Integrated building block grooving machine

A slotting machine and integrated technology, applied in stone processing tools, working accessories, manufacturing tools, etc., can solve the problems of large dust, improve work efficiency, improve construction safety, improve slotting speed and slotting quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

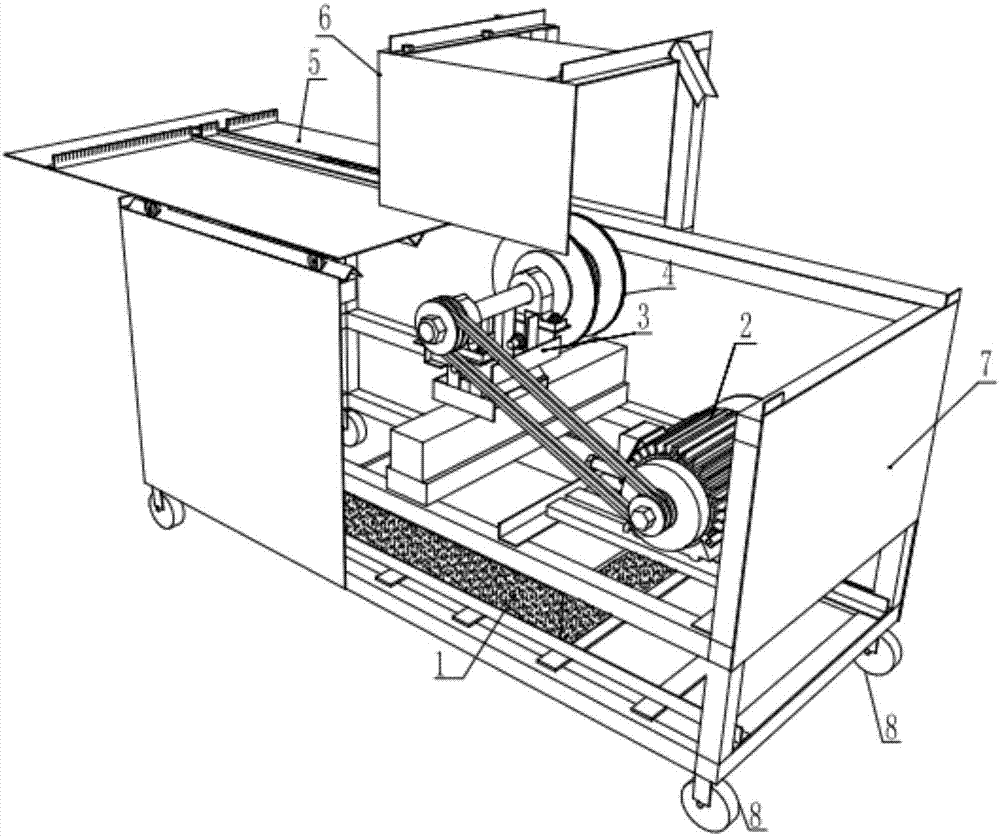

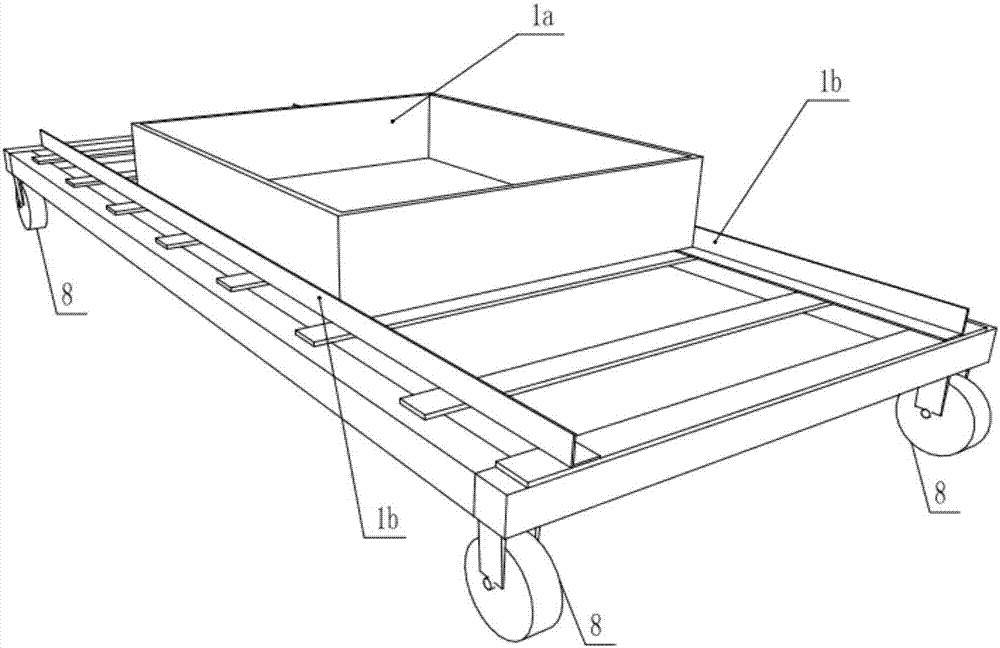

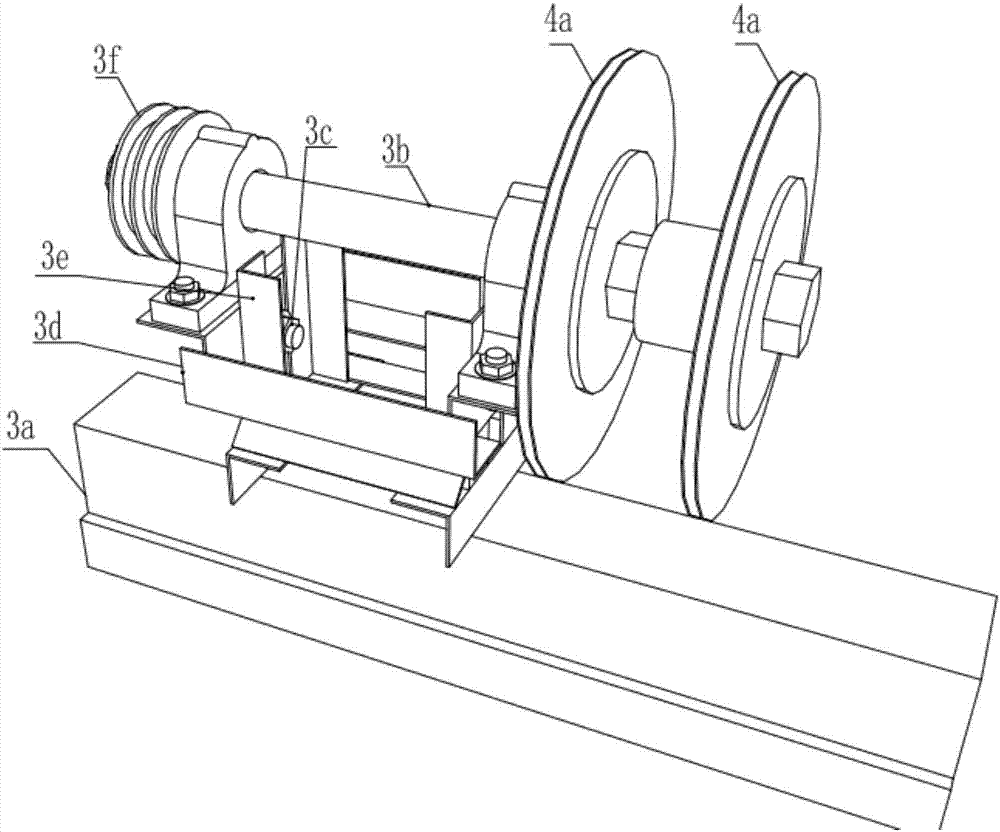

[0022] See figure 1 , an integrated block slotting machine, including a rectangular case 7 and a slotting device arranged in the case 7, the slotting device includes a dust suppression water tank 1 arranged at the lower part of the cabinet and a slotting depth adjustment support arranged above the dust suppression water tank 3. The groove depth adjustment support 3 is respectively connected with the adjustable blade combination device 4 and the motor 2, and a sliding plate 5 is arranged on the top surface of the chassis body, and a sliding plate 5 is arranged above the sliding plate 5 corresponding to the position of the adjustable blade combination device 4. Protective cover 6, protective cover 6 is cantilevered and is installed on the support that is positioned at one side of casing. Scroll wheels 8 are installed at the bottom of the cabinet 7 . In order to make it easier to see the structure inside the box, figure 1 Schematically cut a piece of the box side panel and slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com