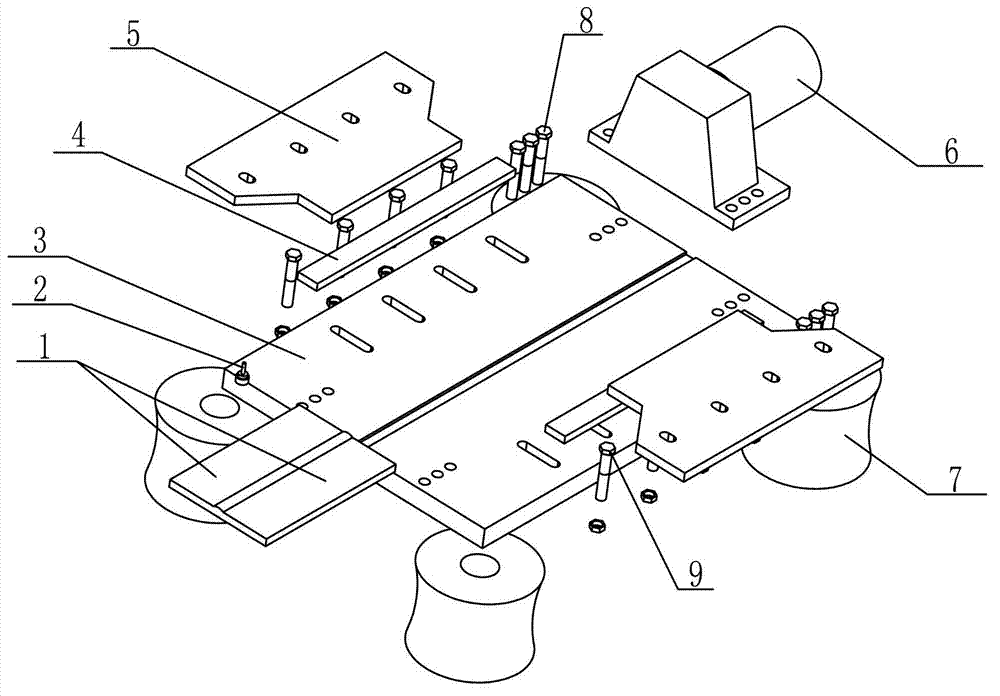

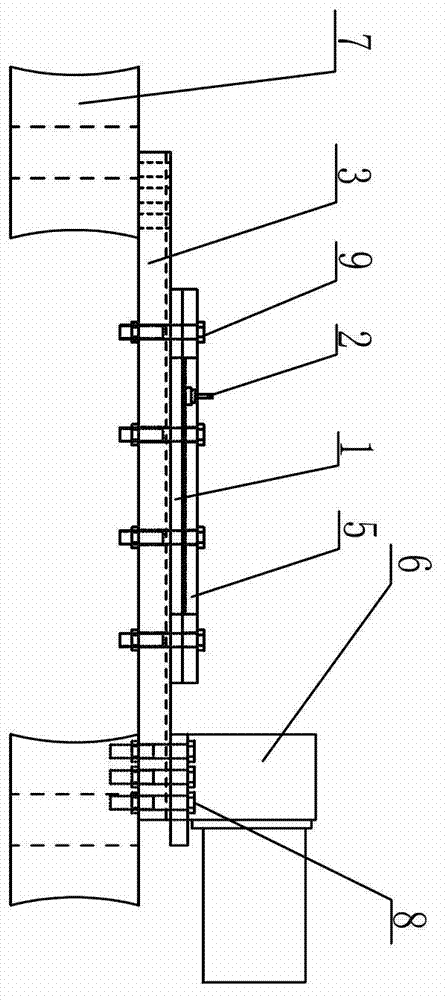

[0020] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment, the specific steps of the method for reducing the residual stress of thick plate welding by using the residual heat of multi-layer multi-pass welding interlayer welding to assist vibration to reduce the residual stress of thick plate welding in this embodiment are:

[0021] Step 1, fixing the vibrator 6 on the vibrating platform 3;

[0022] Step 2, clamping the workpiece 1 to be welded on the vibration platform 3 through the clamping gasket 4 and the workpiece clamping cover plate 5 on the welding fixture;

[0023] Step 3: Scan the frequency before vibration, fix the acceleration sensor 2 on the workpiece 1 to be welded, use the acceleration sensor 2 to pick up the amplitude, and obtain the first-order or second-order resonance by gradually increasing the frequency of the exciter 6 and obtaining the amplitude signal at the same time Frequency, adjust the excitation force at the sub-r...

specific Embodiment approach 2

[0027] Specific embodiment 2: Vibration aging treatment for 10 minutes in step 5 of this embodiment. With such setting, the efficiency of vibration aging is greatly improved, and the residual stress of the welded workpiece is effectively reduced.

Embodiment

[0028] Example: Combine Figure 1-Figure 8 Further illustrate the present invention, the present embodiment adopts workpiece material to be low-alloy high-strength steel, and the main chemical composition mass percentage of this low-alloy high-strength steel: C is 0.15%, Si is 0.32%, Mn is 1.44%, and its tensile strength is 575MPa , with a yield strength of 470Mpa, made as figure 2 The butt joint sample of workpiece 1 to be welded, the workpiece size is 200mm×300mm×14mm, with a 30° groove, and a blunt edge of 2mm. When welding, a 3mm gap is reserved between the two workpieces. Manual arc welding is used, and the welding rod is J422. Weld four layers.

[0029] The thermal cycle curve at the center of the weld is obtained through finite element simulation before welding, such as Figure 6 As shown, it can be seen that after less than 10 minutes (600 seconds) after welding, the temperature of the workpiece drops below 100°C, and then the temperature drops slowly. Therefore, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com