Patents

Literature

71 results about "Power hammer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power hammers are mechanical forging hammers that use a non-muscular power source to raise the hammer preparatory to striking, and accelerate it onto the work being hammered. Also called "Open Die Power Forging Hammers." They have been used by blacksmiths, bladesmiths, metalworkers, and manufacturers since the late 1880s, having replaced trip hammers.

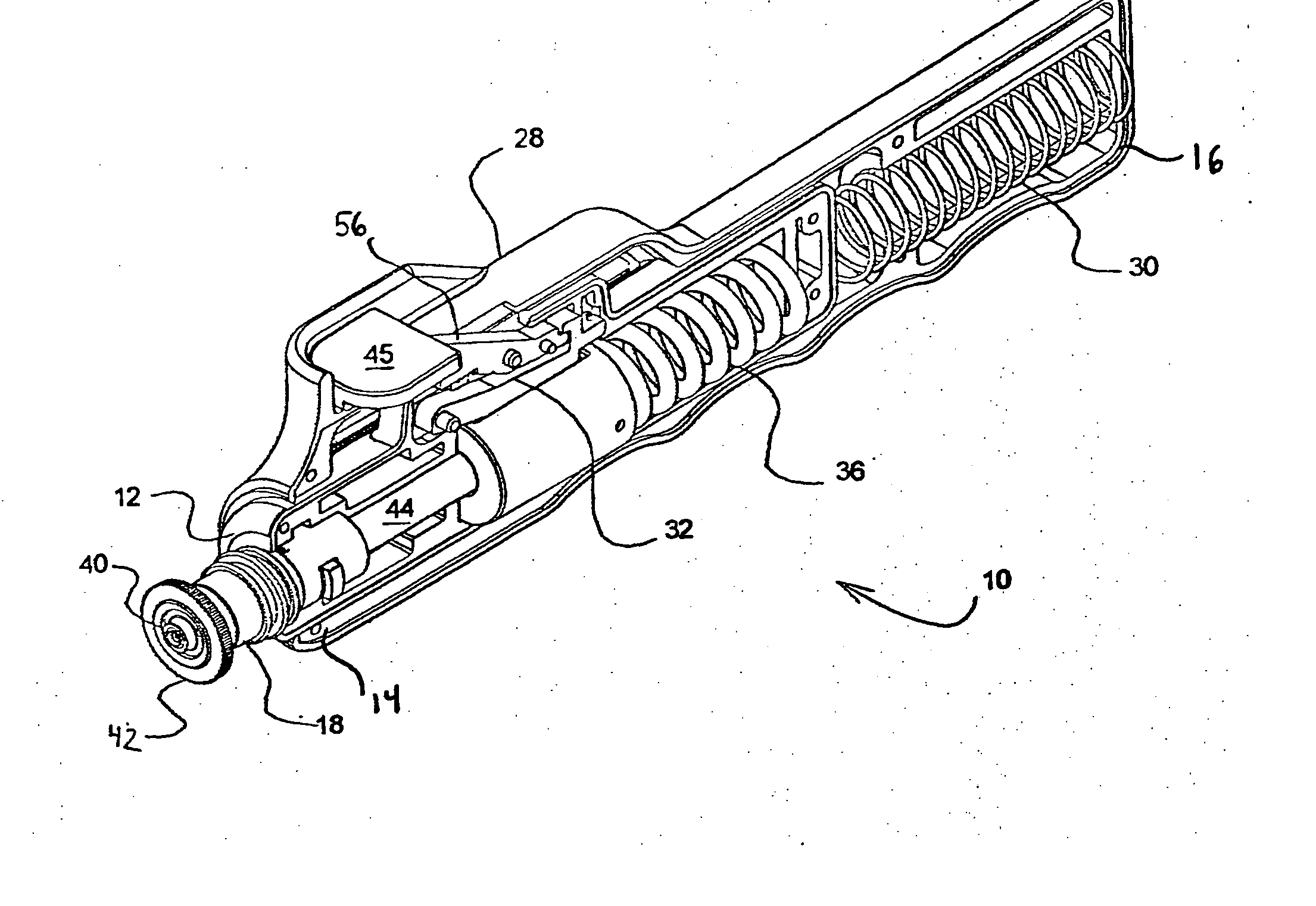

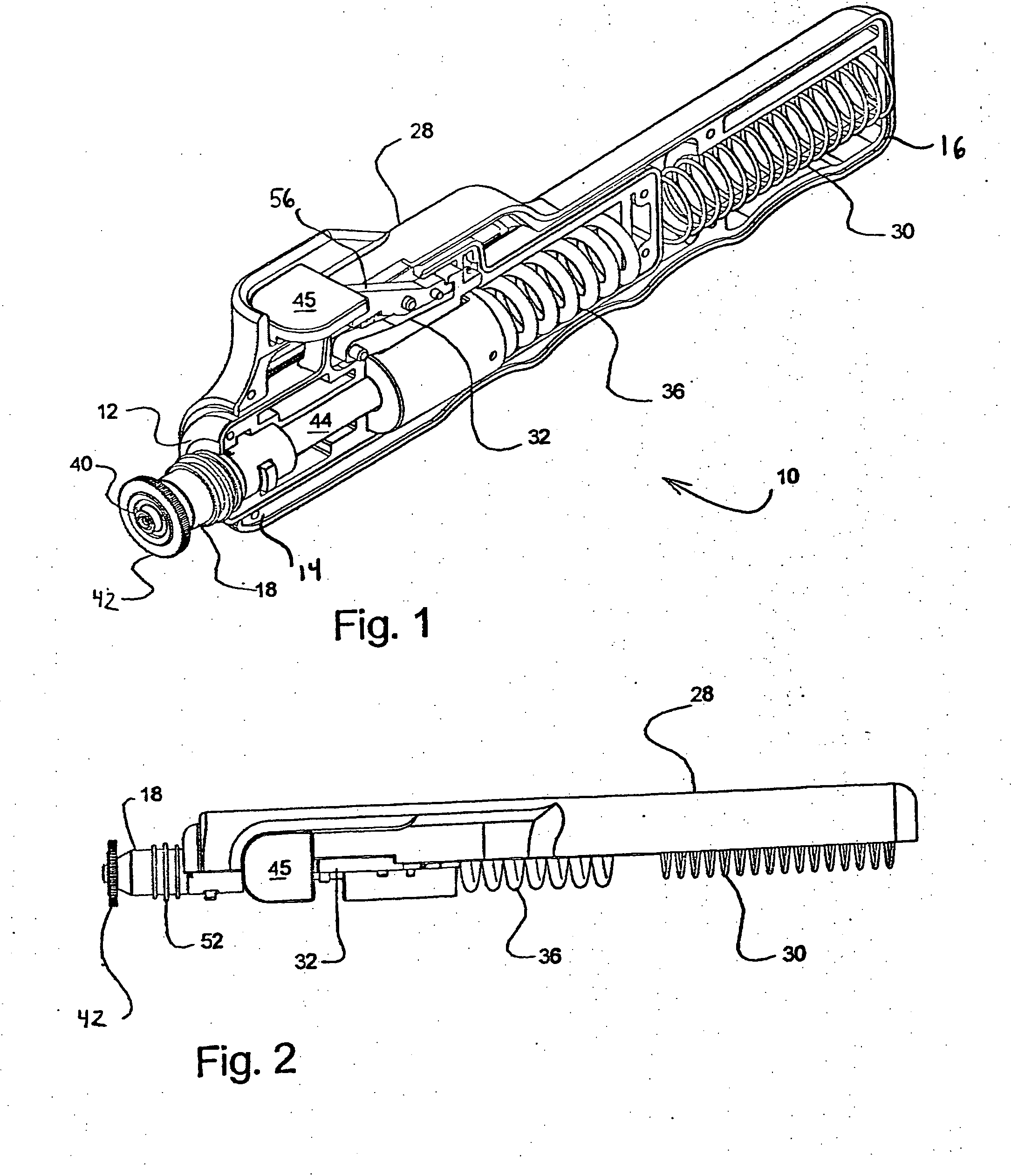

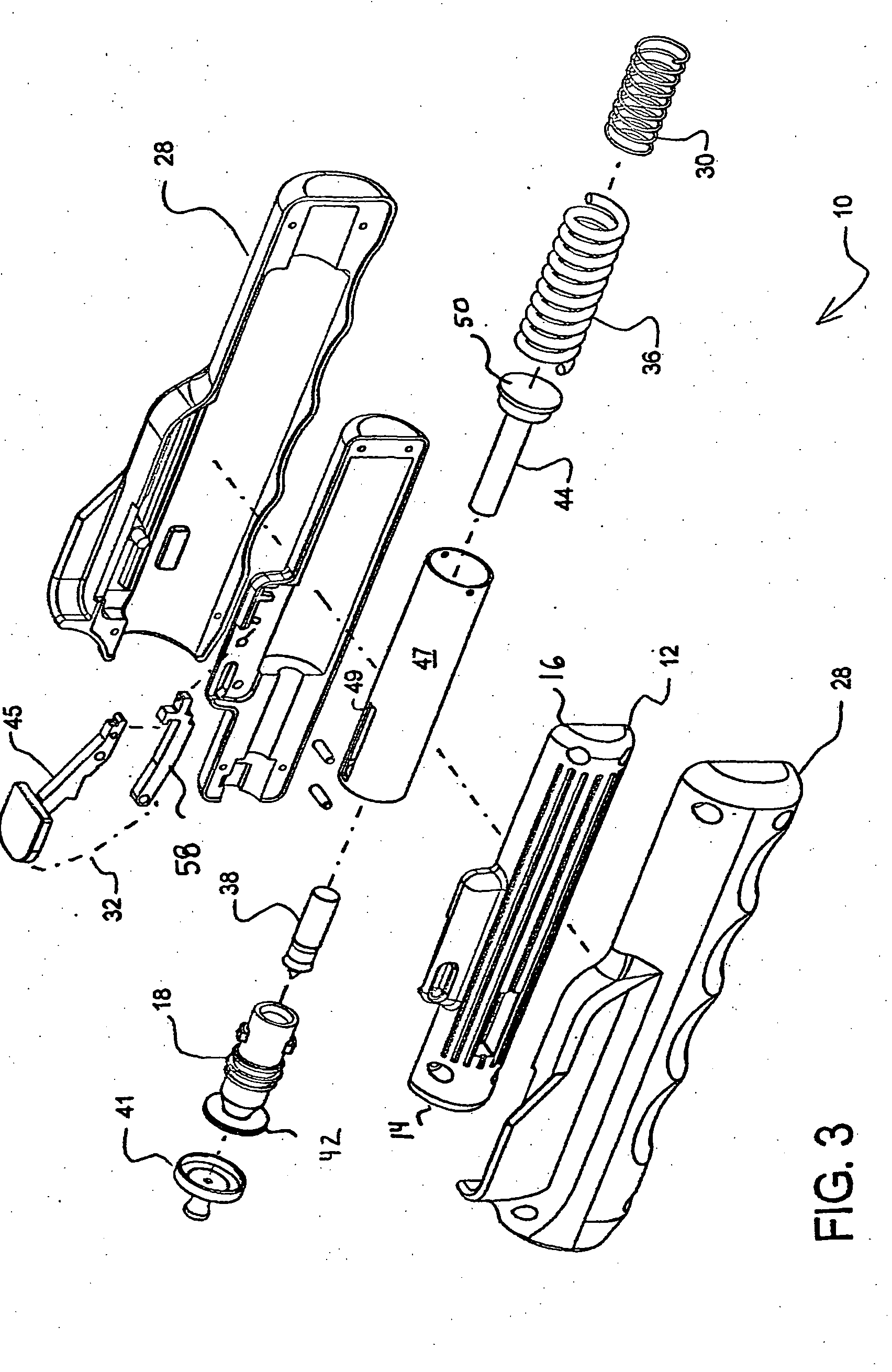

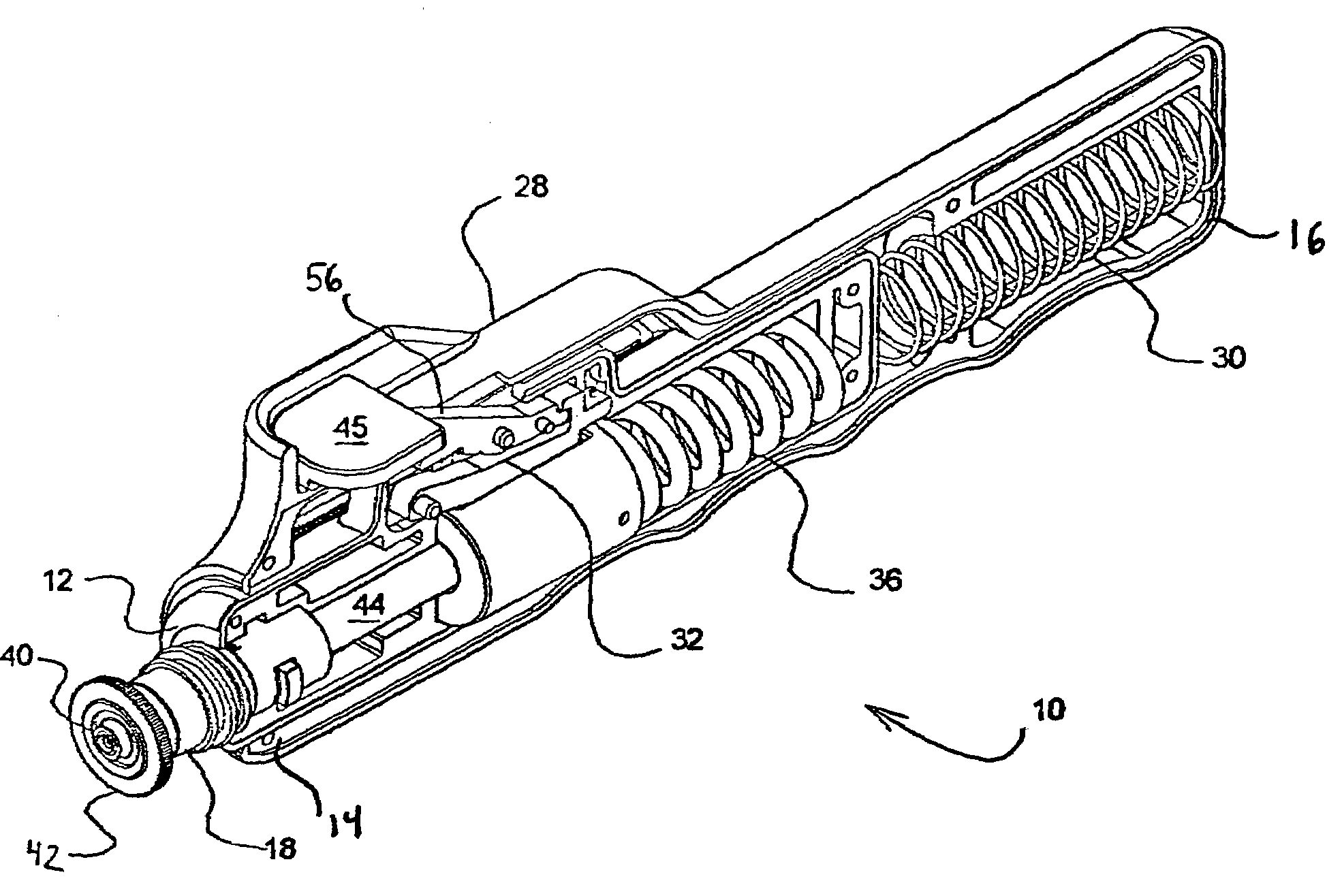

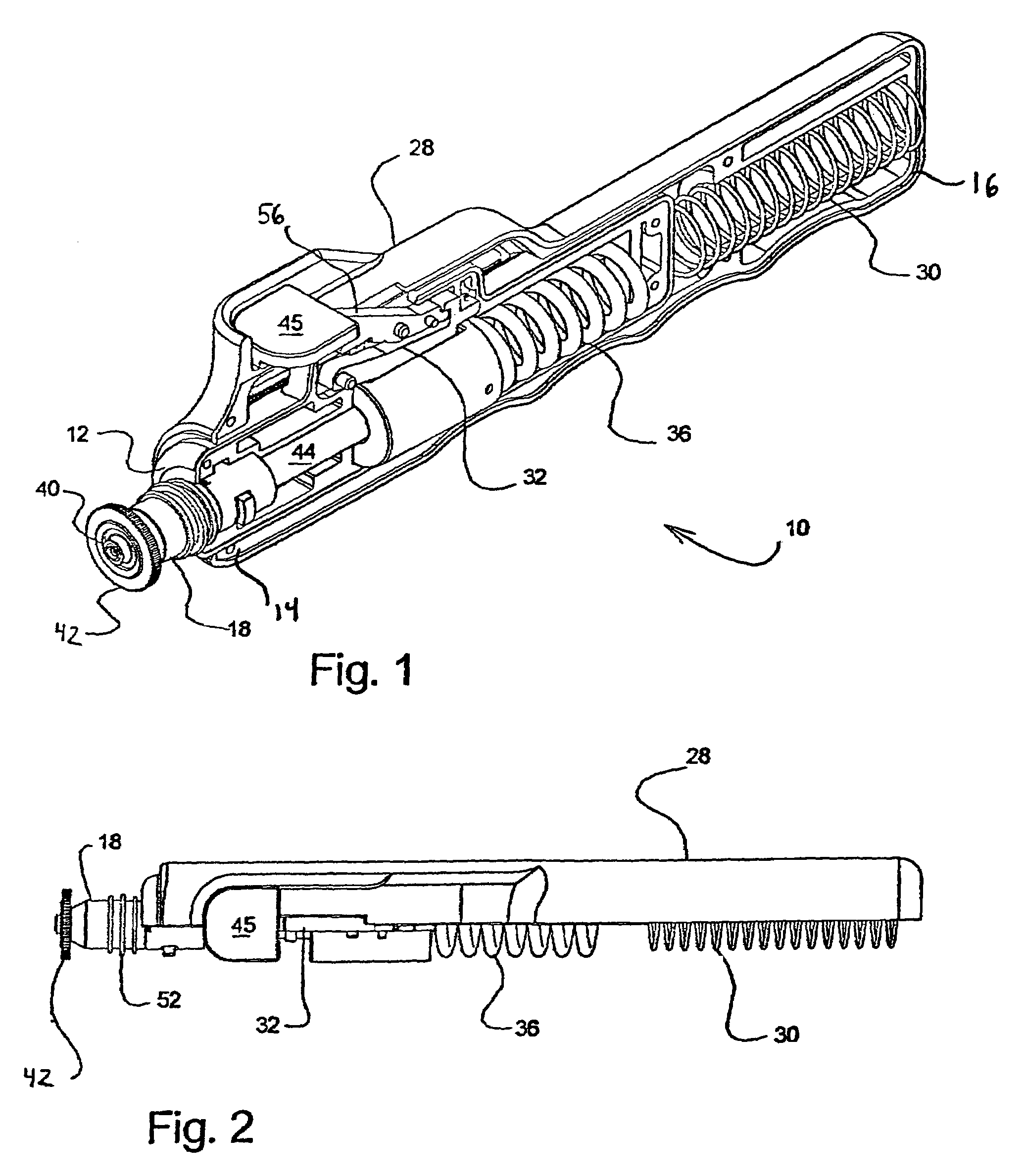

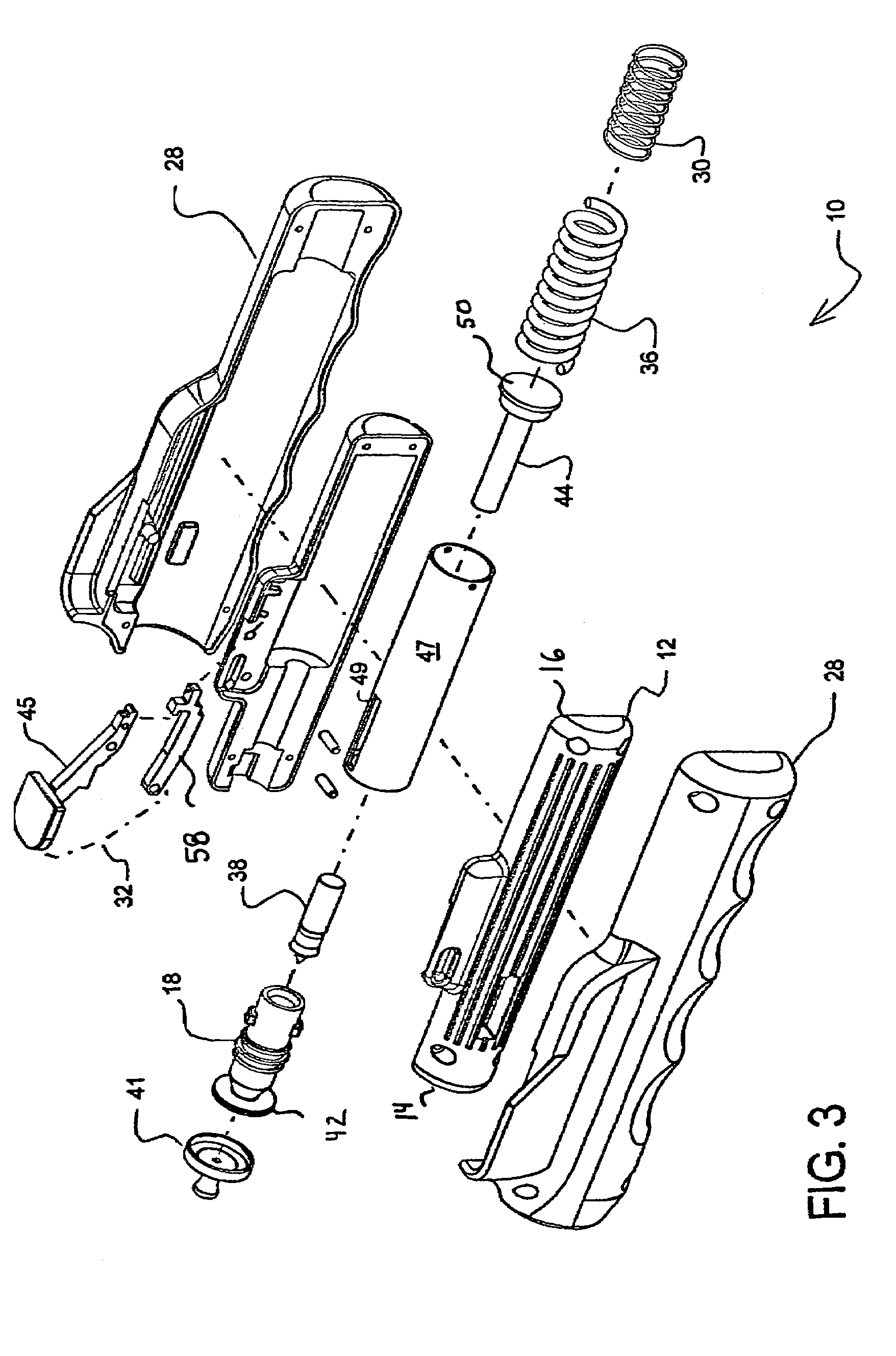

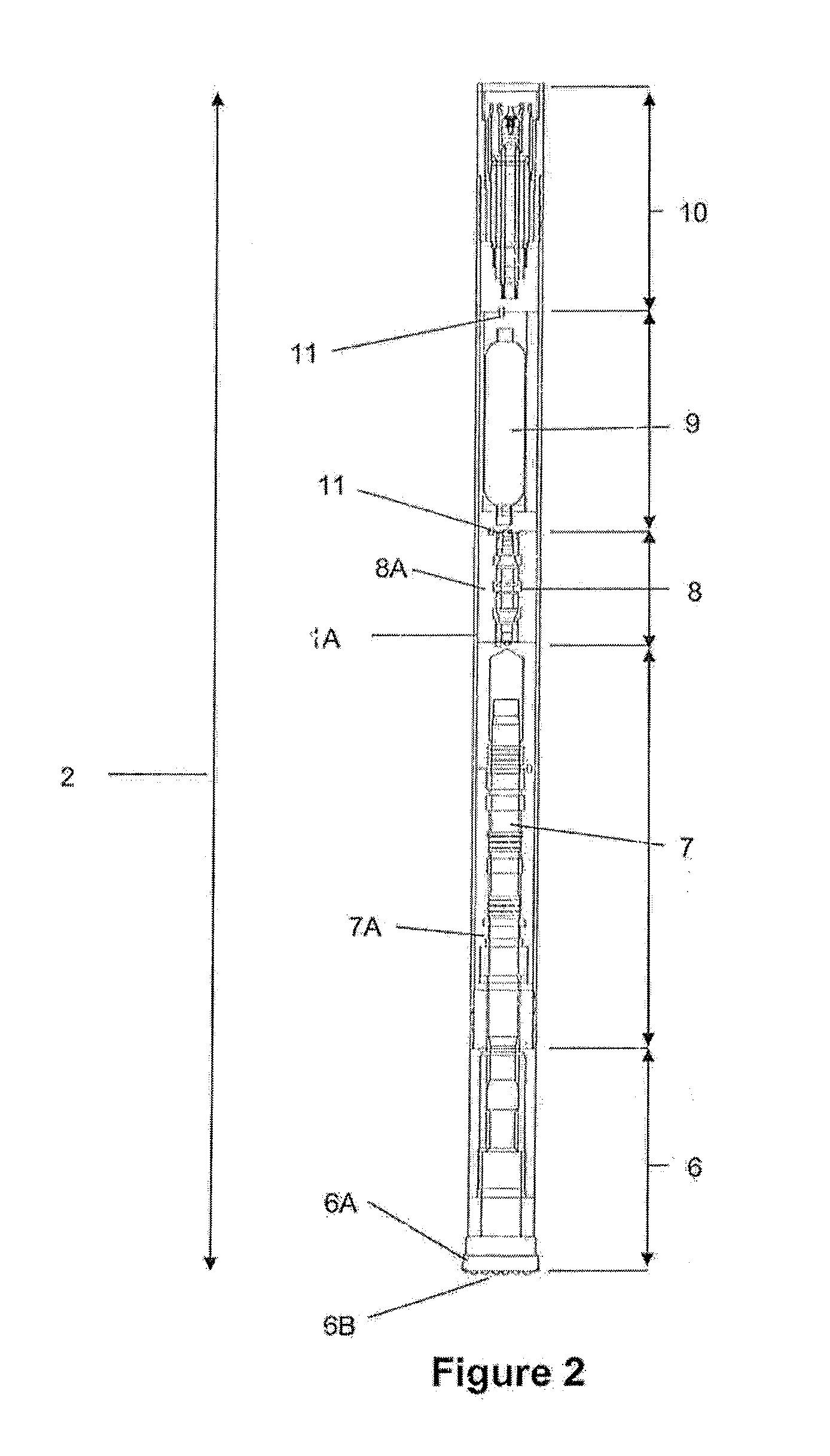

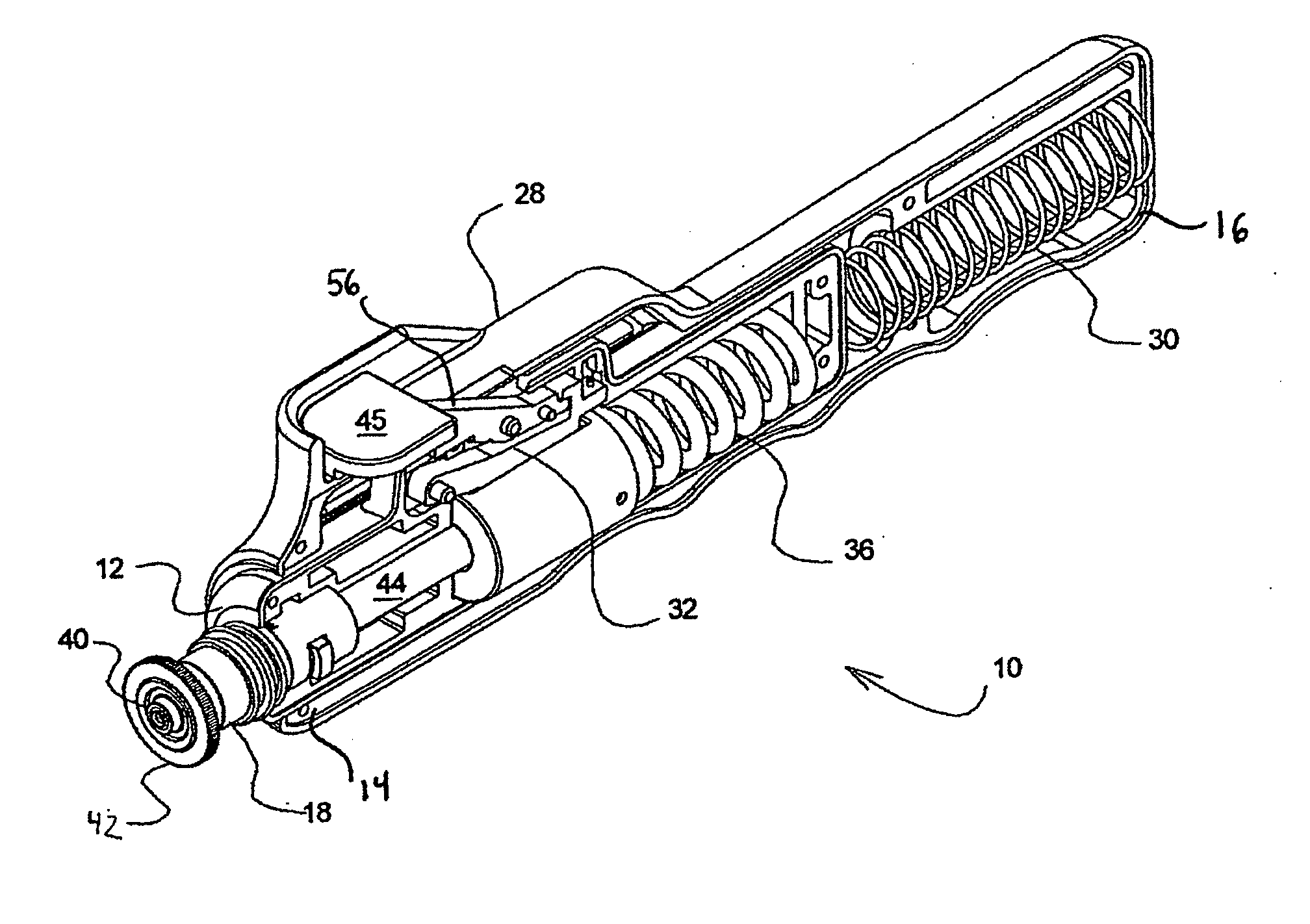

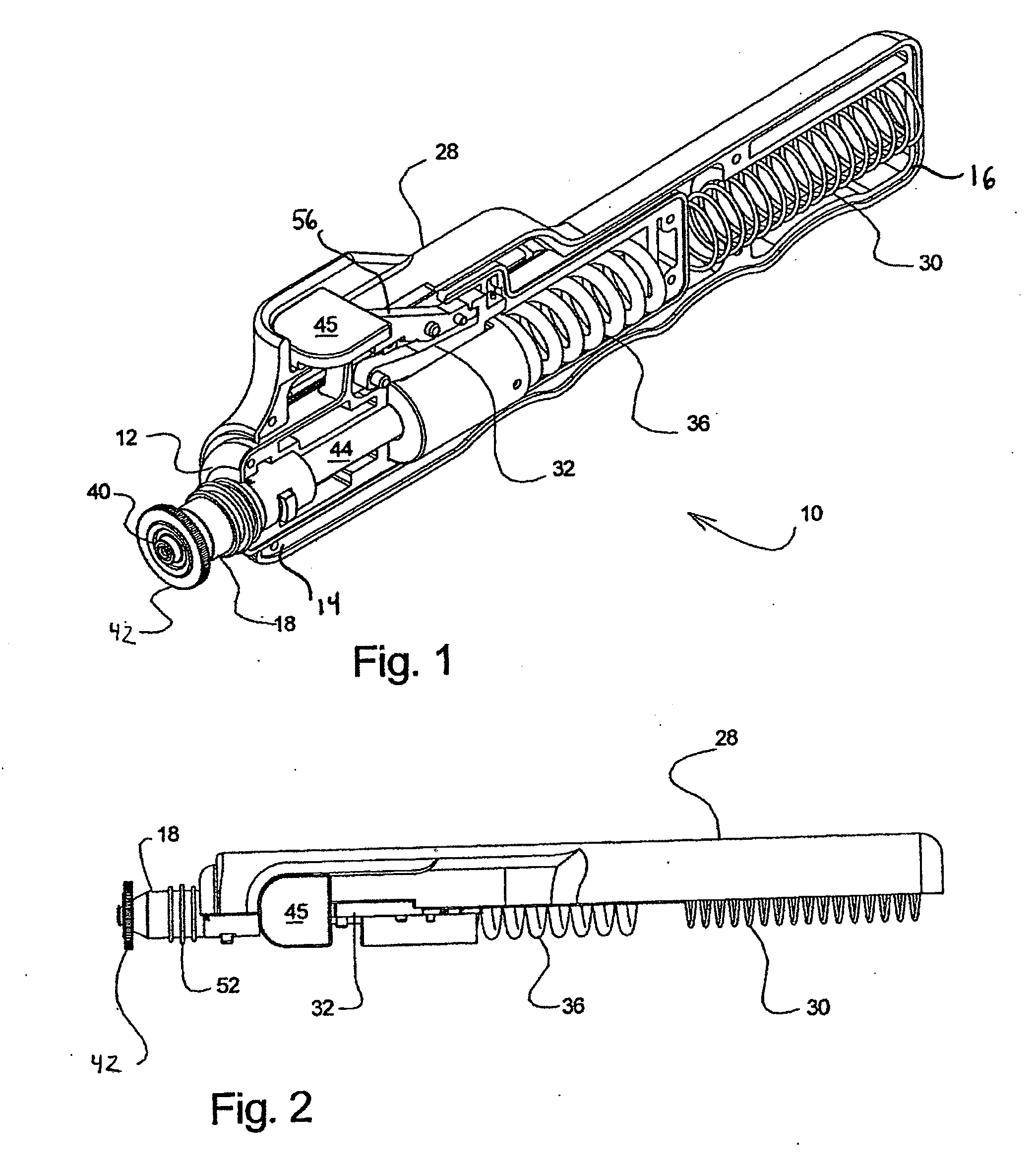

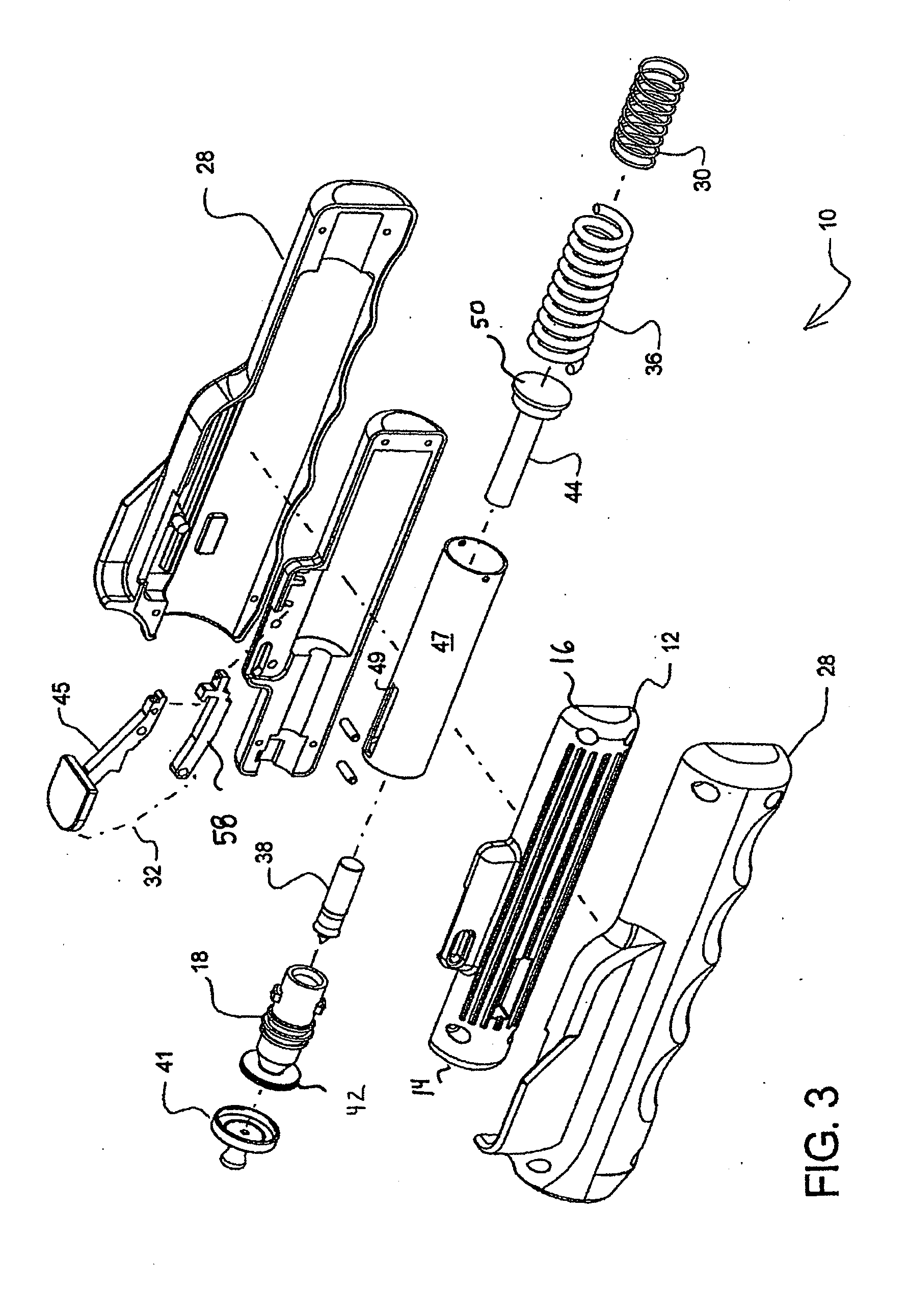

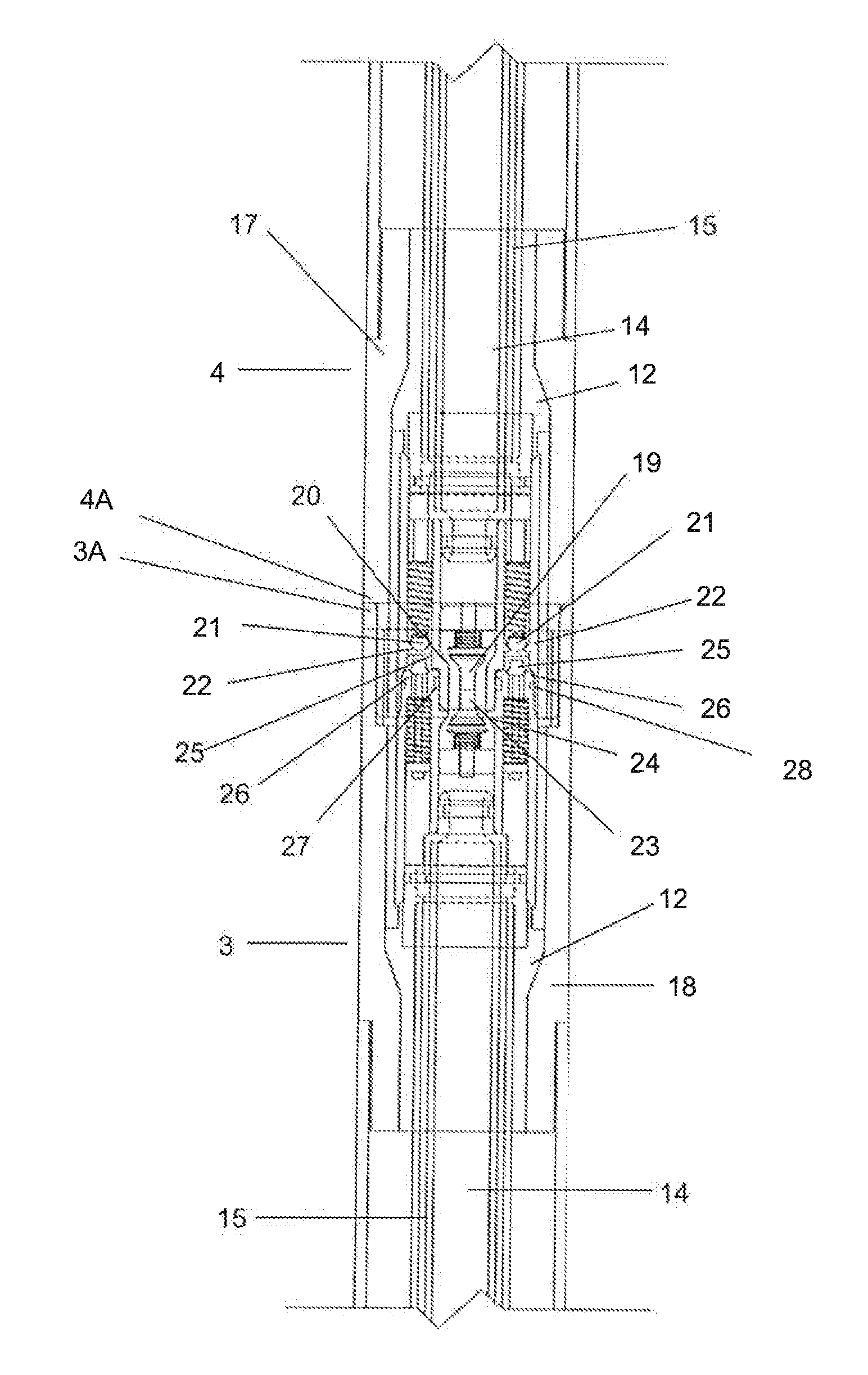

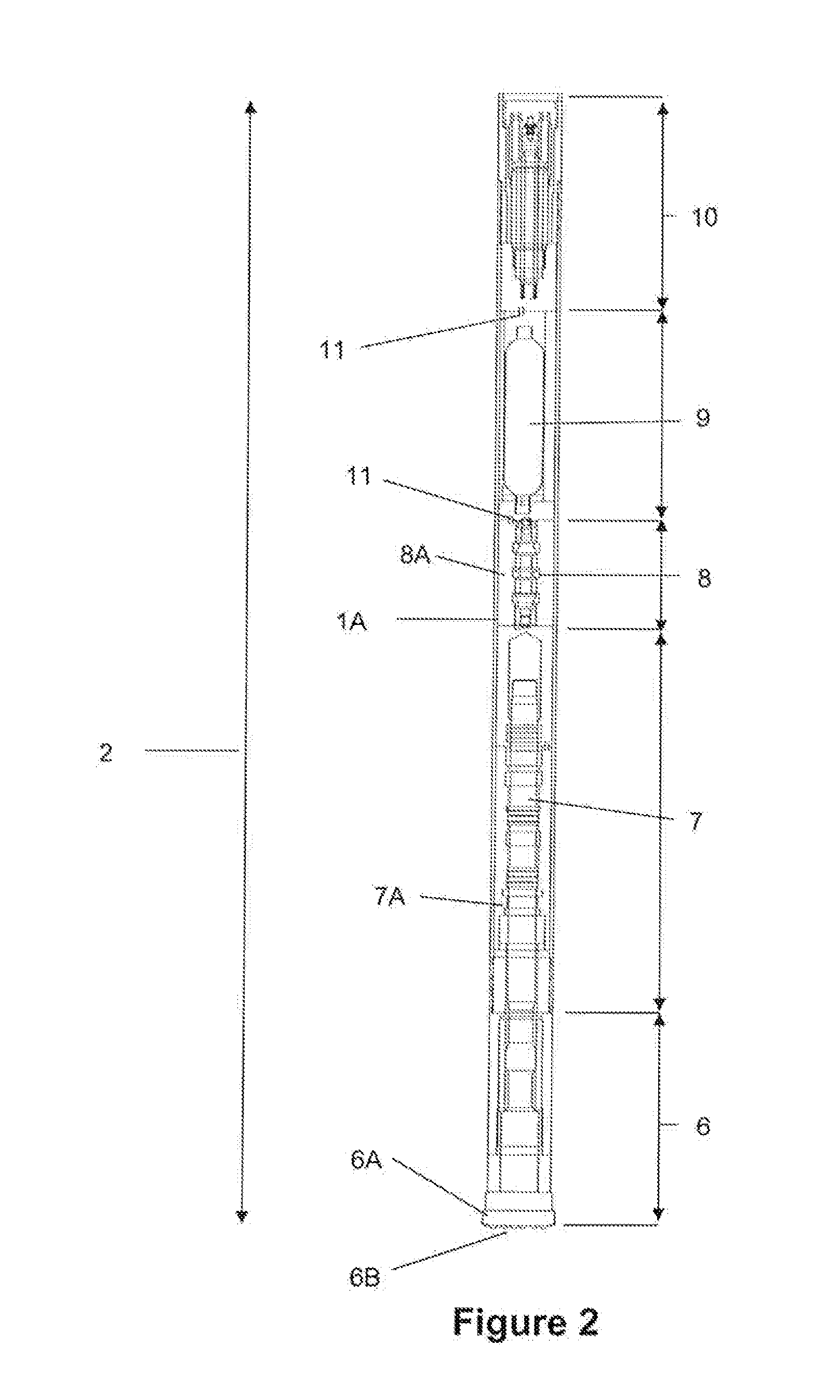

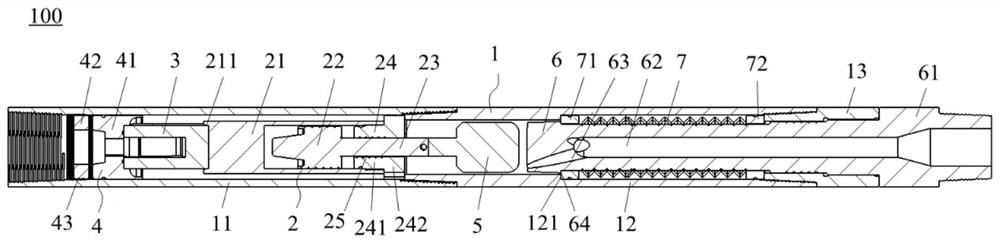

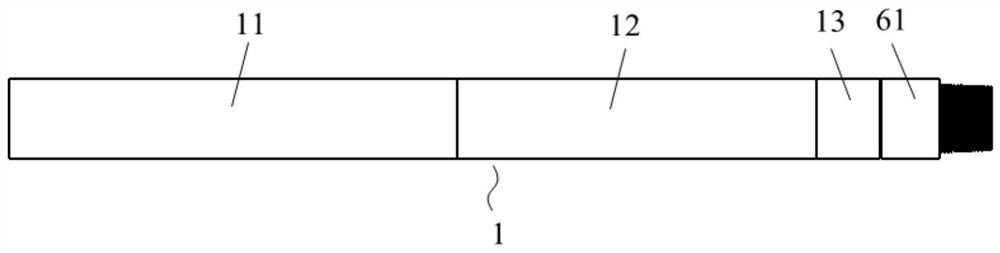

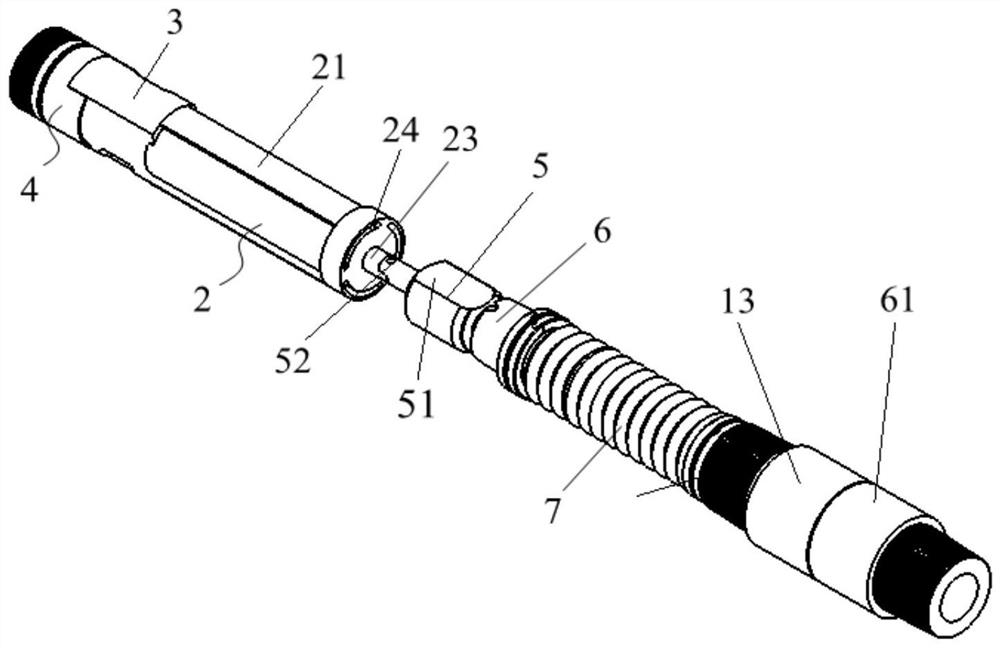

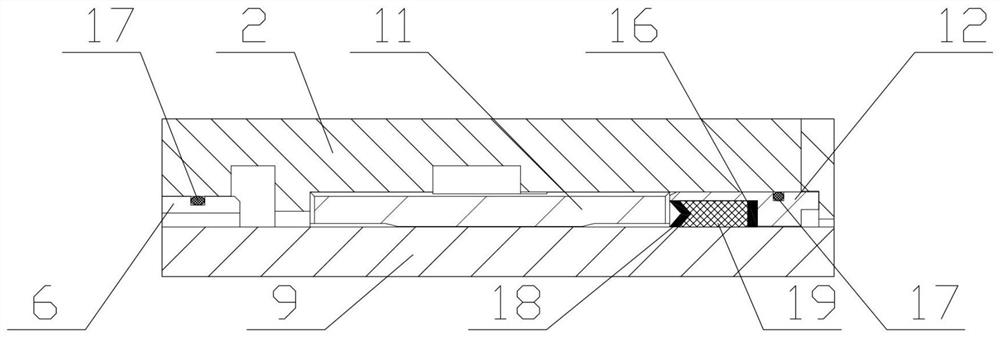

Needle-less injector and method of fluid delivery

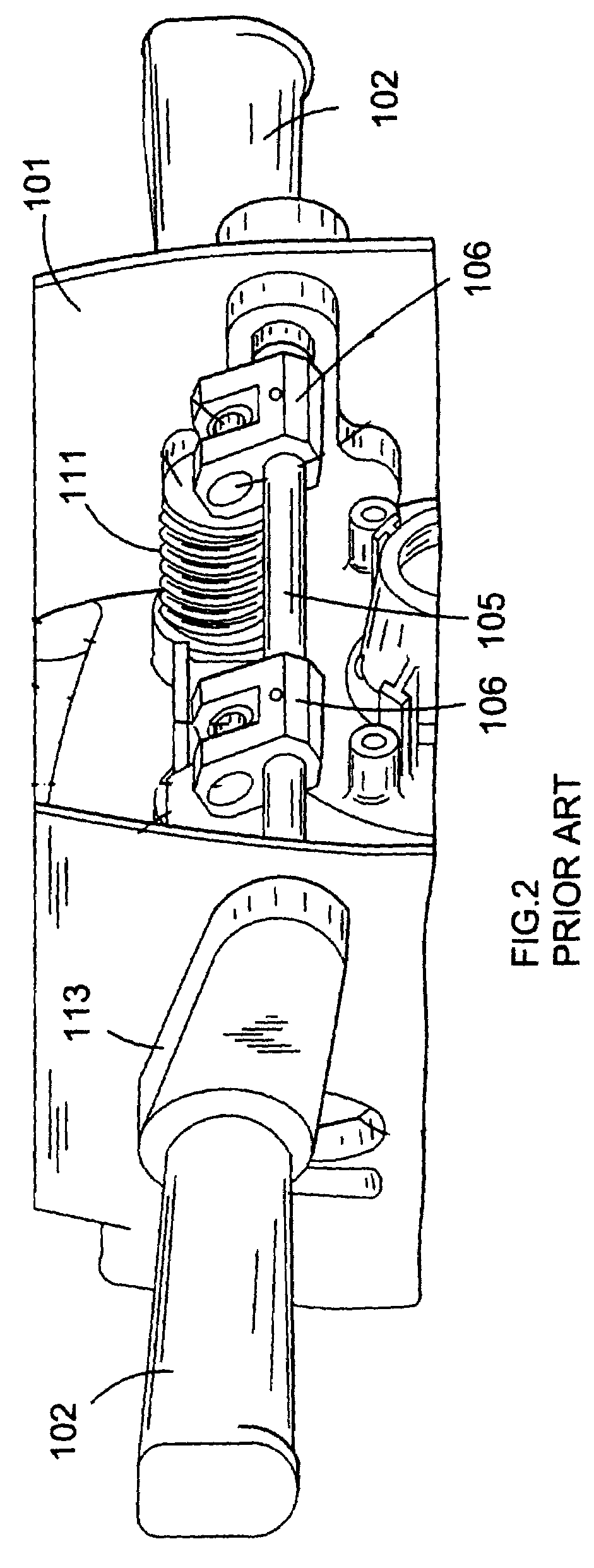

ActiveUS20070118094A1Safe and reliableAvoid accidental dischargeJet injection syringesAutomatic syringesNeedle Free InjectionPlunger

A needle-less injector device for delivering a dose of fluid intradermally, subcutaneously or intramuscularly to an animal or human. The device includes an inner housing having opposed ends. A syringe is disposed in one end of the inner housing. The syringe includes a nozzle for delivering a dose of fluid held within the syringe. A plunger is movably disposed within the syringe. A spring powered hammer is movably disposed within the inner housing. The hammer cooperates with the plunger to drive the dose of medicament from the nozzle. An injection delivery spring for powering the hammer is positioned and compressed between the other end of the inner housing and the spring powered hammer. An outer housing slideably supports the inner housing. A skin tensioning spring is mounted between the inner housing and the outer housing, the skin tensioning spring biasing the nozzle of the syringe against the animal or human. A trigger mechanism is disposed in the outer housing, the trigger mechanism cooperating with the spring powered hammer to release the injection delivery spring, wherein the size of the injection delivery spring and the length of the hammer dictate the amount of dose delivered and whether the dose is delivered intradermally, subcutaneously or intramuscularly to an animal or human.

Owner:PHARMAJET INC

Needle-less injector and method of fluid delivery

ActiveUS7618393B2Safe and reliableAvoid accidental dischargeJet injection syringesAutomatic syringesNeedle Free InjectionPlunger

Owner:PHARMAJET INC

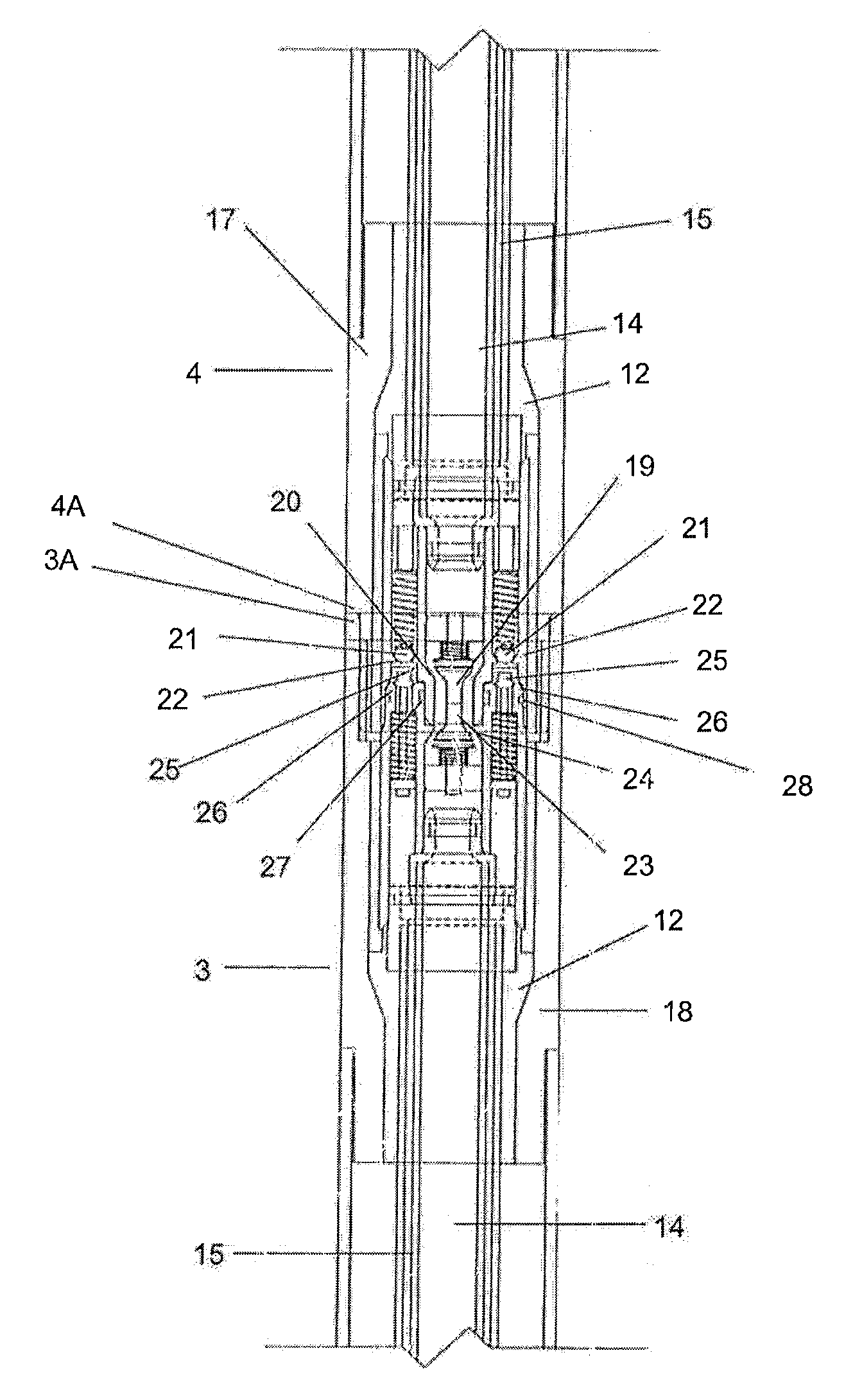

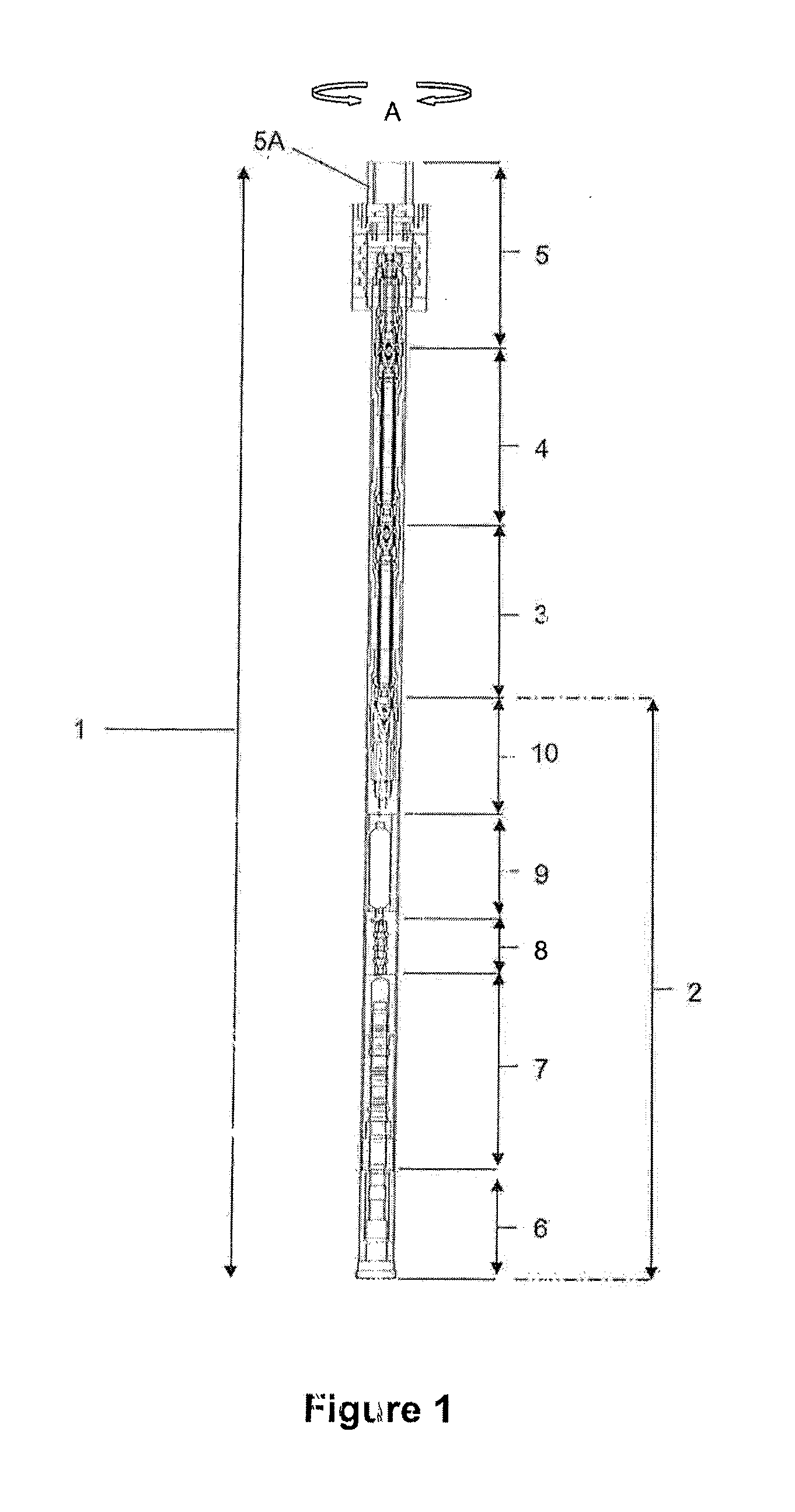

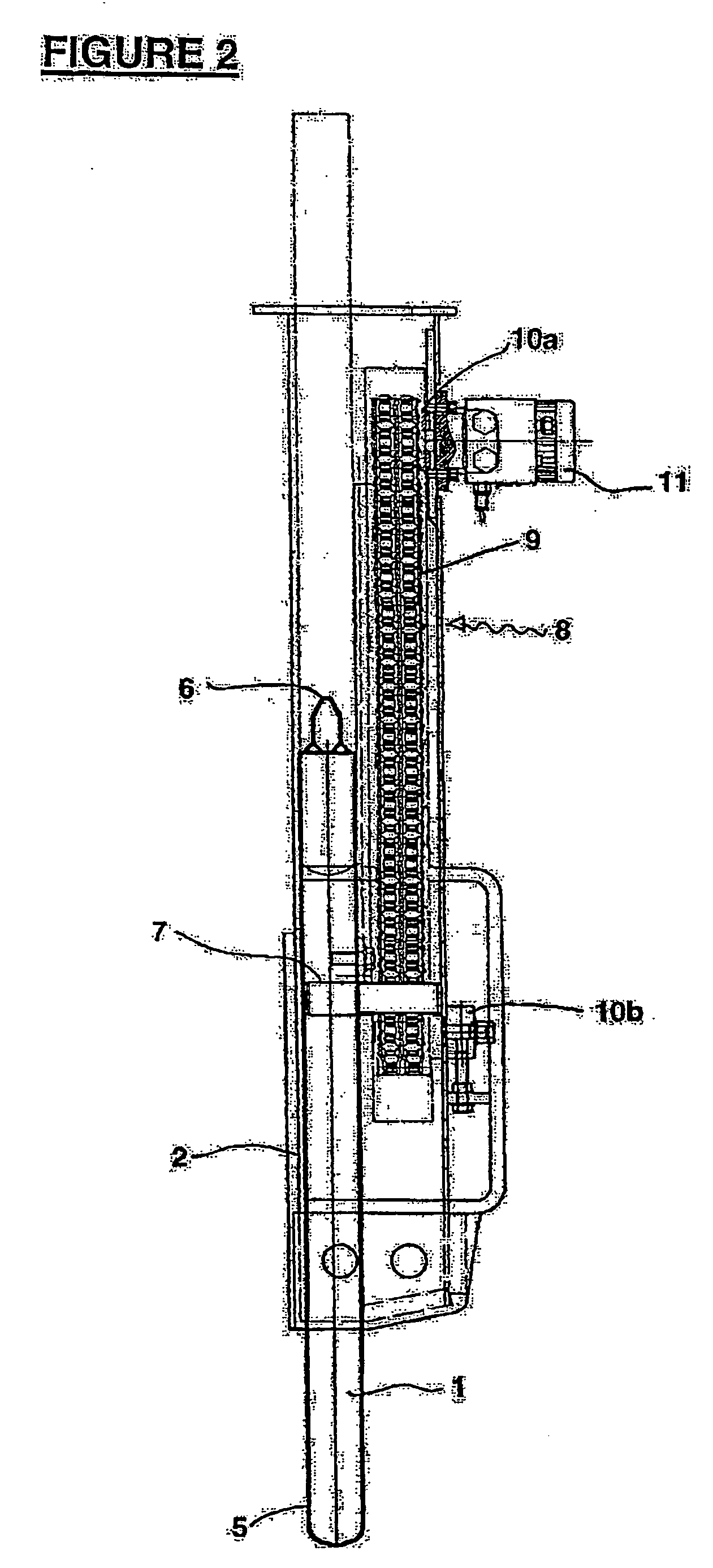

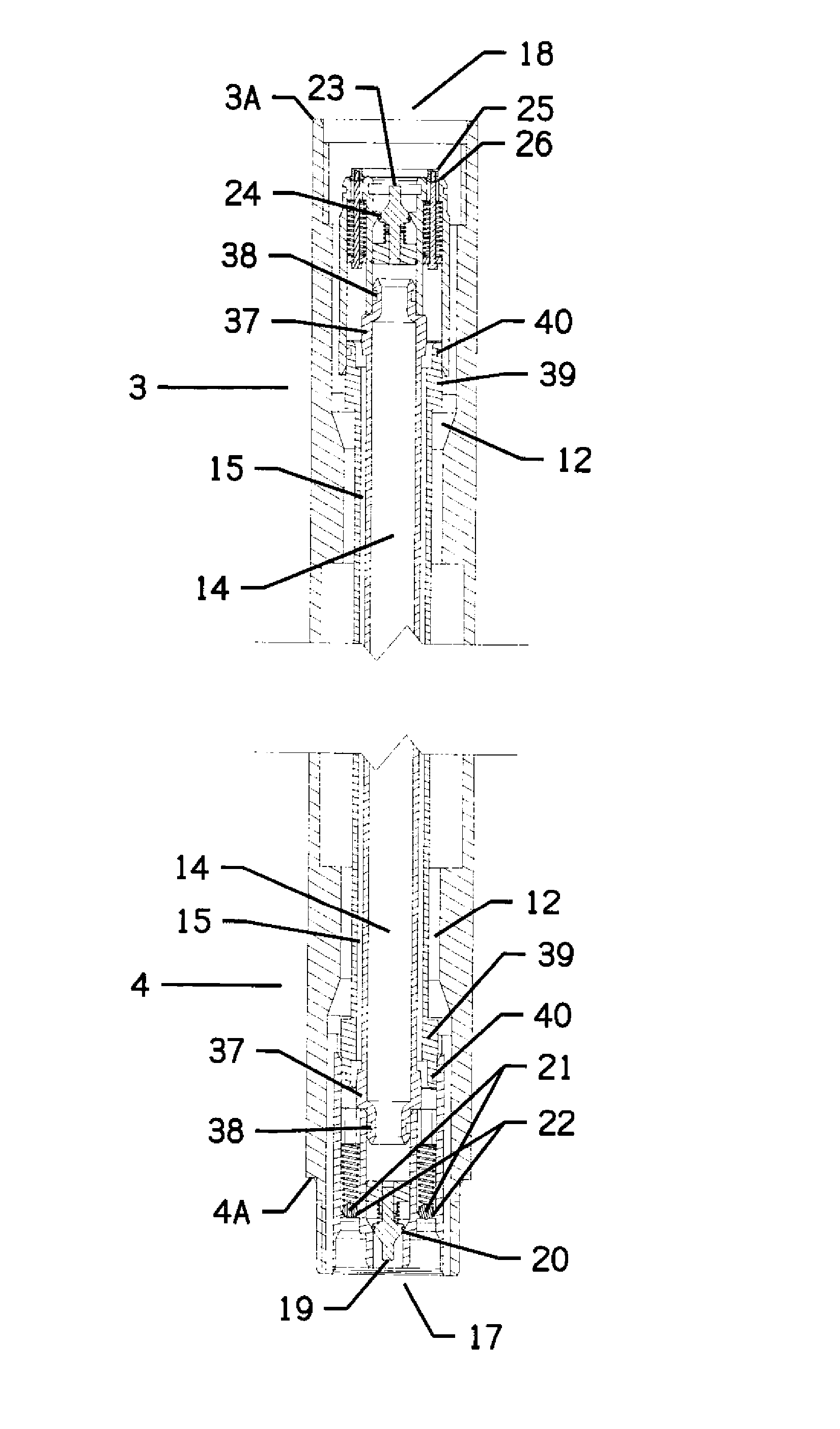

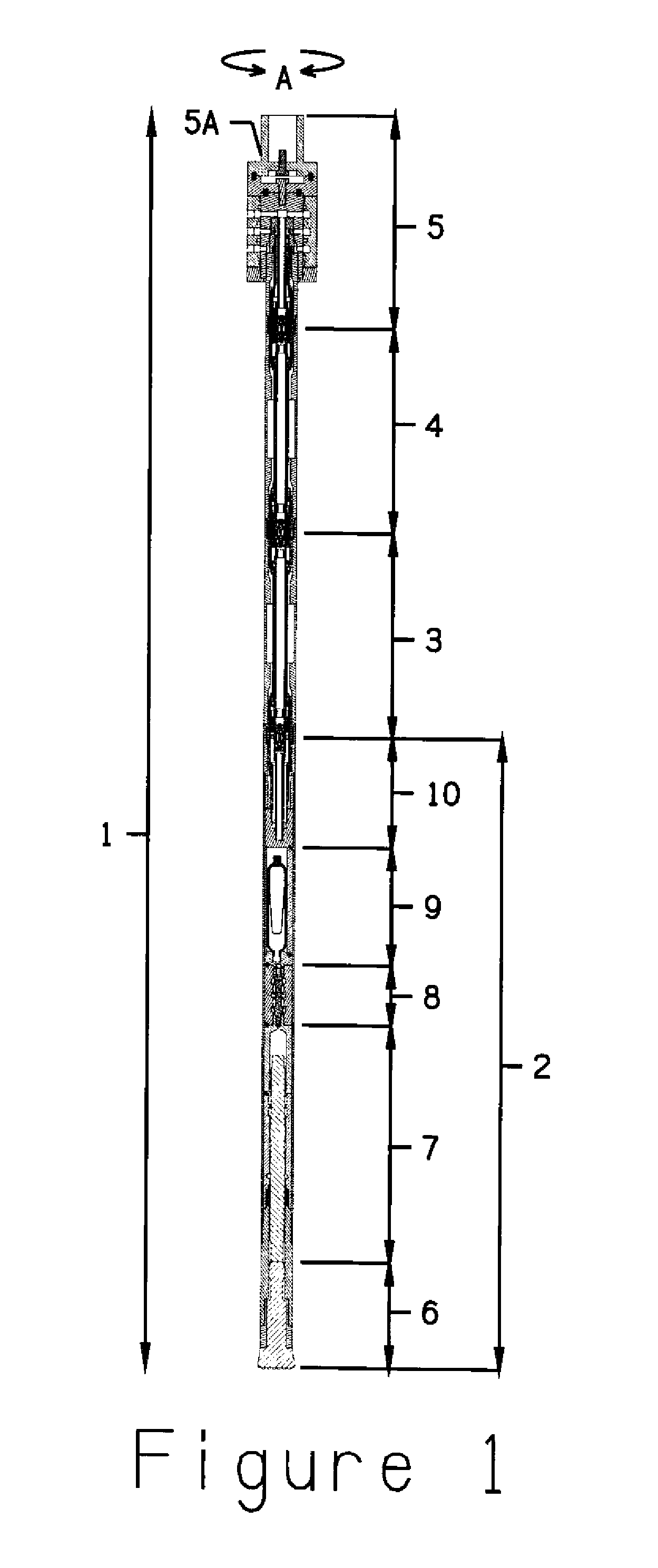

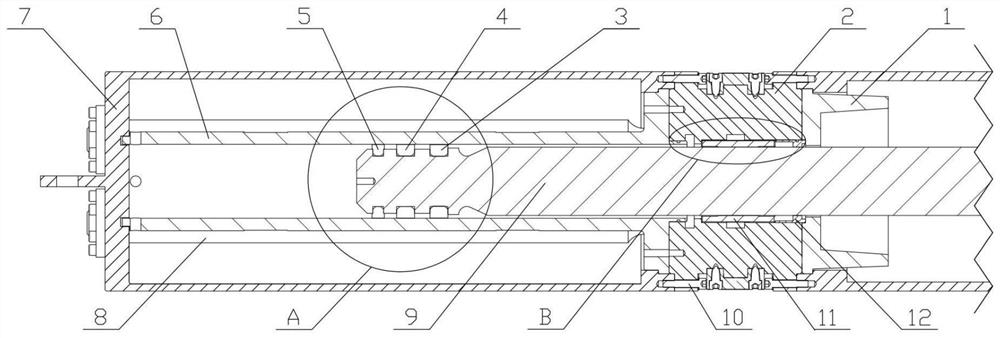

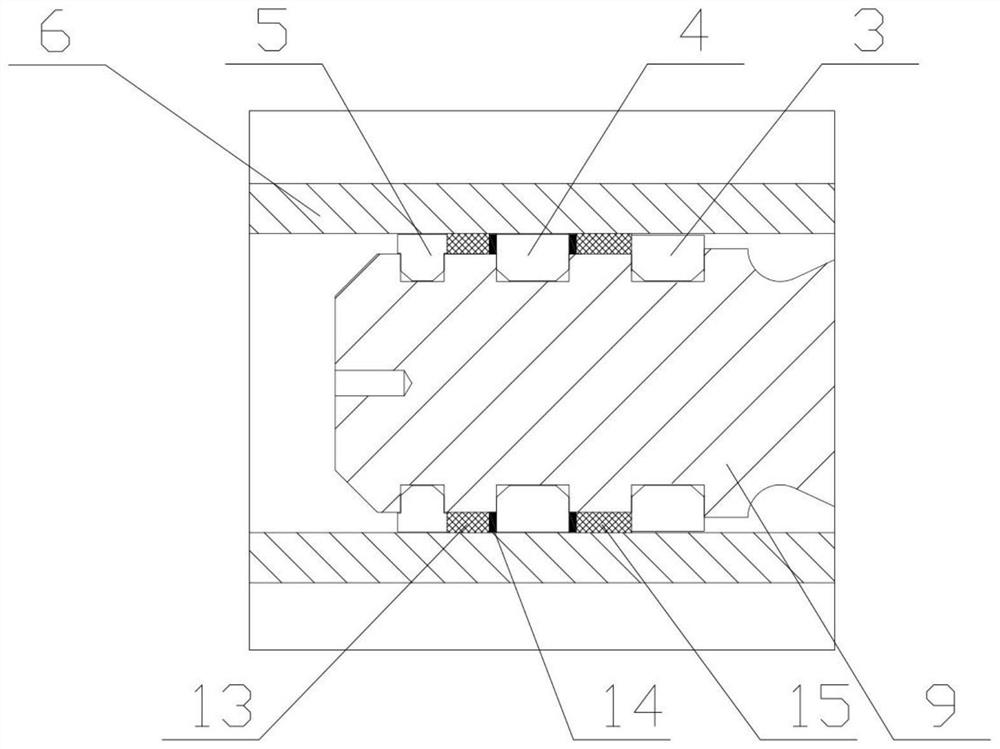

Drilling apparatus

A drilling apparatus including a hydraulically powered hammer having a piston to impact a drill bit; a shuttle valve to control reciprocation of the piston; and an accumulator for hydraulic fluid; at least one drill rod having a first connection valve for connection of the drill rod to the connection valve of the hammer; and a second connection valve for connection of the drill rod to the first connection valve of a like drill rod or to a rotation device. The piston and shuttle valve are positioned substantially in-line to the axis of movement of the hammer. The accumulator is positioned proximate to the shuttle valve; and the first connection valve, and second connection valve having at least one poppet valve positioned proximate to a corresponding valve seat.

Owner:JFK EQUIP

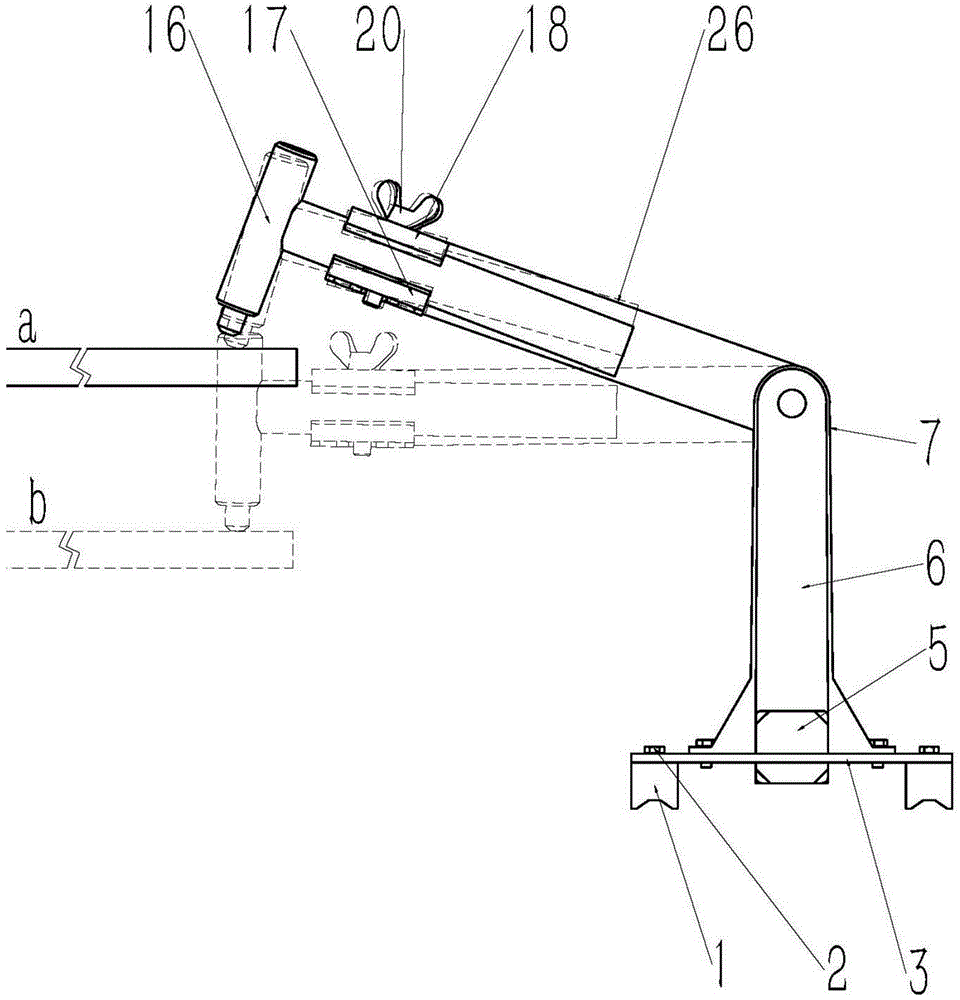

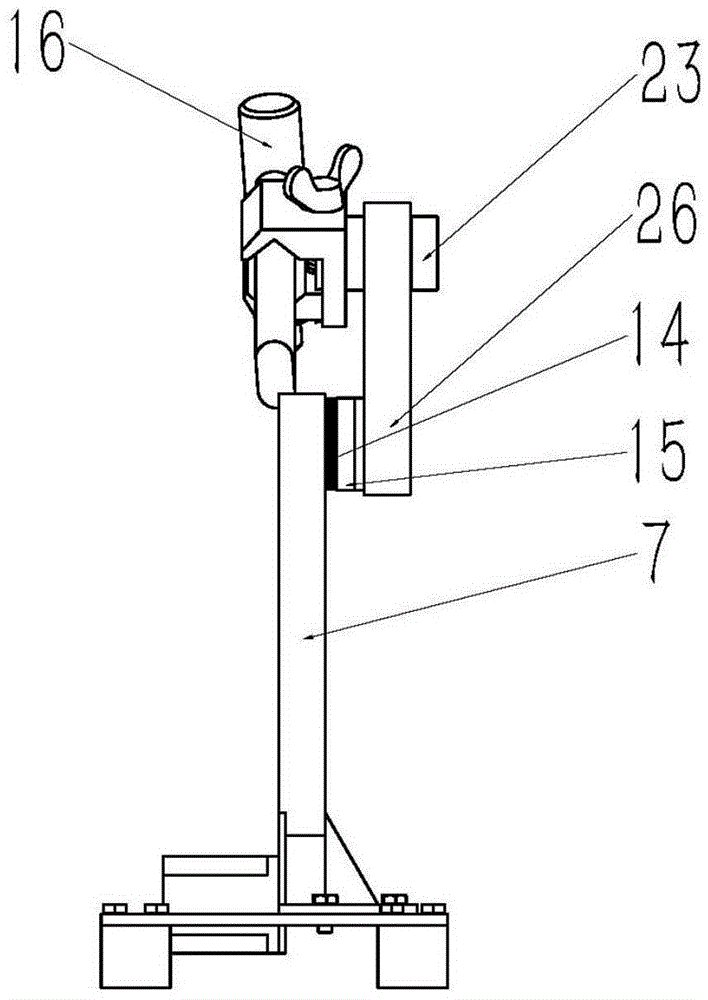

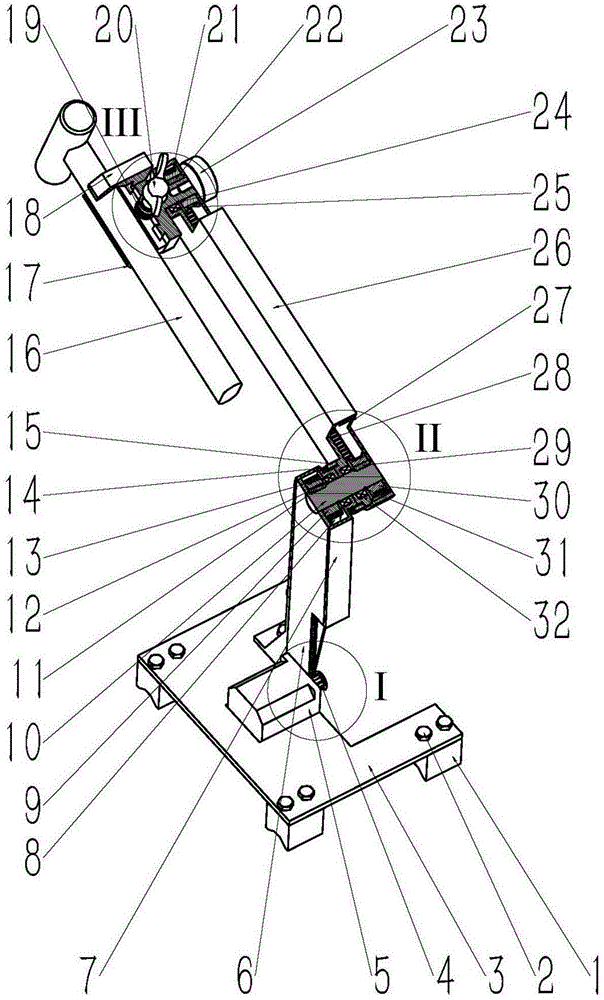

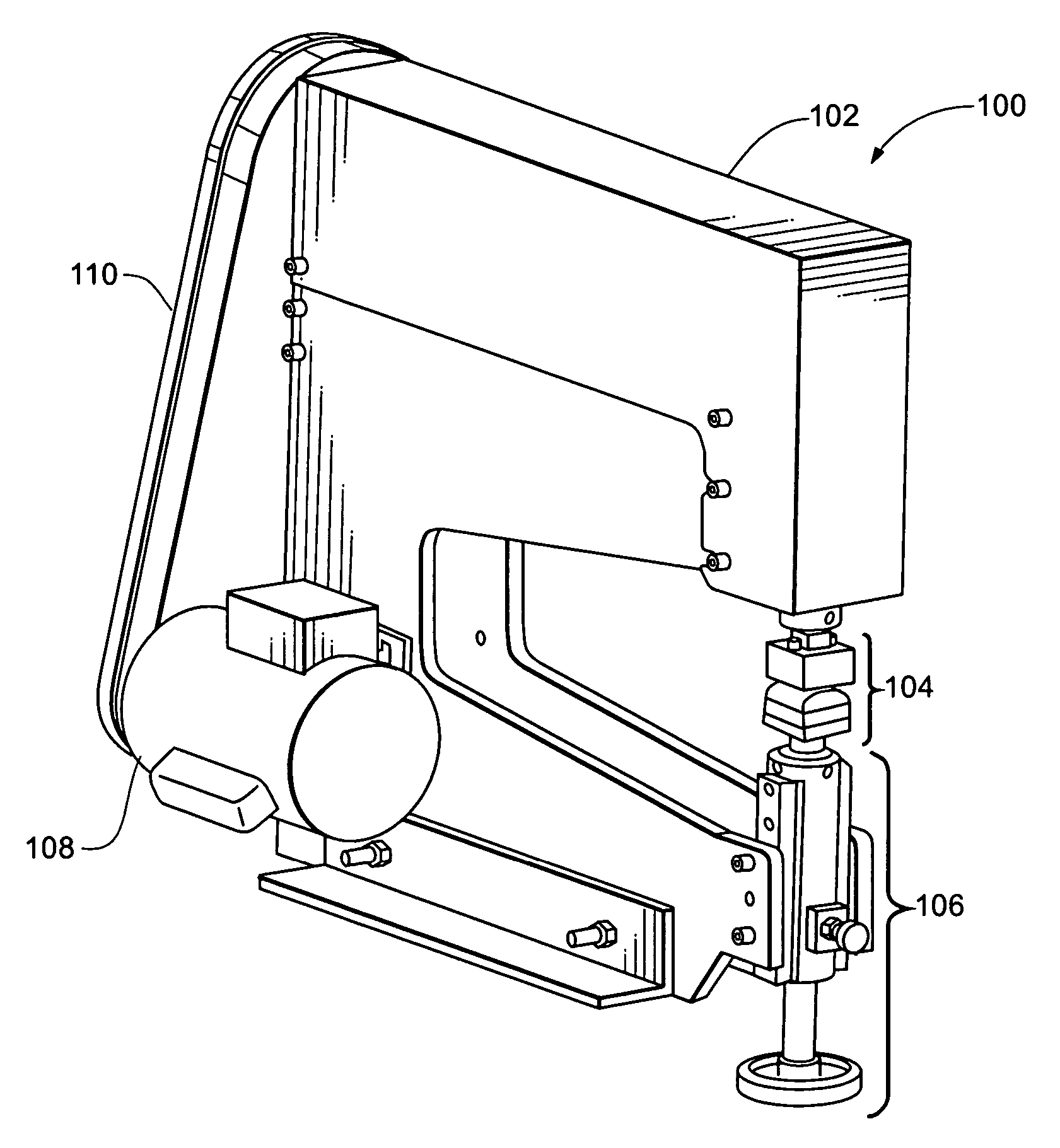

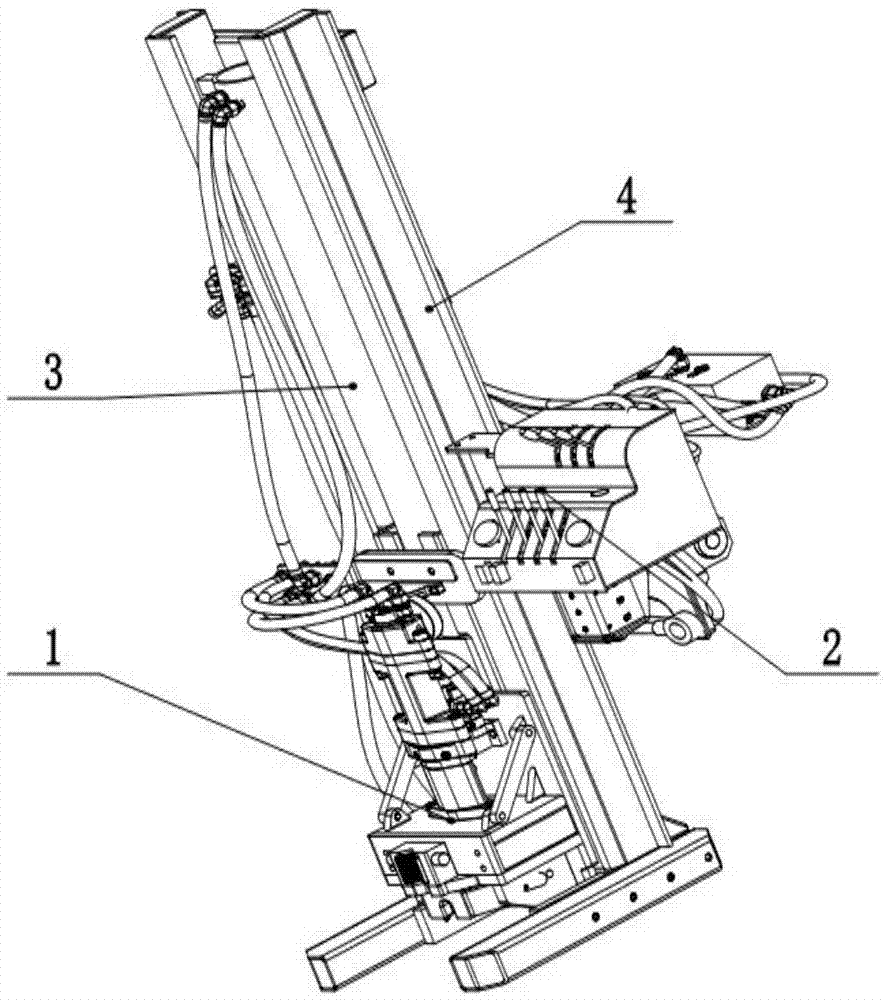

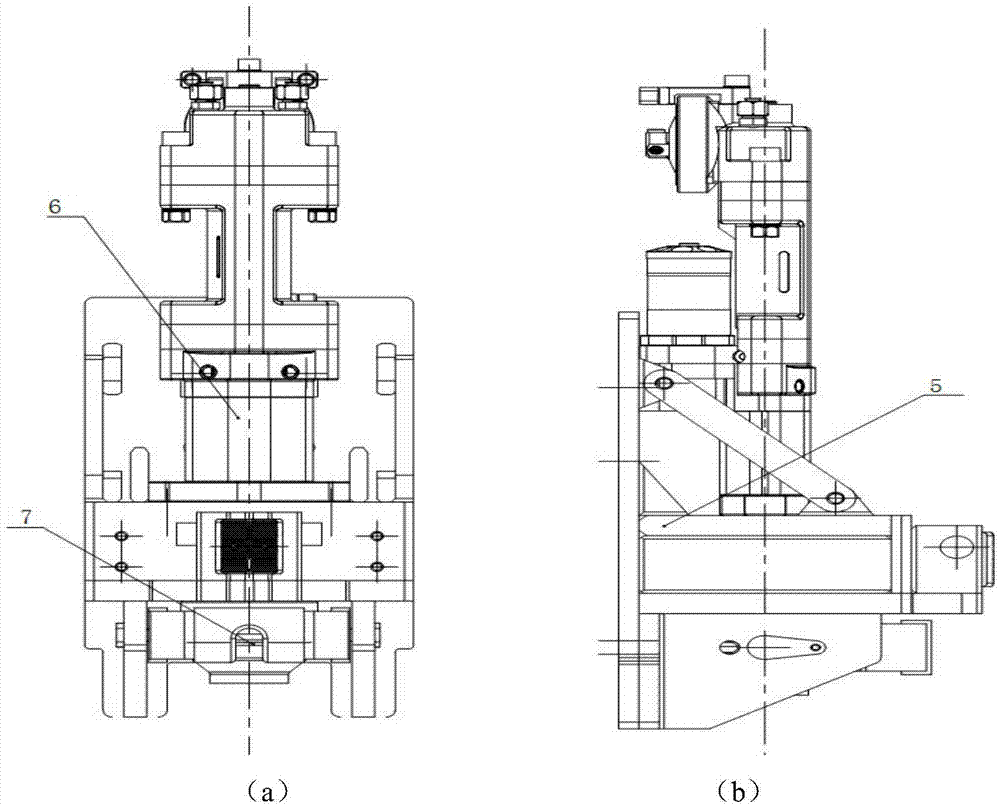

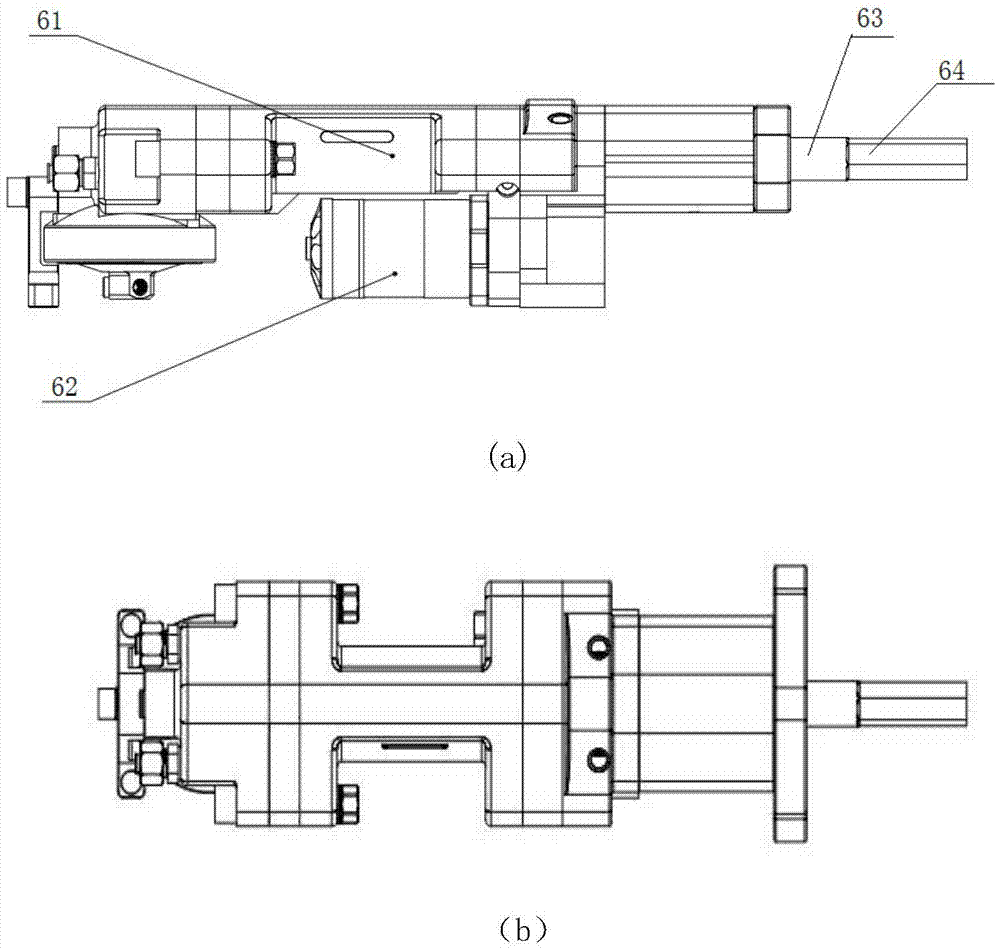

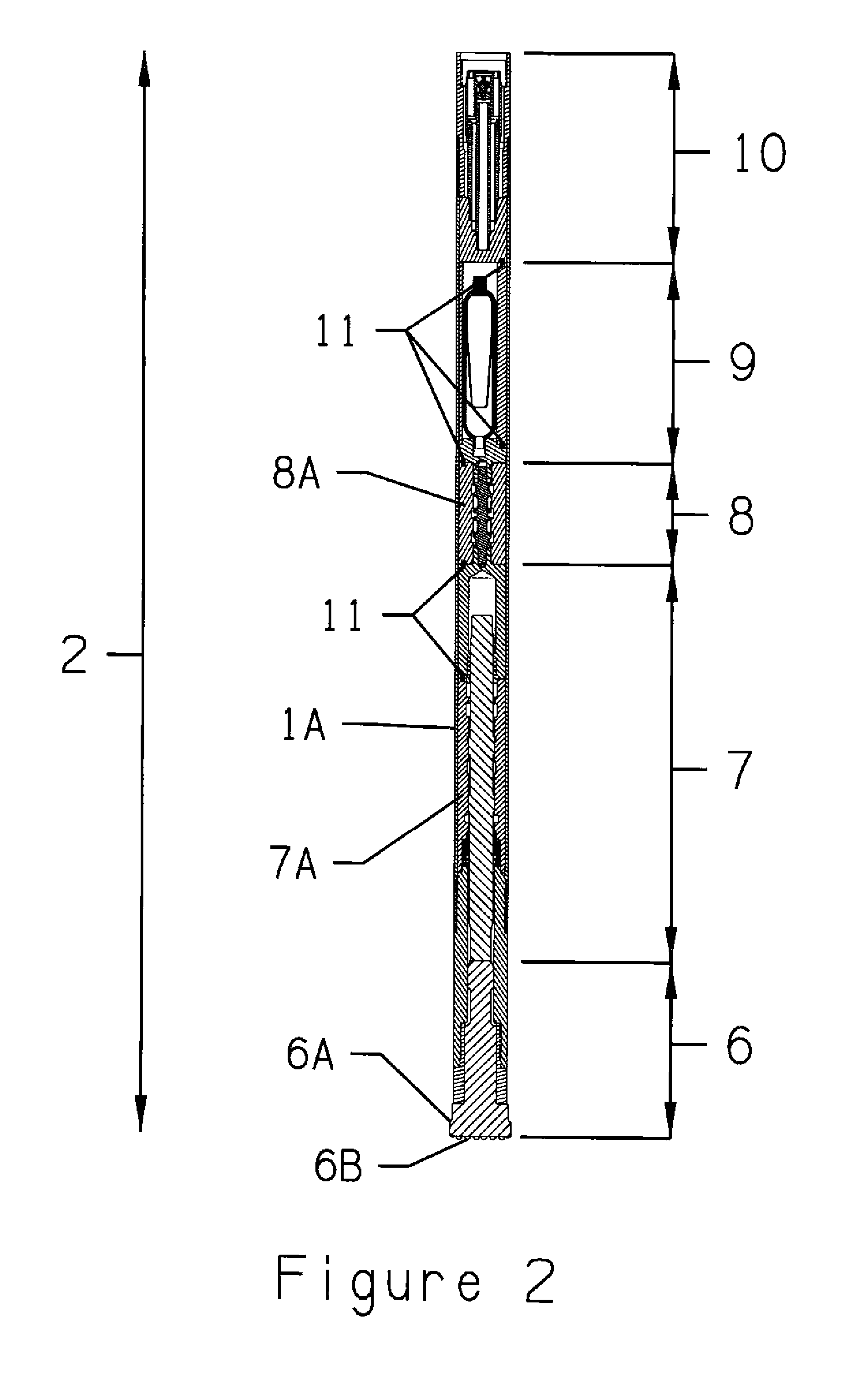

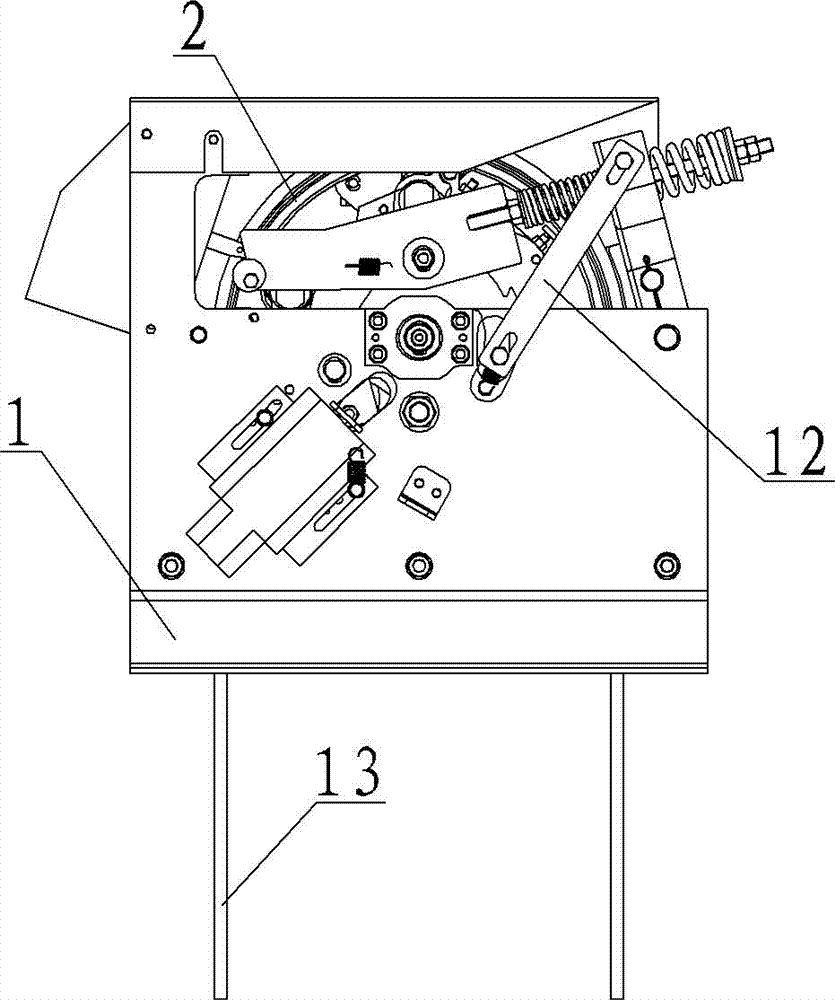

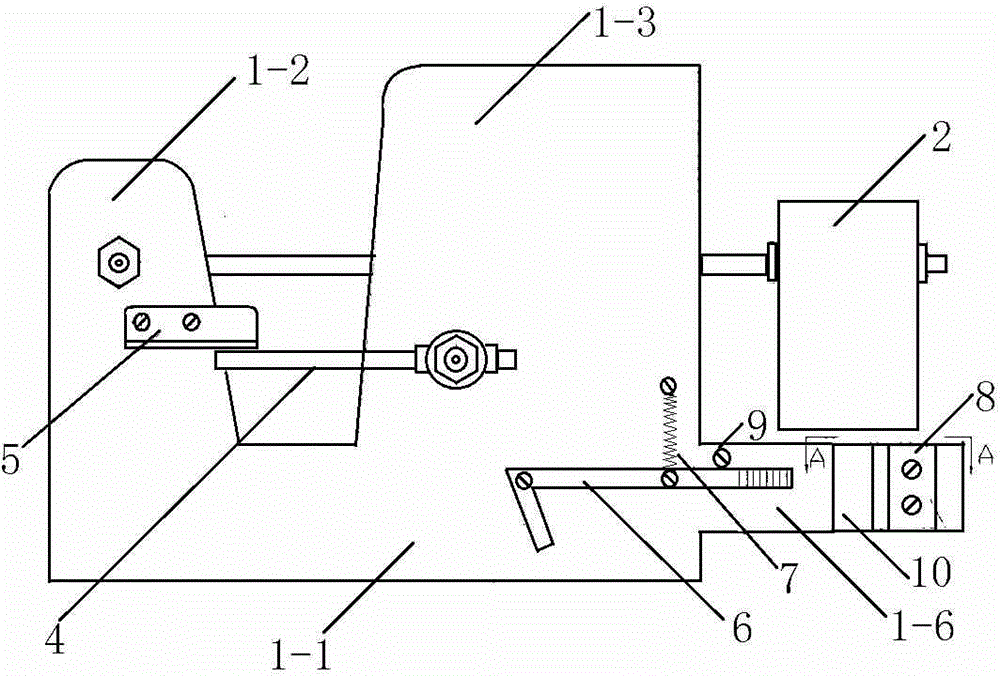

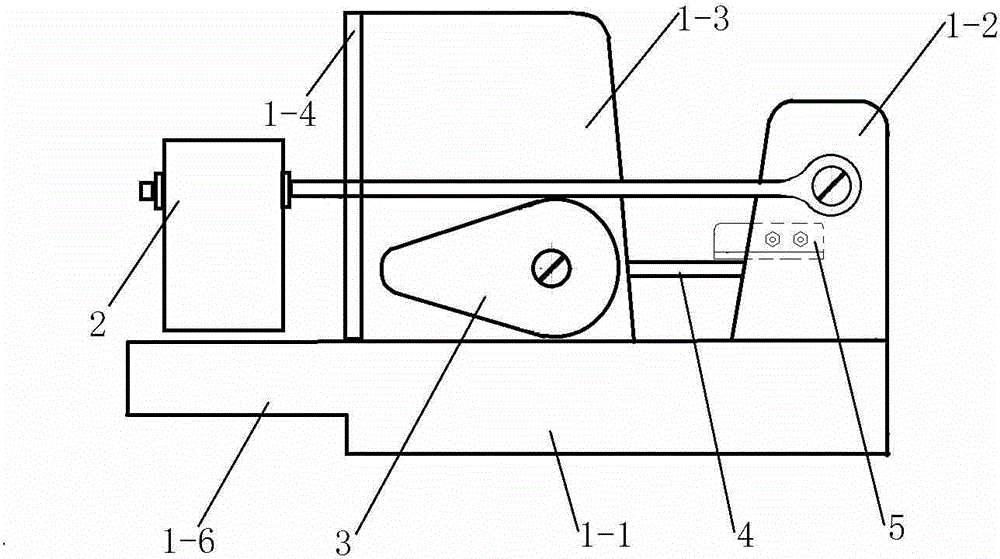

Workbench-type automatic power hammer device and using method thereof

ActiveCN104155076ASolving Consistency IssuesResolution timeMaterial strength using repeated/pulsating forcesShock testingRocker coverContact time

The invention provides a workbench-type automatic power hammer device and a using method thereof, and is suitable for structural mode analysis and vibration shock tests. The workbench-type automatic power hammer device mainly comprises a motor, a base, a stand seat, a positioning gear sleeve rocker, a photoelectric encoder, a movable power hammer clamping clip, a fixed power hammer clamping clip and a power hammer, wherein the motor is fixed at the bottom of the stand seat; the rocker and the stand seat form a specific work angle through a positioning spring and a positioning gear sleeve; the photoelectric encoder is fixed to a rocker cover side at the tail end of the rocker; the power hammer is mounted in a place between the movable power hammer clamping clip and the fixed power hammer clamping clip which are mounted at the tail end of the rocker. A control signal is calculated through input shock speed, distance, shock times and frequency to control the motor to drive the power hammer to hit the surface of a workpiece to be tested according to a set required parameter, so as to realize an excitation test effect. According to the device and the method provided by the invention, the consistency, the repeatability and the regulation performance of the strength and the direction of excitation force can be ensured, so that the contact time, the strength and the shock frequency of the power hammer on the workpiece to be tested can be controlled conveniently, and ideal power pulse can be obtained more easily.

Owner:CHINA UNIV OF MINING & TECH

Needle-less injector and method of fluid delivery

InactiveUS20100168662A1Safe and reliableAvoid accidental dischargeJet injection syringesAutomatic syringesNeedle Free InjectionPlunger

A needle-less injector device for delivering a dose of fluid intradermally, subcutaneously or intramuscularly to an animal or human. The device includes an inner housing having opposed ends. A syringe is disposed in one end of the inner housing. The syringe includes a nozzle for delivering a dose of fluid held within the syringe. A plunger is movably disposed within the syringe. A spring powered hammer is movably disposed within the inner housing. The hammer cooperates with the plunger to drive the dose of medicament from the nozzle. An injection delivery spring for powering the hammer is positioned and compressed between the other end of the inner housing and the spring powered hammer. An outer housing slideably supports the inner housing. A skin tensioning spring is mounted between the inner housing and the outer housing, the skin tensioning spring biasing the nozzle of the syringe against the animal or human. A trigger mechanism is disposed in the outer housing, the trigger mechanism cooperating with the spring powered hammer to release the injection delivery spring, wherein the size of the injection delivery spring and the length of the hammer dictate the amount of dose delivered and whether the dose is delivered intradermally, subcutaneously or intramuscularly to an animal or human.

Owner:PHARMAJET INC

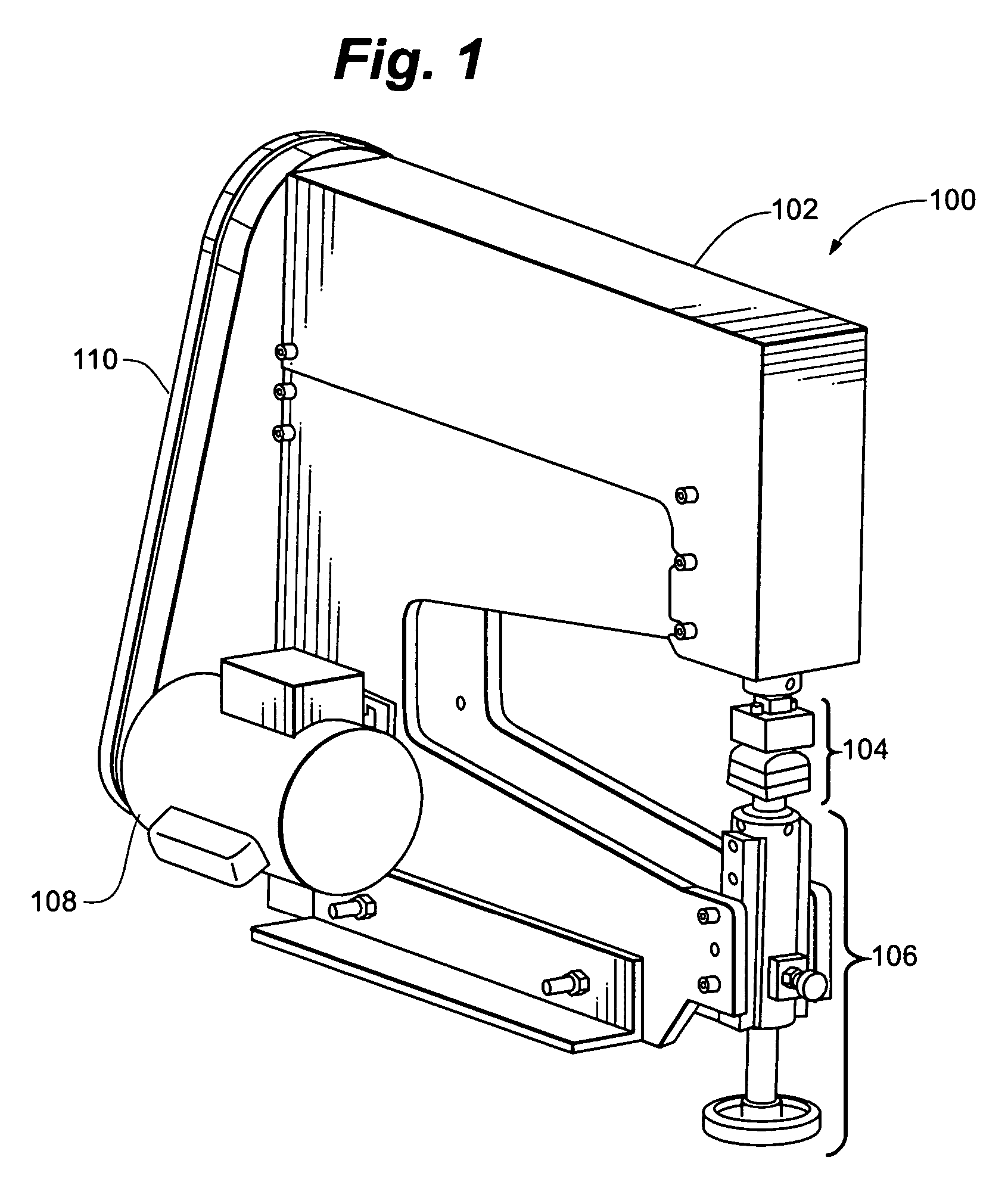

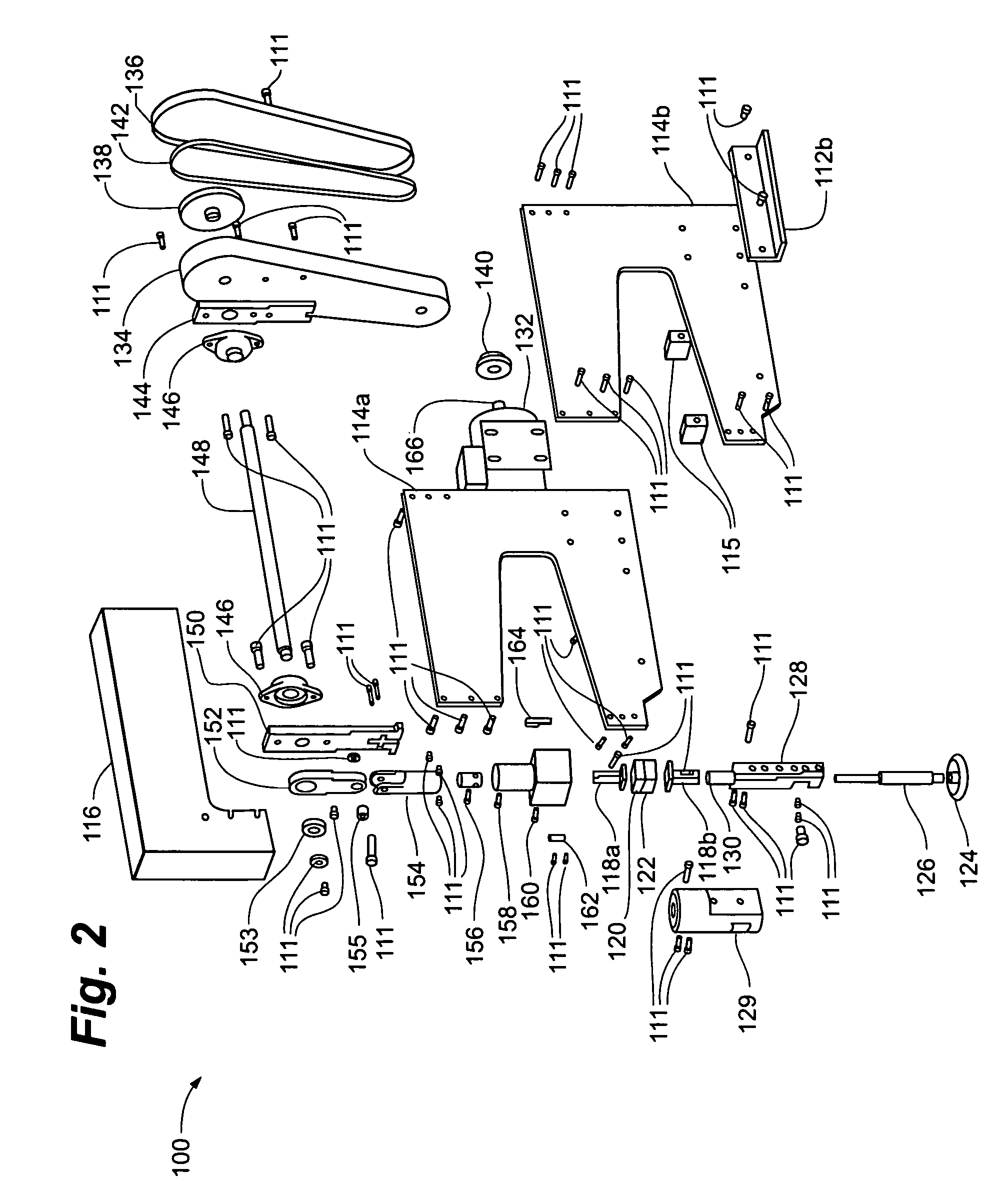

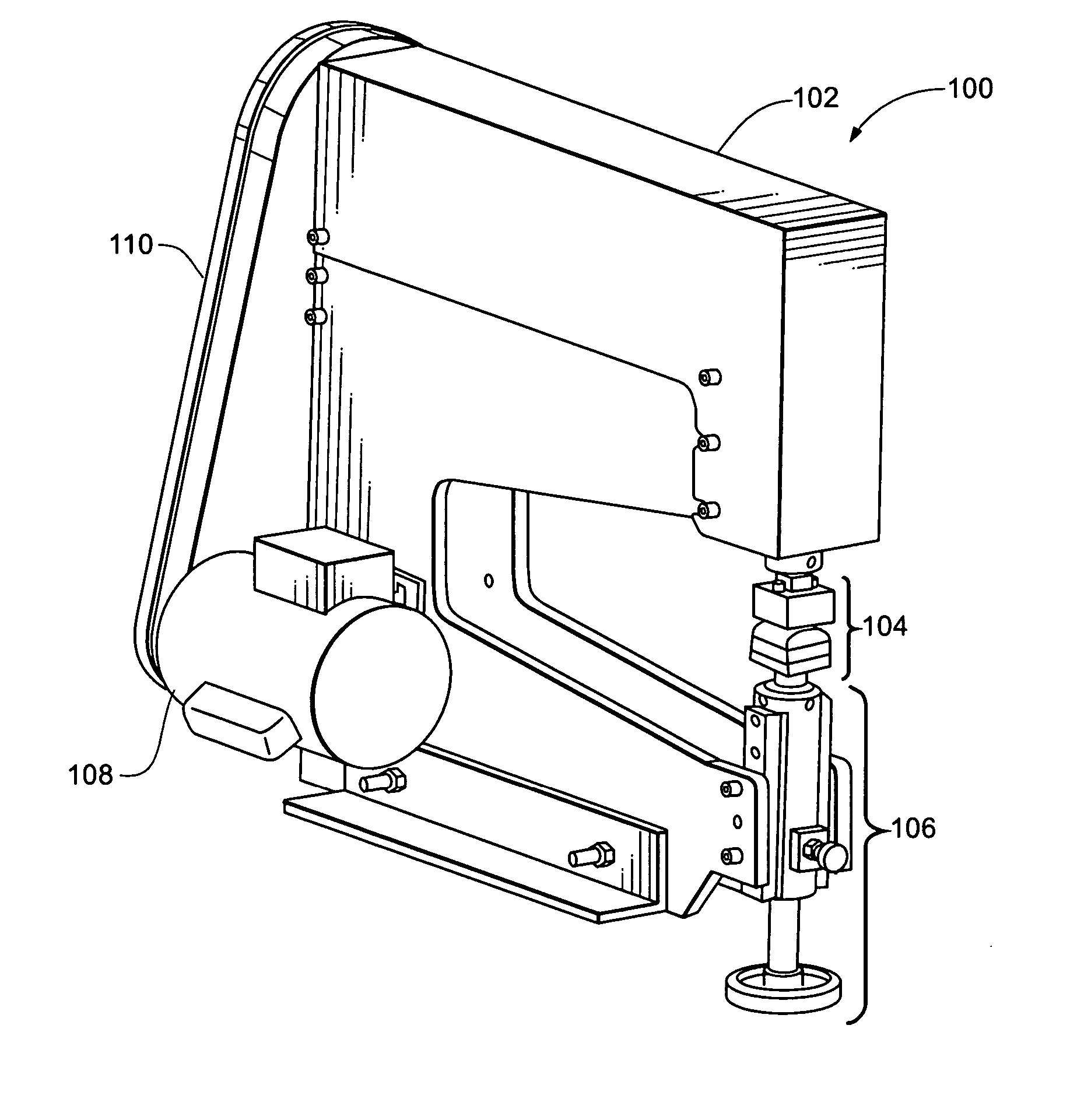

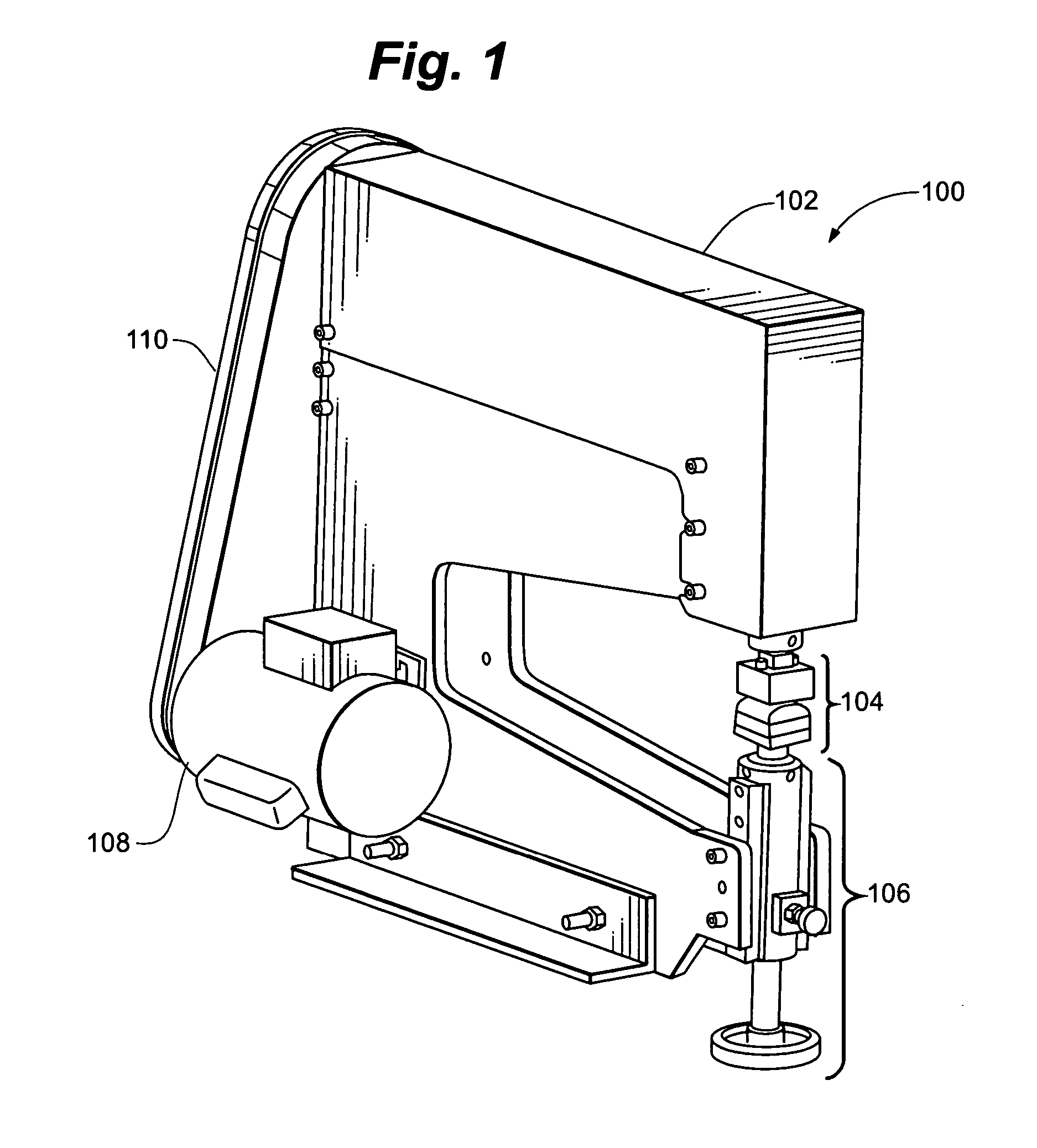

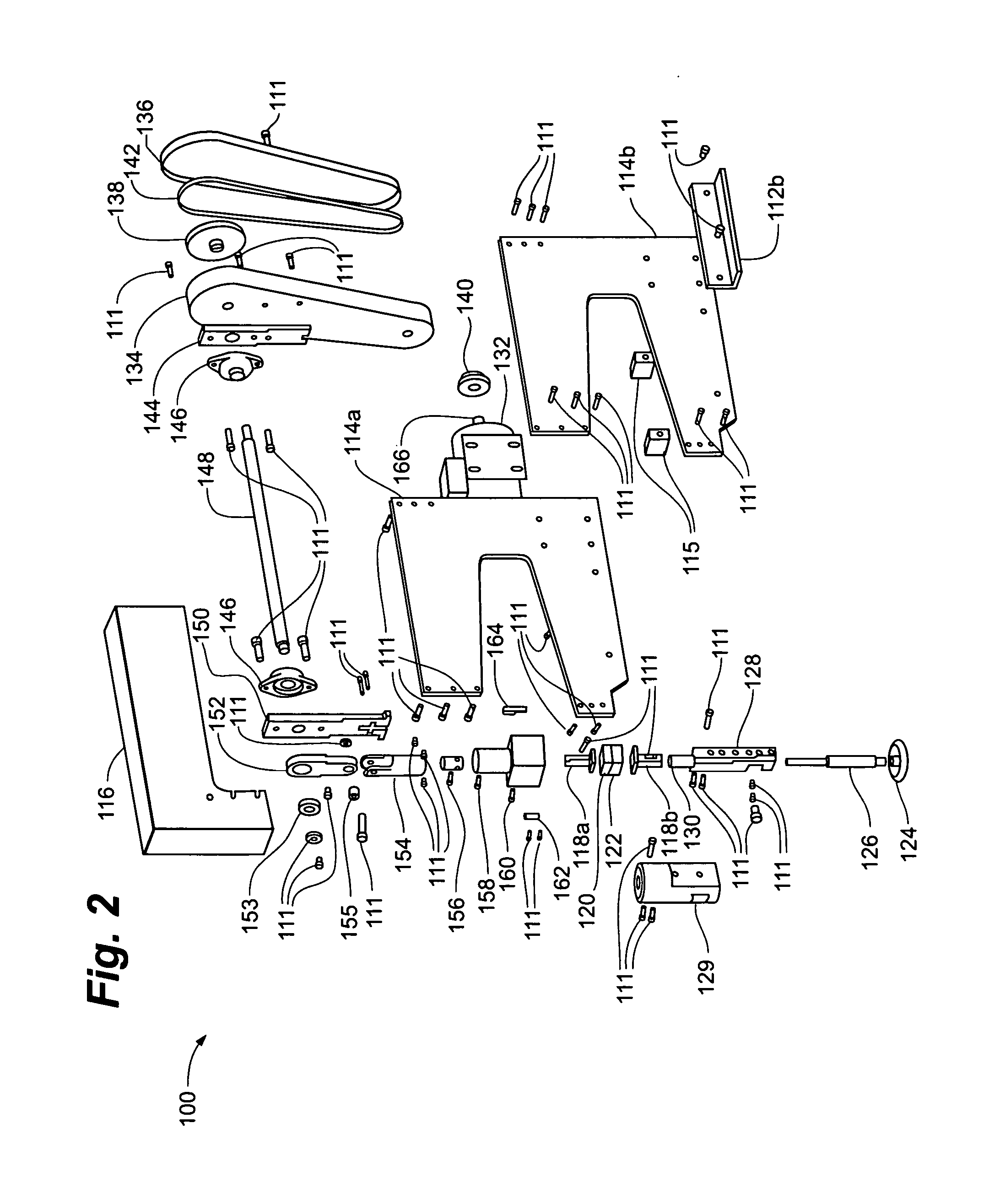

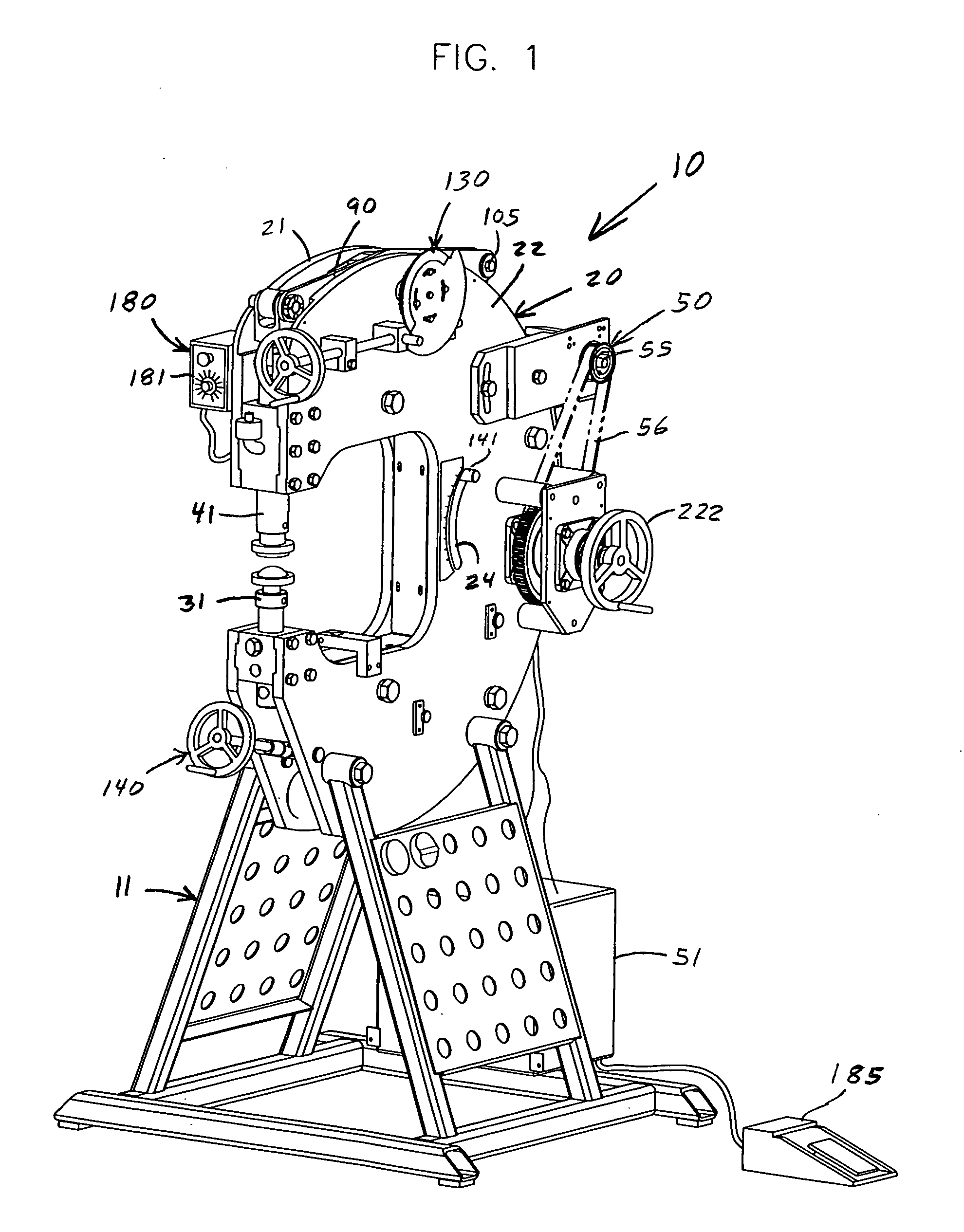

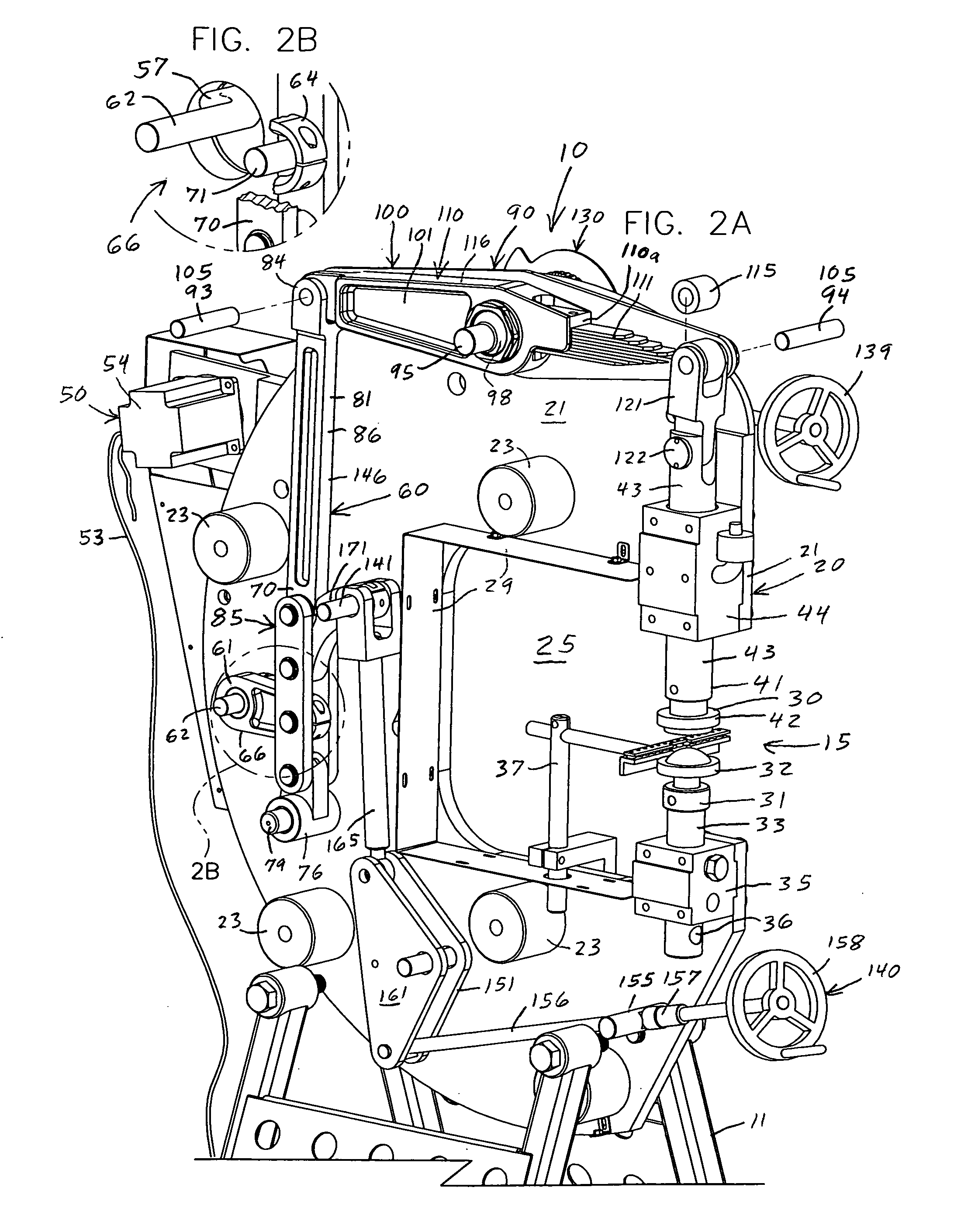

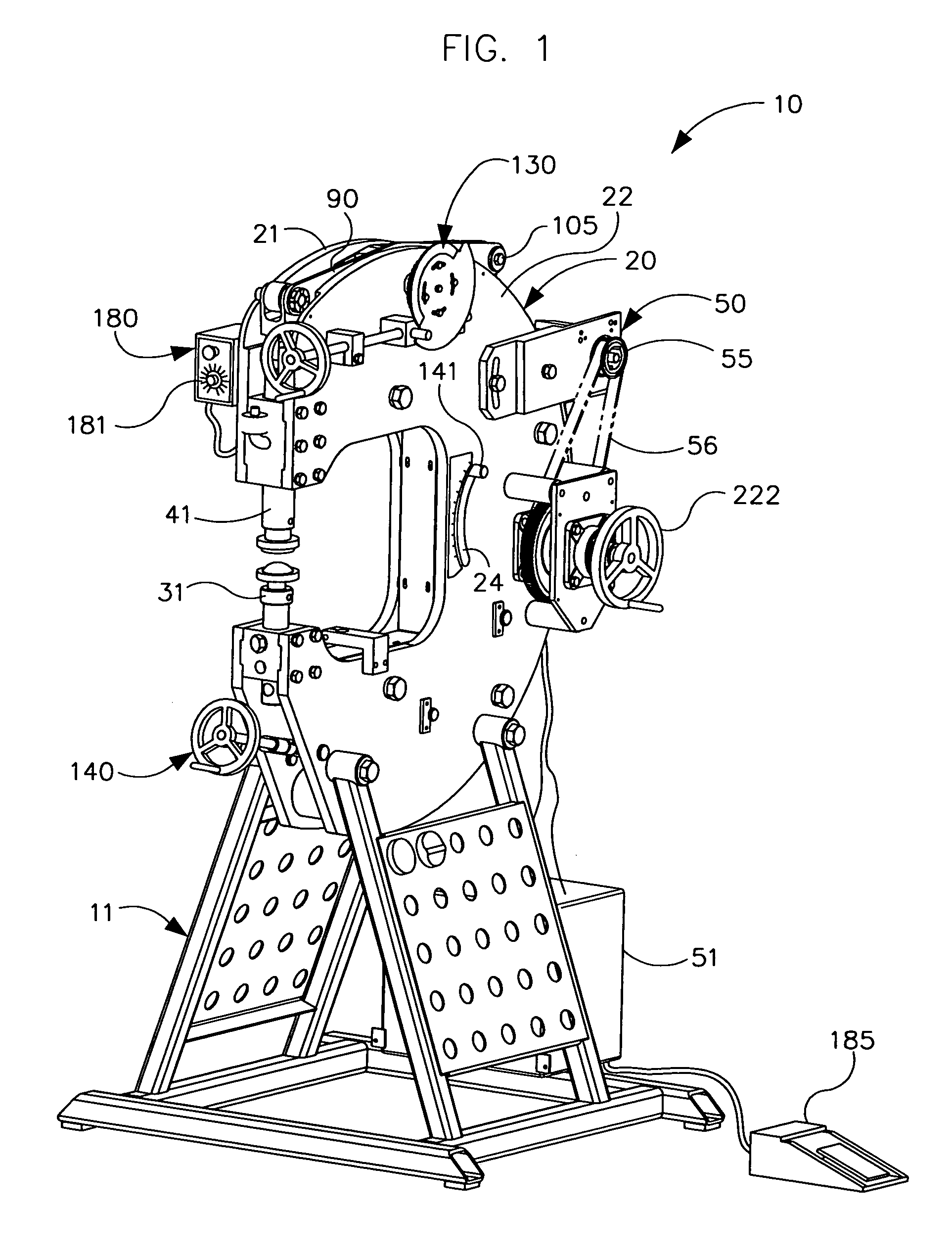

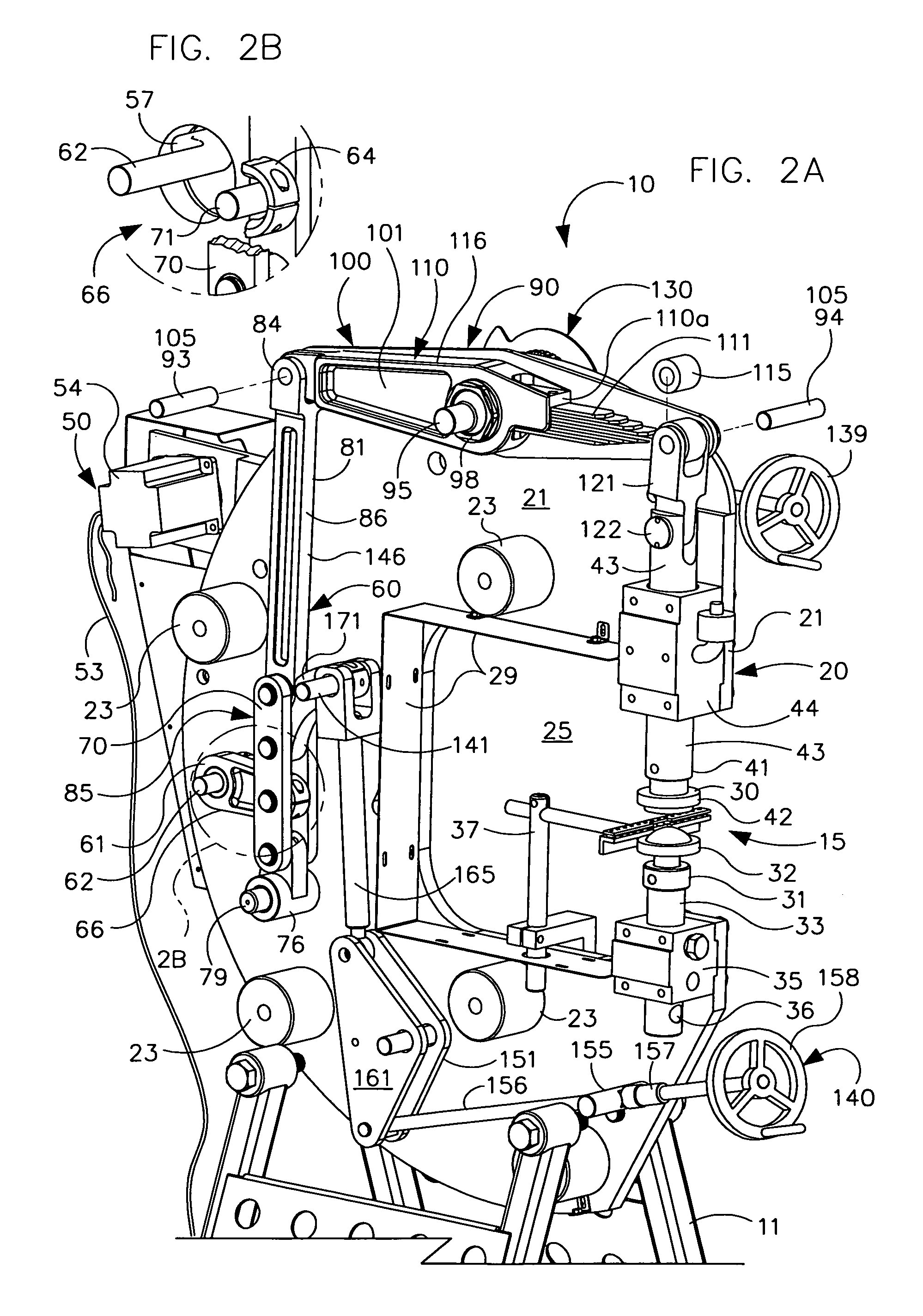

Metal shaping apparatus

A power hammer assembly providing forming capabilities while remaining economical with respect to performance, vibration, footprint size and acquisition costs. The power hammer assembly can provide for a single stroke speed and / or a single set stroke with respect to the striking of die assemblies against a piece of metal. The power hammer assembly can provide for a large throat area and / or a larger die gap for ease of use. The power hammer assembly can include adjustment features allowing for the use of die sets of varying configurations such as, for example, shank size, shank length or alternatively, die sets fabricated for use with other machinery. In addition, the power hammer assembly can include a belt transmission assembly designed to slip in the event of die interference during set-up or operation so as to avoid damaging the power hammer assembly.

Owner:JSJ CORP

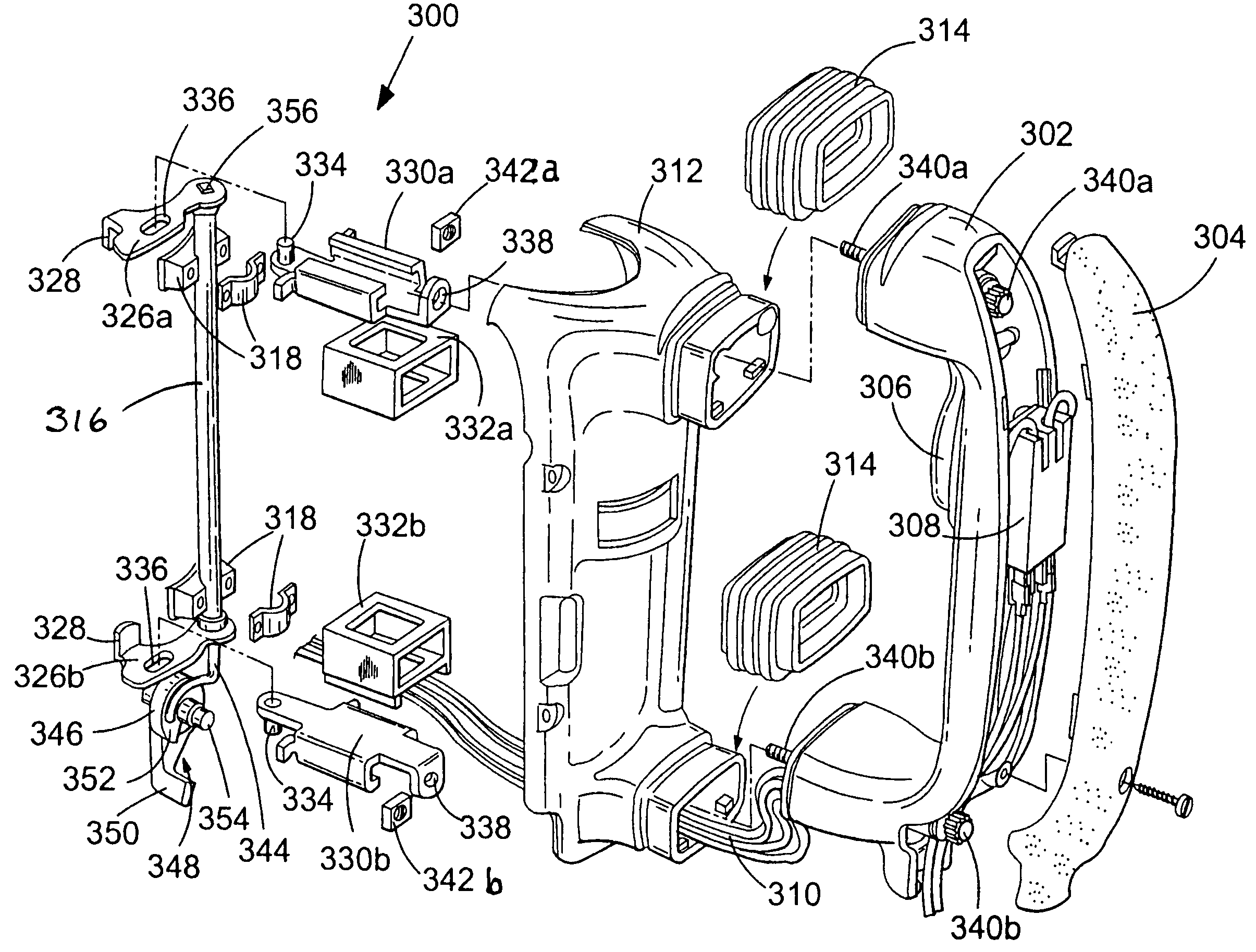

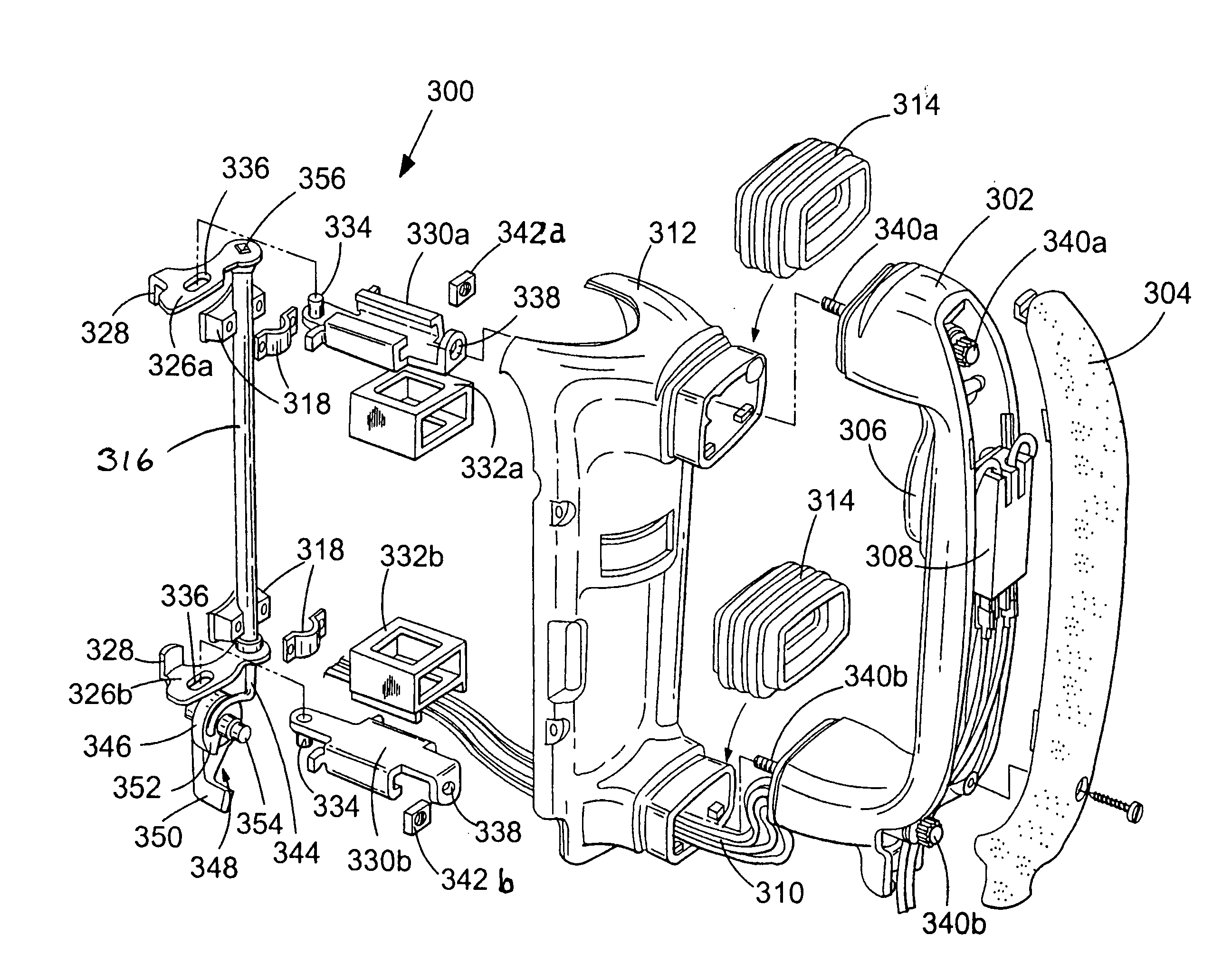

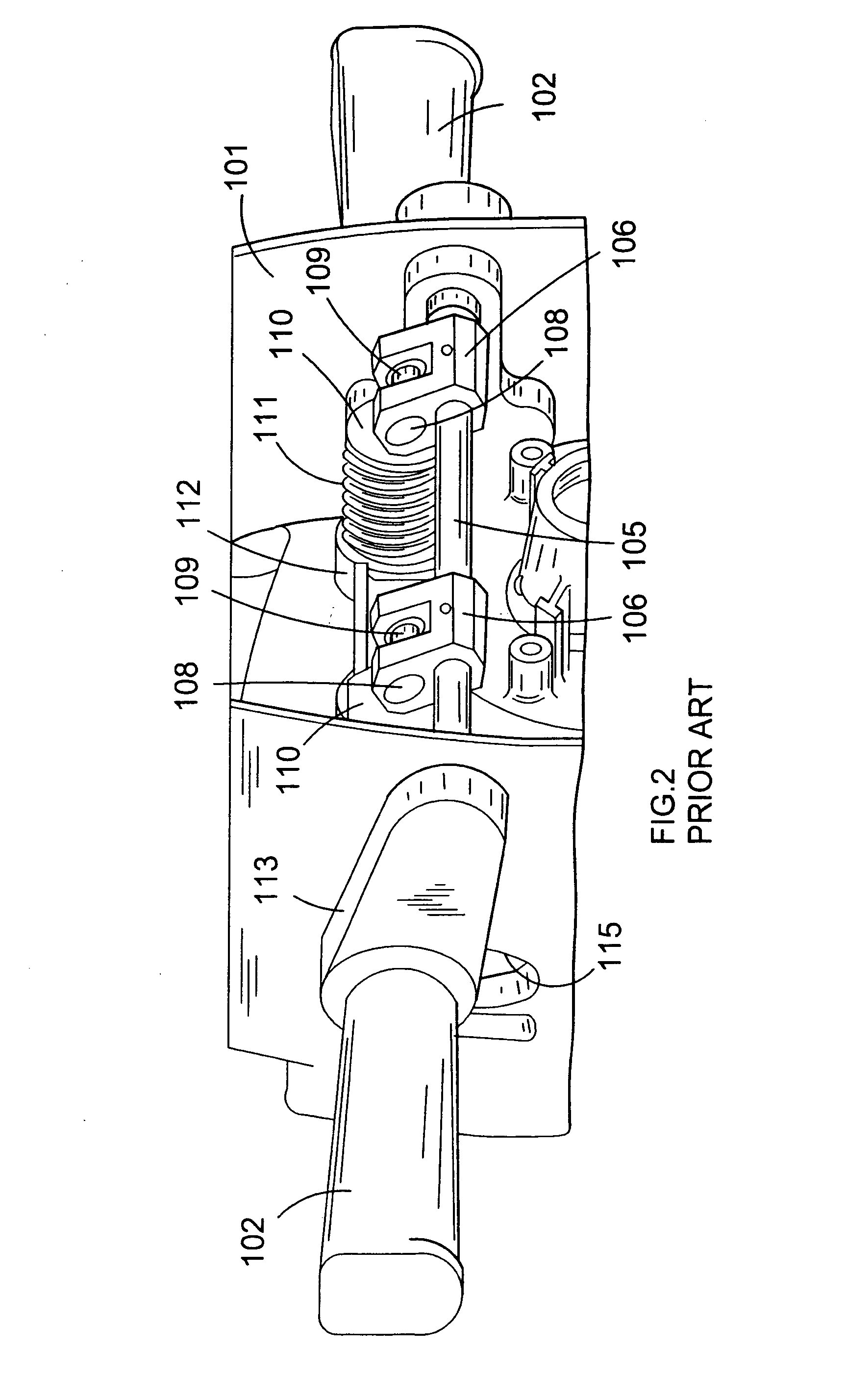

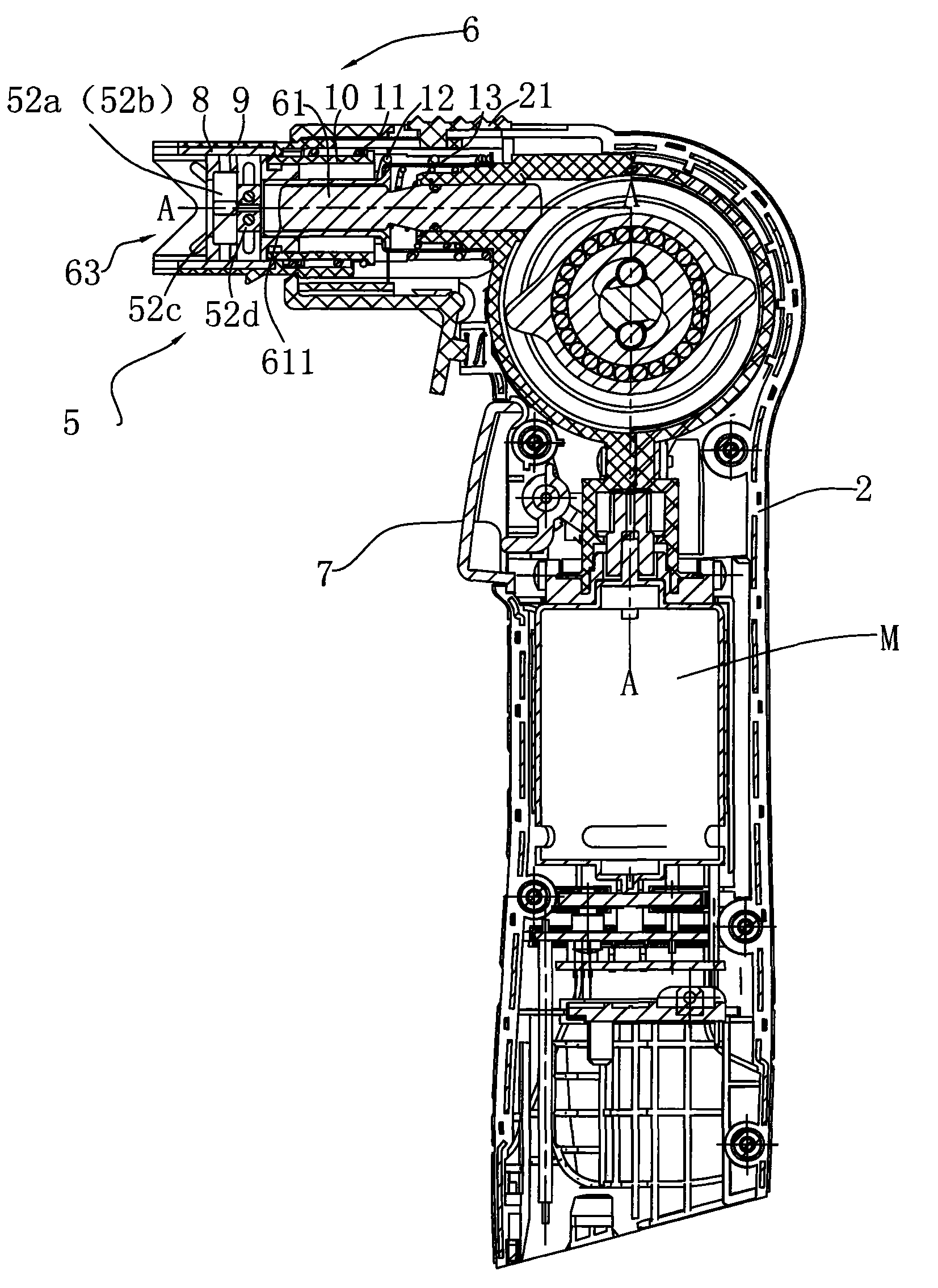

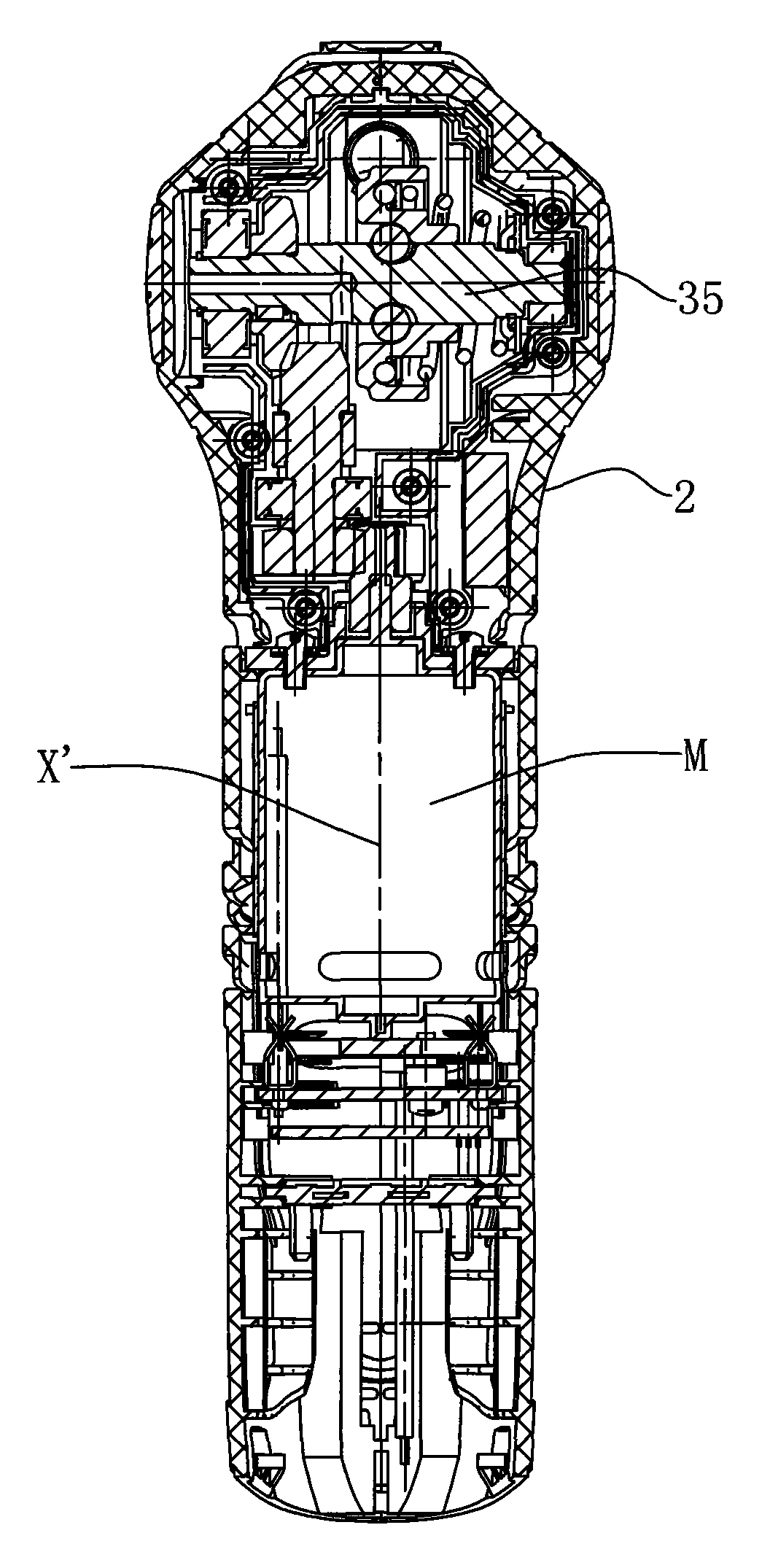

Vibration reduction apparatus for power tool and power tool incorporating such apparatus

InactiveUS7472760B2Weight increaseReduced space requirementsConstructionsReciprocating drilling machinesEngineeringPower tool

A power hammer has a handle mounted to a housing and capable of limited movement relative thereto. A hollow axle is attached to the housing and is rotatable between a first and second position and is biased towards the first position by a torsional spring which extends within the axle. Rotation of the axle causes rotation of arms connected thereto. Connectors are slidably mounted within guides and are respectively connected at one end to each of the arms and at the other end to the handle. Vibrations in the housing cause movement of one end of the handle, which causes movement of the associated connector and arm. Movement of the one arm causes rotation of the axle, which therefore causes movement of the other arm and connector, and the other end of the handle. Thus, the movement of one end of the handle is coupled to the other end.

Owner:BLACK & DECKER INC

Method for quickly detecting quality of gravel pile

InactiveCN101922159AImprove test efficiencyEasy to operateFoundation testingSoil preservationPunchingCrushed stone

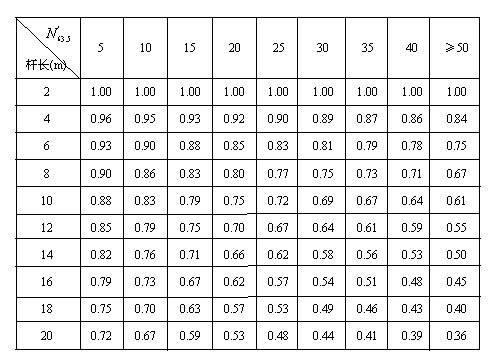

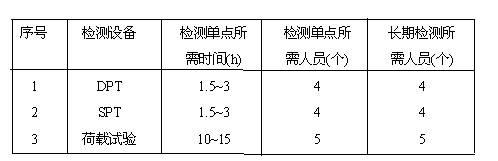

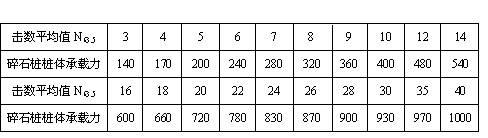

The invention relates to a method for quickly detecting the quality of a gravel pile, which comprises the following steps: the process for carrying out a heavy dynamic penetration test (DPT) on a pile body comprises the following steps: in the heavy dynamic penetration test, by using a power hammer of which the weight is 63.5kg and the drop height is 76cm and using a cone head as a penetration head, carrying out continuous heavy dynamic penetration tests along the depth direction of the pile body, recording the actually measured hammering number when the pile body is penetrated for every 10cm, correcting the hammering number, and then, determining the bearing capacity (kPa) of the foundation according to the corrected heavy cone dynamic penetration hammering number N63.5; and the process for carrying out a standard penetration test (SPT) comprises the following steps: by using a punching hammer of which the weight is 63.5kg and the drop height is 76cm, punching a standard penetrometer into the soil for 15cm and then for 30cm, utilizing the hammering number for last 30cm as a standard penetration test index, and then, computing the bearing capacity of the foundation after correcting the hammering number according to the corrected heavy cone dynamic penetration hammering number N63.5.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD

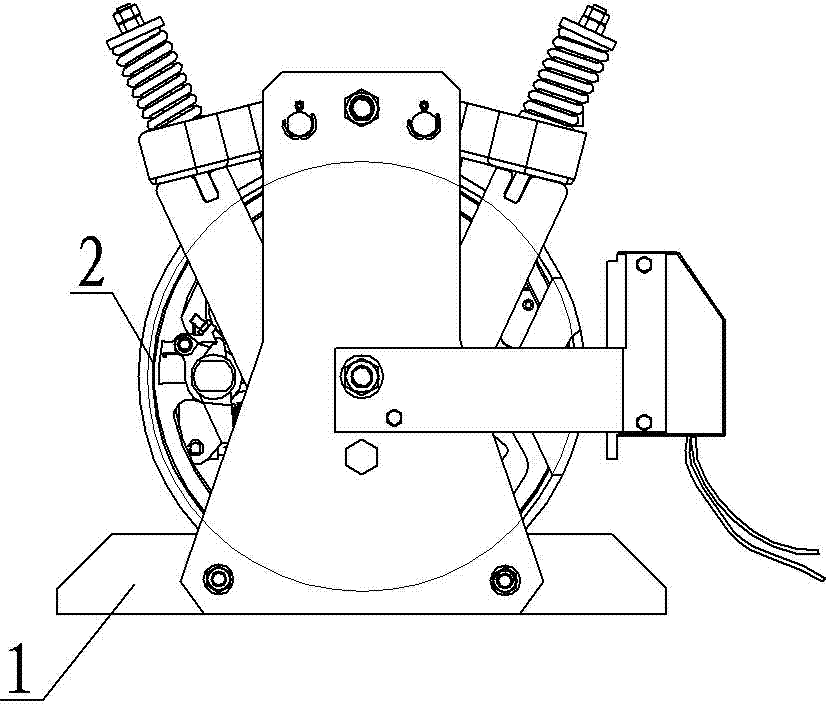

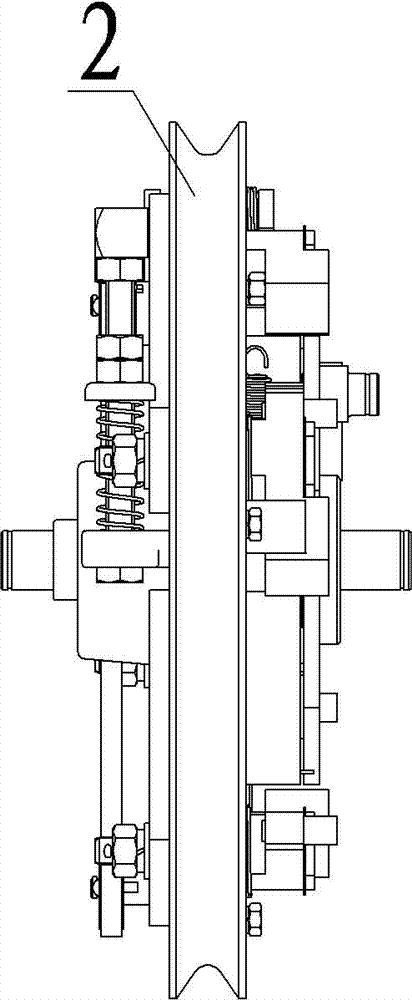

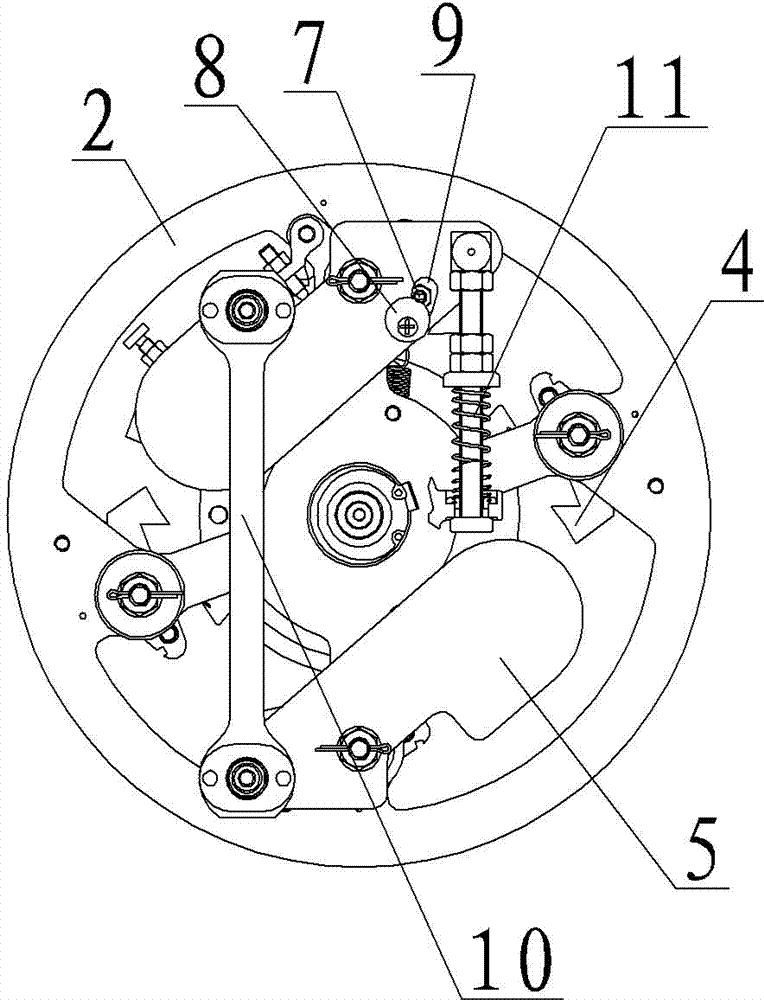

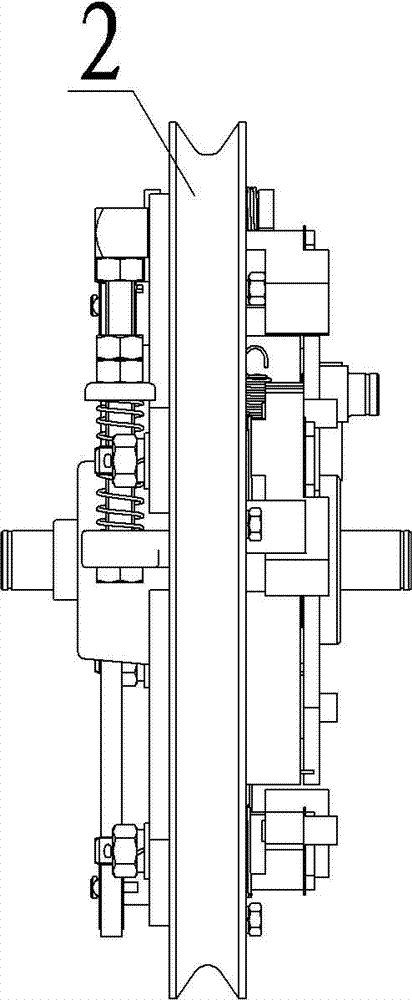

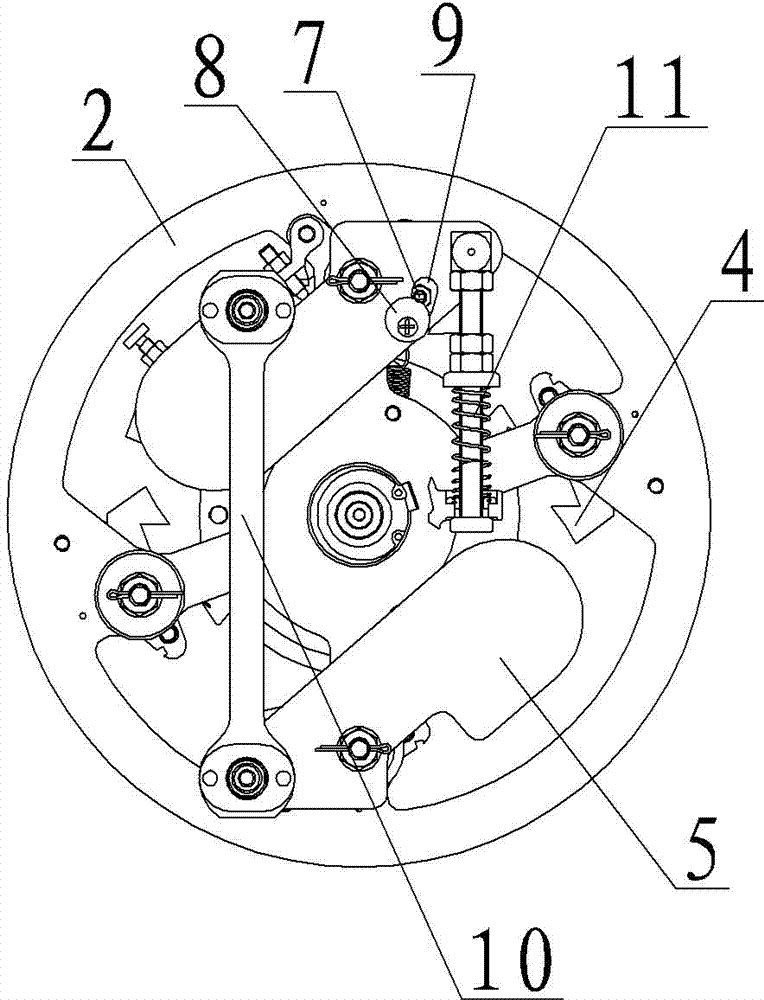

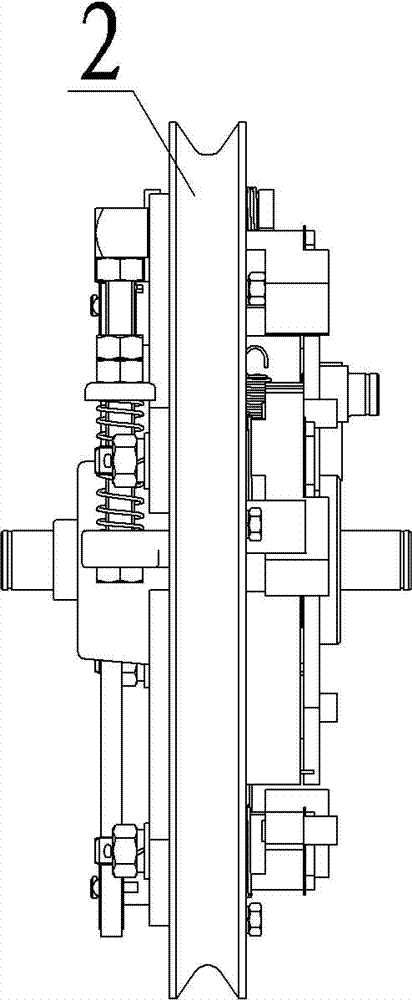

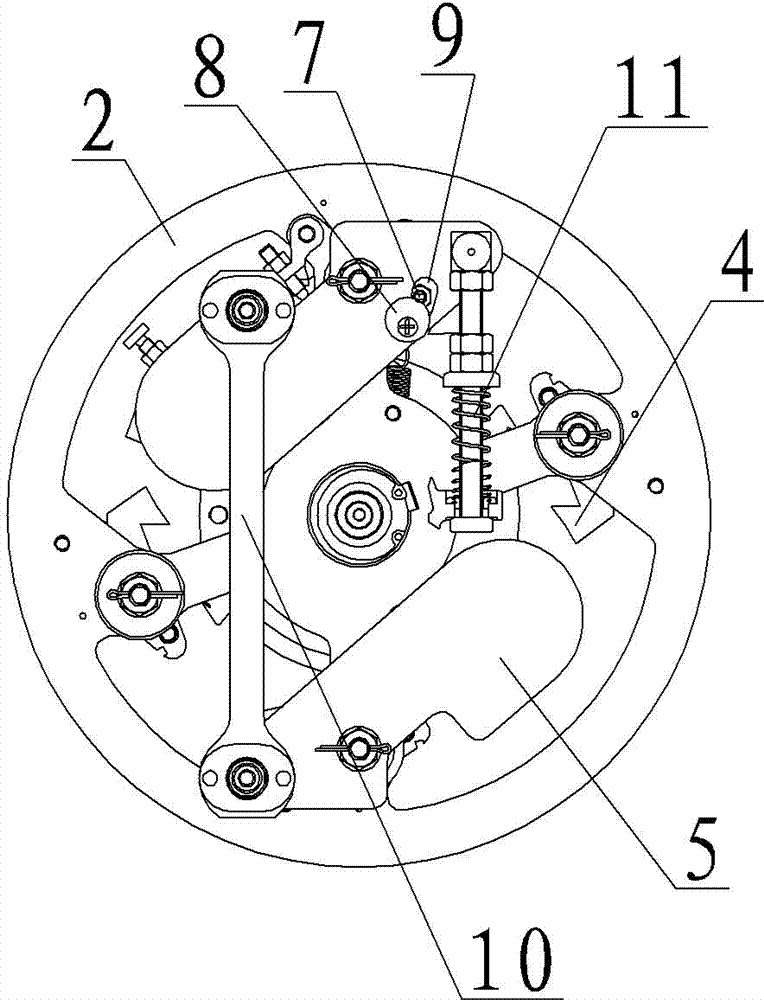

Bidirectional overspeed governor provided with automatic anti-slip function and used on elevator without machine room

The invention discloses a bidirectional overspeed governor provided with an automatic anti-slip function and used on an elevator without a machine room. The main shaft of the overspeed governor is rotationally arranged on a base; a rope sheave and a ratchet wheel are mounted on the main shaft in a splined manner; an encoder is mounted on the main shaft; a pawl is rotationally mounted on one side of one surface of the rope sheave; a pawl torsional spring is arranged between the pawl and the rope sheave, and can enable the pawl to turn to the ratchet wheel and be clamped in the clamping groove of the ratchet wheel; a pawl positioning structure is rotationally mounted on the surface of the rope sheave; the jacking end of the pawl positioning structure is in elastic and jacking fit with the pawl; two gravity hammers are rotationally mounted on another side of the surface of the rope sheave; a raised jacking head is arranged at the trigger part of the pawl positioning structure and can coordinate with the power hammers (i.e. the gravity hammers) in a pushing and pressing manner when the hammerheads of the gravity hammers are turned to the outer edge of the rope sheave; a raised lifting release link is arranged on the pawl; the encoder is in transmission connection with a master elevator control system; the master elevator control system is in control connection with an electromagnet. According to the invention, the pawl and the pawl positioning structure do not need manual reset, and the bidirectional overspeed governor can be used in an elevator without machine room.

Owner:XJ SCHINDLER XUCHANG ELEVATOR

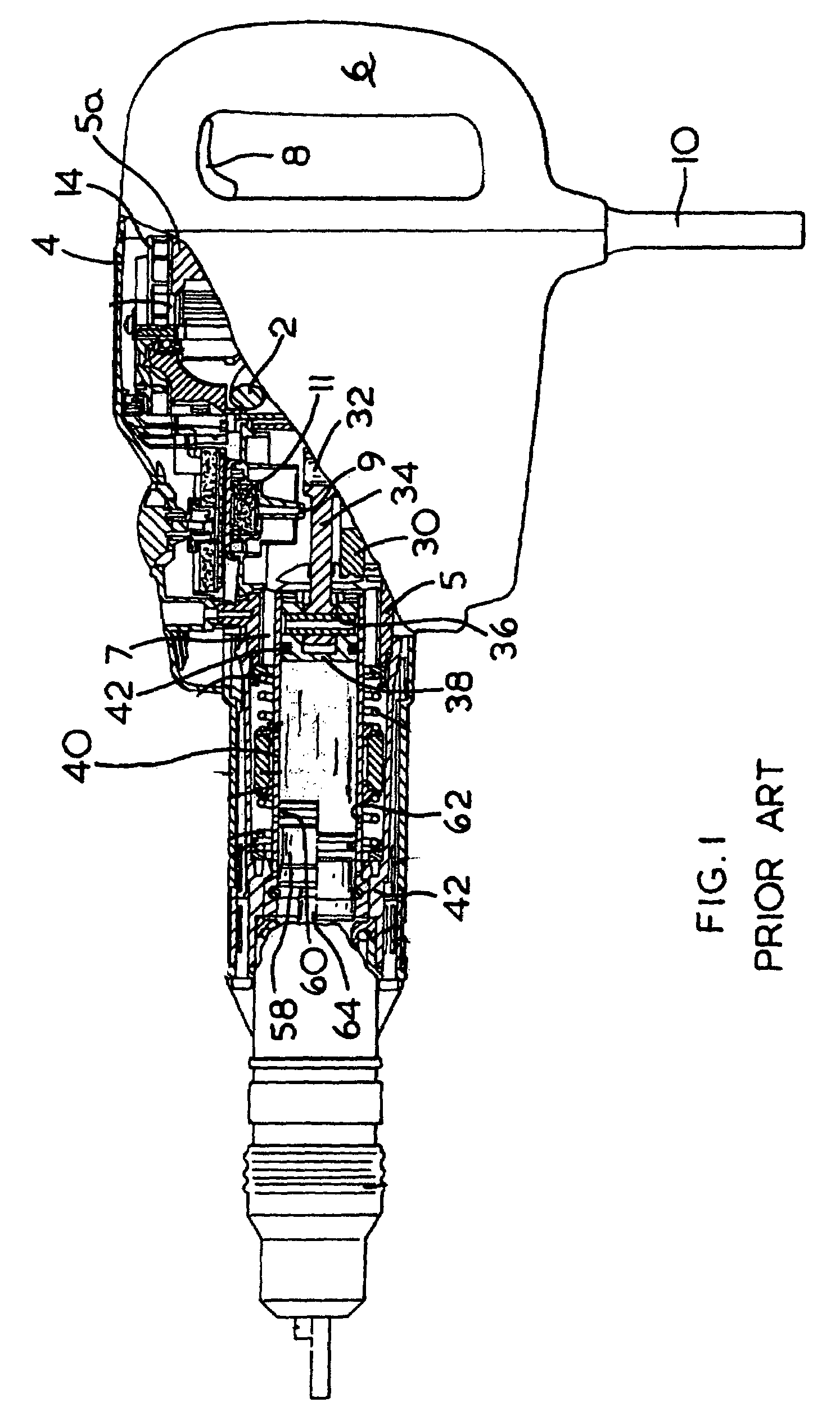

Powered hammer device

InactiveUS20050254904A1Long working timeWear minimizationReciprocating drilling machinesPortable percussive toolsEngineeringCanis lupus familiaris

Owner:TERMINATOR IP II

Metal shaping apparatus

A power hammer assembly providing forming capabilities while remaining economical with respect to performance, vibration, footprint size and acquisition costs. The power hammer assembly can provide for a single stroke speed and / or a single set stroke with respect to the striking of die assemblies against a piece of metal. The power hammer assembly can provide for a large throat area and / or a larger die gap for ease of use. The power hammer assembly can include adjustment features allowing for the use of die sets of varying configurations such as, for example, shank size, shank length or alternatively, die sets fabricated for use with other machinery. In addition, the power hammer assembly can include a belt transmission assembly designed to slip in the event of die interference during set-up or operation so as to avoid damaging the power hammer assembly.

Owner:JSJ CORP

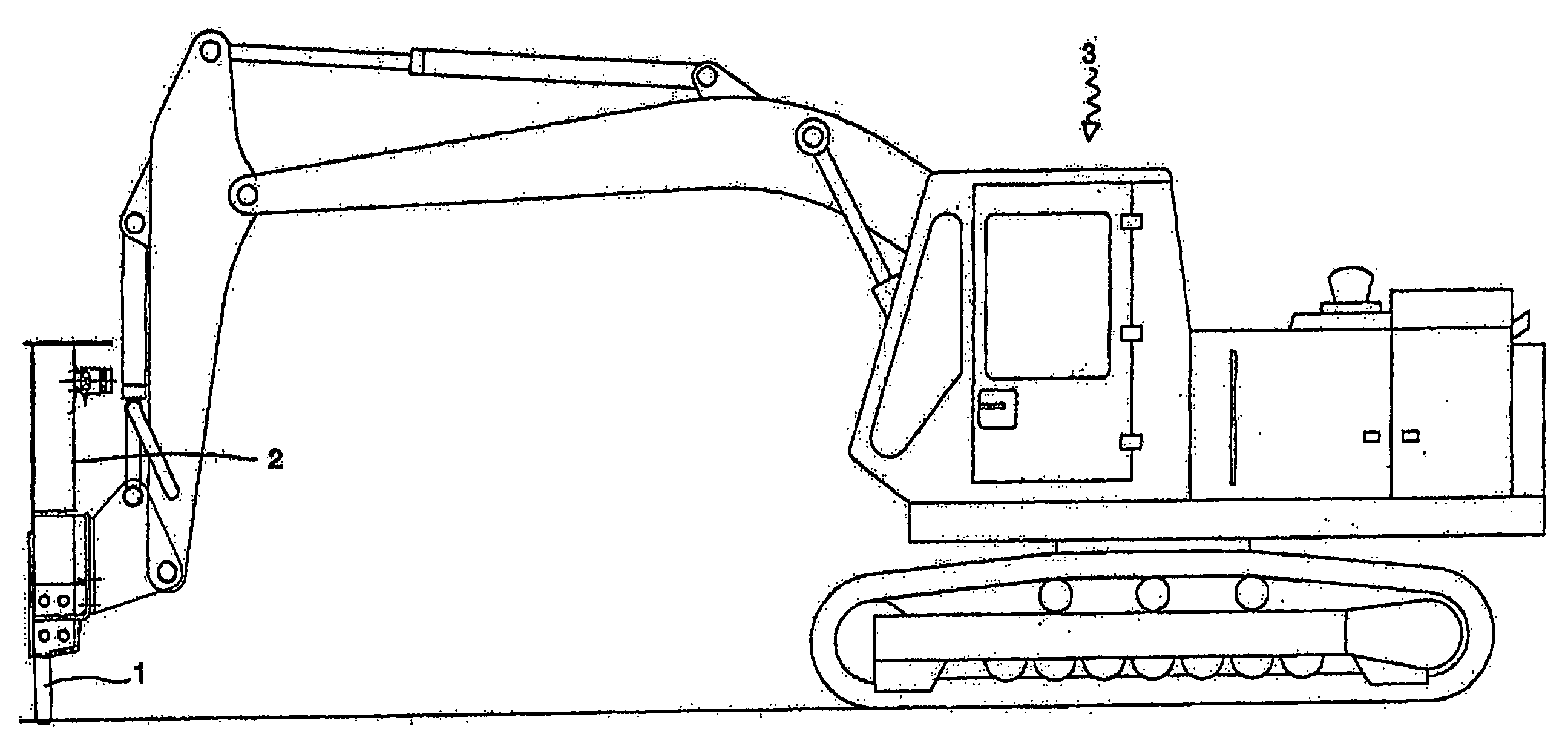

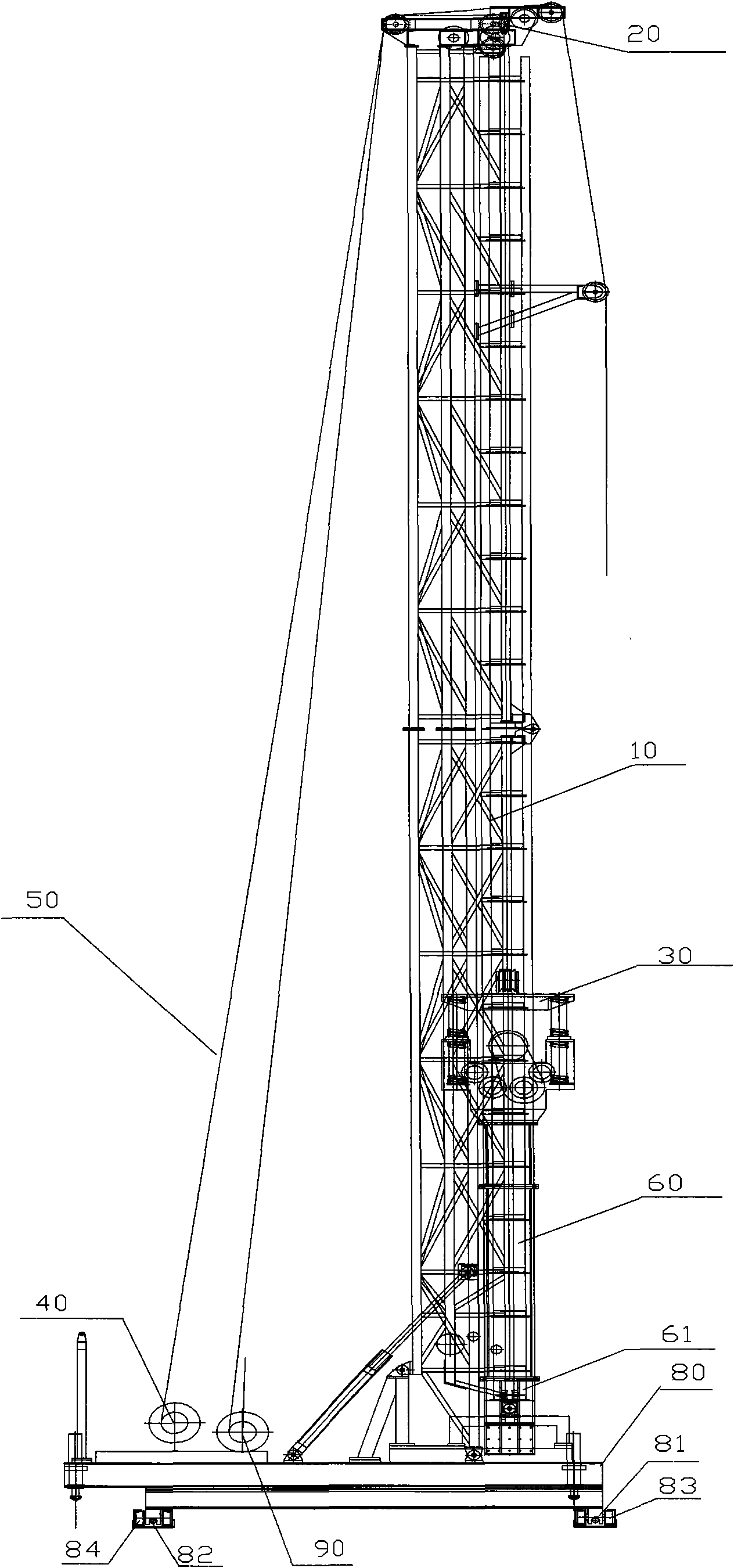

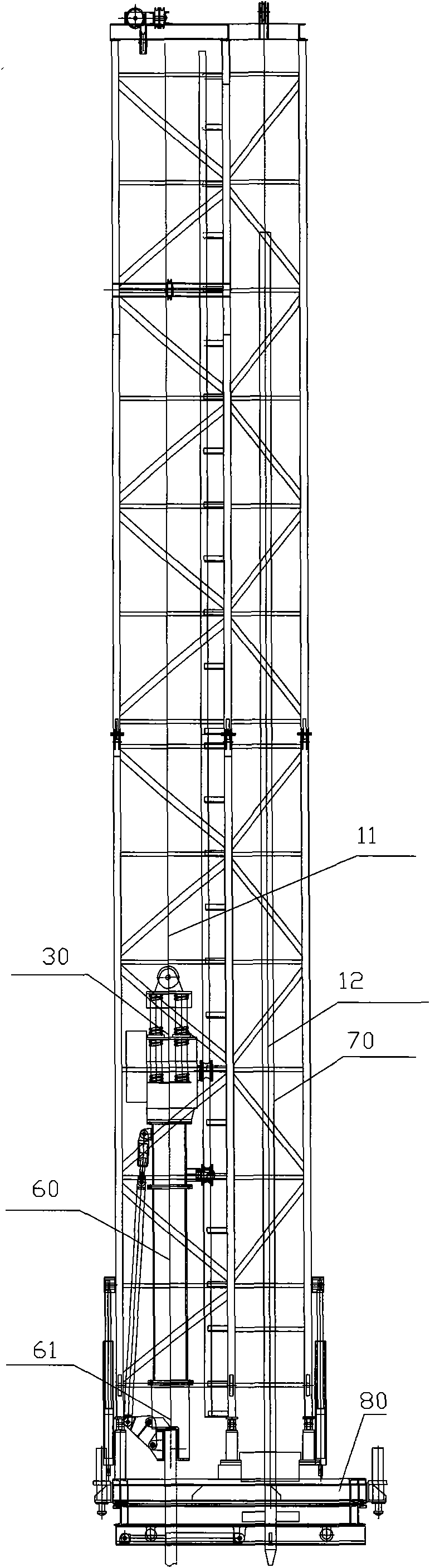

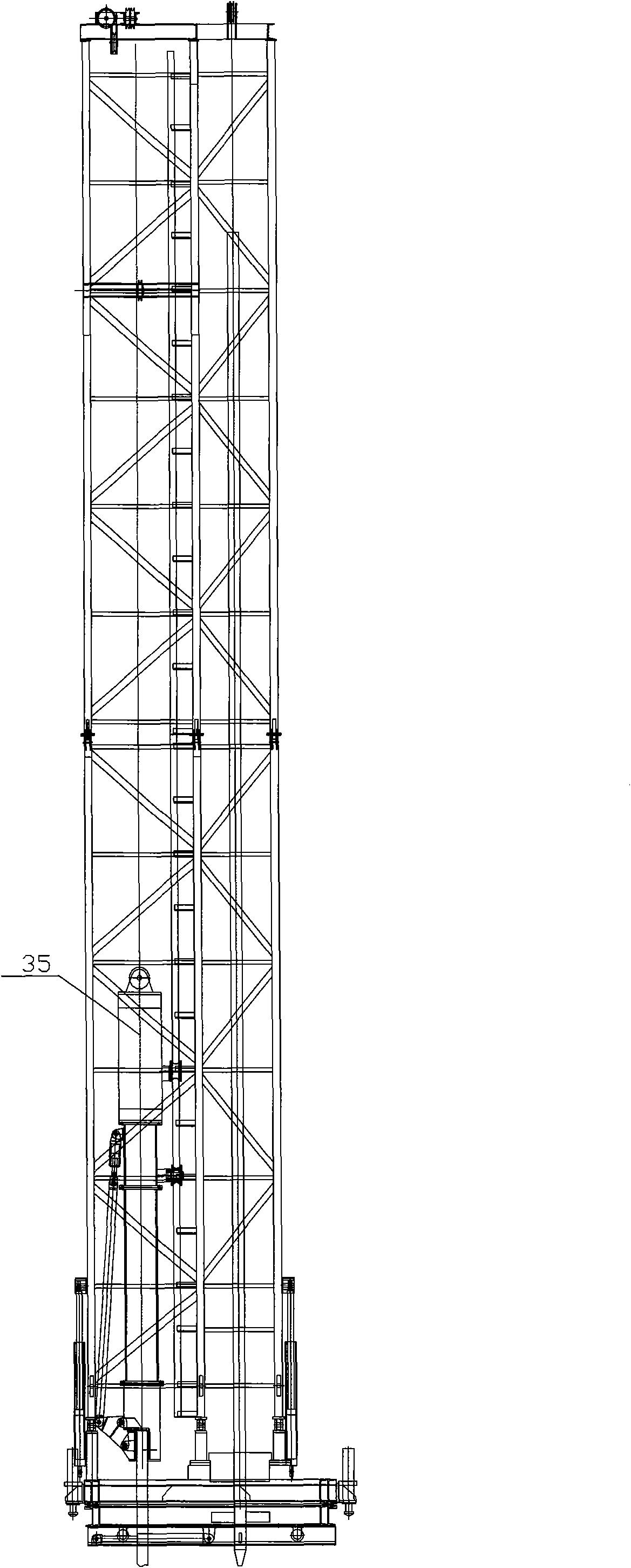

Drop hammer type pile sinking device and pile sinking method thereof

The invention discloses a drop hammer type pile sinking device, which comprises drop hammer guide frames and a sunken pile supporting frame, wherein the drop hammer guide frames are hoisted by a hoister; the top of an engineering pile is supported in a lower engineering pile supporting seat of each drop hammer guide frame; the sunken pile supporting frame comprises a plurality of steel tube piles; a polygonal section steel framework is fixedly connected with the steel tube piles; a plurality of guide frames are arranged on the polygonal section steel framework; and a plurality of engineering piles to be sunken are arranged in the guide frames. The invention also discloses a pile sinking method, which comprises the following steps of: 1) welding the polygonal section steel framework to the steel tube piles of the sunken pile supporting frame, and arranging a plurality of guide frames; and 2) respectively inserting a plurality of engineering piles into the corresponding guide frames, pressing the piles through the gravities of heads of power hammers or continuously hammering the tops of the engineering piles, and gradually finishing sinking the engineering piles one by one. The device has a simple structure and is convenient to manufacture and construct. The pile sinking method is low in cost and high in construction quality. The engineering piles are precisely positioned, and the construction efficiency is improved greatly.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 3RD ENG

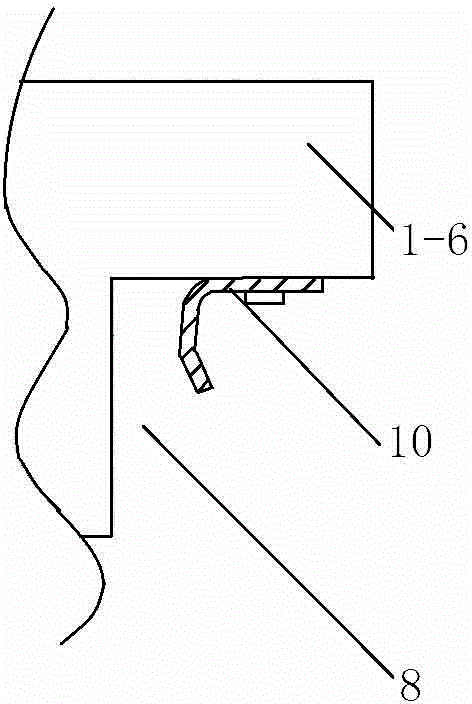

High-frequency hydraulic power head and soil restoration sampling drilling machine using power head

The invention provides a high-frequency hydraulic power head and a soil restoration sampling drilling machine using the power head. The high-frequency hydraulic power head comprises a support frame, a power head transmission box, a hydraulic power hammer and a transmission shaft, wherein the power head transmission box, the hydraulic power hammer and the transmission shaft are arranged on the support frame; the hydraulic power hammer is arranged above the power head transmission box; the transmission shaft is arranged inside the power head transmission box; the lower end of the transmission shaft is connected with a drill rod; the power head transmission box comprises an upper support frame, a box body, a pipe lifting assembly, a pipe pulling mechanism, a support plate assembly, a lower support frame, a bearing and a sealing sleeve. The high-frequency hydraulic power head has the advantages that the design is reasonable; the structure is compact; through the reasonable parameter matching, the unique hydraulic impact hammer is designed; the problem of poor quality of the original soil sampling drilling machine sample is solved; through the special transmission shaft, the working problems of high frequency impact and rotary recombination are solved; the power head transmission box structure is ingeniously matched with the transmission shaft, so that the optimization problem of a thrust conduction route and a stress structure during the drill rod being pressed under impact is solved.

Owner:南京贻润环境科技有限公司

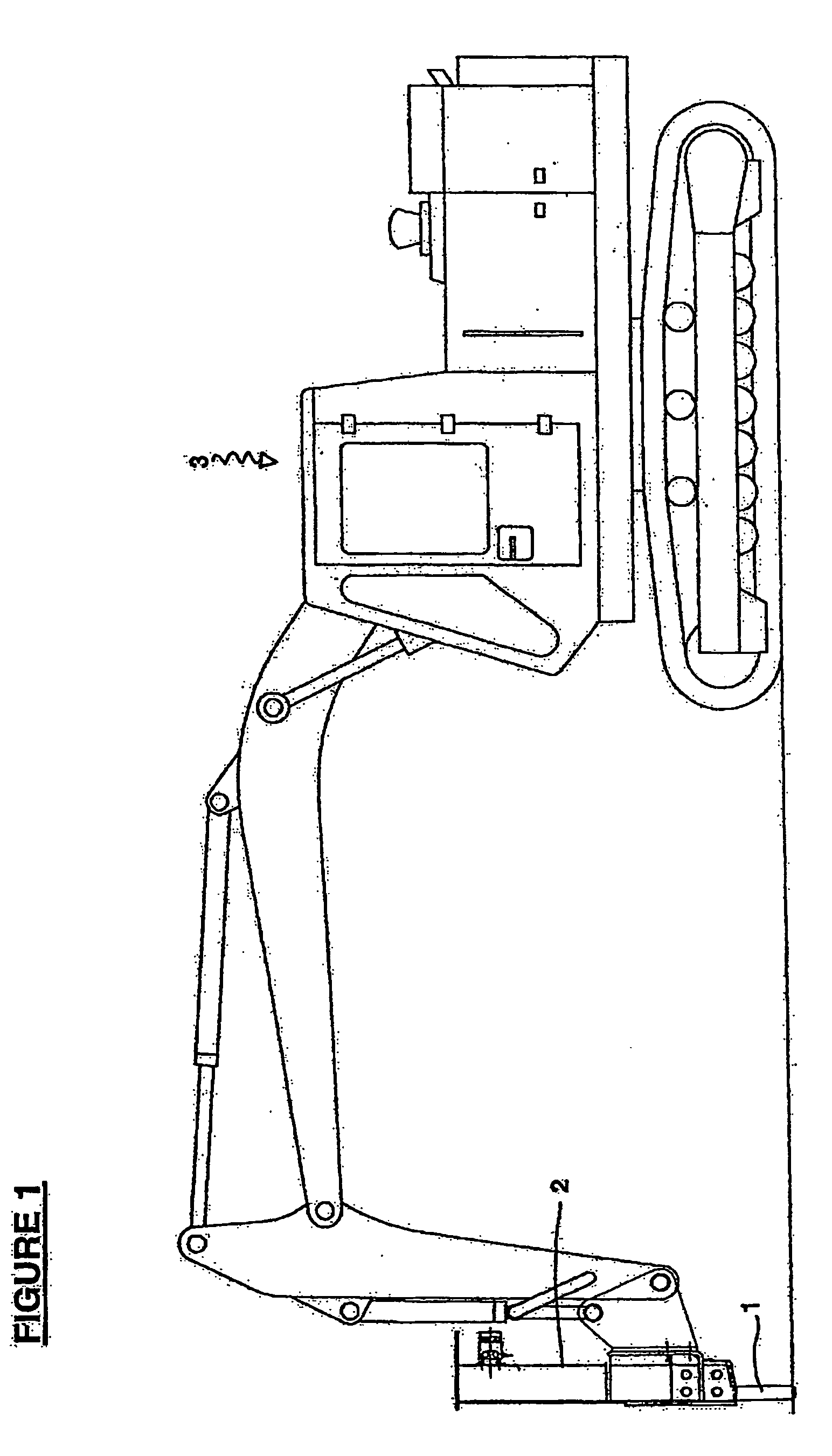

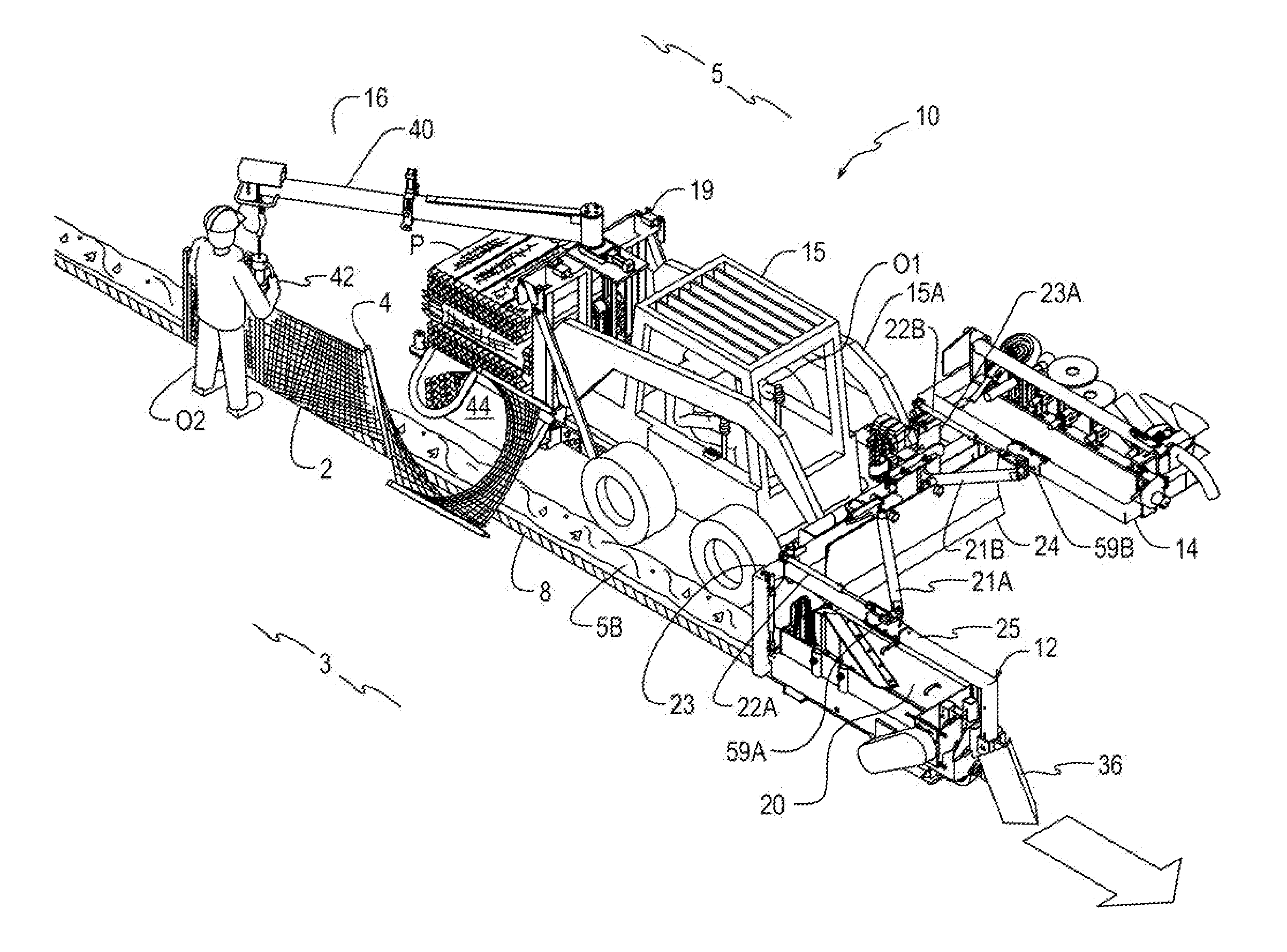

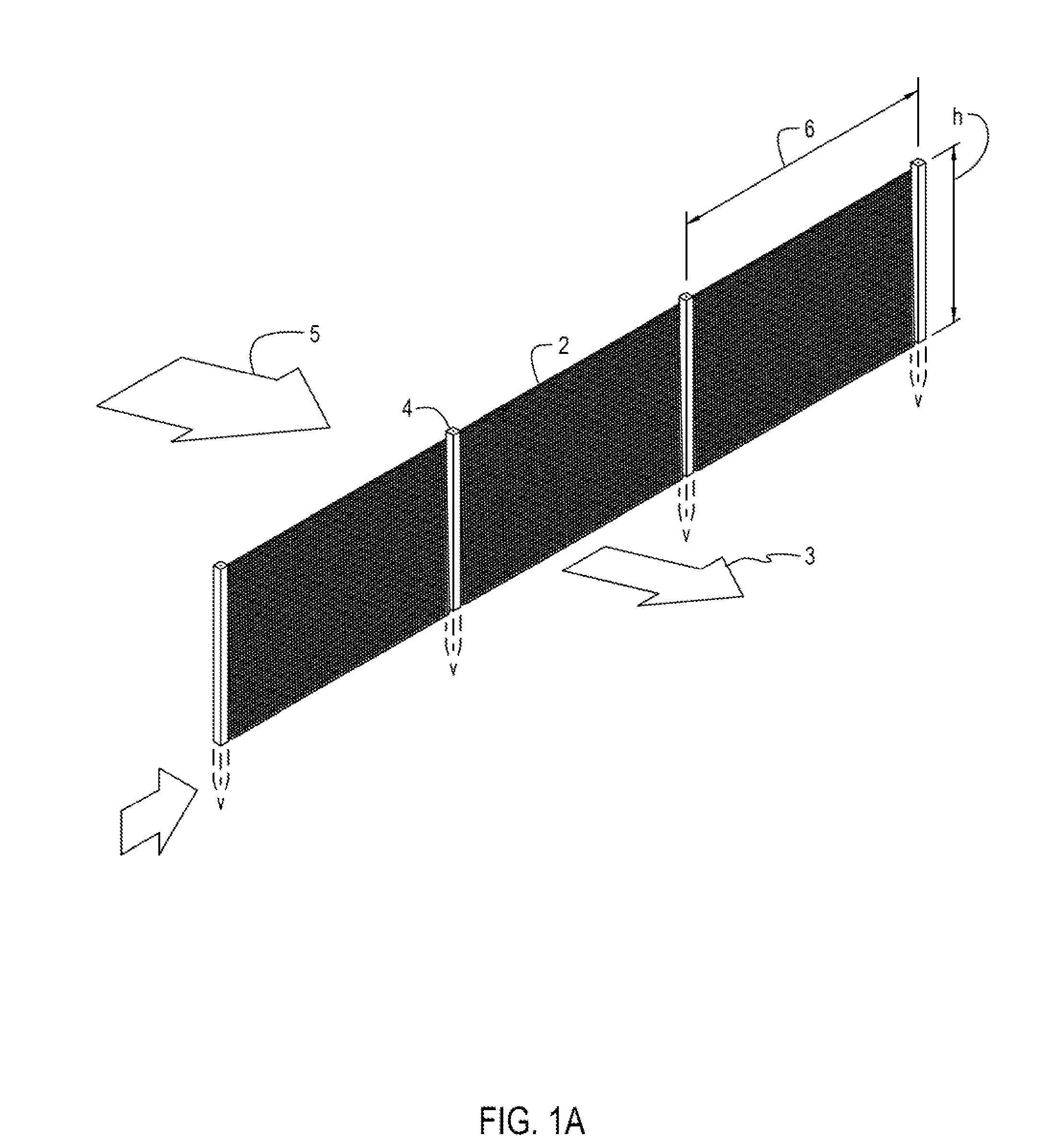

Silt fence installation equipment and method

InactiveUS20160305085A1Improve efficiencyEasy to controlSoil-shifting machines/dredgersExcavationsTerrainEngineering

An equipment for installing silt fencing includes a motive vehicle with an attached trencher to cut a trench having a predetermined depth and width. The trencher includes a cutting wheel and a trenching foot having a predetermined width for determining a width of a trench cut with the trenching assembly. The trencher is vertically positionable and a gauge is provided to the operator for controlling the depth of the trench as terrain and soil condition varies. The cutting wheel and trenching foot are also rotatable to control the orientation of the trench with respect to plumb. The equipment may also include a silt fence installation station including a power hammer on a positionable boom for another operator to use to drive the silt fence stakes into the ground. The equipment may also include a back filler on a side opposite the trencher for backfilling the trench.

Owner:RANEWS OUTDOOR EQUIP INC

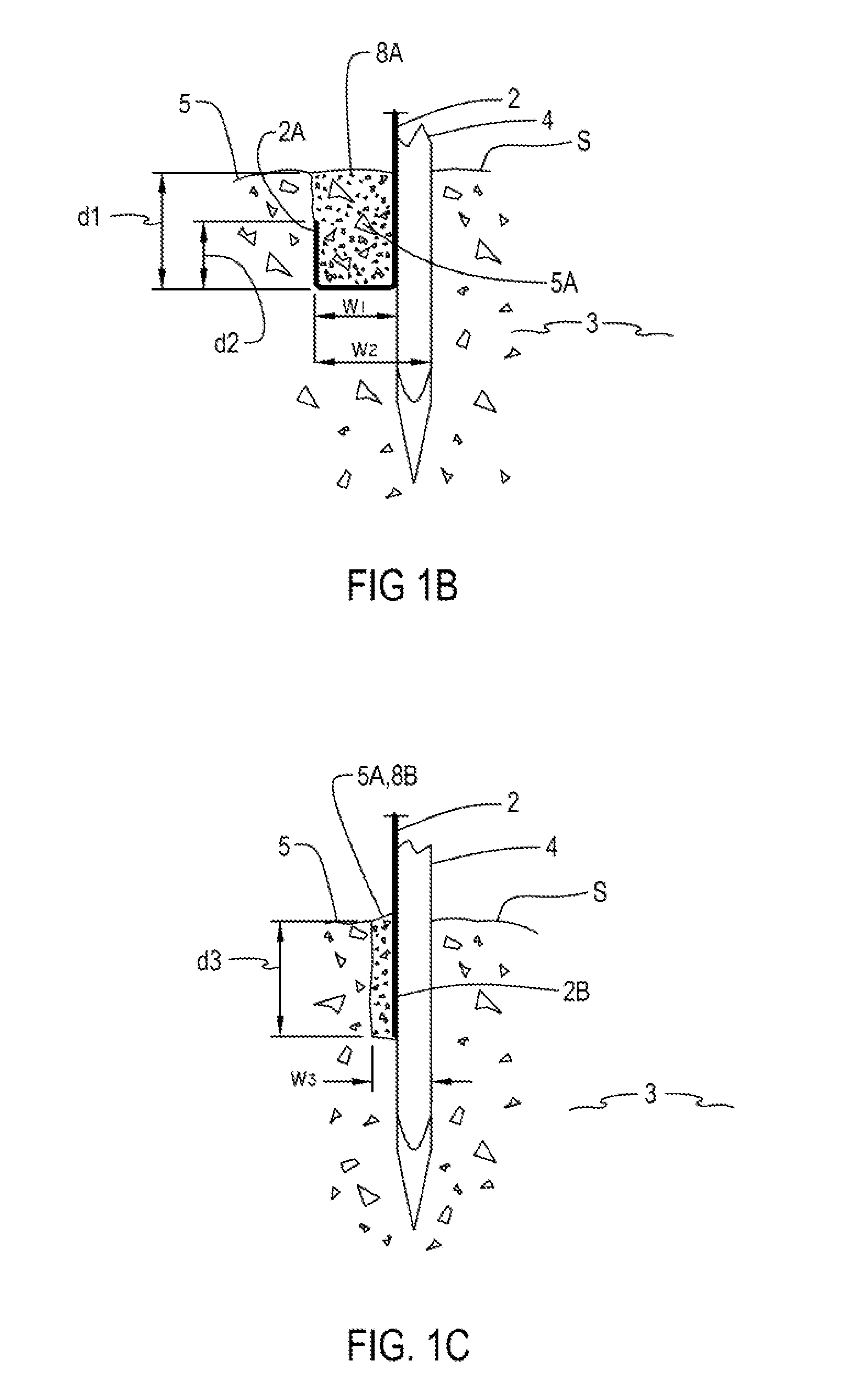

Vibration reduction apparatus for power tool and power tool incorporating such apparatus

InactiveUS20070056757A1Consider sensitivityLarge movementConstructionsReciprocating drilling machinesEngineeringPower tool

A power hammer has a handle mounted to a housing and capable of limited movement relative thereto. A hollow axle is attached to the housing and is rotatable between a first and second position and is biased towards the first position by a torsional spring which extends within the axle. Rotation of the axle causes rotation of arms connected thereto. Connectors are slidably mounted within guides and are respectively connected at one end to each of the arms and at the other end to the handle. Vibrations in the housing cause movement of one end of the handle, which causes movement of the associated connector and arm. Movement of the one arm causes rotation of the axle, which therefore causes movement of the other arm and connector, and the other end of the handle. Thus, the movement of one end of the handle is coupled to the other end.

Owner:BLACK & DECKER INC

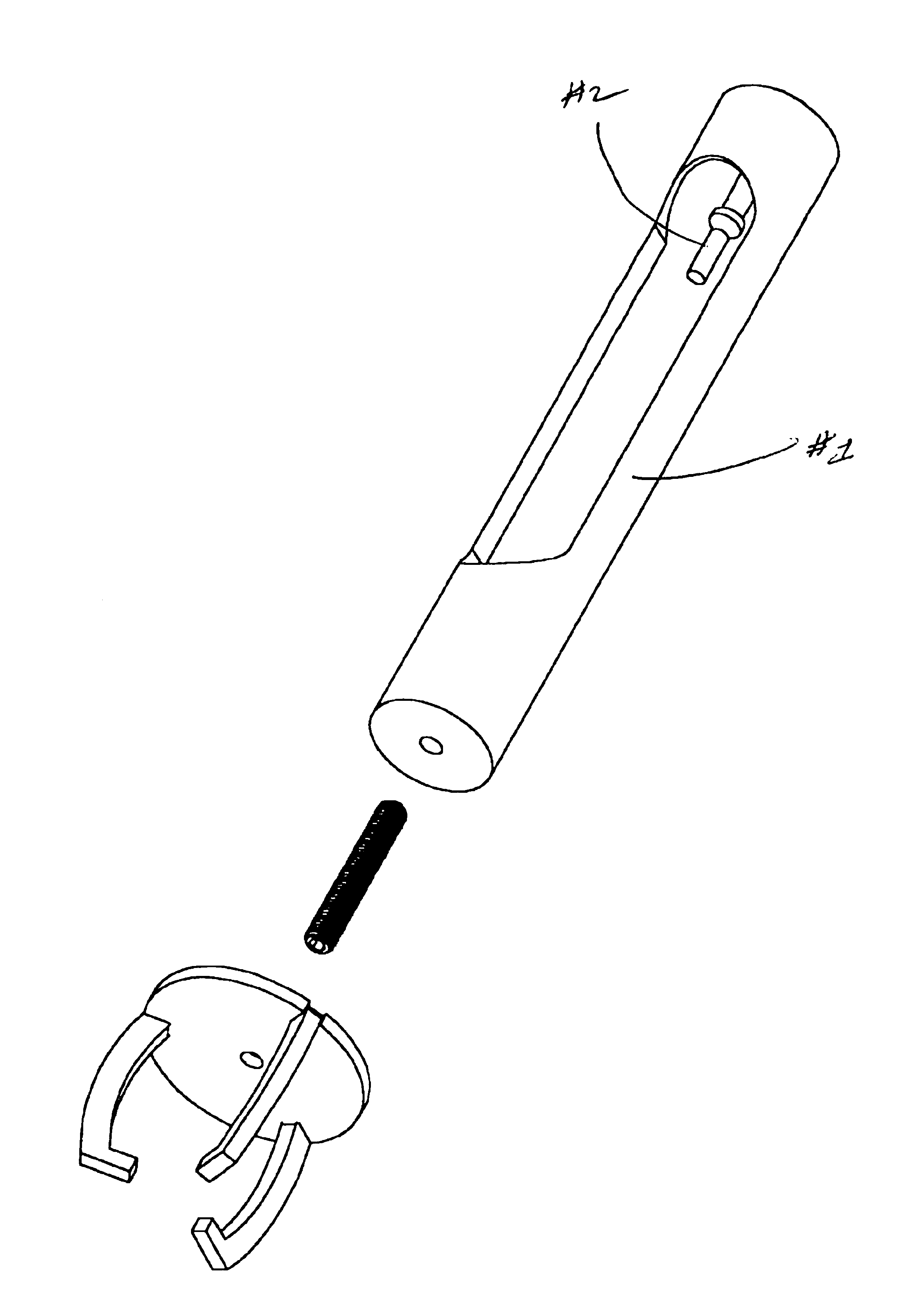

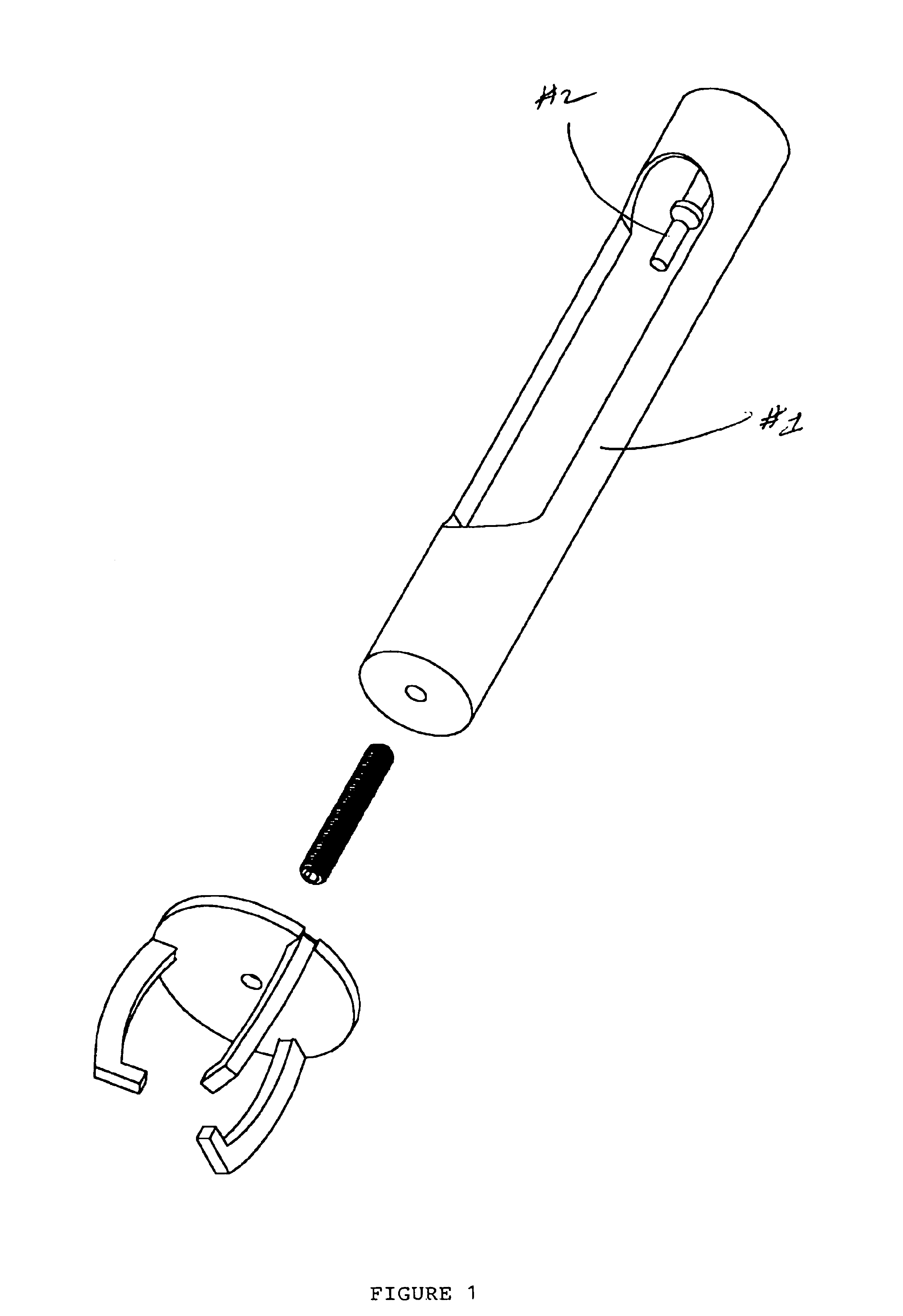

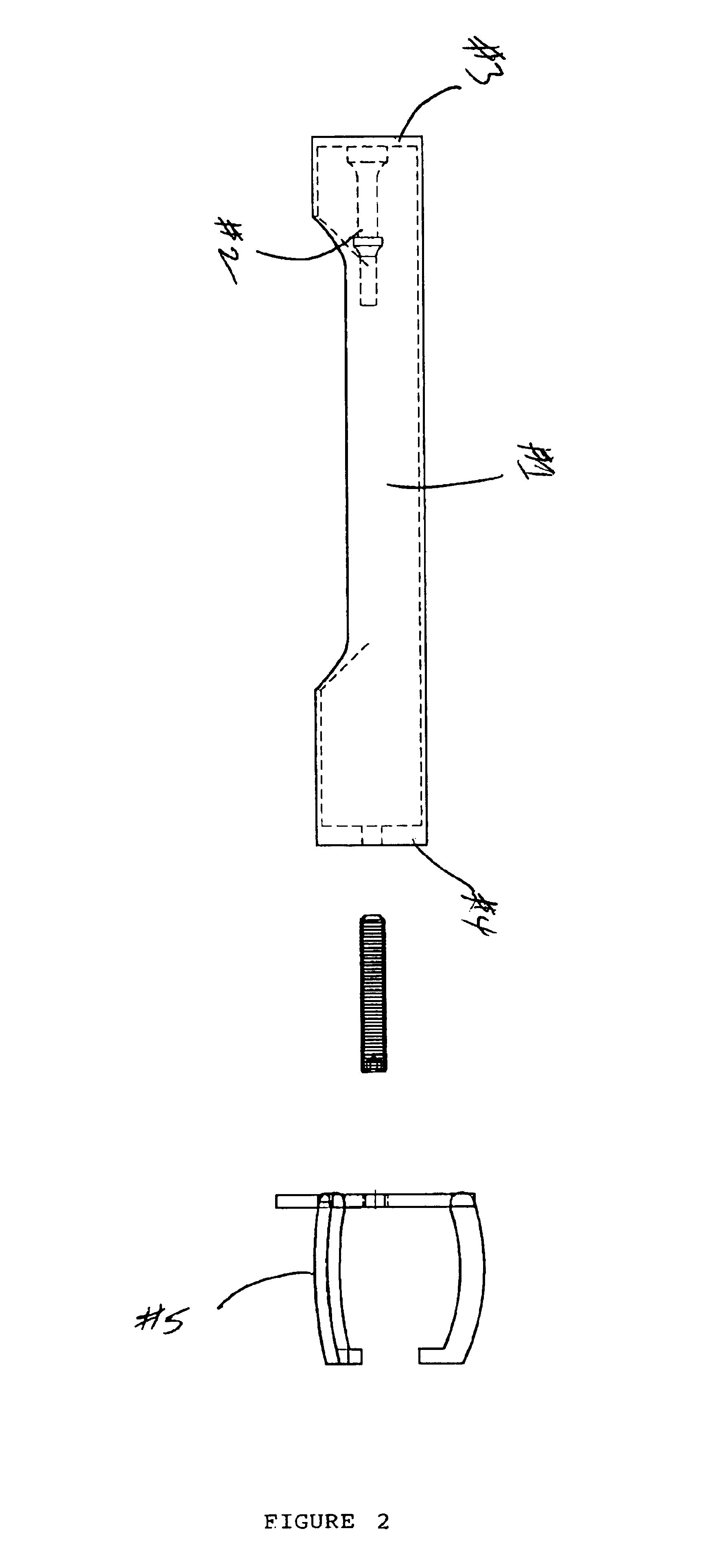

Power hammer puller

InactiveUS6839947B1Quickly and easily and efficiently removeLittle risk of injuryMetal working apparatusMetal-working hand toolsEngineeringScrew thread

The embodiment of this invention is disclosed which describes a power hammer puller to remove items from a shaft. The device consists of a cylindrical tube into which an air hammer fits. A bit is installed on one end of the tube and the other end is threaded to allow items to be removed from shafts. While the embodiments of the invention have been disclosed, certain modifications may be made by those skilled in the art to modify the various size of the tube as well as the size of the bit or the size of the standard threaded hole to accommodate particular applications.

Owner:DUDECK MARTIN J

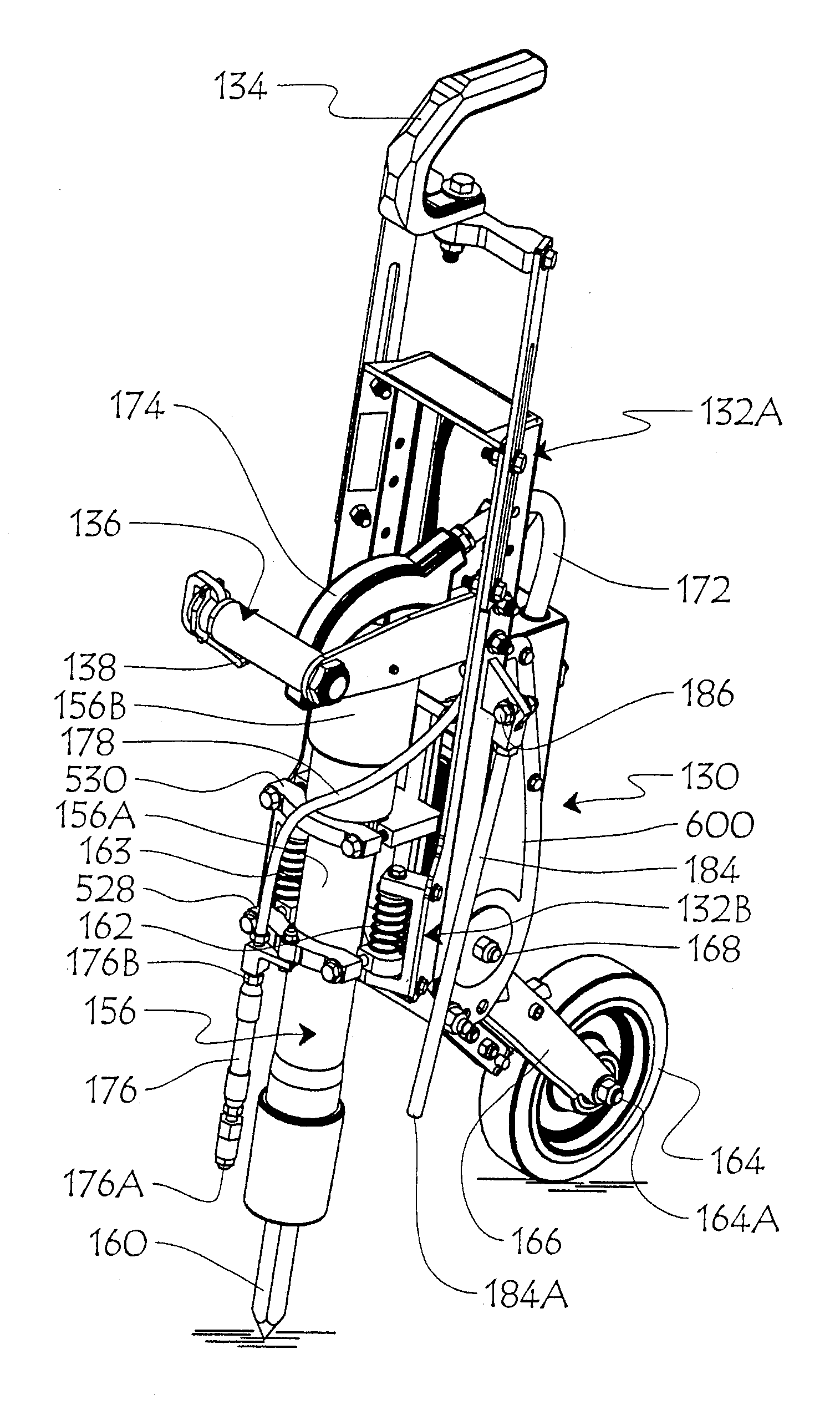

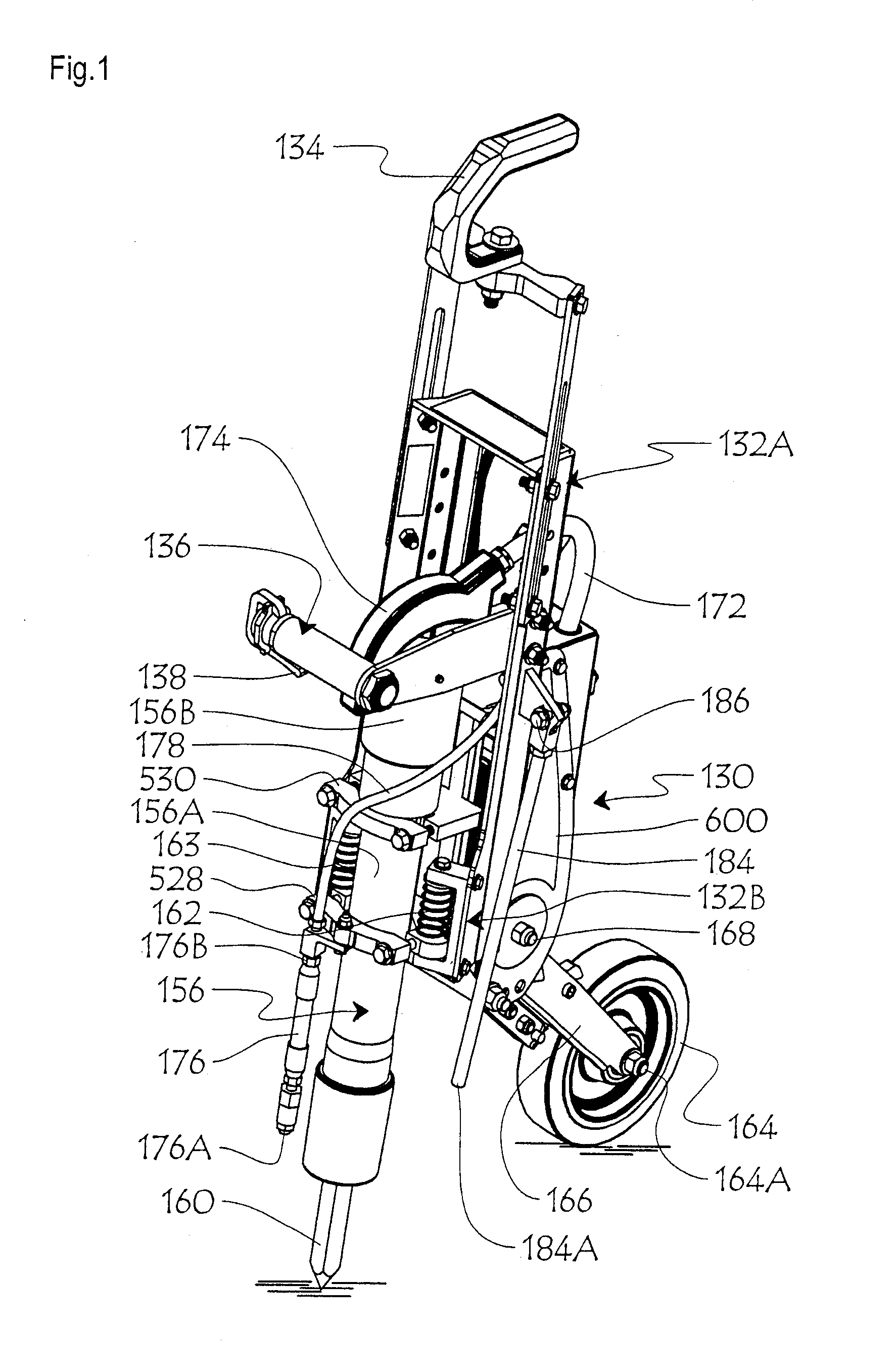

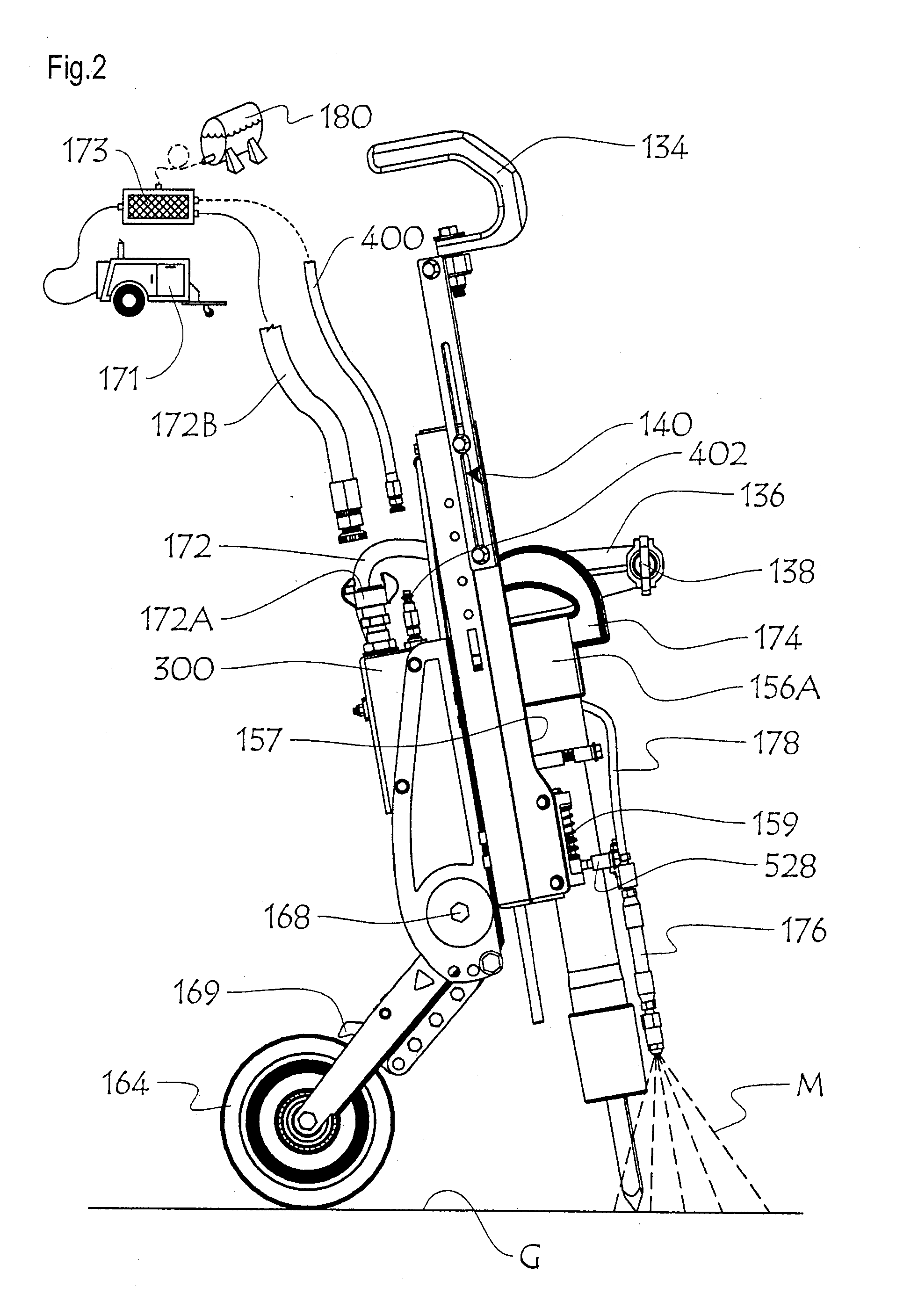

Hand-held ergonomic jackhammer holder for concrete floor chipping, jackhammer and holder assembly, and method of use thereof

InactiveUS20160136799A1Continuous compensationCarriage/perambulator with single axisPortable percussive toolsReciprocating motionJackhammer

A self-adjusting hand-held ergonomic holder for jackhammer for manual use by an operator in chipping a hardened ground surface along a continuously variable chipping strike angle. The holder includes a rigid main frame with an upper load bearing handle and a cradle receiving a pneumatically powered hammer with a reciprocatable elongated pneumatically controlled bit operatively mounted to one end thereof. A coil spring assembly associated with the cradle dampens vibrations generated by the jackhammer. A spring loaded caster member is mounted to the main frame lower portion opposite the jackhammer and providing dynamic continuously variable relative angular chipping tilt of the elongated bit responsive to and acting against the handle bearing load, transversely along the ground surface between a cradle first position, making a generally small acute angle relative to the bearing load downward axis and spaced apart from the caster, and a cradle second position, making a large acute angle relative to the bearing load downward axis and closely proximate the caster.

Owner:R N P IND

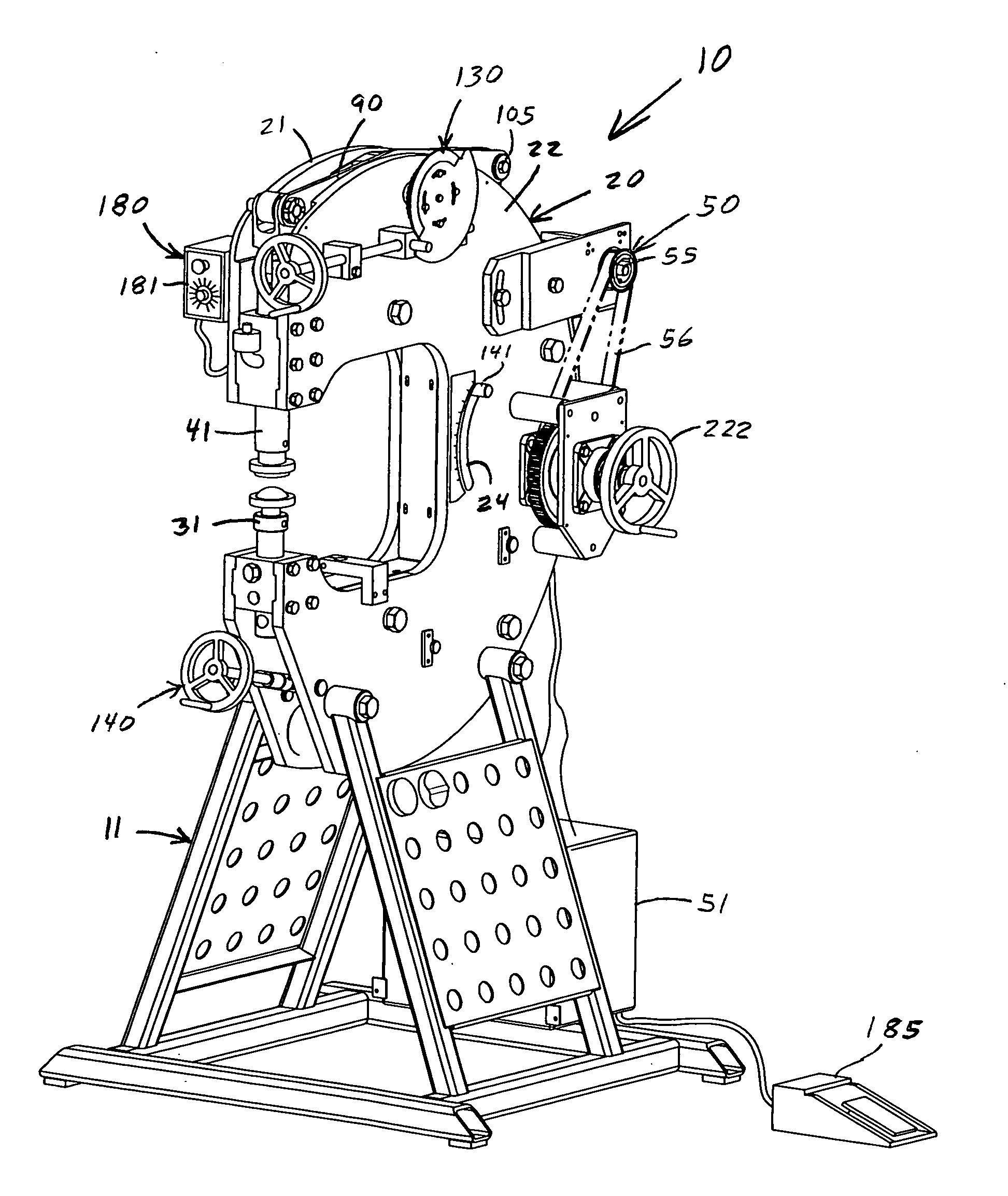

Multi-mode hammering machine

The invention is a multi-mode hammering machine that operates in a rigid mode, a flexible power hammer mode and a machine press mode to contour, shape and form sheet metal products. In all three modes, a ram is linearly stroked toward and away from a fixed die by a common ram drive assembly that includes a lever drive assembly and a reciprocating lever. The lever drive assembly moves in a rigid non-flexing manner. The reciprocating lever includes a rigid mode and a flexible mode. A conversion pin is used to engage one and simultaneously disengage the other. The lever drive assembly includes a control link that interfaces with a stroke adjustment mechanism. The gap adjustment mechanism is located at the fulcrum of the reciprocating lever. Both stroke length and gap are adjusted independently during the operation while the ram is cycling.

Owner:JPW IND

Drilling apparatus

A drilling apparatus including a hydraulically powered hammer having a piston to impact a drill bit; a shuttle valve to control reciprocation of the piston; and an accumulator for hydraulic fluid; at least one drill rod having a first connection valve for connection of the drill rod to the connection valve of the hammer; and a second connection valve for connection of the drill rod to the first connection valve of a like drill rod or to a rotation device. The piston and shuttle valve are positioned substantially in-line to the axis of movement of the hammer. The accumulator is positioned proximate to the shuttle valve; and the first connection valve, and second connection valve having at least one poppet valve positioned proximate to a corresponding valve seat.

Owner:JFK EQUIP

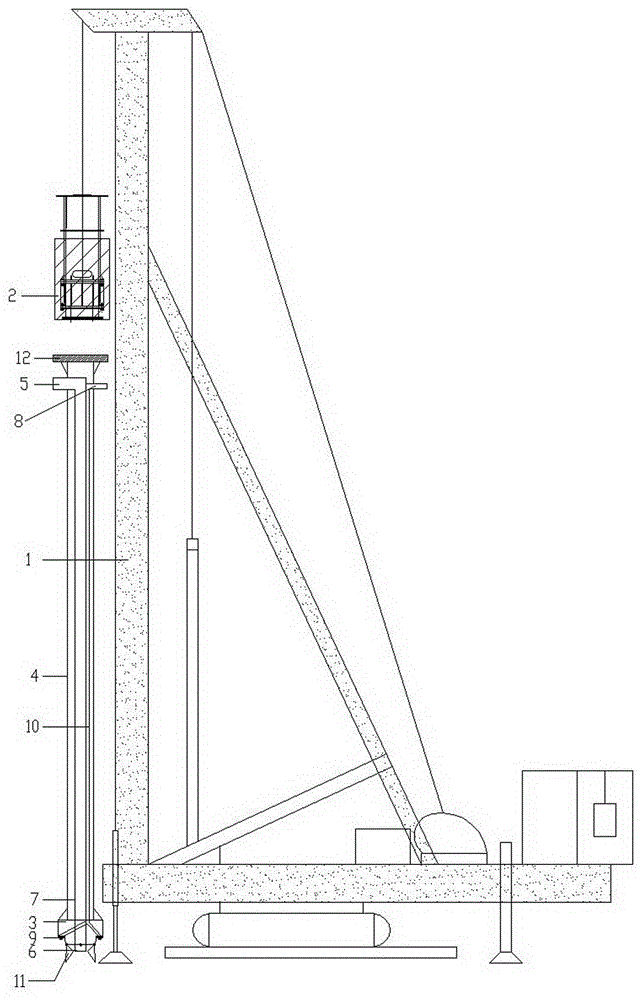

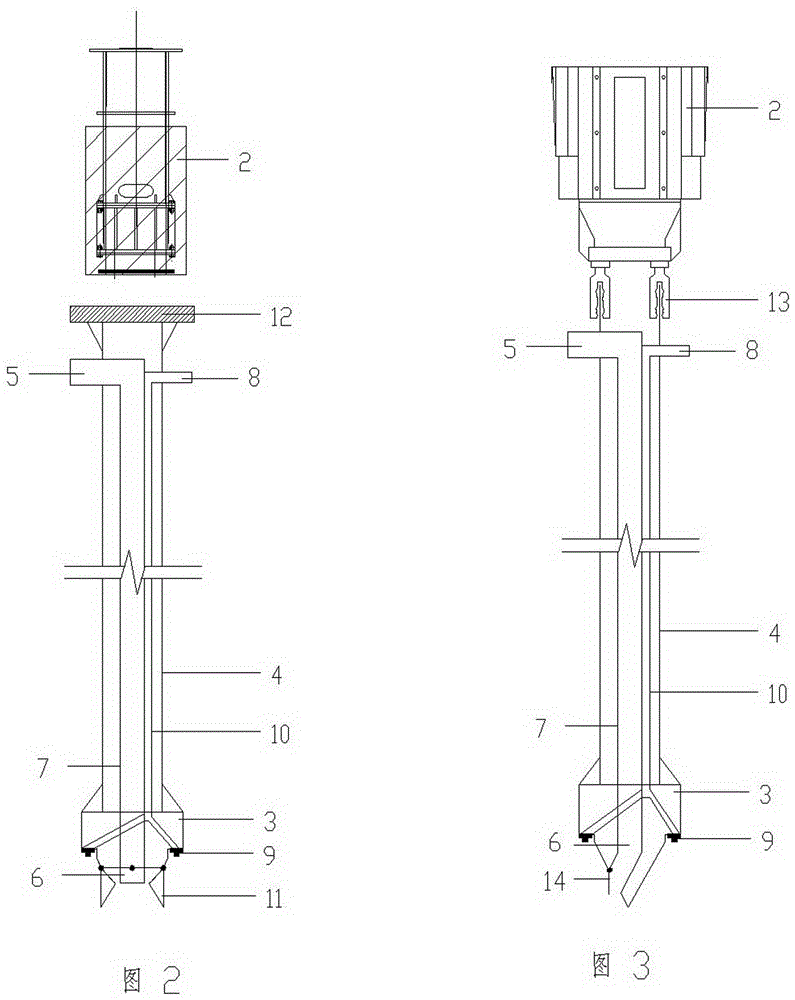

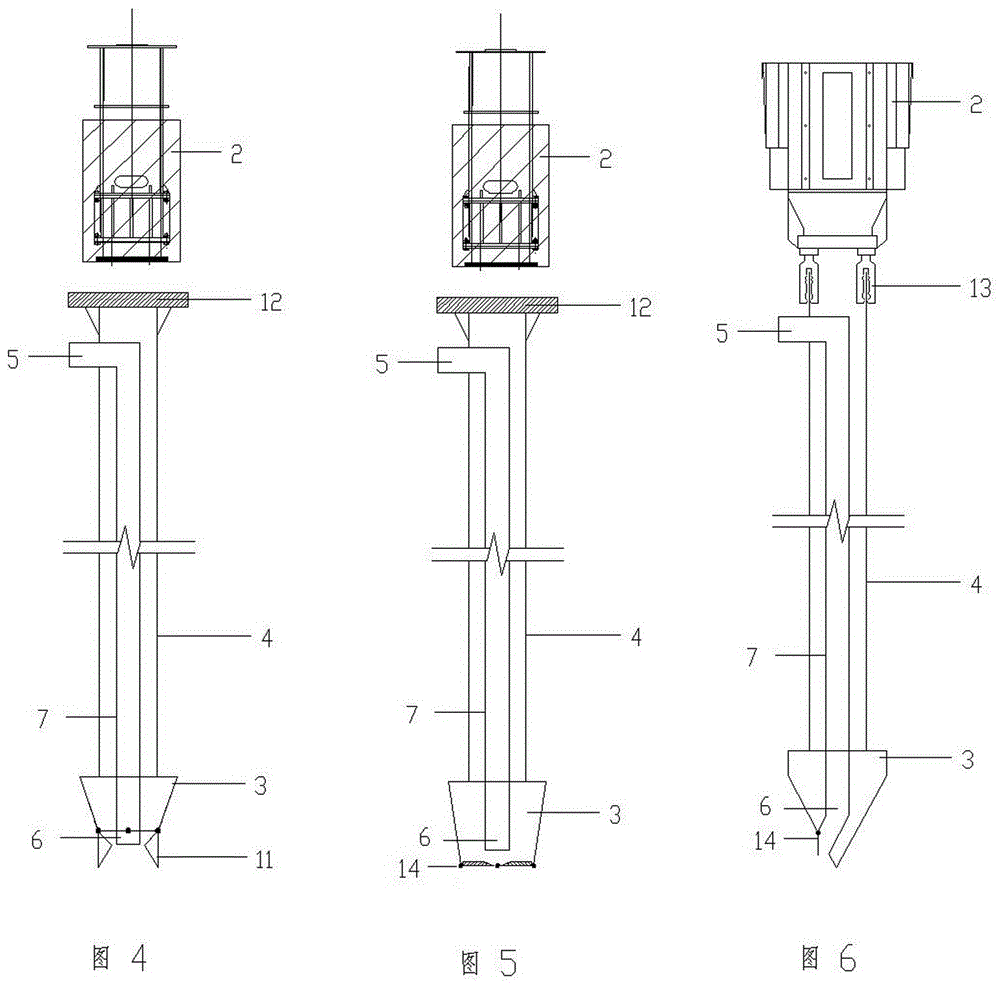

Stirring pile-grafting machine

InactiveCN101603310ASimple structureCompact structureBulkheads/pilesEngineeringConstruction aggregate

The invention provides a stirring pile-grafting machine, which is characterized by comprising the following components: a pile-grafting device, a stirring device, a support frame and a first rope; wherein, the pile-grafting device consists of a power hammer, a pile-grafting pile-delivering device and a power hammer lifter; wherein, the top end of the pile-grafting pile-delivering device is fixedly connected with the bottom part of the power hammer; the center of the bottom part of the pile-grafting pile-delivering device is provided with a pile-grafting chuck for clamping the aggregate to be grafted; the stirring device comprises a stirring pile power head, a clutch, a hydraulic station, a turnplate and a stirring rod; the support frame is used for supporting the stirring device and the pile-grafting device, and the top of the support frame is provided with a pulley block; the first rope is wound on the pulley block, one end thereof is connected with the top of the power hammer, and the other end thereof is connected with the power hammer lifter so that the power hammer lifter can control the up-down movement of the pile-grafting device. The stirring pile-grafting machine has simple and compact structure, which is easy for realizing the technique of grafting preformed piles in the cement-soil pile conveniently.

Owner:广东永基建筑基础股份有限公司

Drilling apparatus

A drilling apparatus including a hydraulically powered hammer having a piston to impact a drill bit; a shuttle valve to control reciprocation of the piston; and an accumulator for hydraulic fluid; at least one drill rod having a first connection valve for connection of the drill rod to the connection valve of the hammer; and a second connection valve for connection of the drill rod to the first connection valve of a like drill rod or to a rotation device. The piston and shuttle valve are positioned substantially in-line to the axis of movement of the hammer. The accumulator is positioned proximate to the shuttle valve; and the first connection valve, and second connection valve having at least one poppet valve positioned proximate to a corresponding valve seat.

Owner:JFK EQUIP

One-way speed limiter without machine room

The invention discloses a one-way speed limiter without a machine room. According to the invention, a base is coaxially and rotationally equipped with a rope wheel and a ratchet wheel; one side of the wheel face of the rope wheel is rotationally equipped with pawls; pawl torsional springs allowing the pawls to turn to the ratchet wheel to be matched with clamping grooves in the ratchet wheel in a clamping manner are arranged between the pawls and the rope wheel; the wheel face of the rope wheel is also rotationally equipped with pawl positioning structures; positioning torsional springs are arranged between the pawl positioning structures and the rope wheel; the supporting and pressing ends of the pawl positioning structures are matched with the pawls in an elastic supporting and pressing manner; the other side of the rope wheel face is rotationally equipped with two gravity hammers; the trigger parts of the pawl positioning structures are convexly provided with ejector headers matched with power hammers in a push-press manner when hammer heads of the gravity hammers turn to the outer edge of the rope wheel; the pawls are convexly provided with lifting release links, and when hammer handles of the gravity hammers turn to the wheel edge of the rope wheel, the lifting release links support and press the hammer handles of the gravity hammers to allow the pawls to be separated from the ratchet wheel and the pawl positioning structures and the pawls to be reset. According to the one-way speed limiter without the machine room, manual reset is not required for the pawl and the pawl positioning structures, and the one-way speed limiter without the machine room can be used in an elevator without the machine room.

Owner:XJ SCHINDLER XUCHANG ELEVATOR

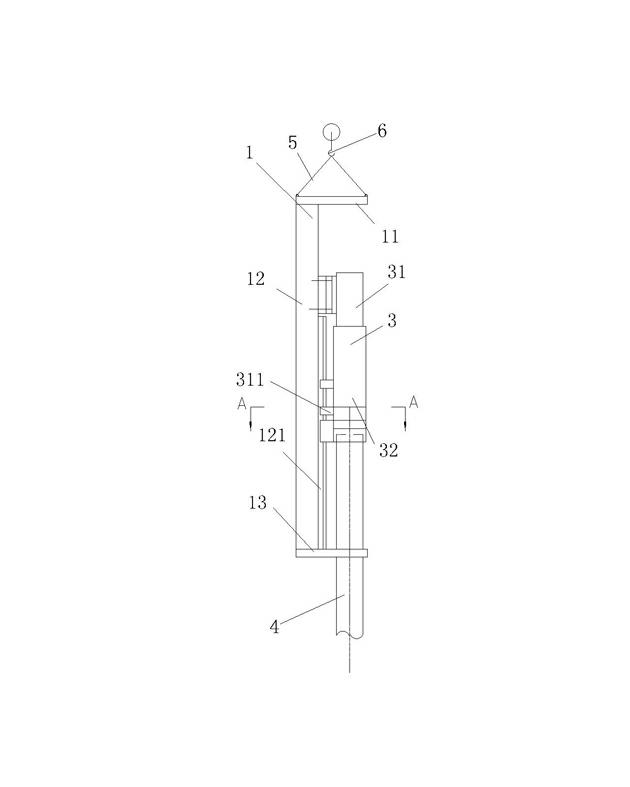

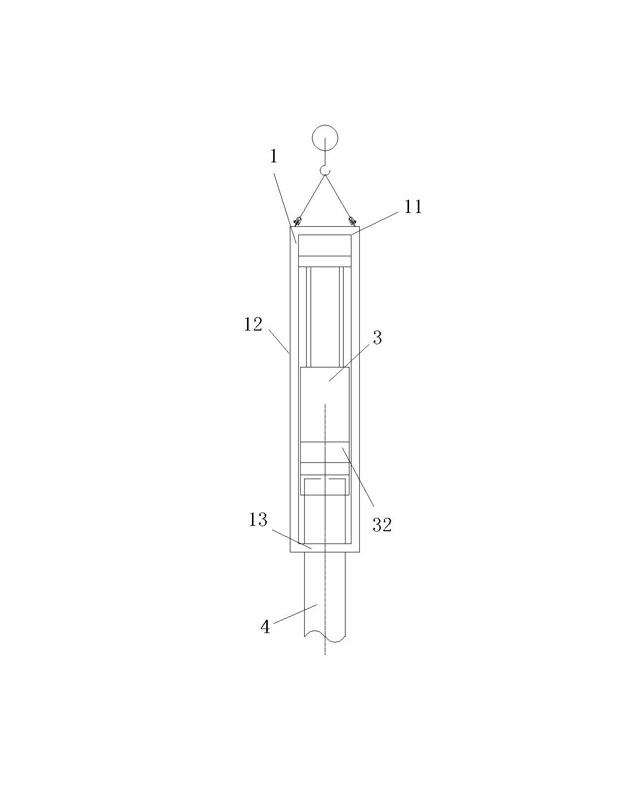

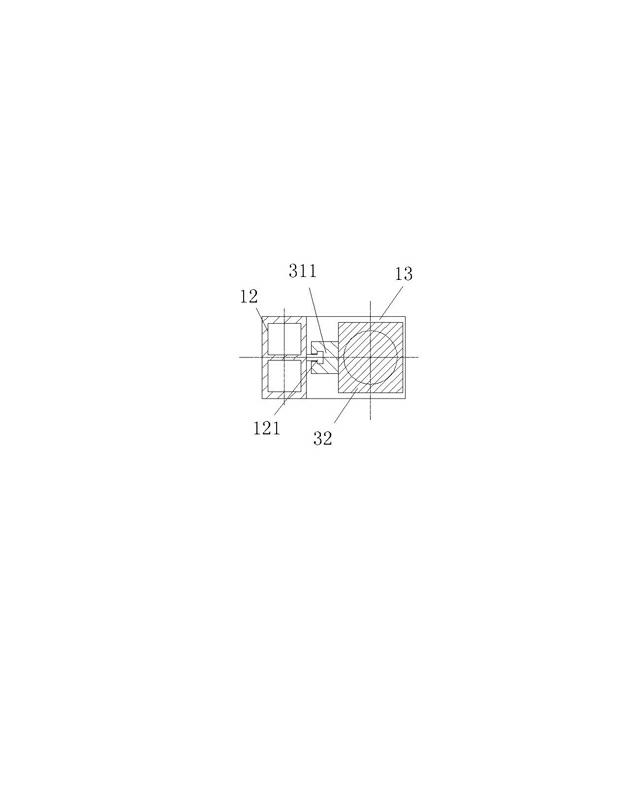

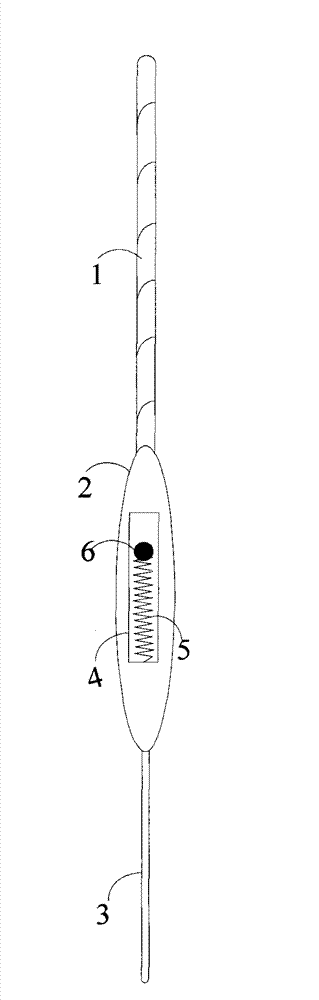

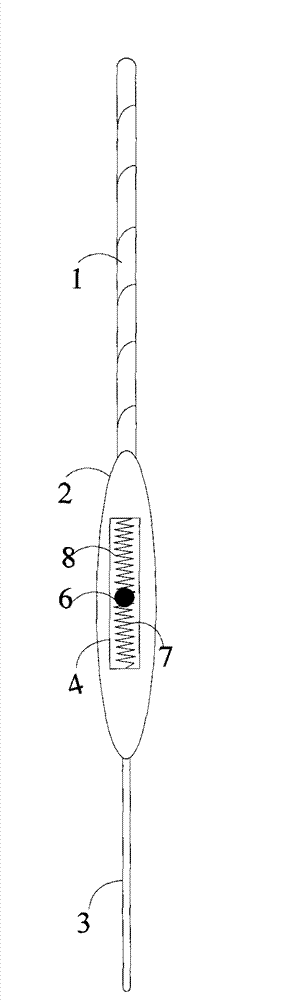

Float

The invention discloses a float, which is used for solving the problem that a fisherman cannot clearly judge whether fish is hooked according to the existing float. The float comprises a float tail, a float body, a float leg, a tubular cavity, a spring and a power hammer, wherein the tubular cavity is arranged in the float body; the spring is arranged at one end, close to the float leg, in the tubular cavity; and the power hammer is arranged at the other end of the spring, and when the float is in a vertical static state, a gap is formed between the power hammer and the other end of the tubular cavity. According to the float disclosed by the invention, the up-and-down swinging motion range of the float is amplified by the spring and the power hammer, so that the fisherman can more clearly judge whether fish is hooked.

Owner:成洪元

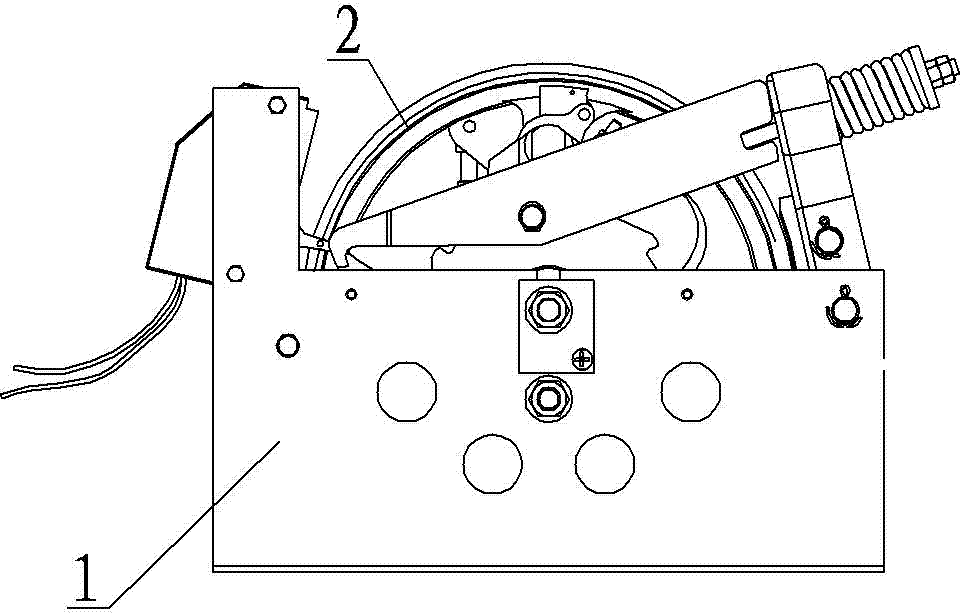

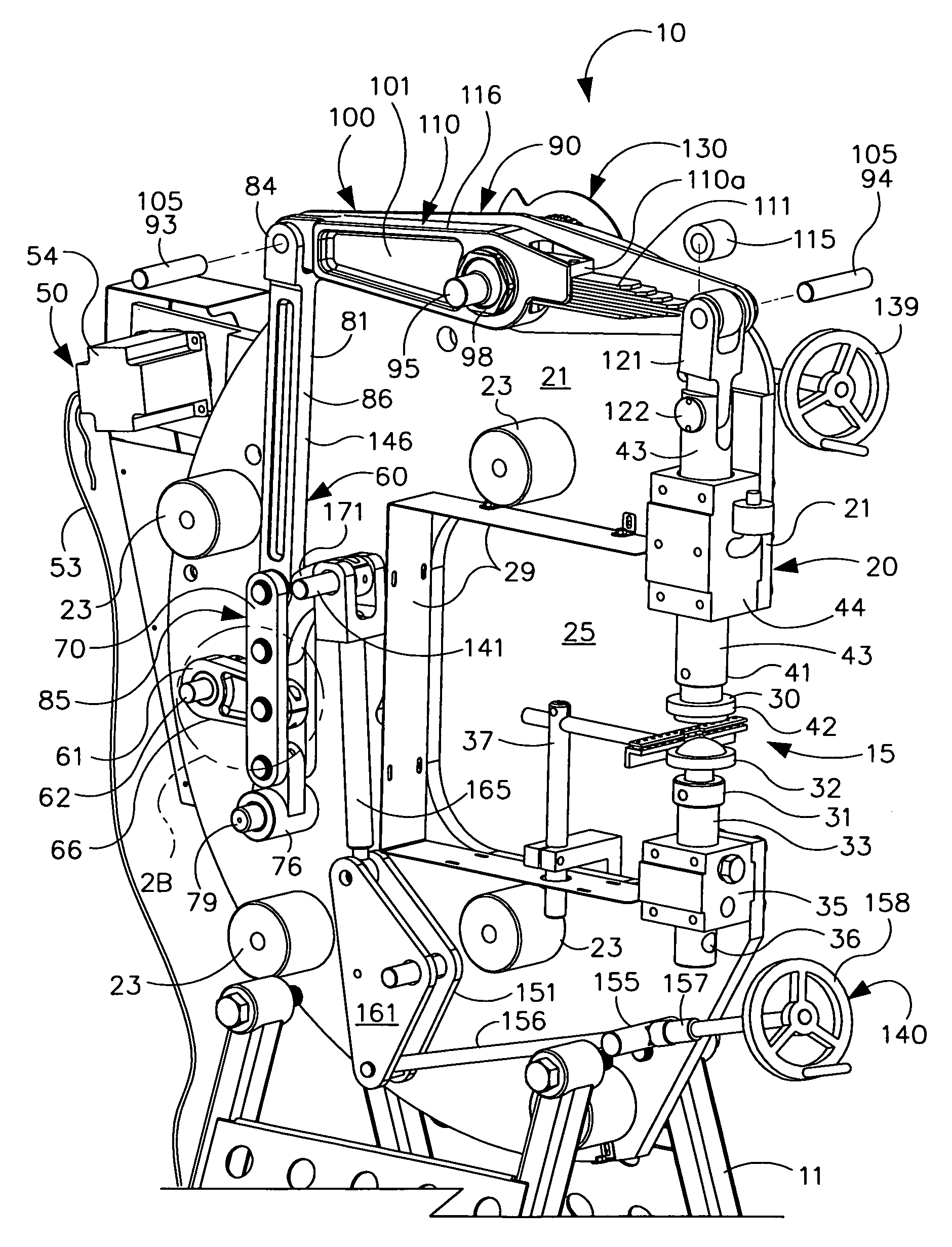

Multi-mode hammering machine

The invention is a multi-mode hammering machine that operates in a rigid mode, a flexible power hammer mode and a machine press mode to contour, shape and form sheet metal products. In all three modes, a ram is linearly stroked toward and away from a fixed die by a common ram drive assembly that includes a lever drive assembly and a reciprocating lever. The lever drive assembly moves in a rigid non-flexing manner. The reciprocating lever includes a rigid mode and a flexible mode. A conversion pin is used to engage one and simultaneously disengage the other. The lever drive assembly includes a control link that interfaces with a stroke adjustment mechanism. The gap adjustment mechanism is located at the fulcrum of the reciprocating lever. Both stroke length and gap are adjusted independently during the operation while the ram is cycling.

Owner:JPW IND

Bidirectional machine-room-free speed limiter of single brake pressing-plate device

The invention discloses a bidirectional machine-room-free speed limiter of a single brake pressing-plate device. A rope wheel and a ratchet wheel are coaxially assembled on a base, a pawl is assembled on one side of the wheel face of the rope wheel in a rotating mode, a pawl torsion spring enabling a pawl steering ratchet wheel to be matched with a clamping groove of the ratchet wheel is arranged between the pawl and the rope wheel, a pawl positioning structure is further assembled on the wheel face of the rope wheel in a rotating mode, and a positioning torsion spring is arranged between the pawl positioning structure and the rope wheel. The jacking-pressing end of the pawl positioning structure is matched with the pawl in an elastic jacking-pressing mode, two gravity hammers are further assembled on the other side of the wheel face of the rope wheel in a rotating mode, the triggering portion of the pawl positioning structure is provided with a jacking head which is matched with a power hammer in a pushing-pressing mode when heads of the gravity hammers turn to the outer edge of the rope wheel in a protruding mode, and the pawl is provided with a lifting reset rod which abuts against and presses hammer handles of the gravity hammers to enable the pawl to be separated from the ratchet wheel and enable the pawl positioning structure and the pawl to be reset when the hammer handles of the gravity hammers turn to the outer edge of the rope wheel in a protruding mode. The pawl and the pawl positioning structure do not need manual resetting and can be used in an elevator without a machine room.

Owner:XJ SCHINDLER XUCHANG ELEVATOR

Sample plate marking and pricking-pressing device and use method of sample plate marking and pricking-pressing device

ActiveCN104907357AQuality assuranceAddressing VulnerabilityMetal working apparatusBrute forceWorkload

The invention discloses a sample plate marking and pricking-pressing device and a method used by the sample plate marking and pricking-pressing device. An end head support arm and a support arm are arranged on a base; a power hammer is arranged on the end head support arm; the power hammer penetrates through a limiting groove in a baffle for limiting; a centrifuge support arm is arranged at the lower part of a rod of the power hammer and is used for controlling and driving the power hammer. By using the device, the technical problems that a worker easily gets hurt, the processing quality can not be ensured, and the working efficiency is low as the manual processing is adopted in the prior art can be solved. By using the device and the method, the original manual pricking-pressing operation by the worker can be completely replaced; in the whole process, the manual pricking-pressing with brute force is avoided, the workload is reduced, the danger coefficient during work is reduced, the phenomenon of arm ache caused by vibration when the pricking-pressing is carried out by adopting a hammer is eliminated, the working efficiency is improved and simultaneously the workpiece processing quality is ensured.

Owner:SHENYANG AIRCRAFT CORP

Construction equipment for concrete piles and construction method of construction equipment

The invention provides construction equipment for concrete piles. The construction equipment comprises a rack, a power hammer and a stamping device, and is characterized in that the power hammer is arranged on an upright of the rack; the stamping device is arranged under the power hammer, and comprises an impact hammer, a hollow rod, a material conveying device and a grouting device, or the impact hammer, the hollow rod and the material conveying device, or the impact hammer, the hollow rod, the material conveying device, the grouting device and a diameter expanding part additionally arranged at the upper end of the hollow rod. The invention further provides a construction method which comprises the following steps: 1) aligning with a pile position; 2) beating the stamping device with the power hammer, so that soil is impacted downwards, extruded and expanded; 3) impacting and lubricating the soil with a high-pressure jet if the grouting device is available, or directly repeating the impacting operation if the grouting device is unavailable; 4) forming a pile hole when a set depth is reached, for example, the diameter expanding part forms an expanded diameter naturally; 5) when lifting the stamping device, conveying concrete in a pressurized manner, and pouring the concrete into the pipe hole; 6) lifting the stamping device out of the soil to form a concrete pile; and 7) inserting a reinforcing cage reversely when the construction method is used for formation of a pile foundation, and laying a cushion layer at the top of the pile when the construction method is used for formation of a composite foundation.

Owner:王继忠 +2

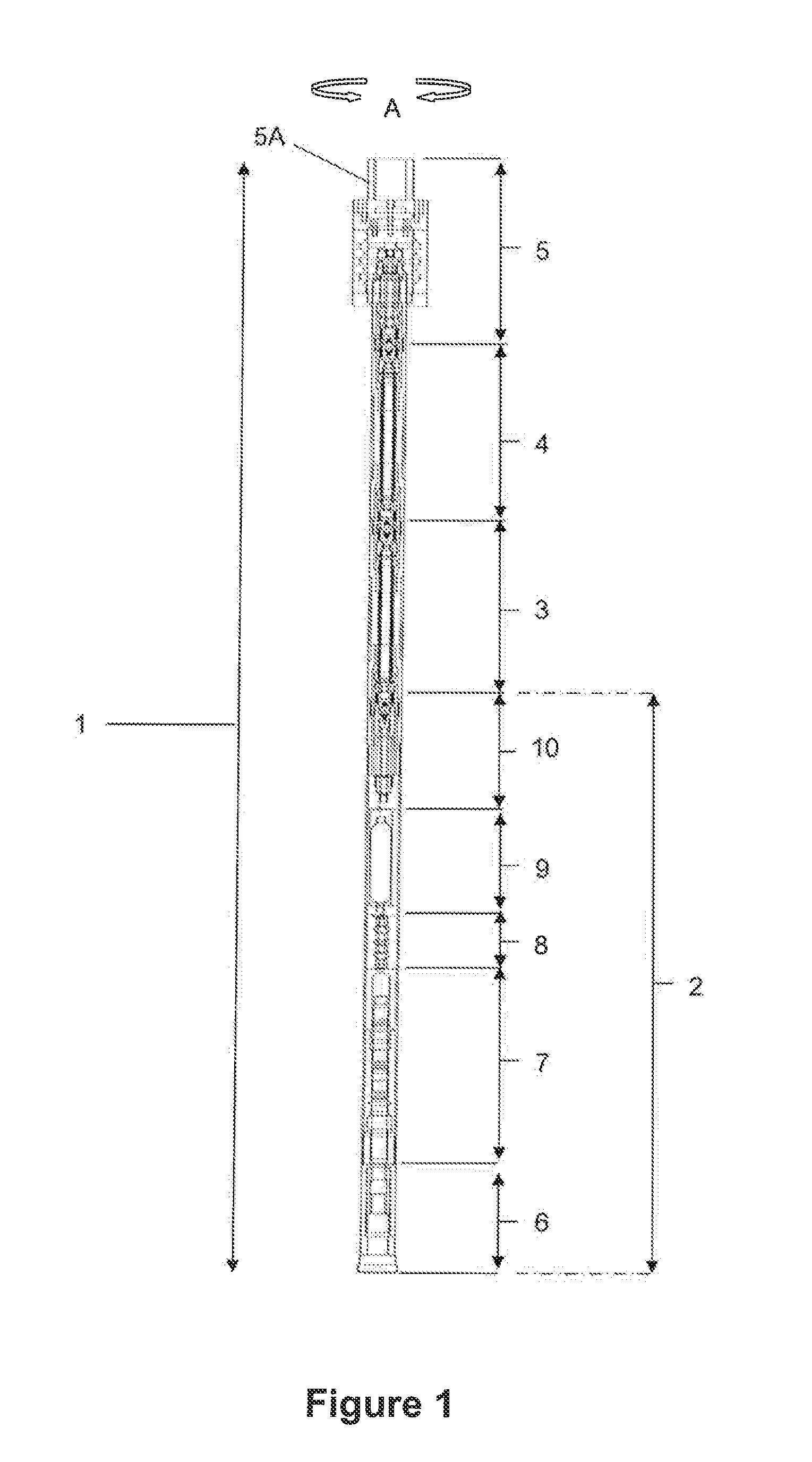

Frequency-adjustable jet impact type oscillator

PendingCN114809922AImprove applicabilityEnhanced Vibration PowerVibration drillingElastic componentJet flow

The invention provides a frequency-adjustable jet flow impact type oscillator. The frequency-adjustable jet flow impact type oscillator comprises a shell; the piston assembly is arranged in the shell and comprises a cylinder body and a piston arranged in the cylinder body, a connecting rod is arranged at one end of the piston, and the free end of the connecting rod extends out of the cylinder body; the jet flow control element is arranged at the upper end of the piston assembly; the power hammer is fixedly connected with the free end of the connecting rod; the short section is arranged at the lower end of the power hammer, and the lower end of the short section forms a lower connector used for being connected with a lower drill column; the elastic component is sleeved on the short section, and the elastic component and the short section form a suspension support for the lower drill column; wherein the jet flow control element can control the piston to reciprocate along the cylinder body and drive the power hammer to synchronously move to impact the short section, and the elastic assembly converts impact energy into elastic deformation under the action of impact force, so that the lower drill column generates axial vibration along with the elastic deformation; the frequency of the axial vibration and the vibration displacement of the lower drill column can be adjusted according to actual working requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

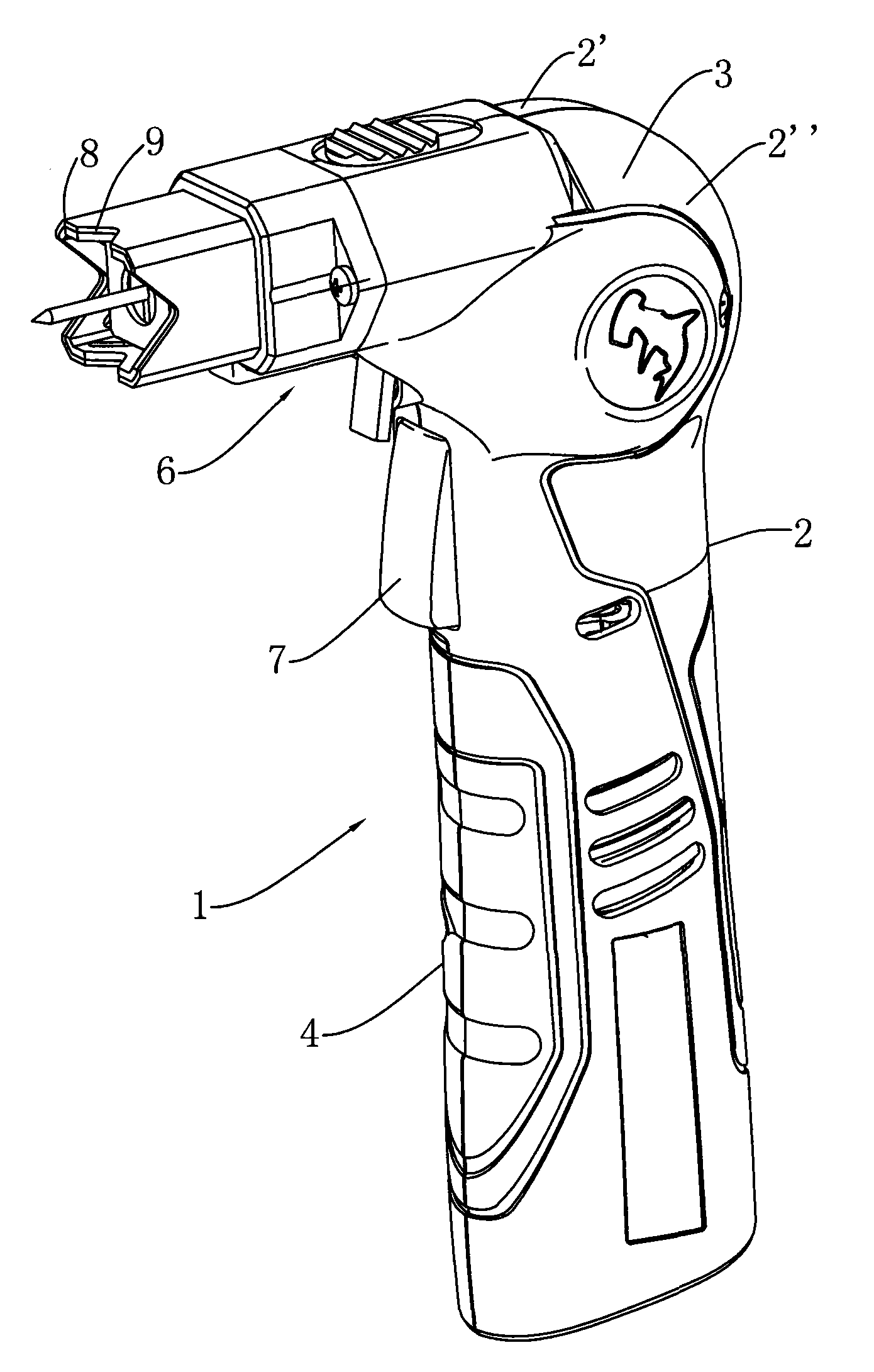

Electric tool

InactiveCN102114624AImprove visibilityEasy to usePortable percussive toolsNailing toolsEngineeringPower tool

The invention relates to an electric tool comprising a beating device, wherein the beating device consists of a clamping mechanism that includes a clamping piece, a sliding element, a first biasing device and a second biasing device, the sliding element is provided with a guiding part, the clamping piece slides in the guiding part, and is closed relative to a first position of the guiding part and opened relative to a second position of the guiding part, and when the clamping piece is positioned at the opening position, the biasing force generated by the first biasing device is weaker than that generated by the second biasing device. Therefore, the clamping piece can be effectively prevented from being closed again and causing damage to the interior of a machine due to beating of the beating device when the clamping mechanism is in a completely opening position. A power hammer is compact in structure and convenient to operate, and can well clamp nails or other elements so as to avoid shifting of the nails or other elements.

Owner:NANJING CHERVON IND

Novel hydraulic and pneumatic composite control cylinder of hydraulic hammer and sealing form

InactiveCN112049833ASolving Installation ComplexitySolve the installation volumeFluid-pressure actuatorsBulkheads/pilesReciprocating motionCylinder block

The invention provides a novel hydraulic and pneumatic composite control cylinder of a hydraulic hammer and a sealing form. The integrated hydraulic and pneumatic composite control cylinder is formedby a piston rod, a piston, an air-tight sealing piece, a liquid sealing piece and a cylinder body, and reciprocating movement and hammering of a pile hammer are achieved through hydraulic force, aerodynamic force and hammer core gravity. The integrated hydraulic and pneumatic composite control cylinder is compact in structure, a cylinder is composed of a shell, a high-pressure energy accumulator,a low-pressure energy accumulator and a closed space between cylinder bodies, the space in the hydraulic hammer is fully utilized, and the structural complexity caused by the fact that cylinder components are additionally arranged in the hammer is reduced. A gas-liquid combined sealing mode is adopted at the piston end, three sets of split mounting type rings, gas sealing pieces, oil sealing pieces etc. are included, the gas sealing pieces and the hydraulic sealing pieces are respectively arranged at two sides with a compression ring as the center, the outermost layer is provided with one setof ring for bearing most oil pressure and air pressure, the bearing capacity of the sealing pieces is reduced, and gas-liquid separation is achieved. By adopting the structure, the complexity of an air-tight sealing structure and an oil sealing structure at the piston can be reduced, and then the combination of hydraulic and pneumatic systems of the pile hammer is realized. A totally-enclosed structure and a piston rod guide mechanism are adopted, and the structure can be used for inclined pile driving and underwater operation.

Owner:ZHEJIANG YONGAN CONSTR MASCH CO LTD +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com