Engineering geological drilling construction method based on thin-walled drilling tool

A technology of engineering geology and construction methods, applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc. Accurate test results and fast drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

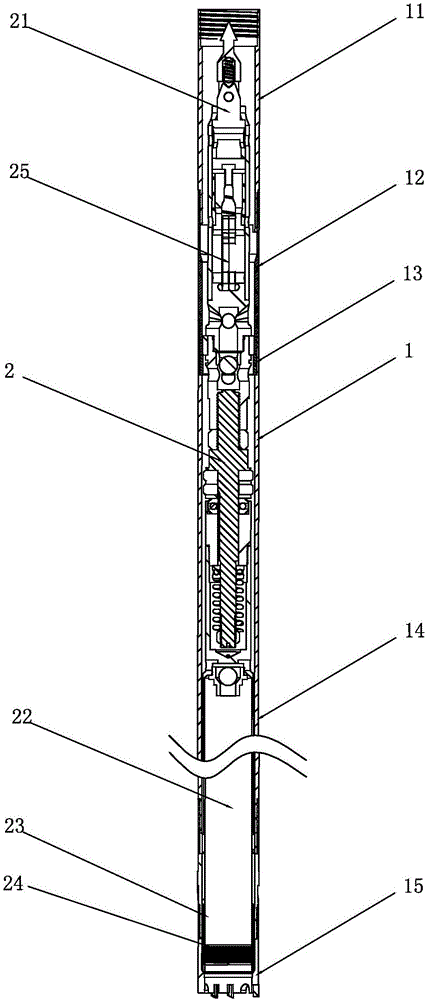

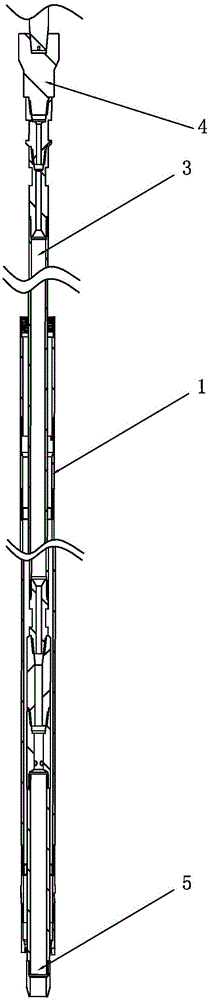

[0025] Such as figure 1 As shown, the drilling tool in the present invention is a single-action double-tube thin-walled drilling tool, including an outer tube assembly 1 and an inner tube assembly 2 inserted in the outer tube assembly 1, and the outer tube assembly 1 includes The bullet stopper 11, the bullet chamber 12, the seat ring 13, the outer tube 14, the reamer 15 and the thin-walled drill bit 16 are sequentially connected from top to bottom, and the minimum inner diameter of the outer tube assembly 1 is not less than 56mm , the thin-walled drill bit 16 is made of cemented carbide, or a composite drill bit or a diamond-impregnated drill bit, with an outer diameter of 75.7 mm and an inner diameter of 56 mm. The inner tube assembly 2 includes sequentially connected from top to bottom Drilling tool head assembly 21, rock core pipe 22, jump ring seat 23 and jump ring 24, seat ring 13 can limit support drilling tool head assembly 21, and drilling tool head assembly 21 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com