Overhead cable vibration testing device and testing method

A kind of overhead cable and vibration test technology, which is applied in the direction of vibration test, measuring device, machine/structural component test, etc. It can solve the problems of strong magnetic field influence, many installation steps, and low measurement accuracy, so as to reduce vibration amplitude and strain, Save manpower, material and financial resources, and achieve high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

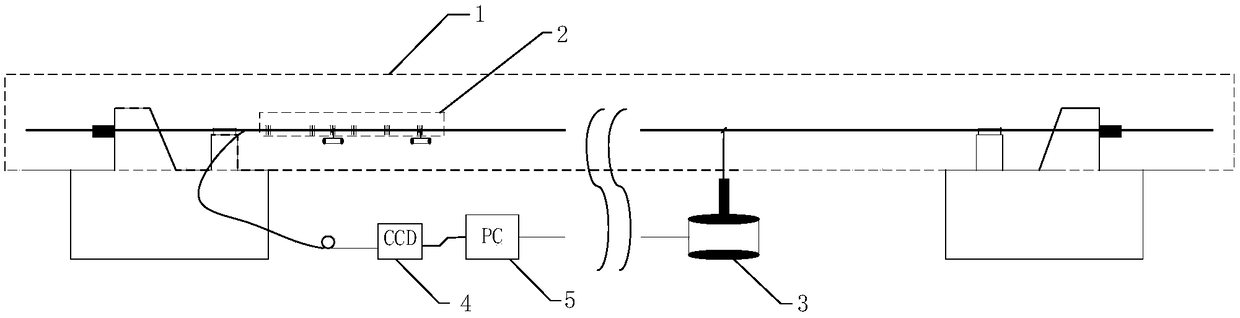

[0052] Such as figure 1 As shown, the entire overhead cable vibration test device includes an overhead cable test bench 1, a fiber grating sensor array 2, a vibration table 3, a fiber grating CCD demodulation device 4, and a PC 5. The vibration table 2 is located on the overhead cable test bench 1 Below, the table top is hinged with the overhead cable 11, and the control port is connected with the PC 5; the optical interface of the fiber grating CCD demodulation device 4 is connected with the fiber grating sensor array 2, and the data transmission port is connected with the PC Machine 5 is connected.

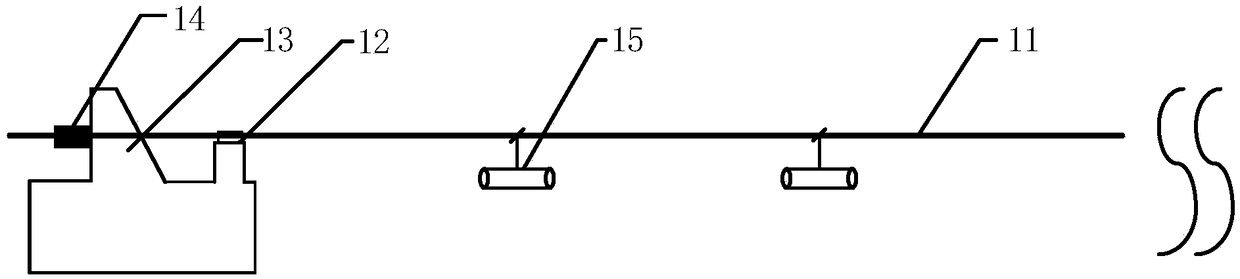

[0053] Such as figure 2 As shown, the overhead cable test bench 1 described in the overhead cable test bench includes a clamp 12, a support 13, and a tension regulator 14. One end of the overhead cable 11 is fixed on the concrete support 13, and the other end passes through the clamp 12. It is fixed on the bracket 13 by the tension adjuster 14 . The surface of the overhead c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com