Impact test device and method for impact testing products

An impact test and product technology, applied in the field of impact test device and impact test of products, can solve the problems of difficult control of test control accuracy, inability to effectively simulate the real flying boundary, lack of auxiliary bearing devices and protective measures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

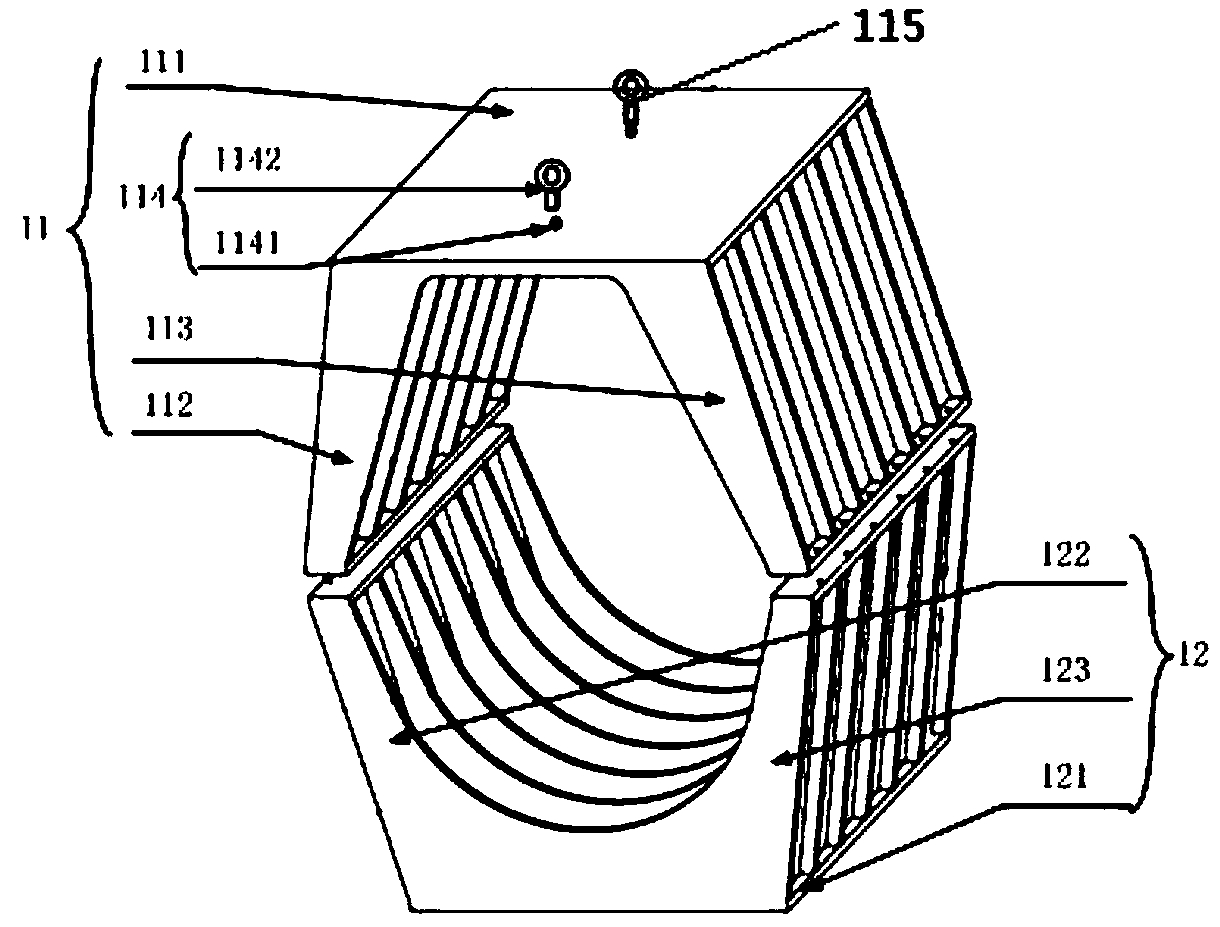

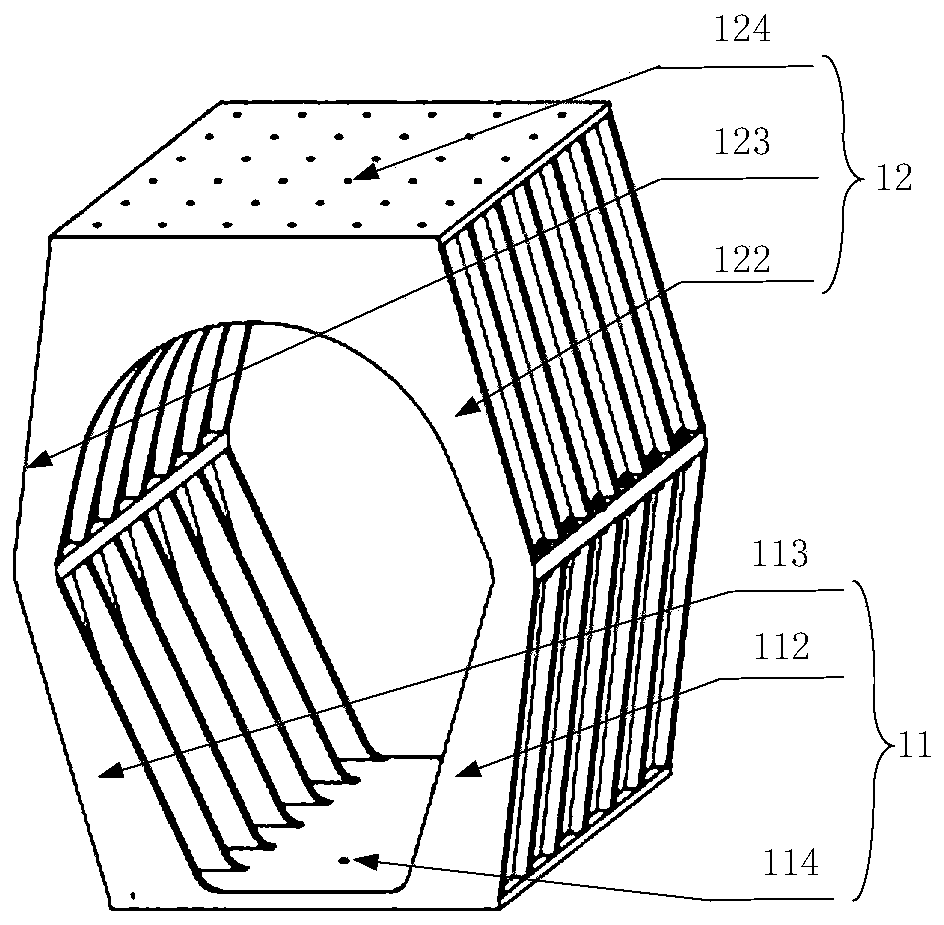

[0045] figure 1 and figure 2 An exploded view and an assembled view of the tooling according to specific embodiments of the present disclosure are shown.

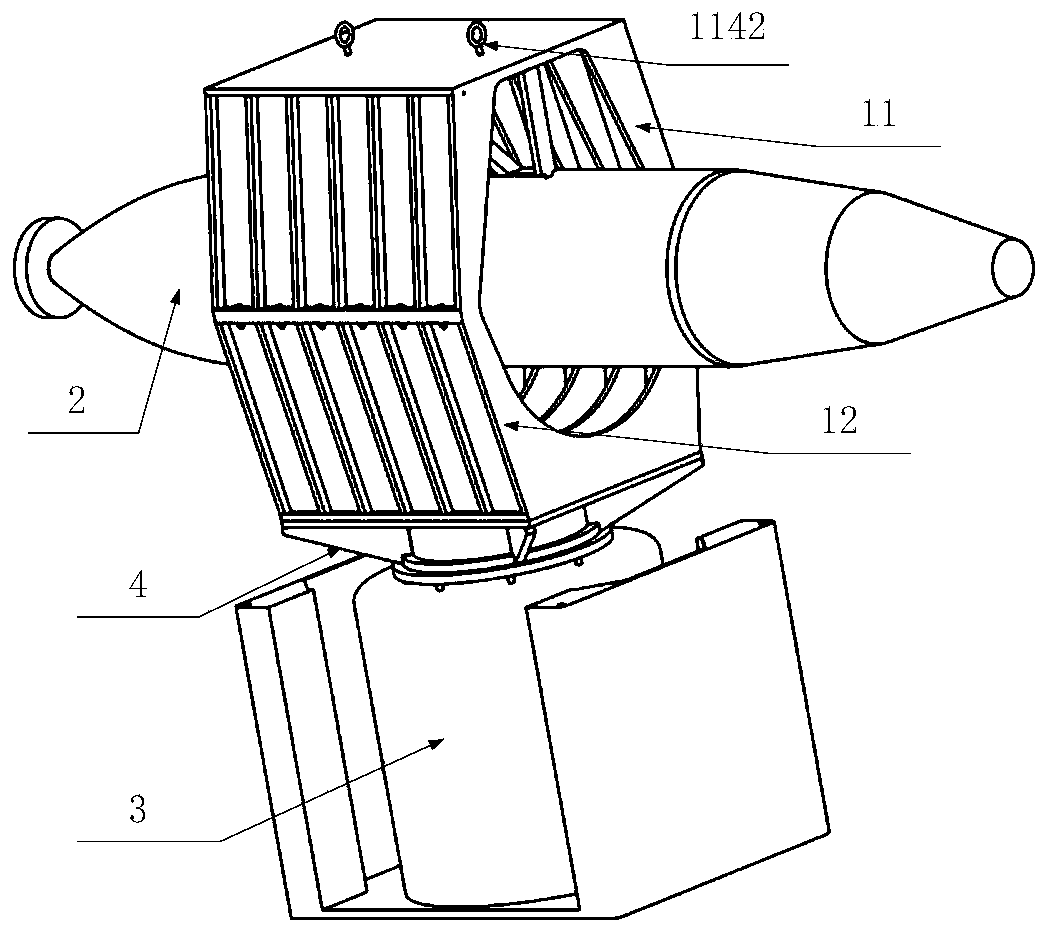

[0046] refer to figure 1 and figure 2 As shown, embodiment 1 provides a kind of impact test device, comprises the tooling 1 for testing and the vibrating table 3 for transmitting impact energy to the tooling, and the tooling 1 includes the first part 11 and the first part 11 that are arranged oppositely Two components 12, wherein the first component 11 comprises a first mounting plate 111 and a first side wall 112 and a second side wall 113 extending from the first mounting plate to the second component 12; the second component 12 comprises a second mounting plate 121 And the third side wall 122 and the fourth side wall 123 extending from the second mounting plate 12 to the first part 11, wherein the end face of the third side wall 122 is connected with the end face of the first side wall 112 and the end face of the fo...

Embodiment 2

[0072] Image 6 A flow chart of a method for impact testing a product according to a specific embodiment of the present disclosure is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com