Visualization detection method of electronic product electronic design automation (EAD) design manufacturability

A technology for electronic products and detection methods, applied in the fields of computing, electrical digital data processing, special data processing applications, etc., can solve problems such as the inability to solve various practical problems of enterprises, single practical problems of enterprises, etc., to solve the problem of inconsistent file coordinates, improve Efficiency and quality, the effect of reducing the number of trial runs and adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

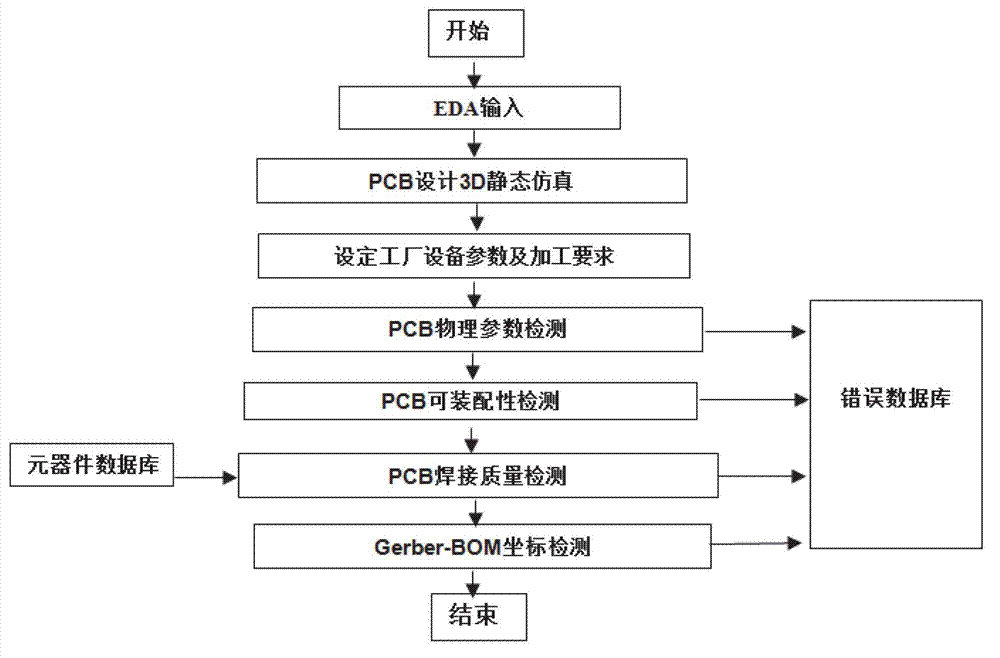

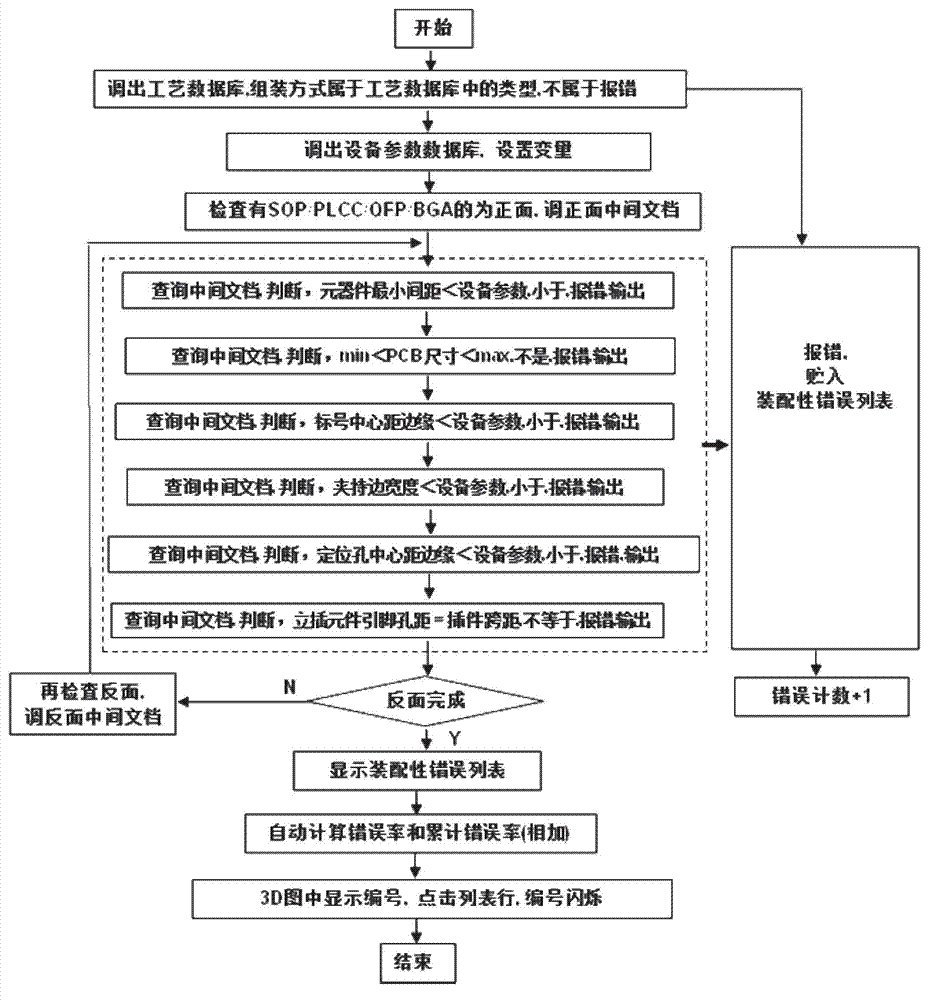

[0055] See figure 1 , the electronic product EDA design manufacturability visual detection method of the present embodiment, carry out PCB 3D simulation to EDA design file, then carry out PCB physical parameter detection detection, PCB assembleability detection, PCB soldering quality detection and Gerber BOM coordinate detection sequentially , and 3D visually display the specific error locations and types of the aforementioned four detections on the PCB 3D simulation graphics. Generally speaking, the following steps are included:

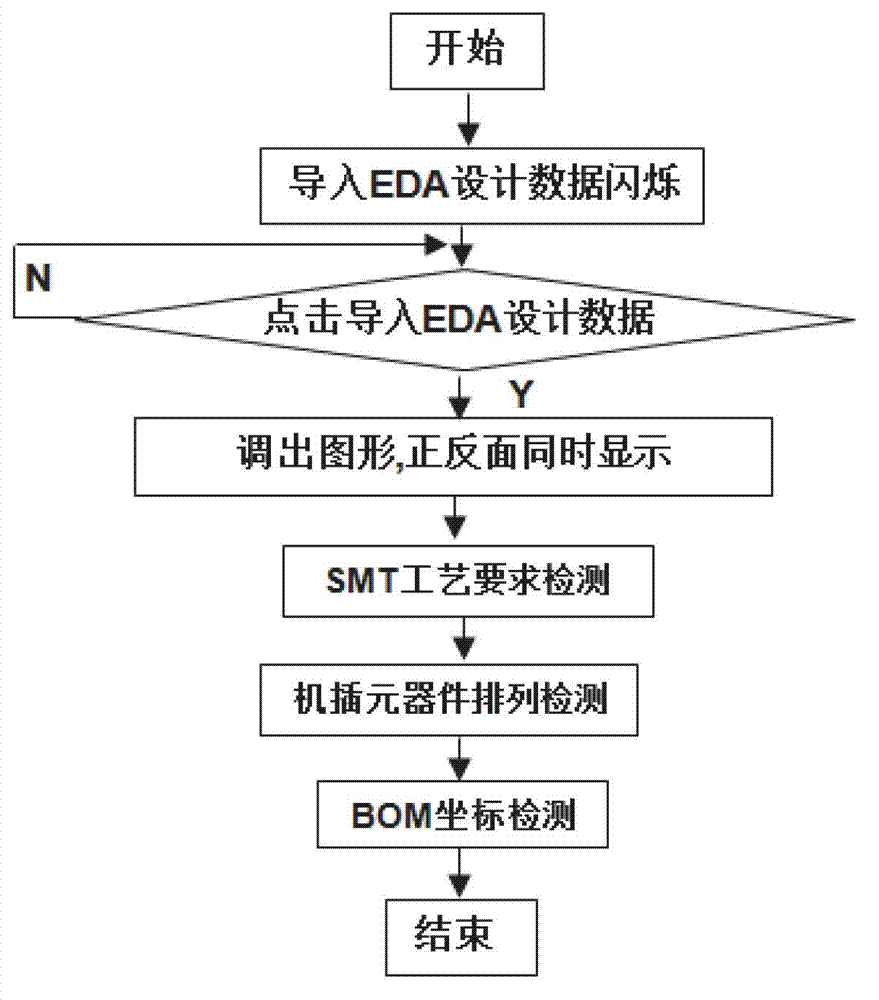

[0056] Step 1: EDA input: extract information from the EDA design file or Gerber file, and convert it into a PCB intermediate file with a unified format; the specific method is: extract the component information and pad information of the EDA design file, and convert it into a virtual simulation The virtual EDA file EDASim.txt; then extract the component information of the Gerber file and BOM file respectively, and convert it into a virtual simulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com