Method for quickly detecting quality of gravel pile

A detection method and technology of gravel piles are applied in soil protection, foundation structure testing, construction and other directions, which can solve problems such as inability to quickly and accurately evaluate project quality, high detection cost, and impact on construction progress, etc. Work efficiency, ensure project quality, and improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Further description will be given below in conjunction with the examples.

[0040] The rapid detection method of gravel pile quality comprises the following steps:

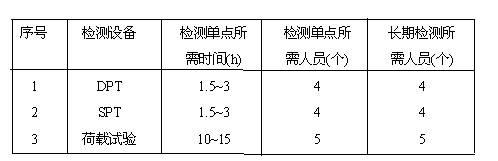

[0041] (1) Preparations before the DPT test:

[0042] Leveling the site: so that the drilling rig can be placed smoothly.

[0043] The drill pipe used in the heavy-duty dynamic penetrating test should be checked regularly, the relative bending of the drill pipe is less than 1 / 1000, and the joints should be firm, otherwise the drill pipe will shake sideways after being hammered.

[0044] The heavy-duty dynamic penetrating test should adopt the free-fall hammer method with automatic decoupling, and reduce the frictional resistance between the guide rod and the hammer to keep the hammering energy constant.

[0045] (2) DPT test procedure: After the installation and inspection work is done, select the point to be tested, and move the DPT to the test site for testing.

[0046] ① Stand the sliding rod vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com