Safe standard penetration test device and test method

A penetration test device and safety standard technology, applied in the field of standard penetration test devices for in-situ safety in engineering geology, can solve problems such as difficulty in maintaining a vertical state and high safety risk of hammering, and achieve simple structure, strong practicability, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

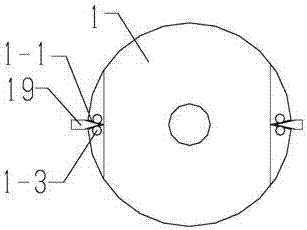

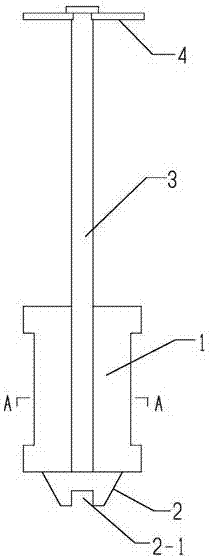

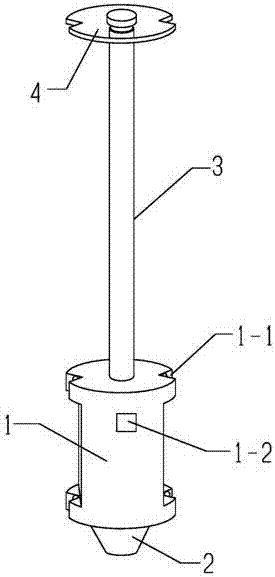

[0038] Embodiment: The safety standard penetration test device in the embodiment of the present invention includes a frame 7, a horizontal movement mechanism of the frame, a piercing hammer 1, a guide rod 3, a pad 2, a piercing hammer lifting system, and penetration depth and hammer Strike number detection and display device; the frame horizontal movement mechanism is composed of a frame translation track 21 horizontally installed on the drilling rig mast 20, a chute 12 arranged on the back of the frame 7, and a telescopic oil cylinder 13. The frame is 1.8-2m high, rectangular in cross-section, 350-400mm long, and 250-280mm wide. The front of the frame is equipped with a piercing hammer limit guide rail 19 along the height direction. The cross-section of the piercing hammer limit guide rail 19 is triangular. 3-4 degree beams are set on both sides and the back to enhance the rigidity of the rack. The weight of the piercing hammer is 63.5kg, the cross section is a ring with an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com