Groove cutting method and cutting equipment for trackless circular part board

A circular parts and bevel cutting technology, which is applied in welding equipment, metal processing equipment, gas flame welding equipment, etc., can solve the problems of circular parts plate quality defects, etc., to improve the bevel quality and processing speed, bevel Good-quality, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

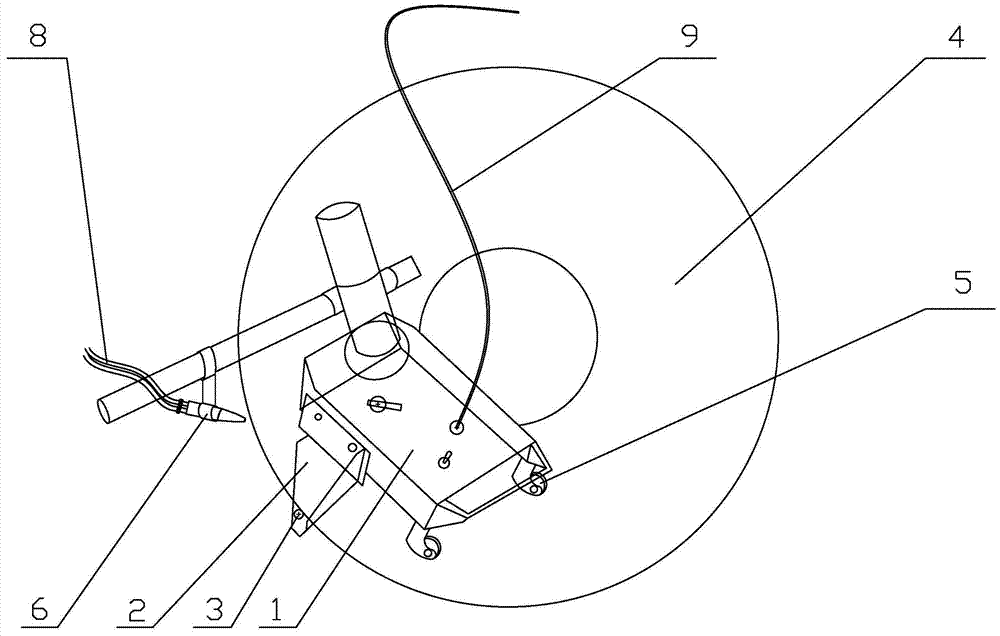

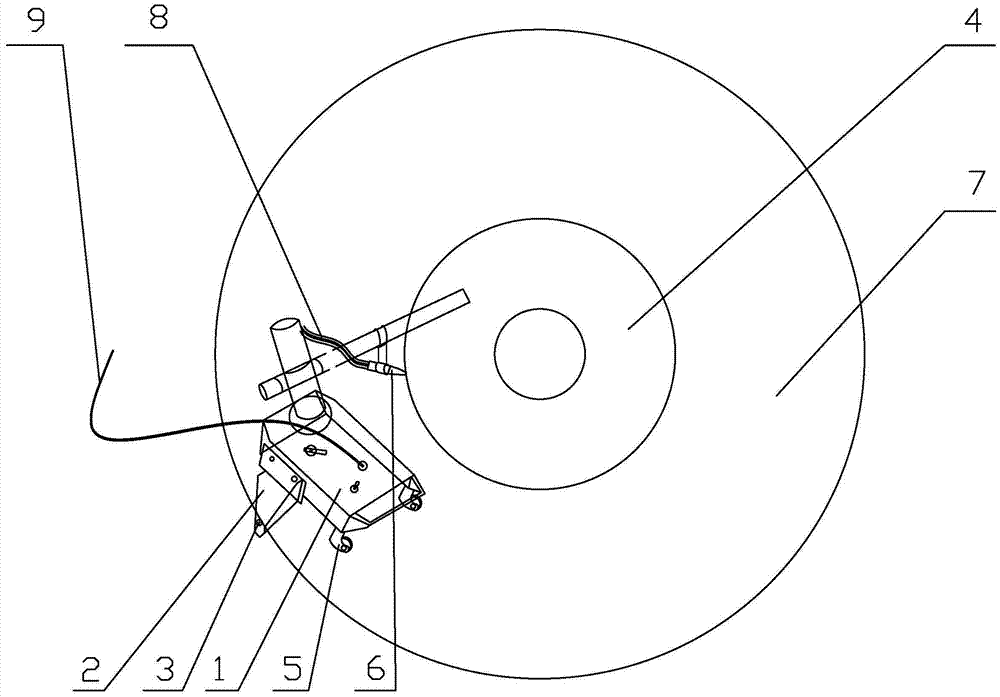

[0023] The technical solutions of the present invention will be further described below in conjunction with the implementation manners shown in the accompanying drawings.

[0024] An embodiment of the groove cutting equipment for the trackless circular part plate of the present invention is as follows: figure 1 As shown, the bevel cutting process is performed on a circular part plate 4 with a diameter ≥ 1000mm. Its main body is a semi-automatic flame cutting machine 1. The side of the machine 1 is provided with a roller 3 that rolls and fits with the circumferential end surface of the circular part plate 4, and the roller 3 is installed and connected with the semi-automatic flame cutting machine 1 through the wheel frame 2 (the member of the three ribs); the semi-automatic flame cutting machine is adjusted. The steering angle of the front guide wheel 5 of the cutting machine 1 makes the turning radius of the semi-automatic flame cutting machine 1 consistent with the circular a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com