Belt transfer point negative-pressure dust removal system

A technology of dust removal system and transfer point, which is applied in the direction of dust prevention, safety devices, mining equipment, etc., can solve the problems of dust exceeding the standard, weight gain or condensation or retention and reduction at the transfer point, and achieve huge economic and social benefits. Dust control, the effect of solving the dust exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

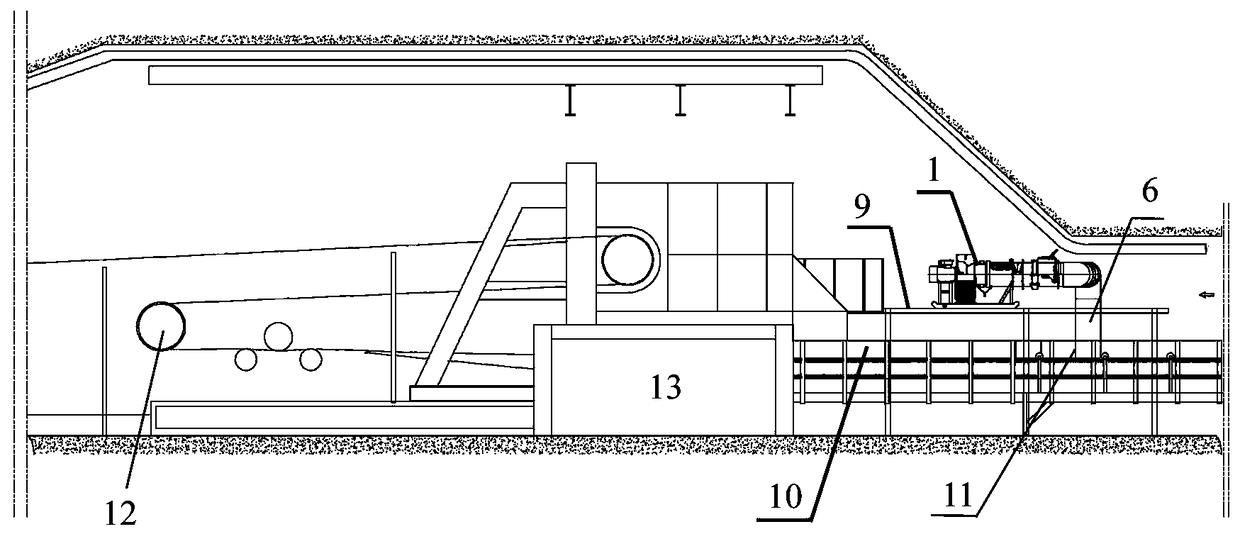

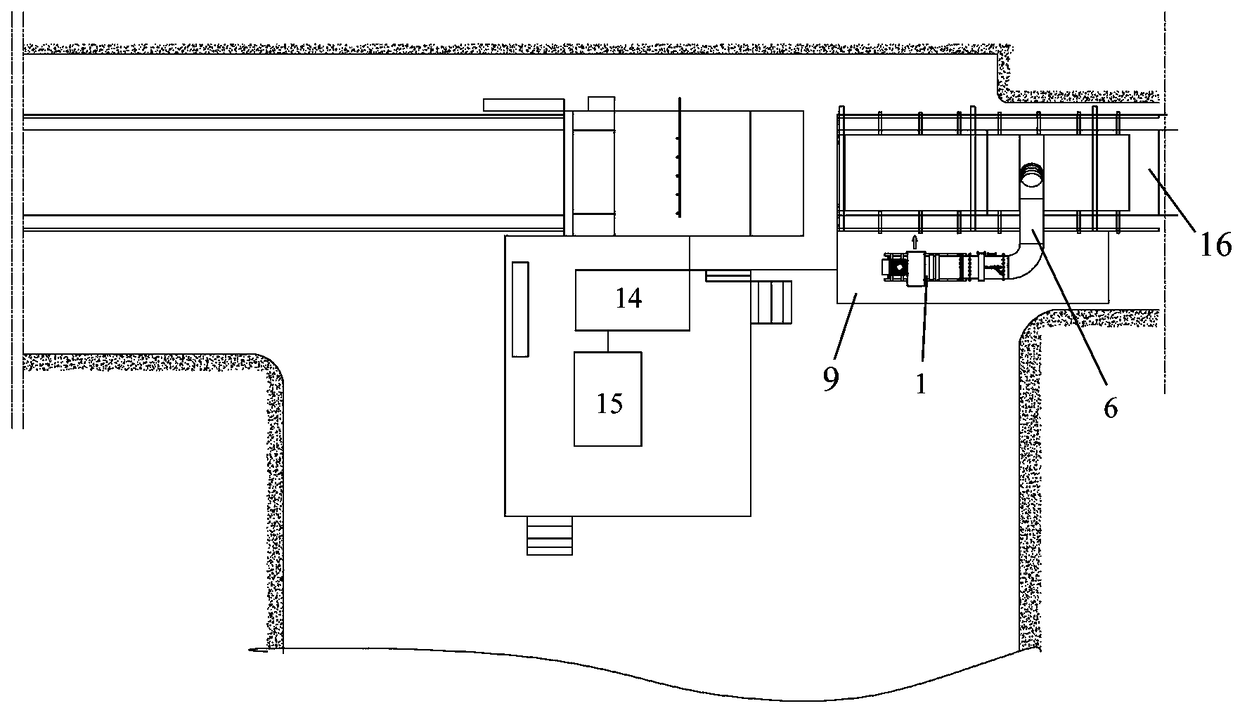

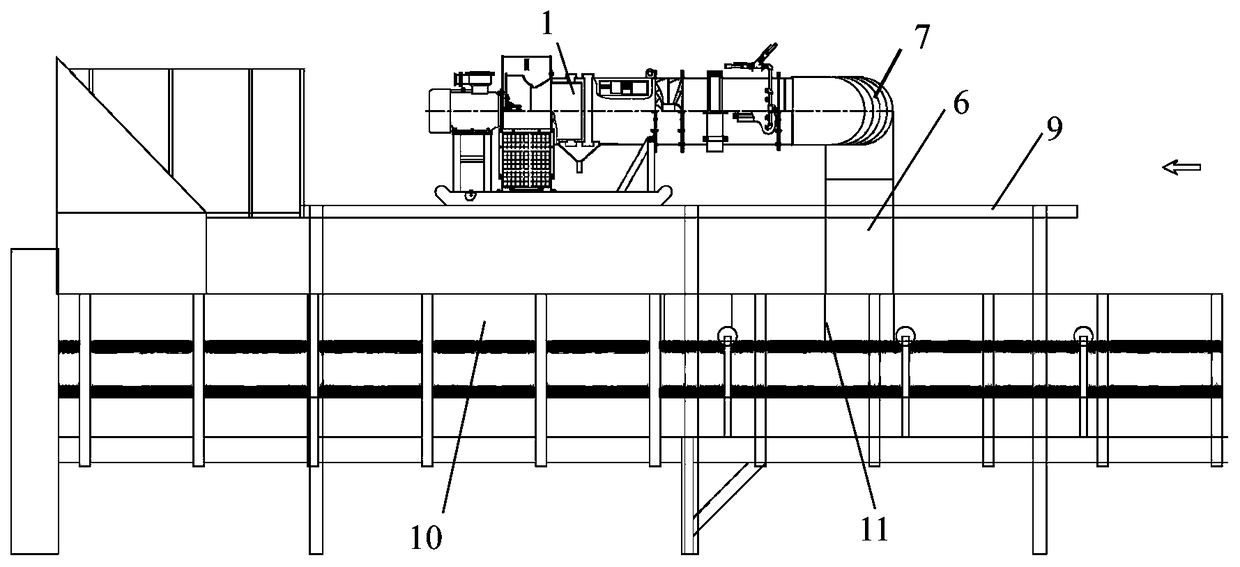

[0024] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0025] A belt transfer point negative pressure dust removal system, such as Figure 1-Figure 6 As shown, it includes a dust removal fan 1 and a sealing cover 10 covered on the transfer point belt 16. The dust removal fan 1 is connected to the sealing cover 10 through the dust suction cover 6 and the dust suction cover side plate 11, and one part of the sealing cover 10 An equipment platform 9 is arranged on the side, and the dust removal fan 1 is located on the equipment platform 9; in the dust removal fan 1, from right to left, there are water sprayer 4, vibrating wire filter plate 3, cyclone 2, air outlet 17 and motor 5. The water sprayer 4 is located at the air inlet of the dust removal fan 1 , the bottom between the cyclone 2 and the air outlet 17 is provided with a dust and sludge discharge port 8 , and the motor 5 is located at the tail of the dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com