Bidirectional machine-room-free speed limiter of single brake pressing-plate device

A technology of brake plate and single brake, which is applied in the direction of elevator, transportation and packaging, etc., and can solve the problem that the speed limiter cannot be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

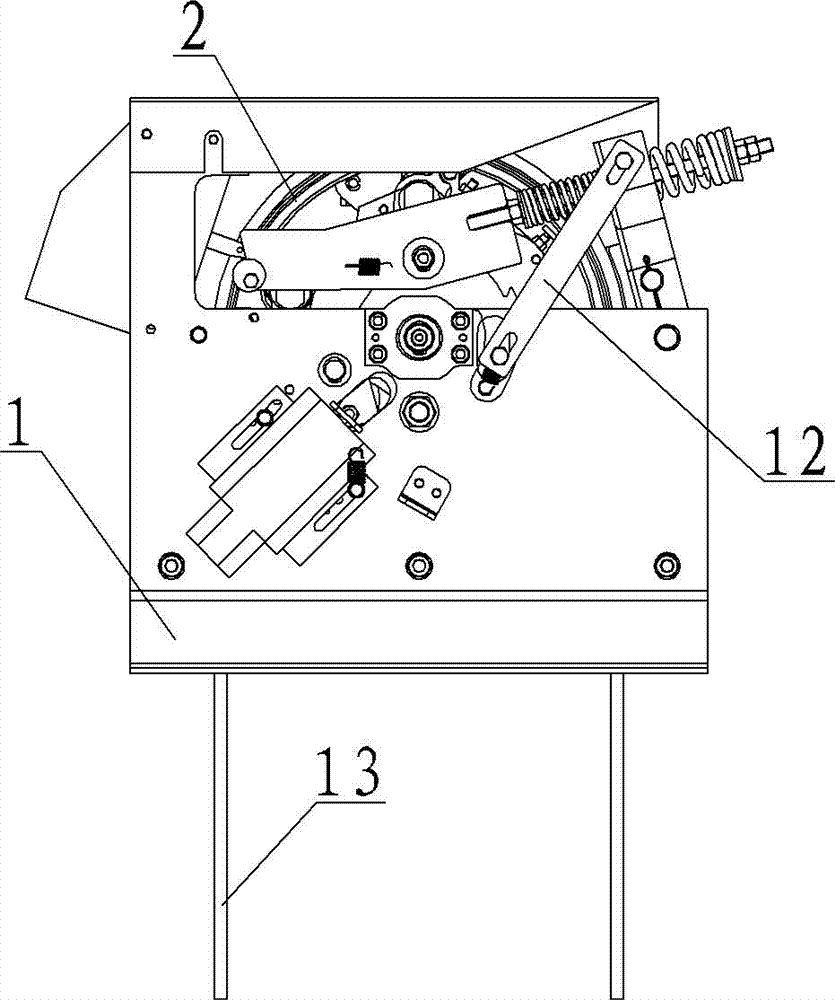

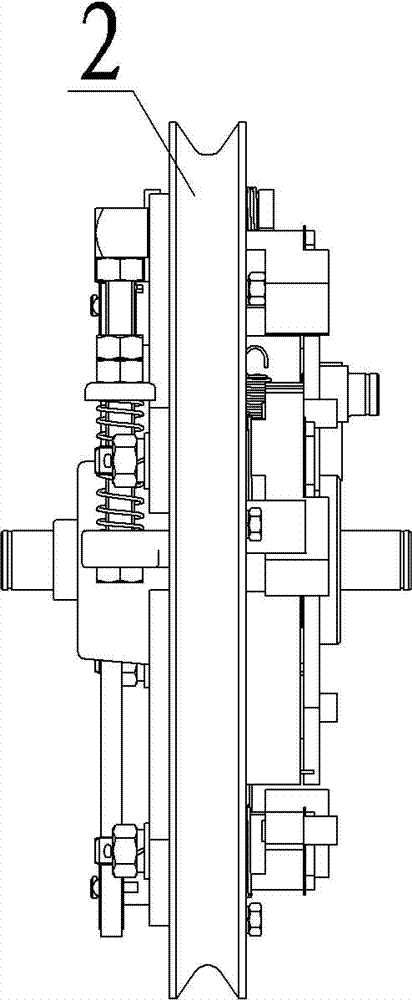

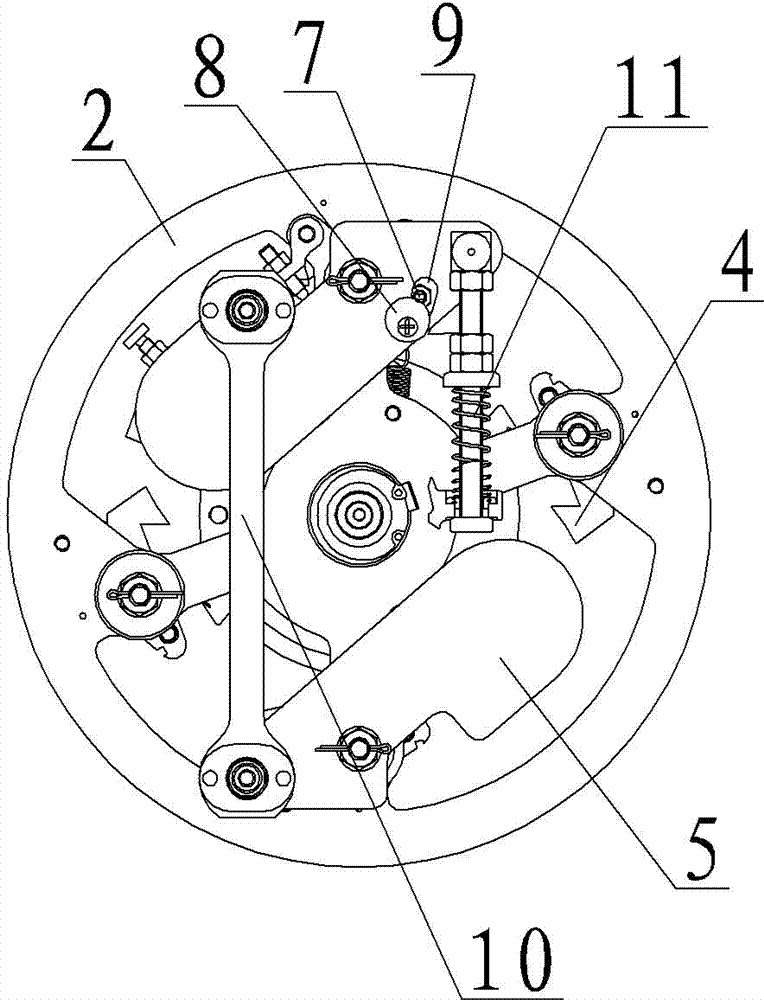

[0014] An embodiment of a two-way machine room-less speed governor with a single brake pressure plate device, in Figure 1~5Among them, the so-called two-way speed limiter is exactly the speed limiter that can play a role when the elevator goes up and down. Its base 1 is equipped with a sheave 2 and a ratchet 3 coaxially rotating, and a wire rope 13 is wound on the sheave 2. The diameter of the ratchet 3 is smaller than the diameter of the sheave 2, and a ratchet 4 is installed on the wheel surface of the sheave 2. A torsion spring is arranged between the pawl 4 and the sheave 2, and the torsion spring gives the torsion force to the pawl 4, so that the ratchet The rotation of the pawl 4 always has a tendency to engage with the slot of the ratchet 3. When the pawl 4 is in a free state, the pawl 4 and the ratchet 3 will be in a clamped state, and a pawl is also rotated on the rope wheel 2. The positioning structure 6, the pawl positioning structure 6 has a pressing end, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com