Workbench-type automatic power hammer device and using method thereof

An automatic force and bench-top technology, which is applied in the direction of measuring devices, test material strength by applying repetitive force/pulsation force, instruments, etc., can solve problems such as poor repeatability, difficult control of excitation time, and difficulty in exciting force pulses, etc., to achieve cost savings , Extensive practicability, good repeatability and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

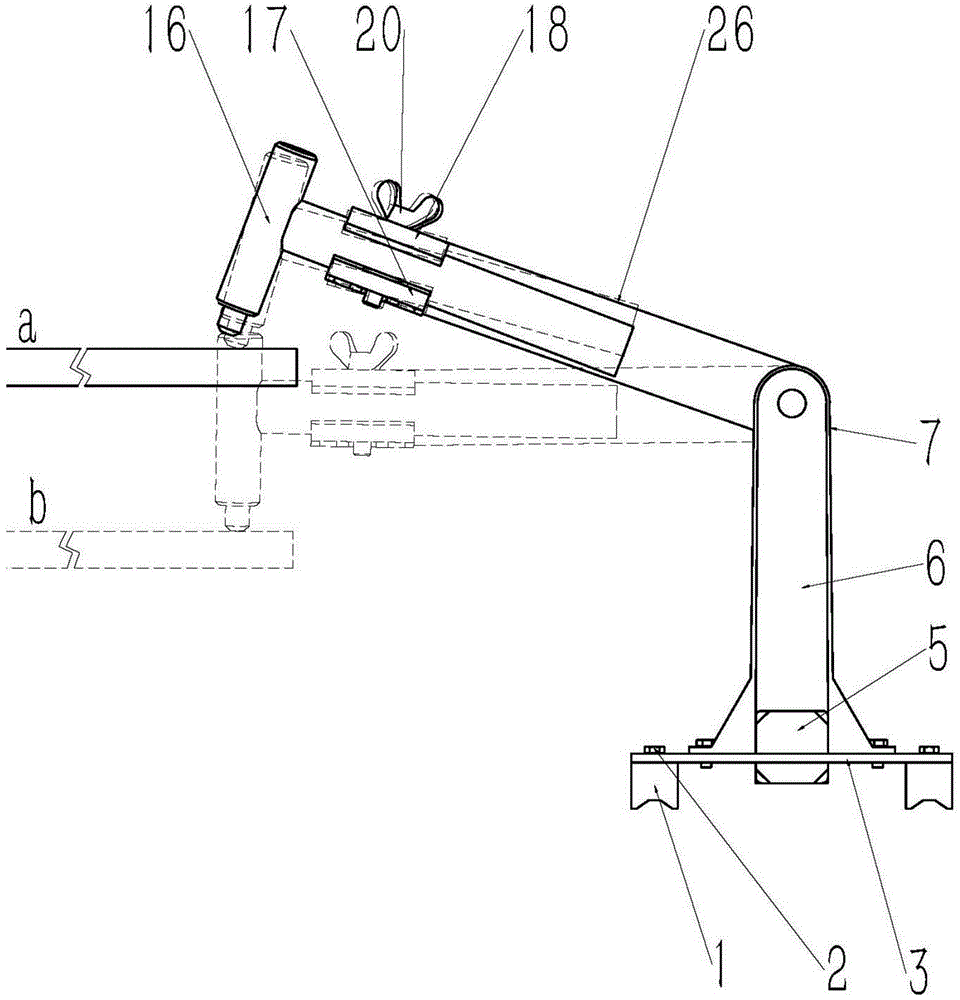

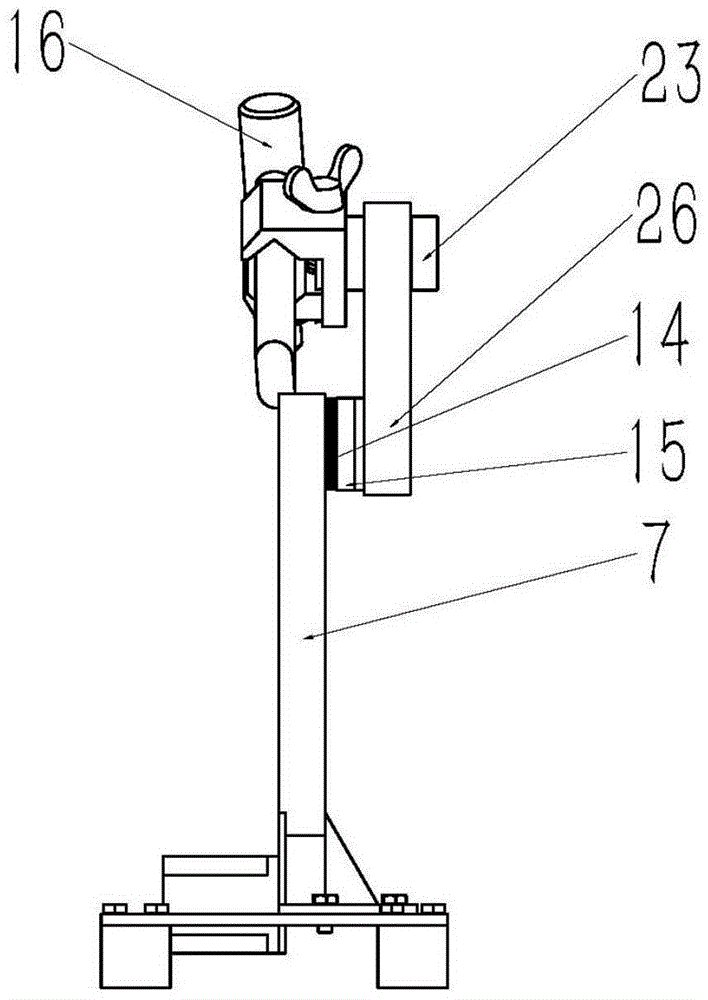

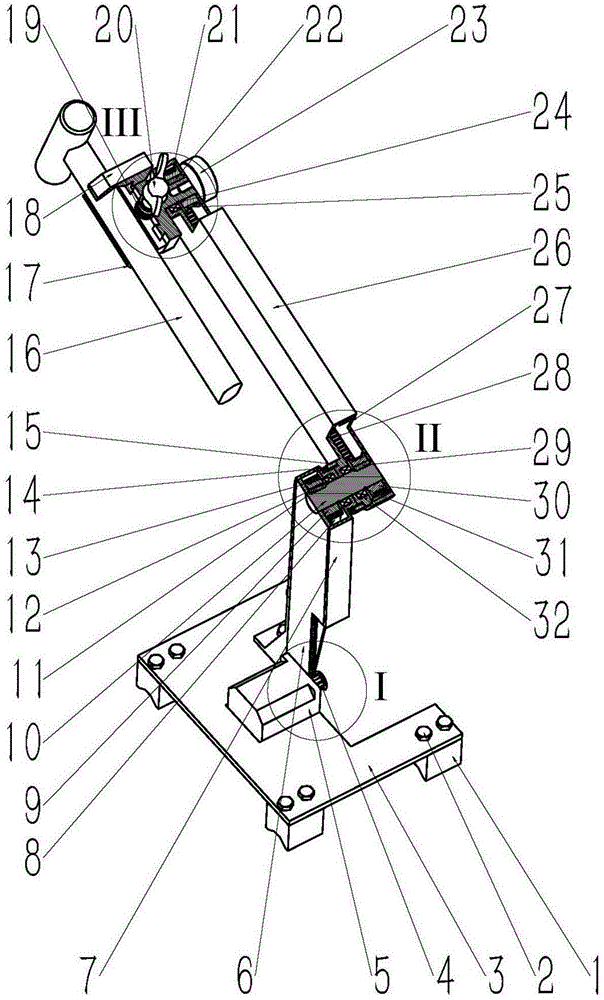

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0020] The table-type automatic power hammer device of the present invention is mainly composed of a motor 5, a base 3, a stand 7, a stand cover 6, a positioning spring 14, a positioning tooth sleeve 15, a rocker arm 26, a photoelectric encoder 23, and a force hammer clamping fixed Clip 18, power hammer clamping movable clip 17, power hammer 16 constitute. The motor 5 is fixed on the bottom of the stand cover 6, the first synchronous pulley 4 is fixed on the output shaft of the motor 5, the stand cover 6 is fastened on the stand 7, and the stand 7 is installed on the base 3, and the base 3 The lower leg is the magnetic watch base 1 . The rocker arm 26 is fixed on the stand 7 by the positioning spring 14 and the positioning tooth sleeve 15, and forms a specific working angle with the vertical base 7. The seat 7 and the rocker arm 26 are axially and radiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com