Patents

Literature

66 results about "Standard penetration test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The standard penetration test (SPT) is an in-situ dynamic penetration test designed to provide information on the geotechnical engineering properties of soil. This test is the most frequently used subsurface exploration drilling test performed worldwide. The test procedure is described in ISO 22476-3, ASTM D1586 and Australian Standards AS 1289.6.3.1. The test provides samples for identification purposes and provides a measure of penetration resistance which can be used for geotechnical design purposes. Many local and widely published international correlations which relate blow count, or N-value, to the engineering properties of soils are available for geotechnical engineering purposes.

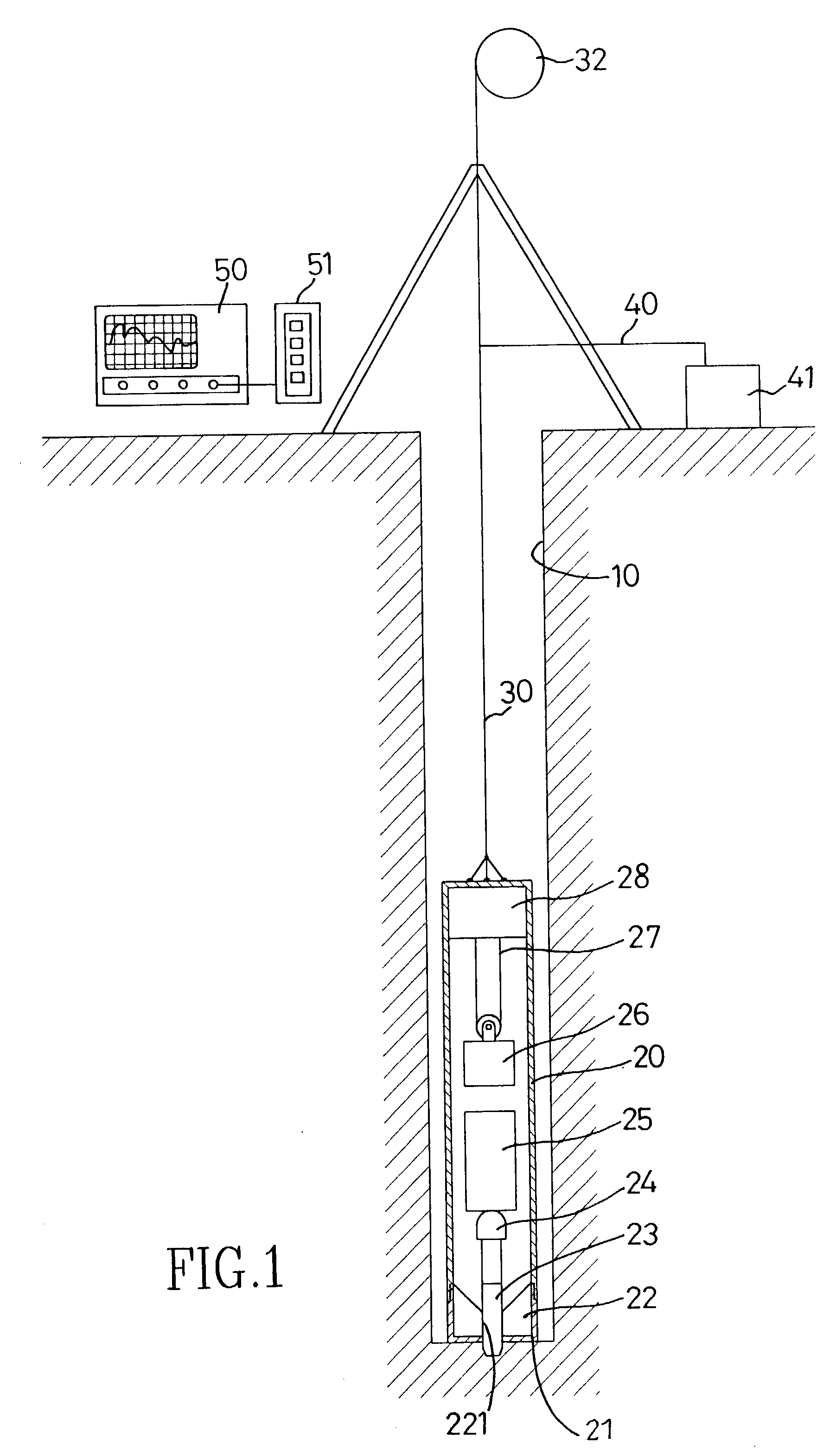

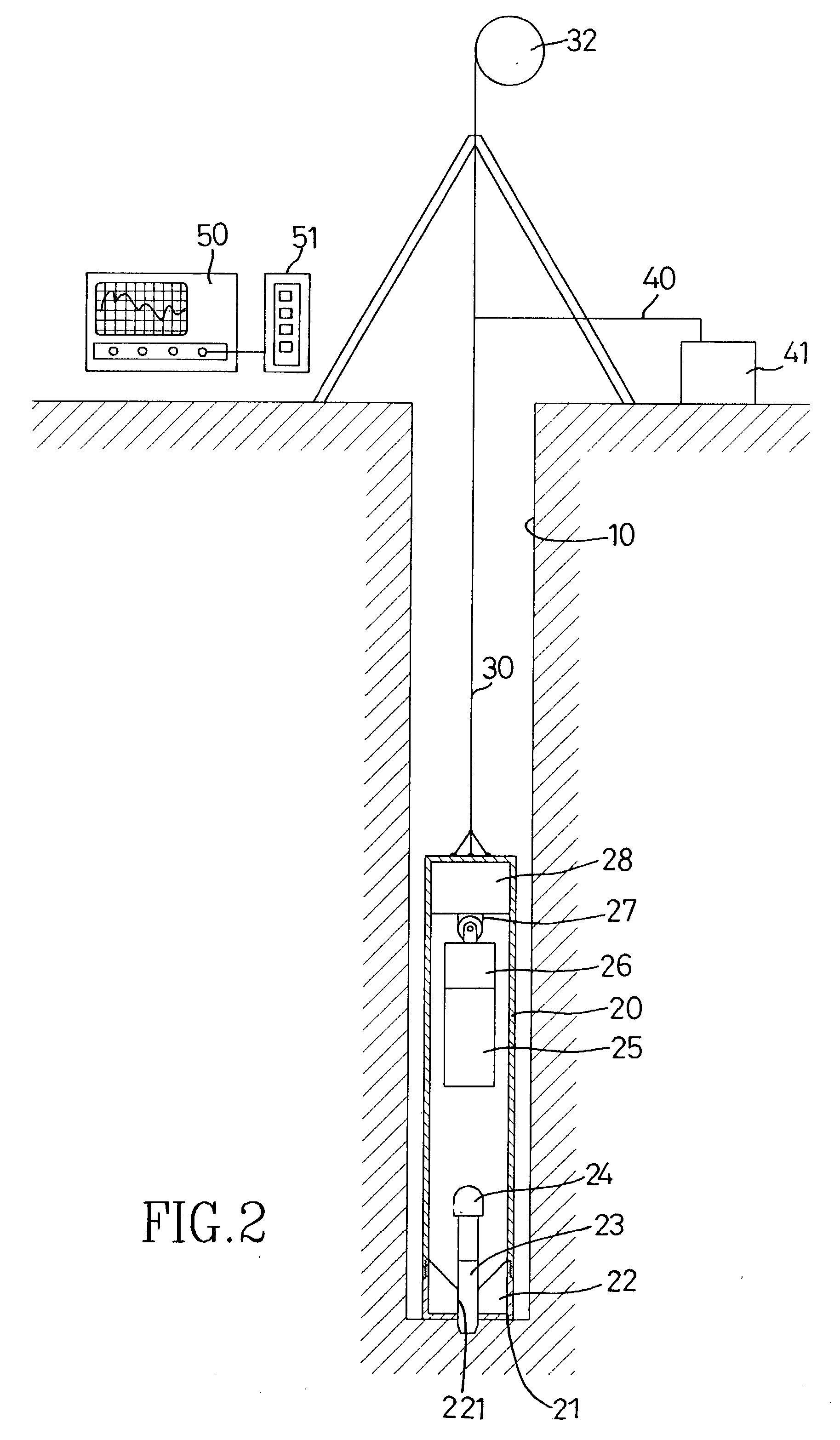

Automatic SPT monitor

An apparatus is used with an impact hammer penetration assemble such as standard penetration test (SPT) in geotechnical engineering. The impact hammer penetration assembly comprises a penetration sample, a series of rods coupled together and an impact hammer apparatus. The drop of the hammer from a constant height hits the coupled rods and sampler in series and forces the sampler deeper into the ground. The apparatus includes a tip depth transducer and sampler to output a first electrical signal that is a function of the sampler tip position. A shock force transducer communicates the axial shock force in the rod to output a second electrical signal that is a function of the rod shock force and hammer blows. A shock penetration transducer communicates the movement of the coupled rods and sampler to output a third electrical signal that is a function of the sampler penetration due to the hammer blows. A micro-process controller monitors and processes the first, second and third signals in real time.

Owner:HONG KONG THE UNIV OF

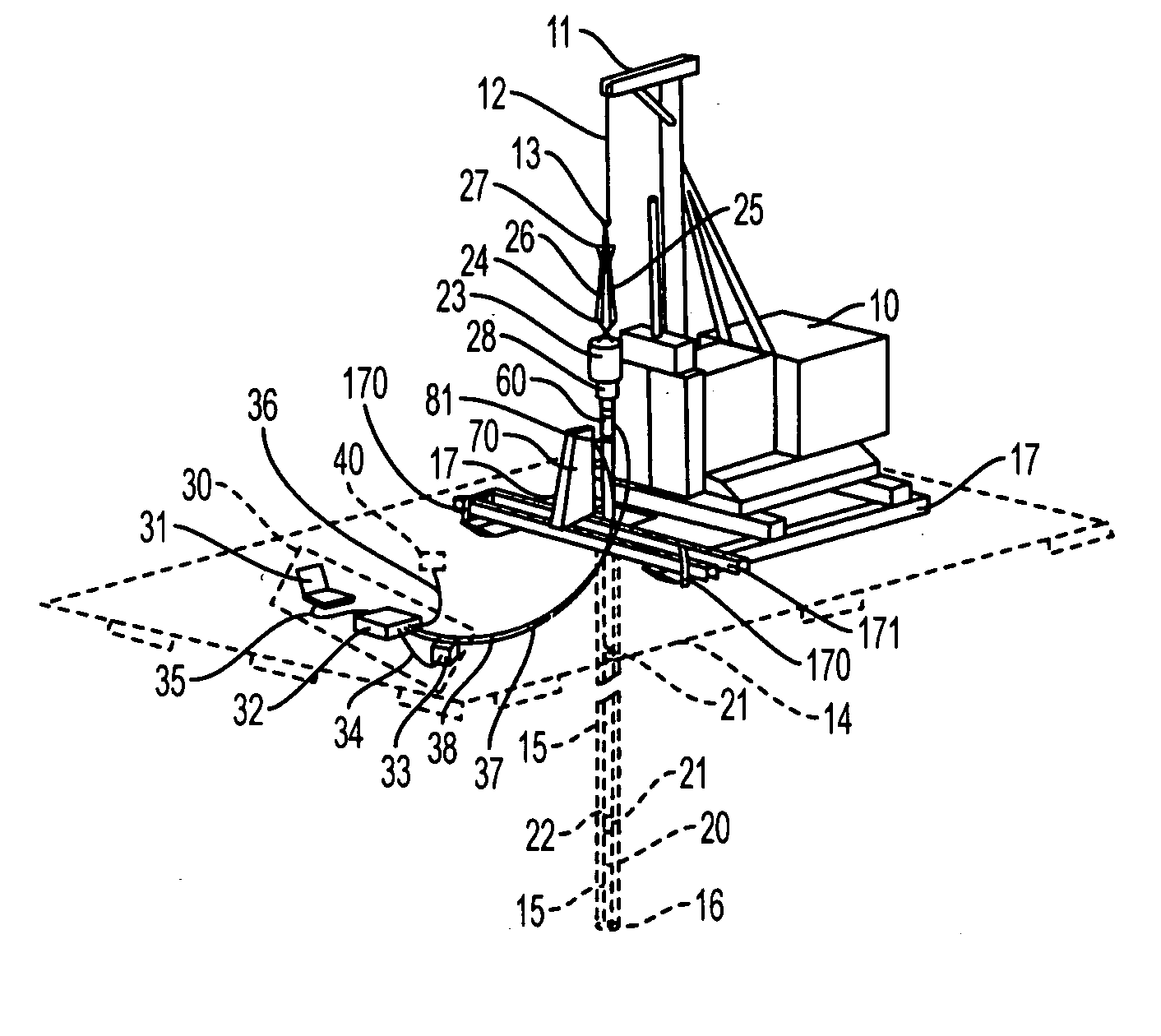

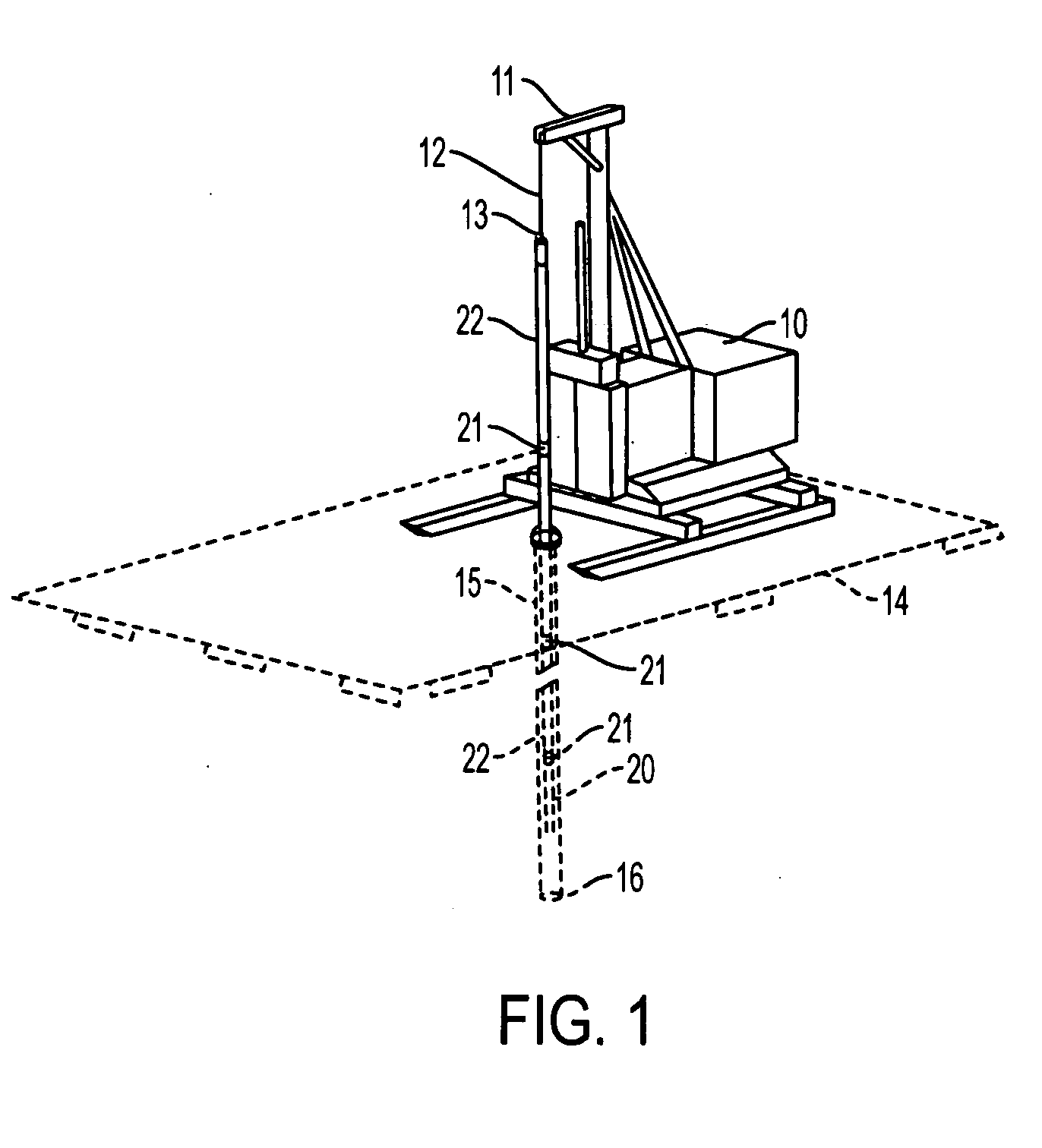

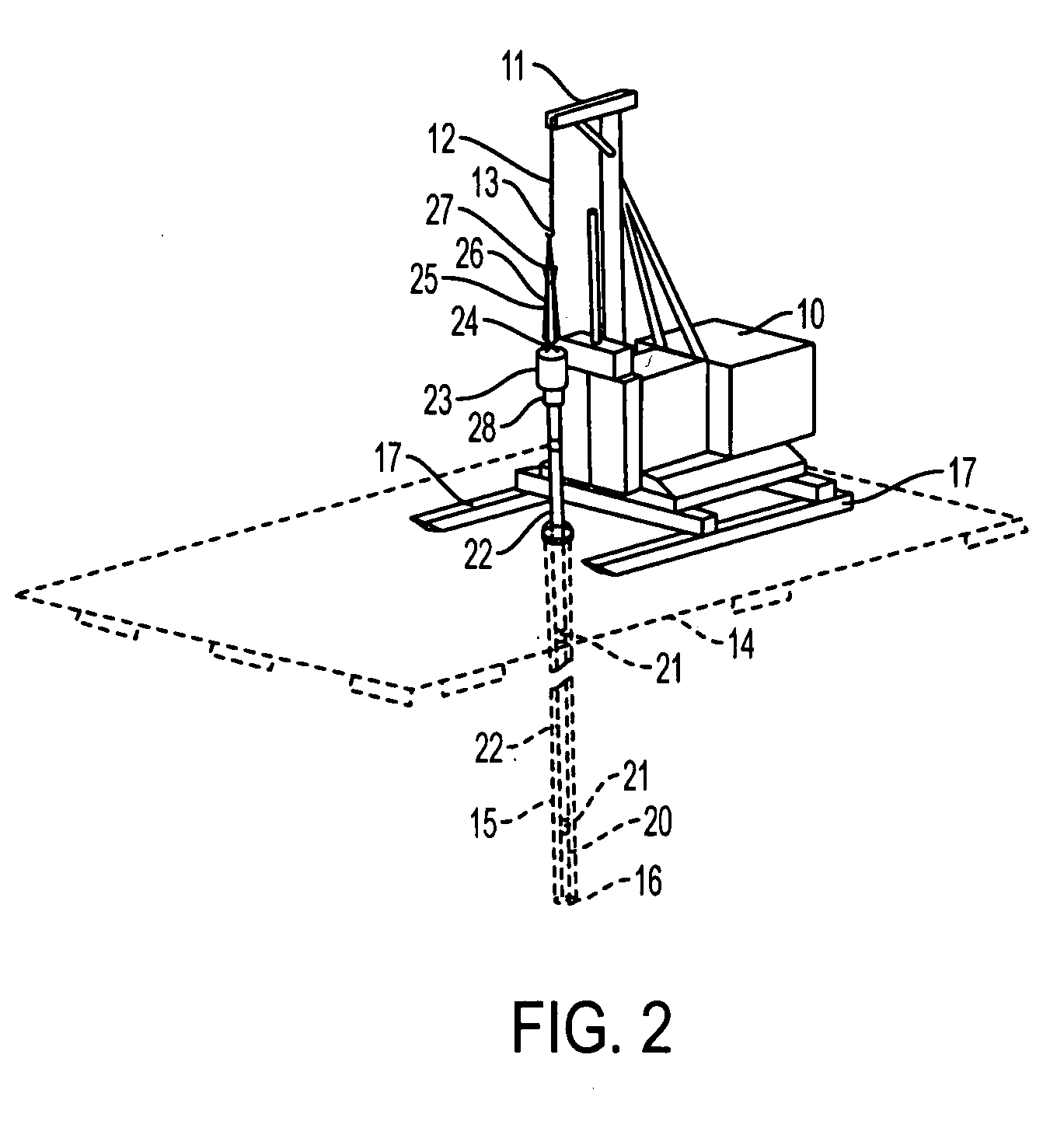

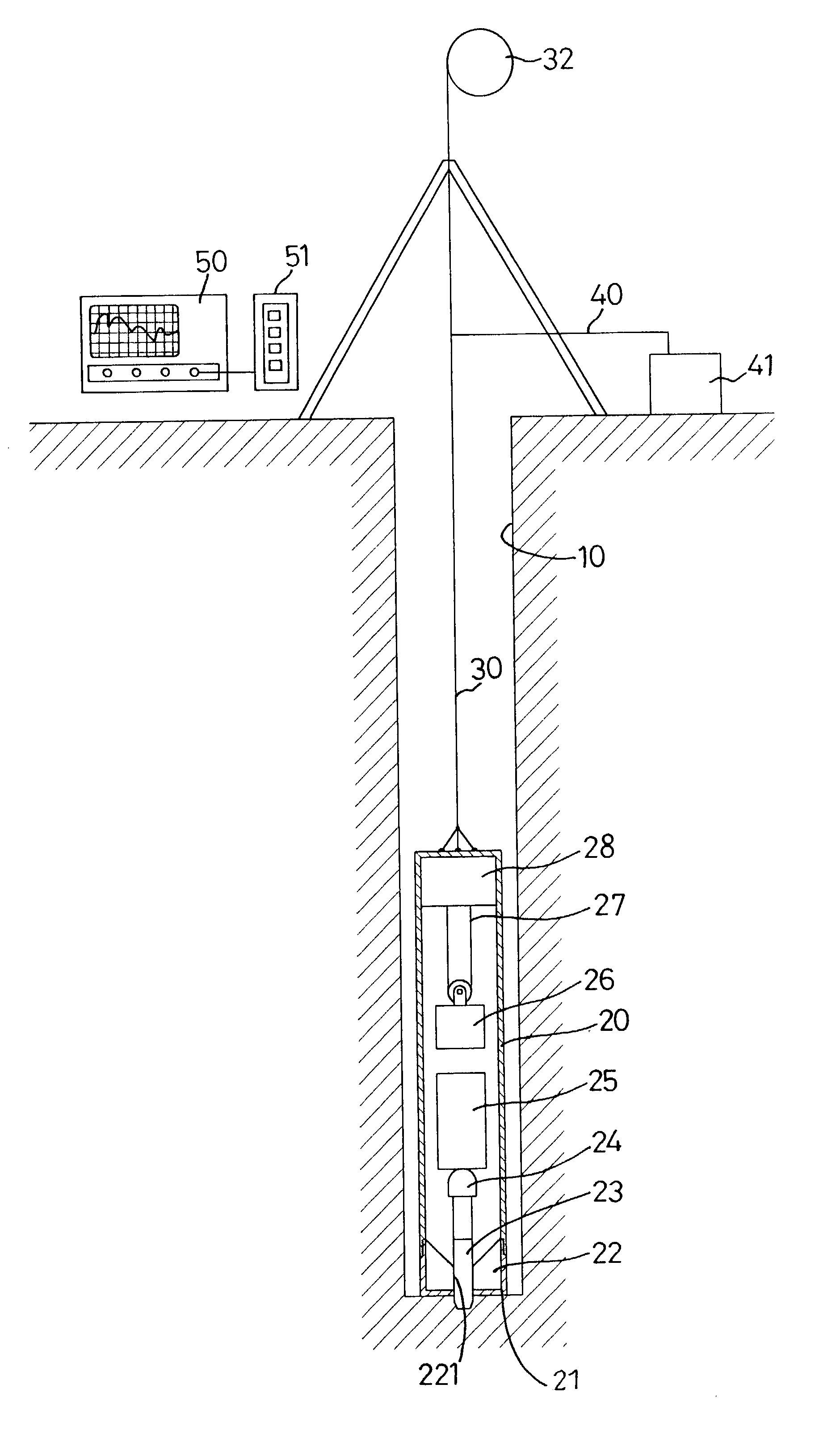

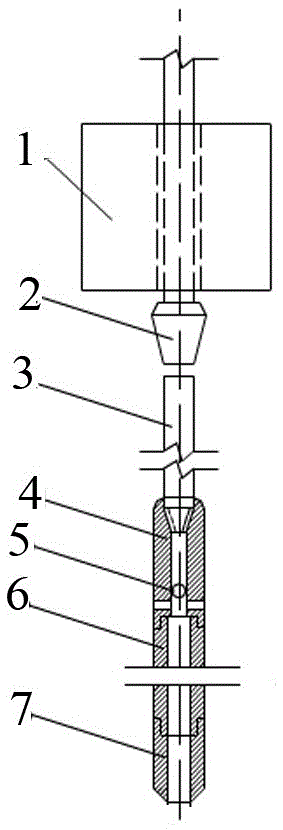

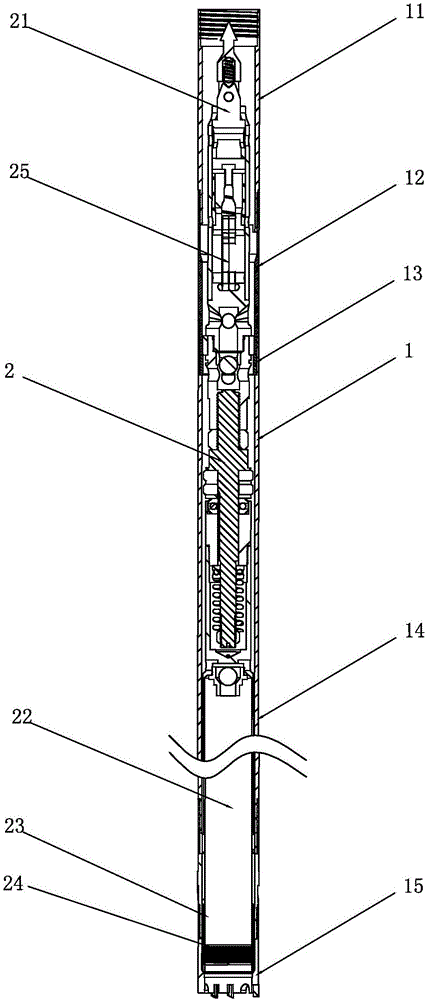

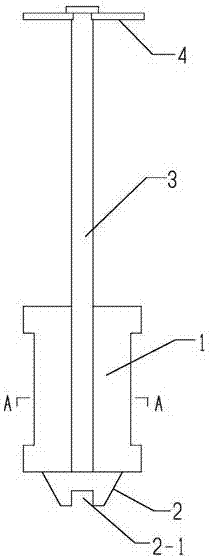

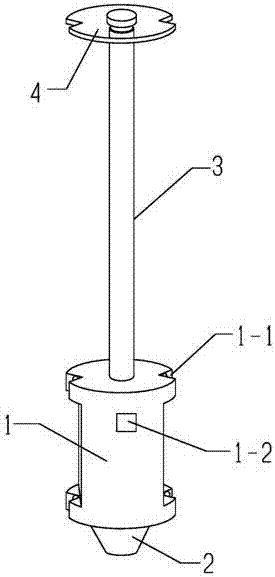

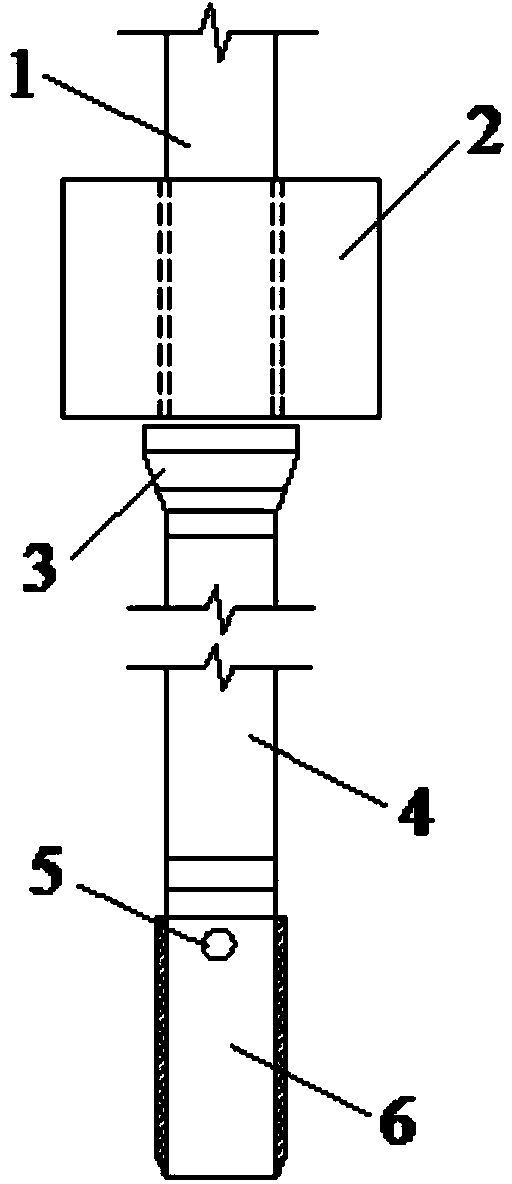

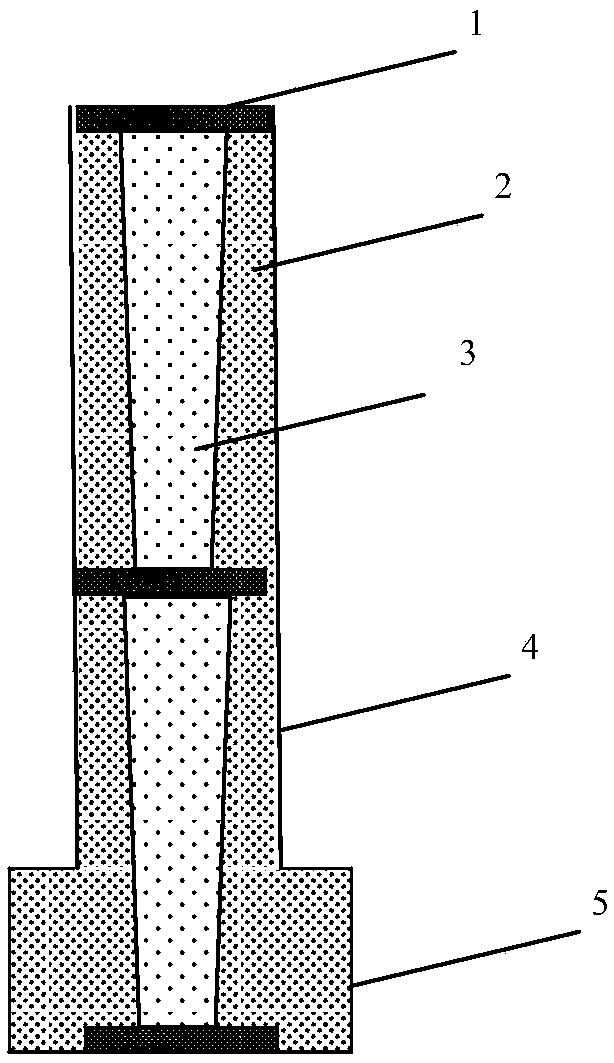

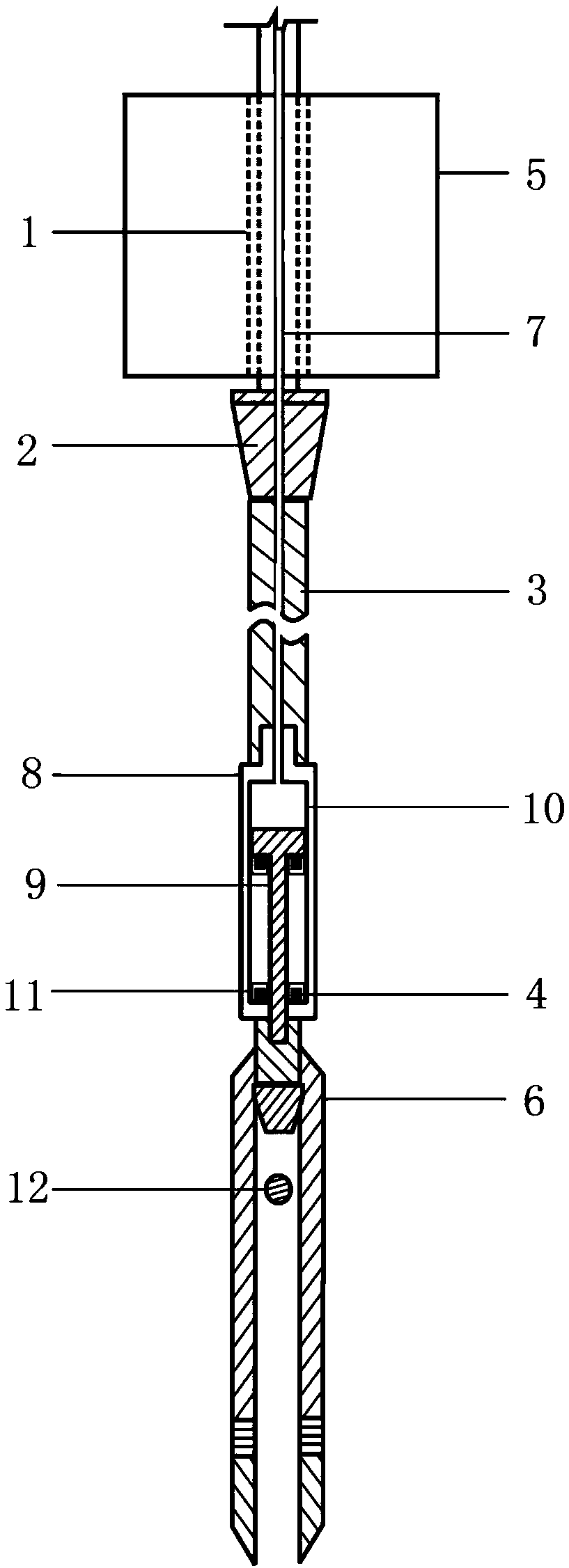

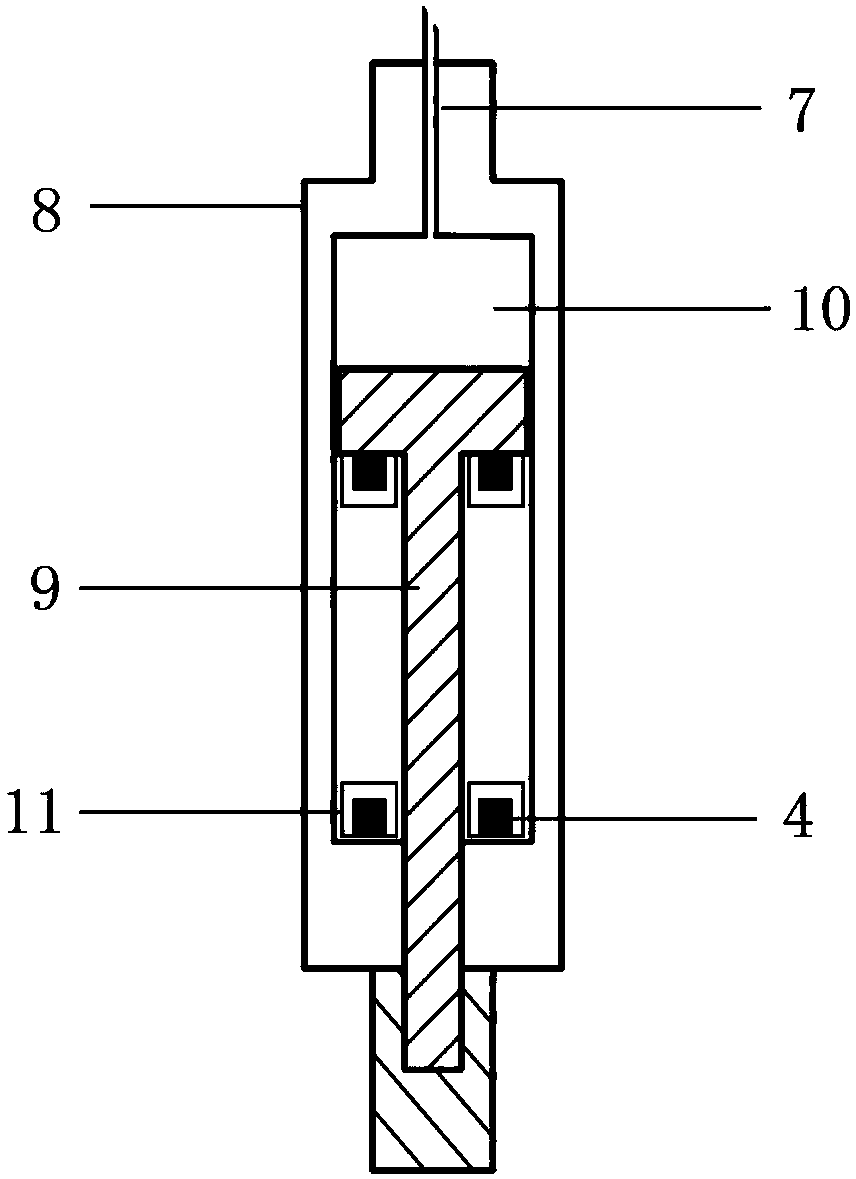

Downhole sampling method and device used in standard penetration test

InactiveUS20040065453A1Earth material testingInvestigating material hardnessEngineeringStandard penetration test

A sampling device has a closed housing, a split-barrel sampler, an anvil, a drop hammer and a lifting device. The split-barrel sampler is mounted in and extends out from the bottom end of the housing. The anvil is attached to the top of the split barrel sampler. The drop hammer is moveably mounted in the housing and is located above the anvil. The lifting device is mounted in the top end of the closed housing to lift the drop hammer to a specific height above the top of the anvil. With the sampling device, the impact energy generated by the hammer is directly transmitted to the sampler through the anvil. The impact energy lost is minimized, and the accuracy of the Standard Penetration Test result is improved.

Owner:TSAI JIIN SONG

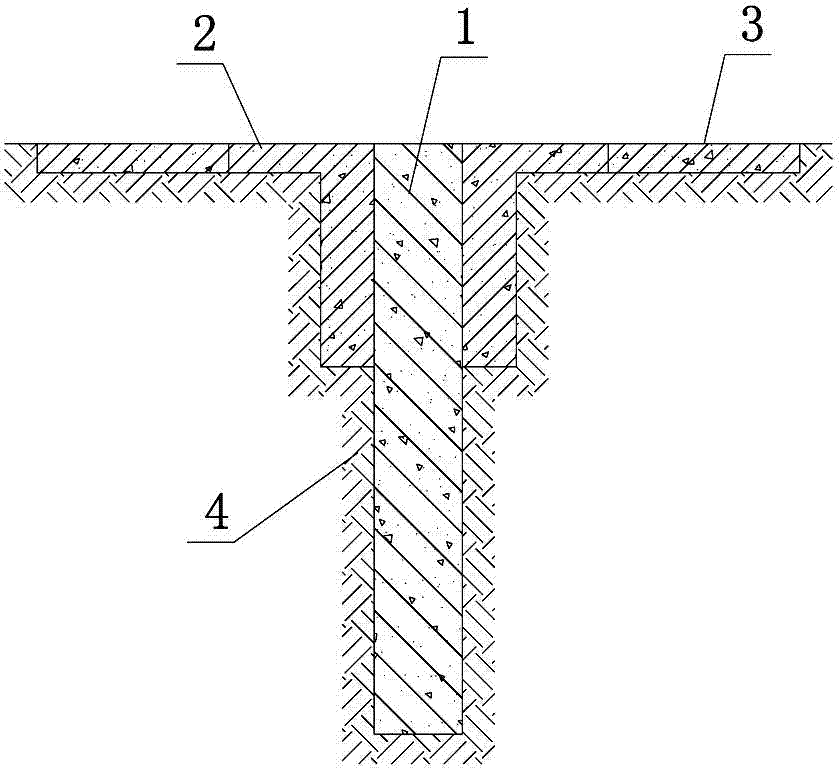

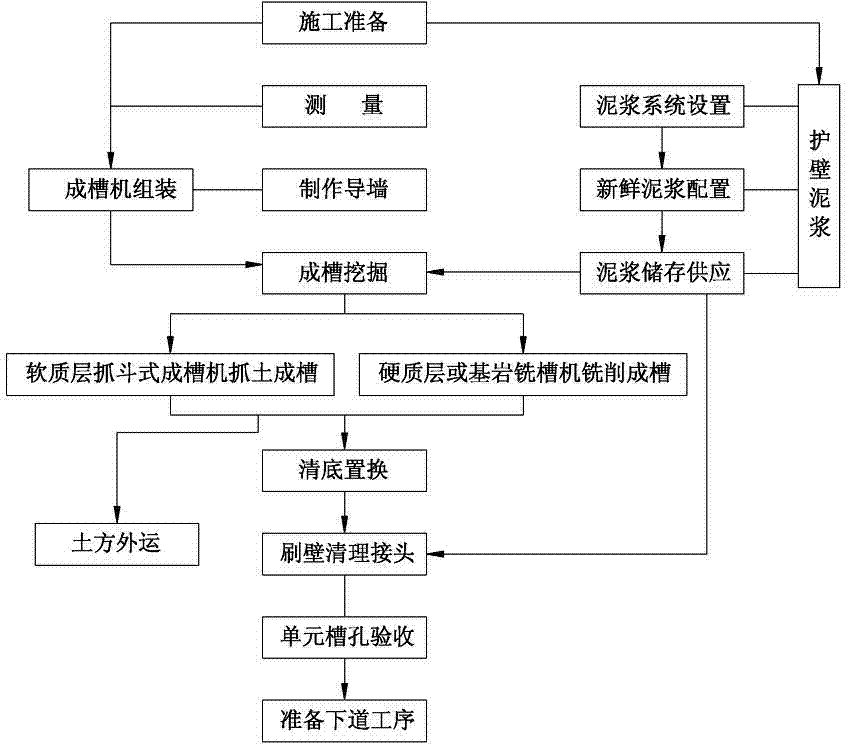

Super-deep underground continuous wall and construction method thereof

The invention relates to a super-deep underground continuous wall which comprises an underground continuous wall body. Guide walls are symmetrically arranged on the two sides of the wall body, the cross sections of the guide walls are in the shape of an L, the lower ends of the guide walls are located on underground rock-soil, and the lug edges of the guide walls are connected with a concrete pavement. The invention further discloses a construction method of the super-deep underground continuous wall. The method includes the following steps of construction preparation, measuring, guide wall manufacturing, wall protection slurry manufacturing, grooving construction, bottom-clearing replacement, connector cleaning through wall brushing and unit slot section inspection, wherein a grabbing-milling integrated grooving method is used in the grooving construction. The method is high in grooving efficiency, short in construction time and short in groove wall soaking time, the grabbing-milling integrated grooving method is used in the grooving construction, technologies can be changed timely according to different stratum hardness situations, the characteristics that a grab bucket is high in digging speed at the soft soil layer and milling wheel can achieve rapid milling and digging footage at a hard soil layer or bed rod with standard penetration test blow count exceeding 45 are fully used, and therefore rapid and efficient grooving of the whole wall can be achieved.

Owner:ZHONGDING INT ENG

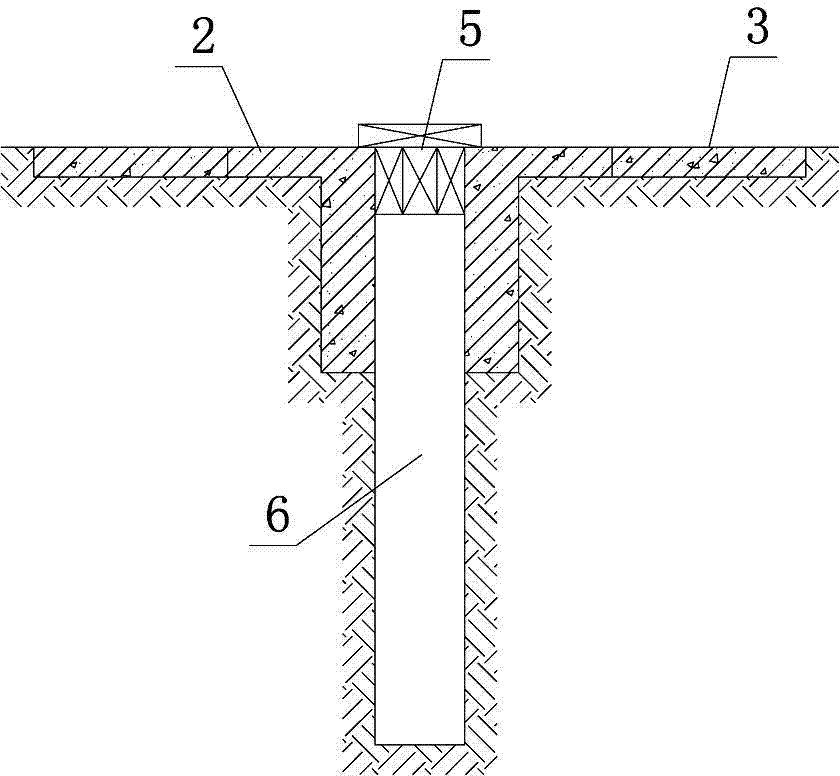

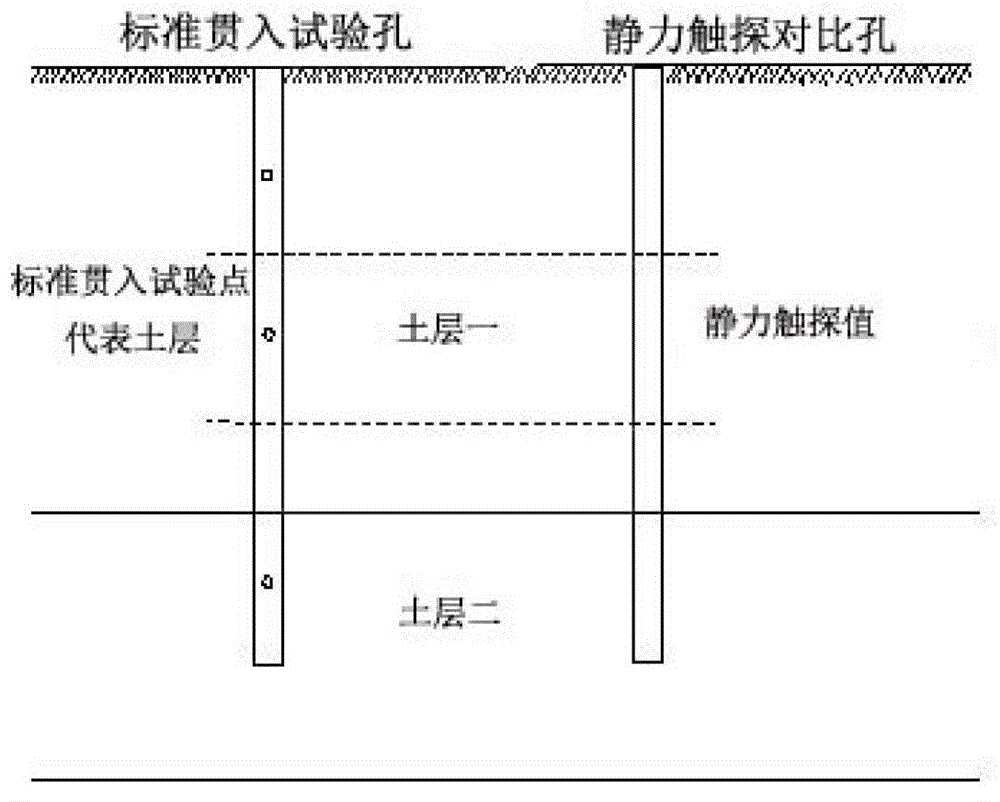

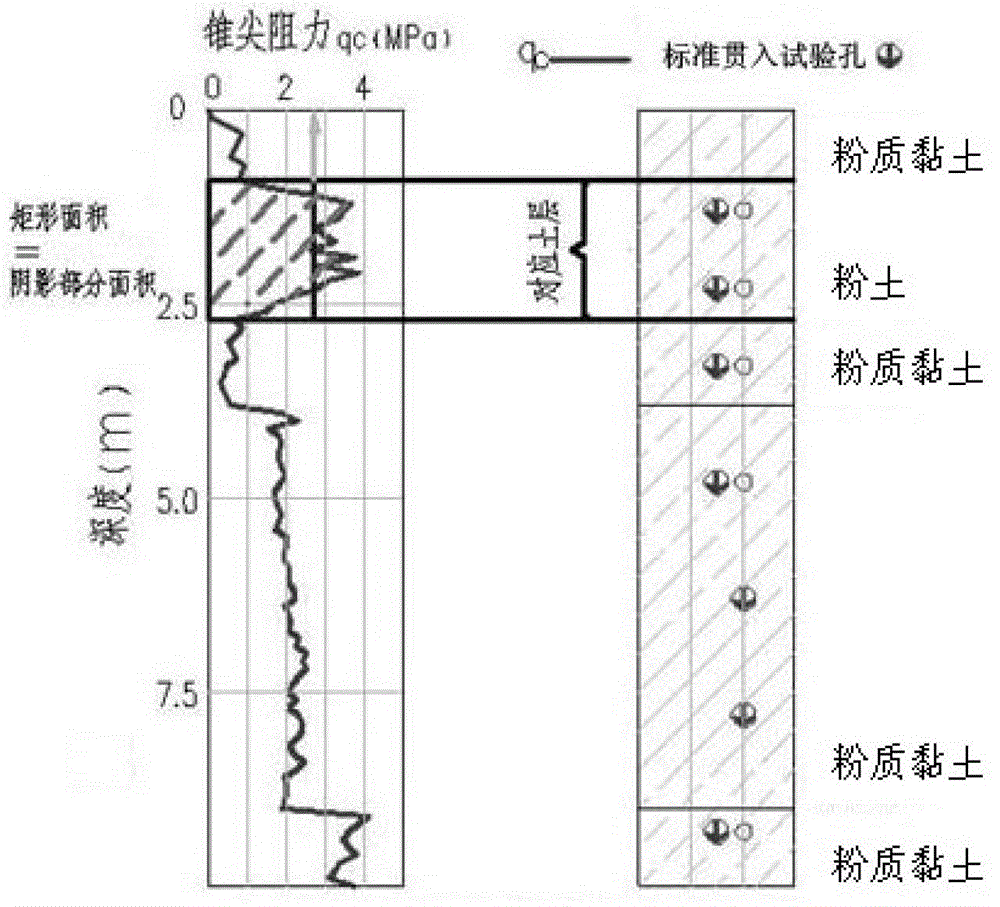

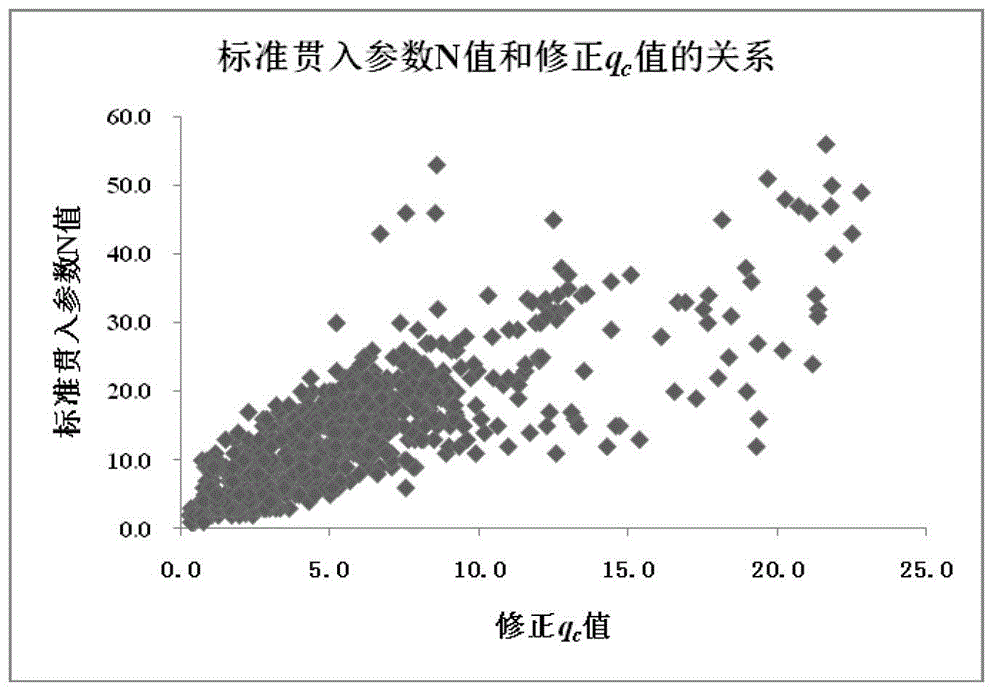

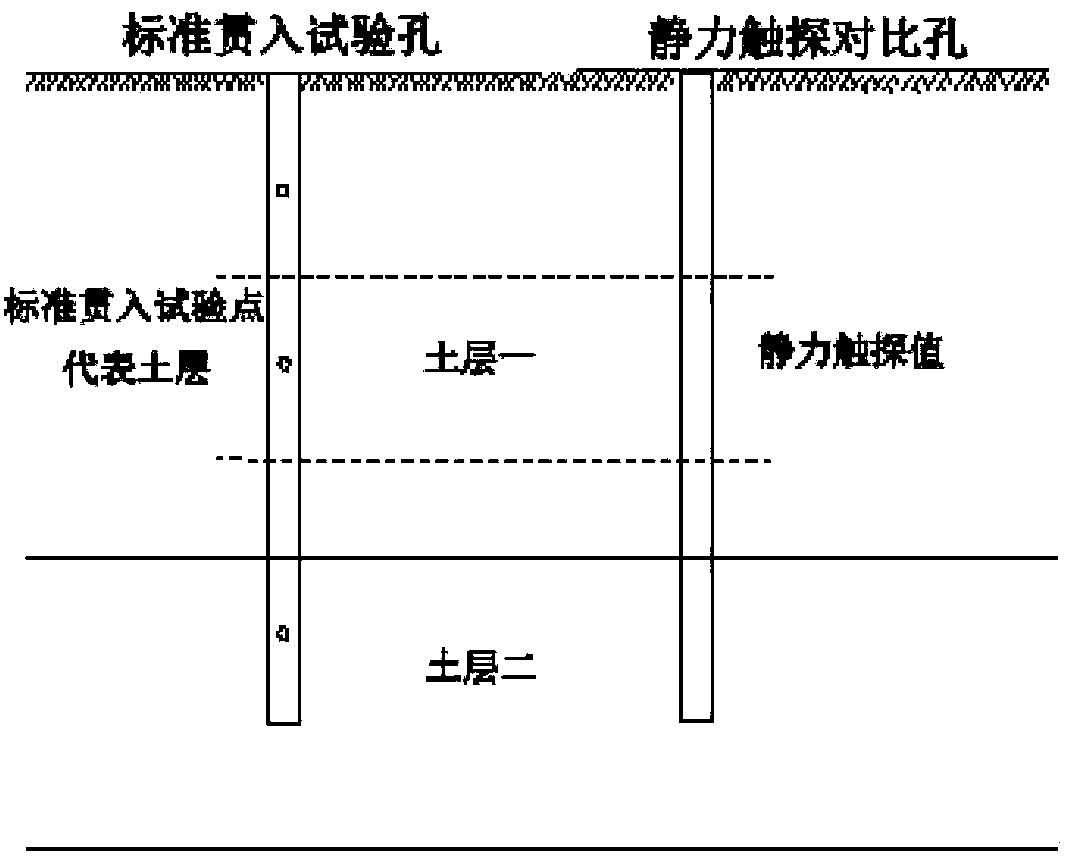

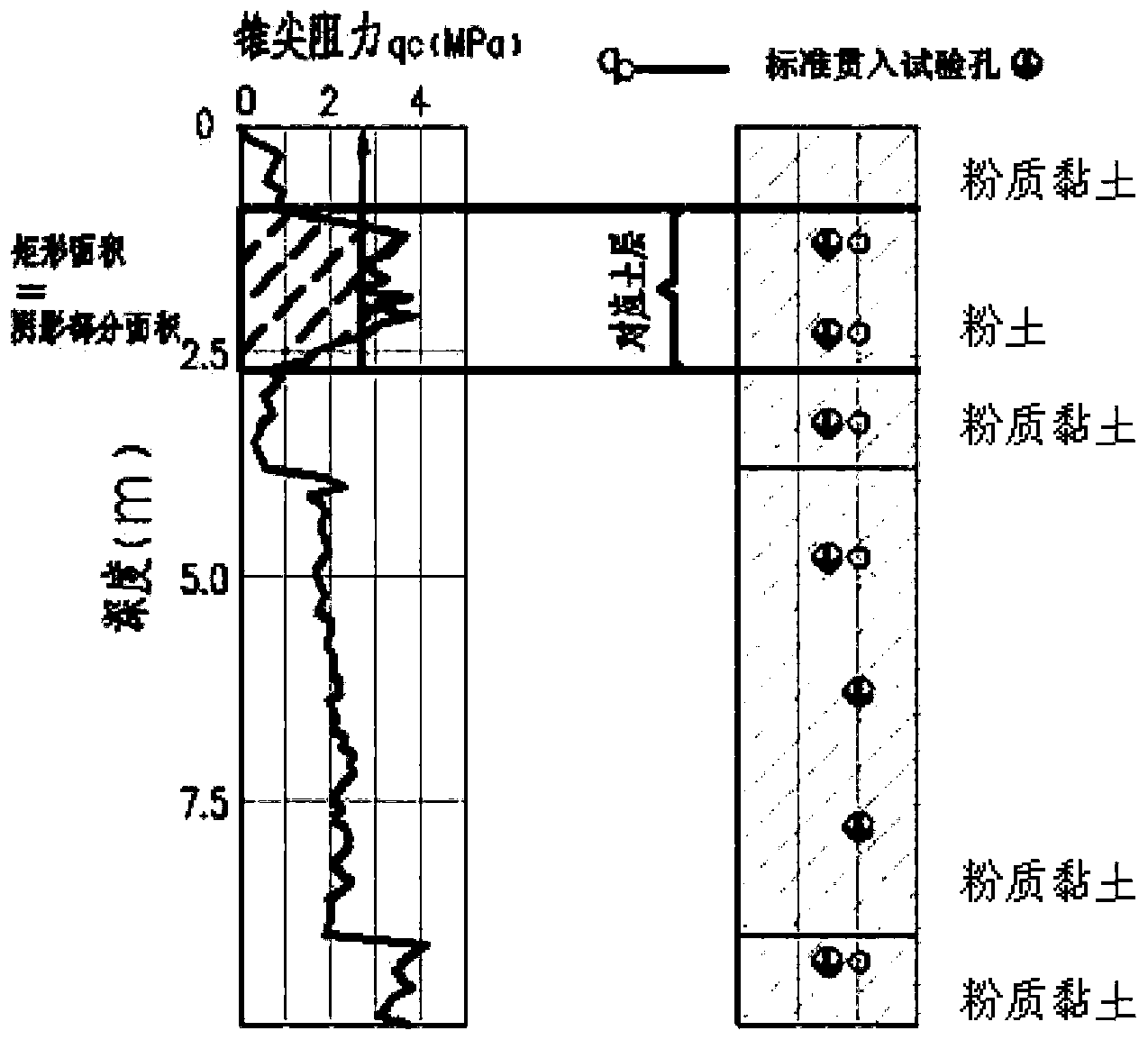

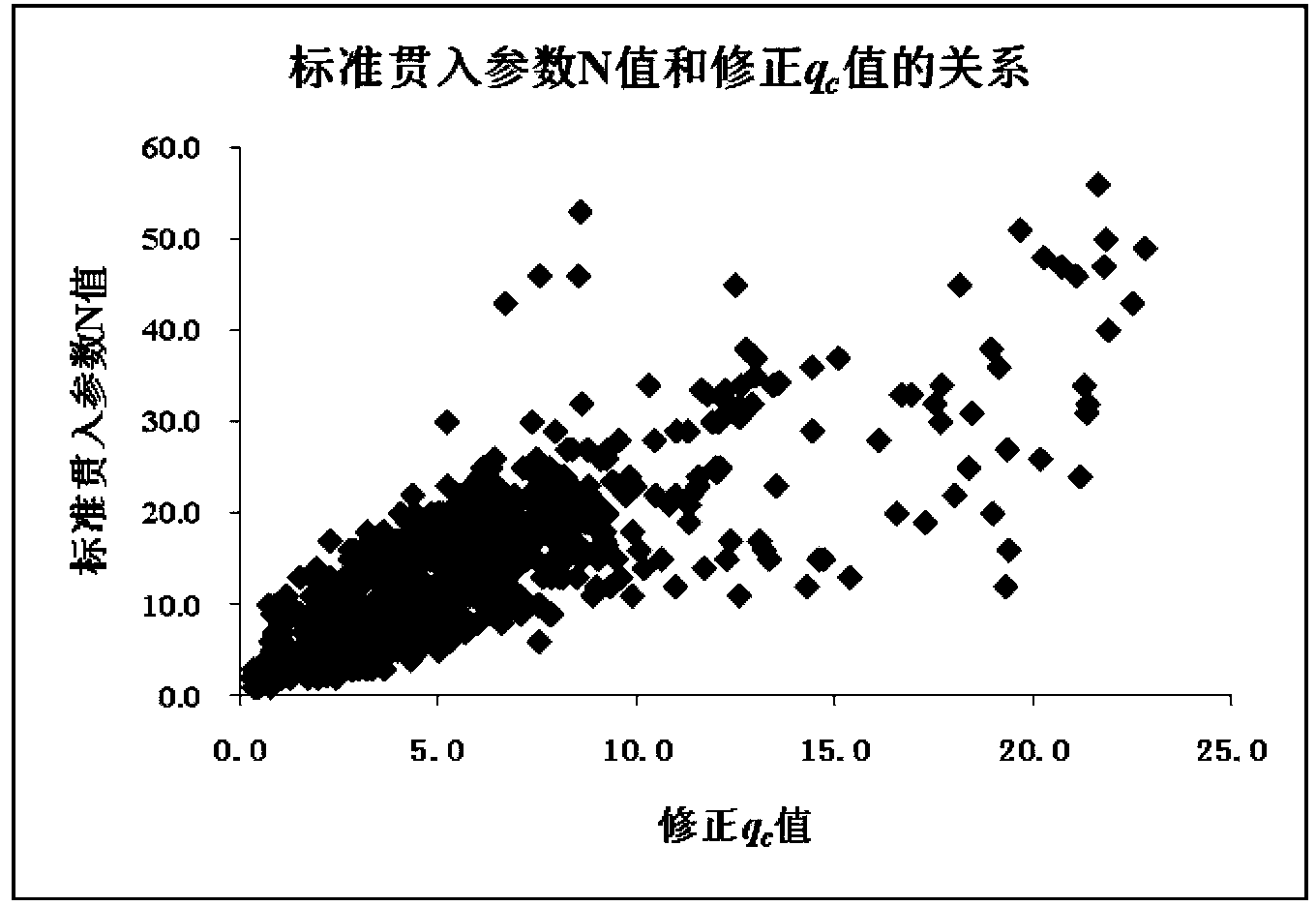

Liquefaction judgment method based on standard penetration and static cone penetration test correlation

ActiveCN102864766ALiquefaction identification is simple and economicalAccurate and fast liquefaction discriminationIn situ soil foundationSoil liquefactionEngineering

The invention relates to a liquefaction judgment method based on standard penetration and static cone penetration test correlation. A principle of selecting a static cone penetration test contrast hole of a standard penetration test hole and a reading method for a standard penetration parameter value N and a static cone penetration parameter tip resistance value qc are provided; three influence factors of clay content rhoc, average particle size D50 and soil parameter alphap are considered, the value N and the value qc are fitted, and a statistically correlative relationship of N-qc is provided; and on the basis, a foundation soil liquefaction judgment method based on a static cone penetration test is provided. By the method, the liquefaction judgment of foundation soil can be made relatively quickly and accurately; and compared with the conventional method, the method is simple, economic and quick, and has a good engineering application value.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST +1

Method of Determining Liquefaction of Shallow Sand Soil Using Variable Energy Dynamic Penetration Sounder

InactiveCN102286967ASolve the shortcomings of liquefactionEasy to useIn situ soil foundationEngineeringStandard penetration test

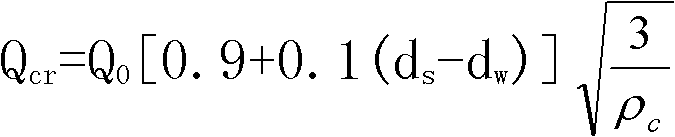

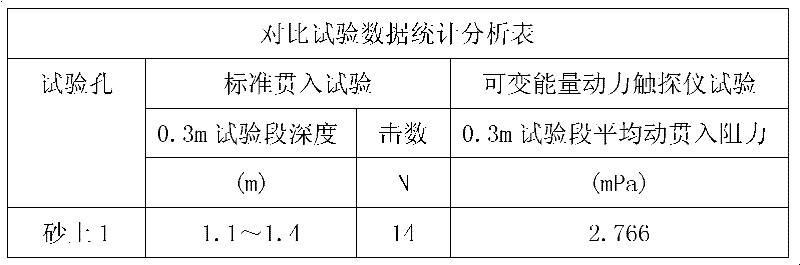

The invention relates to an exploration method, in particular to a method for judging the liquefaction of shallow sand with a variable energy dynamic penetrating sounder. Carry out exploration; use the formula qd=(0.185~0.187)N+(0.68~0.7) to calculate the obtained data; where: qd is the dynamic penetration resistance of the cone head in the variable energy dynamic penetration test, unit: mPa, N is: standard Penetration test blow count; comparison; when the test value qd<critical value Qcr, it can be judged as liquefaction; Qcr is the critical value of penetration resistance Qcr. The invention converts the reference value N0 of the standard penetration hammer number and the critical value Ncr of the standard penetration hammer number into dynamic penetration resistance, so that the liquefaction can be judged by the variable energy dynamic penetrating test. The method has the characteristics of being convenient to carry and use, saving time and labor, and being economical and quick.

Owner:NINGXIA HUI AUTONOMOUS REGION ELECTRIC POWER DESIGN INST

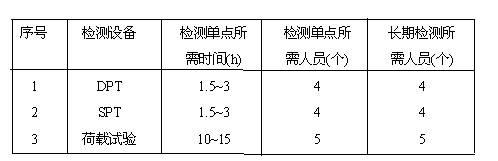

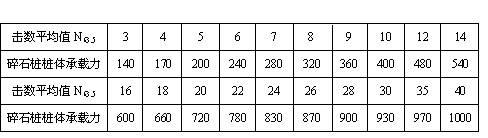

Method for quickly detecting quality of gravel pile

InactiveCN101922159AImprove test efficiencyEasy to operateFoundation testingSoil preservationPunchingCrushed stone

The invention relates to a method for quickly detecting the quality of a gravel pile, which comprises the following steps: the process for carrying out a heavy dynamic penetration test (DPT) on a pile body comprises the following steps: in the heavy dynamic penetration test, by using a power hammer of which the weight is 63.5kg and the drop height is 76cm and using a cone head as a penetration head, carrying out continuous heavy dynamic penetration tests along the depth direction of the pile body, recording the actually measured hammering number when the pile body is penetrated for every 10cm, correcting the hammering number, and then, determining the bearing capacity (kPa) of the foundation according to the corrected heavy cone dynamic penetration hammering number N63.5; and the process for carrying out a standard penetration test (SPT) comprises the following steps: by using a punching hammer of which the weight is 63.5kg and the drop height is 76cm, punching a standard penetrometer into the soil for 15cm and then for 30cm, utilizing the hammering number for last 30cm as a standard penetration test index, and then, computing the bearing capacity of the foundation after correcting the hammering number according to the corrected heavy cone dynamic penetration hammering number N63.5.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD

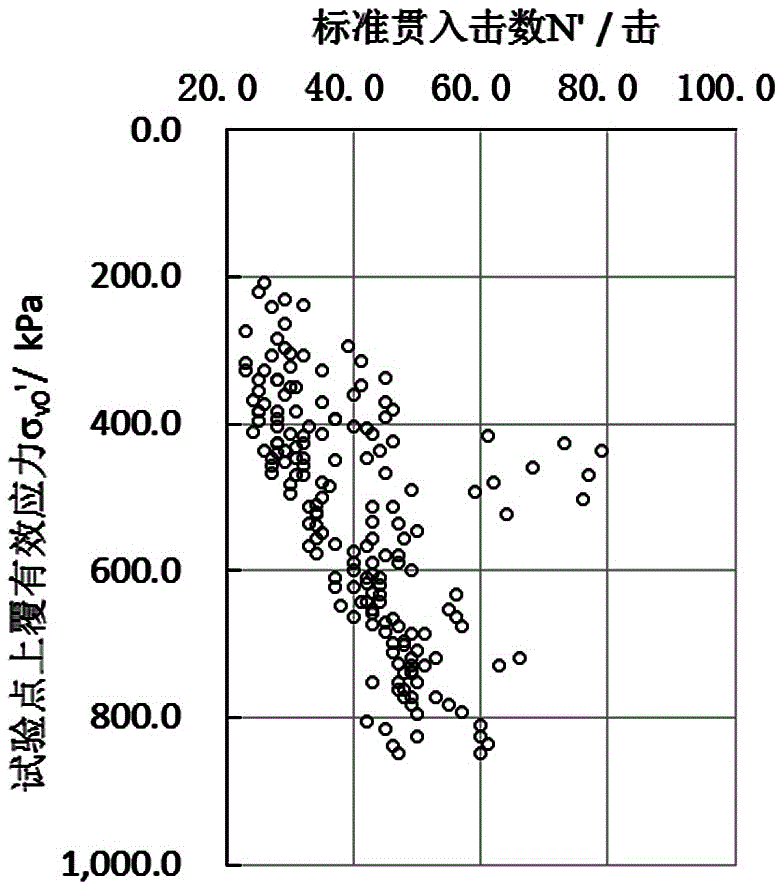

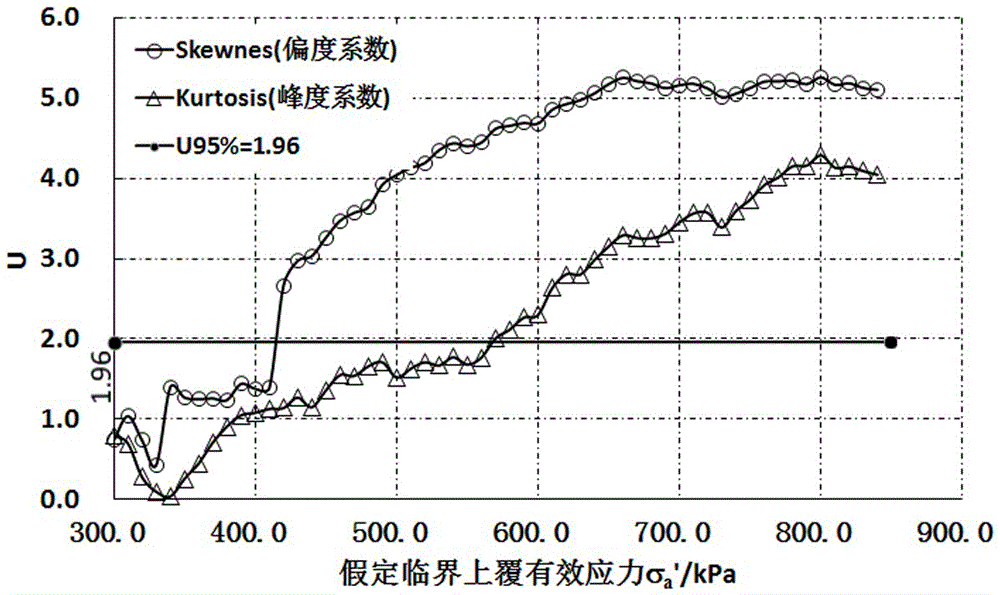

Deep saturated sand earthquake-induced liquefaction judgment method

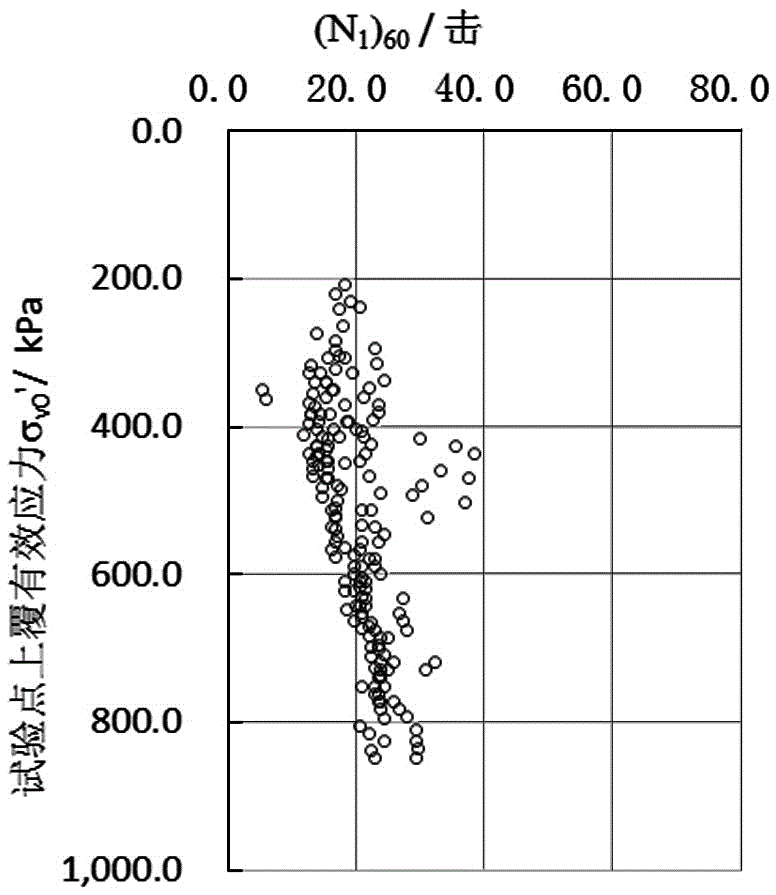

ActiveCN106408211AOvercome the defect that it is not suitable for the soil layer below 20mOvercome cannot be applied to deep buriedDesign optimisation/simulationResourcesSoil scienceStress ratio

The invention provides a deep saturated sand earthquake-induced liquefaction judgment method, which comprises six steps: 1) determining standard penetration numbers of a deep saturated sand layer at different positions and in different depths; 2) determining seismic cyclic shear stress ratio CSR of different standard penetration test points of the deep saturated sand layer; 3) determining actual critical overlying effective stress of standard penetration test through a hypothetical test method; 4) obtaining normalized standard penetration numbers of the different standard penetration test points at different positions and in different depths; 5) determining liquefaction-resistance cyclic shear stress ratio CRR7.5; and 6) making a comparison between the seismic cyclic shear stress ratio CSR and the liquefaction-resistance cyclic shear stress ratio CRR7.5, and carrying out earthquake-induced liquefaction judgment. The method can overcome the defect that a standard penetration number liquefaction judgment method in the current specifications cannot be applied to the soil layer, the depth of which is larger than 20m, and can enable the existing standard penetration number liquefaction judgment method to be expanded and applied to deep saturated sand earthquake-induced liquefaction judgment.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

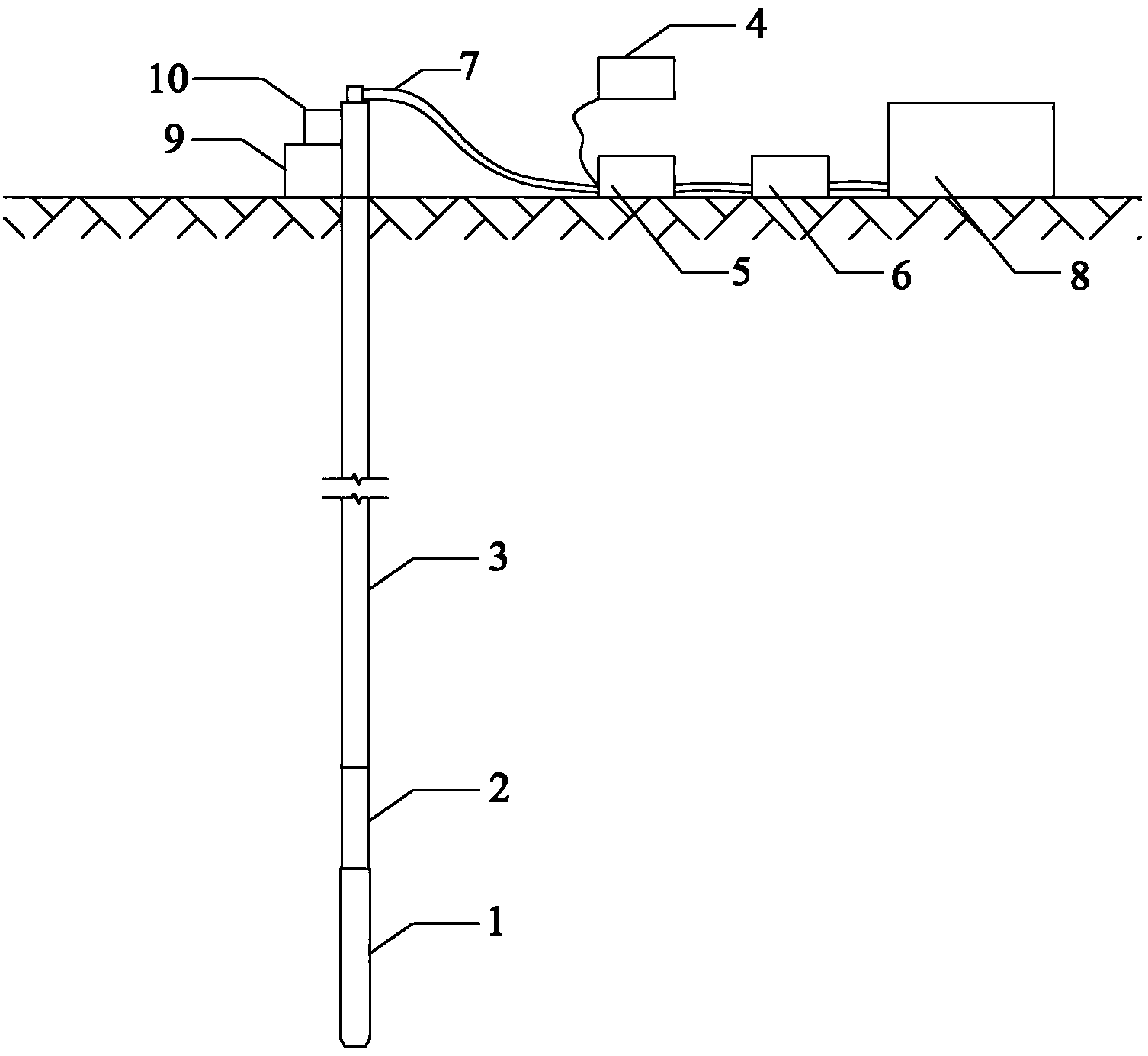

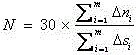

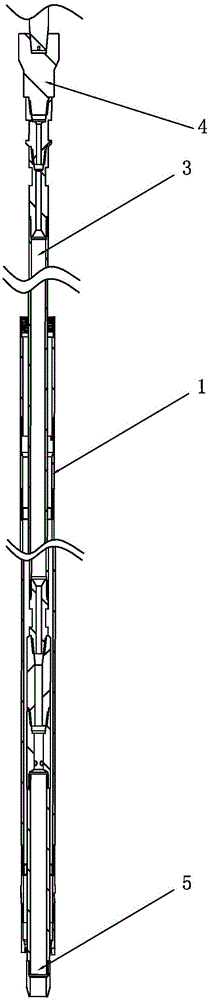

Standard penetration test apparatus and test method thereof

The invention provides a standard penetration test apparatus and a test method thereof. A standard penetration device of the standard penetration test apparatus is sequentially connected with an air hammer and a sounding rod; the other end of the sounding rod is connected with the air outlet of a three-way electromagnetic valve through an air transmission rubber hose; the air inlet of the three-way electromagnetic valve is connected with the air outlet of an air source treatment triplet, and the air inlet of the air source treatment triplet is connected with a small-sized air compressor; a counter and a depth recorder are arranged on one side of the upper end part of the sounding rod; an air hammer control instrument is electrically connected with the three-way electromagnetic valve and the counter, and the counter is electrically connected with the depth recorder. The invention has the benefits that the penetration test apparatus is simple in structure and convenient to operate, and data obtained through a test is accurate and reliable; and as the sounding rod does not perform impacting, absorption to impacting energy by deformation of the sounding rod is eliminated, and energy loss generated by friction of a pore wall and the sounding rod in bending deformation is avoided, so that the standard penetration test apparatus can perform effective tests in the deeper stratum without rod length correction.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

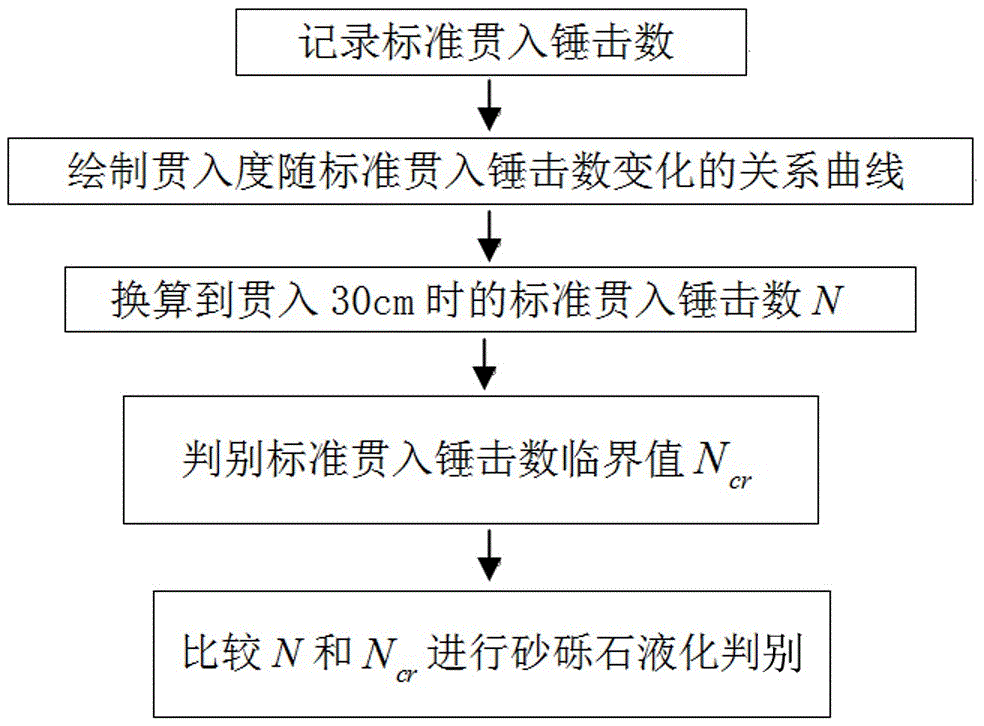

Method for discriminating sand-gravel stratum liquefaction through standard penetration test

Provided is a method for discriminating sand-gravel stratum liquefaction through a standard penetration test. The method comprises the steps that a test sand-gravel stratum is drilled 5cm above the elevation of the test sand-gravel stratum; a standard penetration test device is connected and an injection device is put to the bottom of a drill hole after a connector of a feeler lever is inspected; then the injection device is driven into a saturated sand-gravel stratum by 5cm through a pilereing hammer, the standard penetration hammering number starts to be recorded for every 3cm of driving, and the total test range is 30cm and is divided into 10 test sections; a relation curve graph between the hammering number of each test section and the corresponding penetration degree is drawn, the invalid test sections affected by sand gravel of large grain sizes are removed according to the relation curve graph, and the standard penetration hammering number of 30cm of penetration is equivalently converted according to the standard penetration hammering number and the penetration degree of the valid test sections; and seismic liquefaction discrimination of saturated sand gravel is conducted according to the standard penetrate hammering number equivalent to 30cm of penetration into the saturated sand gravel. By adoption of the method for discriminating sand-gravel stratum liquefaction, the defect that in the prior art, the standard penetration hammering number tends to be large due to the effect of the sand gravels of the large grain sizes, and the seismic liquefaction discrimination result tends to unsafe accordingly is overcome.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Method of using standard penetration test blow count N for detecting relative density Dr of sandy soil of Yangtze River estuary, sand spit and barrier island stratums

InactiveCN104179164AReduce testing costsEasy to calculateIn situ soil foundationTest efficiencySoil science

The invention relates to a method of using standard penetration test blow count N for detecting relative density Dr of sandy soil of Yangtze River estuary, sand spit and barrier island stratums. The method includes the steps: (1) penetrating a standard penetrometer into a sandy soil layer, and recording blow count when penetration depth of the penetrometer is 30cm as the standard penetration test blow count N; (2) calculating overlying effective pressure, in corresponding depth, of the soil layer; (3) according to the detected standard penetration test blow count N and the calculated overlying effective pressure, working out the relative density Dr of the sandy soil according to a formula. By adoption of the method, calculation of the relative density of the sandy soil is facilitated, the problem of difficulty in taking undisturbed samples of sandy soil for testing is solved, exploration test efficiency is improved, soil sample test cost is saved, and calculation results are reliable.

Owner:TONGJI UNIV

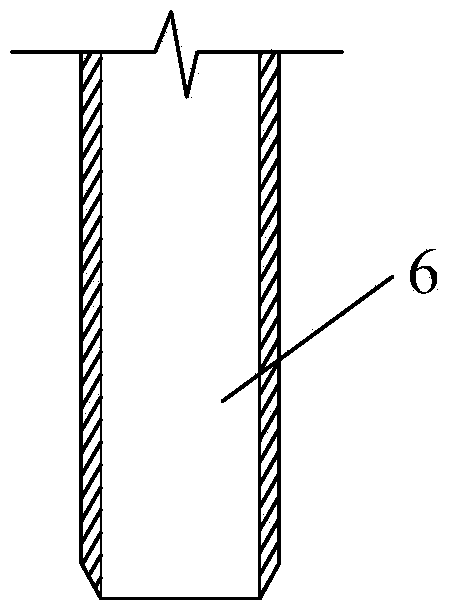

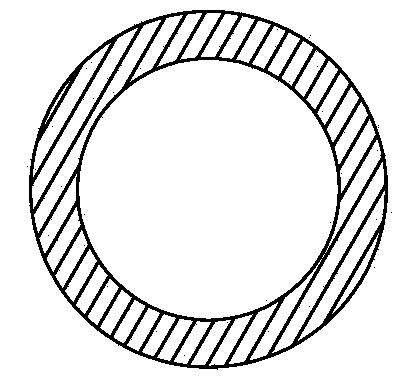

Sand bailing mechanism and drilling tool

InactiveCN103573202AAutomatic collectionTimely collectionBorehole/well accessoriesCore removalSlurryEngineering

The invention relates to the technical field of geotechnical engineering investigation and geological exploration and discloses a san bailing mechanism. The sand bailing mechanism comprises a bailing bucket which is arranged outside a drill rod and along the axial direction of the drill rod; the bailing bucket comprises a sealing end which is connected with the drill rod and an annular-shaped lateral wall; a gap is formed between the drill rod and the annular-shaped lateral wall, so that sand filling space is formed; an inclined opening is formed in the upper end of the lateral wall; a plurality of sand inlet holes and water outlet holes are formed in the lateral wall. According to the sand bailing mechanism which is arranged on the periphery of the drilling rod, suspending gravel in drilling holes enters into the sand filling space through the inclined opening which is formed in the lateral wall and the sand inlet holes and precipitates in the sand filling space and fluid such as slurry inside the sand filling space is effused through the water outlet holes. The sand bailing mechanism has the advantages of automatically collecting gravel during a process that the drilling tool is drilling holes or tripping out, effectively preventing the gravel precipitating at the hole bottoms, avoiding gravel precipitation causing drilling tool burying accidents, guaranteeing data accuracy of standard penetration tests during an investigation process, enabling the data to reflect characteristics of rock-soil, guaranteeing drilling quality and greatly improving the construction efficiency.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

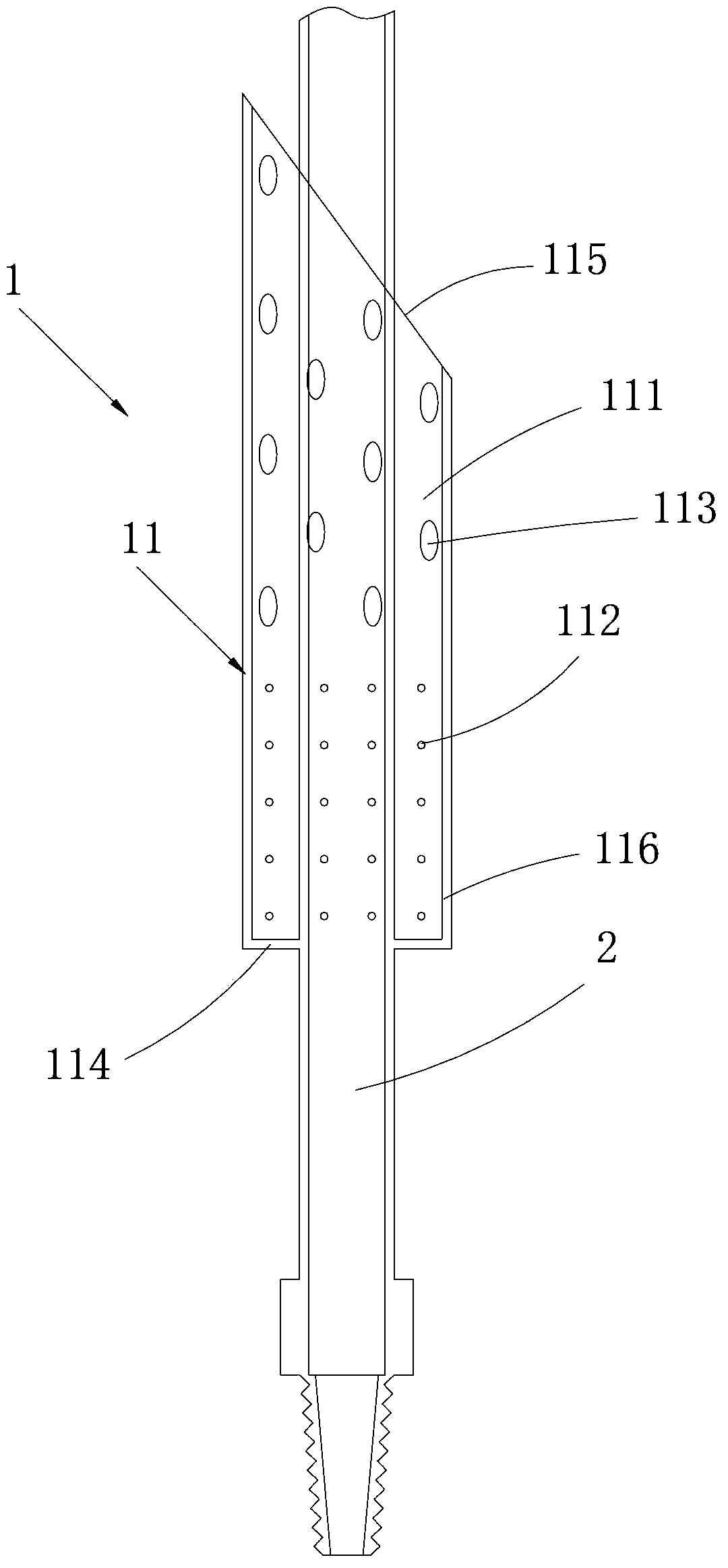

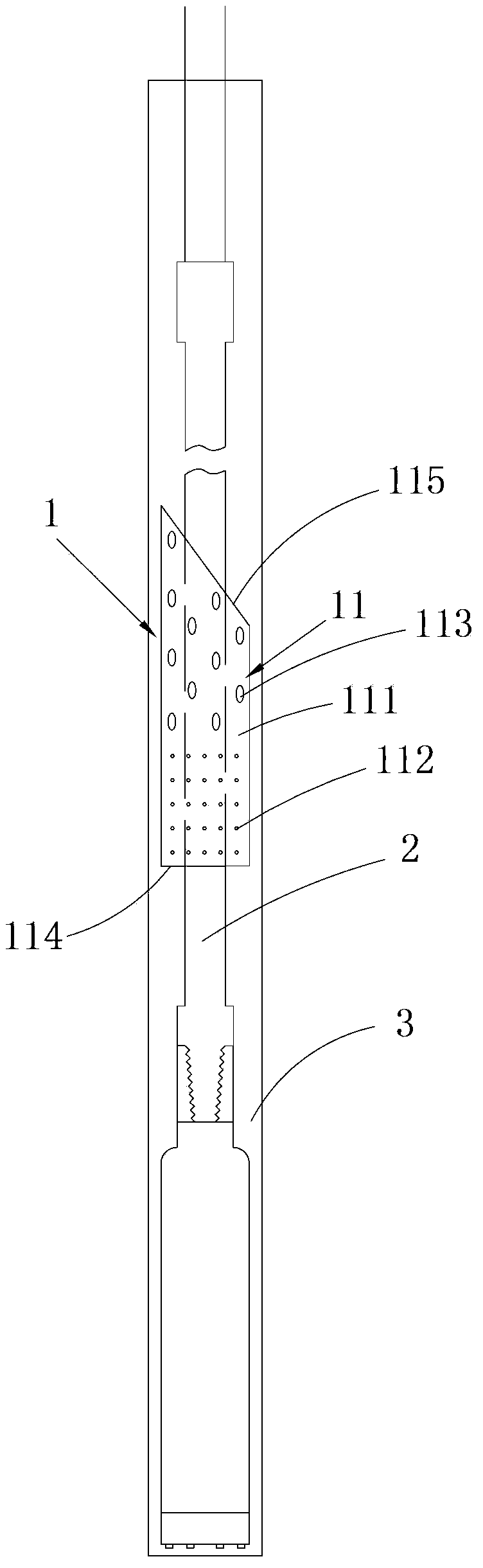

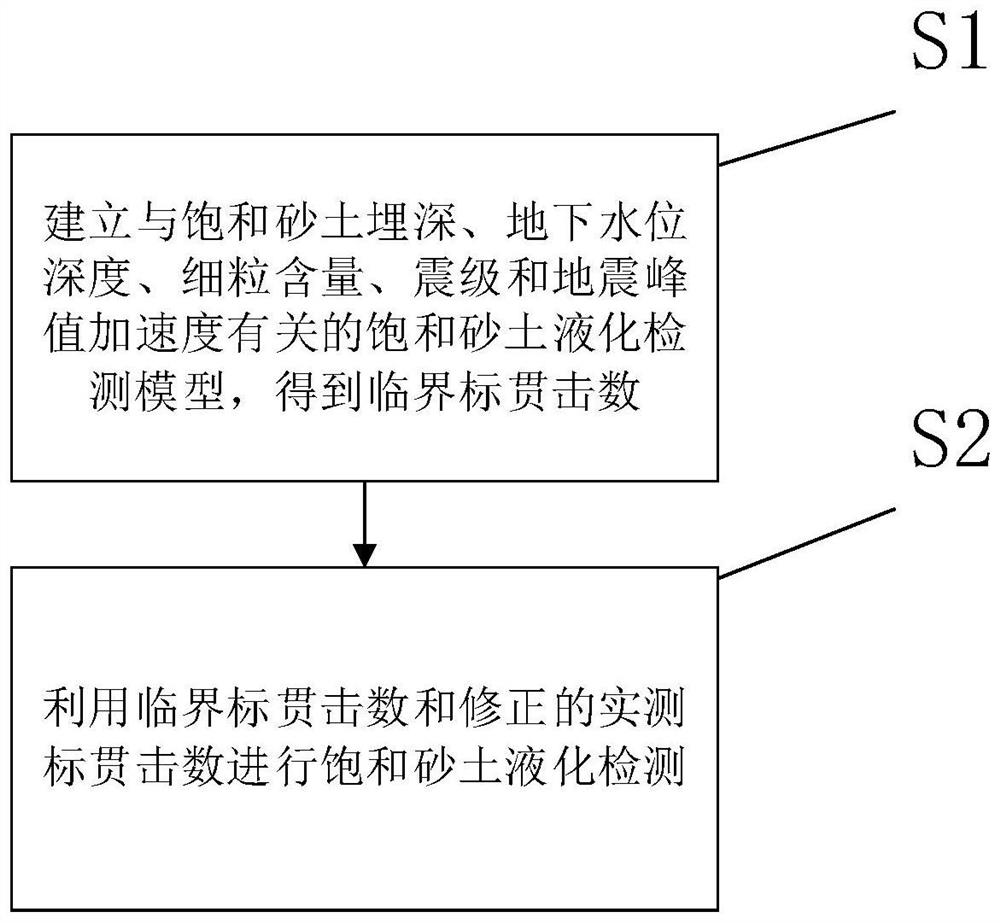

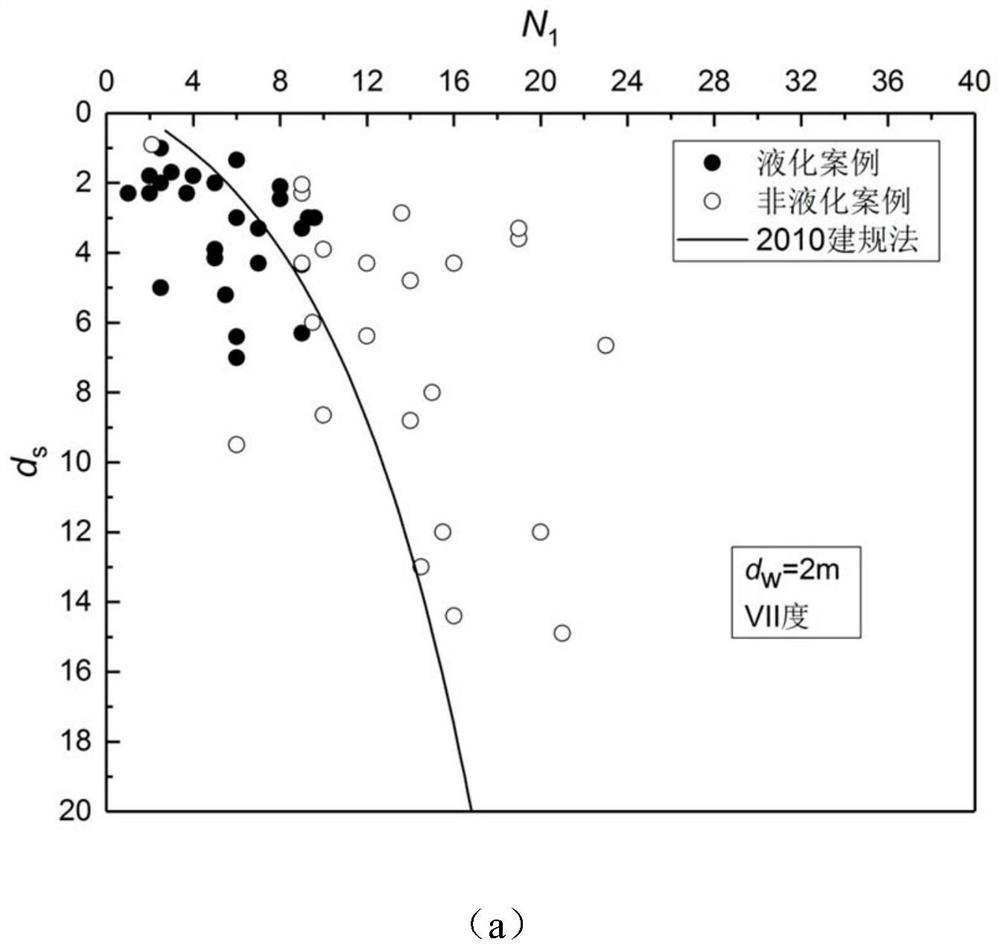

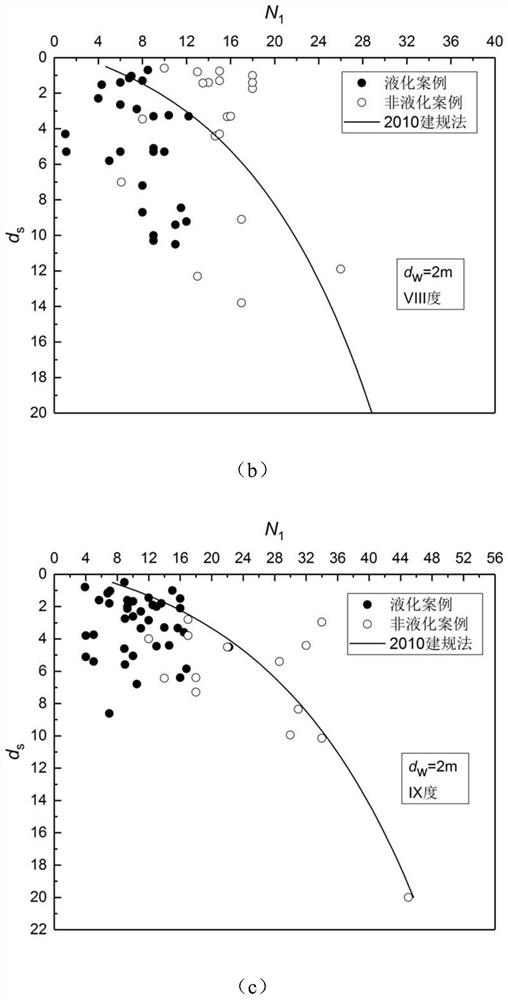

Saturated sand liquefaction detection method based on standard penetration test

ActiveCN111705774AThe test result is accurateWide applicabilityIn situ soil foundationWater levelStandard penetration test

The invention relates to a saturated sand liquefaction detection method based on a standard penetration test. The method comprises the following steps of: establishing a saturated sand liquefaction detection model related to saturated sand burial depth, underground water level depth, fine particle content, earthquake magnitude and earthquake peak acceleration, and obtaining a critical standard penetration number; and carrying out saturated sand liquefaction discrimination by utilizing the critical standard penetration number and a corrected actually measured standard penetration number. Compared with the prior art, the method has the advantages that the defects that a liquefaction discrimination formula in a building anti-seismic design specification (GB 50011-2010) is inclined to risk ina saturated sand shallow layer and is inclined to conservative in a saturated sand deep layer are overcome, so that a detection result is more accurate; liquefaction discrimination of soil bodies withvarious burial depths and fine particle contents can be met under various intensities, and the method has wide applicability; and the discrimination formula is simple in form, comprehensive in consideration and suitable for being used in actual engineering; and based on a foreign liquefaction database, the earthquake site is more, the data size is large, good representativeness is achieved, and popularization is easy.

Owner:SOUTHWEST COMM CONSTR GRP +2

Engineering geological drilling construction method based on thin-walled drilling tool

The invention discloses an engineering geological drilling construction method based on a thin-walled drilling tool. According to the engineering geological drilling construction method based on the thin-walled drilling tool, a single rotary double-tube drilling tool is adopted, pressing drilling is conducted in rotation, the full-hole follow-pipe drilling speed is quick, slurry consumption is little, a rock core tube is kept to be in a non-rotation state, and disturbance on a soil layer is small; and when the drilling depth reaches the length of the rock core tube, an oil cylinder lifts the whole drilling machine away from the hole bottom for a section of distance to break off a rock core. The core taking quality is high, and an undisturbed soil sample can be extracted; during core taking and a standard penetration test, a drill rod and an outer tube assembly are kept in a drilled hole to be still all the time, the hole wall is protected, and damage, caused by repeatedly drill pipe lifting, to the hole wall is avoided; and meanwhile, friction between a test rod and the hole wall is reduced, uncertain factors are reduced, and the test result is more accurate.

Owner:ZHUHAI EAGLER SPECIALTY DRILLING EQUIP CO LTD

Automatic SPT monitor

Owner:HONG KONG THE UNIV OF

Safe standard penetration test device and test method

The invention provides a safe standard penetration test device and a test method. The standard penetration test device comprises a rack, a rack horizontal movement mechanism, a pilereing hammer, a guide rod, a hammering cushion and a pilereing hammer lifting system, wherein a threaded opening, connected with a feeler lever or drill pipe connected with a penetrometer, is formed in the lower part of the hammering cushion; during the specific test, the standard penetration test device is mounted on a drilling machine gantry, a high-pressure oil pipe is utilized to connect the hydraulic motor of the pilereing hammer lifting system and the telescopic oil cylinder of the rack horizontal movement mechanism with a drilling machine hydraulic source through a valve; when the drilling machine drills to a desired standard penetration test depth, the standard penetrometer is connected onto the drill pipe, the telescopic oil cylinder pushes the rack to move along rack horizontal movement tracks until the guide rod is coaxial with the driving drill pipe of the drilling machine, the drill pipe on the standard penetrometer is enabled to be connected with the hammering cushion, and a power supply is turned on to enable the hammering test to be carried out. According to the safe standard penetration test device and the test method, the structure is simple, the automatic penetration is realized, the practicability is high, the testing speed is high, the safety risks are reduced greatly, and the testing reliability is improved.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

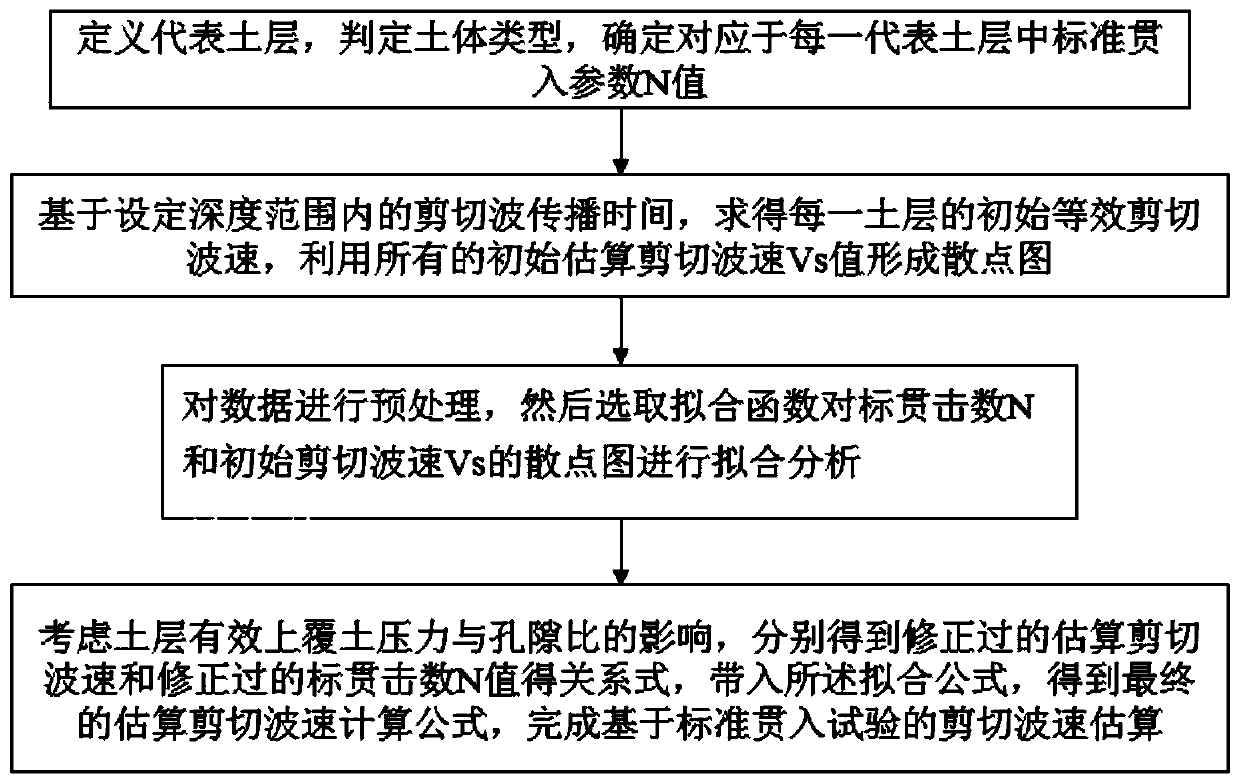

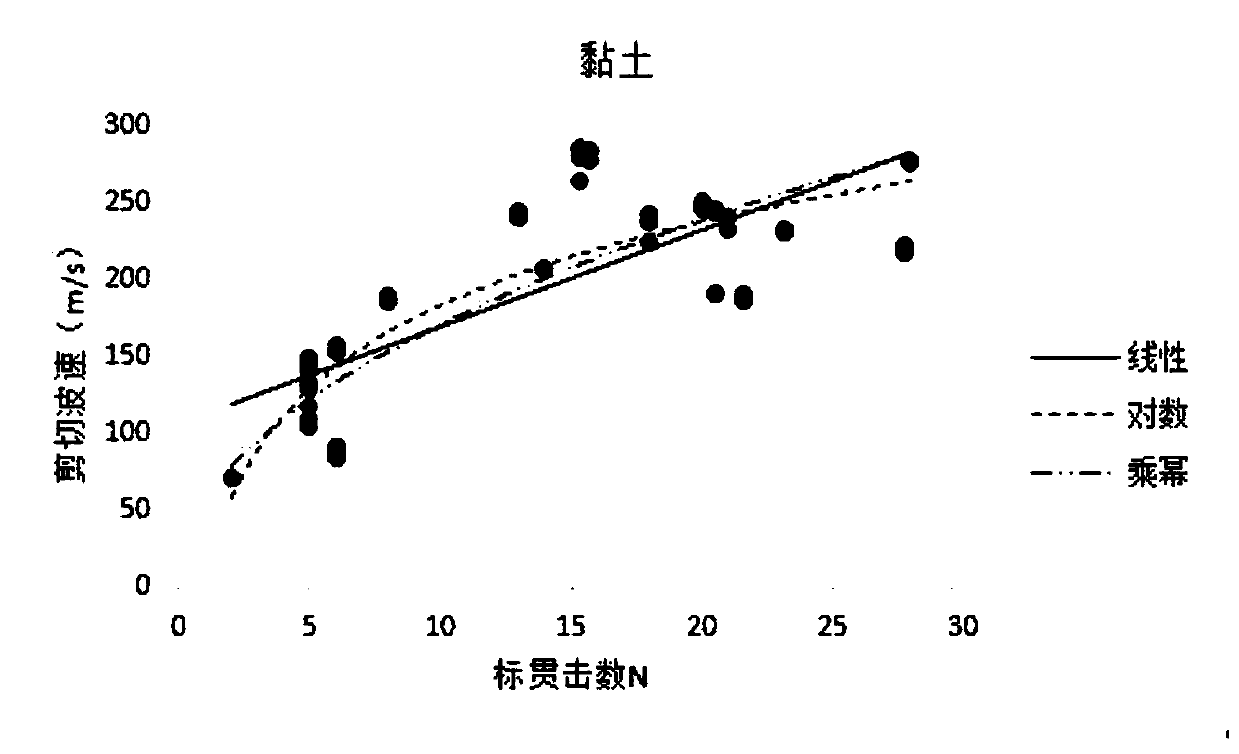

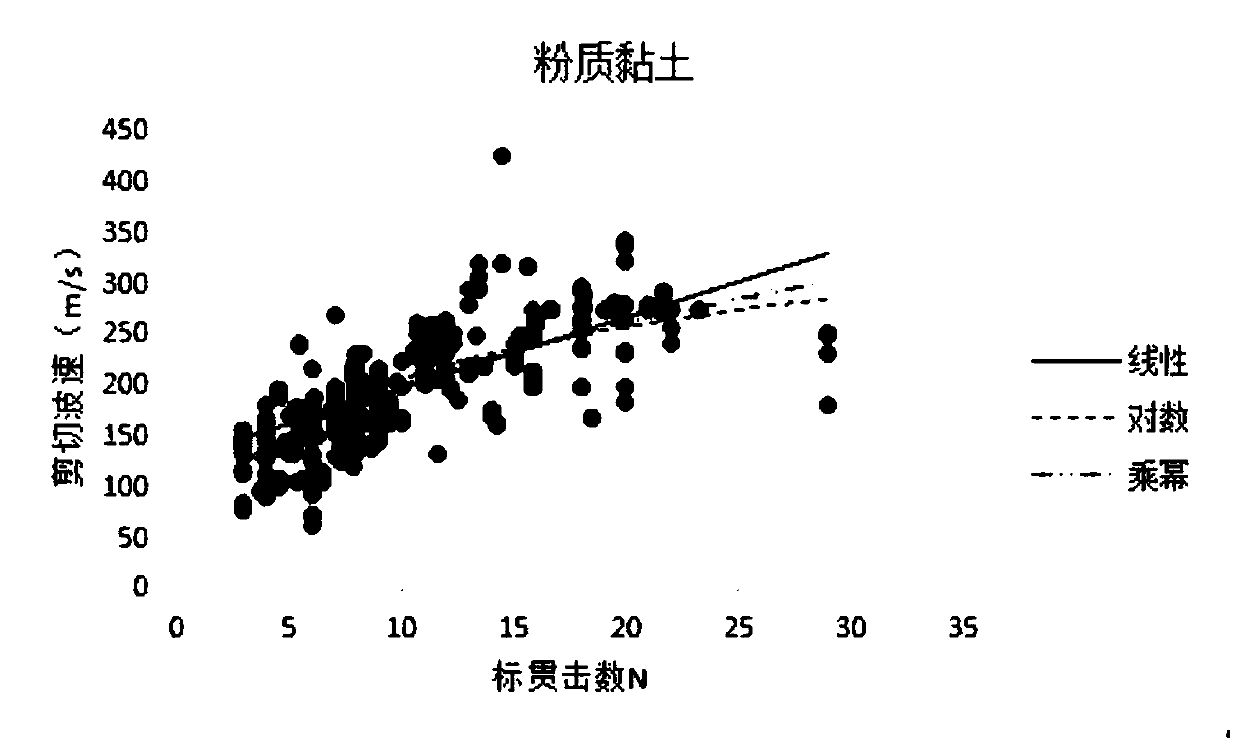

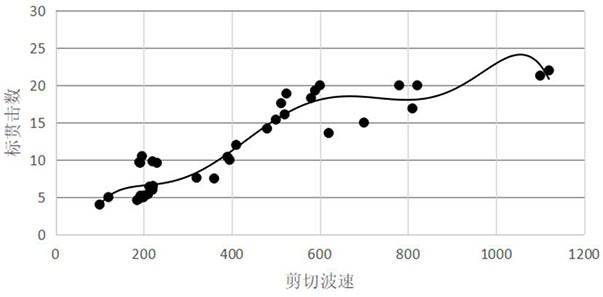

Shear wave velocity estimation method based on standard penetration test

InactiveCN109763474AEasy and fast measurementEasy to useIn situ soil foundationVoid ratioEstimation methods

The invention discloses a shear wave velocity estimation method based on a standard penetration test. The method applies grey relational analysis and takes account the influence of a soil layer effective upper overbarden pressure sigma'v and void ratio e; a relationship expression of a standard penetration value N, the soil layer effective upper overbarden pressure sigma'v, a void ratio e value and shear wave velocity is established by a function fitting method, and thereby the shear wave velocity is estimated. The method can be used for conveniently measuring and calculating the shear wave velocity on the basis of a conventional standard penetration test and has high measuring accuracy.

Owner:SOUTHEAST UNIV +1

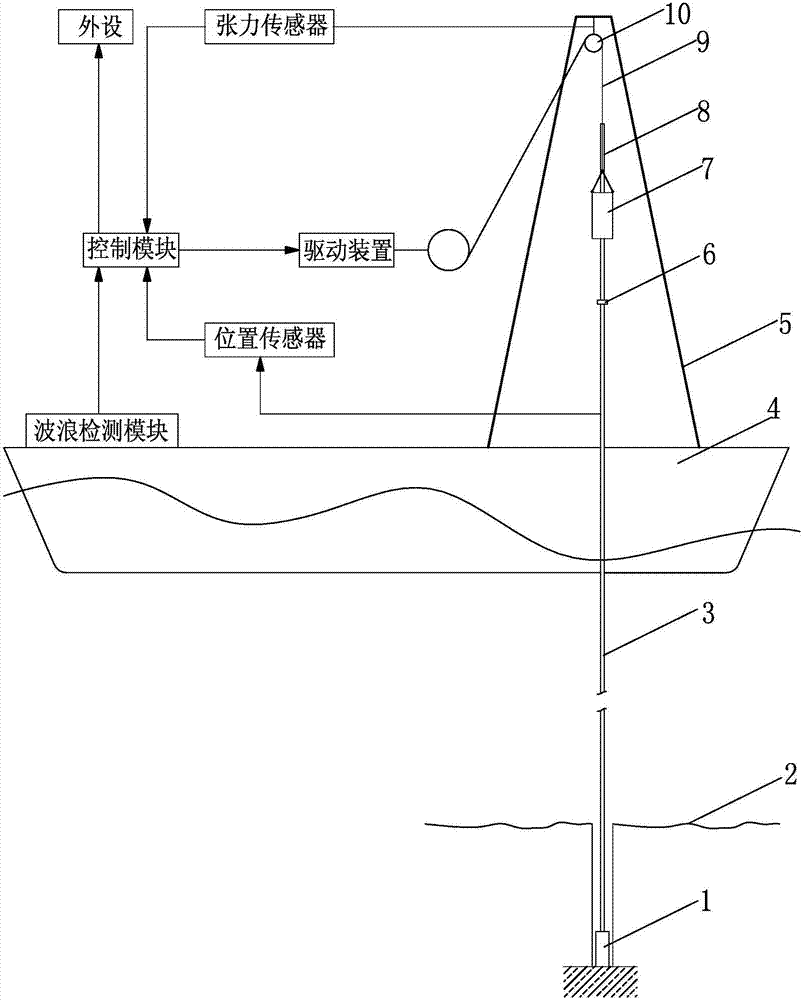

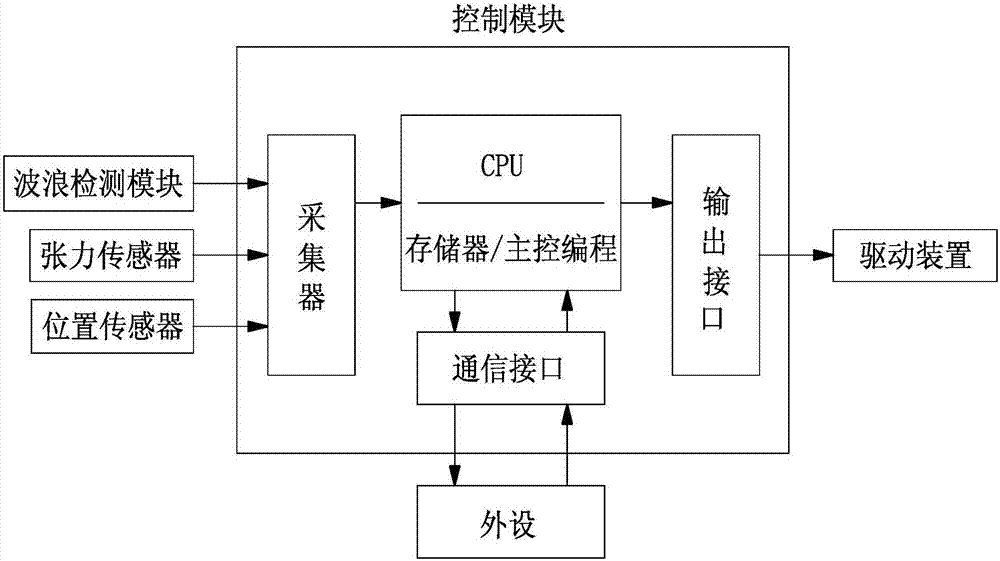

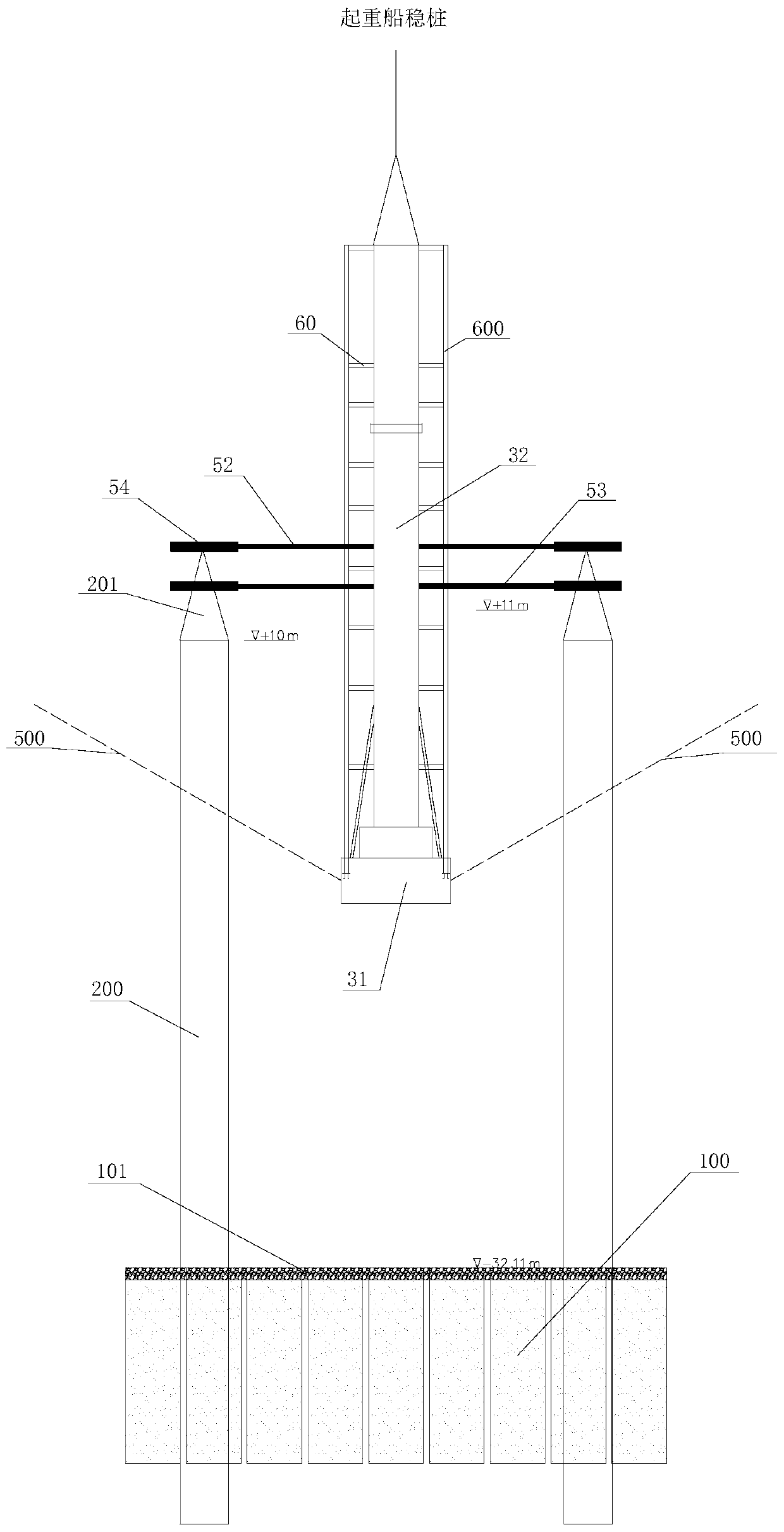

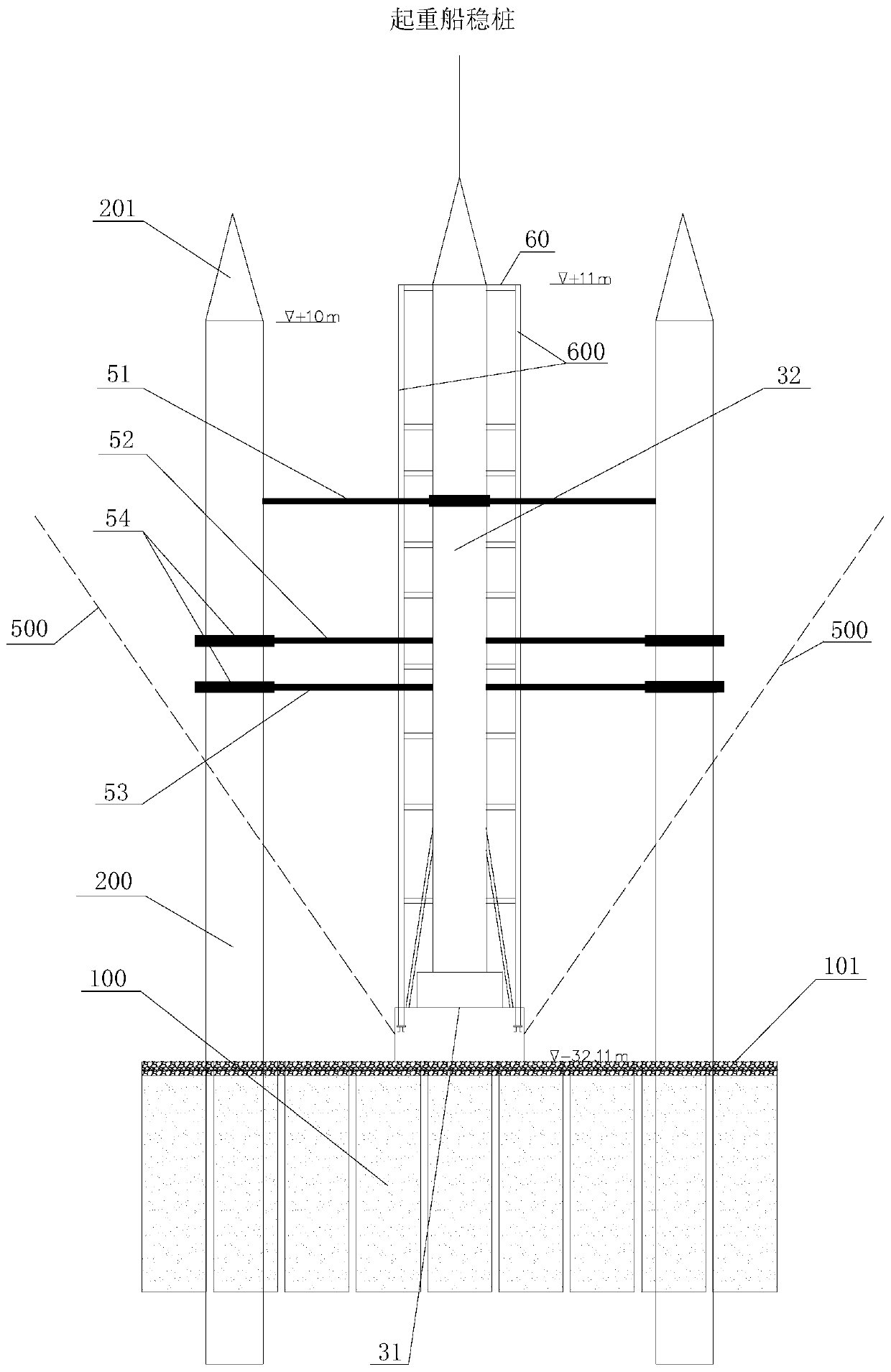

Drop hammer control device for marine standard penetration test and method thereof

The invention discloses a drop hammer control device for a marine standard penetration test and a method thereof. The drop hammer control device for the marine standard penetration test comprises a drill rod, a wire rope, and a pilereing hammer connected with one end of the wire rope, and the other end of the wire rope is connected with a driving device. the drop hammer control device further comprises a wave detection module and a control module, wherein the wave detection module comprises an inclinometer and a gyro sensor, the inclinometer is used for measuring the tilt angle of a ship, the gyro sensor is used for measuring the angular velocity of the ship, and the tilt angle and the angular velocity of the ship are transmitted to the control module in real time. According to the data measured by the wave detection module, the control module calculates the heaving variation in the next step of the ship, and adjusts the momentum of the driving device to drive the pilereing hammer to achieve a drop distance meeting the standard requirement. By arranging the wave detection module and the control module, the heaving variation in the next stop of the ship can be predicted in real time, therefore the driving device can be controlled to adjust the momentum of the wire rope, the free fall of pilereing hammer with the accurate drop distance can be guaranteed, and an accurate standard penetration blow count can be obtained.

Owner:CCCC THIRD HARBOR CONSULTANTS

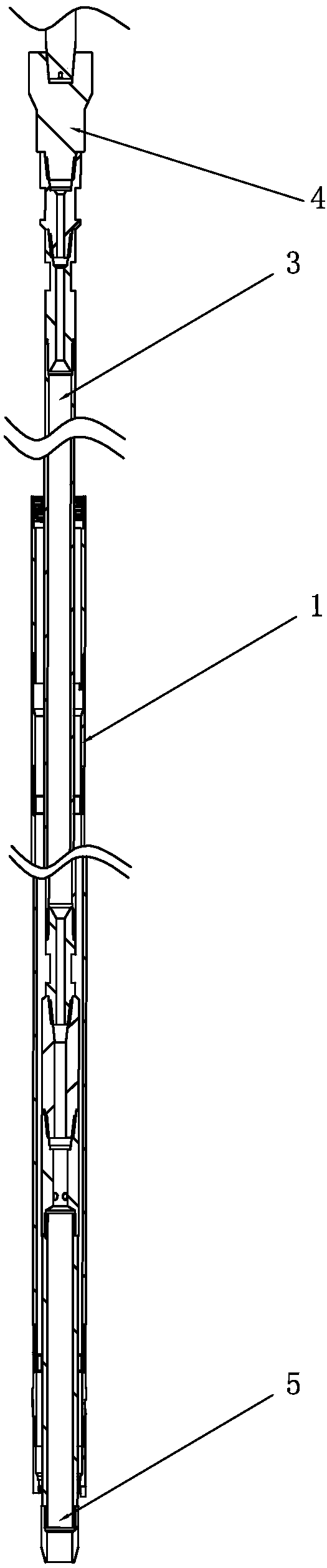

Standard penetration test device for partitioning rock weathering degree

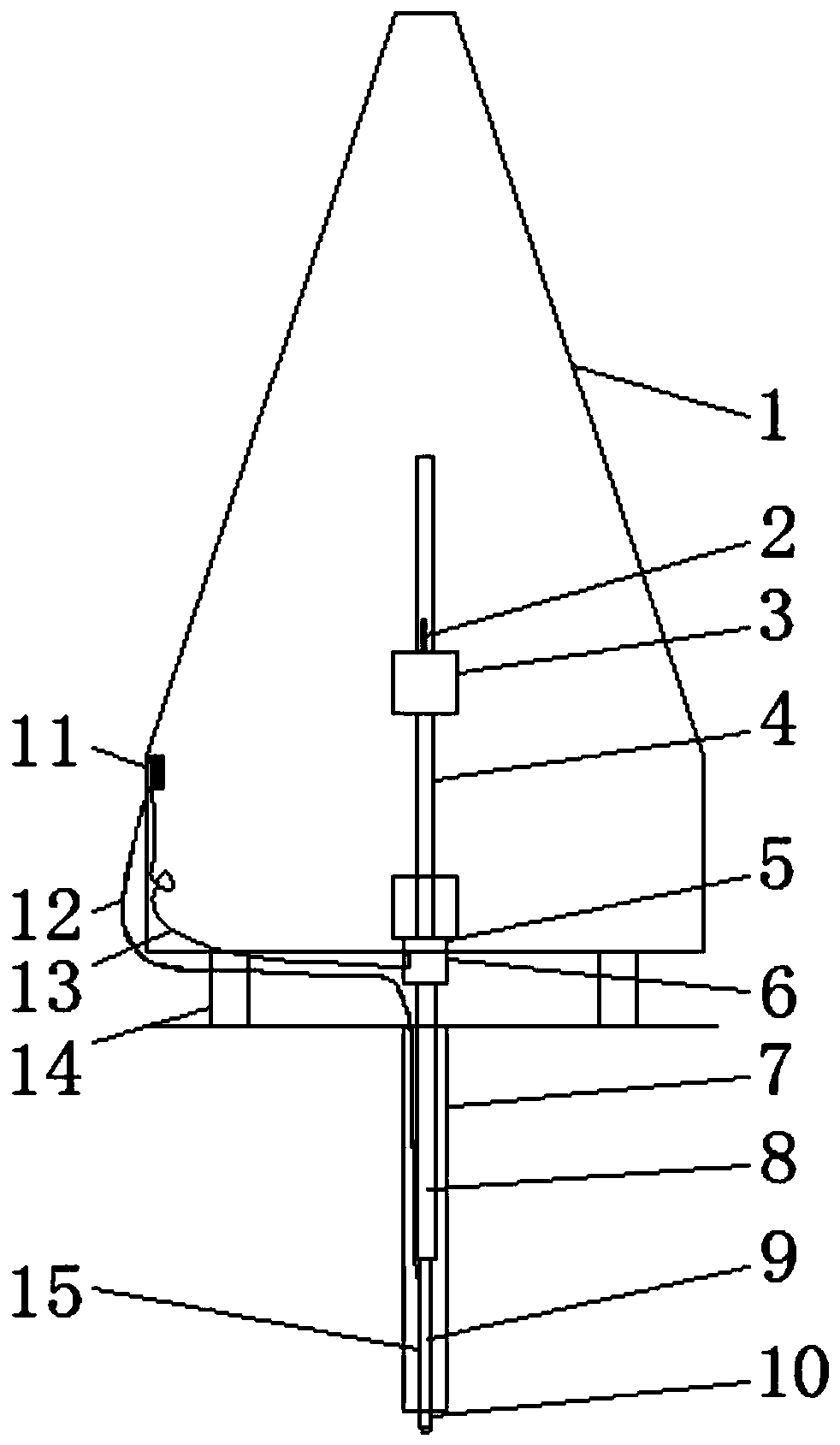

ActiveCN103469779AAvoid eccentricityReduce frictional resistanceIn situ soil foundationEngineeringRock weathering

The invention belongs to the technical field of in-situ test equipment, and relates to a standard penetration test device for partitioning rock weathering degree. A guide rod is embedded into the middle of a piercing hammer; the bottom of the piercing hammer provided with an automatic unhooking device is provided with a hammer cushion; the bottom of the hammer cushion is firmly connected with a penetration sounding rod by adopting a screw thread; the penetration sounding rod is provided with scale lines; a penetrometer which is provided with a cutting edge and has a hollow metal tube structure is firmly connected with the penetration sounding rod through a screw thread; a water outlet hole is formed in the top end of the penetrometer. The standard penetration test device is simple in structure, is convenient to operate, install, test and read, and can be used for directly partitioning the weathering degree of weathered rock, dividing strongly-weathered rock and medium-weathered rock and subdividing strongly-weathered rock into upper, middle and lower subzones.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

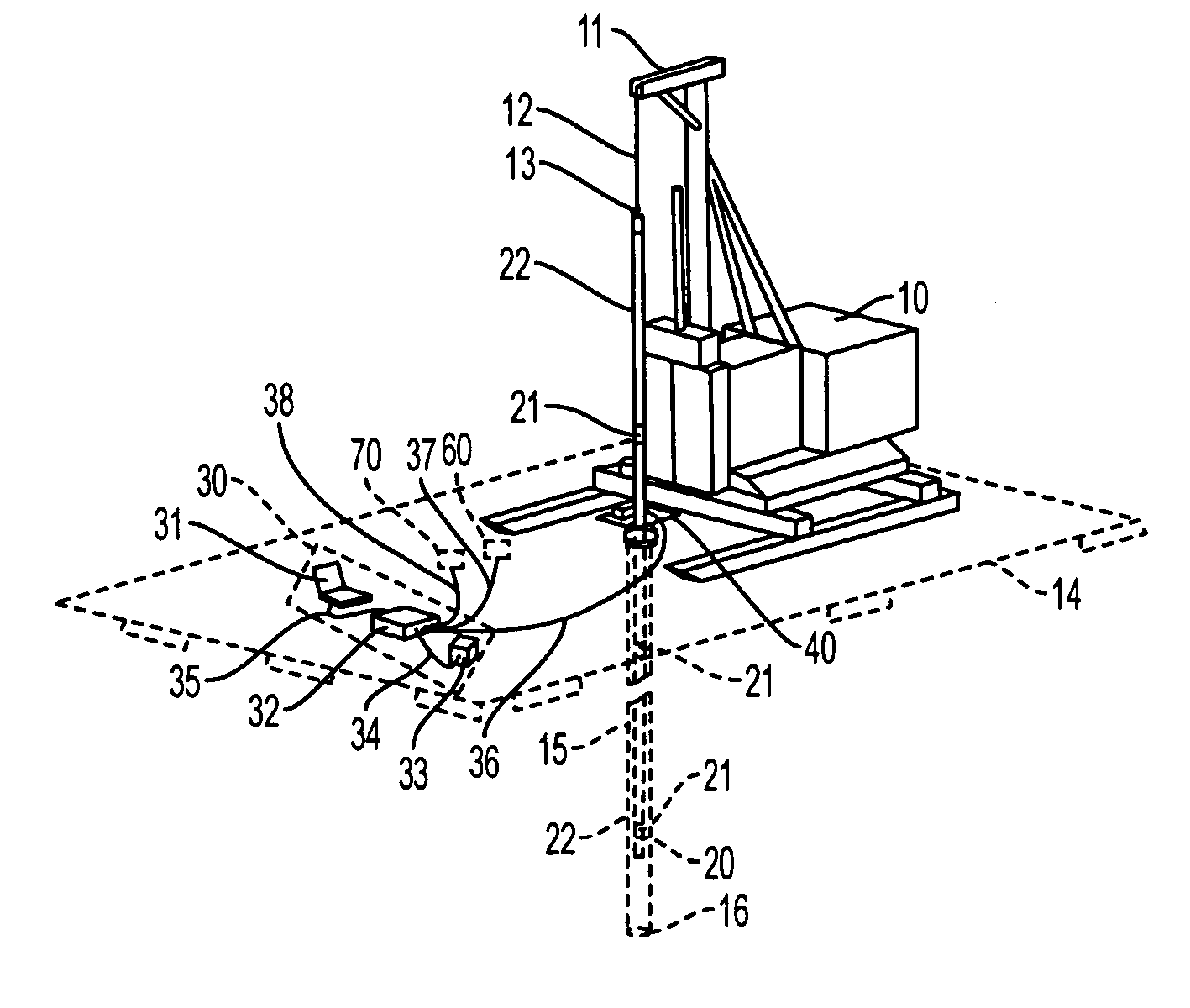

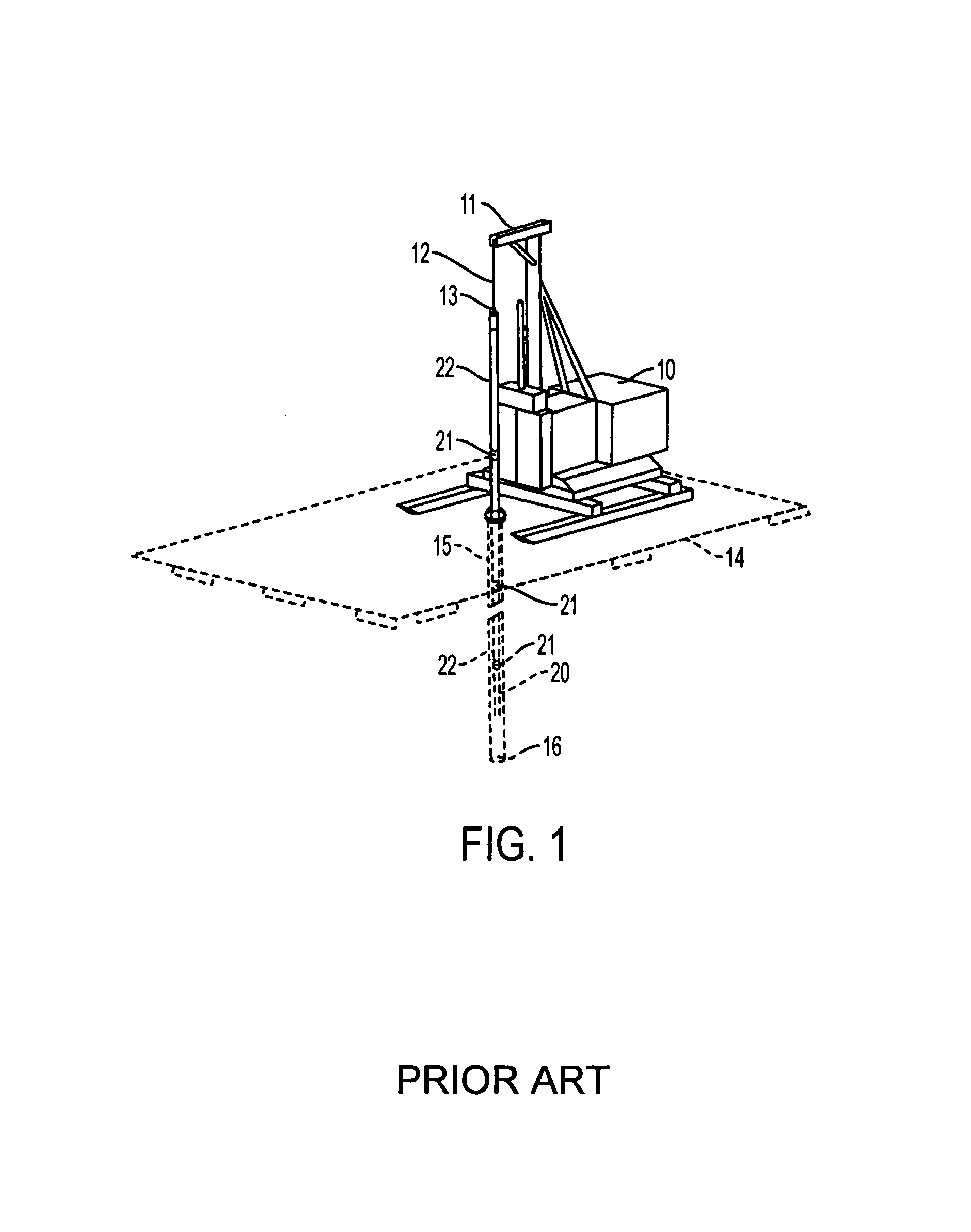

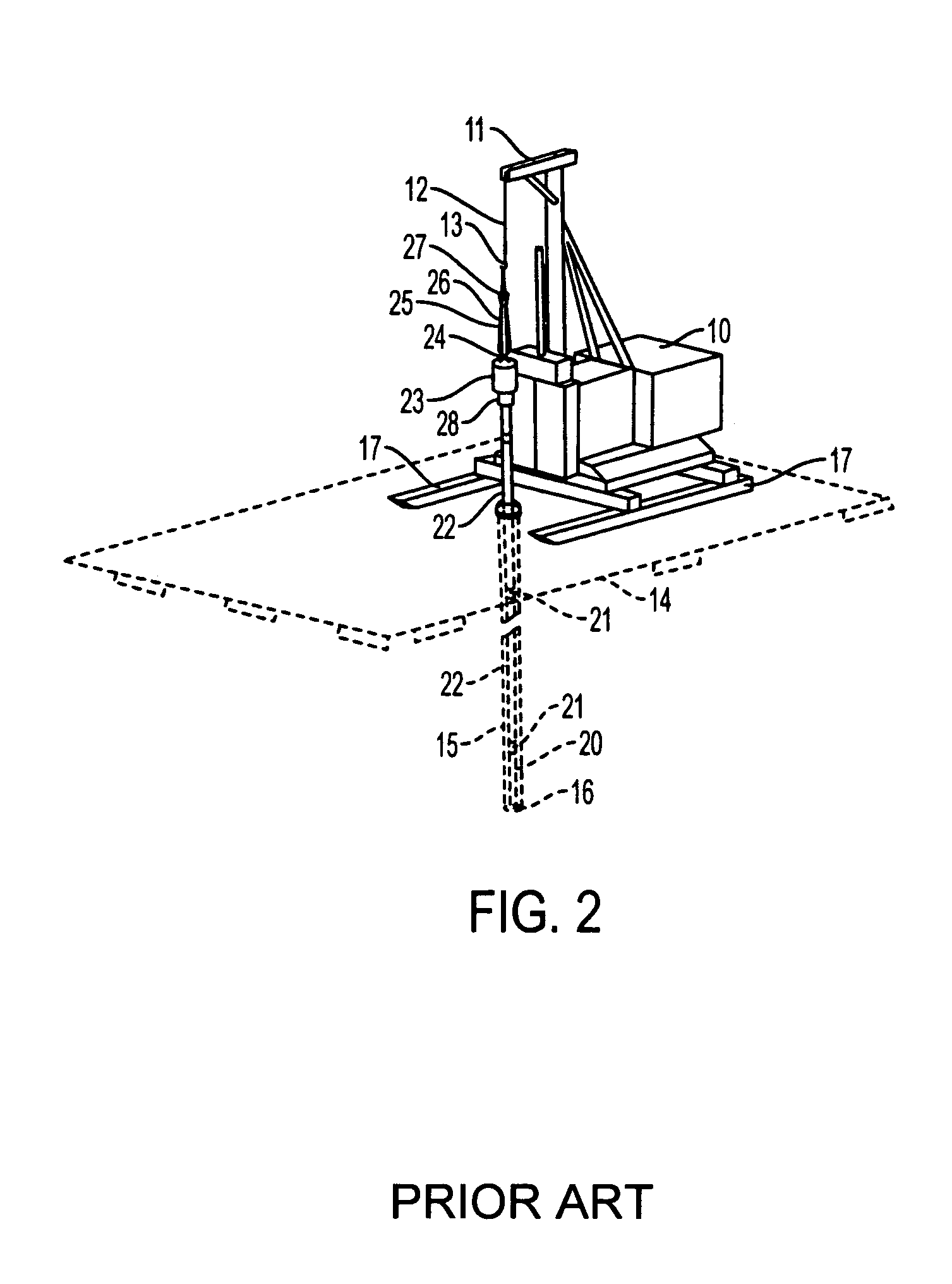

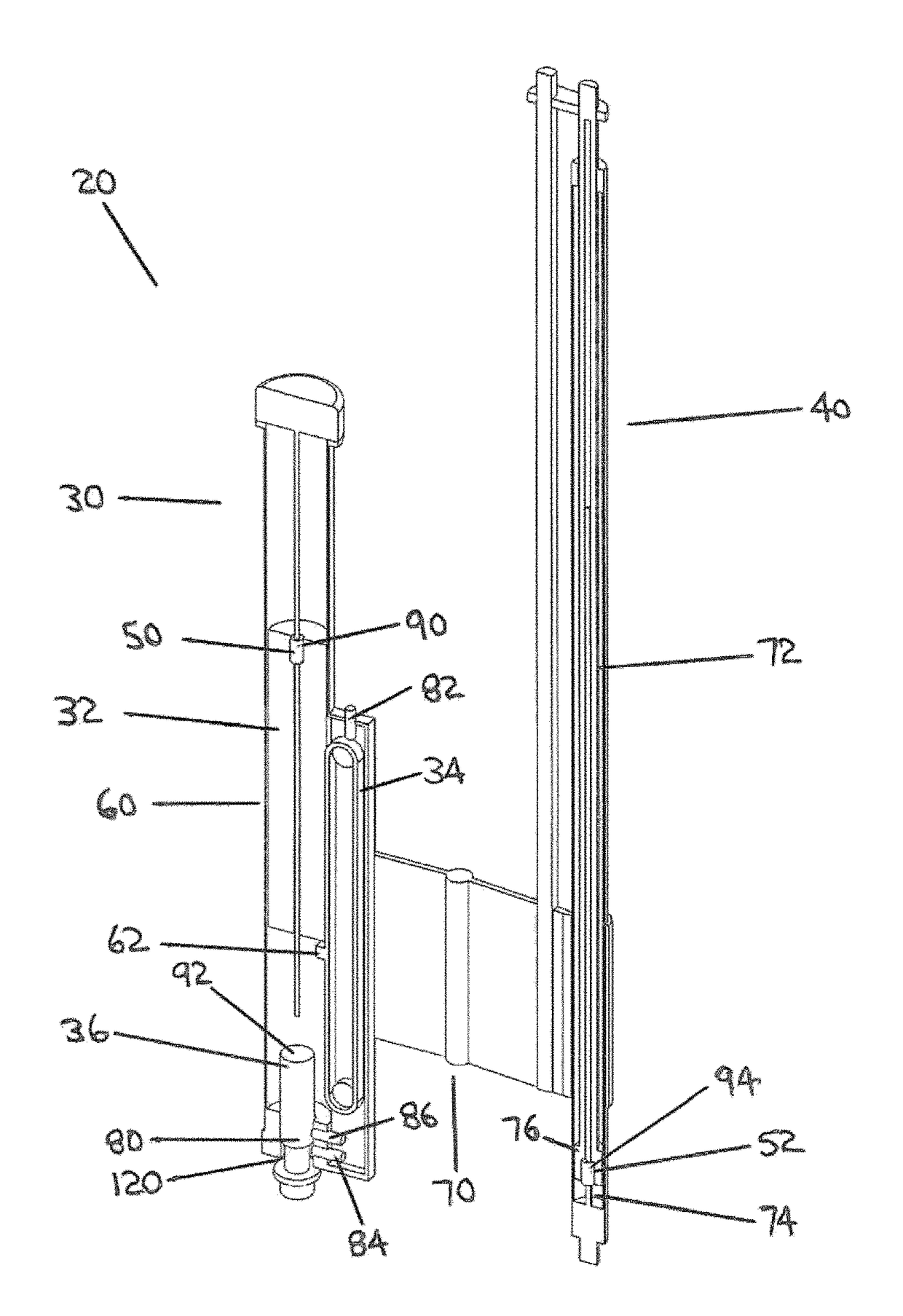

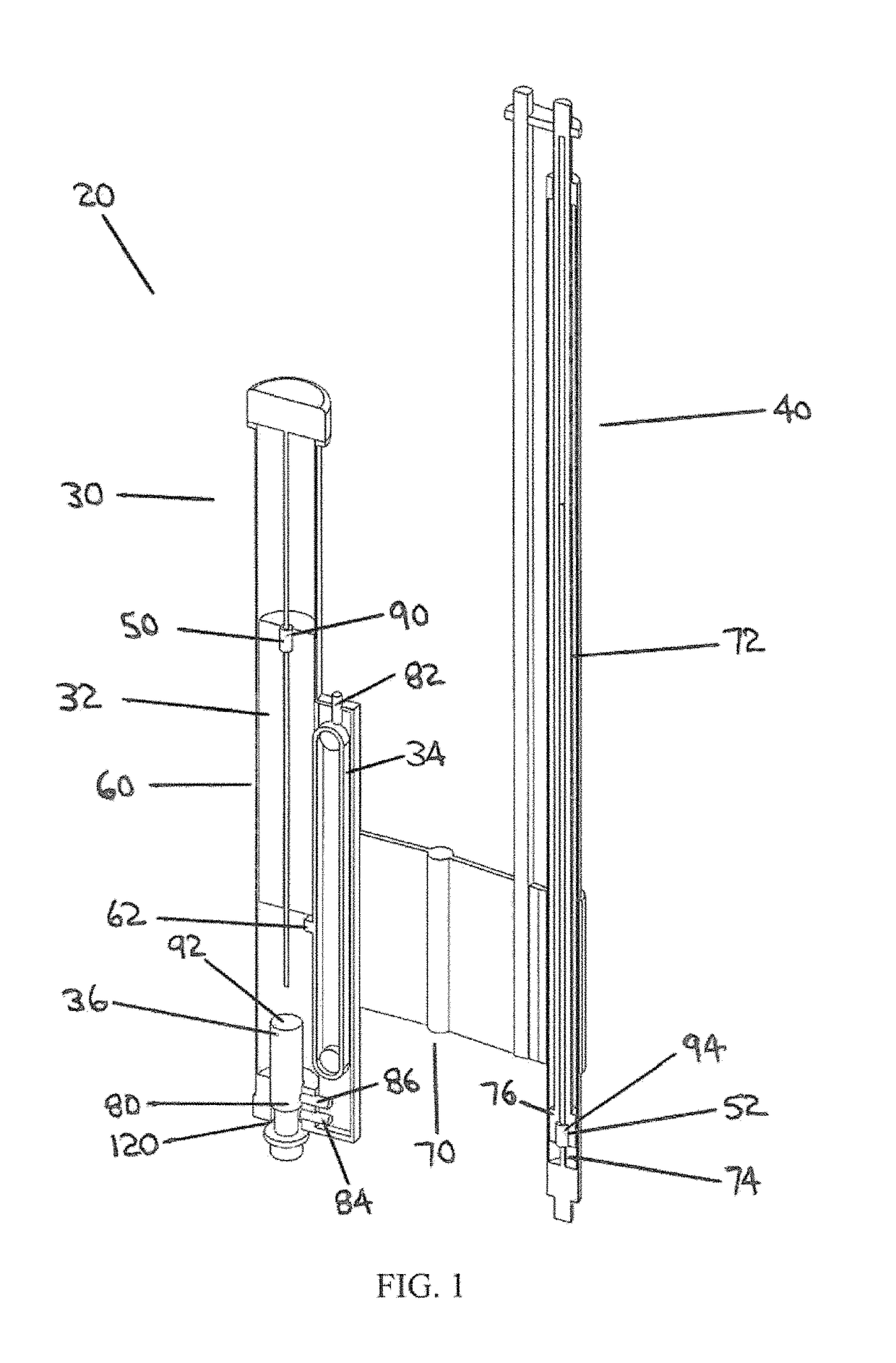

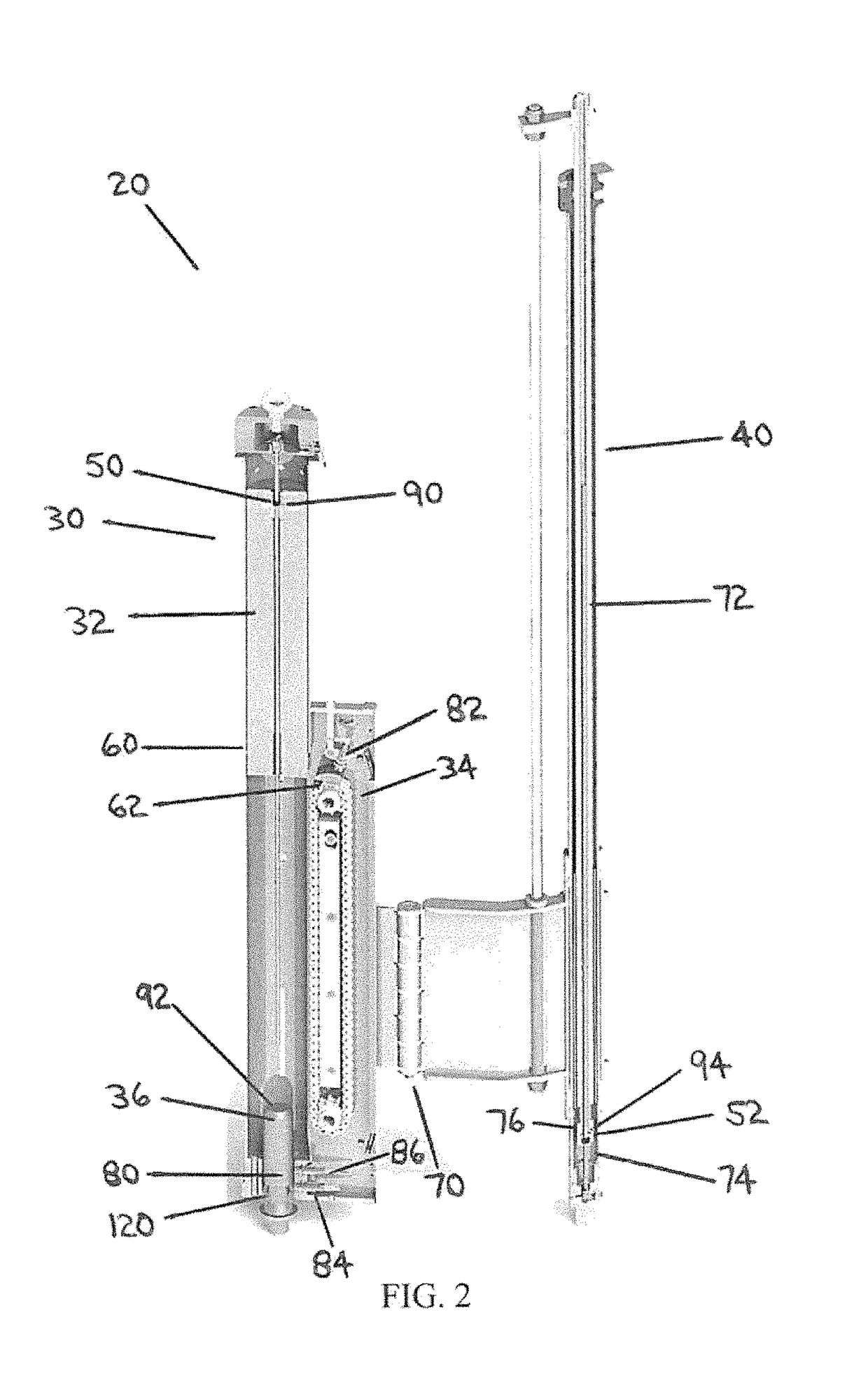

An apparatus and a method for performing a standard penetration test

ActiveUS20180259435A1Reduce inertiaSlow growth rateEarth material testingSeismologyStandard penetration testElectrical and Electronics engineering

A system for performing a standard penetration test, including a hammer assembly with a hammer and a hammer lifting device, an elevator assembly for raising and lowering the hammer assembly, a hammer sensor for sensing a position of the hammer within the hammer assembly, and an elevator sensor for sensing a position of the hammer assembly relative to the elevator assembly. A method for performing a standard penetration test, including positioning a hammer assembly at a hammer assembly ready position, sensing with an elevator sensor a reference position of a hammer assembly relative to the elevator assembly, sensing with a hammer sensor a zero position of a hammer, lifting the hammer with a hammer lifting device from the zero position to a drop position of the hammer, sensing with the hammer sensor the drop position, and dropping the hammer onto an anvil.

Owner:MARL TECH

Composite pile as well as construction method and single-pile vertical bearing capacity calculation method thereof

ActiveCN108221972APrevent slippingExpand the effective pile diameterFoundation testingDesign optimisation/simulationStructure of the EarthEngineering

The invention discloses a composite pile as well as a construction method and a single-pile vertical bearing capacity calculation method thereof. The composite pile comprises a prefabricated pile coreand a stone body wrapped around the outer side the prefabricated pile core, the prefabricated pile core is formed by connecting a plurality of prefabricated pile bodies in a segmented mode, rigid connecting plates are arranged at the pile tip, the pile top and the segmented joint of the prefabricated pile core, each prefabricated pile body is provided with a large-cross-section end and a small-cross-section end, and the pile cross-sectional area of each prefabricated pile body is gradually decreased from the large-cross-section end to the small-cross-section end along the axis. The compositepile as well as the construction method and the single-pile vertical bearing capacity calculation method thereof have the advantages that by means of the structure of the composite pile, the prefabricated pile bodies and the stone body can be tightly bonded to form a whole, slippage of the contact surfaces of the prefabricated pile bodies and the stone body can be prevented, the effective pile diameter can be increased, and the single-pile bearing capacity can be greatly increased compared with the bearing capacity of a common prefabricated pile; and in addition, the single-pile bearing capacity can be estimated through a simple standard penetration test, the calculation process is simple and convenient, and the calculation result is reliable.

Owner:SICHUAN INSITITUTE OF BUILDING RES

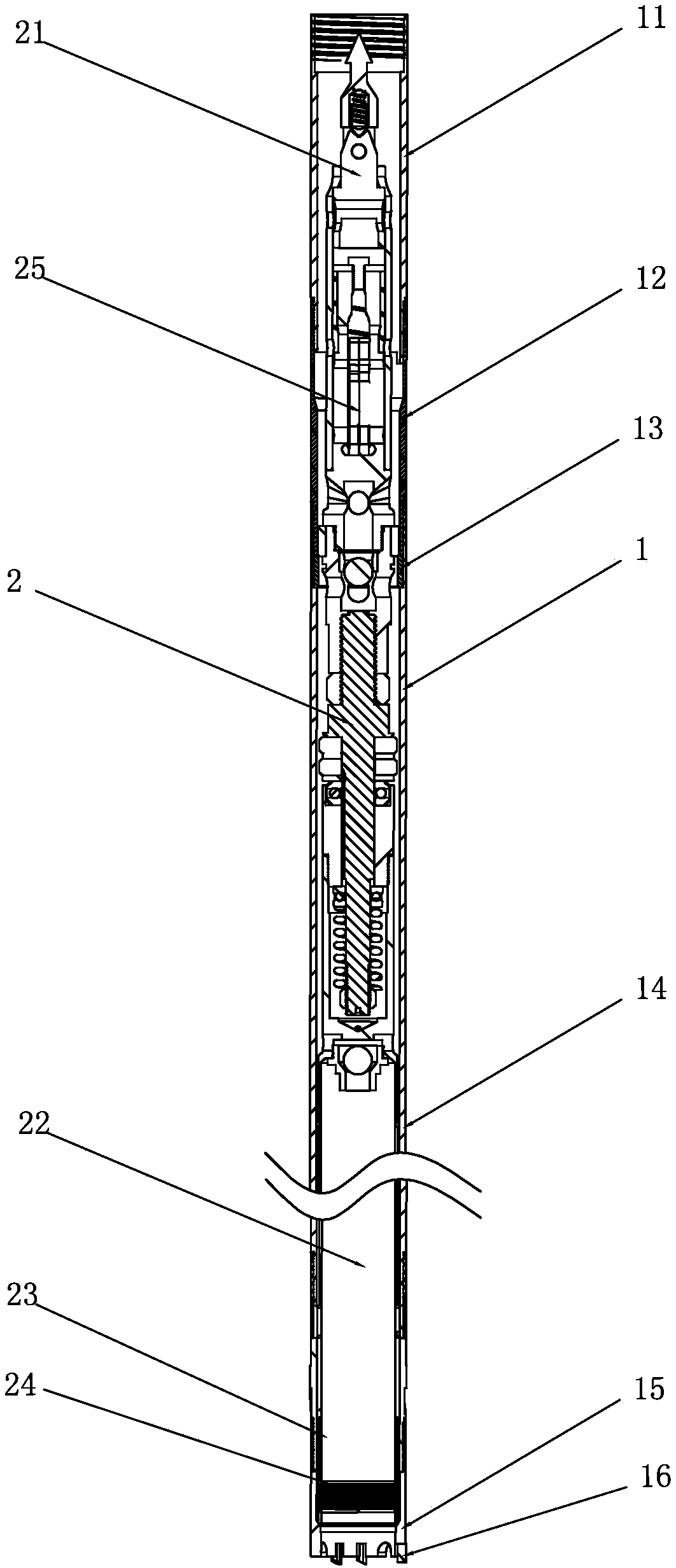

Deep soil mass load deformation test standard penetrometer and operation method thereof

InactiveCN107607405ASolve the problem of inability to evaluate the law of load and deformation of underground soilSolve the shortcomings of static parametersMaterial strength using tensile/compressive forcesQuality controlNot evaluated

The invention discloses a deep soil mass load deformation test standard penetrometer successively including from top to bottom a guide rod, a hammer cushion, a sounding rod and a hydraulic penetrationsystem, a displacement sensor is arranged in the hydraulic penetration system, the guide rod is sheathed with a pilereing hammer, the telescopic end of the hydraulic penetration system is connected with a standard penetrometer body, and the invention also discloses an operation method of the deep soil mass load deformation test standard penetrometer. The deep soil mass load deformation test standard penetrometer and the operation method thereof solve the shortcomings that domestic standard penetration test systems cannot evaluate underground soil mass load deformation rules and static parameters, has the advantages of simple structure, good quality control, convenient operation, fast detection speed, high measurement efficiency, detection result accuracy and reliability, and good repeatability, and provides a powerful testing tool for civil engineering exploration and practice.

Owner:SOUTHEAST UNIV

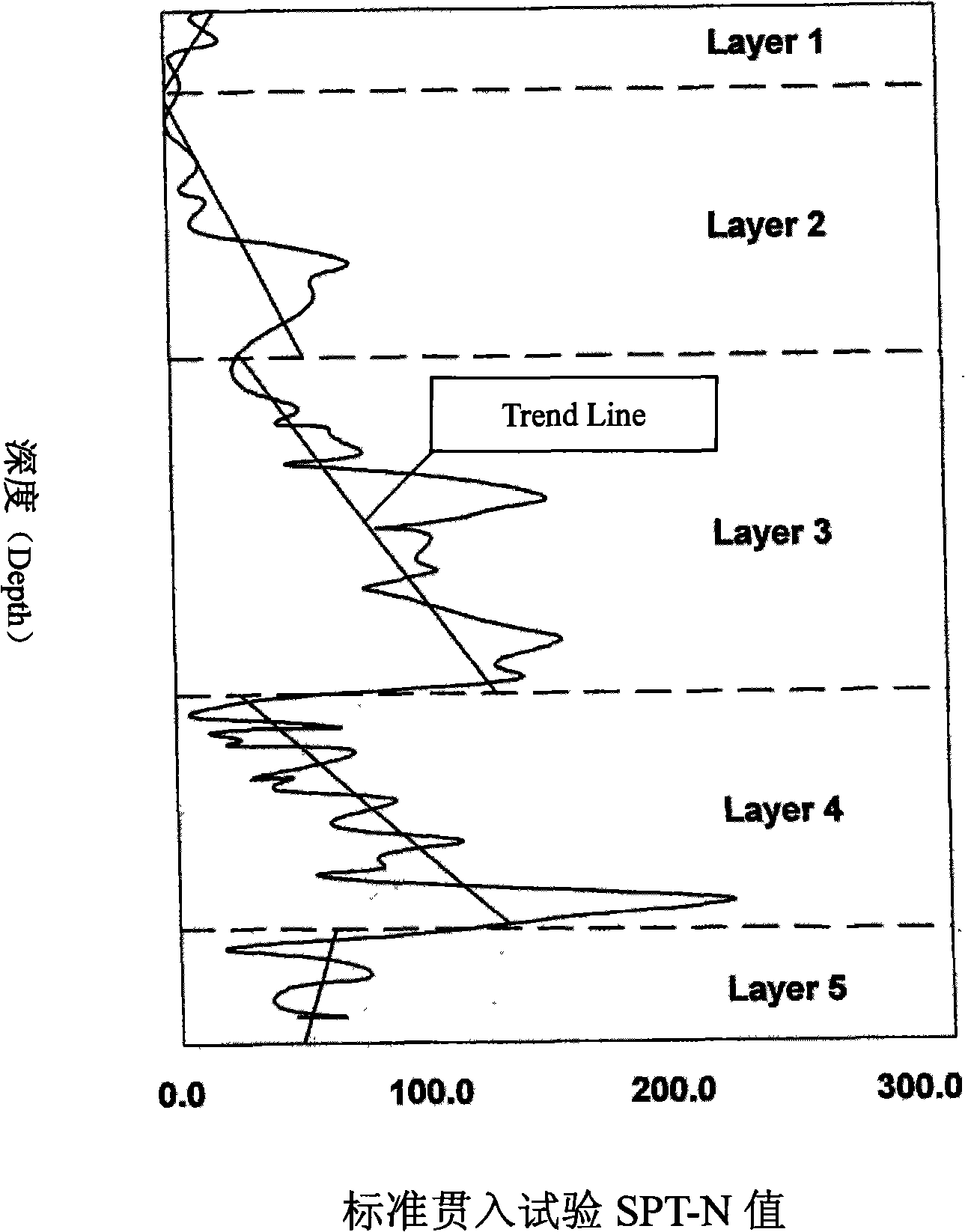

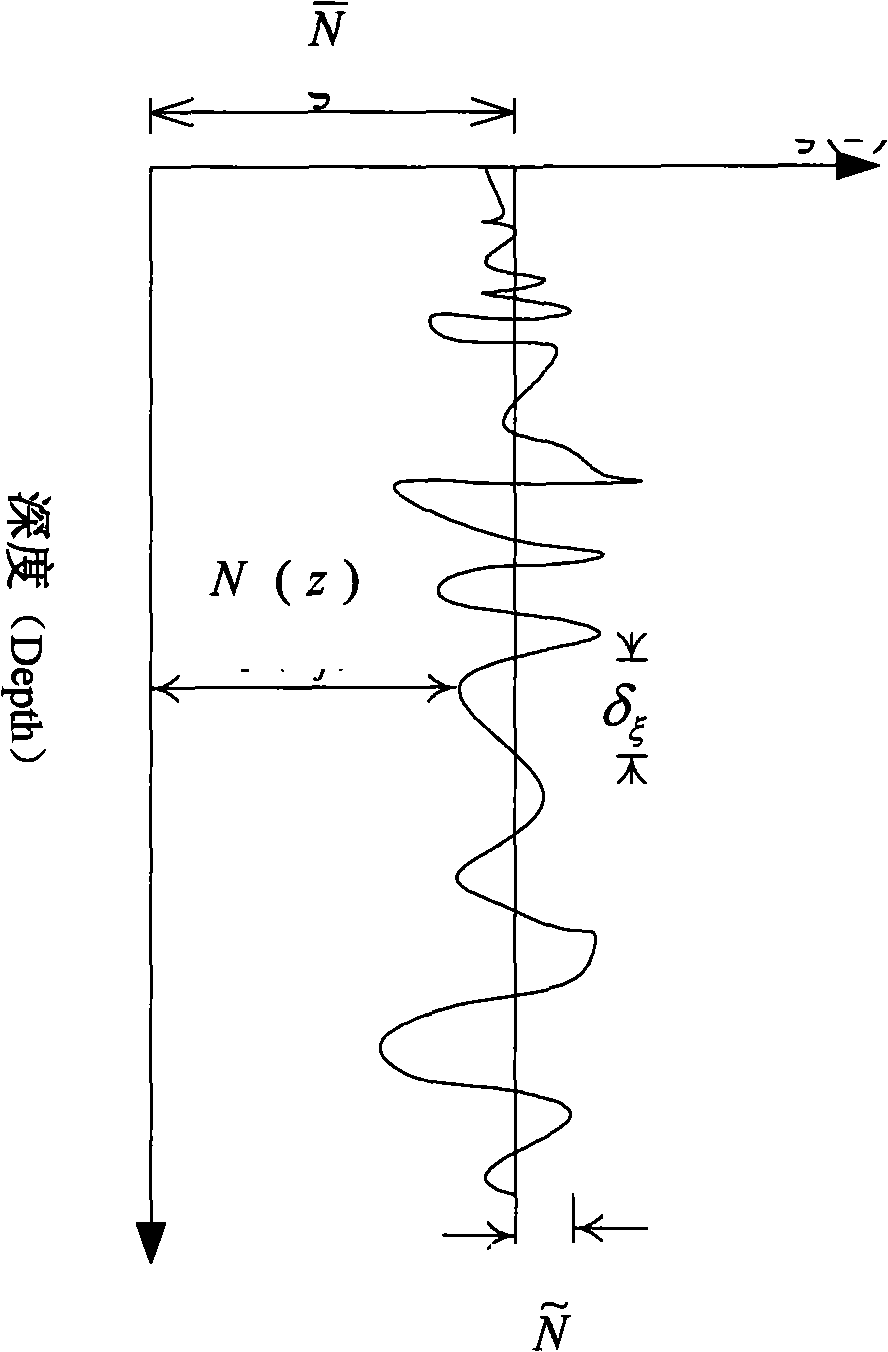

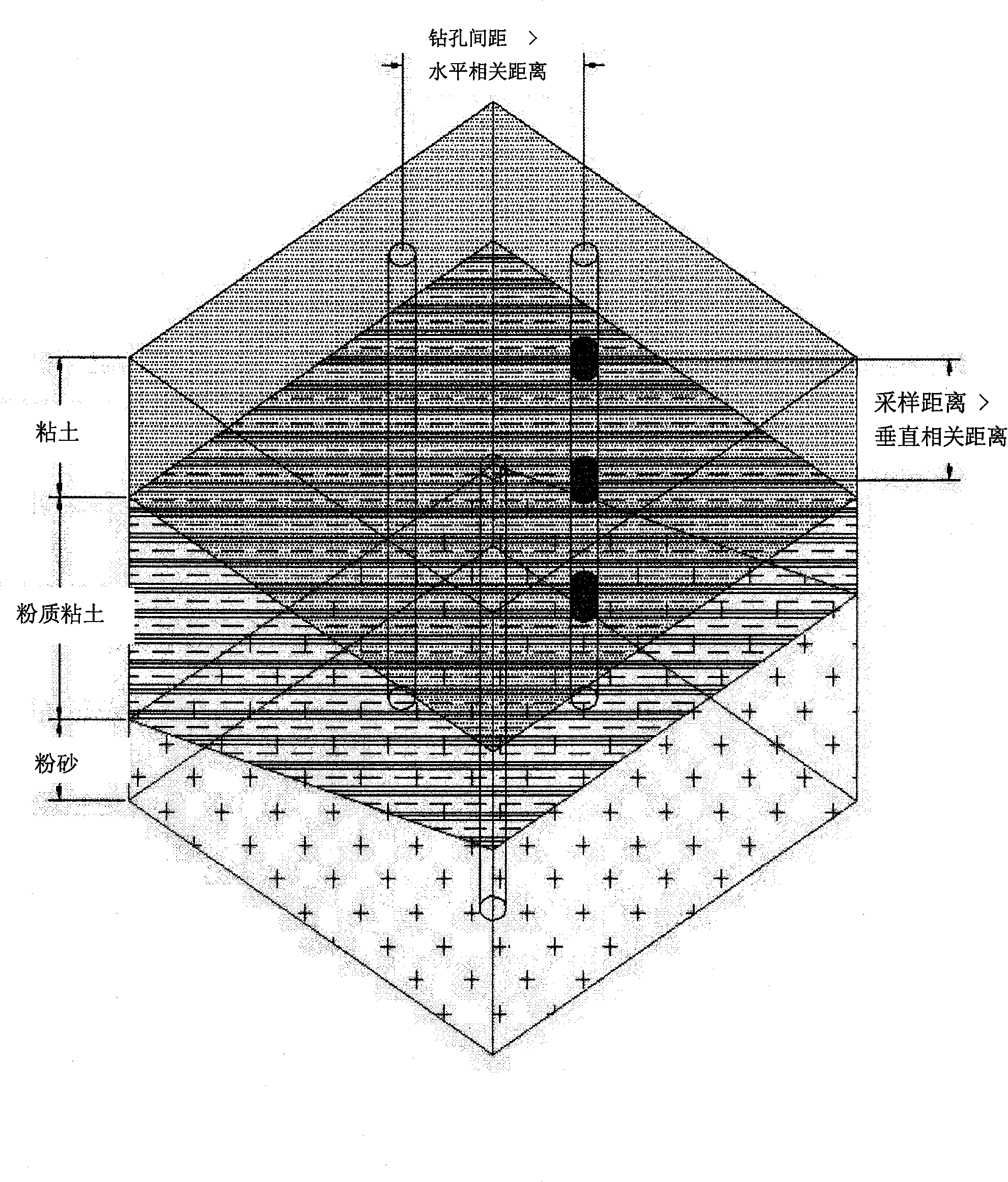

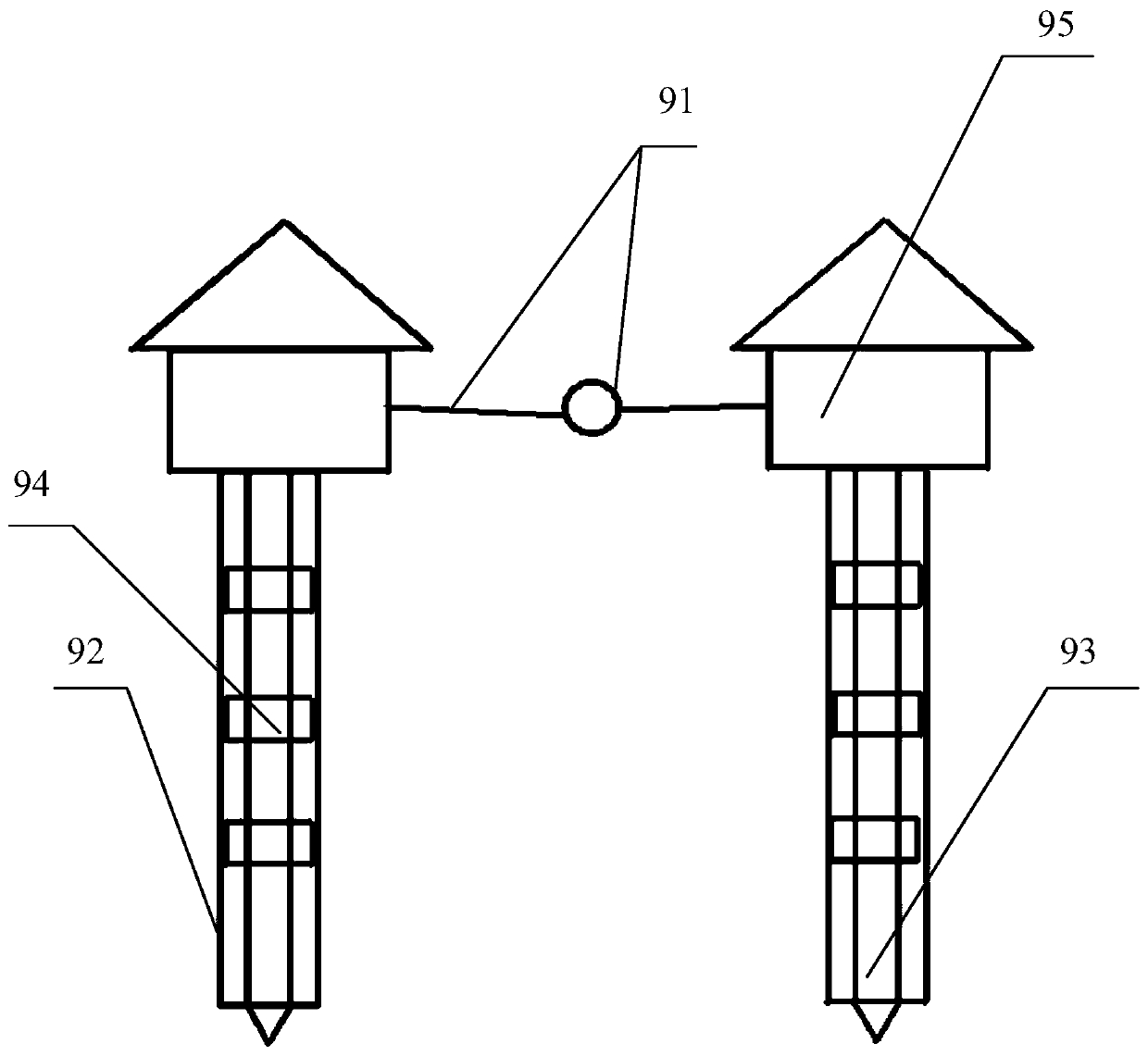

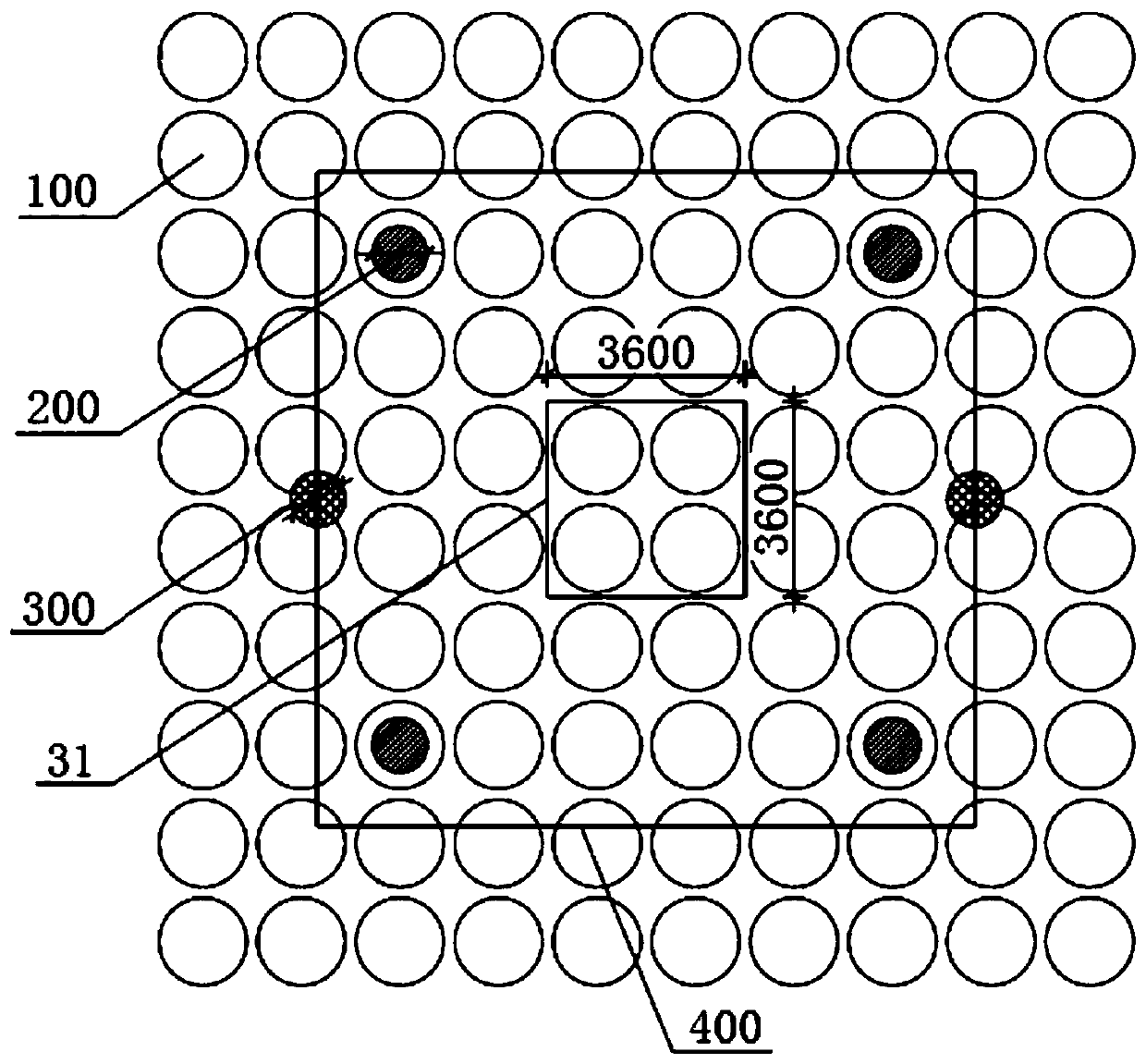

Technique and method for geotechnical engineering investigation and sampling based on soil variability

The invention provides a technique and a method for geotechnical engineering investigation and sampling based on soil variability, which is characterized in that the technique and the method are implemented by establishing quantized soil variability databases and calculating vertical correlation distance, horizontal correlation distance and variability coefficients of soil; main implementation steps are as follows: (1) establishing a quantifiable soil variability database based on investigation and sampling data of neighboring regions, including the species, thickness and standard penetration test SPT-N values of soil layers; (2) utilizing the SPT-N value of each soil layer to plot a trend line changing along depth and dividing different soil layers in broken positions; (3) calculating the vertical correlation distance and the horizontal correlation distance of each soil mass and estimating the optimum vertical interval and horizontal exploration drilling interval of engineering investigation and sampling; and (4) calculating the variability coefficient of each soil mass in order to determine the minimum amount of test samples and exploration drilling. The technique and the method have the advantages of providing a quantification method taking soil variability into consideration, systematically and reliably designing geotechnical engineering investigation and sampling and using obtained data to design economical and safe foundations.

Owner:SUN YAT SEN UNIV

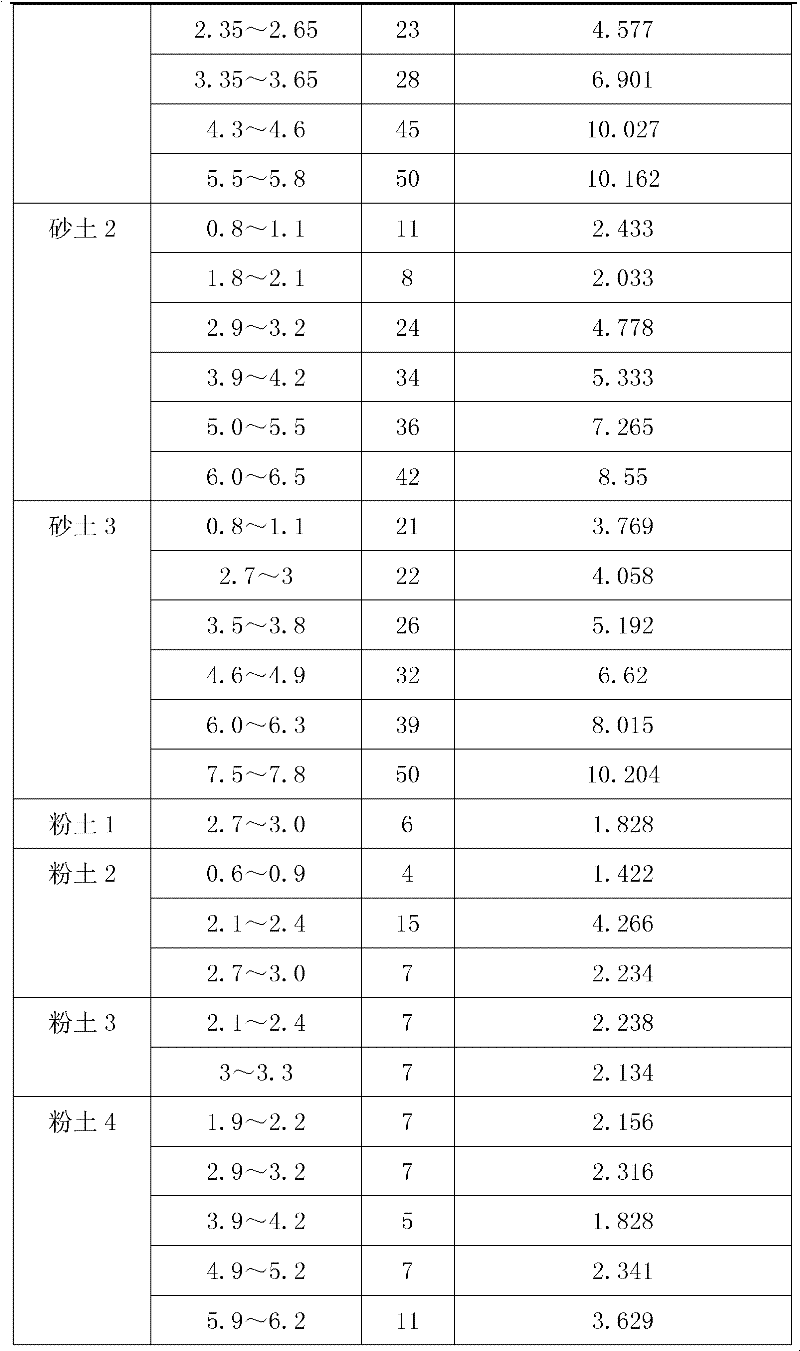

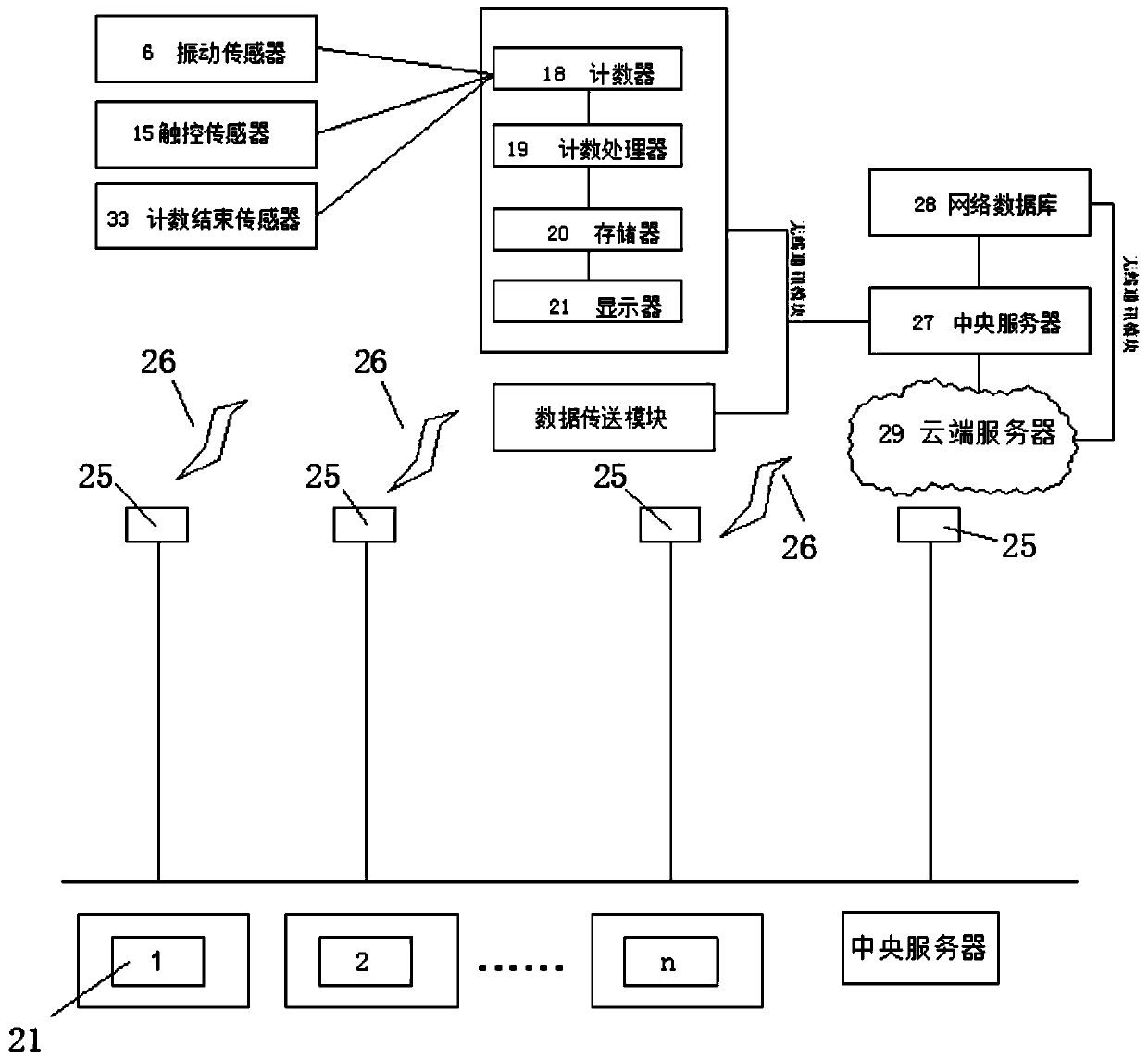

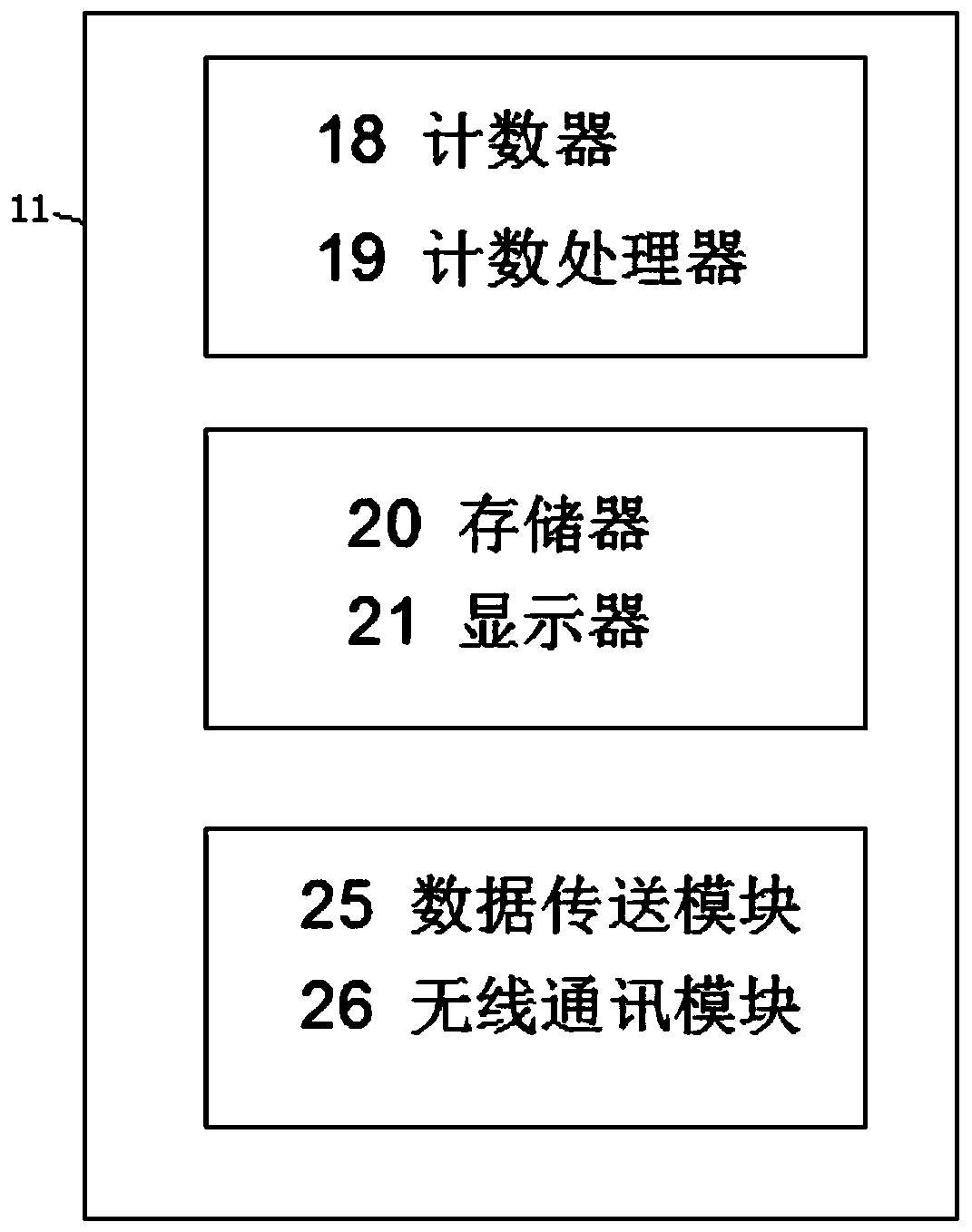

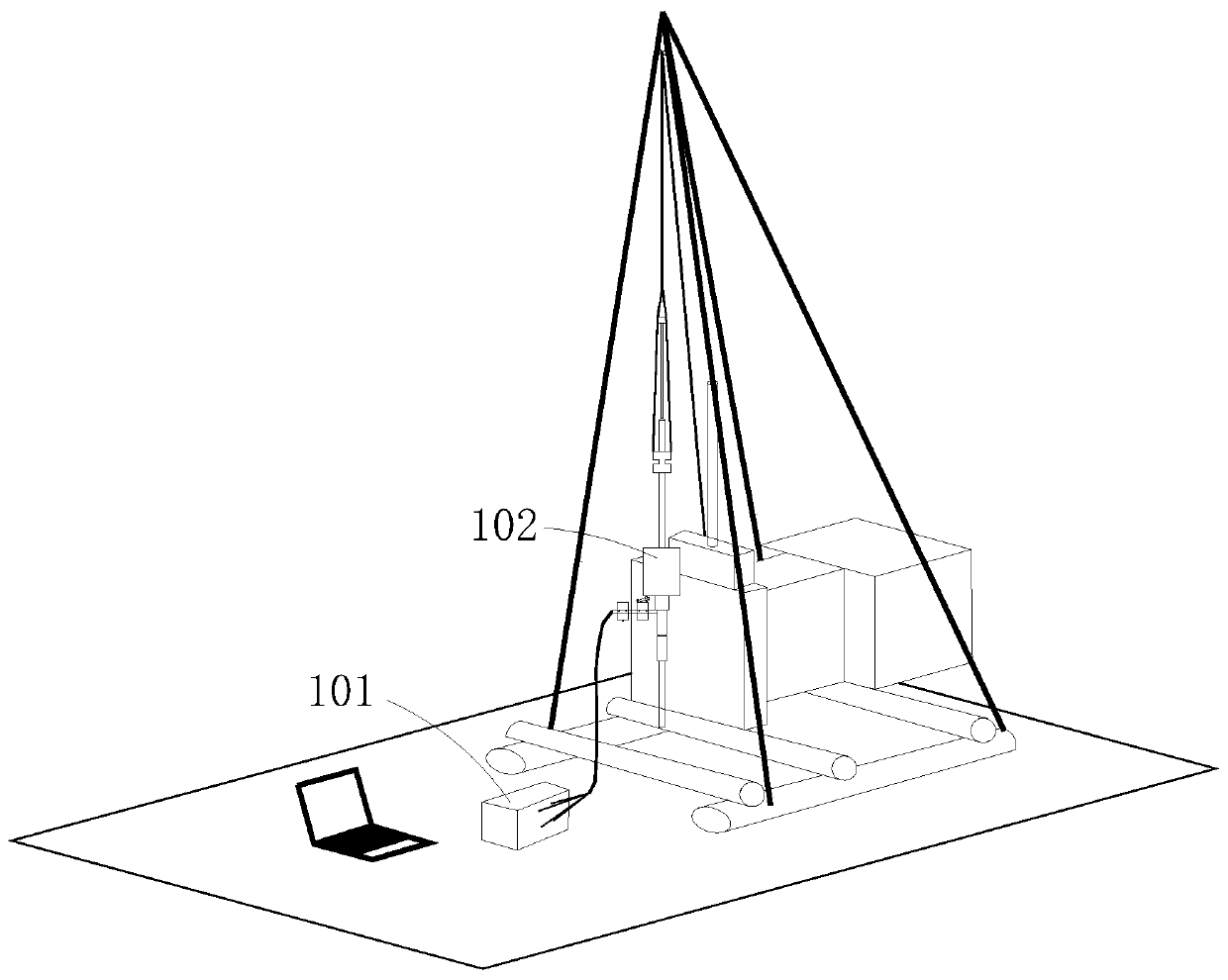

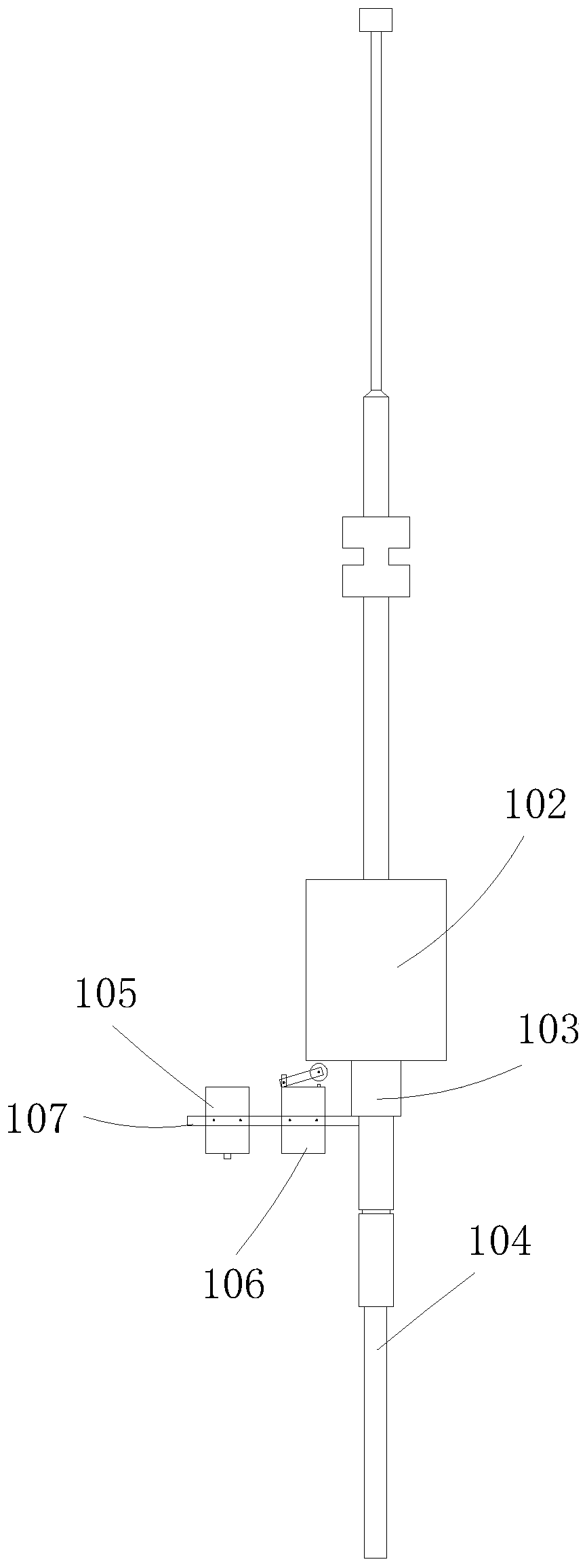

Multi-functional dynamic penetration automatic recording system based on Internet of Things and test method

PendingCN110042823ARigorous structureFlexible approachIn situ soil foundationThe InternetSystem configuration

The invention discloses a multi-functional dynamic penetration automatic recording system based on the Internet of Things and a test method. The multi-functional dynamic penetration automatic recording system based on the Internet of Things comprises a drilling machine supporting frame and a counting recording integrated device, and the system is configured with a central server and a data transmission system to realize synchronous and high-efficiency control over multiple drilling machine dynamic penetration tests. According to the disclosed test method, a standard penetration test and a conedynamic penetration test method are optimized, a rod length correction formula suitable for the standard penetration test and the cone dynamic penetration test is developed, programmed and input a counting processor and a computer. According to the multi-functional dynamic penetration automatic recording system based on the Internet of Things and the test method, the method is rigorous in structure, a counting module, a recording module, a data transmission module and a wireless communication module are integrated into a whole, the appearance is simple, use is convenient, automatic recordingof the number of hits can be realized, and count is accurate; and complexity of the dynamic penetration test in engineering investigation is reduced, and working efficiency of an in-situ test in geotechnical engineering investigation is greatly improved.

Owner:南京南大岩土工程技术有限公司

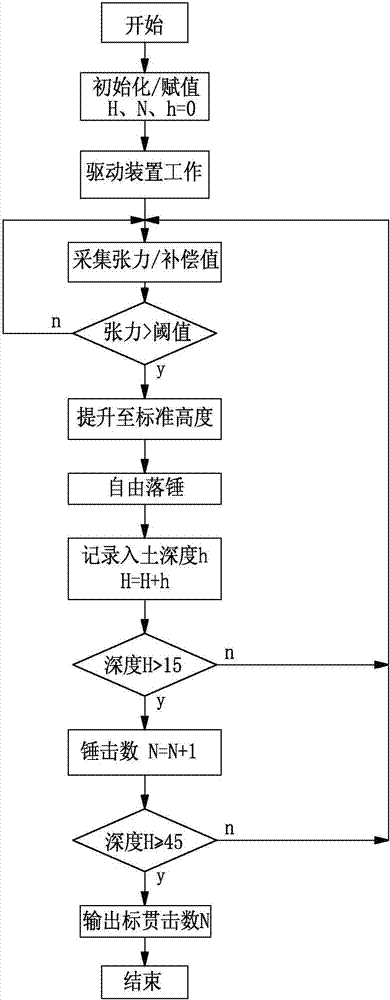

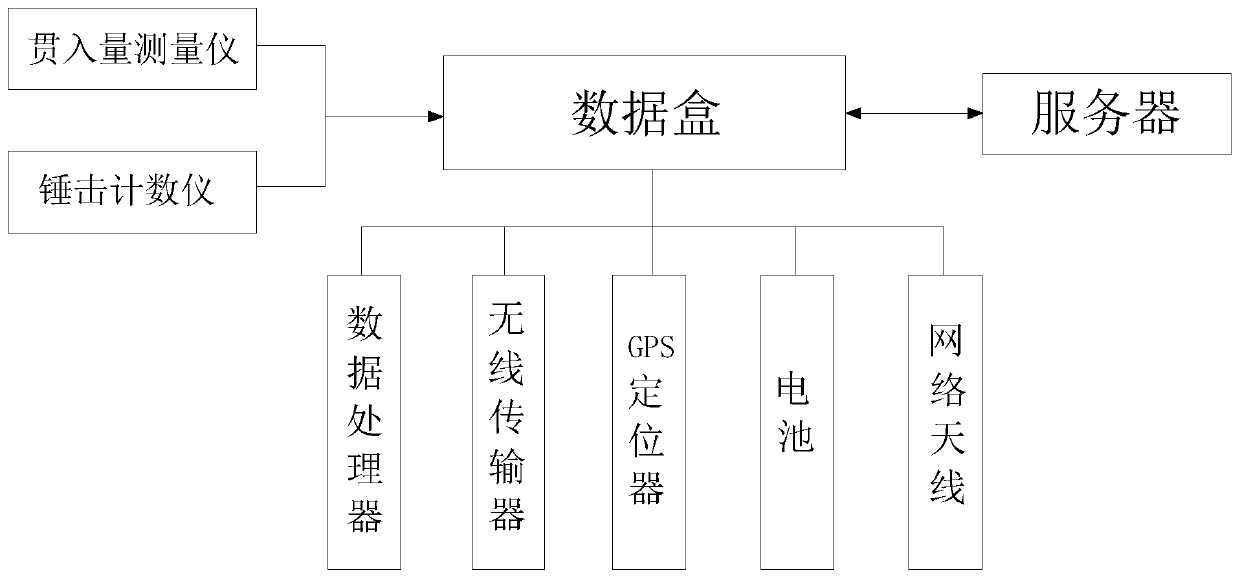

Automatic recording method for standard penetration test

ActiveCN109914376AAvoid mistakesHigh precisionCounting mechanisms/objectsIn situ soil foundationMeasuring instrumentData treatment

The invention relates to the technical field of standard penetration tests, and discloses an automatic recording method for a standard penetration test. The method comprises the following constructionsteps of: 1) installing a penetration amount measuring instrument and a hammering counter; 2) connecting a data box, respectively connecting a data processor with the penetration amount measuring instrument and the hammering counter, and wirelessly communicating the data processor with a server through a wireless transmitter and a network antenna; 3) newly establishing a test drill hole; 4) newlyestablishing a standard penetration position; (5) a cross-core hammer beginning to hammer, wherein for each time of hammering, the cross-core hammer triggering the hammering counter one time, the penetration amount measuring instrument automatically measuring the penetration depth of the penetration amount, and the data processor collecting the hammering number of the hammering counter in real time so as to feed back the penetration depth measured by the penetration amount measuring instrument to the server in real time; and (6) the cross-core hammer hammering repeatedly, and when the penetration depth measured by the penetration amount measuring instrument exceeds 45cm, the data processor stopping acquiring the data.

Owner:SHENZHEN GEOTECHN INVESTIGATION & SURVEYING INST

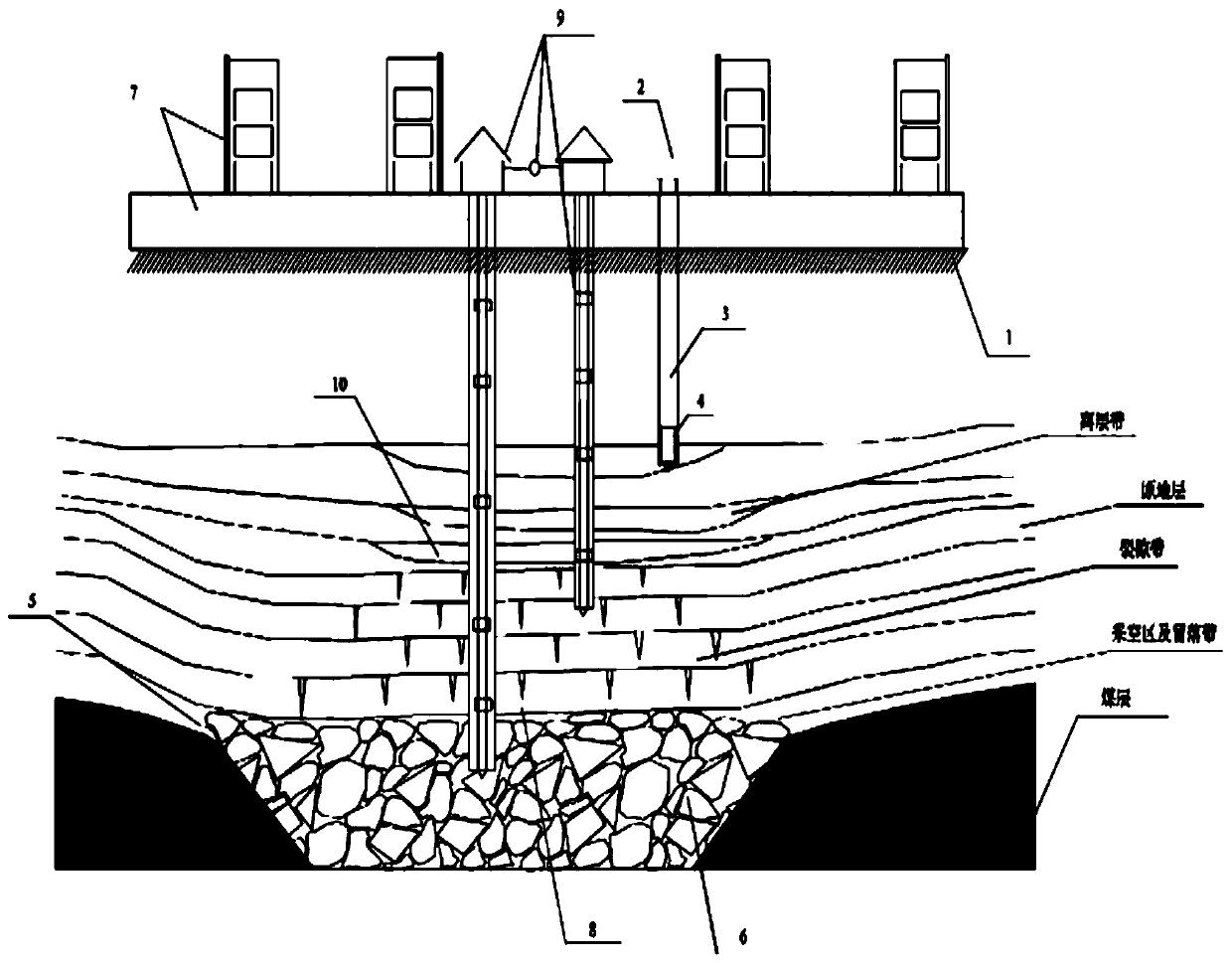

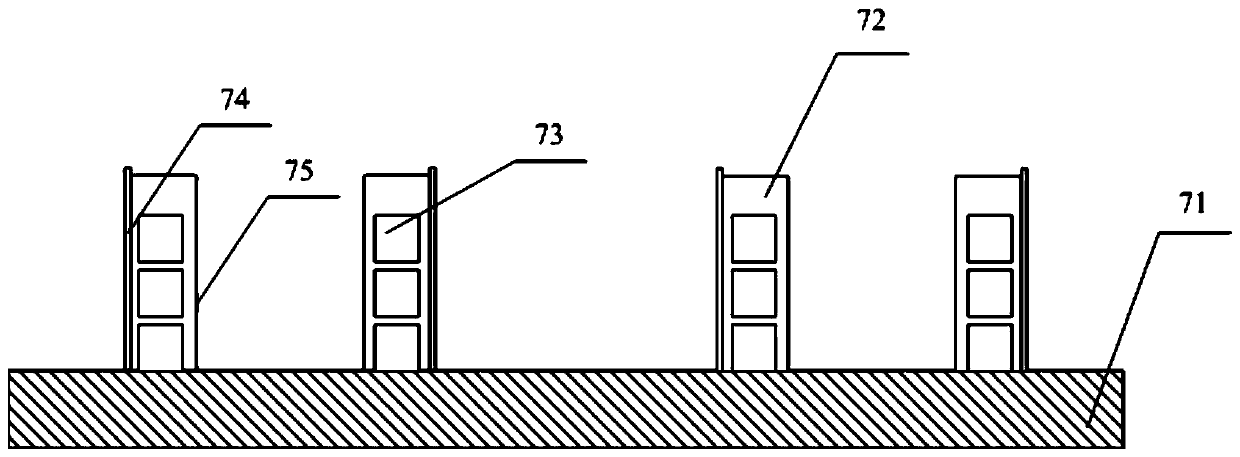

Detection method and detection method for grouting filling treatment effect of coal mine goaf

ActiveCN111366403AGood for evaluation researchEfficient collectionWithdrawing sample devicesHydrostatic levellingMining engineeringEarth surface

Owner:SHANDONG LUNAN GEOLOGICAL ENG SURVEY INST

A construction method for engineering geological drilling based on wireline core drilling tools

ActiveCN106677701BReduce consumptionReduce disturbanceSurveyCore removalEngineering geologySoil horizon

The invention discloses an engineering geological drilling construction method based on a rope core drilling tool. It adopts a single-action double-tube drilling tool to press-in drilling during rotation. The full-hole and tube drilling speed is very fast, the mud consumption is small, and the rock The core tube remains in a non-rotating state, causing little disturbance to the soil. When the drilling depth reaches the length of the core tube, the oil cylinder lifts the entire drilling tool a certain distance from the bottom of the hole to pull out the core. The core quality is high and can be Extract undisturbed soil samples; during coring and standard penetration tests, the drill pipe and outer pipe assembly always remain motionless in the borehole, protecting the hole wall and avoiding damage to the hole wall by repeatedly lifting the drill. At the same time, it also reduces the risk of the test rod and the The friction of the hole wall reduces uncertain factors and makes the test results more accurate.

Owner:ZHUHAI EAGLER SPECIALTY DRILLING EQUIP CO LTD

Test method for sand compaction pile of offshore wind power

The invention discloses a test method for a sand compaction pile of offshore wind power. The method includes the following steps: driving and arranging a test pile, installing a compression resistancetest device, erecting a test platform, testing bearing capacity of a composite foundation of the sand compaction pile, testing pile body quality of the sand compaction pile, detecting a protuberanceheight of a mud surface, and performing indoor experiment on a sand sample of the sand compaction pile. When the step of driving and arranging the test pile is carried out, 100 sand piles are driven into an underwater sand layer in square arrangement; and when the step of installing the compression resistance test device is performed, installation of a counter force frame, installation of a loading system, installation of a reference system and installation of a settlement measurement system are included. When the step of erecting the test platform is carried out, four anchor piles are utilized as a supporting base of the test platform. When the step of testing the bearing capacity of the composite foundation of the sand compaction pile, settlement measurement and earth pressure measurement are included. When the step of testing the pile body quality of the sand compaction pile, a standard penetration test is employed. The test method of the invention can determine the bearing capacityof the composite foundation, and a disturbance condition of driving and arranging an underwater sand compaction pile to a soil body is mastered.

Owner:CCCC THIRD HARBOR ENG +2

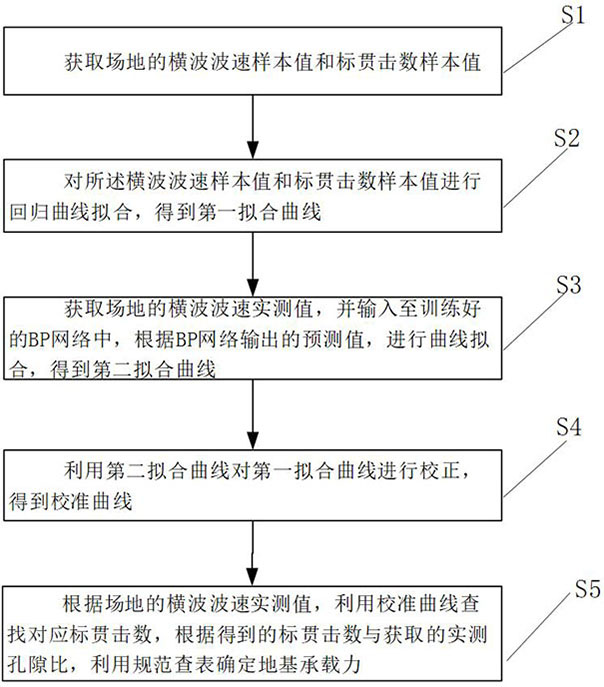

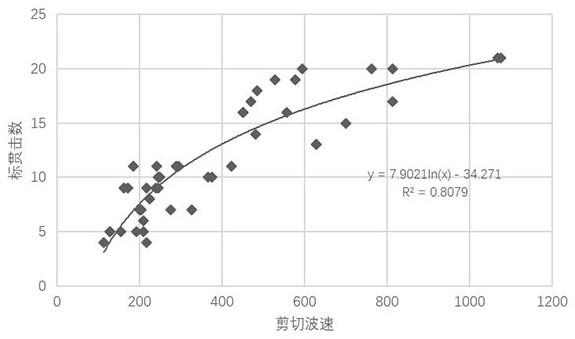

Correction method for determining bearing capacity of cohesive soil foundation through transverse wave velocity based on BP network

ActiveCN113204830AEasy to determineQuick fixGeometric CADDesign optimisation/simulationVoid ratioNetwork output

The invention provides a correction method for determining the bearing capacity of a cohesive soil foundation through transverse wave velocity based on a BP network. The correction method comprises the steps of acquiring a transverse wave velocity sample value and a standard penetration test blow count sample value of a site; performing regression curve fitting to obtain a first fitting curve; obtaining a transverse wave velocity measured value of the site, inputting the measured value into the BP network, and obtaining a second fitting curve according to a predicted value output by the BP network; and correcting the first fitting curve by using the second fitting curve to obtain a calibration curve, searching the corresponding standard penetration test number, and determining the foundation bearing capacity by using a standard look-up table according to the obtained standard penetration test number and the obtained actually measured void ratio. According to the invention, after linear regression fitting is carried out by using the neural network, nonlinear factors are fully considered, and the fitting curve is corrected. Compared with a conventional exploration method, the method has the advantages that the influence of external factors on the geological exploration progress can be greatly weakened, the workload of in-situ testing of real objects is reduced, and a new technical means is provided for better and faster determination of the bearing capacity of the cohesive soil foundation.

Owner:CHINA RAILWAY DESIGN GRP CO LTD +1

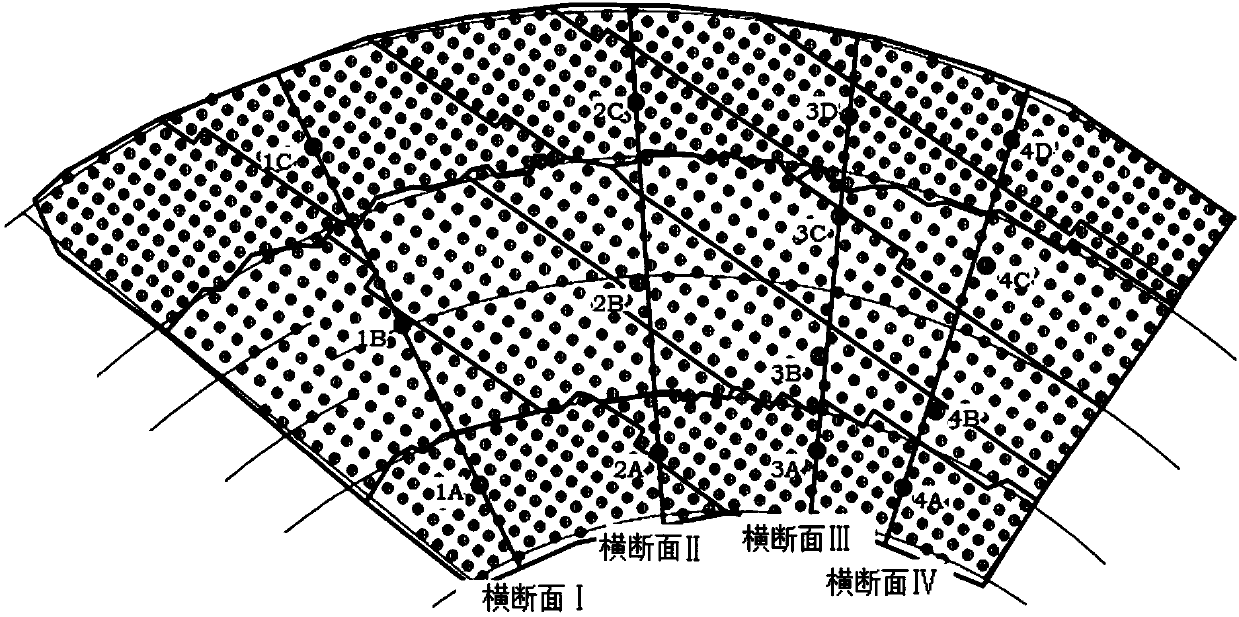

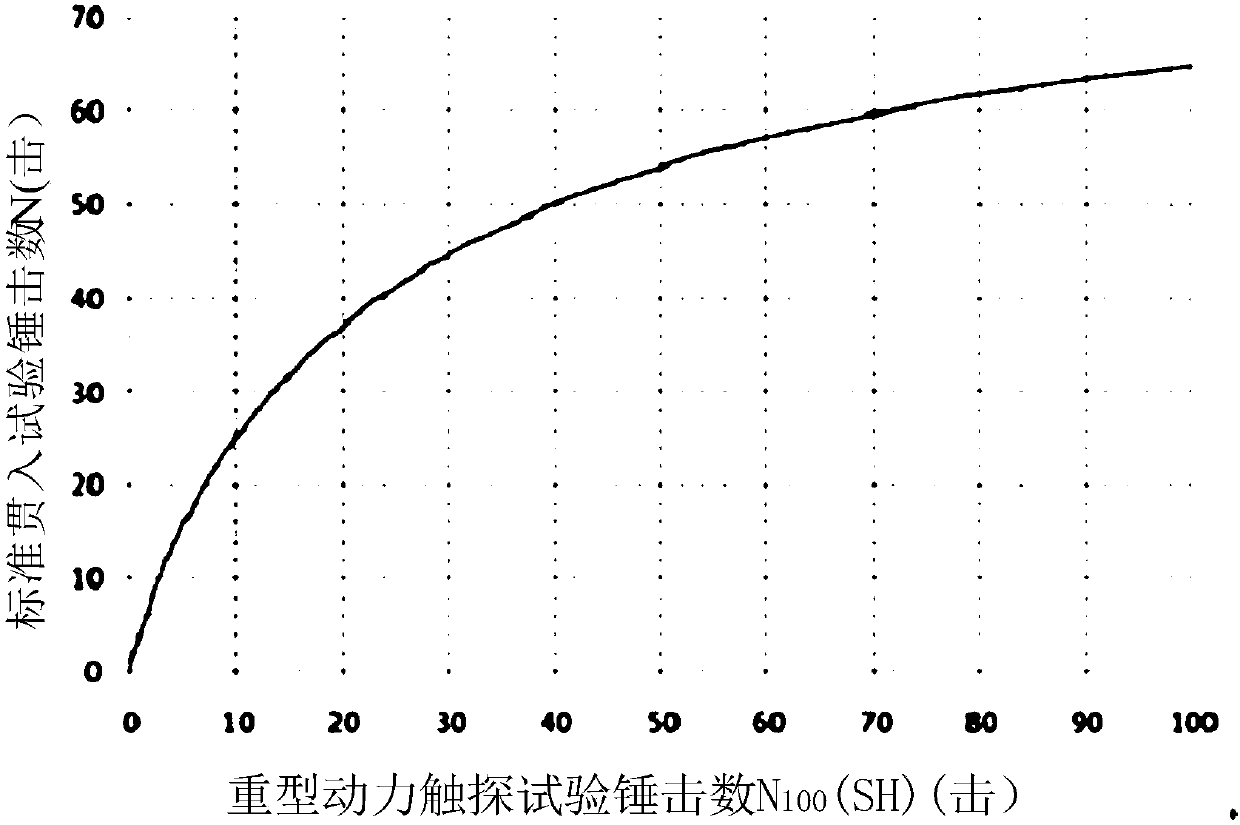

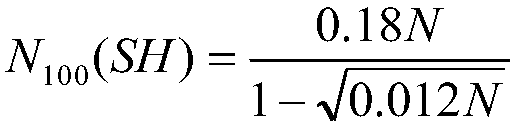

Cross section analysis method for gravel pile compactness detection

InactiveCN109555167AAccurately reflect construction qualityQuick determination of construction qualityFoundation testingCrushed stoneEngineering

The invention discloses a cross section analysis method for gravel pile compactness detection. The method includes the steps that first, a to-be-detected gravel pile area is divided into segments, a plurality of test cross sections are selected in each segment, and a plurality of test sites are selected in each cross section; a heavy dynamic penetration test is carried out at the selected test sites, the hammering number N200 (SH) of the dynamic penetration test at each test site of each cross section is obtained, N200 (SH) is converted to N100 (SH), and then a standard penetration test hammering number N is calculated according to N100 (SH); and the standard penetration test hammering number is corrected, the frictional angle of each cross section is judged according to the corrected standard penetration test hammering number, and if the frictional angles of the cross sections in each segment are all larger than or equal to 40 degrees, it is judged that gravel piles in the segment arequalified. By means of the cross section analysis method, the construction quality of the gravel piles can be accurately reflected, and thus analysis results better meet the actual condition; the construction quality of the gravel piles can be quickly determined, the gravel pile compactness detecting time is shortened, and the gravel pile construction speed is increased.

Owner:CHINA MCC20 GRP CORP

Liquefaction judgment method based on standard penetration and static cone penetration test correlation

ActiveCN102864766BLiquefaction identification is simple and economicalAccurate and fast liquefaction discriminationSamplingIn situ soil foundationSoil liquefactionEngineering

The invention relates to a liquefaction judgment method based on standard penetration and static cone penetration test correlation. A principle of selecting a static cone penetration test contrast hole of a standard penetration test hole and a reading method for a standard penetration parameter value N and a static cone penetration parameter tip resistance value qc are provided; three influence factors of clay content rhoc, average particle size D50 and soil parameter alphap are considered, the value N and the value qc are fitted, and a statistically correlative relationship of N-qc is provided; and on the basis, a foundation soil liquefaction judgment method based on a static cone penetration test is provided. By the method, the liquefaction judgment of foundation soil can be made relatively quickly and accurately; and compared with the conventional method, the method is simple, economic and quick, and has a good engineering application value.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com