Ceramic large plate of anhydrous glaze line all-digital jet printing process and manufacturing method thereof

A technology of digital printing and production method, which is applied in the field of architectural ceramic tiles, can solve problems such as complex production processes, and achieve the effects of widening visual effects, reducing labor, and flexible cutting applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

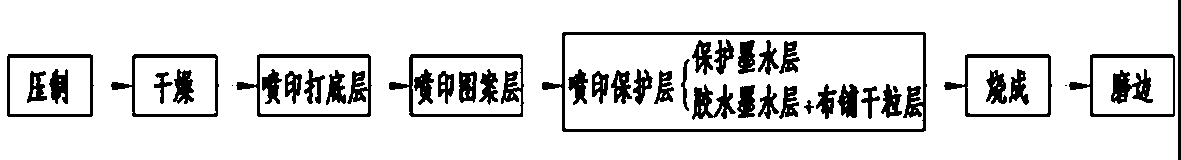

Method used

Image

Examples

Embodiment 1

[0048] (1) Select kaolin, feldspar, quartz and other raw sand materials, and prepare ceramic powder for the bottom blank according to the matching brick shape control requirements, and set aside.

[0049] (2) Prepare the base layer ink, color pattern layer ink, sagging / or peeling function ink, and protective layer ink for printing, and set them aside.

[0050] (3) In the glaze line section where the inkjet machine works, install 3 inkjet printers in series, the first inkjet printer has 2 channels, the second inkjet printer has 8 channels, and the third inkjet printer has 2 channels channels.

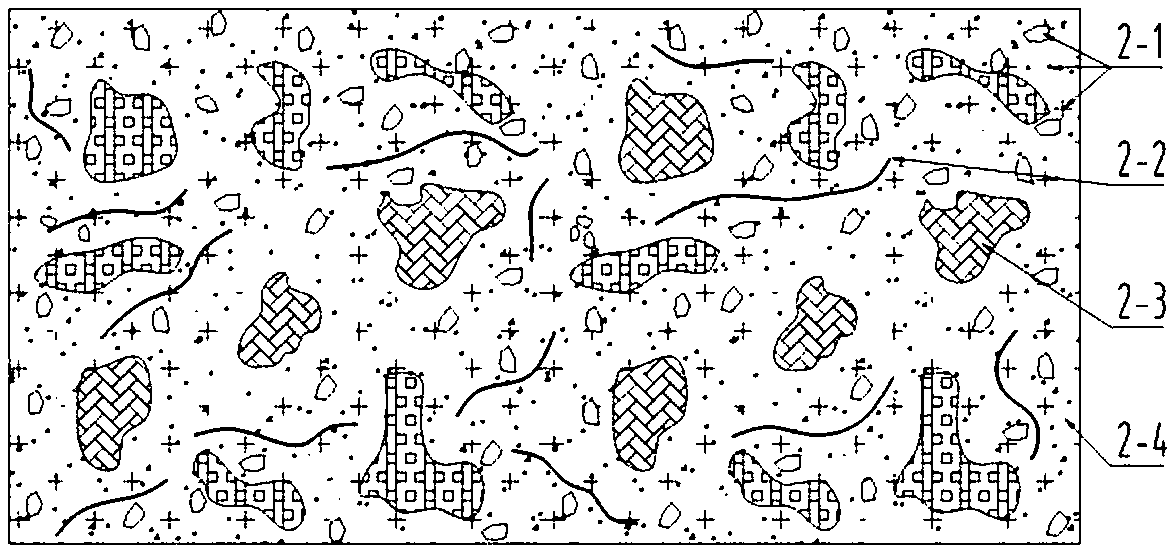

[0051] (4), ceramic powder is loaded into the installed distributing equipment; All the ceramic inks containing zirconium are loaded into the 2 passages of the first inkjet machine, and the 8 passages of the second inkjet machine are respectively pressed White, blue, brown, yellow, black, orange, wrapped red, sunken (Jingdiao) are filled with 8 kinds of ceramic inks, and the 4 channels ...

Embodiment 2

[0061] (1) Select kaolin, feldspar, quartz and other raw sand materials, and prepare ceramic powder for the bottom blank according to the matching brick shape control requirements, and set aside.

[0062] (2) Prepare the base layer ink, color pattern layer ink, sagging / or peeling function ink, and protective layer ink for printing, and set them aside.

[0063] (3) In the glaze line section where the inkjet machine works, install 3 inkjet printers in series, the first inkjet printer has 2 channels, the second inkjet printer has 8 channels, and the third inkjet printer has 4 channels channels.

[0064] (4), ceramic powder is loaded into the installed distributing equipment; All the ceramic inks containing zirconium are loaded into the 2 passages of the first inkjet machine, and the 8 passages of the second inkjet machine are respectively pressed White, blue, brown, yellow, black, orange, wrapped red, sunken (Jingdiao) are loaded with 8 kinds of ceramic inks, and the 4 channels ...

Embodiment 3

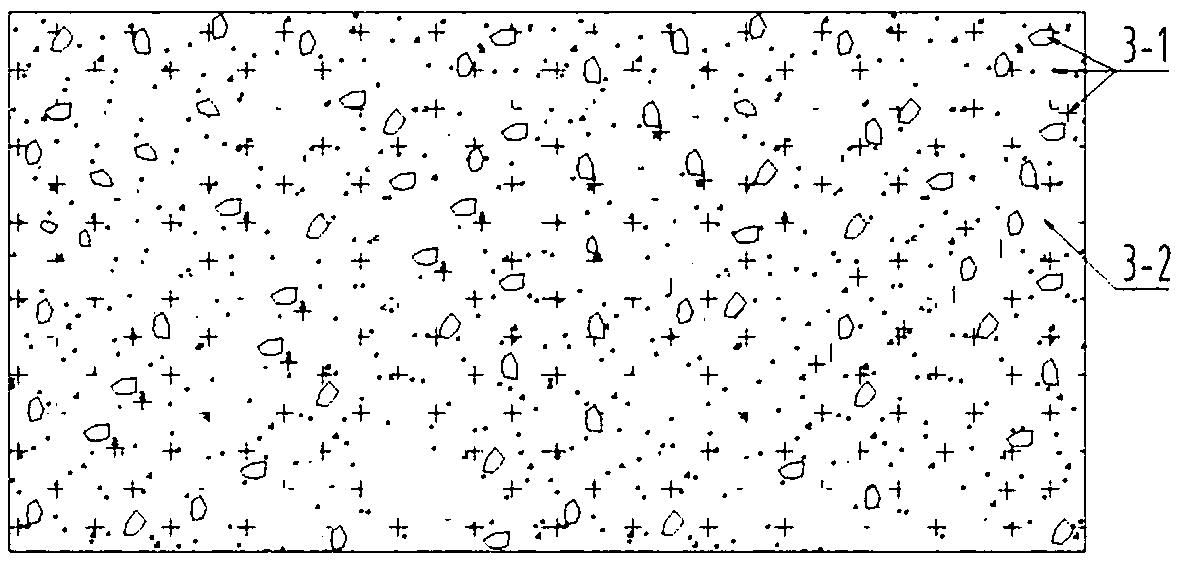

[0075]In step (6) of Example 2, the glue ink can be printed according to the digital texture, and some pre-designed positions are not sprayed with glue. After the dry grain layer is tiled, the next process is to use the action of the suction / or blow dry grain device , to absorb / or blow away the dry grains in the area without glue voids in the digital texture, and then fire, edge, polish or soft light, and finally the shiny or soft light surface is a dry grain layer and has a grooved texture The dry grain marble ceramic slab product (such as Figure 4 shown)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com