Patents

Literature

58 results about "Jackhammer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A jackhammer (pneumatic drill or demolition hammer in British English) is a pneumatic or electro-mechanical tool that combines a hammer directly with a chisel. It was invented by William Mcreavy, who then sold the patent to Charles Brady King. Hand-held jackhammers are generally powered by compressed air, but some are also powered by electric motors. Larger jackhammers, such as rig mounted hammers used on construction machinery, are usually hydraulically powered. They are typically used to break up rock, pavement, and concrete.

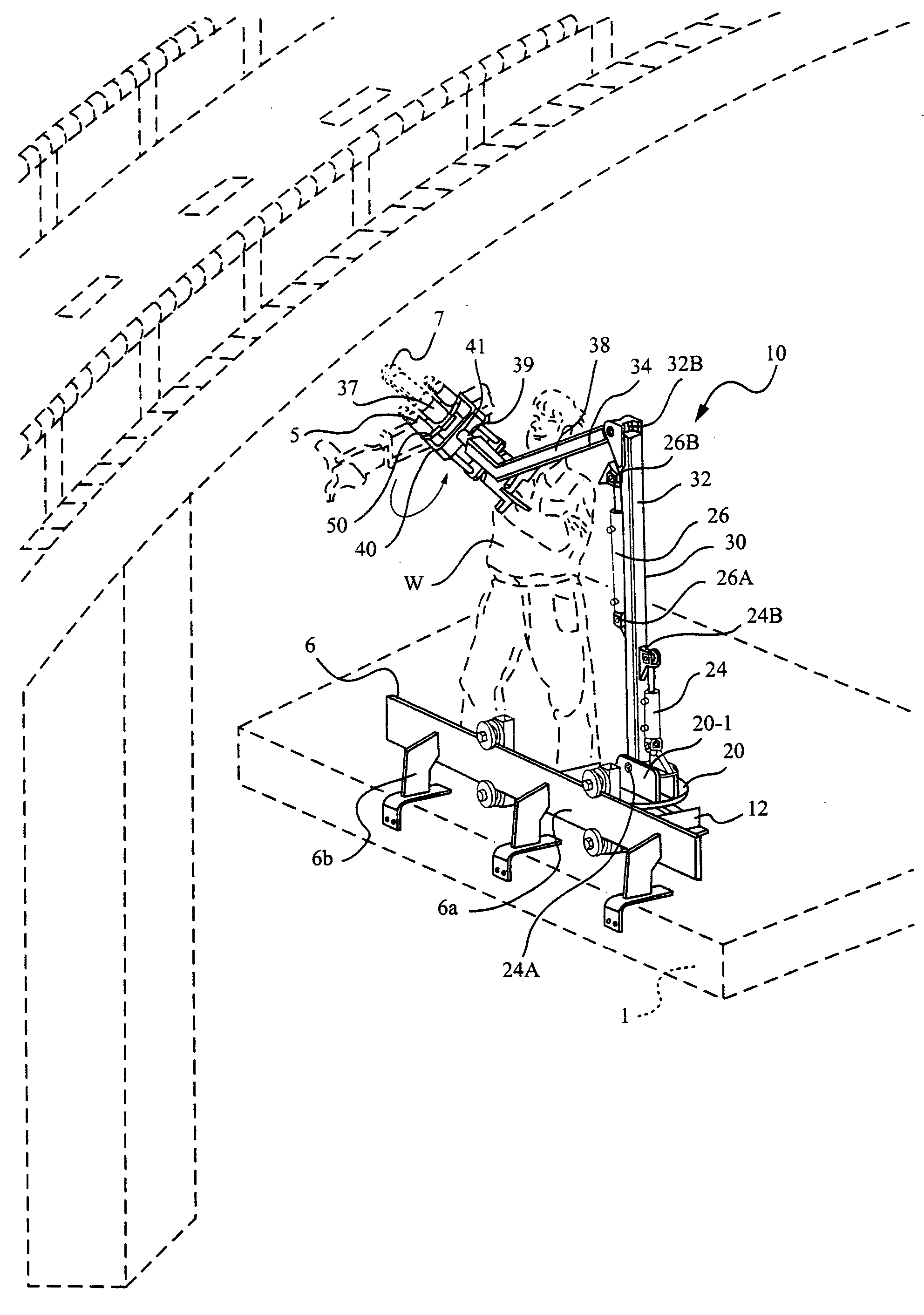

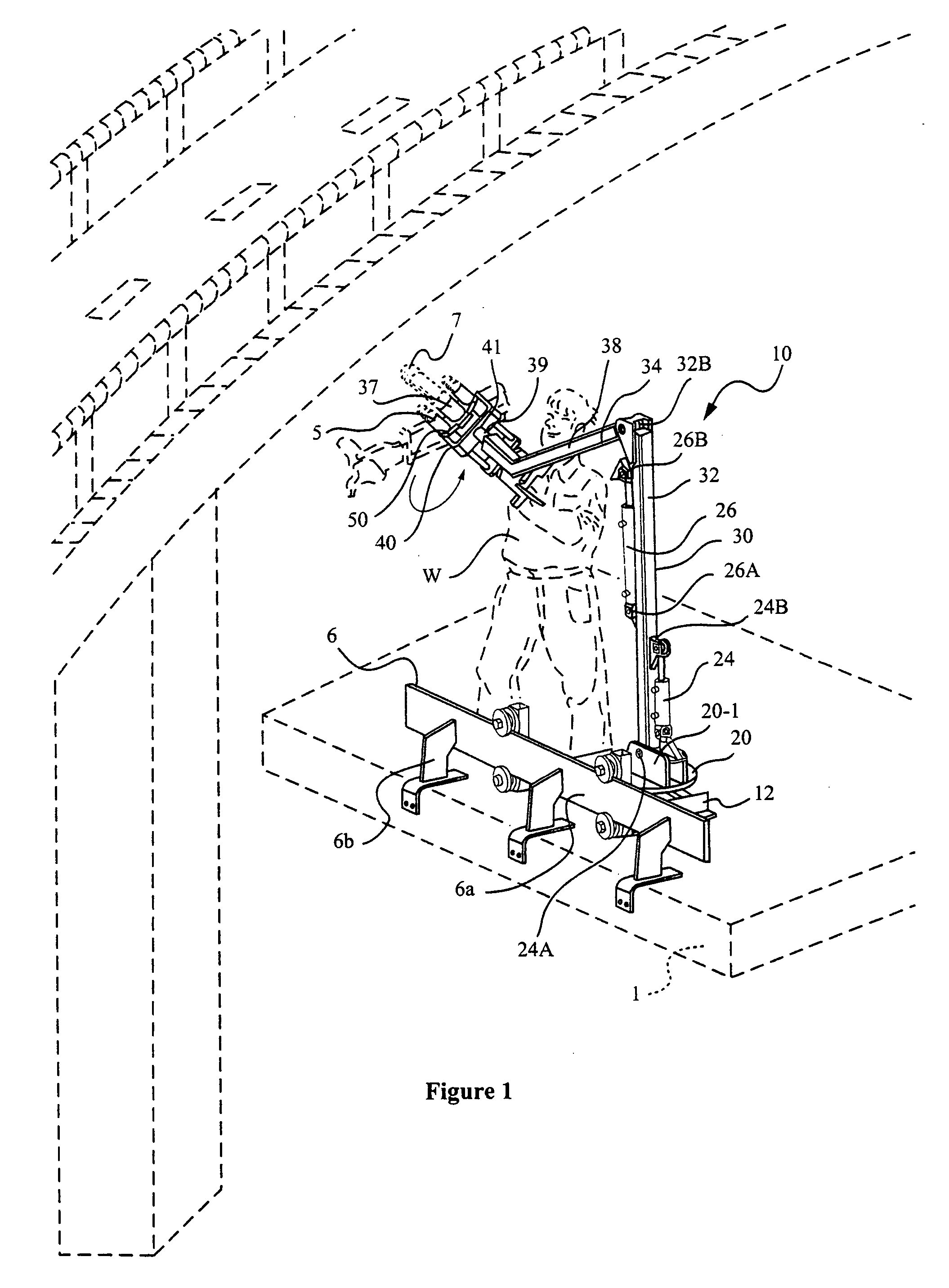

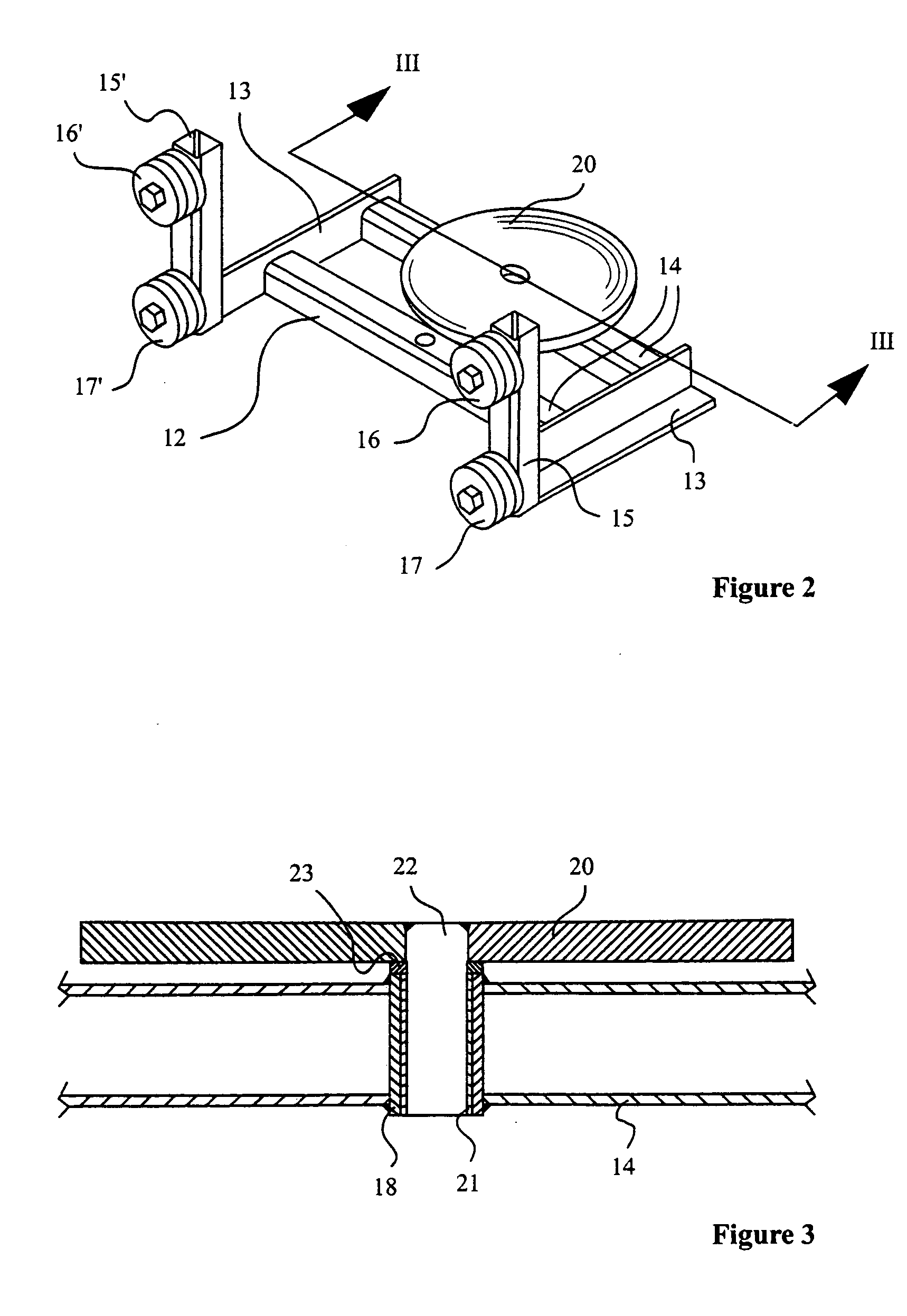

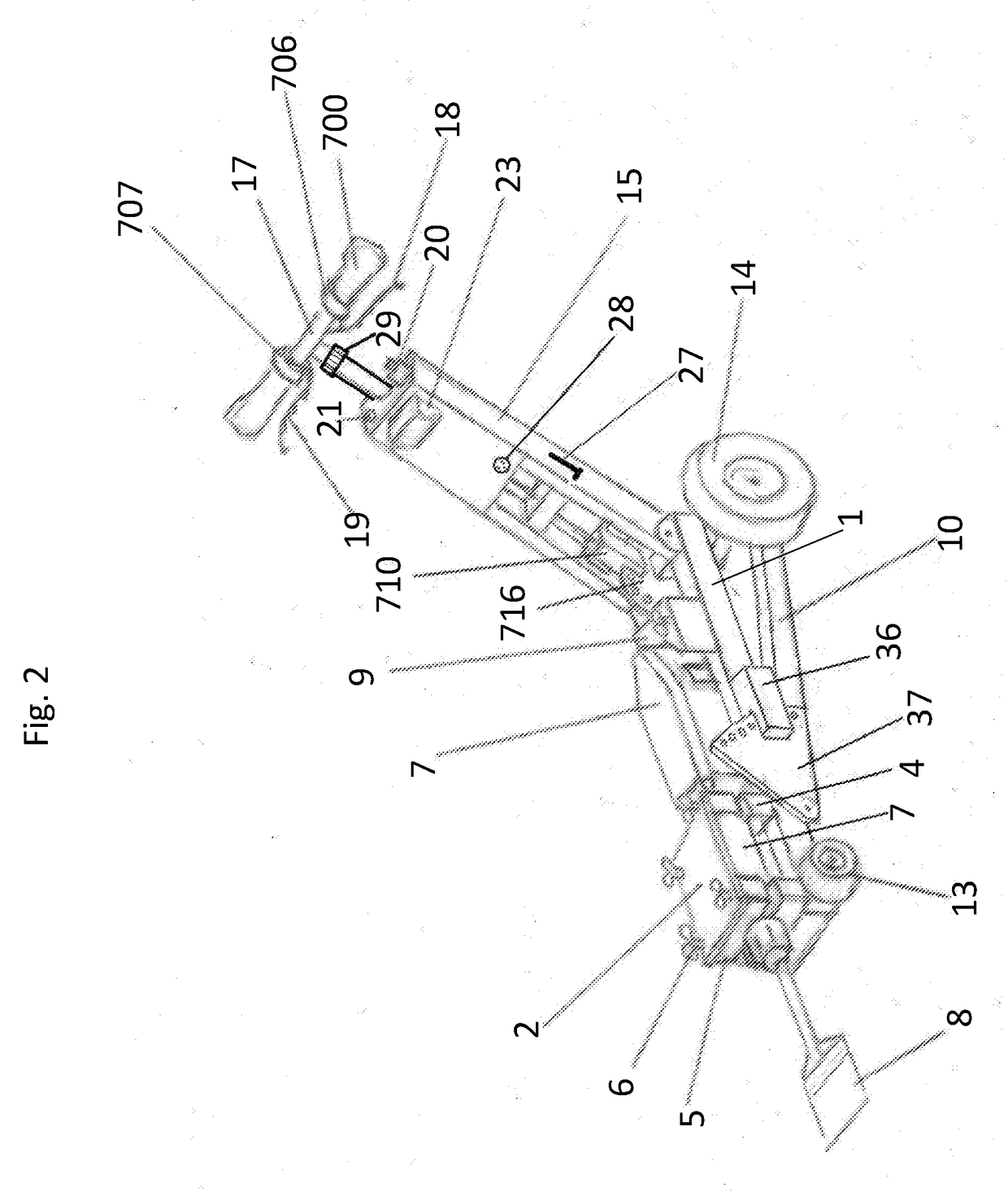

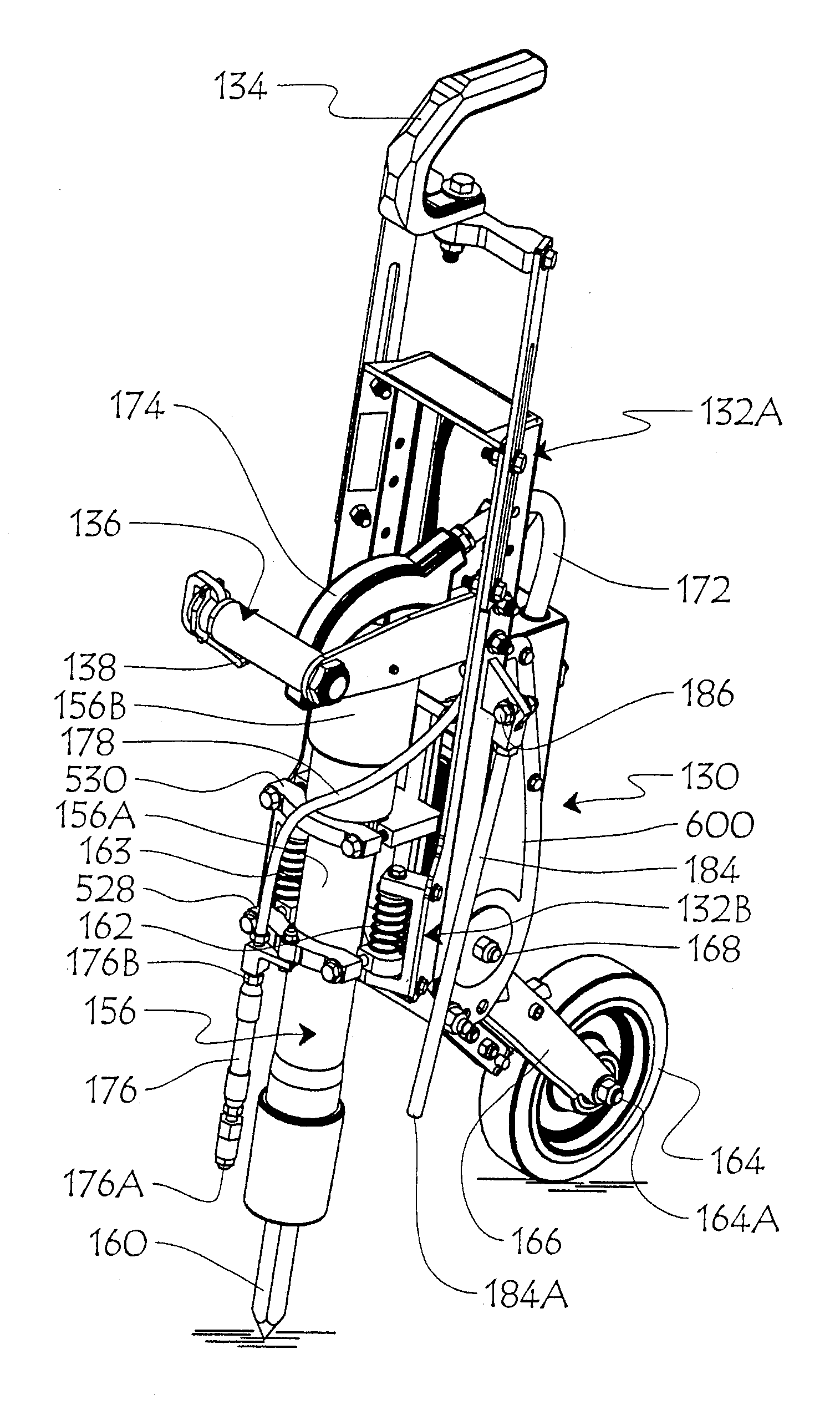

Power-assisted multidirectional jackhammer positioner

A jackhammer positioner comprising a support structure displaceably or fixedly resting on the ground, a base pivotally mounted onto the support structure, and an articulated arm pivotally connected to the base carrying a jackhammer. The articulated arm comprises two pivotally interconnected arm portions. A yoke is pivotally installed at the end of the arm opposite its connection to the base. The yoke pivotally carries a jackhammer support mechanism for carrying a jackhammer, the mechanism providing the positioner with the ability to linearly translate the jackhammer. The positioner thus comprises five pivot joints and one translation joint, and can consequently be operated to take a large number of different conformations. The operative tip of a jackhammer suspended to the positioner can thereby be easily and rapidly juxtaposed to a surface which needs to be worked.

Owner:LES INDS PIRANDELLO

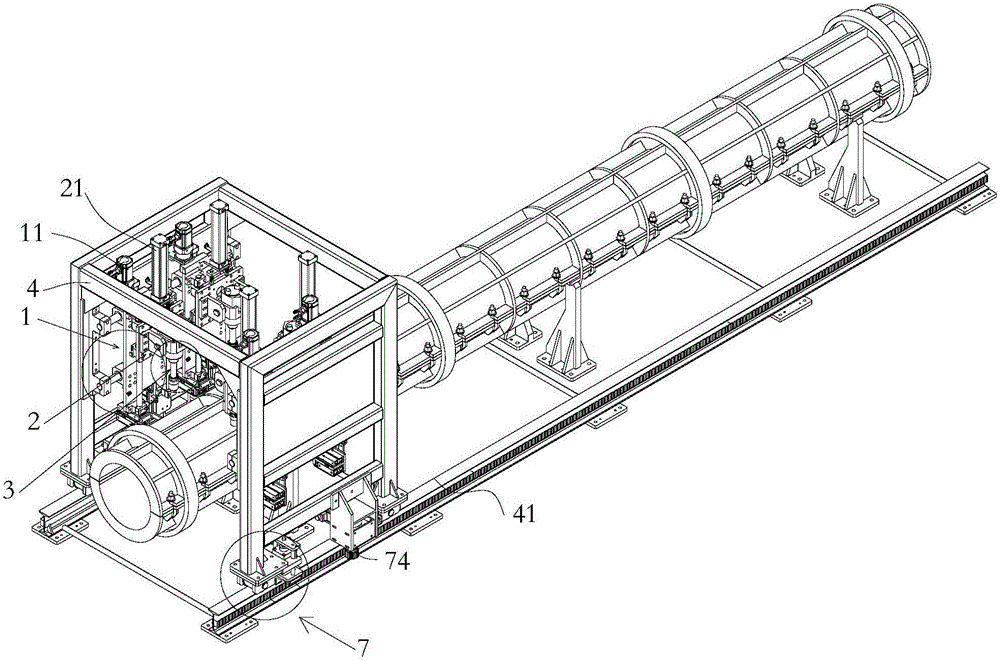

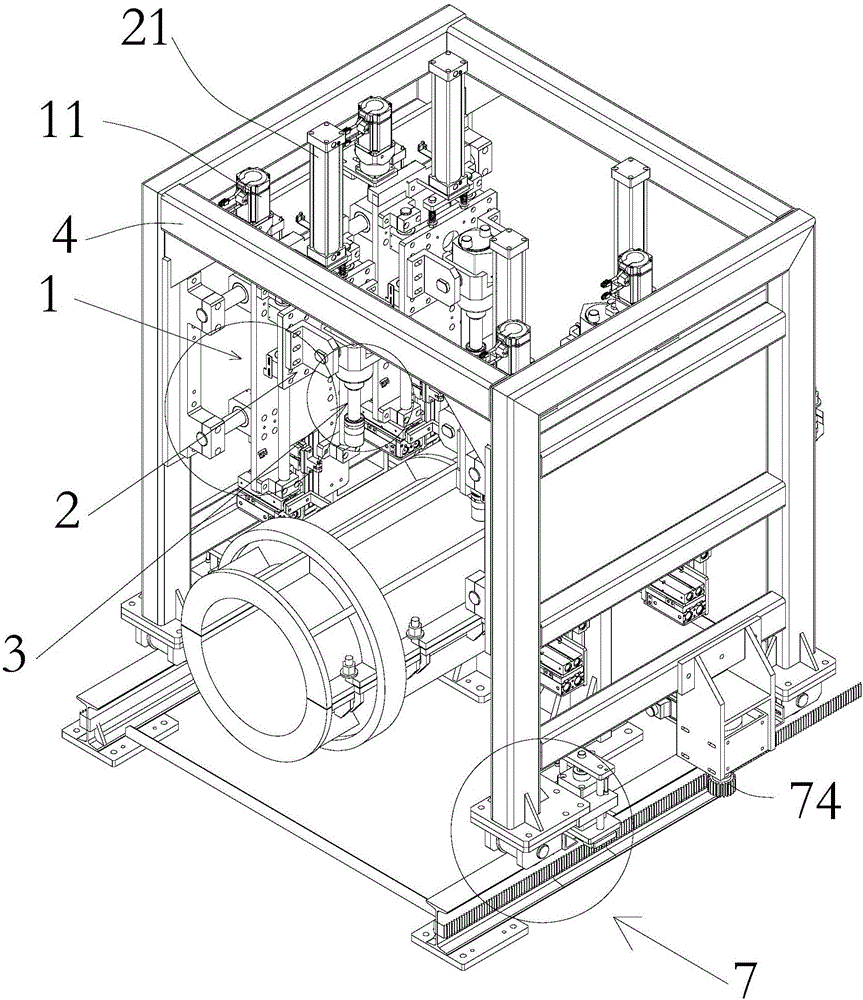

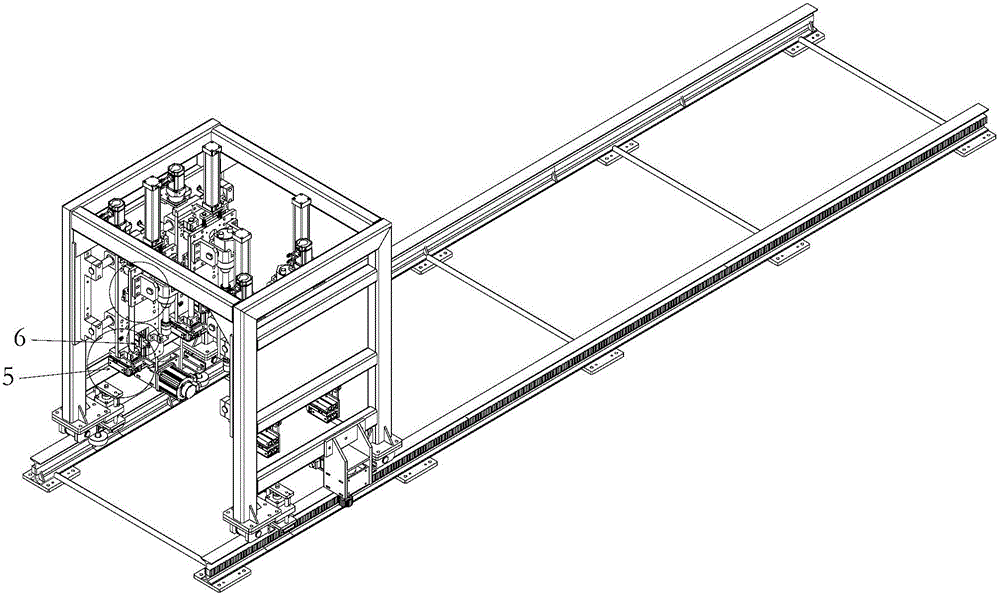

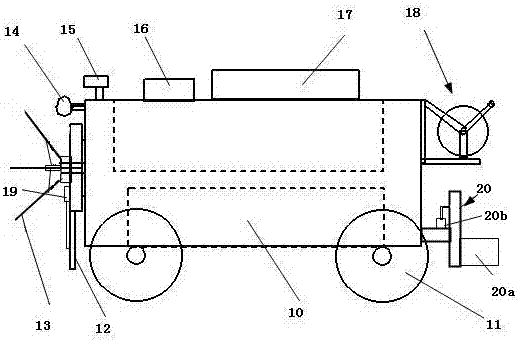

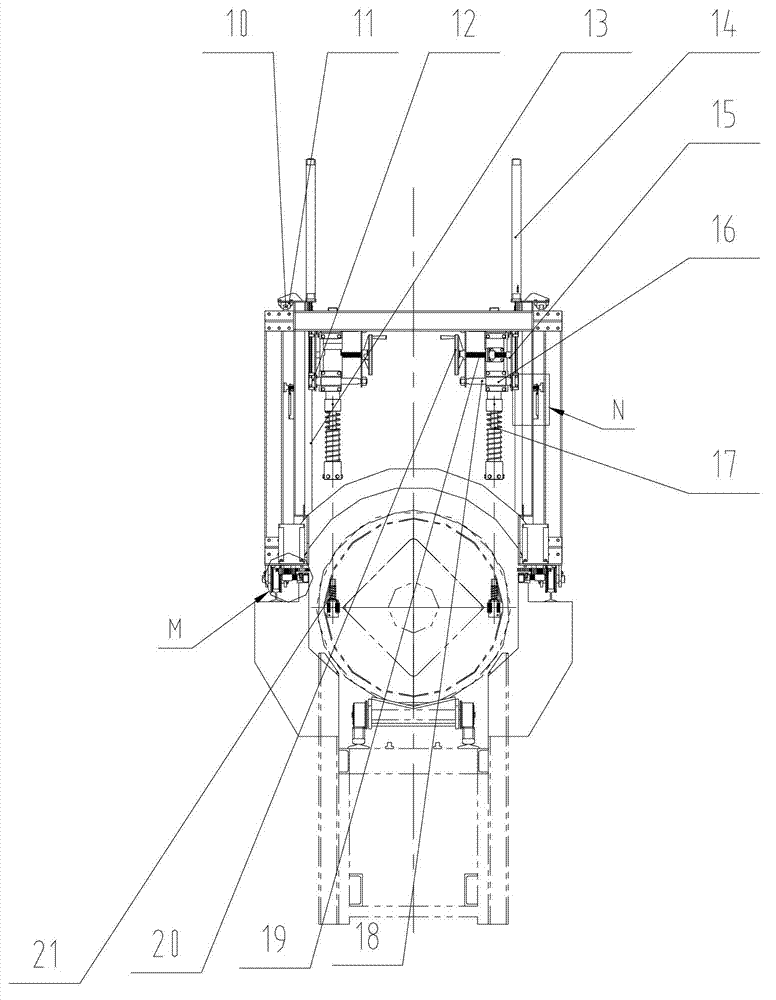

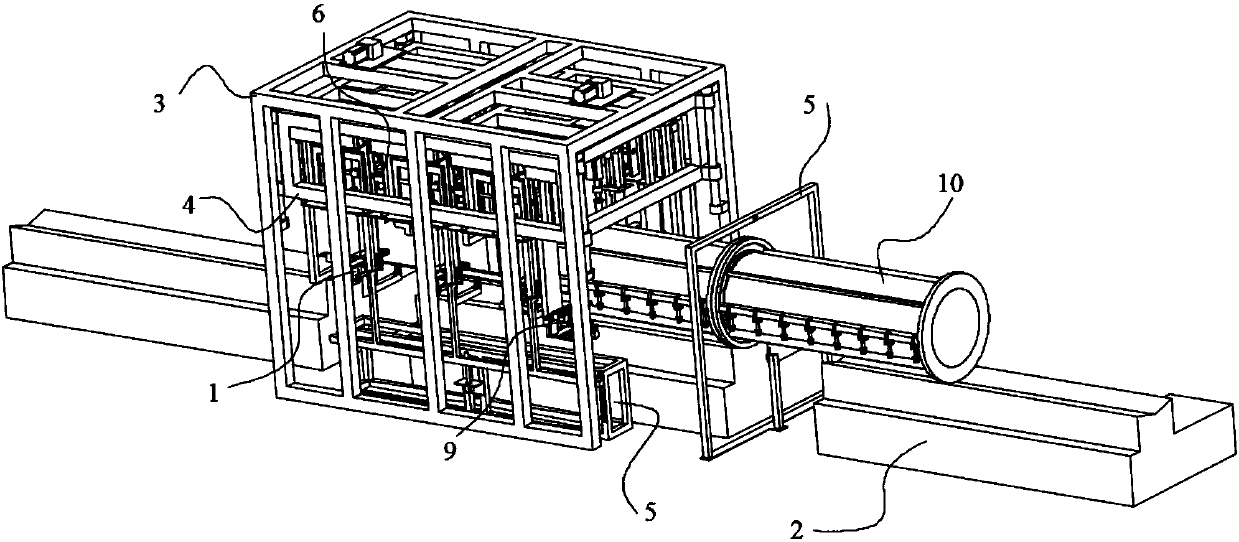

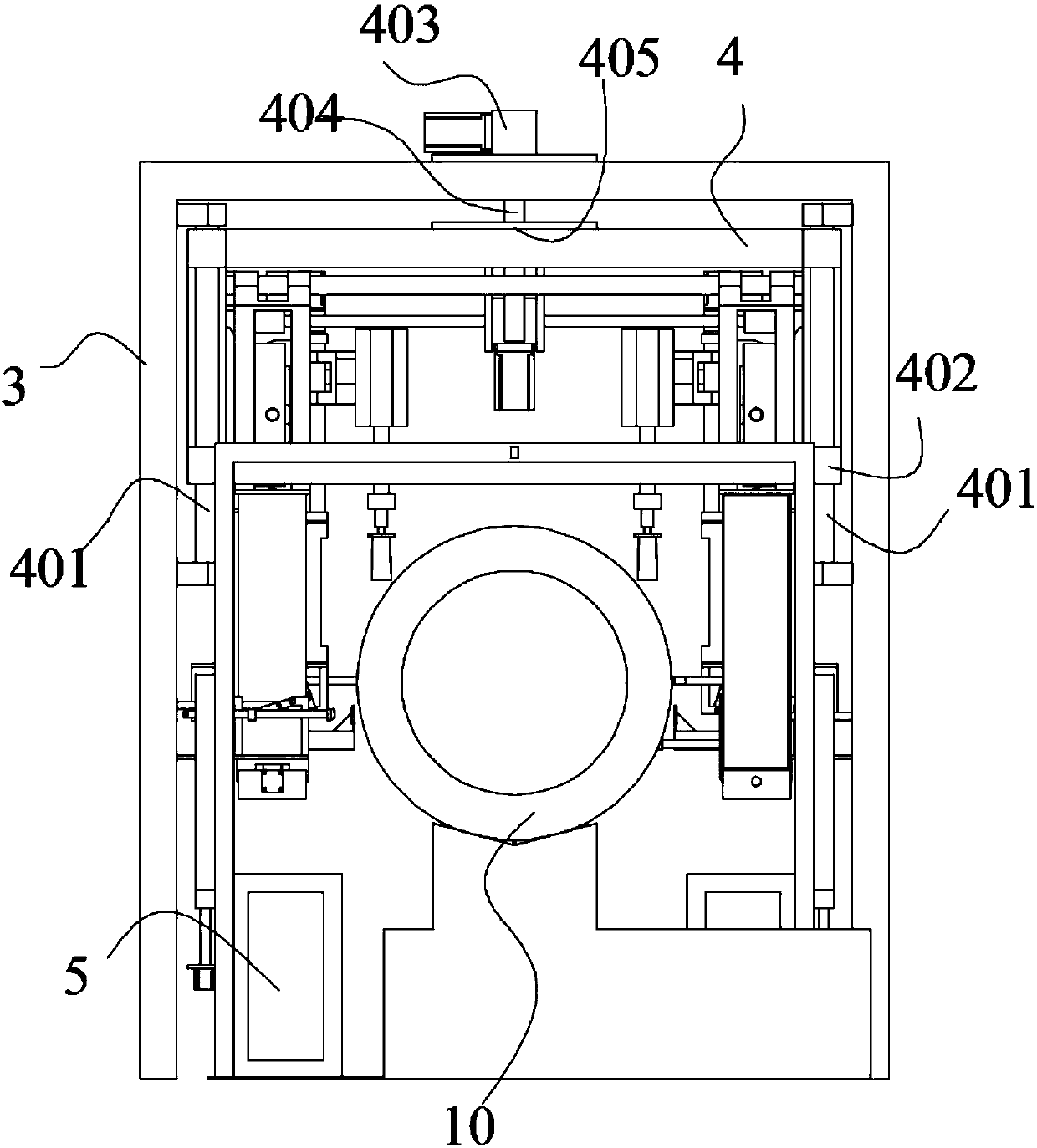

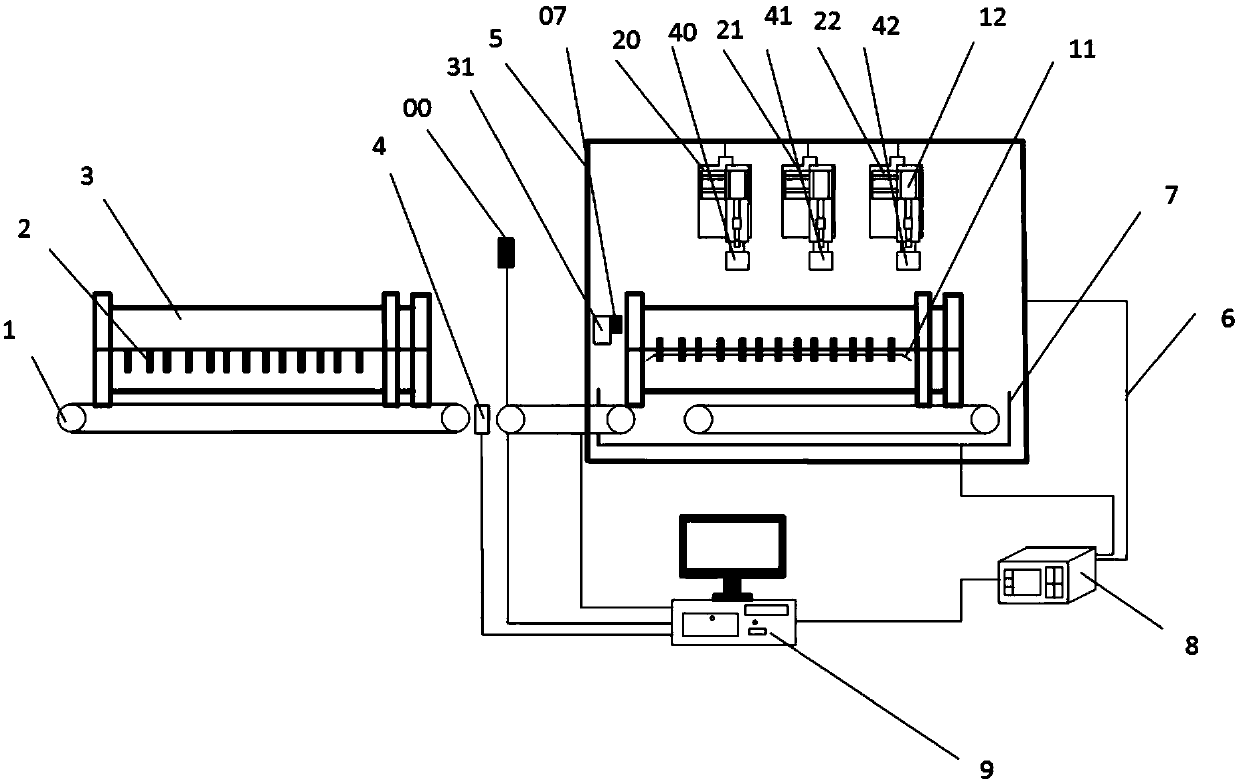

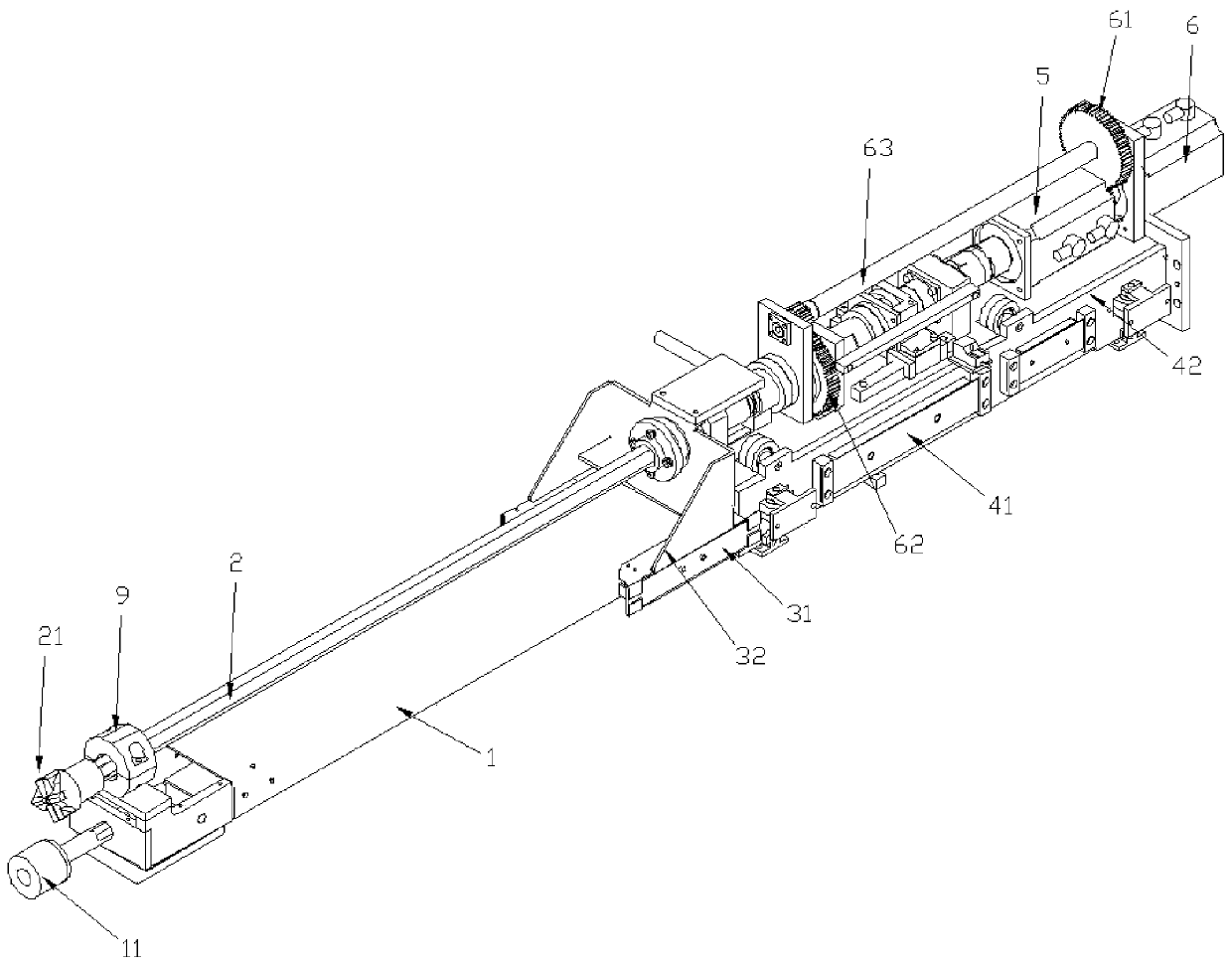

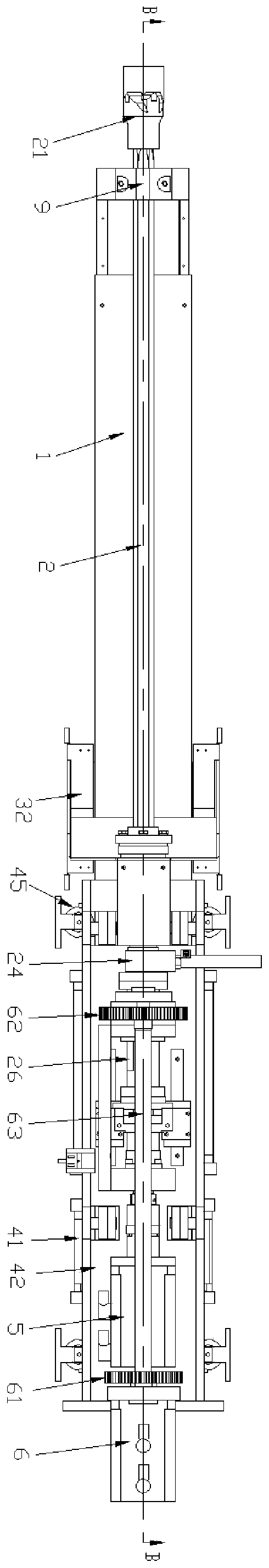

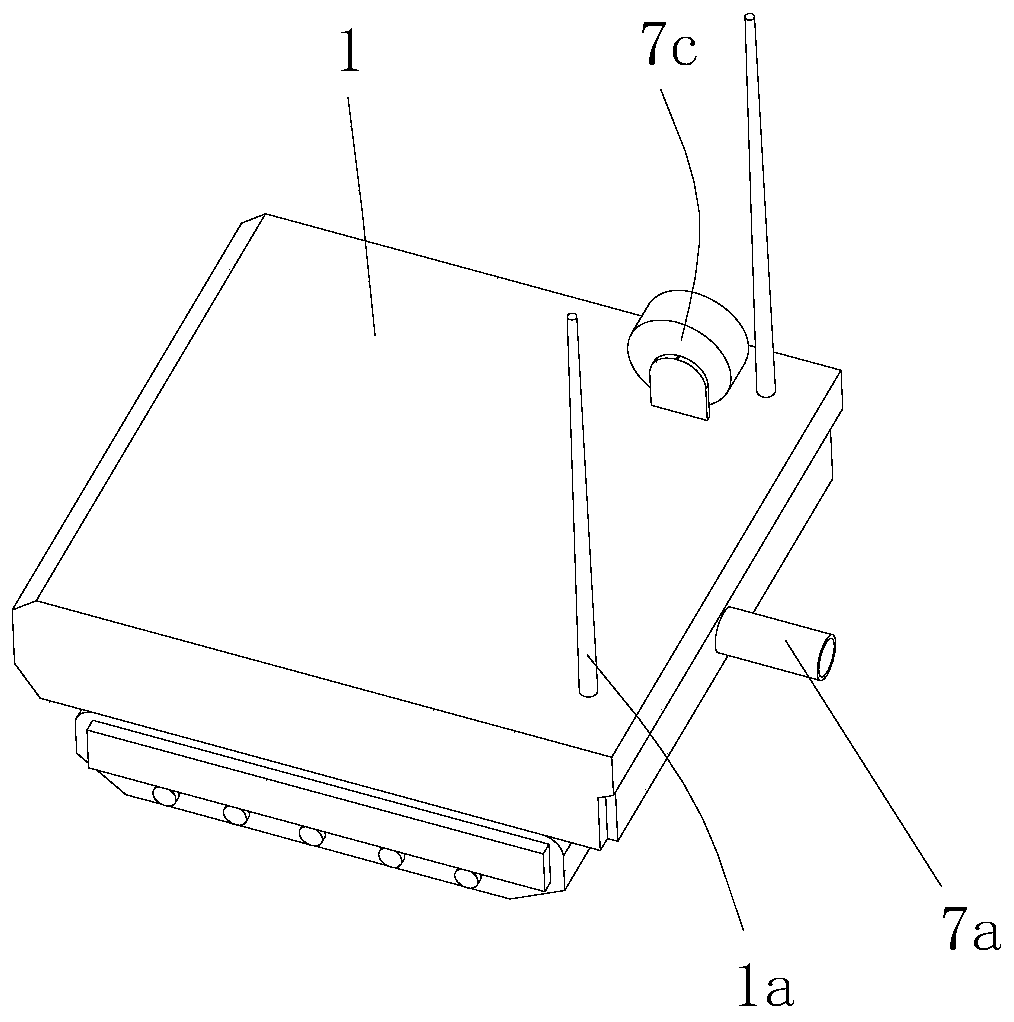

Automatic pipe die dismantling and mounting all-in-one machine

The invention discloses an automatic pipe die dismantling and mounting all-in-one machine which comprises a transverse driving device, a vertical driving device and a jackhammer device. According to the invention, as the transverse driving device, the vertical driving device and the jackhammer device are included, the jackhammer device can automatically mount a bolt; when the bolt of a pipe die is needed to be mounted, the transverse driving device and the vertical driving device are started, the transverse driving device drives the vertical driving device to move in the horizontal direction (under the initial state, the bolt of the pipe die is positioned below the pipe die), the bolt is turned over from the position below the pipe die to the position above the pipe die through matching of transverse driving and vertical driving, then, the vertical driving device drives the jackhammer device to move downwards to clamp the jackhammer device on the bolt, and the bolt is automatically mounted; and during the process, manual operation is not needed, so that manpower and material resources are saved, and the mounting efficiency is high.

Owner:GUANGZHOU DEYA MACHINERY MFG

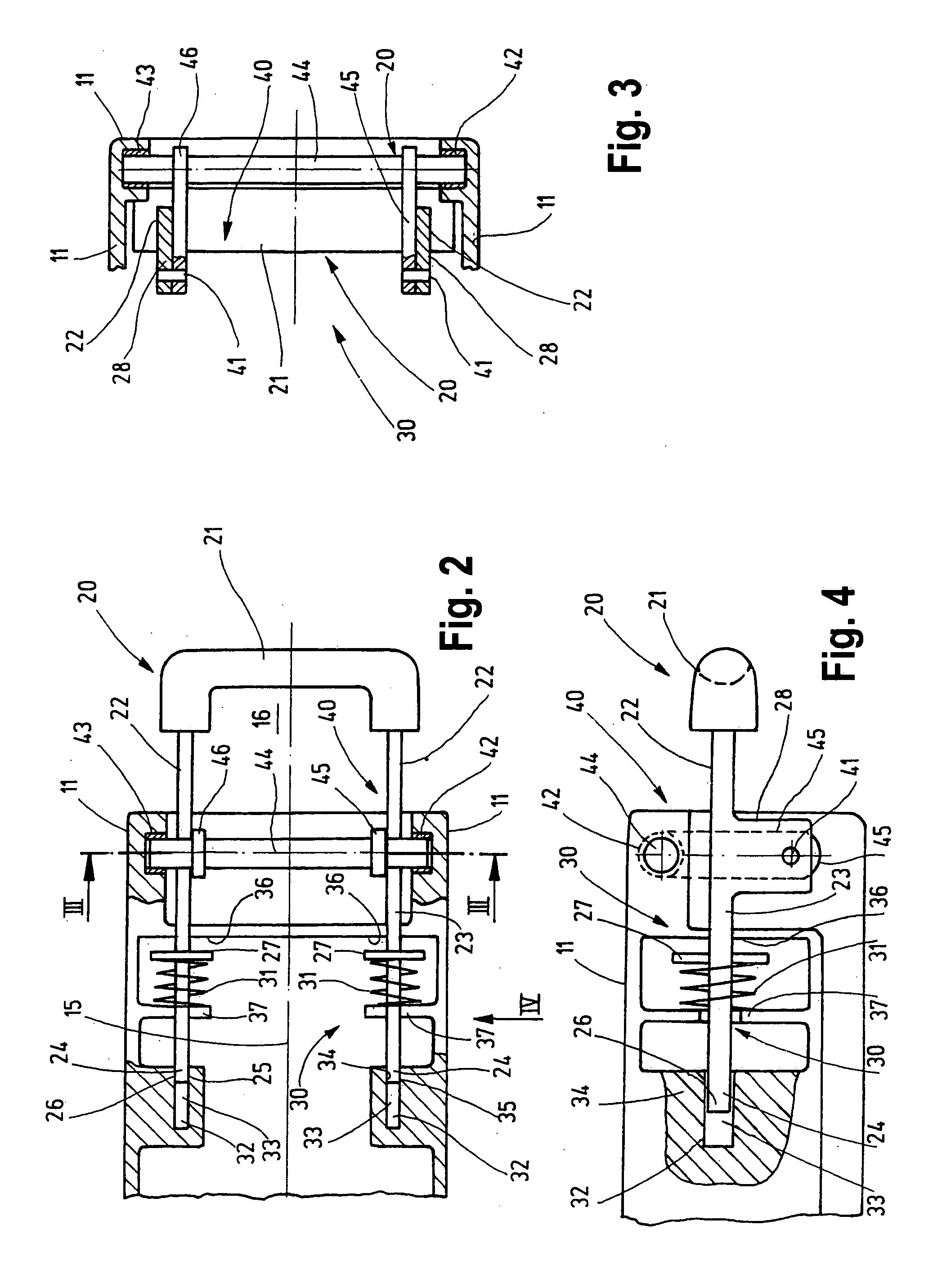

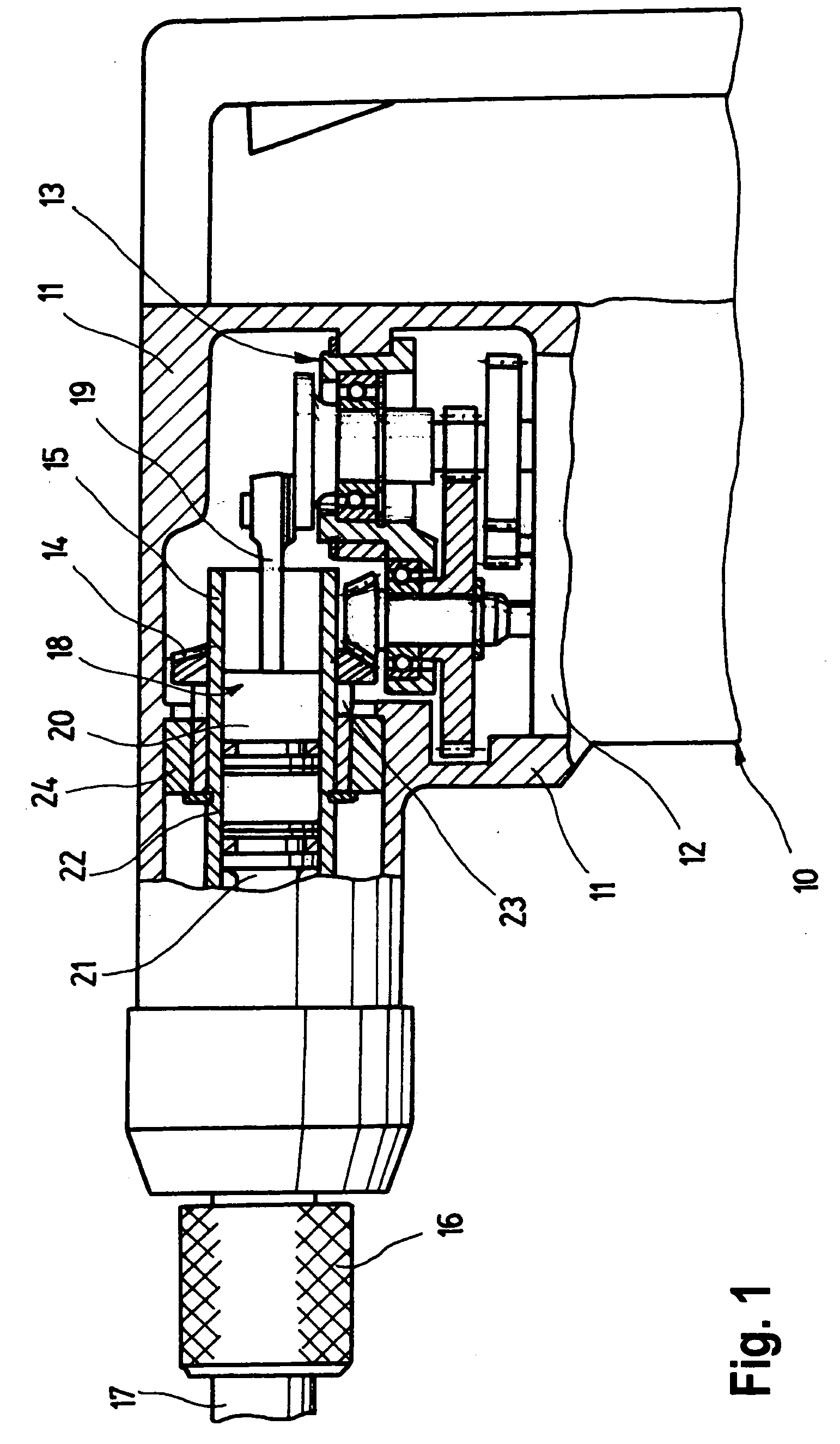

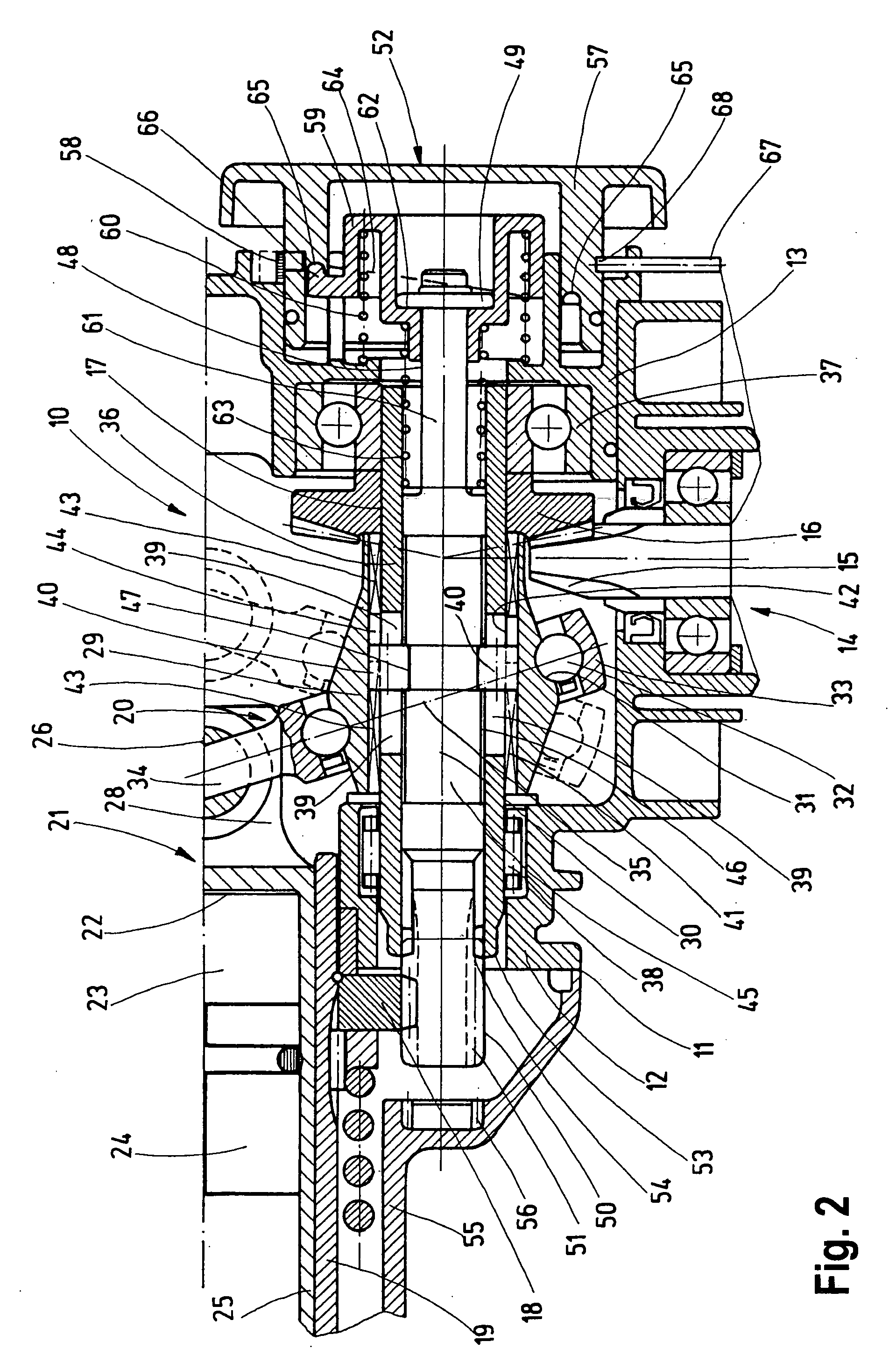

Power tool with a rotating and/or hammering drive mechanism

InactiveUS20050247464A1Simple dispositionLow costPortable percussive toolsPortable power-driven toolsJackhammerPower tool

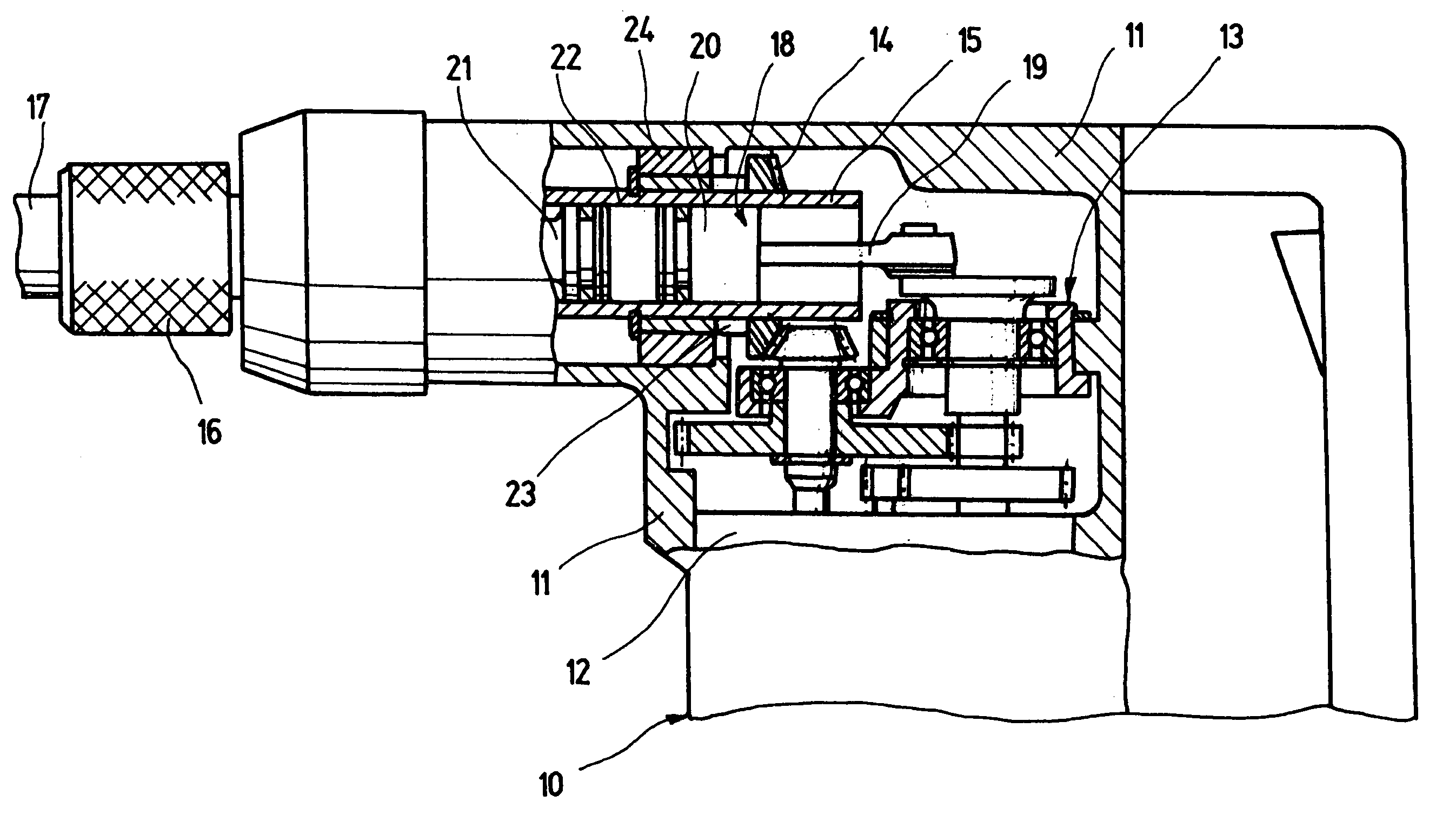

A hand-operated power tool (10), in particular a drill hammer and / or jackhammer, has a housing (11) which has a drive mechanism for driving a tool (12) that is receivable in a tool receptacle (13) and, in the rear region (14), remote from the tool receptacle (13), has a handle assembly (20) for grasping and handling that engages the housing (11). The handle assembly (20) is vibration-damped with respect to the housing (11), with the components contained in it, at least and substantially in the axial direction, by means of a vibration-damping device (FIG. 1).

Owner:ROBERT BOSCH GMBH

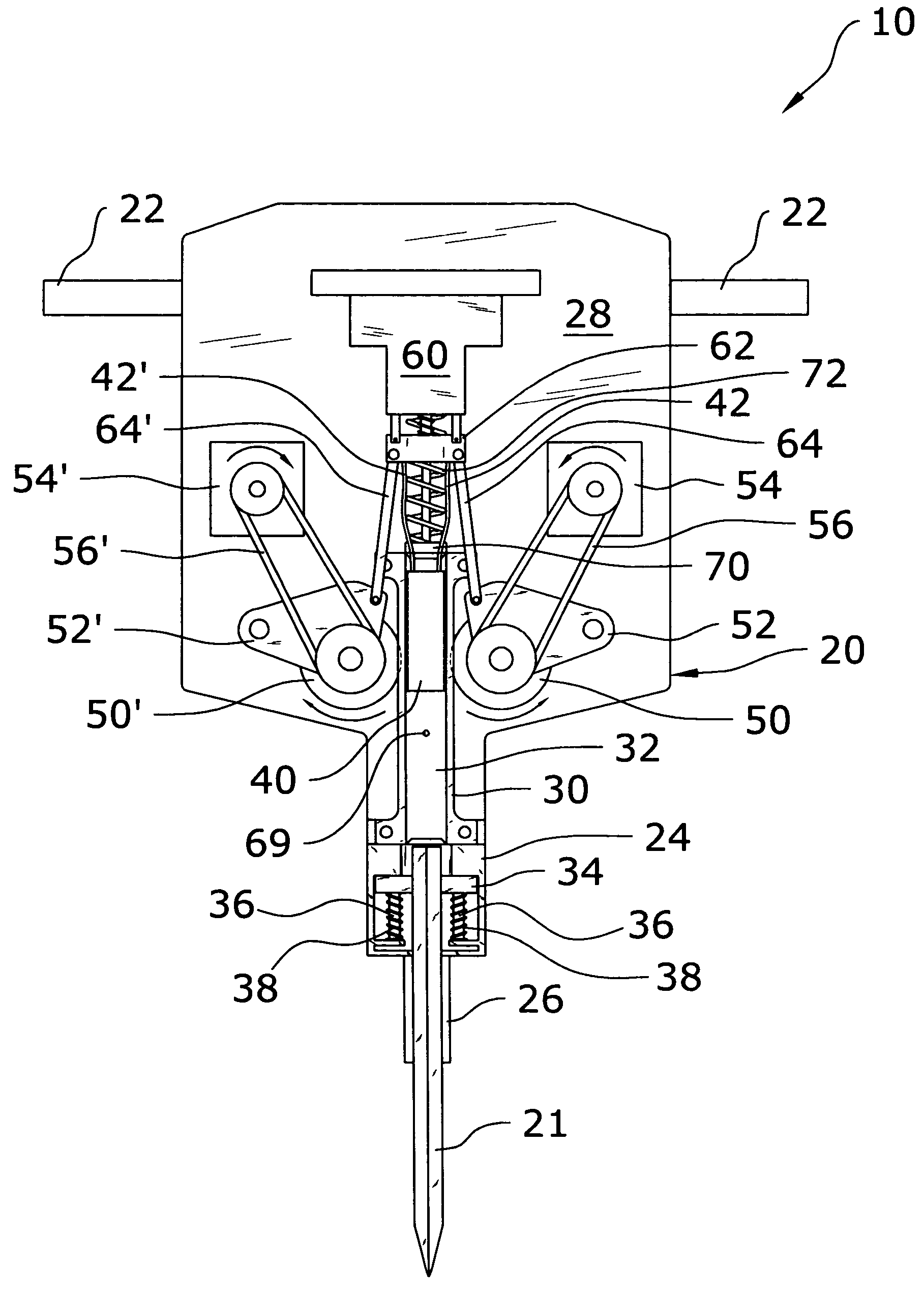

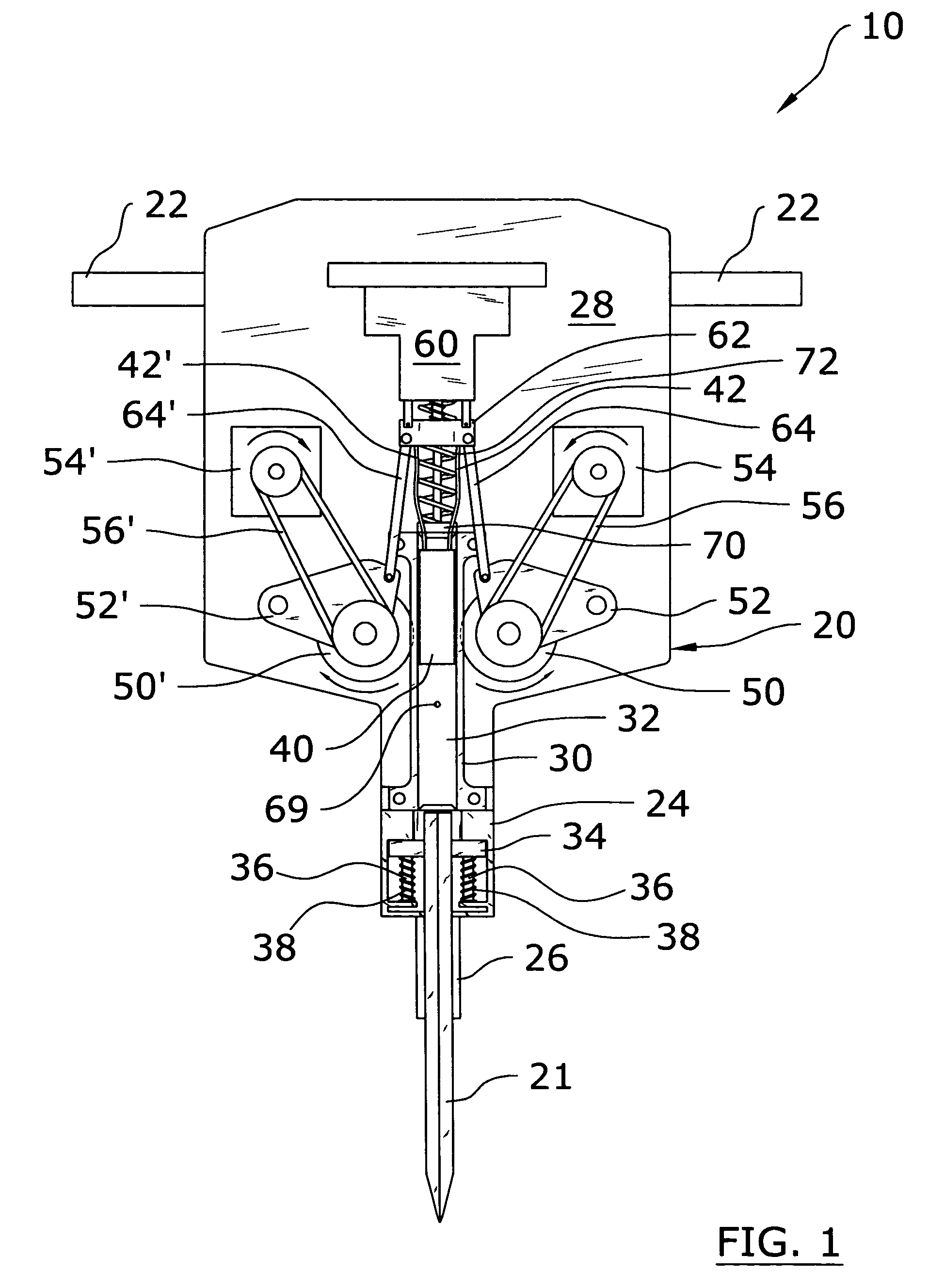

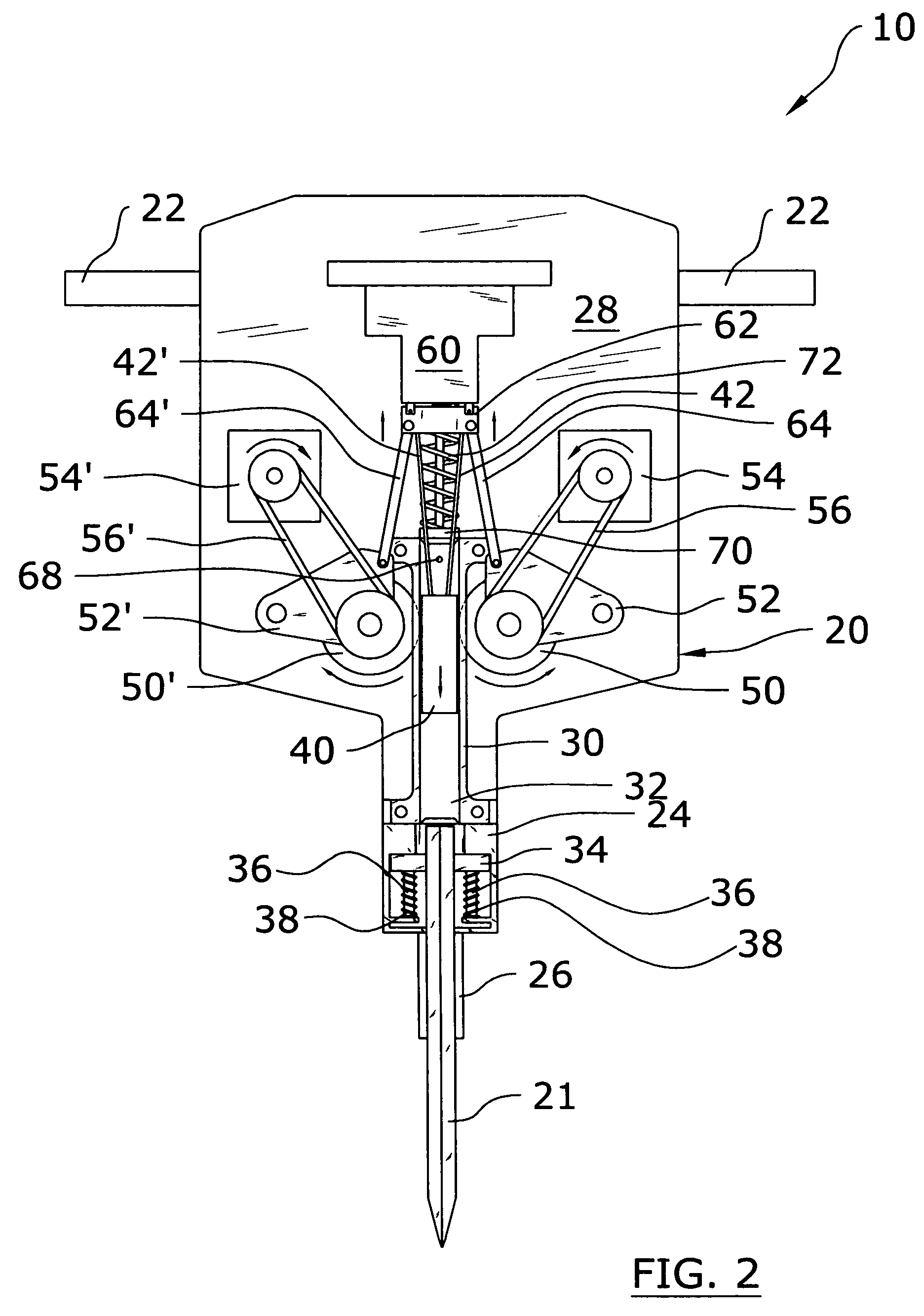

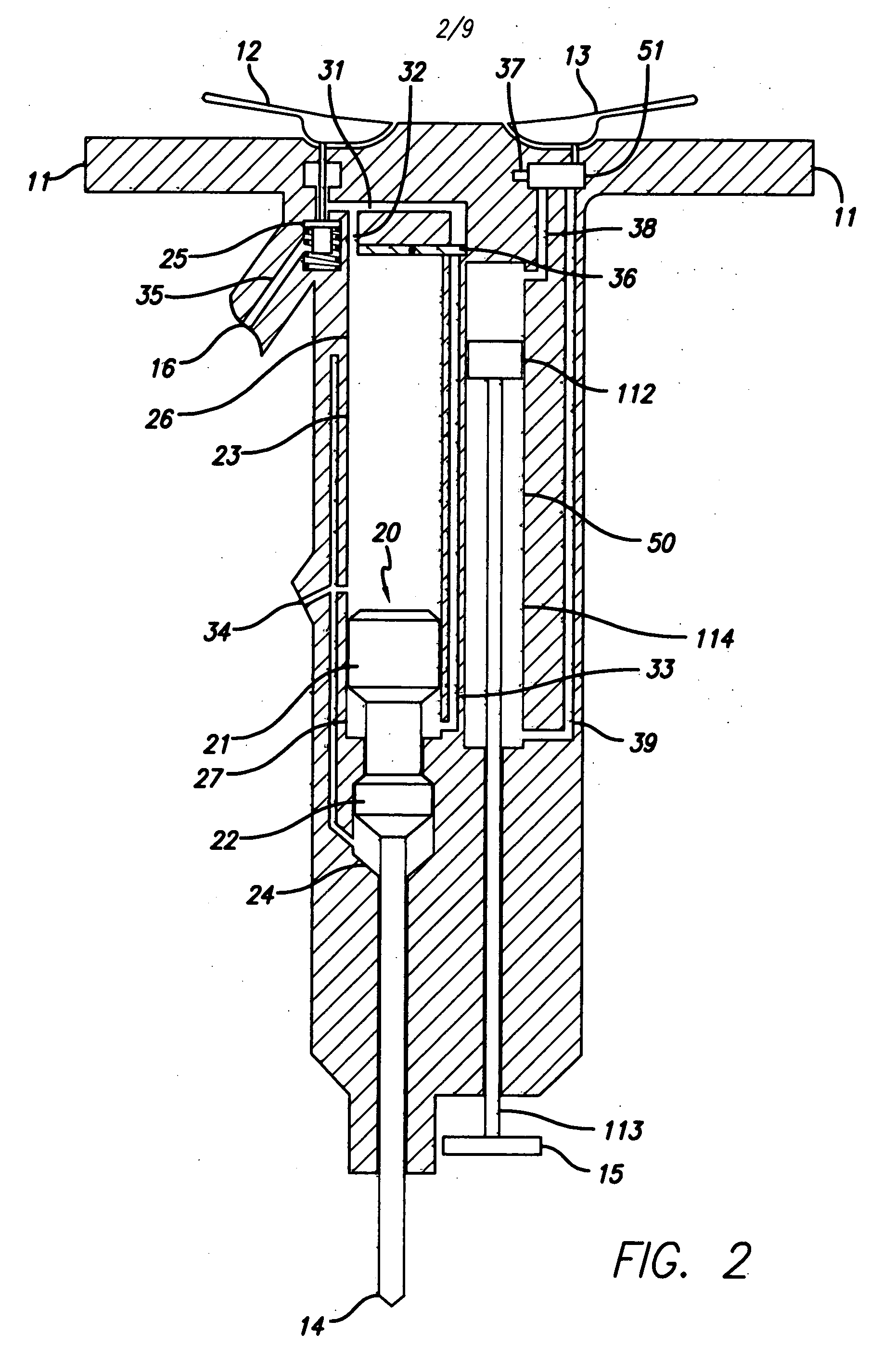

Jackhammer system

InactiveUS7059423B1Reduce vibrationReduce the soundStapling toolsReciprocating drilling machinesJackhammerEngineering

A jackhammer system for reducing the vibration and noise experienced by an operator of the jackhammer. The jackhammer system includes a housing, a chisel movably positioned within a lower neck of the housing, a pair of flywheels rotatably attached to a pair of support brackets, a ram slidably positioned within a guide channel and engageable by the flywheels to engage the chisel, a plurality of elastic members attached to the ram, and an actuator mechanically connected to the support brackets for controlling a position of the flywheels. An upper sensor and a lower sensor determine the position of the ram within the guide channel. An engaging plate supported by a plurality of compression springs receives the downwardly impact of the ram when driving the chisel downwardly. A recoil absorber having a recoil spring is attached to an upper portion of the housing for absorbing the recoil of the ram.

Owner:HOGGARTH DEVERNE

Ultrasonic/sonic jackhammer

ActiveUS20070193757A1Improve vibrationReciprocating drilling machinesConstructionsRobotic systemsJackhammer

The invention provides a novel jackhammer that utilizes ultrasonic and / or sonic vibrations as source of power. It is easy to operate and does not require extensive training, requiring substantially less physical capabilities from the user and thereby increasing the pool of potential operators. An important safety benefit is that it does not fracture resilient or compliant materials such as cable channels and conduits, tubing, plumbing, cabling and other embedded fixtures that may be encountered along the impact path. While the ultrasonic / sonic jackhammer of the invention is able to cut concrete and asphalt, it generates little back-propagated shocks or vibrations onto the mounting fixture, and can be operated from an automatic platform or robotic system.

Owner:CALIFORNIA INST OF TECH

Pipeline inner wall coating machine

PendingCN107008606AWalking smoothlyWalk; through the spray evenlySpraying apparatusJackhammerIndustrial engineering

The invention discloses a pipeline inner wall coating machine and belongs to the field of pipeline equipment. Travelling wheels are connected to a driving device output shaft. Nozzles are at least arranged on the coating machine and are evenly distributed on the periphery of the inner wall of a pipeline. A jackhammer, an illuminating device and a camera device are arranged on the upper portion of the front portion of the pipeline. An automatic take-up wheel is arranged behind the pipeline. A coaxial compression air pipe roller is arranged beside the take-up wheel. A steel wire rope traction hole is further formed in the rear portion of the coating machine. The nozzles and the jackhammer are arranged on rotary plates correspondingly. Through the pipeline inner wall coating machine, obstacles in the pipeline can be cleared, smooth flowing of liquid in the pipeline can be ensured, the labor intensity of painters is relieved, physical discomfort of workers due to the harsh paint environment is avoided, automatic operation is achieved, the paint efficiency is improved, and the health of the workers is ensured.

Owner:ANYANG GUOLONG MACHINERY

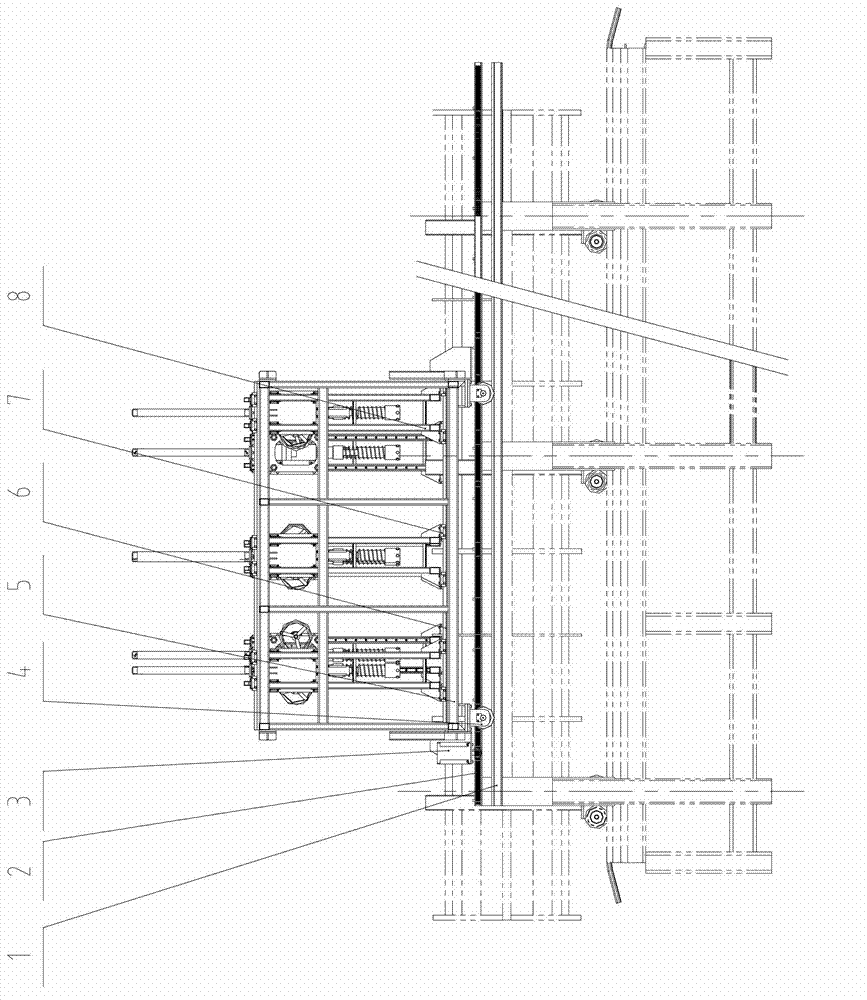

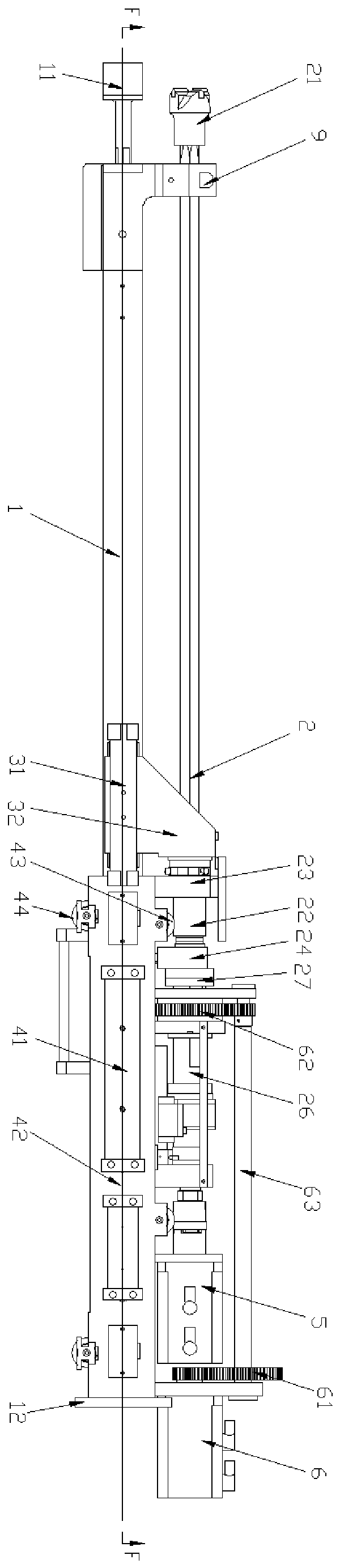

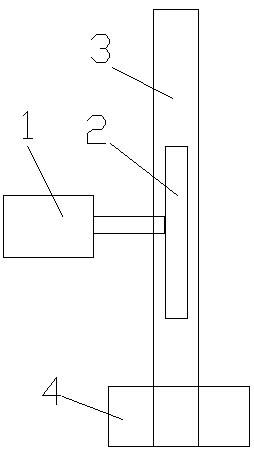

Intelligent locating full-automatic bolt loosening and tightening machine

InactiveCN102814646AMove preciselyPrecise positioningMetal working apparatusIntelligent lightingJackhammer

The invention discloses an intelligent locating full-automatic bolt loosening and tightening machine which adopts an intelligent optical measuring instrument and a programmable logic controller (PLC) to send working commands to a trolley frame traveling driving device, a jackhammer frame traveling driving device and a jackhammer base air cylinder. A jackhammer can loose or lock a die assembly bolt correctly through effects of all driving devices. The intelligent locating full-automatic bolt loosening and tightening machine has the advantages of being high in automation and overturning the existing operation mode. Due to the fact that a whole working process is controlled through the PLC, the machine can intelligently locate correct moving of positions of the jackhammer and a die bolt and can locate automatically and vertically, and automation of bolt loosening and tightening is achieved. Labor intensity and cost can be reduced, and safety coefficient is high.

Owner:江苏中技桩业有限公司

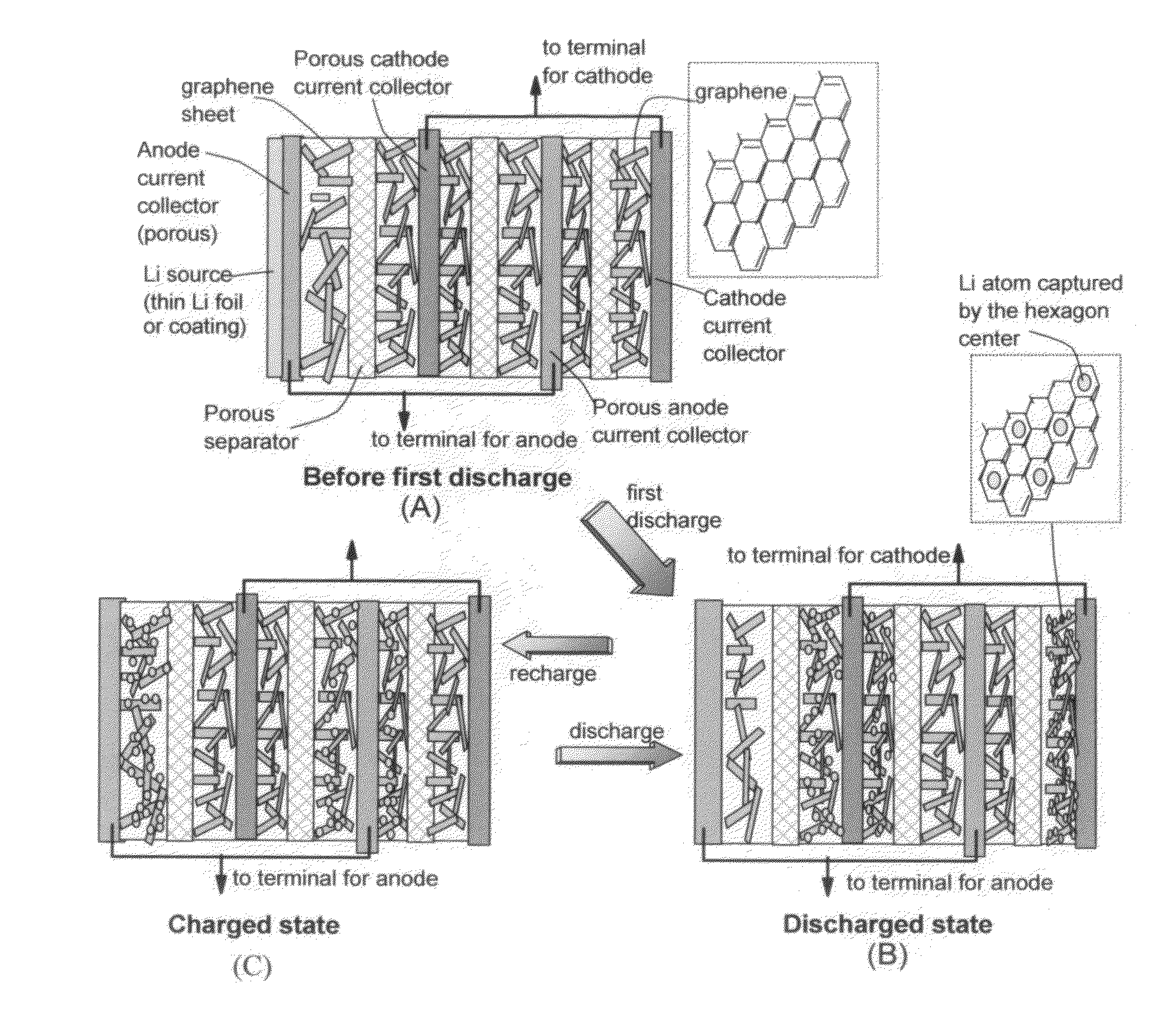

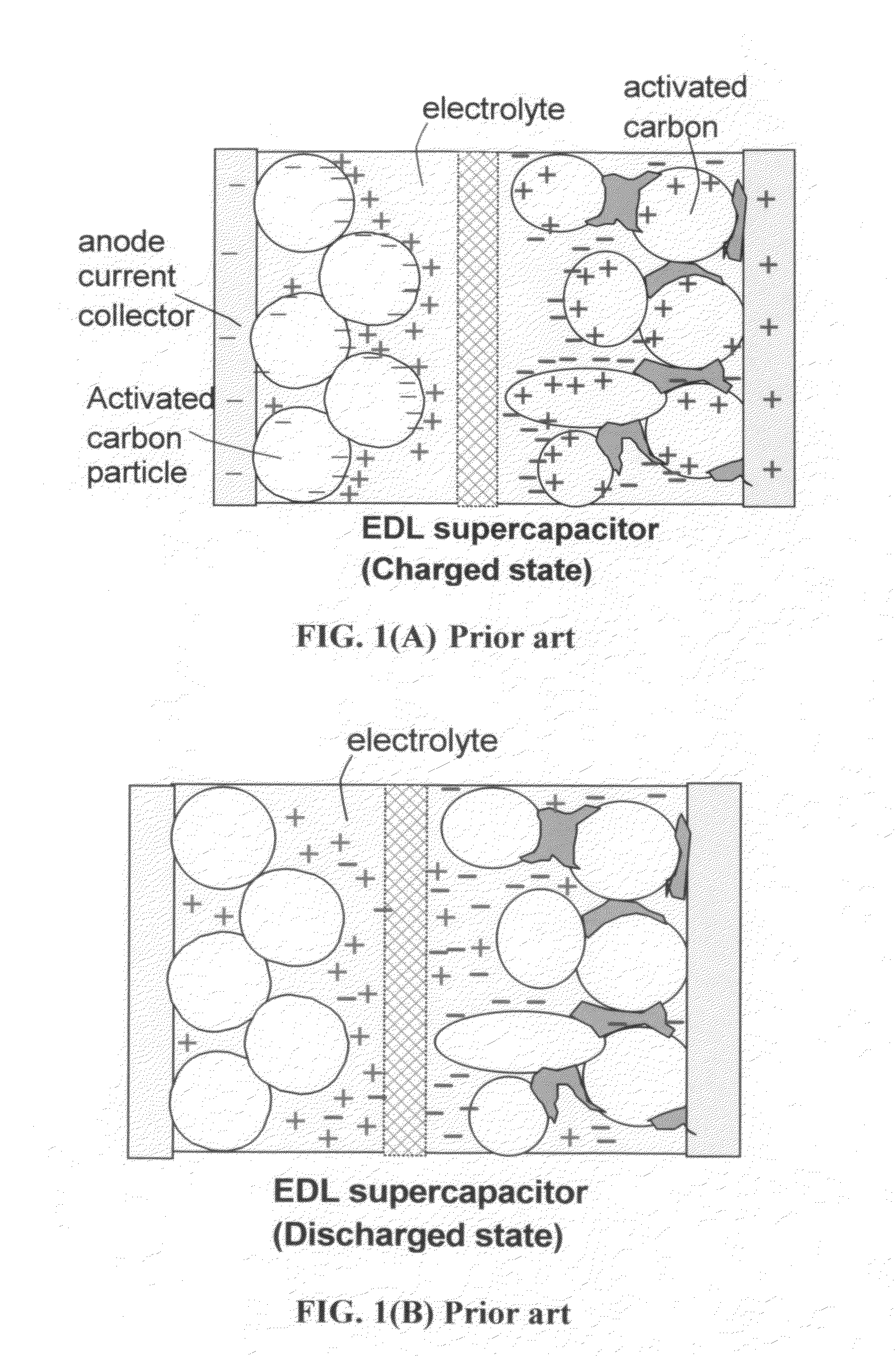

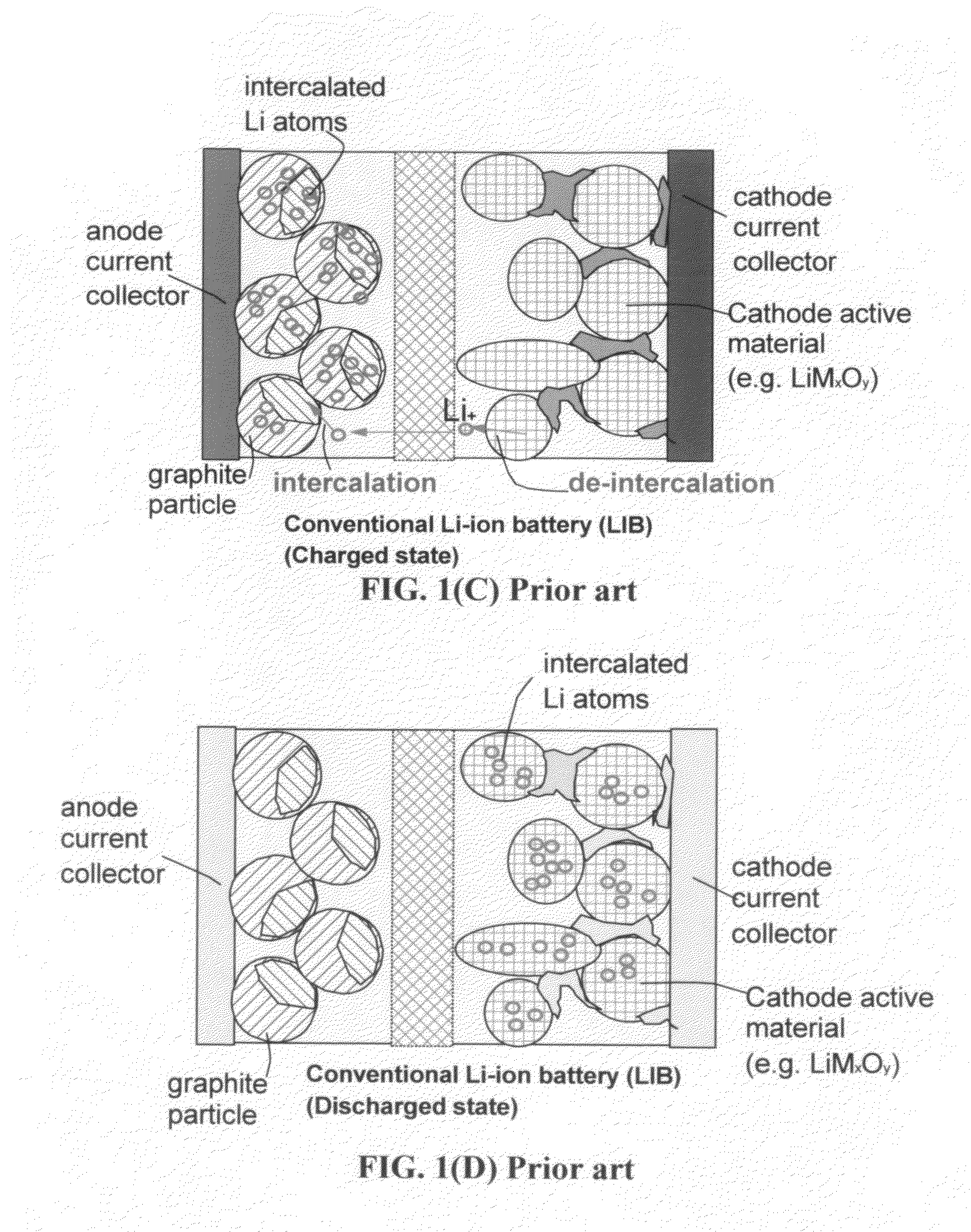

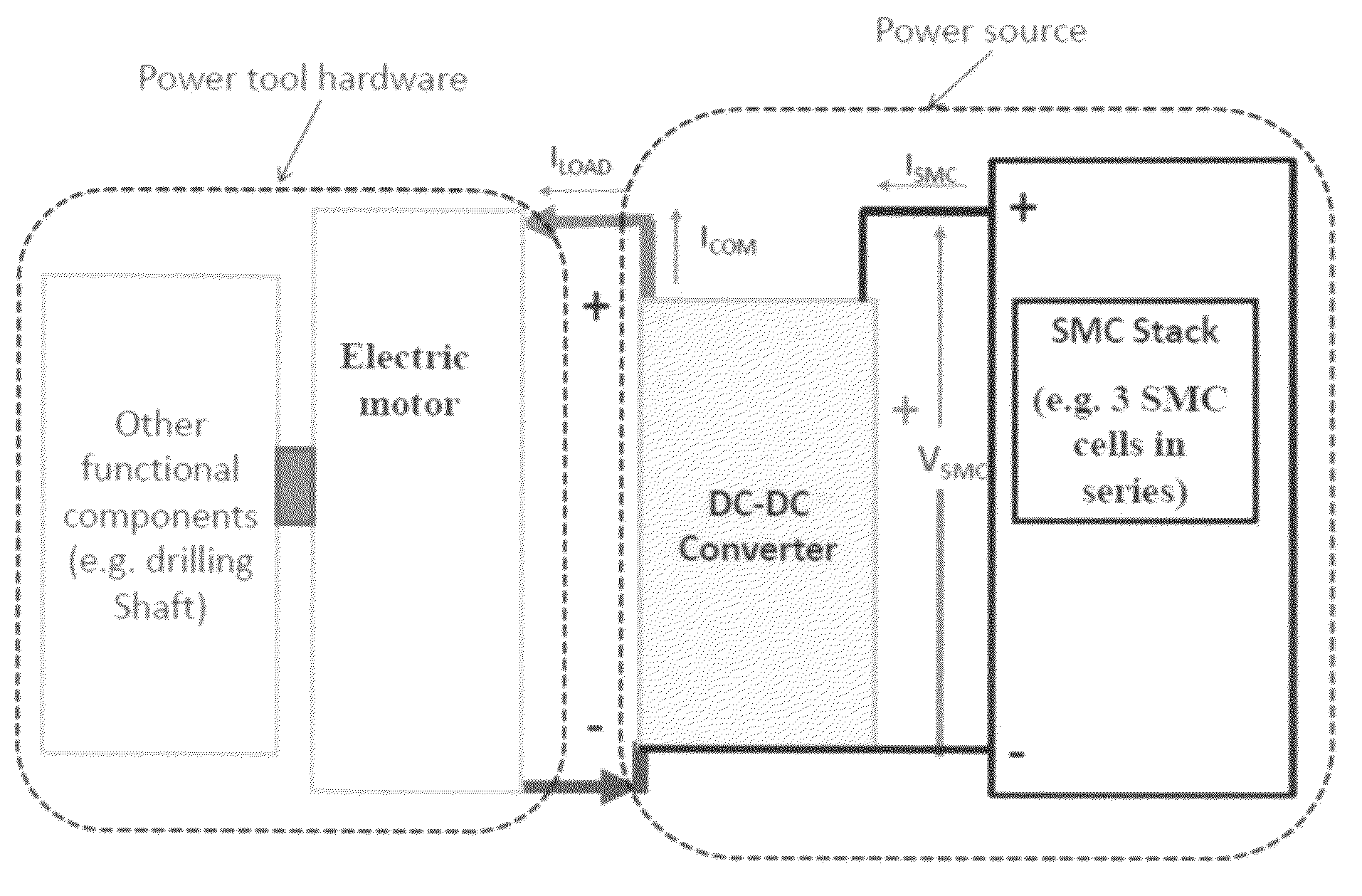

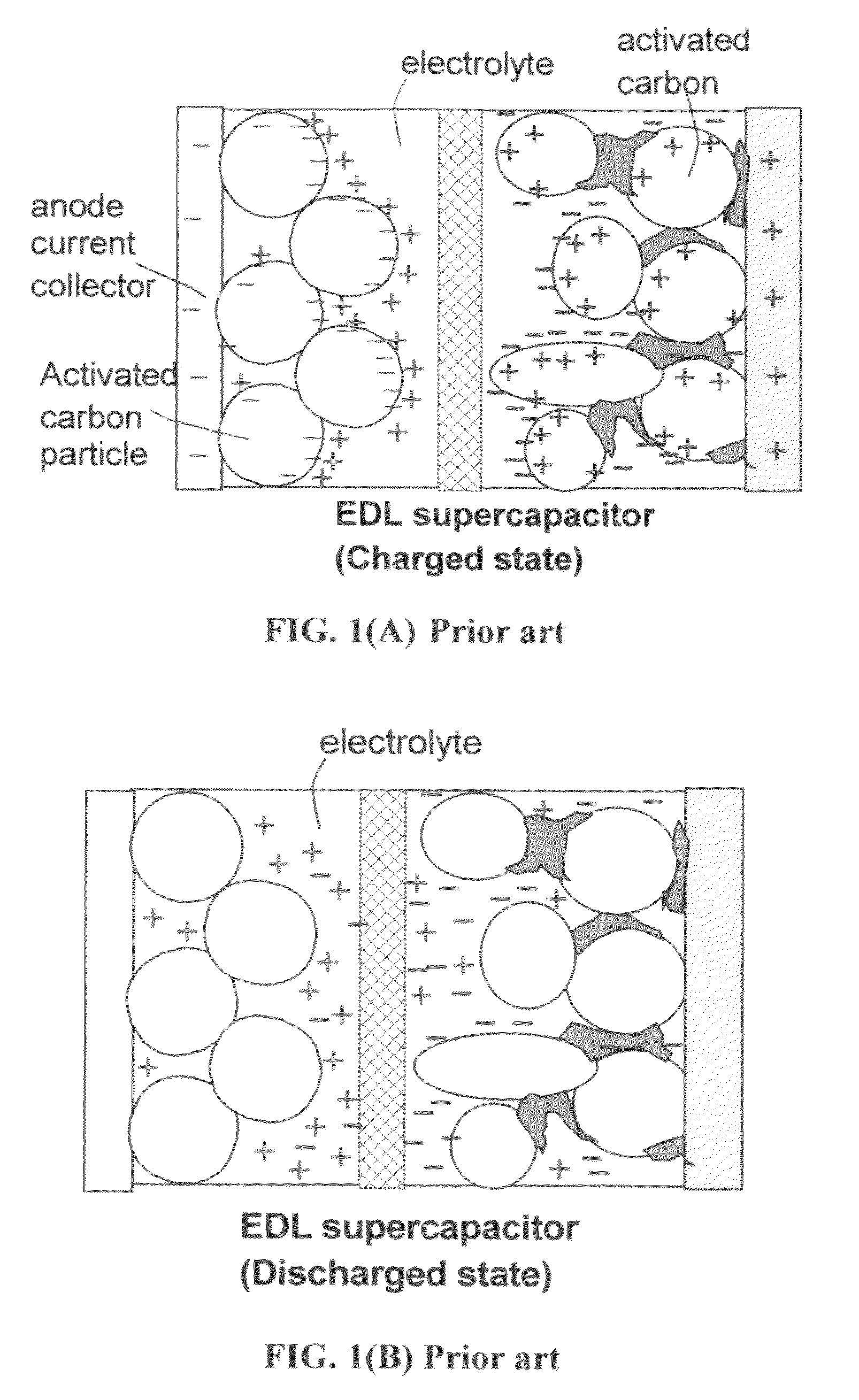

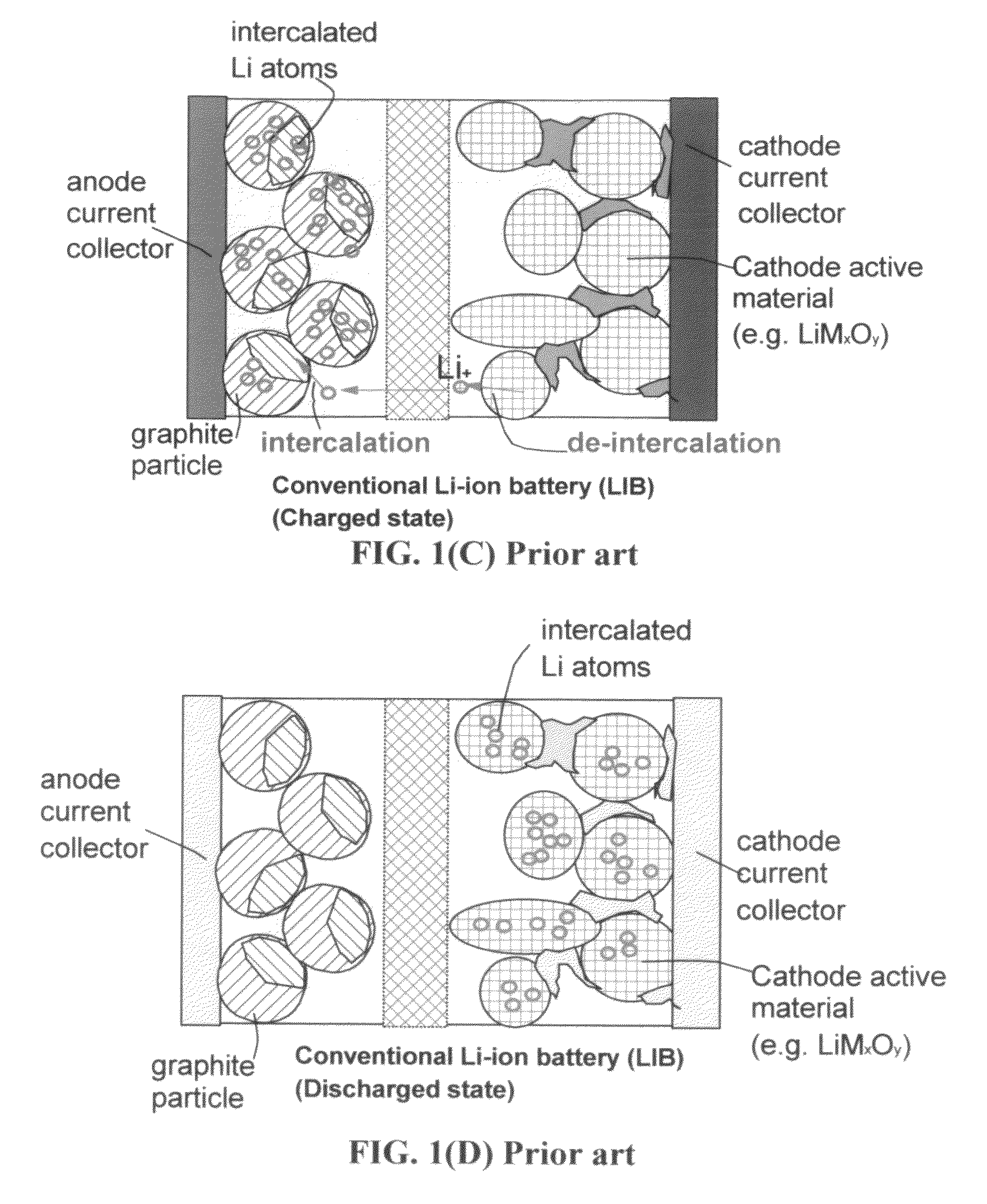

Surface-mediated cell-driven power tools and methods of operating same

ActiveUS20130213677A1Improve power densityEasy dischargeDrilling rodsCapacitor and primary/secondary cellsSanderAngle grinder

A portable power tool comprises an electric motor, actuator, or light-emitting hardware and a rechargeable power source connected to the electric motor, actuator, or light-emitting hardware, wherein the power source contains at least a surface-mediated cell (SMC). The power tools include, but are not limited to, impact driver, air compressor, alligator shear, angle grinder, band saw, belt sander, biscuit joiner, ceramic tile cutter tile saw, chainsaw, circular saw, concrete saw, cold saw, crusher, diamond blade, diamond tools, disc sander, drill, floor sander, grinding machine, heat gun, impact wrench, jackhammer, jointer, jigsaw, lathe, miter saw, nail gun, needle scaler, torque wrench, powder-actuated tools, power wrench, radial arm saw, random orbital sander, reciprocating saw, rotary reciprocating saw, rotary tool, sabre saw, sander, scroll saw, steel cut off saw, table saw, thickness planer, trimmer, wall chaser, wood router, or flashlight.

Owner:GLOBAL GRAPHENE GRP INC +1

Stylus system for modifying small structures

InactiveUS7375324B2Rapidly and accurately modifyingFix bugsNanostructure manufactureMaterial analysis using wave/particle radiationDefect repairJackhammer

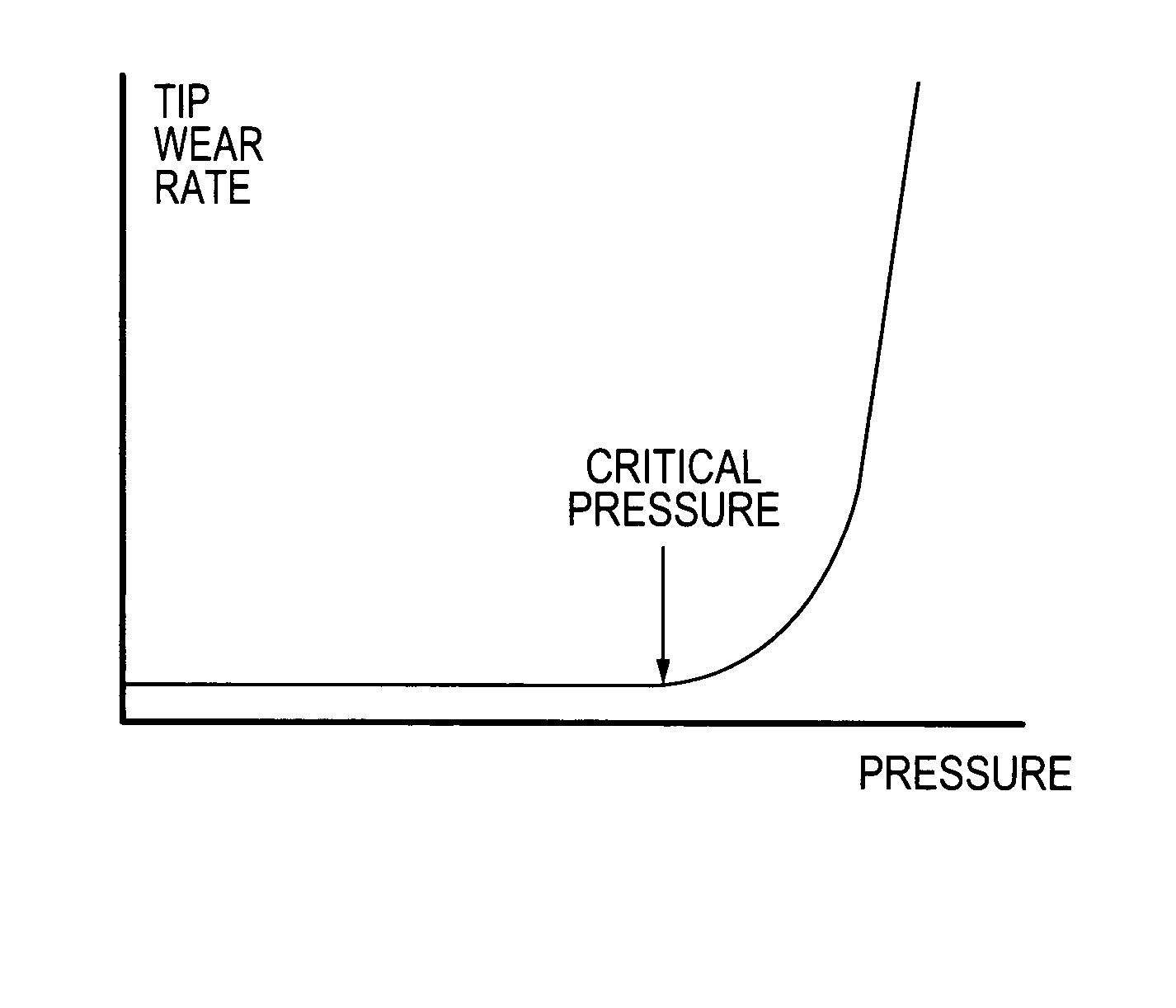

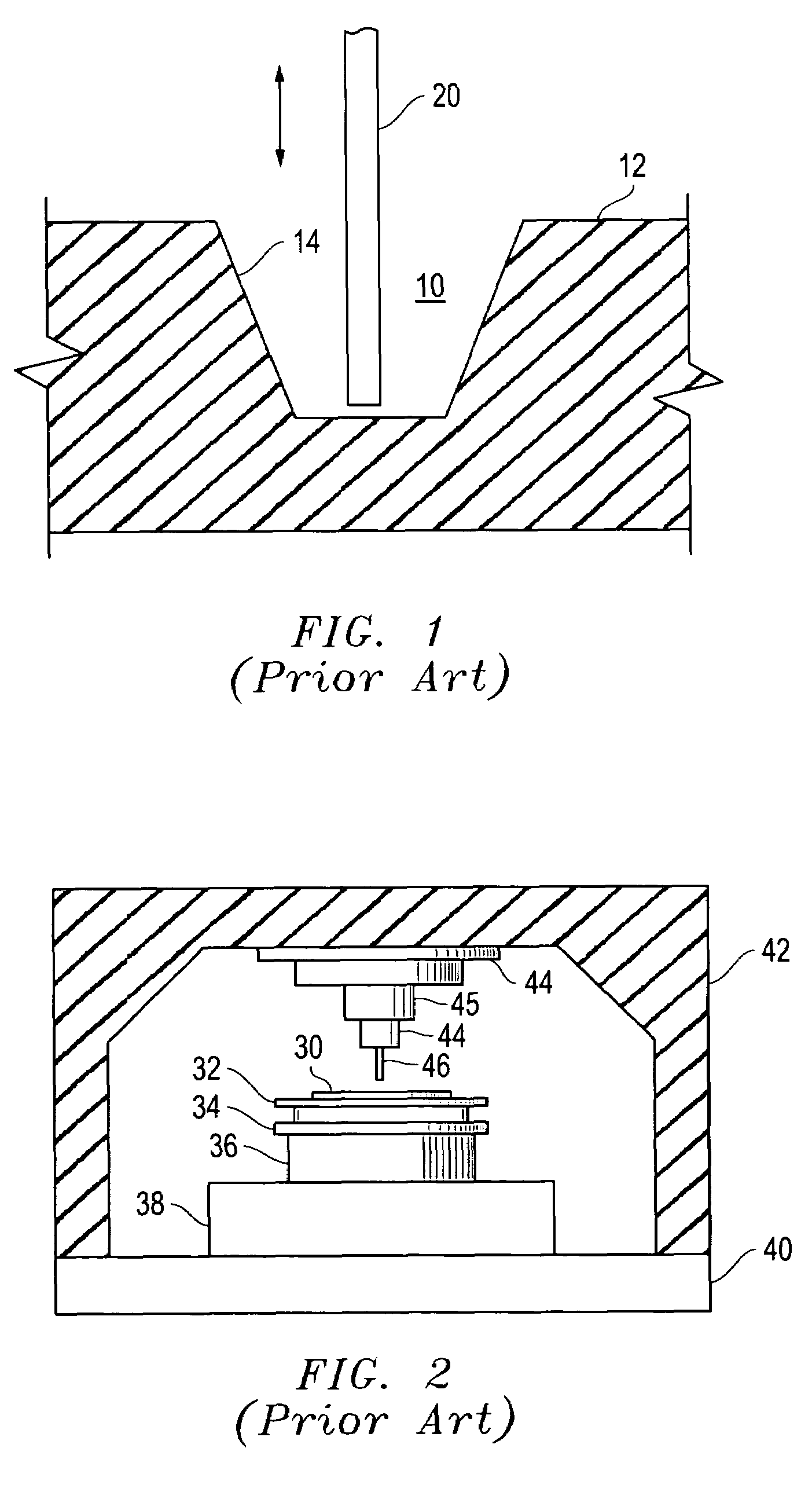

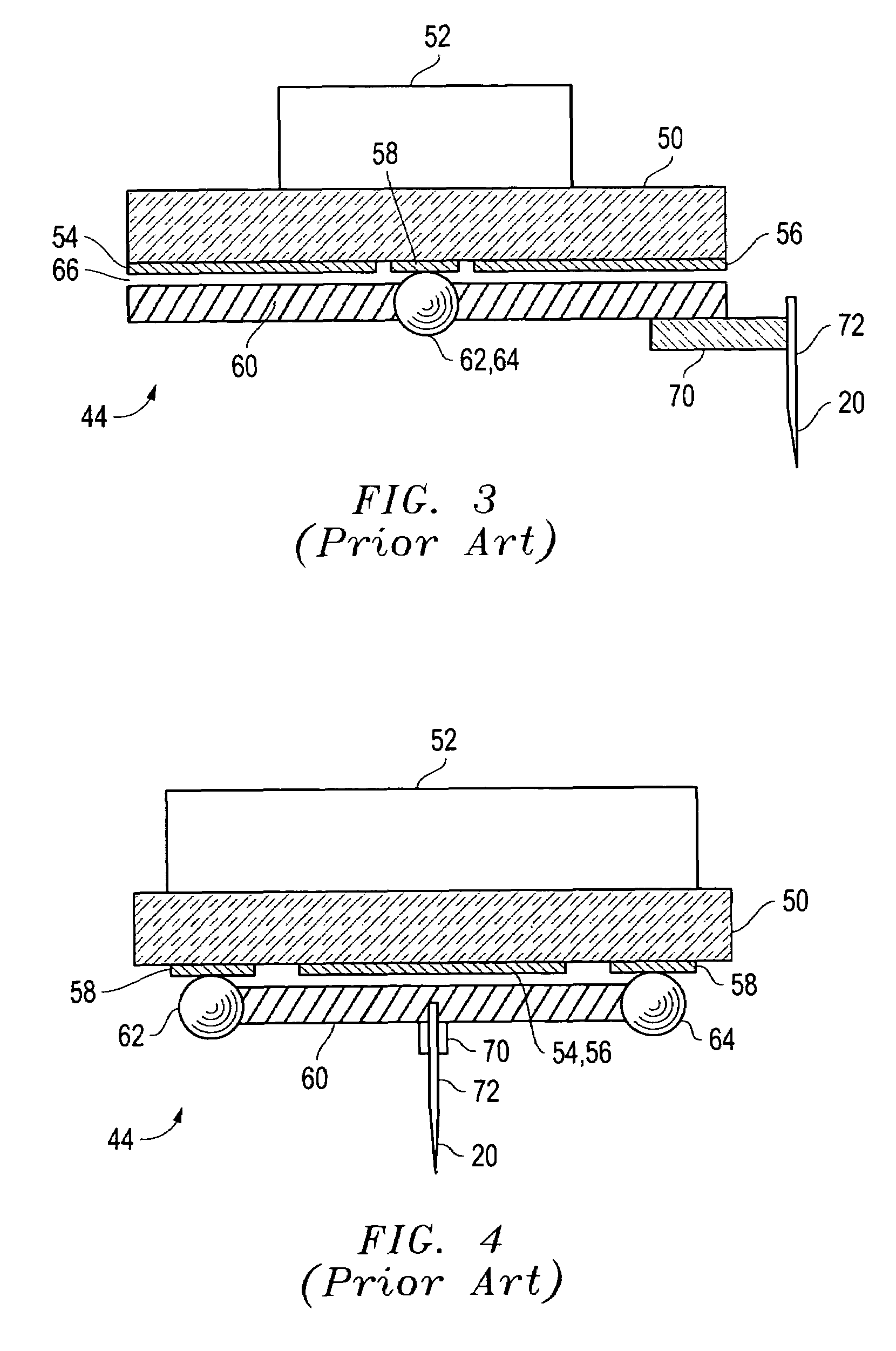

An improved method for rapidly and accurately modifying small structures, including structures on a micron or nanometer scale, suitable for the repair of defects in lithographic photo-masks and semiconductors on a nano-scopic level. Features or samples repaired may be conductive or non-conductive. A single instrument can be employed to both observe the surface of the mask or wafer, and to effectuate the repair of conductive and non-conductive features thereon. Using a Stylus-Nano-Profilometer probe, rapid lateral strokes across the sample surface in a definable pattern at known high applied pressure are used to effectuate defect repair. The tip of the probe can also be dithered rapidly in a pattern or used as to create a jackhammer effect to more effectively remove material from the sample surface.

Owner:FEI CO

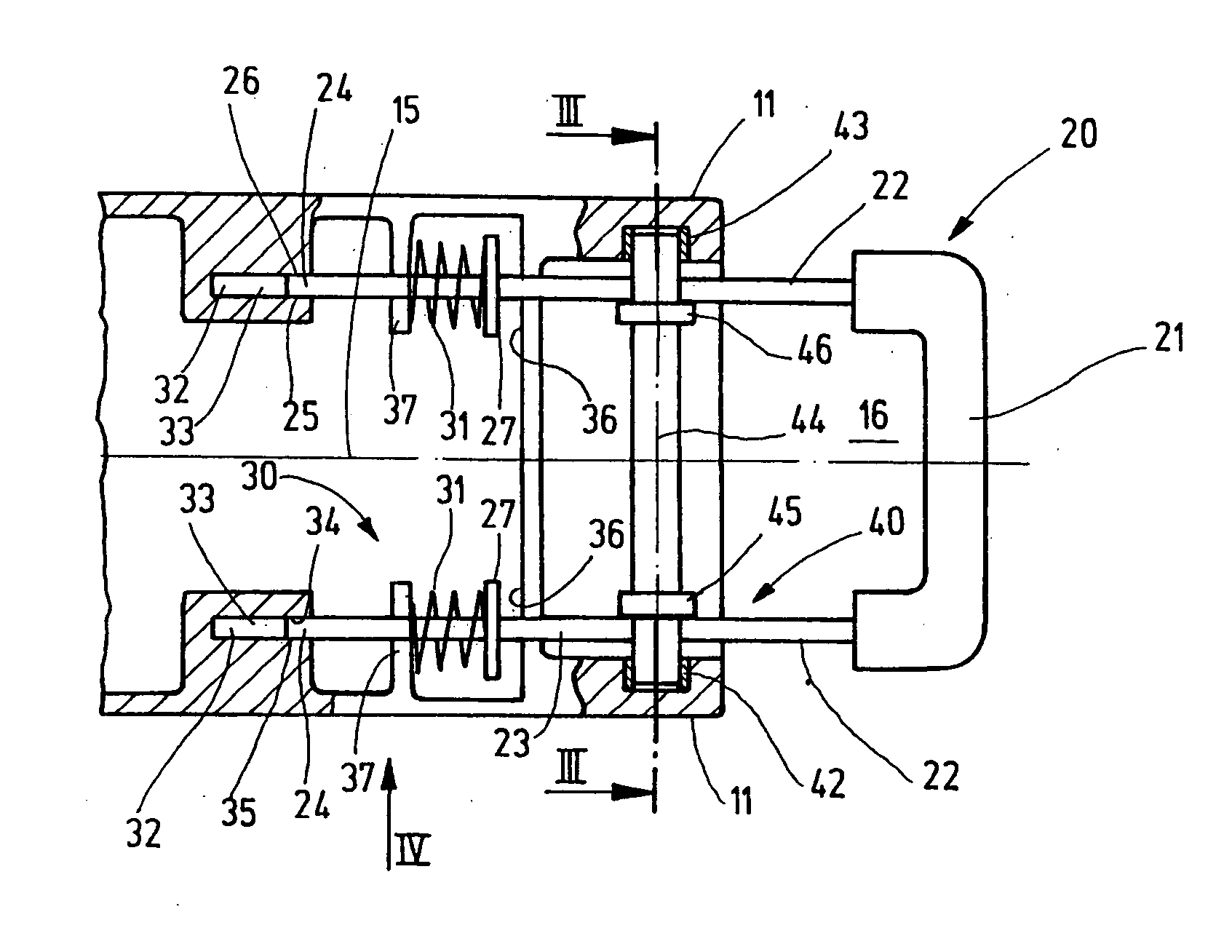

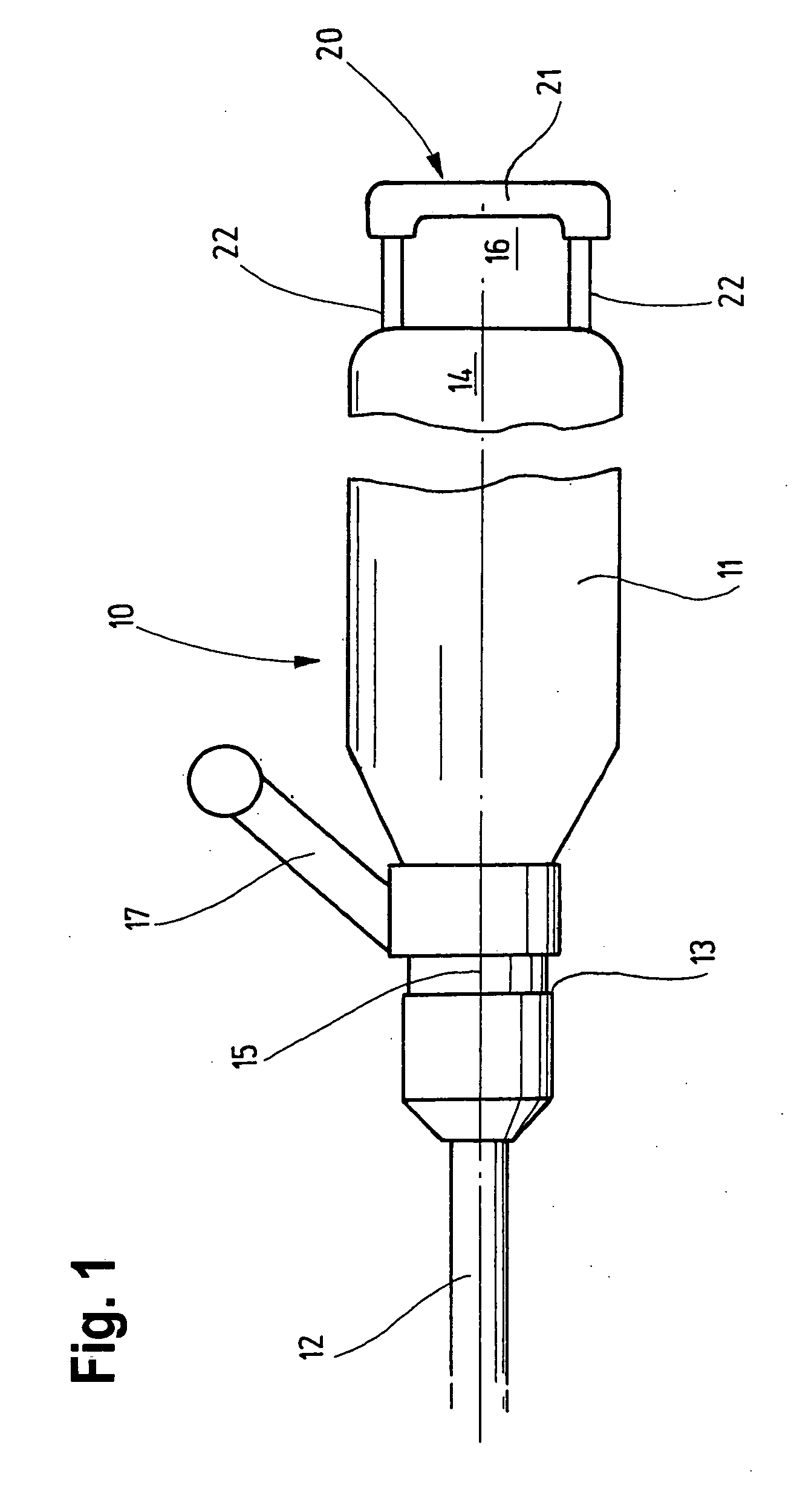

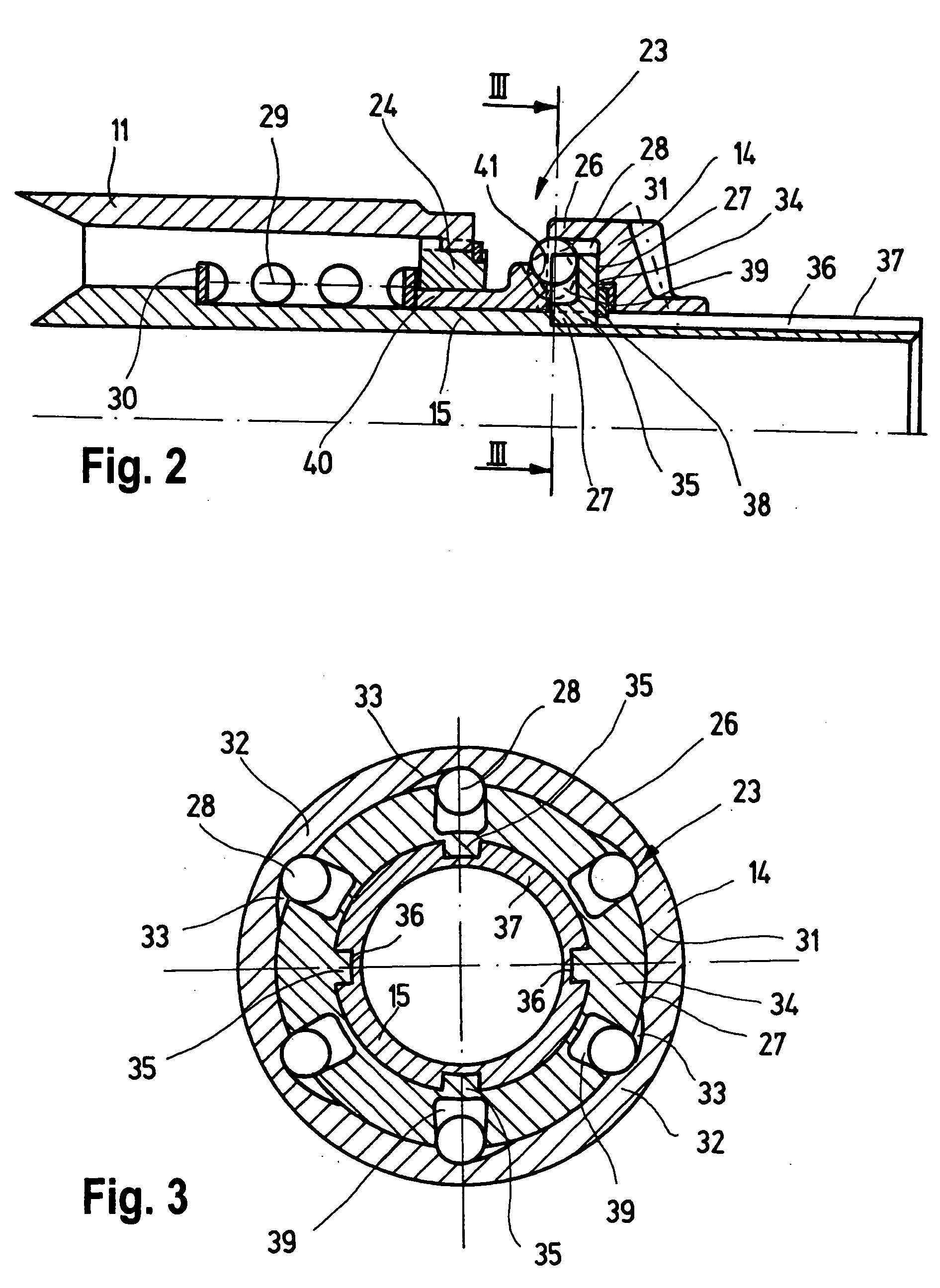

Hand power tool, in particular drill hammer and/or jackhammer

InactiveUS20050263306A1Eliminate disadvantagesLess expensiveReciprocating drilling machinesSlip couplingCouplingGear wheel

A hand power tool has a housing, and drive motor accommodated in the housing, a tool receptacle in which a tool is guided, a gear mechanism, a driving gear, and rotary sleeve arranged so that via the gear mechanism, the driving gear, and the rotary sleeve the tool receptacle is drivable in rotation, a crank drive mechanism and a hammering mechanism located inside the rotary sleeve so that the tool receptacle is drivable through the crank drive mechanism and the hammering mechanism translationally, and a safety coupling provided between the driving gear wheel and the rotary sleeve and formed so that the safety coupling separates if a limit torque is exceeded, the safety coupling being formed as an overlock coupling seated on the rotary sleeve and having two axially adjacent coupling parts that mesh in a form-locked manner by torque-transmitting transmission elements and are overlockable if the limit torque is exceeded counter to an axially acting elastic force, one of the coupling parts being a part associated with the driving gear wheel and rotatable relative to the rotary sleeve while the other of the coupling parts is coupled to the rotary sleeve in a way that transmits torque.

Owner:ROBERT BOSCH GMBH

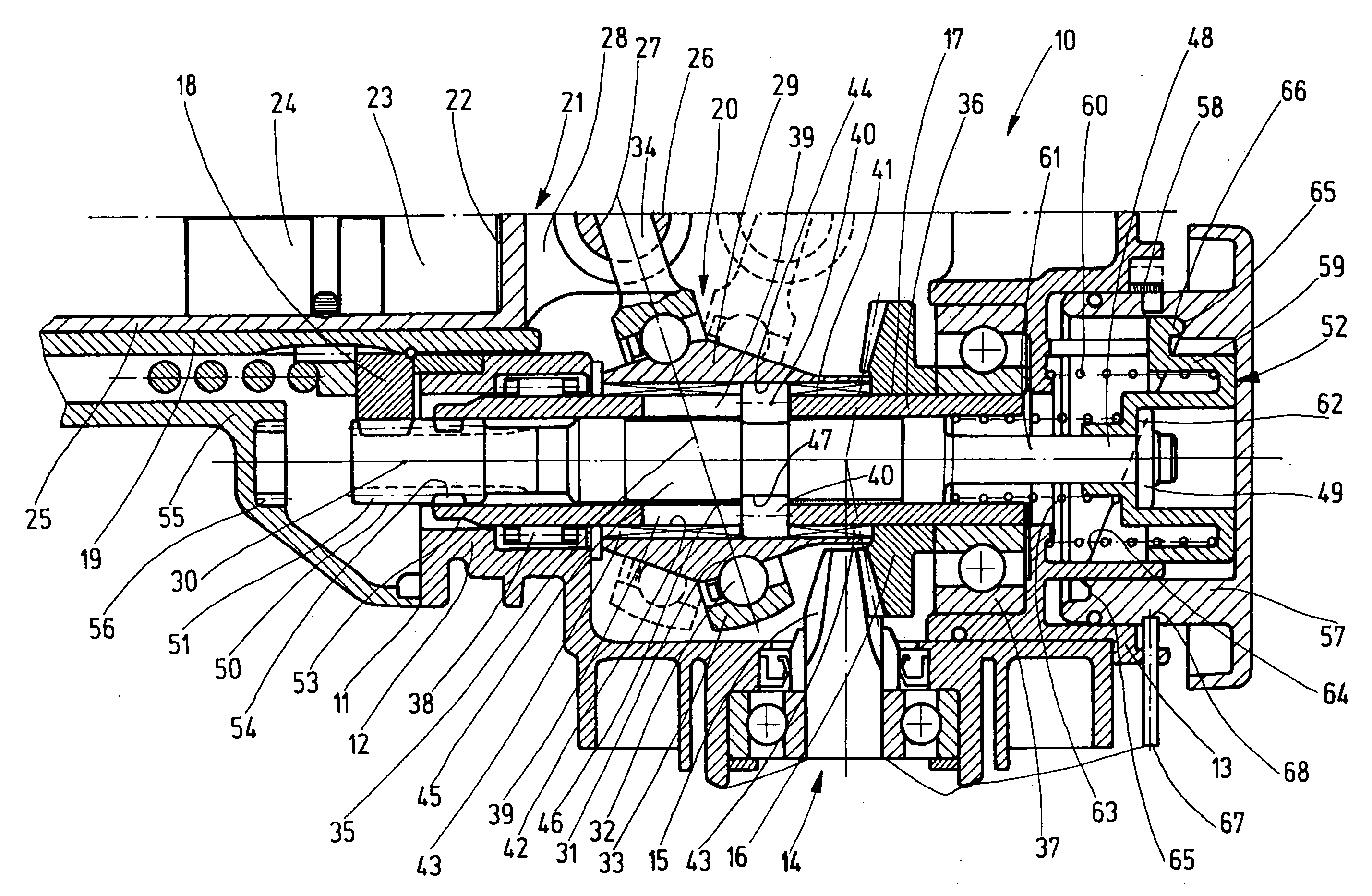

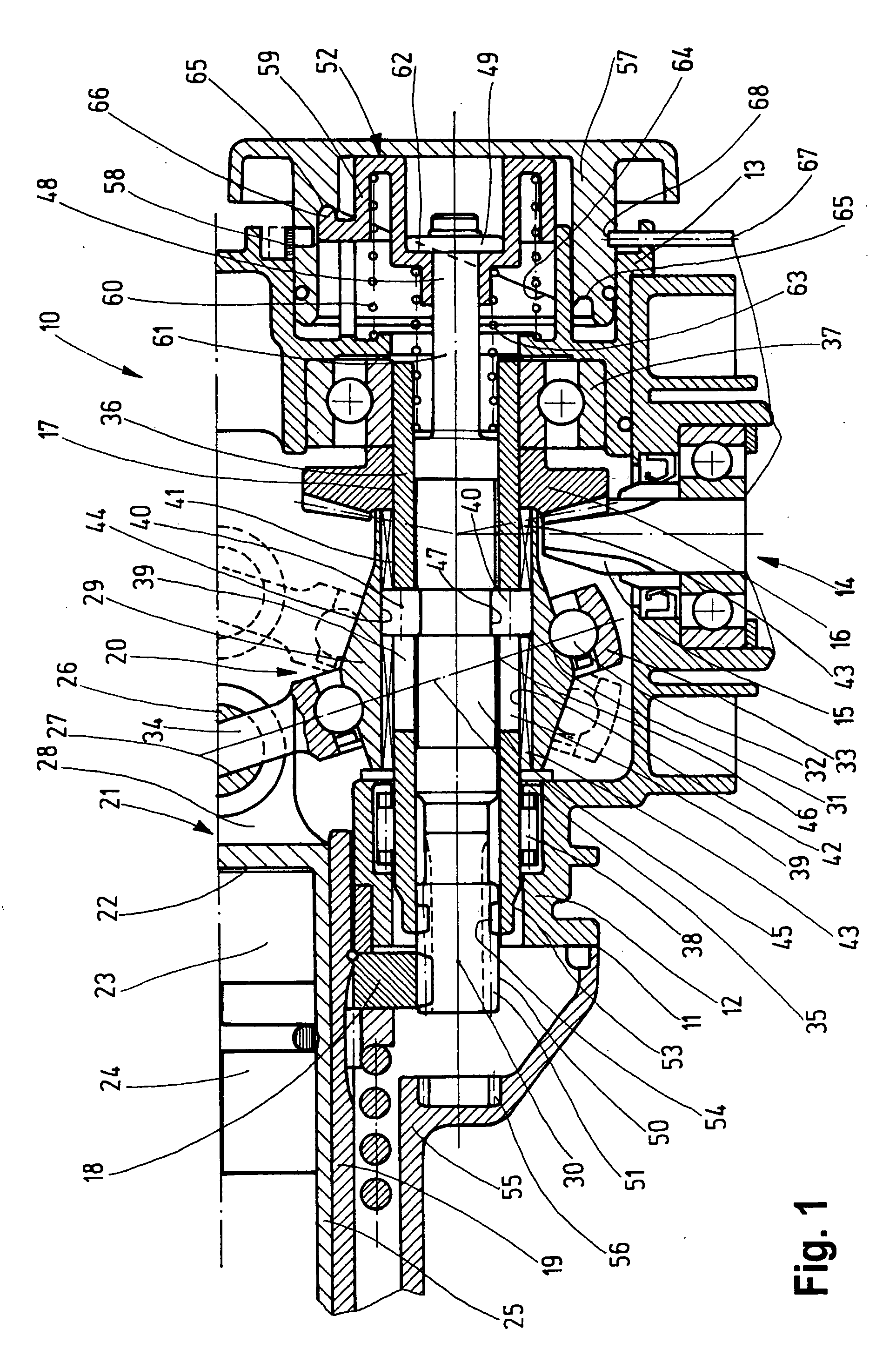

Hand power tool, in particular a drilling hammer and/or jackhammer

InactiveUS20060289181A1Eliminate disadvantagesReduce in quantityDrilling rodsReciprocating drilling machinesGear wheelJackhammer

A hand power tool has a housing, a drive motor and a gear mechanism arranged in the housing, a tool receptacle in which a tool is guidable, a gear wheel via which a rotary sleeve is driven in rotation from the drive motor and the gear mechanism and thereby the tool receptacle is driven in rotation, a hammering mechanism located inside the rotary sleeve and drivable translationally via a wobble gear, wherein the gear mechanism has a driving gear wheel meshing with a motor pinion and arranged on a shaft by which the wobble gear mechanism is drivable to revolve, the shaft is configured as a hollow shaft on which the driving gear wheel is retained nondisplaceably and in a manner fixed against rotation, and the wobble gear mechanism is located adjacent to the driving gear wheel on the shaft rotatably and couplably to the hollow shaft.

Owner:ROBERT BOSCH GMBH

Surface-mediated cell-driven power tools and methods of operating same

ActiveUS9085076B2Increase electrode areaHigh currentDrilling rodsCapacitor and primary/secondary cellsSanderAngle grinder

A portable power tool comprises an electric motor, actuator, or light-emitting hardware and a rechargeable power source connected to the electric motor, actuator, or light-emitting hardware, wherein the power source contains at least a surface-mediated cell (SMC). The power tools include, but are not limited to, impact driver, air compressor, alligator shear, angle grinder, band saw, belt sander, biscuit joiner, ceramic tile cutter tile saw, chainsaw, circular saw, concrete saw, cold saw, crusher, diamond blade, diamond tools, disc sander, drill, floor sander, grinding machine, heat gun, impact wrench, jackhammer, jointer, jigsaw, lathe, miter saw, nail gun, needle scaler, torque wrench, powder-actuated tools, power wrench, radial arm saw, random orbital sander, reciprocating saw, rotary reciprocating saw, rotary tool, sabre saw, sander, scroll saw, steel cut off saw, table saw, thickness planer, trimmer, wall chaser, wood router, or flashlight.

Owner:GLOBAL GRAPHENE GRP INC +1

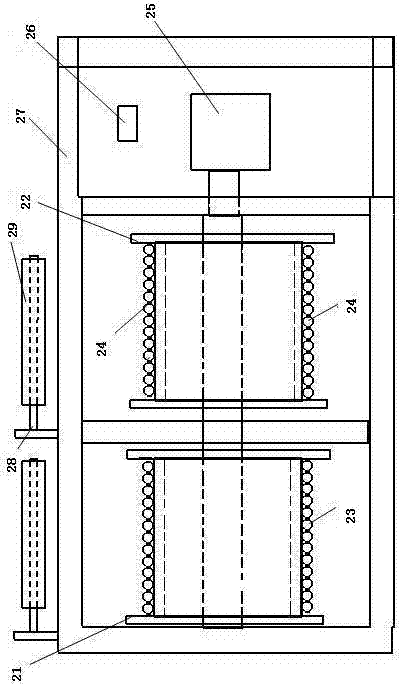

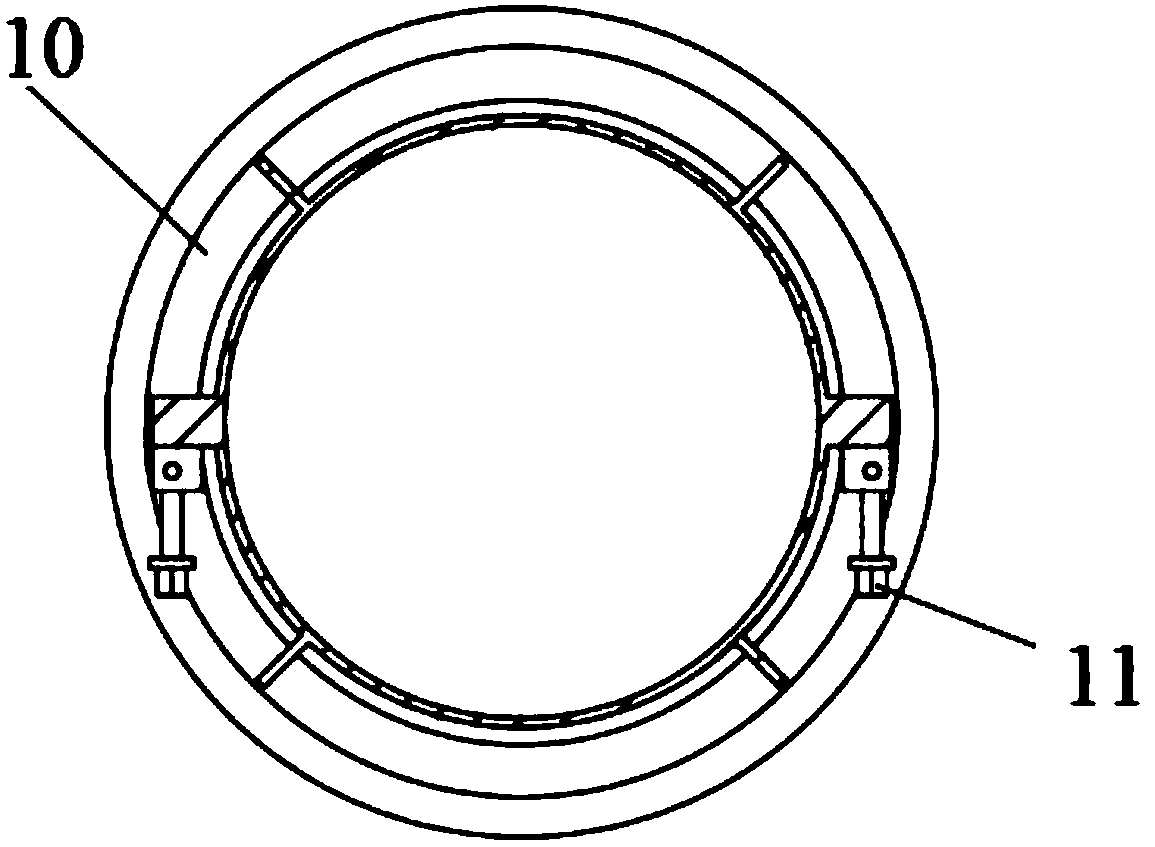

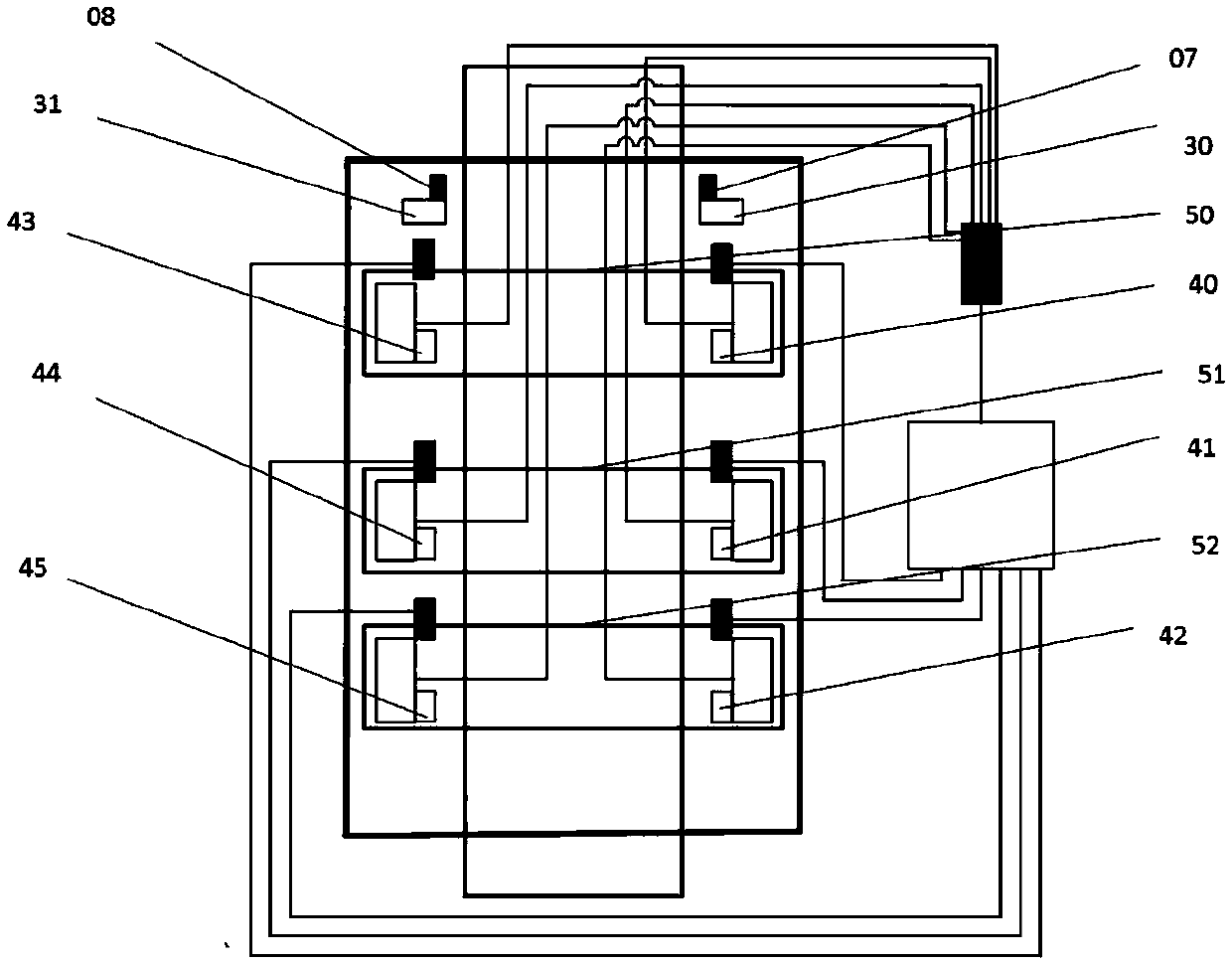

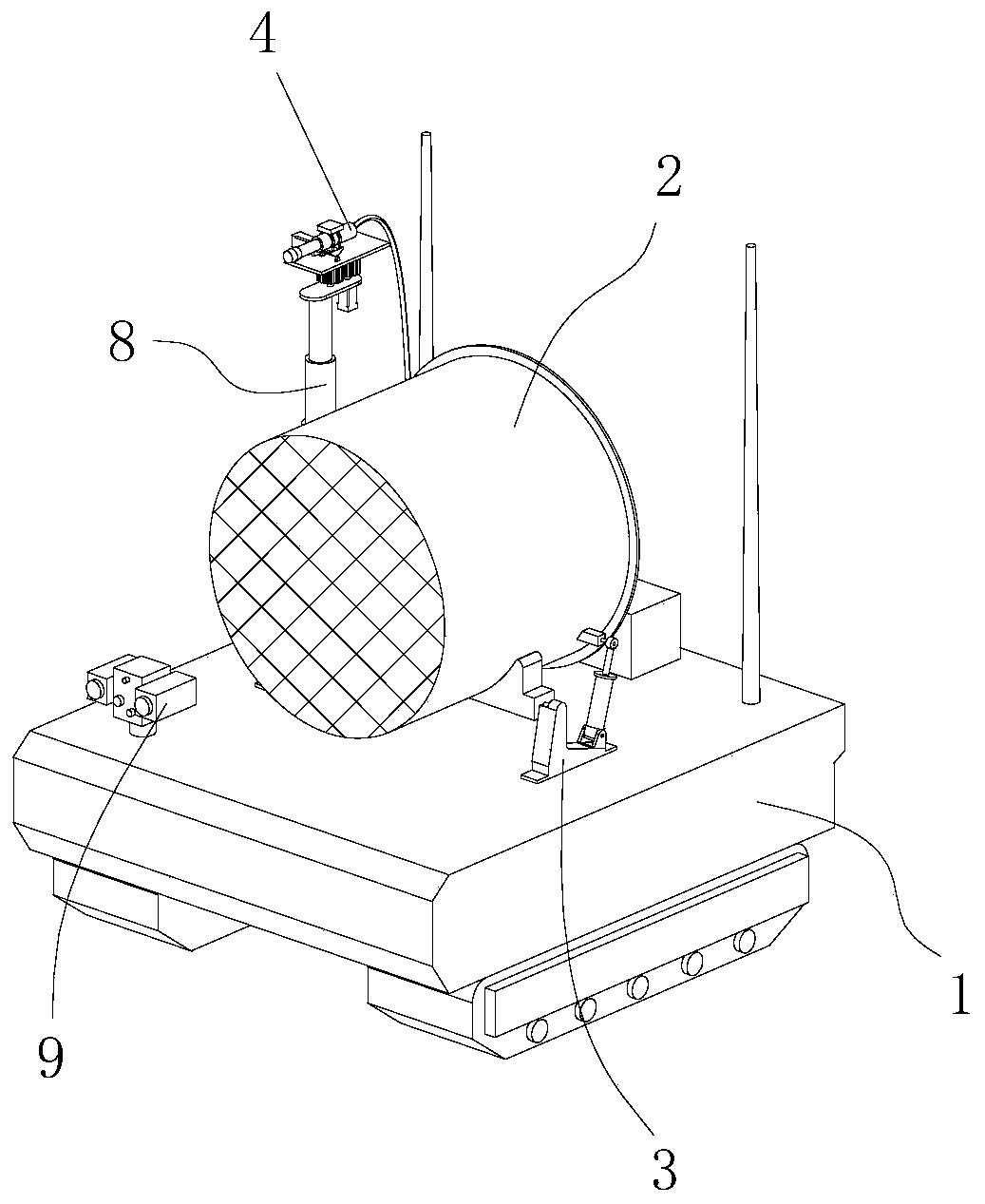

Mold compounding system adapting to pipe pile molds of multiple specifications

The invention discloses a mold compounding system adapting to pipe pile molds of multiple specifications. The mold compounding system comprises a pipe pile mold conveying device, an outer frame, an inner frame, a detecting device, bolt supporting guide rails, jackhammer devices, bolt leveling mechanisms and bolt straightening and locating mechanisms, wherein the jackhammer devices, the bolt leveling mechanisms and the bolt straightening and locating mechanisms are mounted on jackhammer mounting rods. The pipe diameters of the pipe pile molds are detected through the detecting device, then theheight of the inner frame and the height of the detecting device are adjusted through lifting mechanisms, the distance of the two jackhammer mounting rods is adjusted through a translation mechanism to adapt to the pipe diameters of the pipe pile molds, then bolts are leveled through four-connecting-rod mechanisms with electromagnets, the horizontal bolts are placed on the bolt supporting guide rails to advance, then the bolts are turned over through the four-connecting-rod mechanisms of the bolt straightening and locating mechanisms and pushed to groove openings to be located through telescopic push rods, and finally the jackhammer devices move downwards to complete tightening work. The mold compounding system can achieve automatic detecting and adapt to mold compounding of the pipe pilemolds different in pipe diameter, pipe length and bolt distance specification, during mold compounding, bolt tightening is accurate, and efficiency is high.

Owner:HUBEI UNIV OF TECH

Jackhammer lift assist

The present invention relates to a lift assist device which is used to alleviate the physical demands for the operation of a heavy percussion power tool, such as a pneumatic jackhammer, by facilitating lifting and freeing the percussion power tool. In general, the lift assist device contains an actuating cylinder with a lifting foot attached to the outside end of its piston rod and a control unit which comprises a directional control valve and a hand lever. The control unit is on the top of the lift assist device and can be used to control the lifting speed and height. The lift assist device is secured to the body of the percussion power tool with one or more mounting elements.

Owner:INTEGRATED TOOL SOLUTIONS

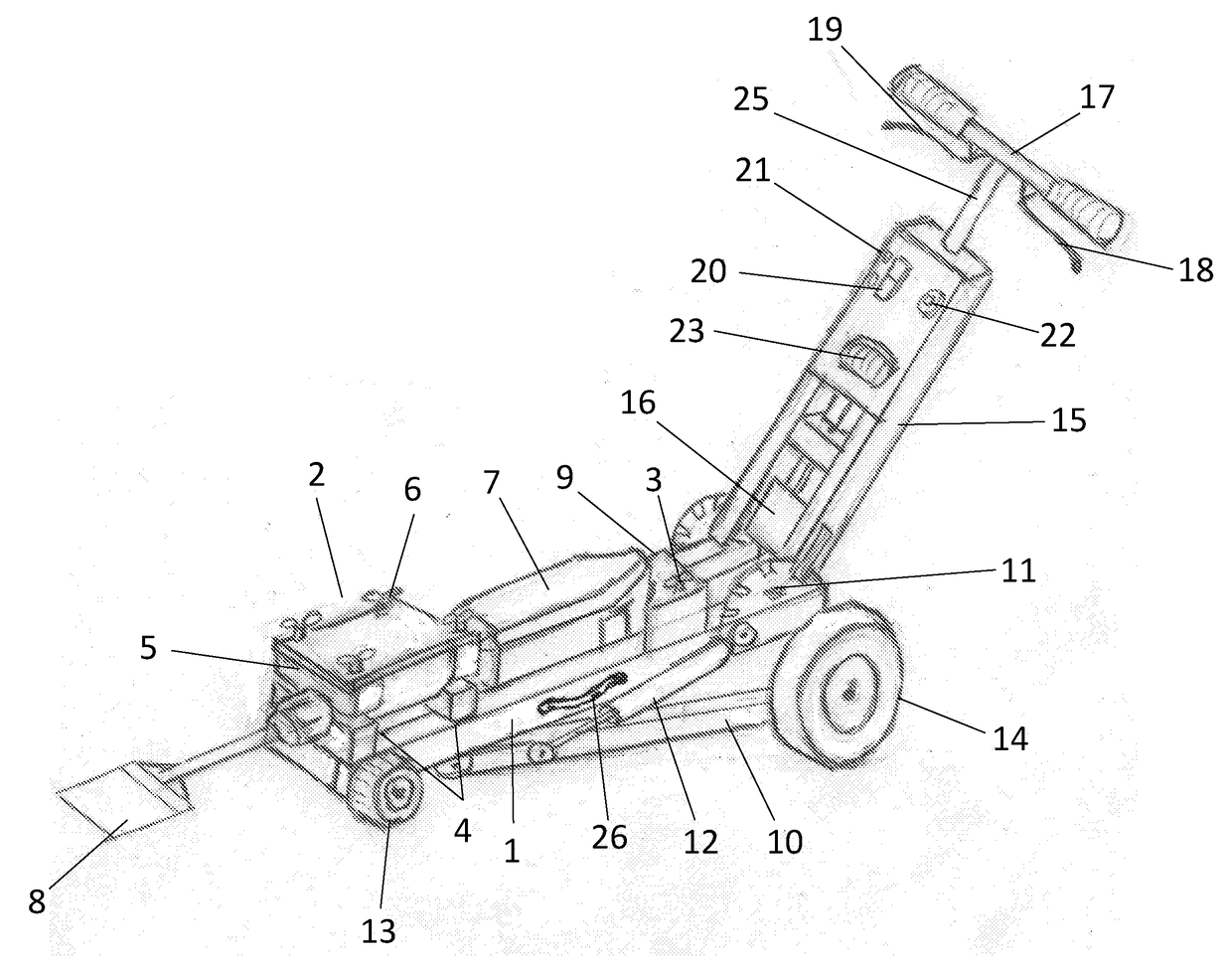

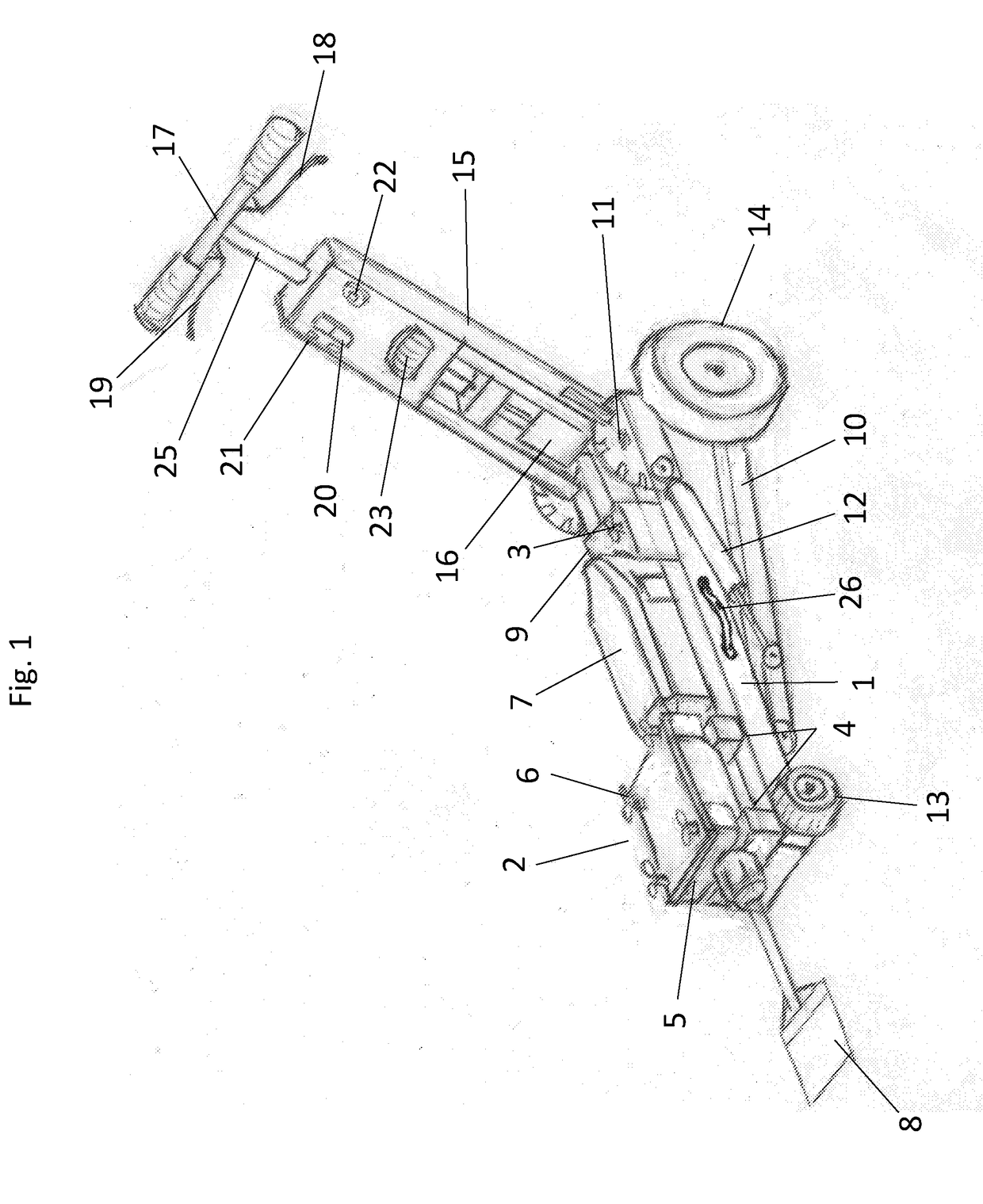

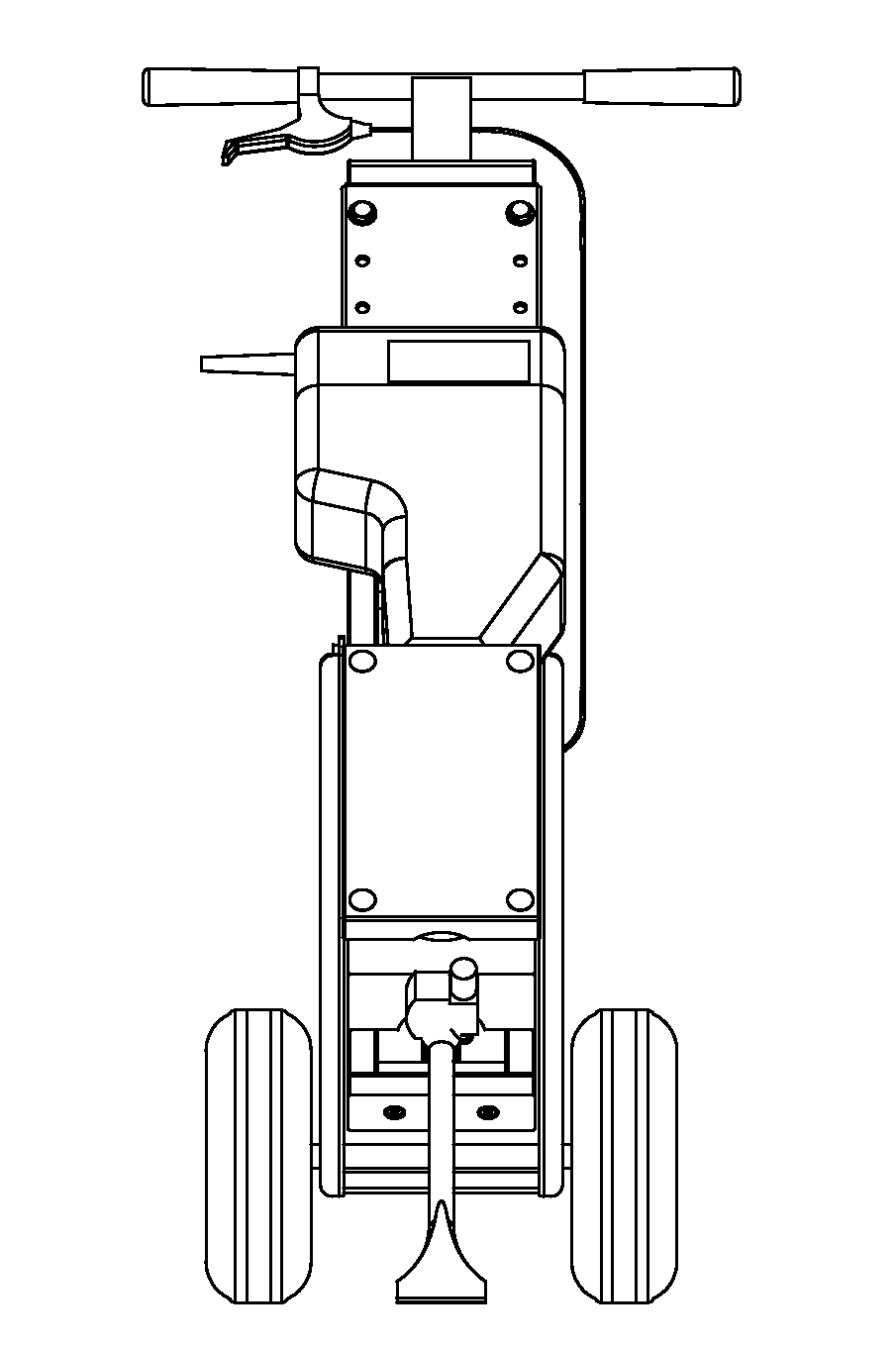

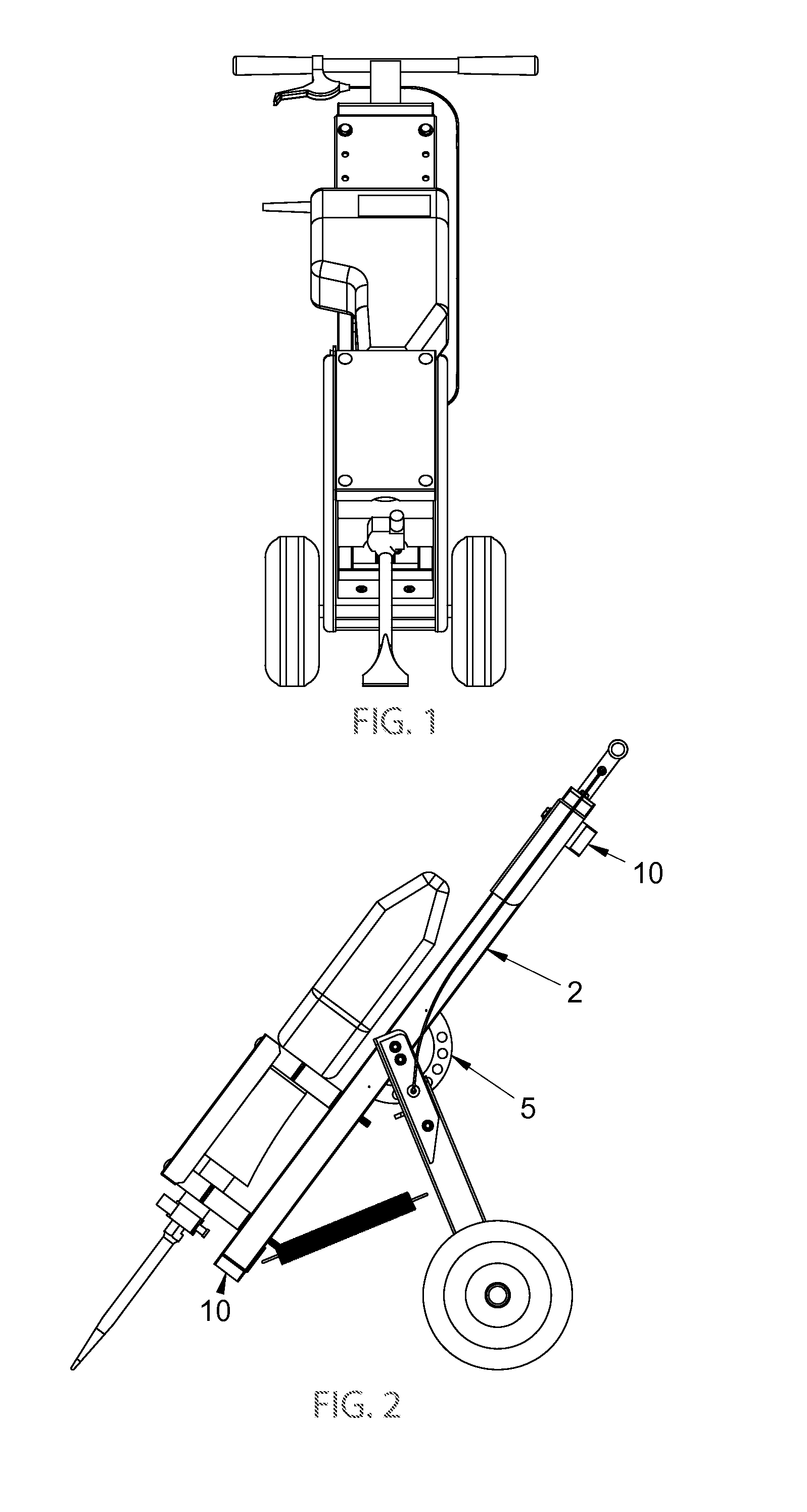

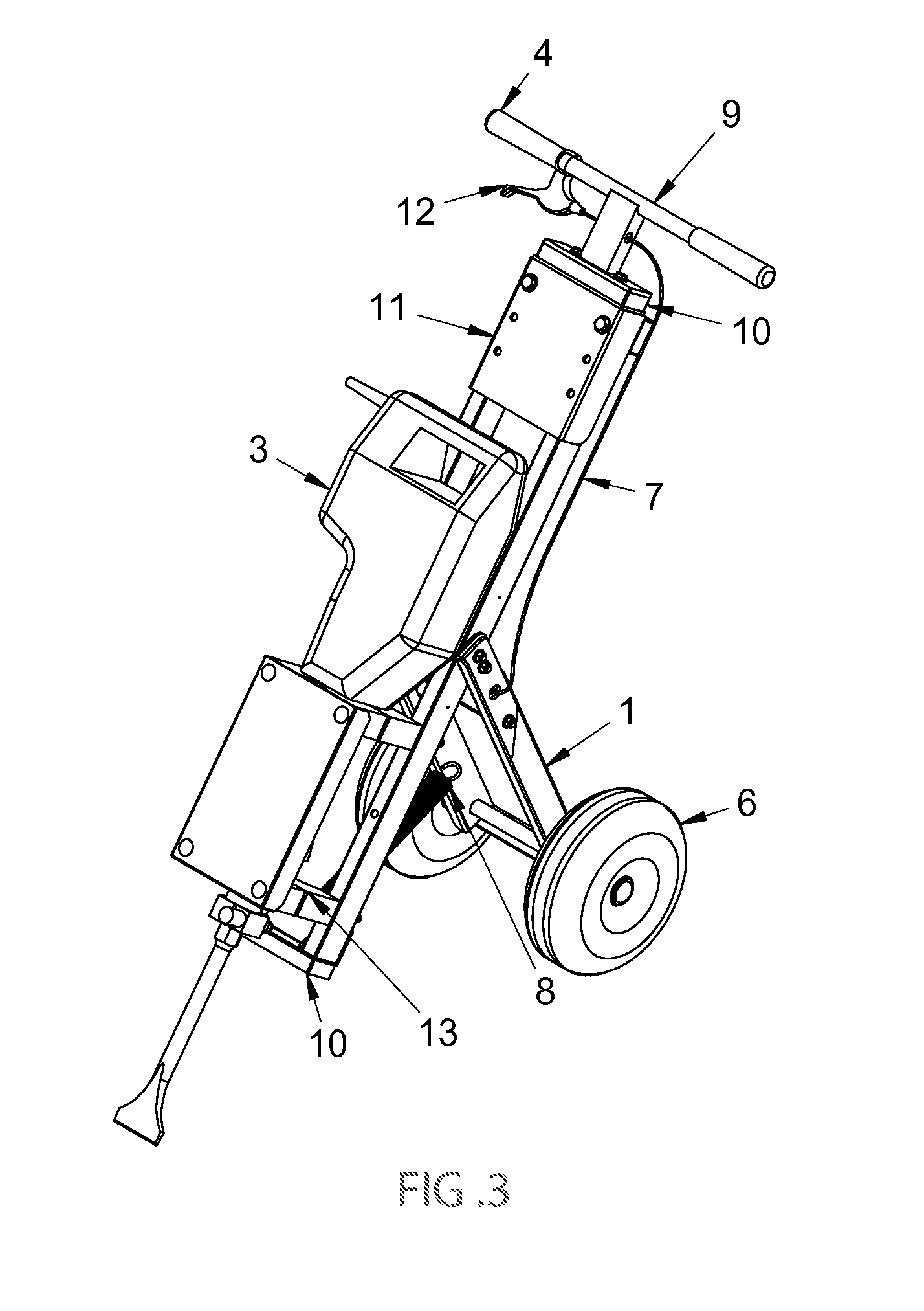

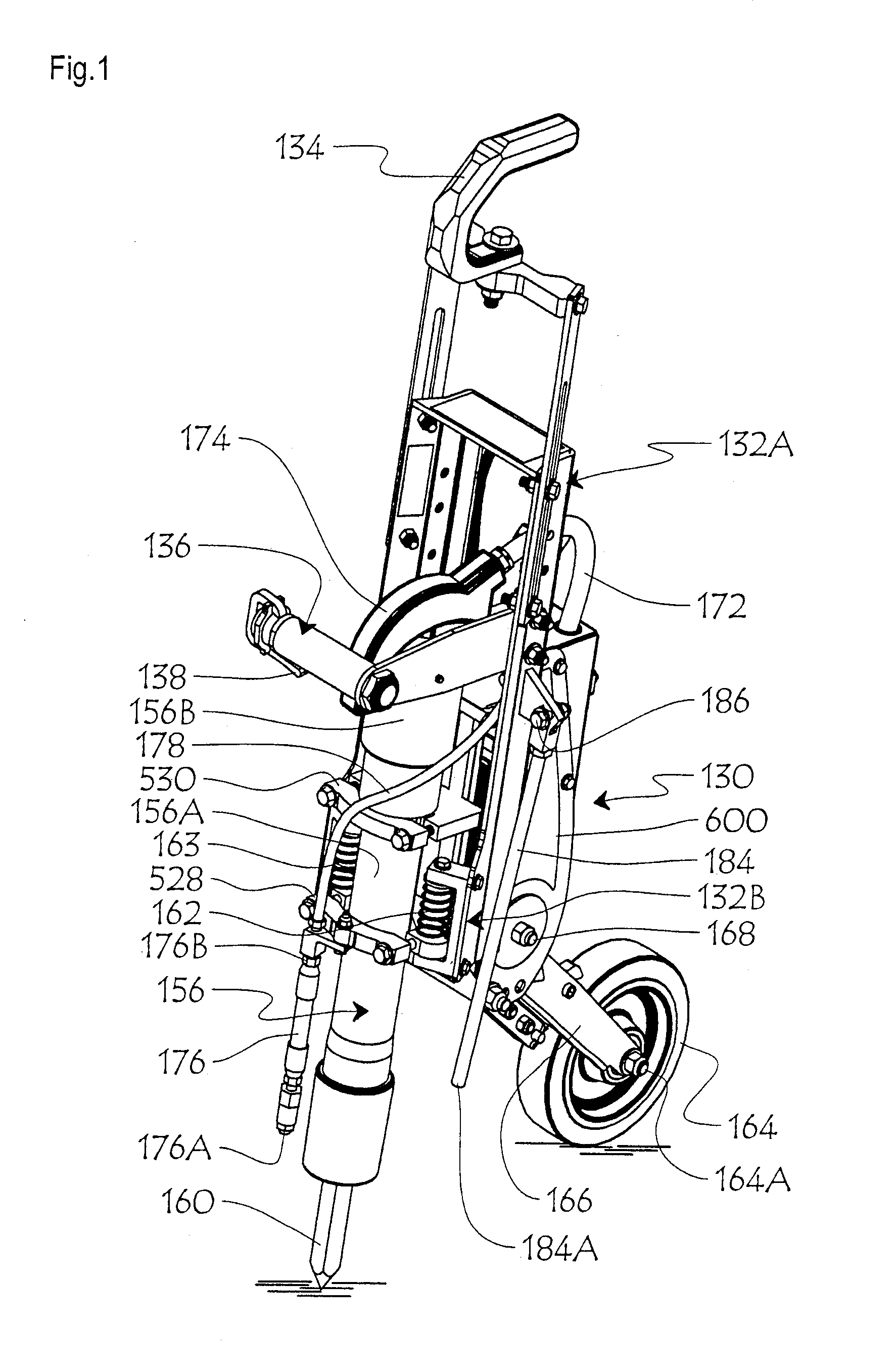

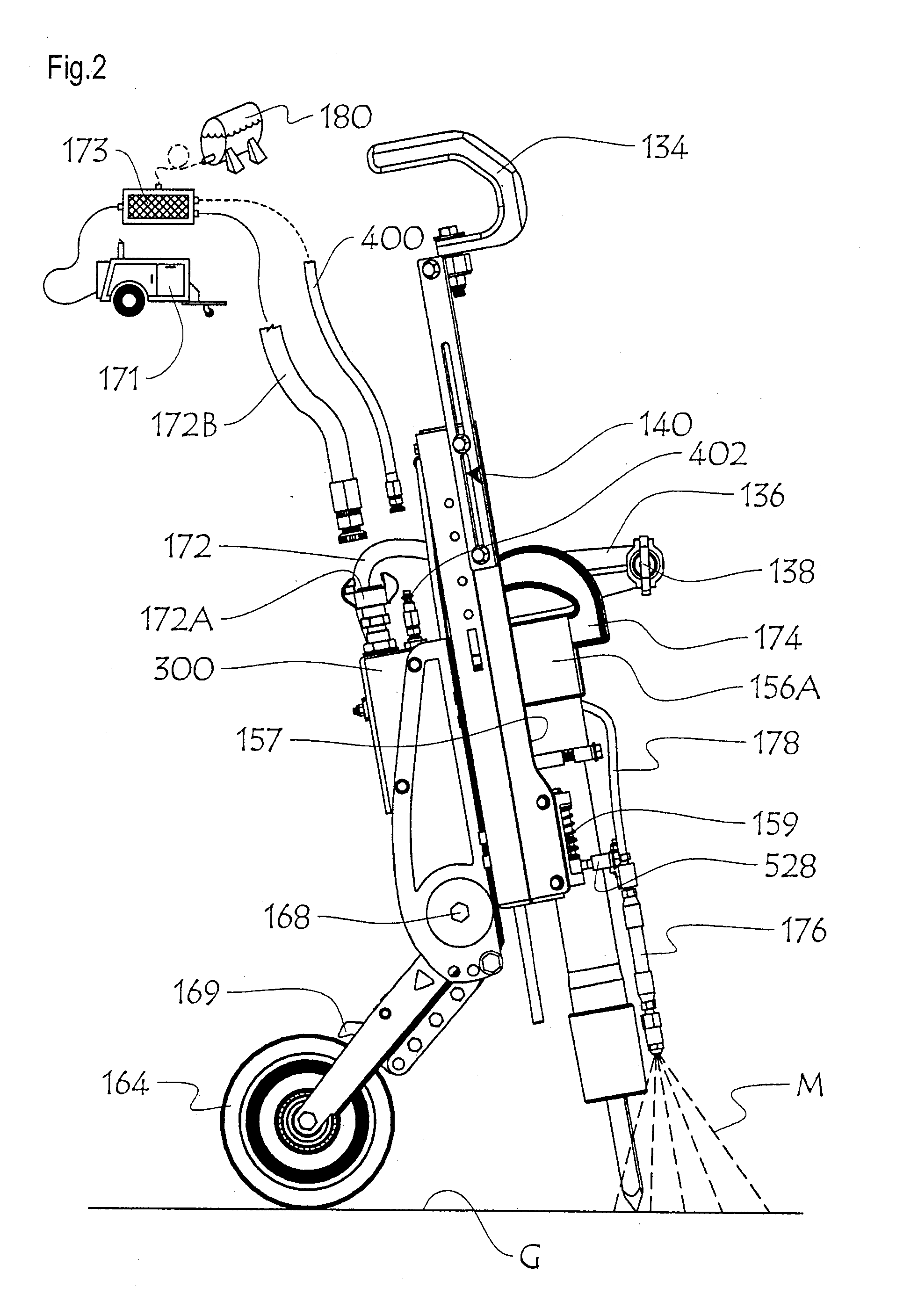

Jackhammer Folding Trolley

InactiveUS20180085907A1Suppress recoilEfficient removalBuilding repairsPortable percussive toolsJackhammerLocking mechanism

The present invention is a folding jackhammer trolley. The trolley is comprised of a main frame, wheel frame, and handle frame. One or more adjustable brackets are provided on the main frame to retain a jackhammer. The brackets are adjustable by hand and require no tools to properly secure a jackhammer. Rollers are provided on the front end of the main frame, and wheels are provided on the wheel frame to allow the trolley to be mobile. Clutch locking mechanisms are actuated by levers provided on the handle bars. When the levers are engaged by a user the angles of the handle frame and wheel frame are adjustable relative to the main frame. The adjustments allow for prying motions to be carried out and for the handle frame to suit different user heights.

Owner:WILSON JOHN

Jackhammer lift assist

ActiveUS7607491B2Reduce stepsFacilitating the lifting and the extracting of the equipmentDrilling rodsConstructionsJackhammerEngineering

The present invention relates to a lift assist device which is used to alleviate the physical demands for the operation of a heavy percussion power tool, such as a pneumatic jackhammer, by facilitating lifting and freeing the percussion power tool. In general, the lift assist device contains an actuating cylinder with a lifting foot attached to the outside end of its piston rod and a control unit which comprises a directional control valve and a hand lever. The control unit is on the top of the lift assist device and can be used to control the lifting speed and height. The lift assist device is secured to the body of the percussion power tool with one or more mounting elements.

Owner:INTEGRATED TOOL SOLUTIONS

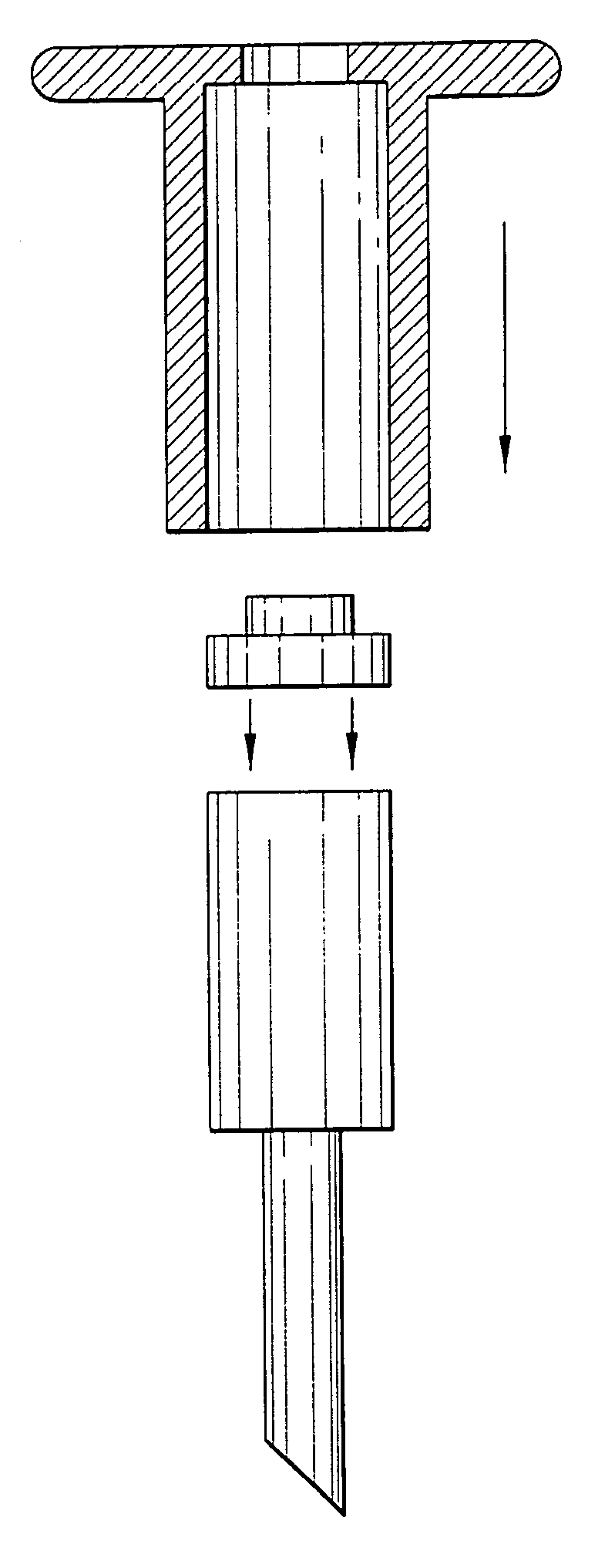

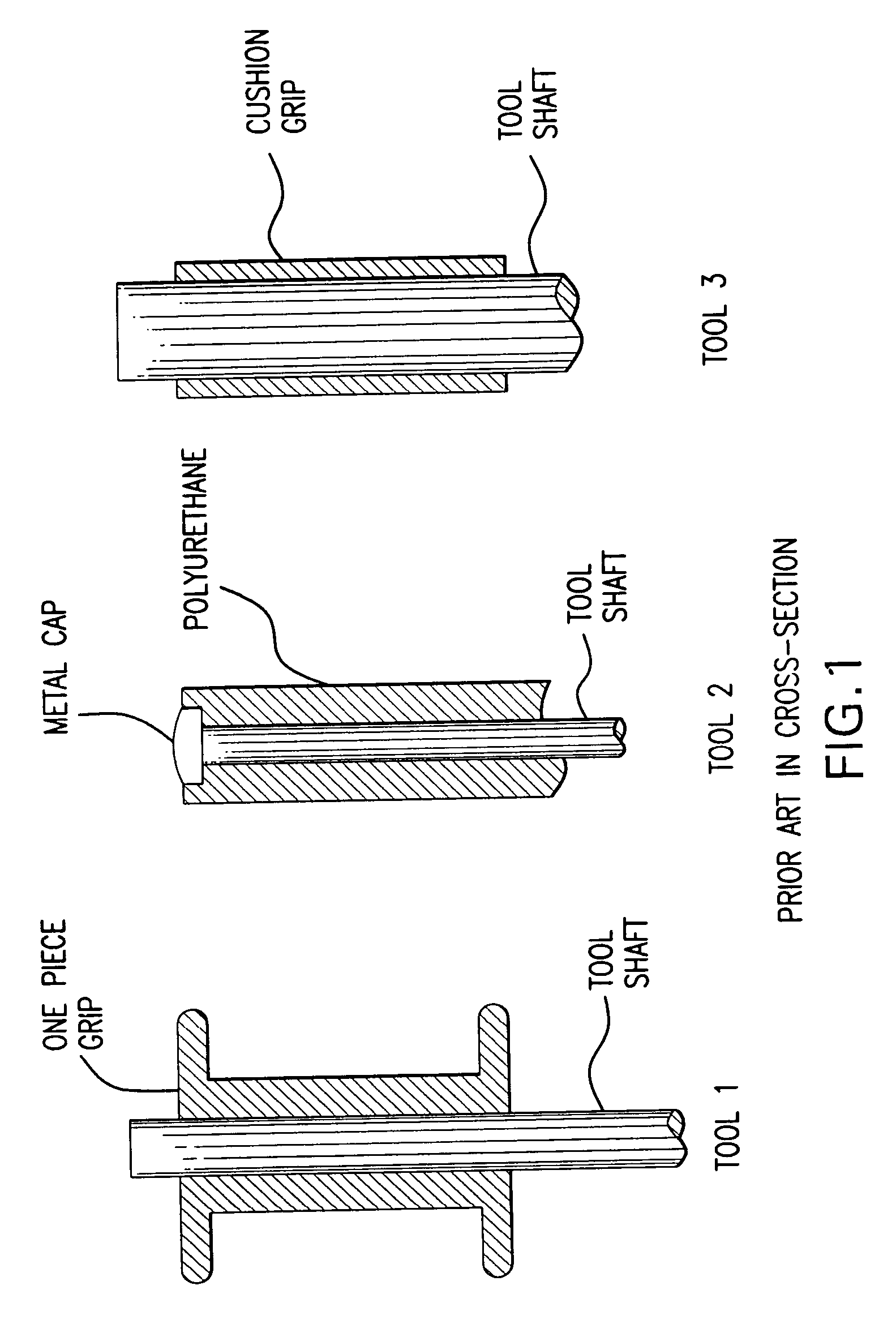

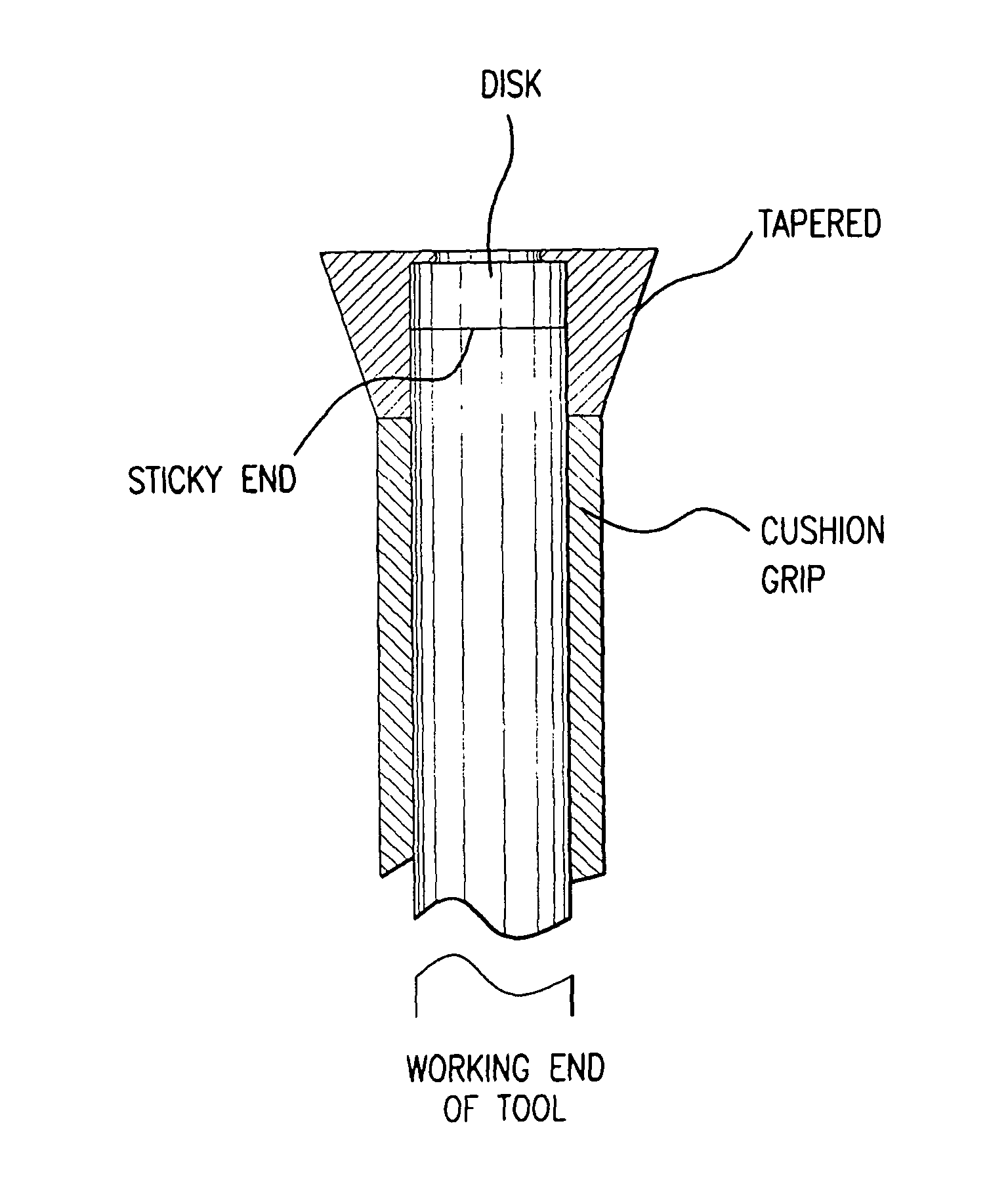

Anti-spalling combination on an impact tool with an improved holding system

InactiveUS20040016330A1Avoid injuryExtend your lifeLighting and heating apparatusHand chiselsJackhammerChisel

The invention is a tool to be struck, or a striking tool, (collectively referred to as an "impact tool"), or alternatively, a cap, that will not suffer metal spall and the attendant dangers of spalling and flying or cutting metal slivers. The preferred mode is on a chisel (wood or cold) or repeated impact tool. The chisel would have a striking end cut square to the shaft. The striking end would be opposite the working end. Other tools such as impact wrenches, jackhammers, wedges, spikes, hammers, mallets or other tools being struck or striking forcibly benefit from the invention by use of a disk insert of polymeric material to alter ergonomic and noise characteristic.

Owner:HARD HAT TECH

Jackhammer trolley

ActiveUS8240682B2Add supportCompressed against the spring easilyReciprocating drilling machinesConstructionsJackhammerEngineering

According to the present invention, there is provided a jackhammer trolley comprising a mainframe member with a clamp member at the bottom end and an extension bracket portion at the top end, a base frame member removably attached to the mainframe member by pivoting joints with at least one wheel member removably attached to its bottom, a handle member having a hand lever attached to said top end, and at least one vibration dampener fixed to said top or bottom end of the mainframe member.

Owner:MAKINEX IP PTY LTD

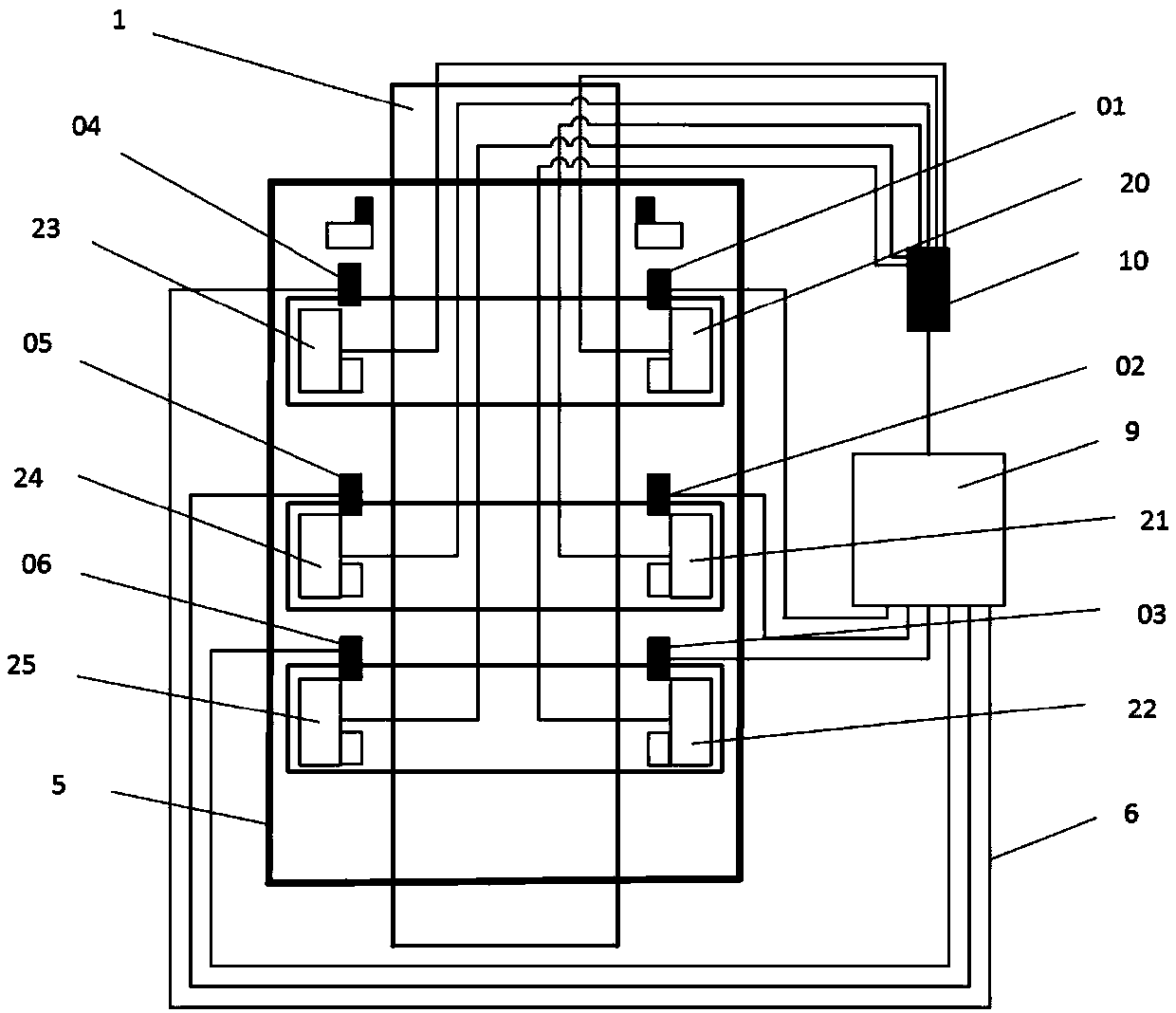

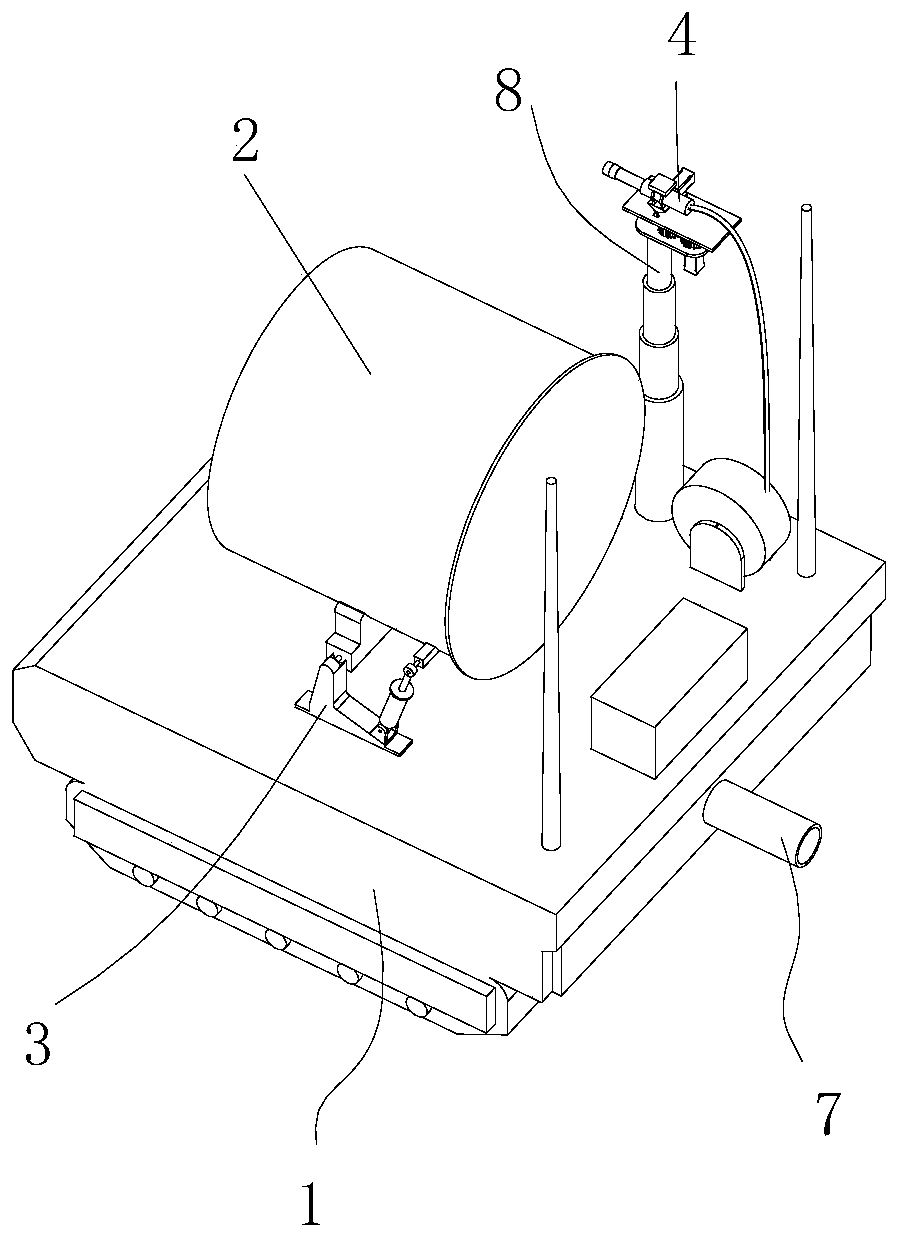

Pipe pile mold bolt tightening system

ActiveCN107932046AGuaranteed detection accuracyGuaranteed accuracyMetal working apparatusLaser rangingControl system

The invention discloses a pipe pile mold bolt tightening system. A mechanical system, a control system and a detection system are included; and the mechanical system comprises a mechanical station adjusting table, a detection station adjusting table, a pipe pile mold conveying device, a supporting mechanism, flattening mechanisms, a straightening and pushing mechanism, a jackhammer workbench and ajackhammer device. The detection station adjusting table is located on the two sides of the pipe pile mold conveying device; the jackhammer workbench is arranged above the inner side of the mechanical station adjusting table; the jackhammer device is arranged on the jackhammer workbench; the straightening and pushing mechanism is arranged under the jackhammer device; and the flattening mechanismsare arranged on one side of the straightening and pushing mechanism side by side. The detection system comprises a pipe diameter detection unit, a bolt detection unit and a notch detection unit; thepipe diameter detection unit comprises a laser range finder and a limiting switch located under the pipe pile mold conveying device; and the control system is used for controlling the device. The pipepile mold bolt tightening system achieves efficient and automatic pipe pile mold closing.

Owner:HUBEI UNIV OF TECH

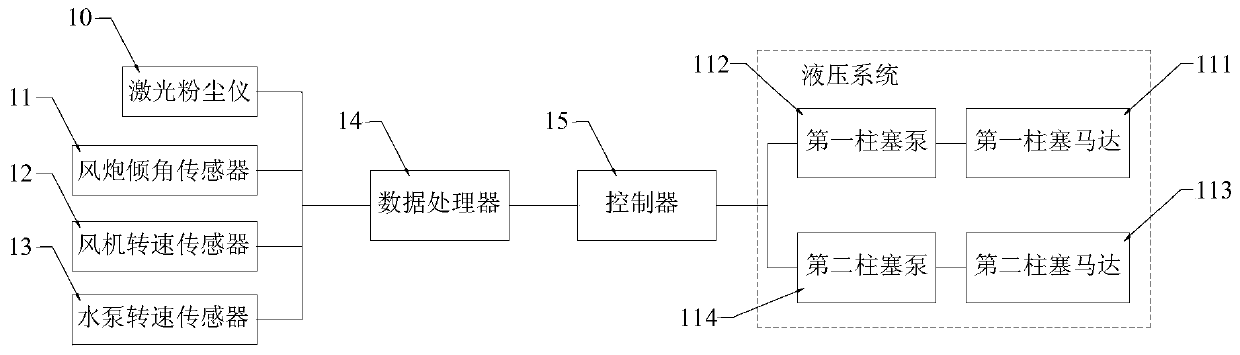

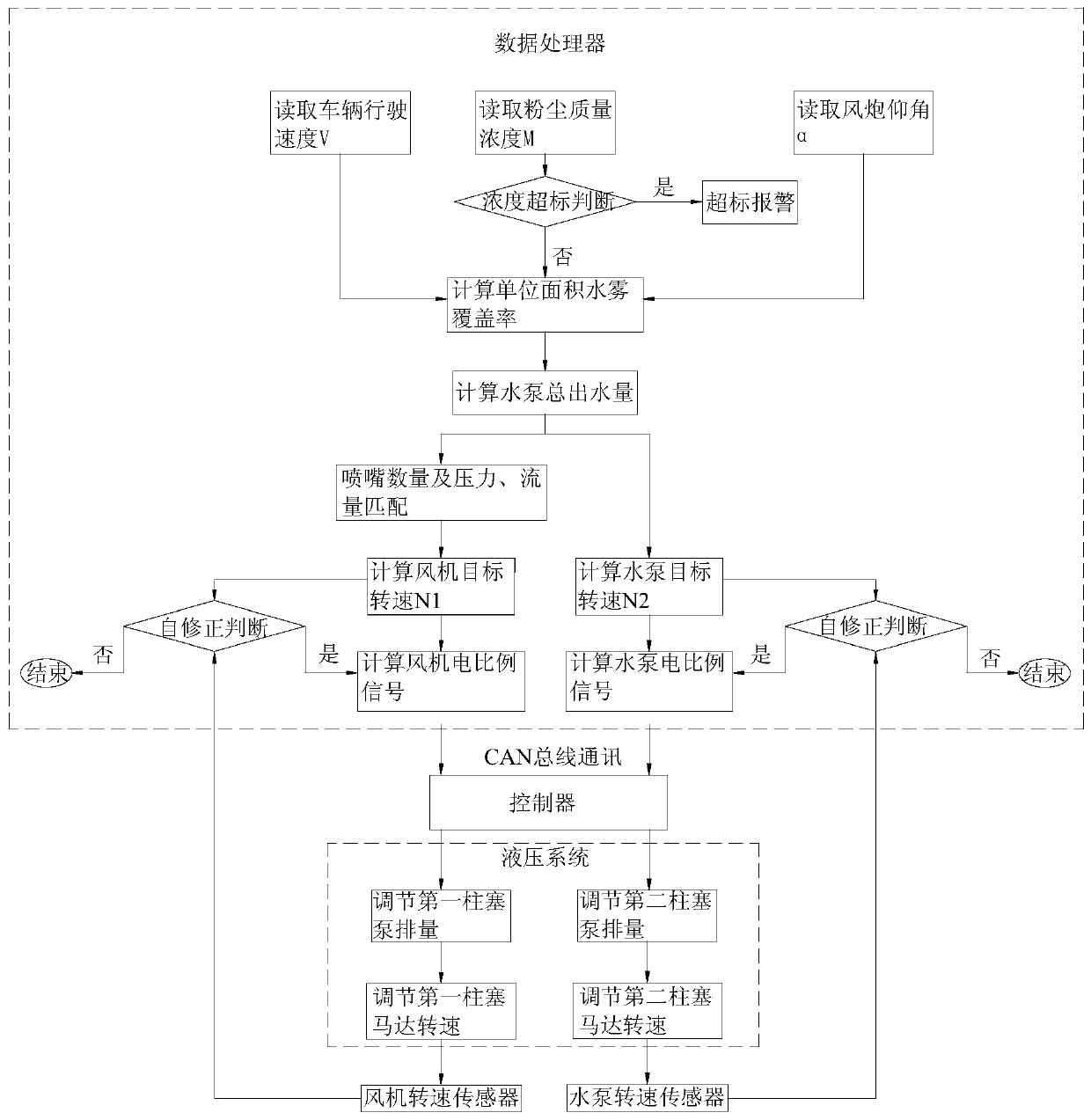

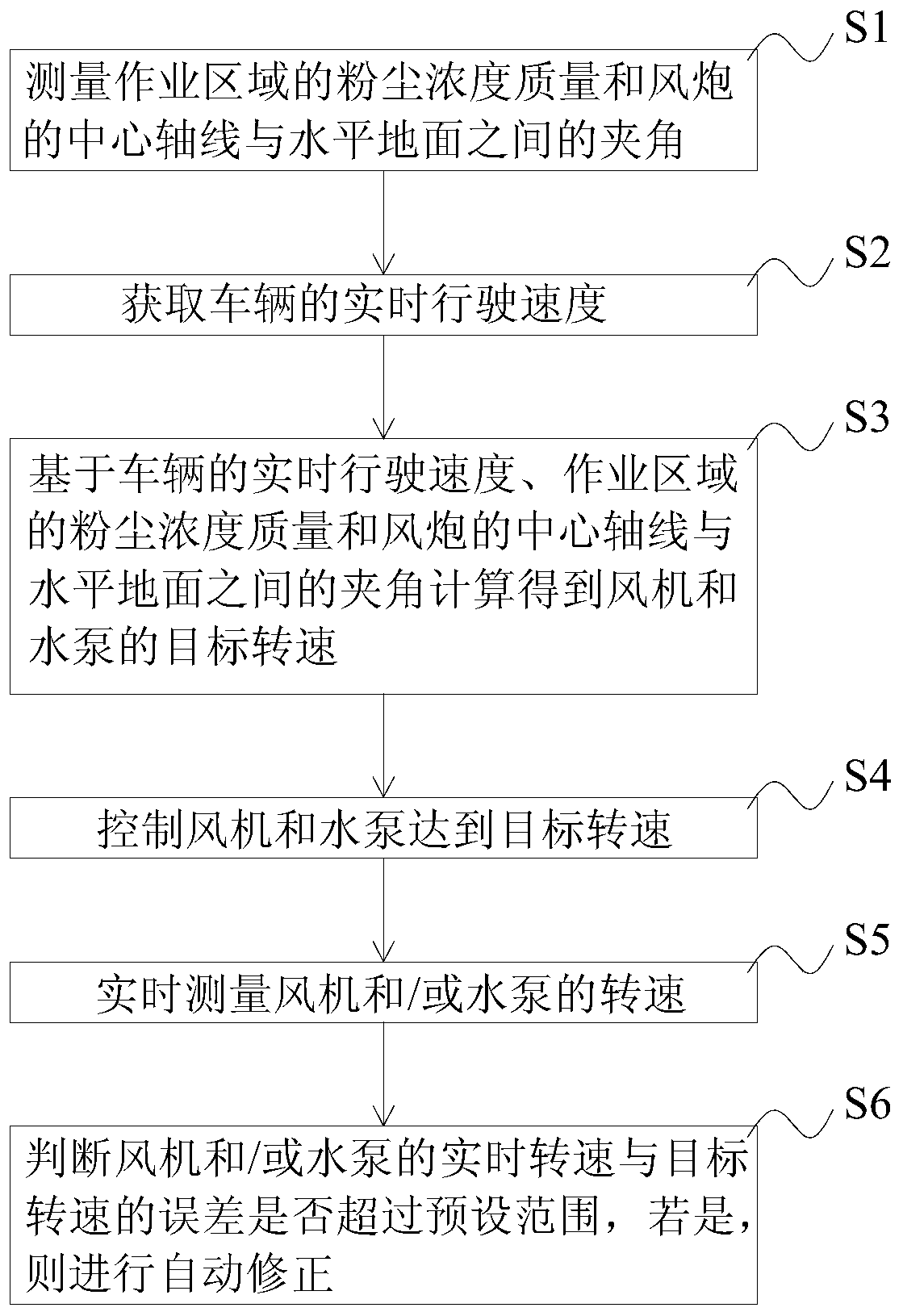

Intelligent spraying control system and method and dust suppression vehicle

ActiveCN110917772APrecise control of spray volumeExcellent spray dust effectUsing liquid separation agentControl systemJackhammer

The invention discloses an intelligent spraying control system and method and a dust suppression vehicle. The invention discloses the intelligent spraying control system. A laser dust meter is used for measuring the dust concentration mass M of an operation area, the pitch angle alpha of a jackhammer is measured through a jackhammer tilt angle sensor, then the real-time running speed V of a vehicle is obtained through a data processor, the data processor calculates target rotating speeds of a fan and a water pump based on the dust concentration mass M, the pitch angle alpha of the jackhammer and the vehicle driving speed V, and finally, the working states of the fan and the water pump are controlled through the controller to reach the target rotating speeds. Therefore, the intelligent adjustment of the fan and the water pump is completed, the whole adjusting process does not need human intervention, the rotating speeds of the fan and the rotating speed of the water pump are closely related to the dust concentration mass M of the operation area, the pitch angle alpha of the jackhammer and the running speed V of the vehicle, therefore, the spraying amount can be accurately controlled, the optimal spraying and dust reduction effect is achieved, and the system can be well suitable for an unmanned sanitation vehicle.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

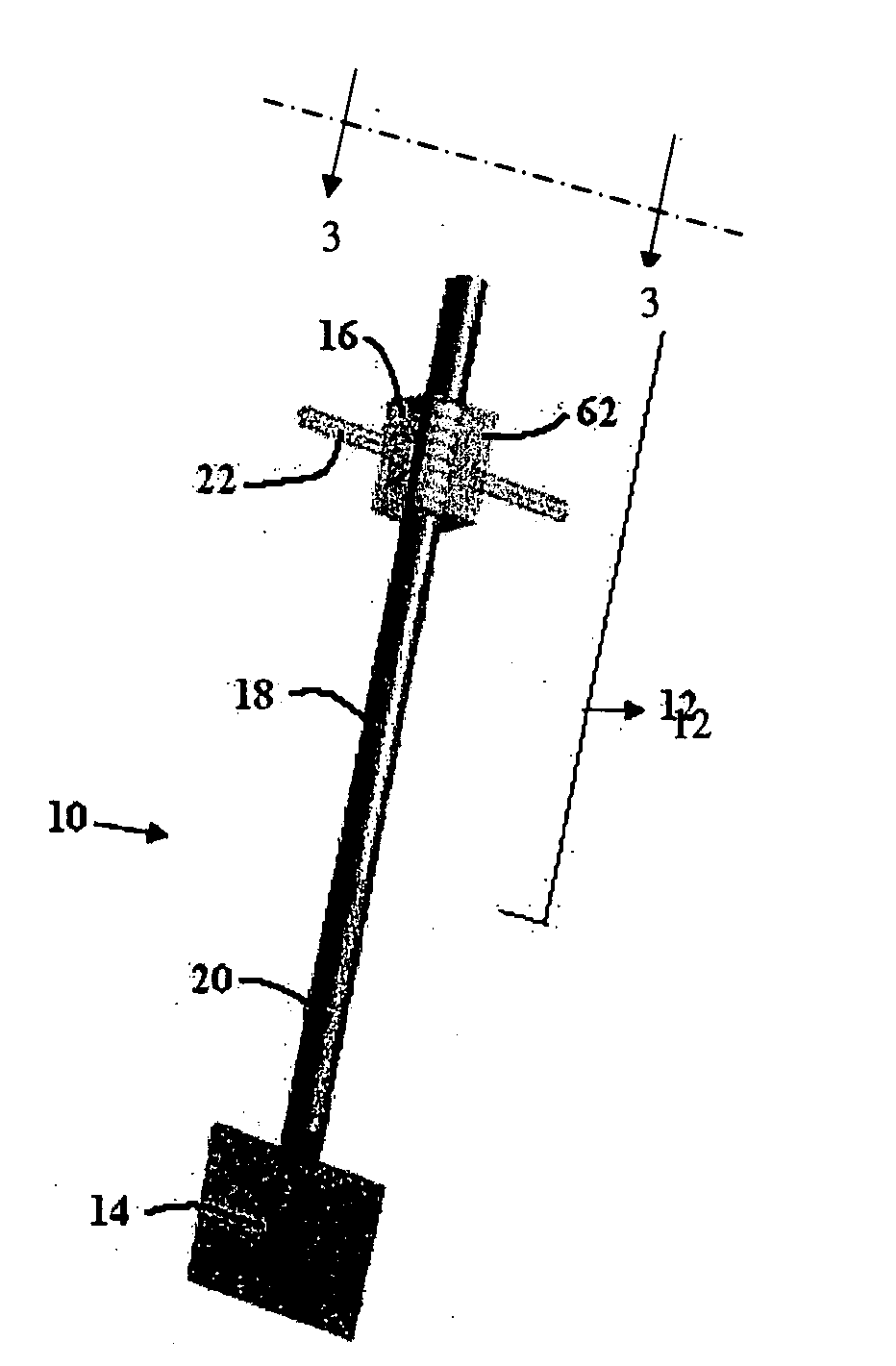

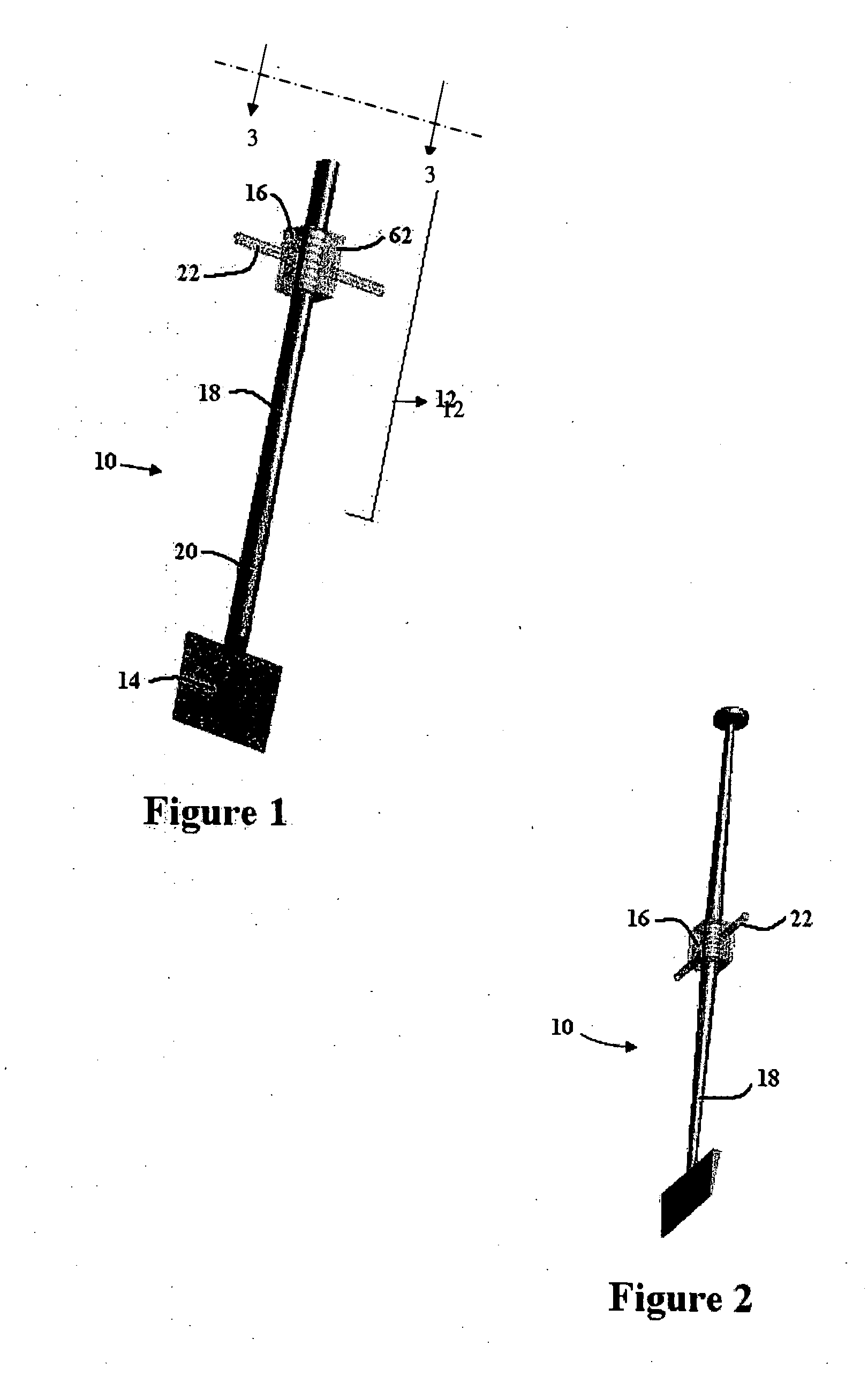

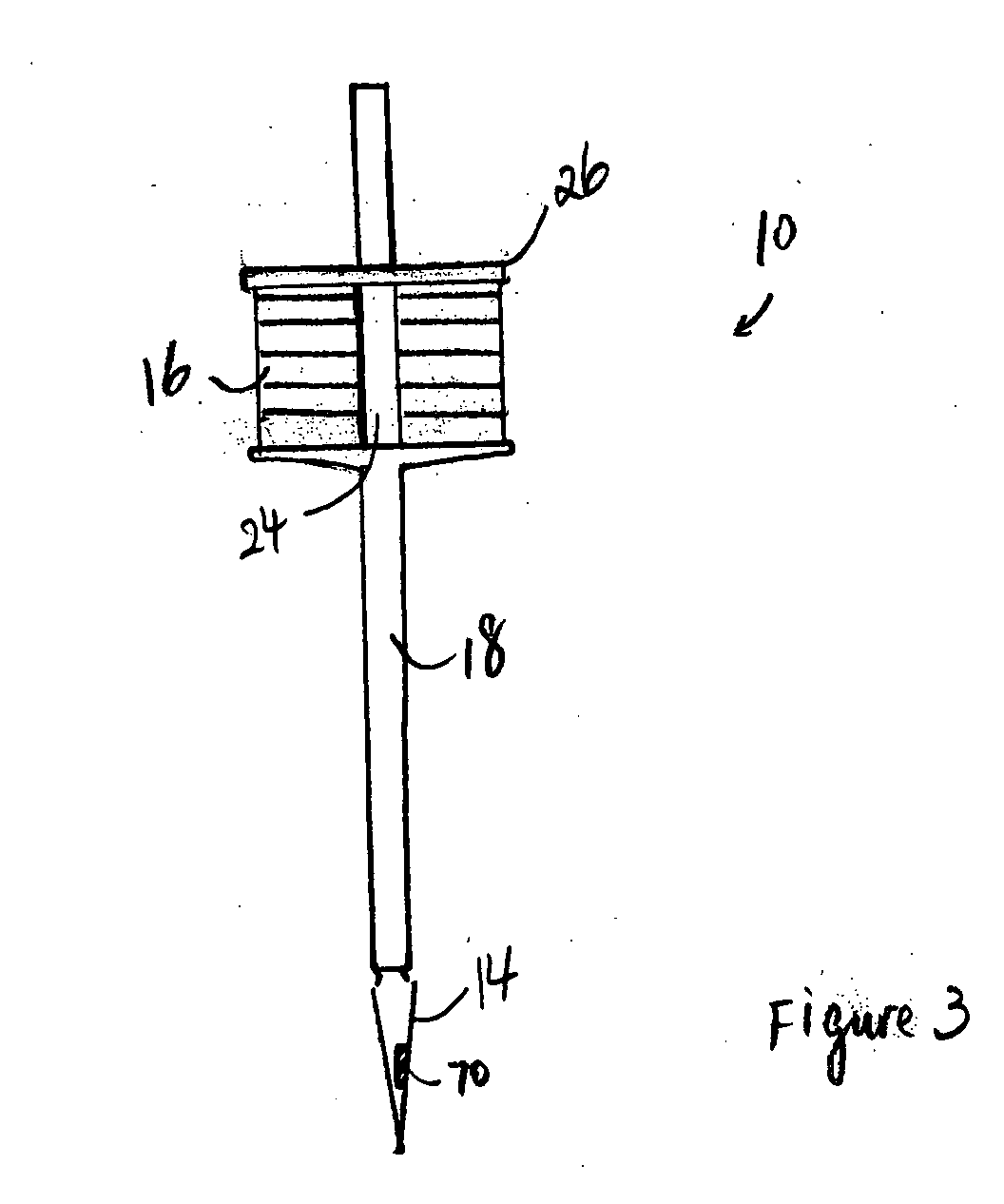

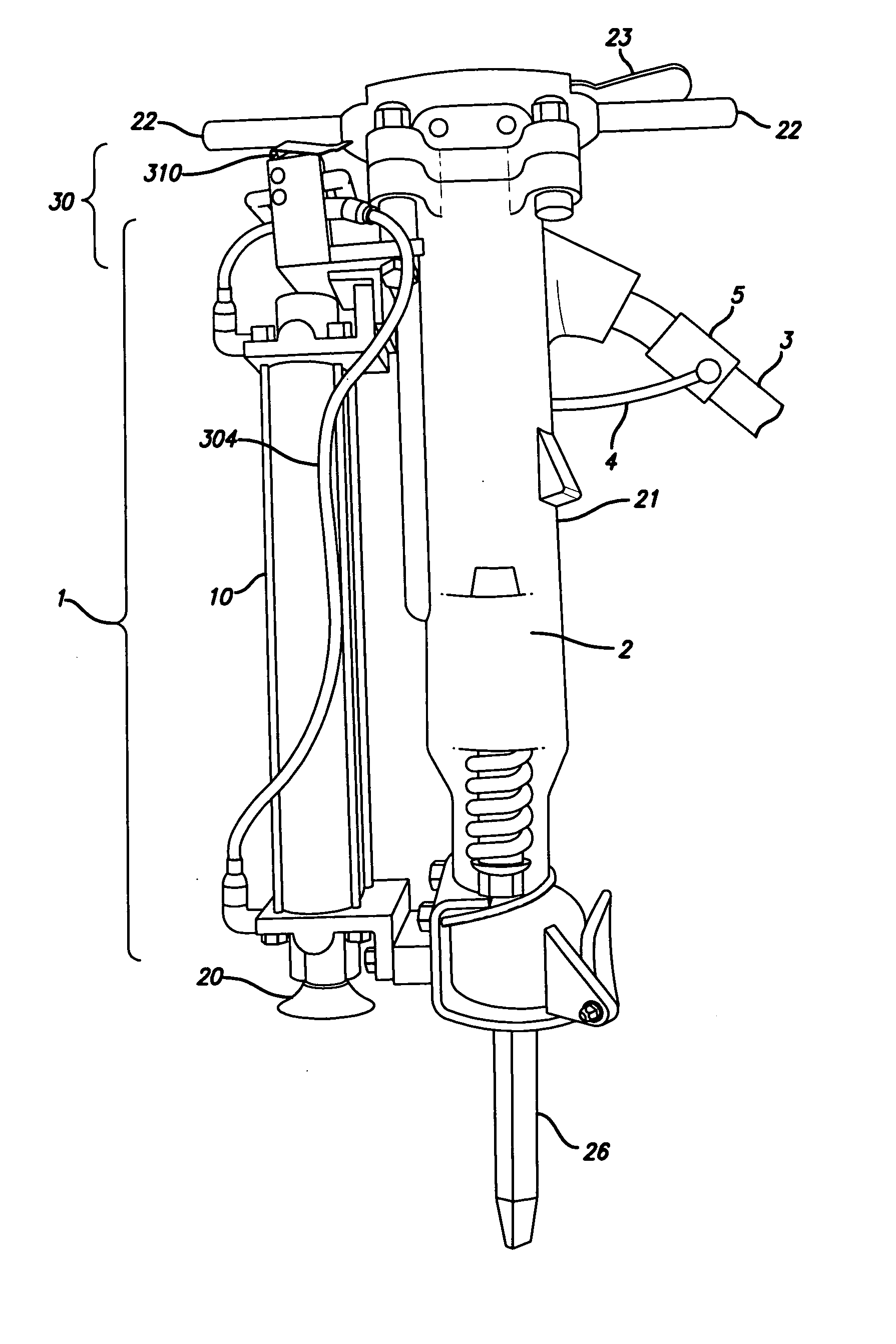

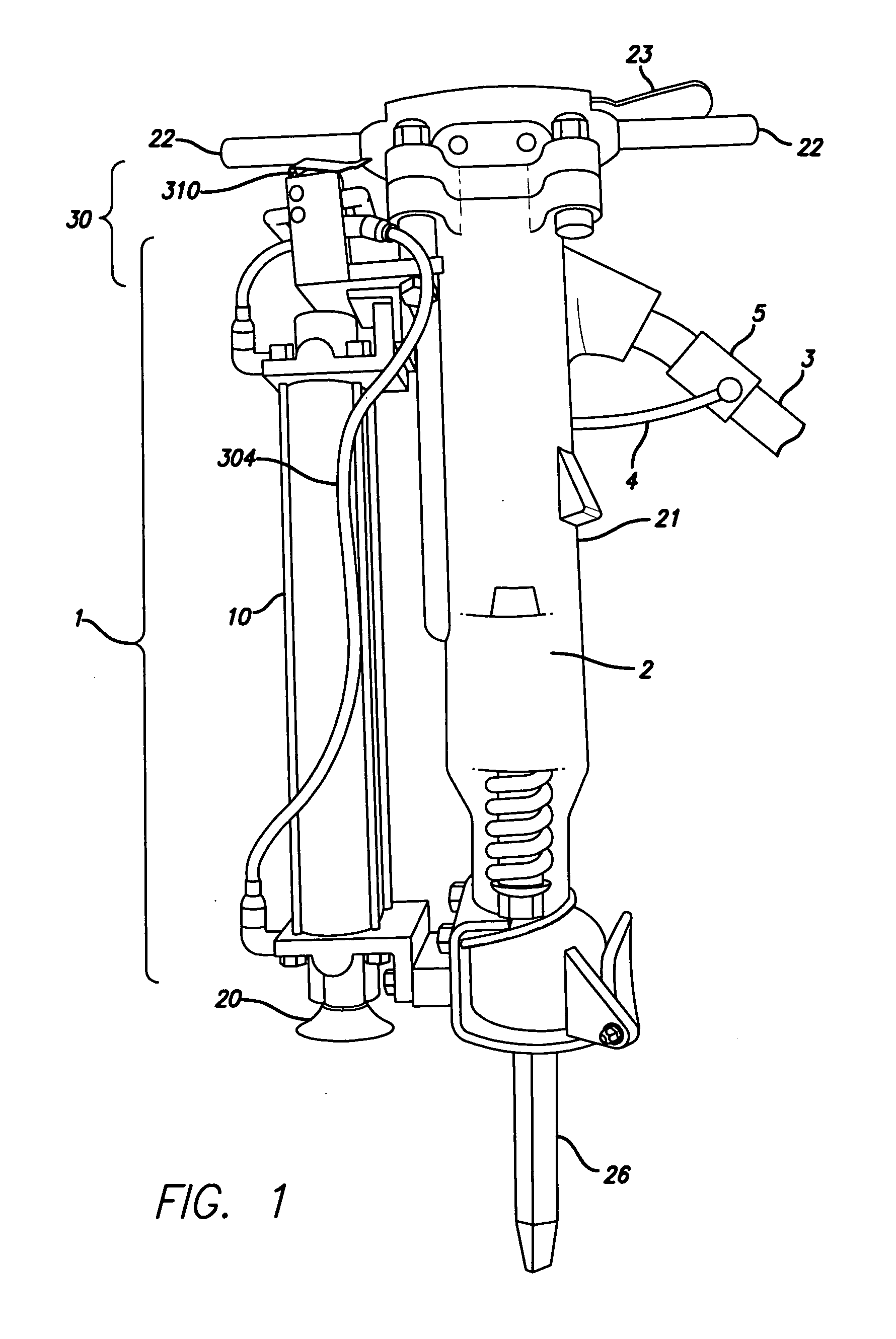

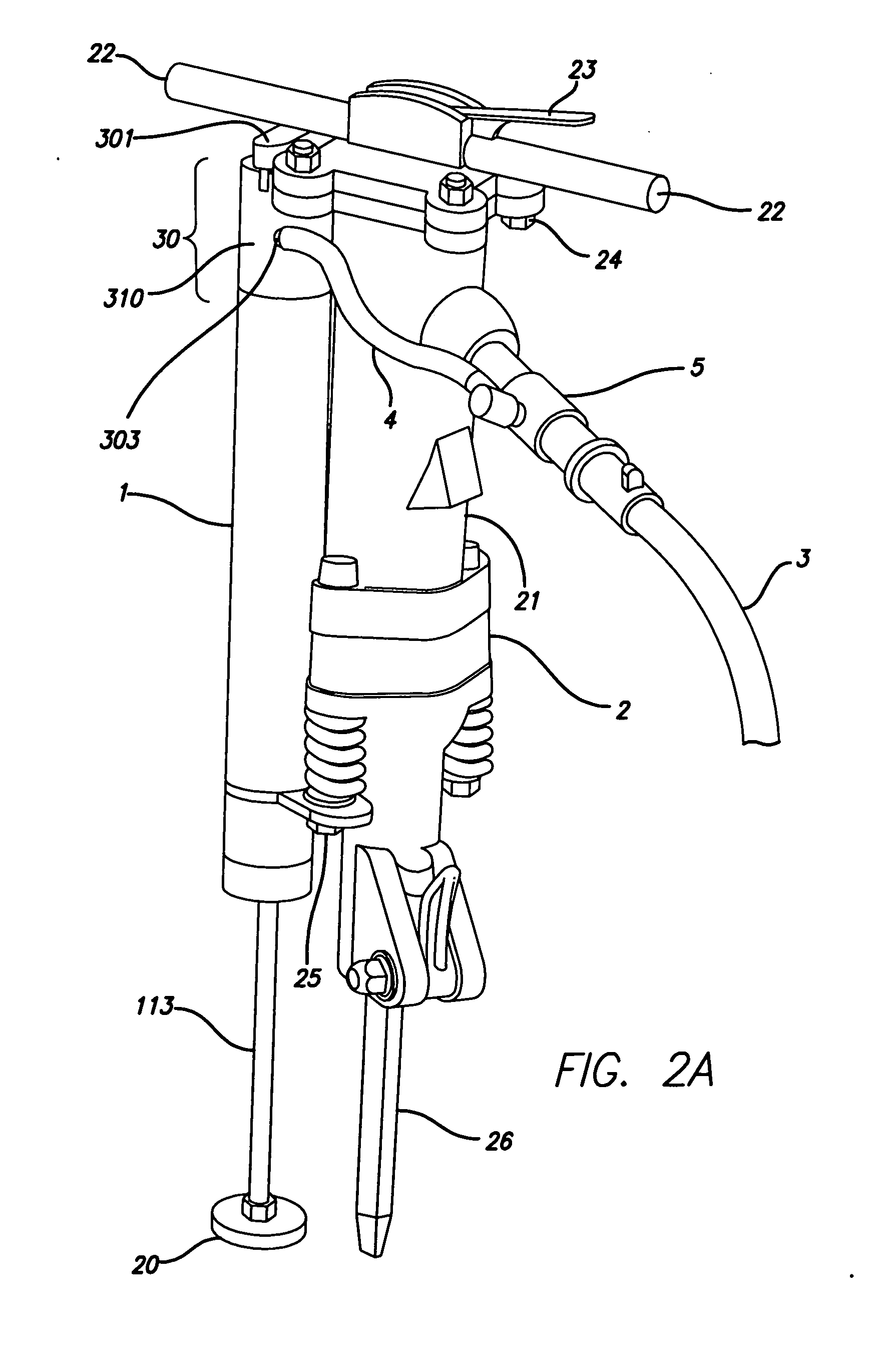

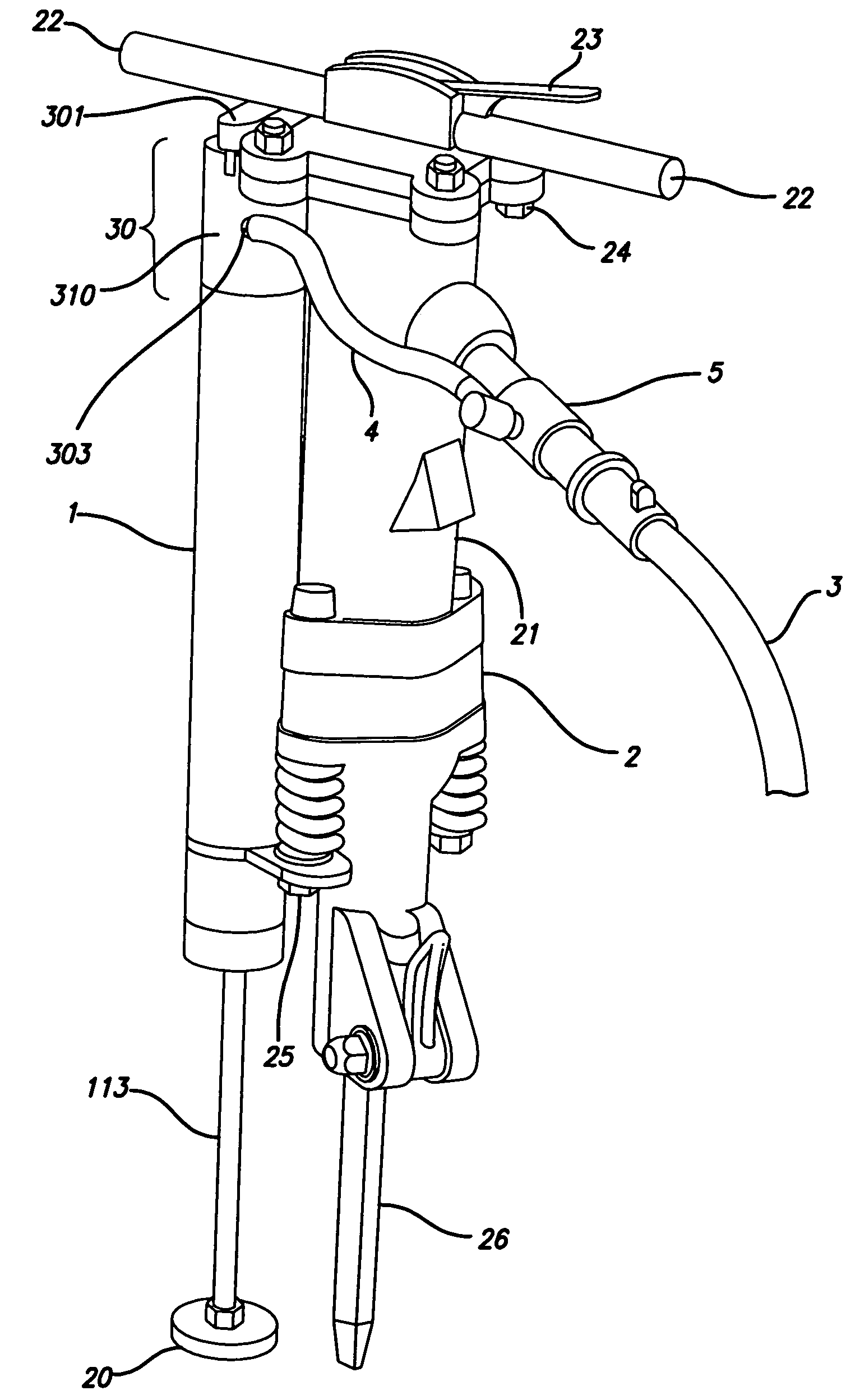

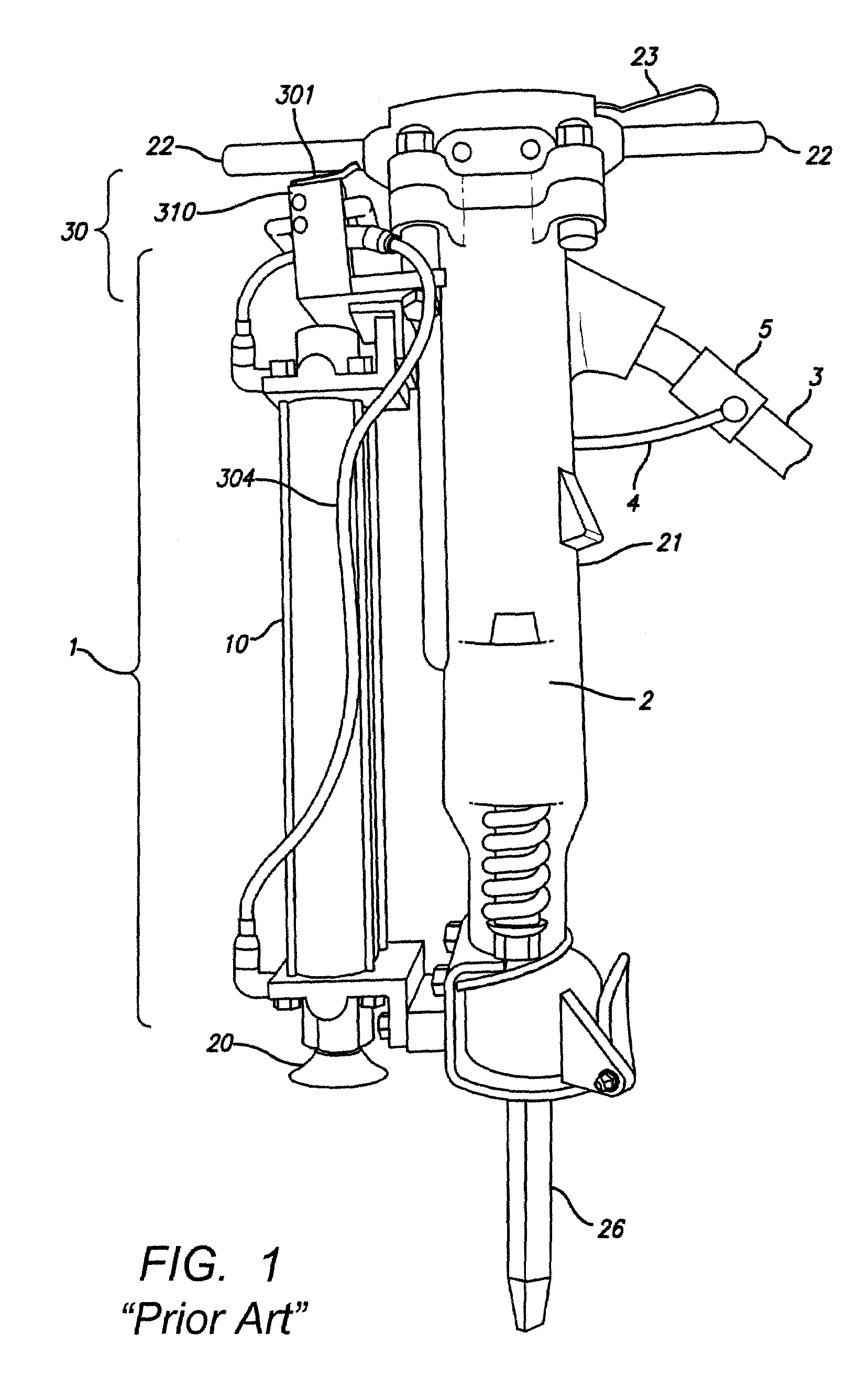

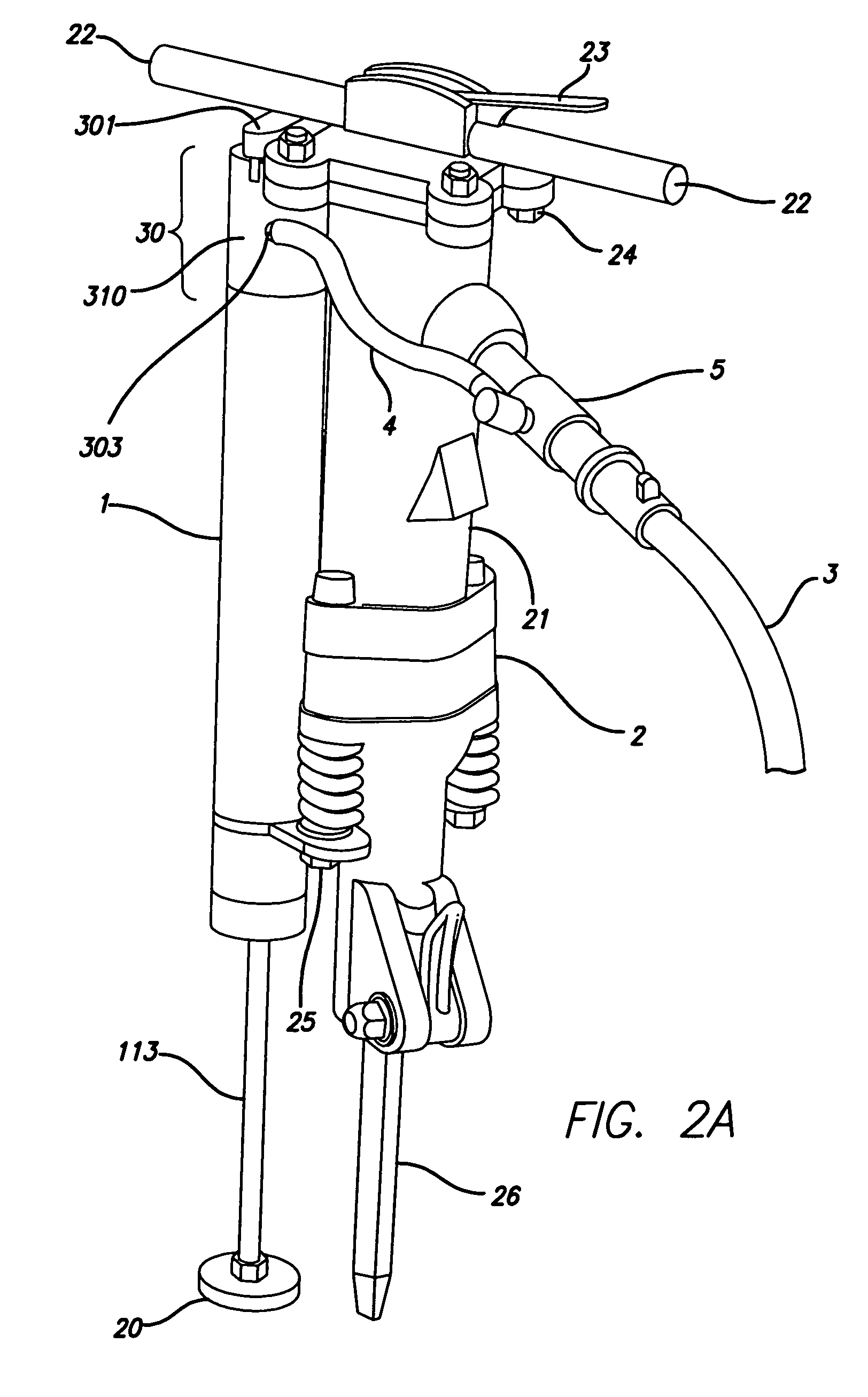

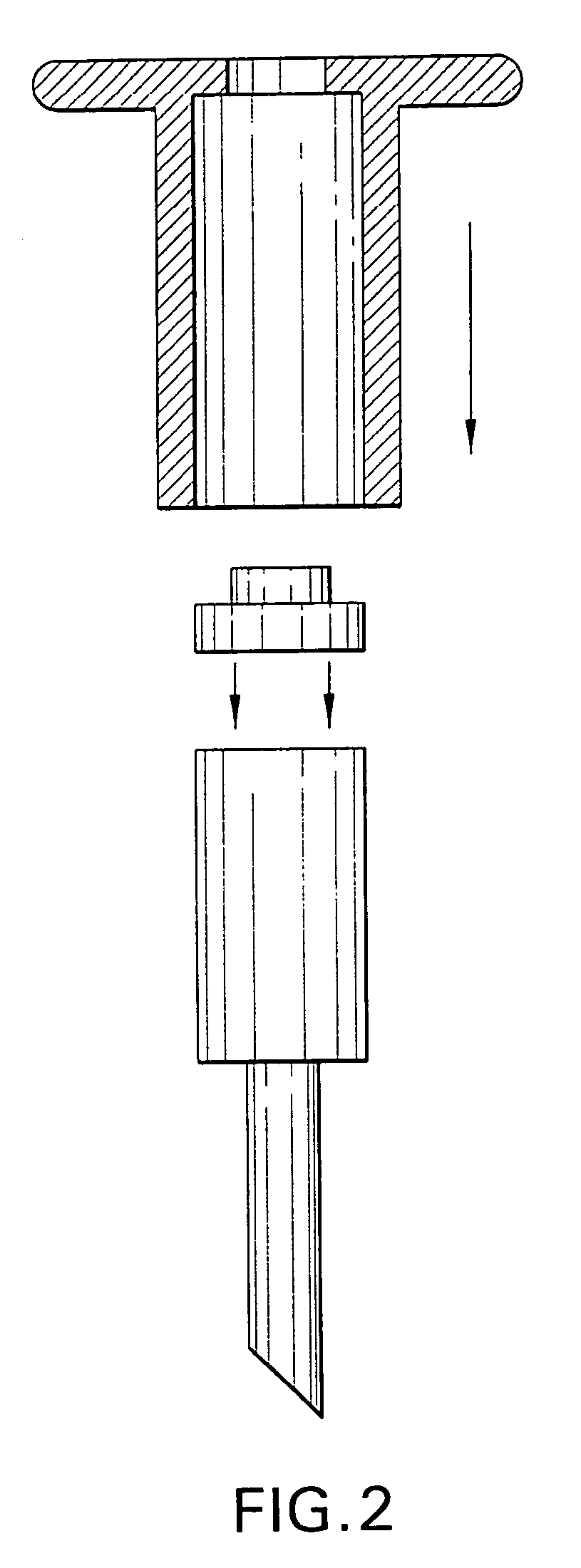

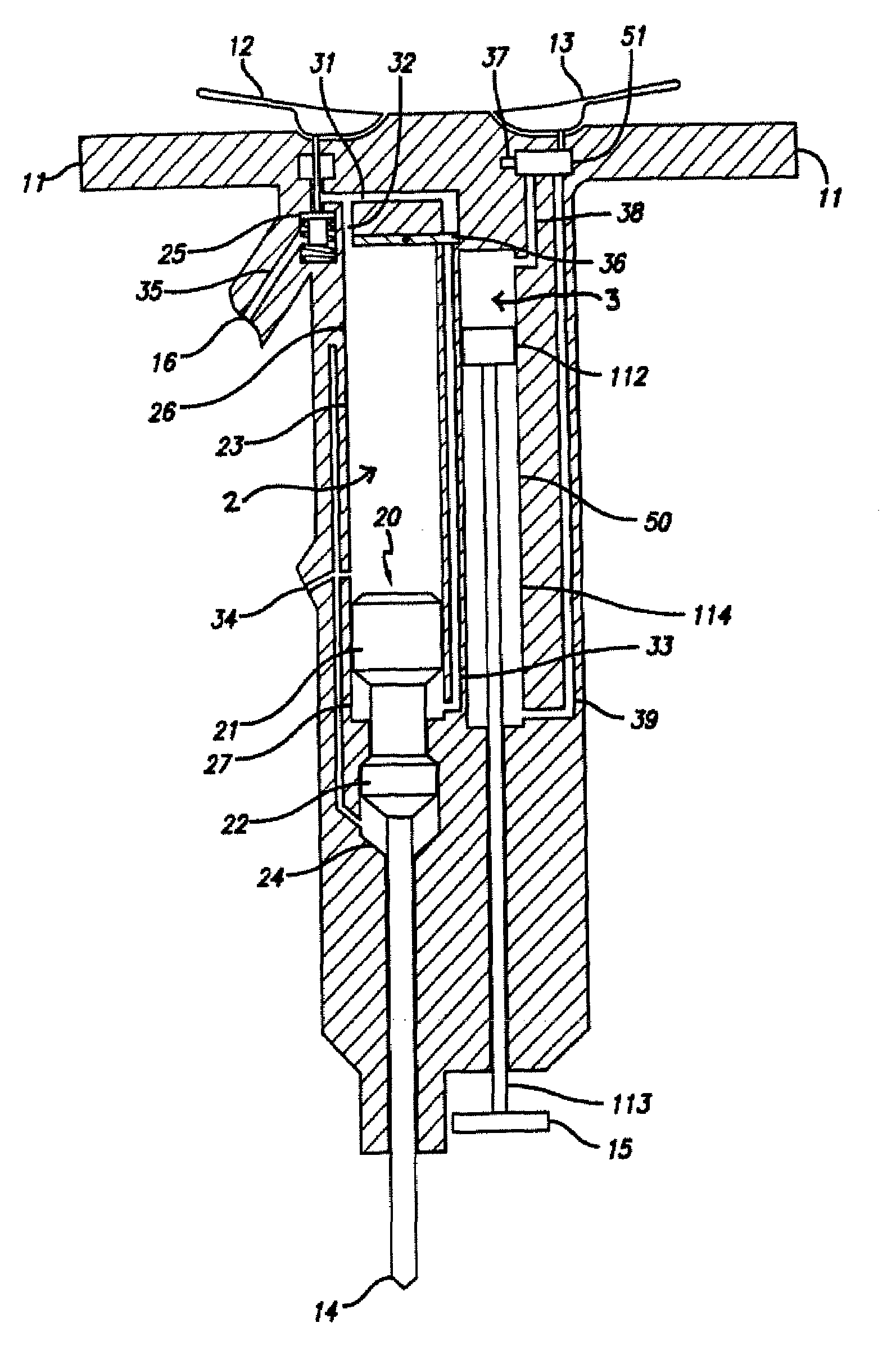

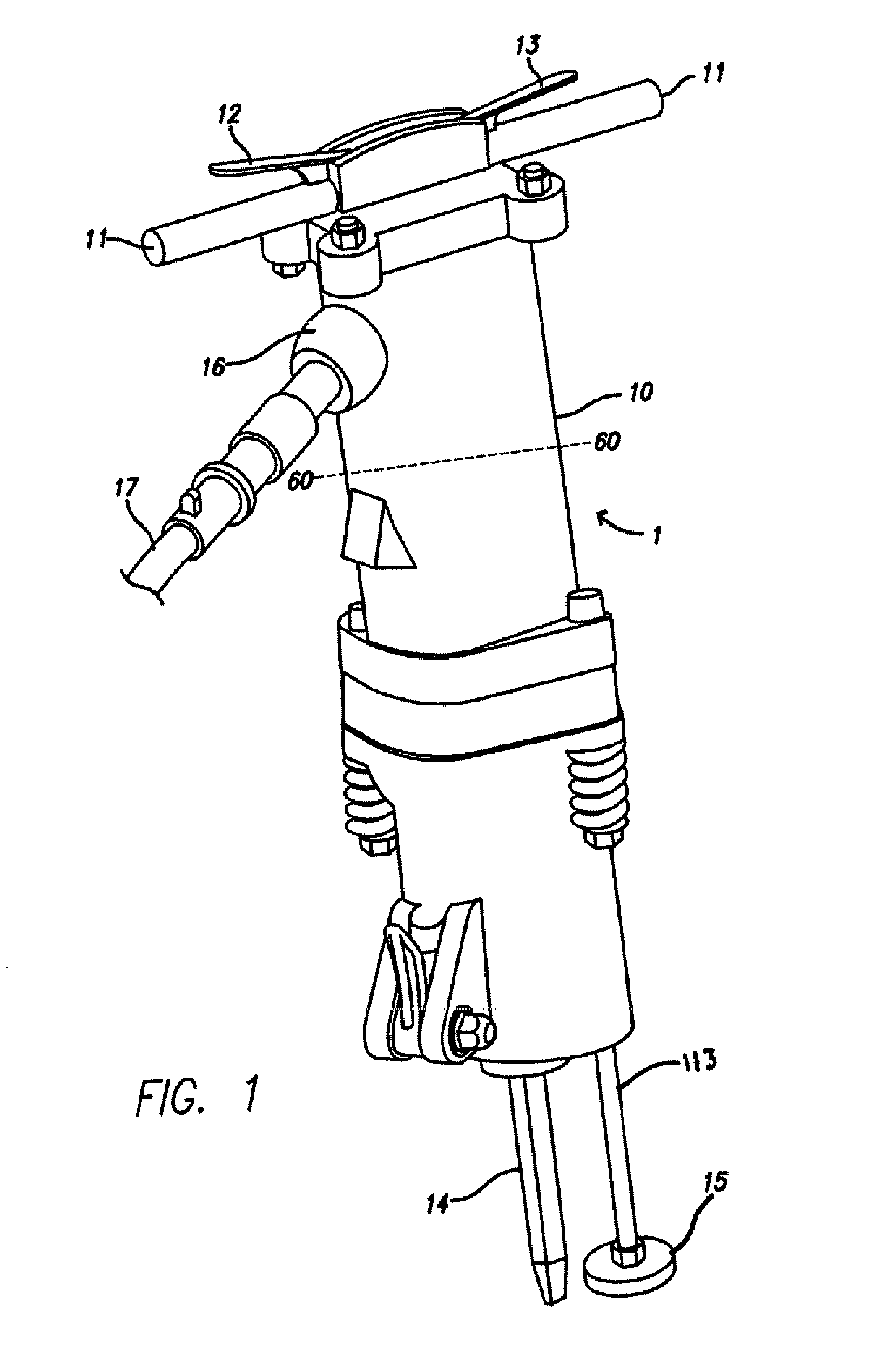

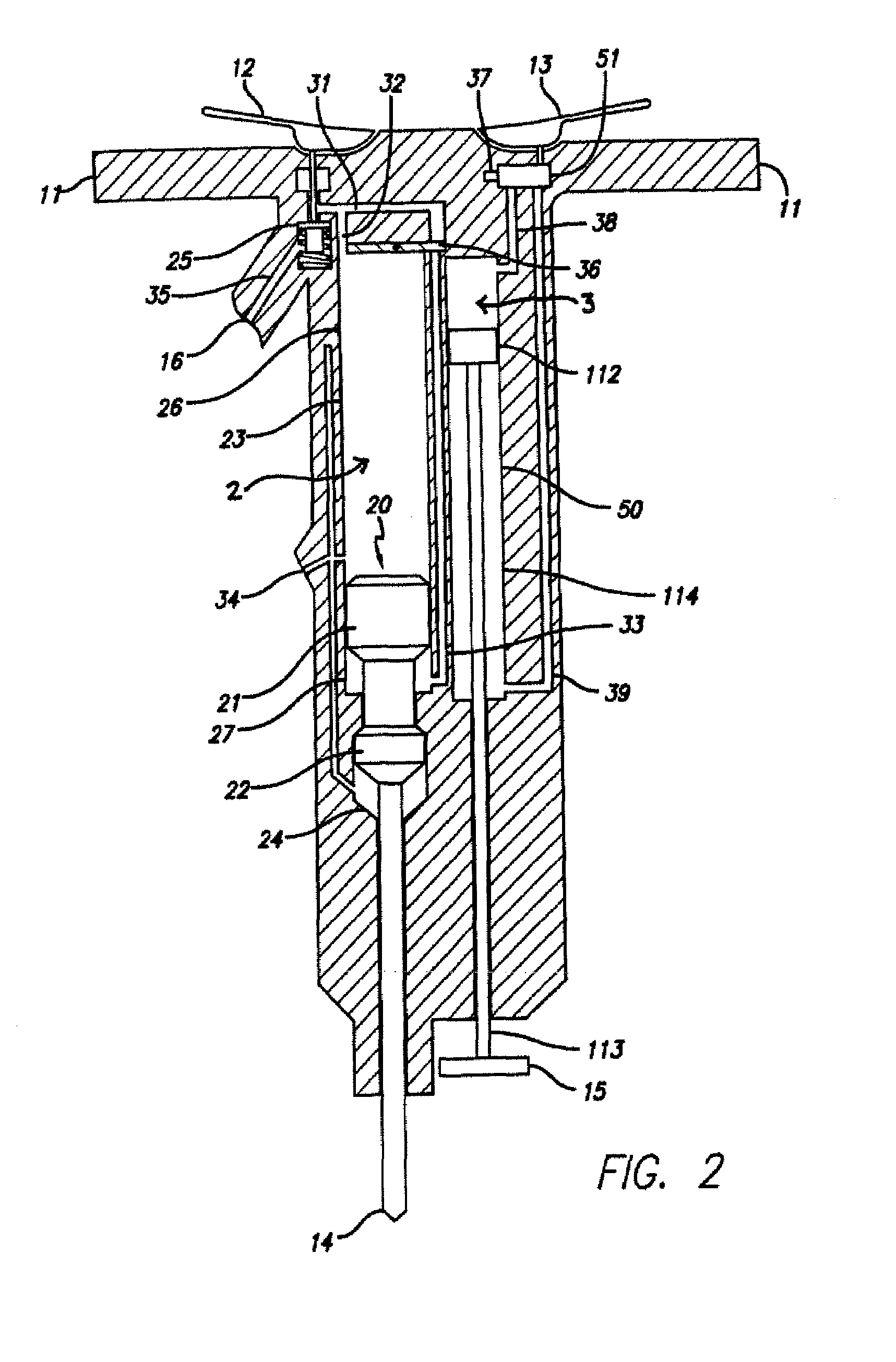

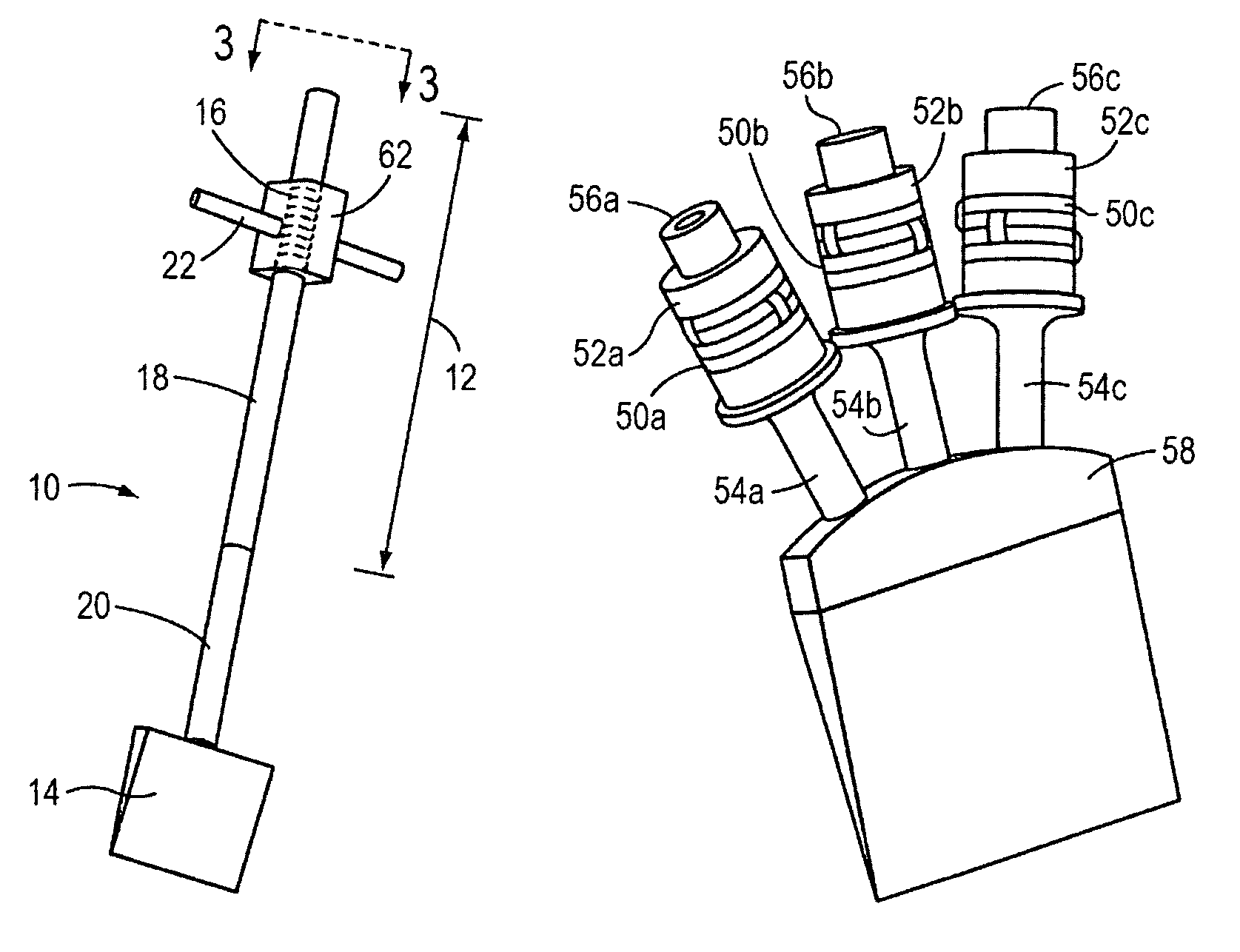

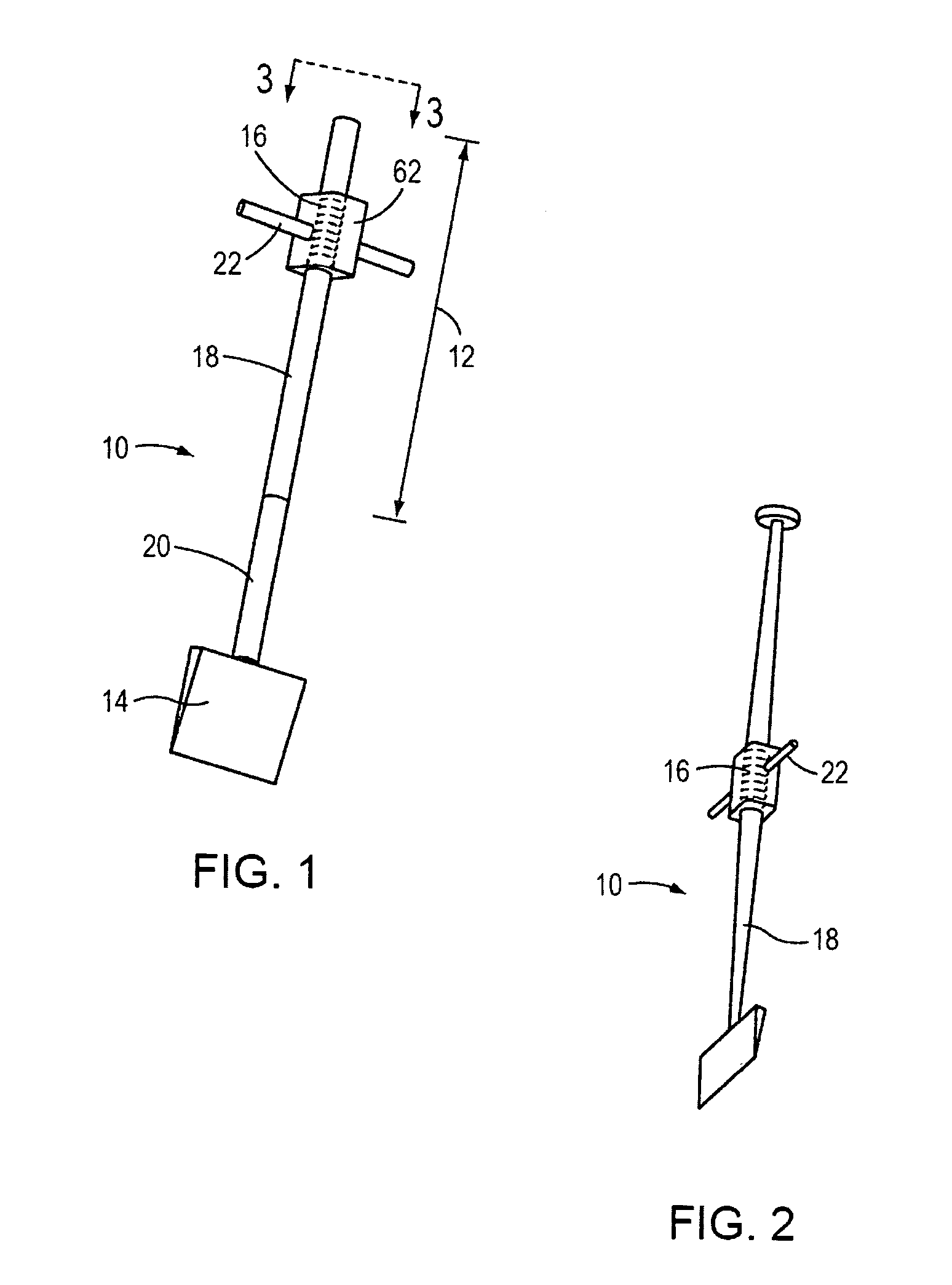

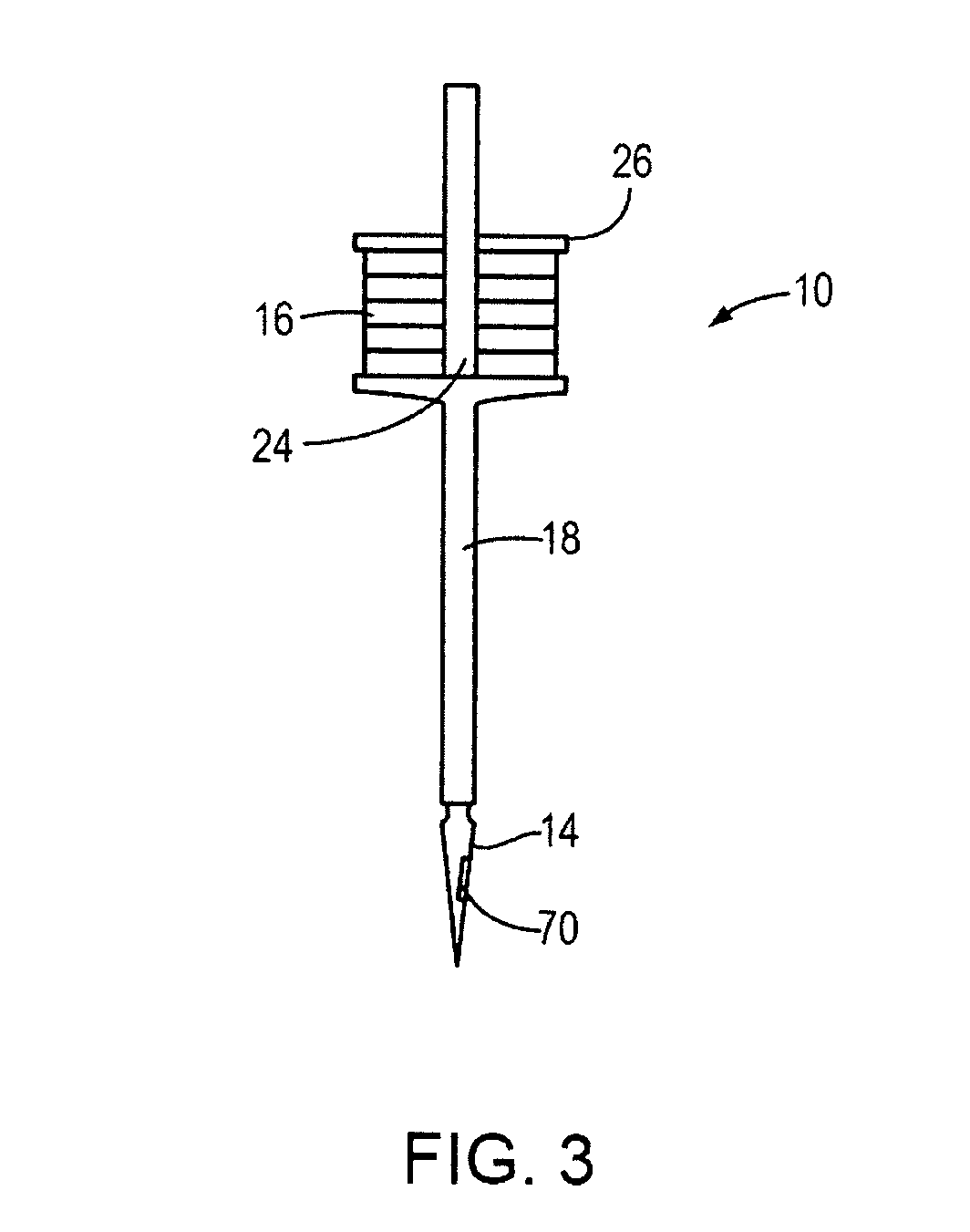

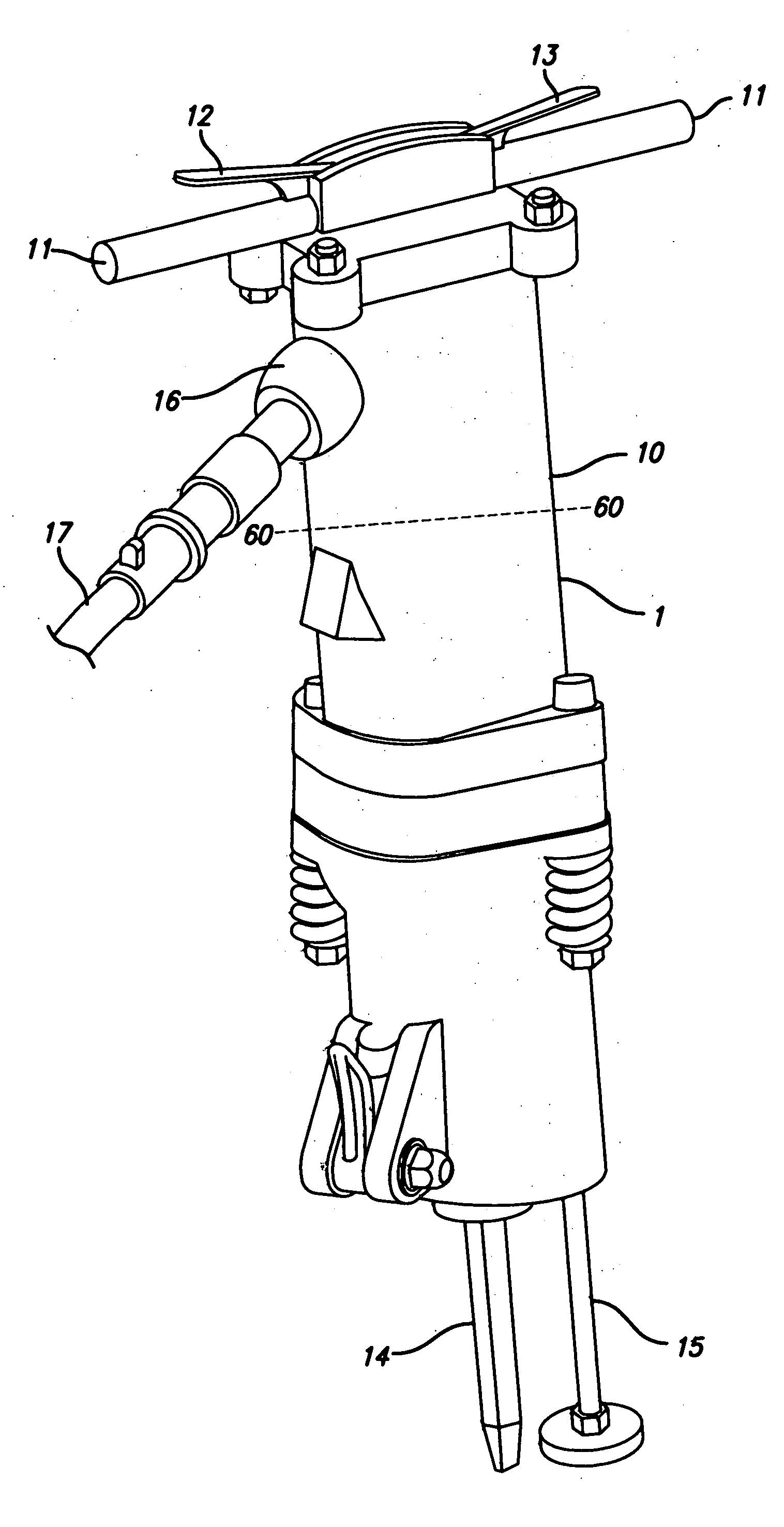

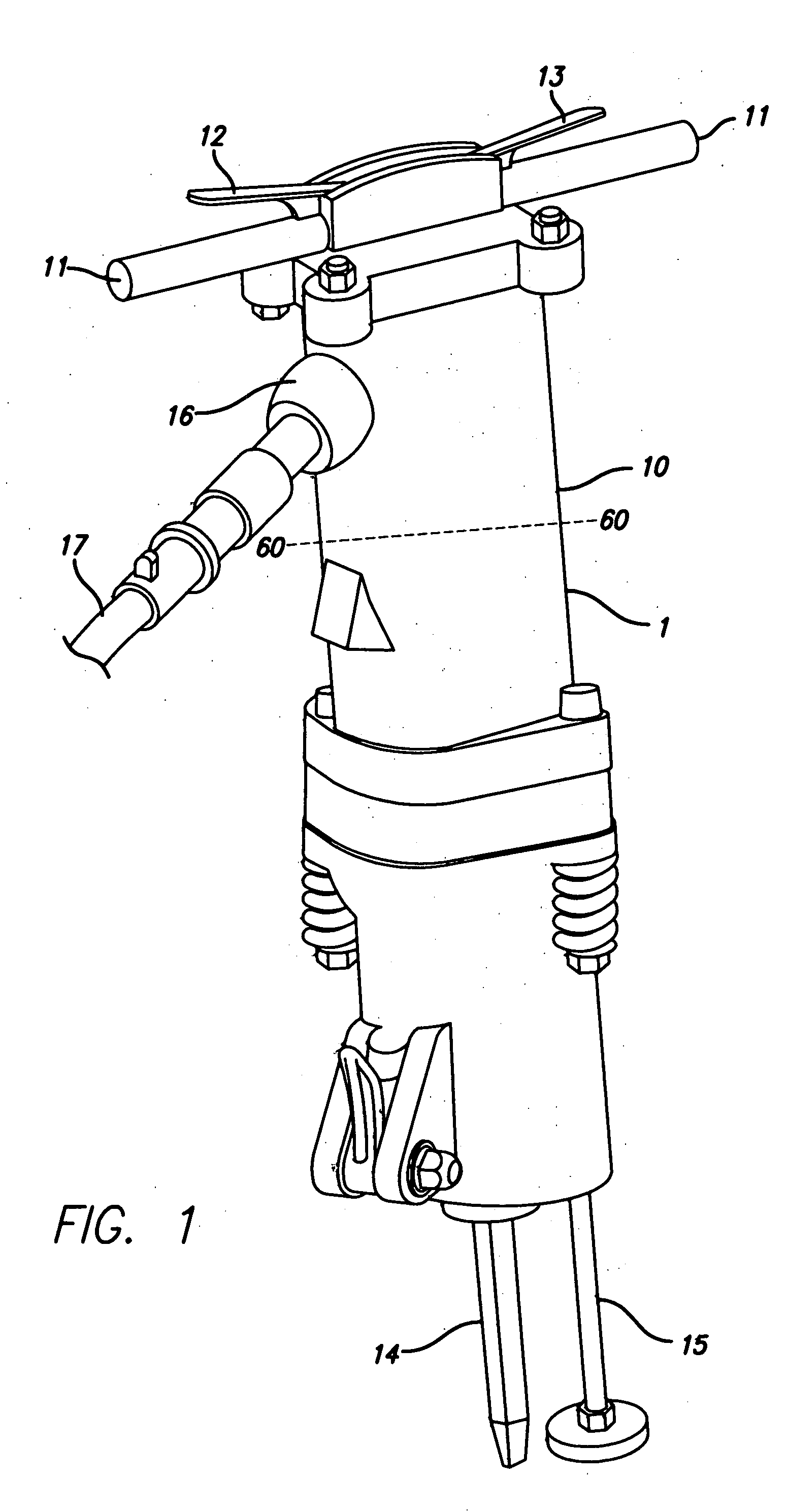

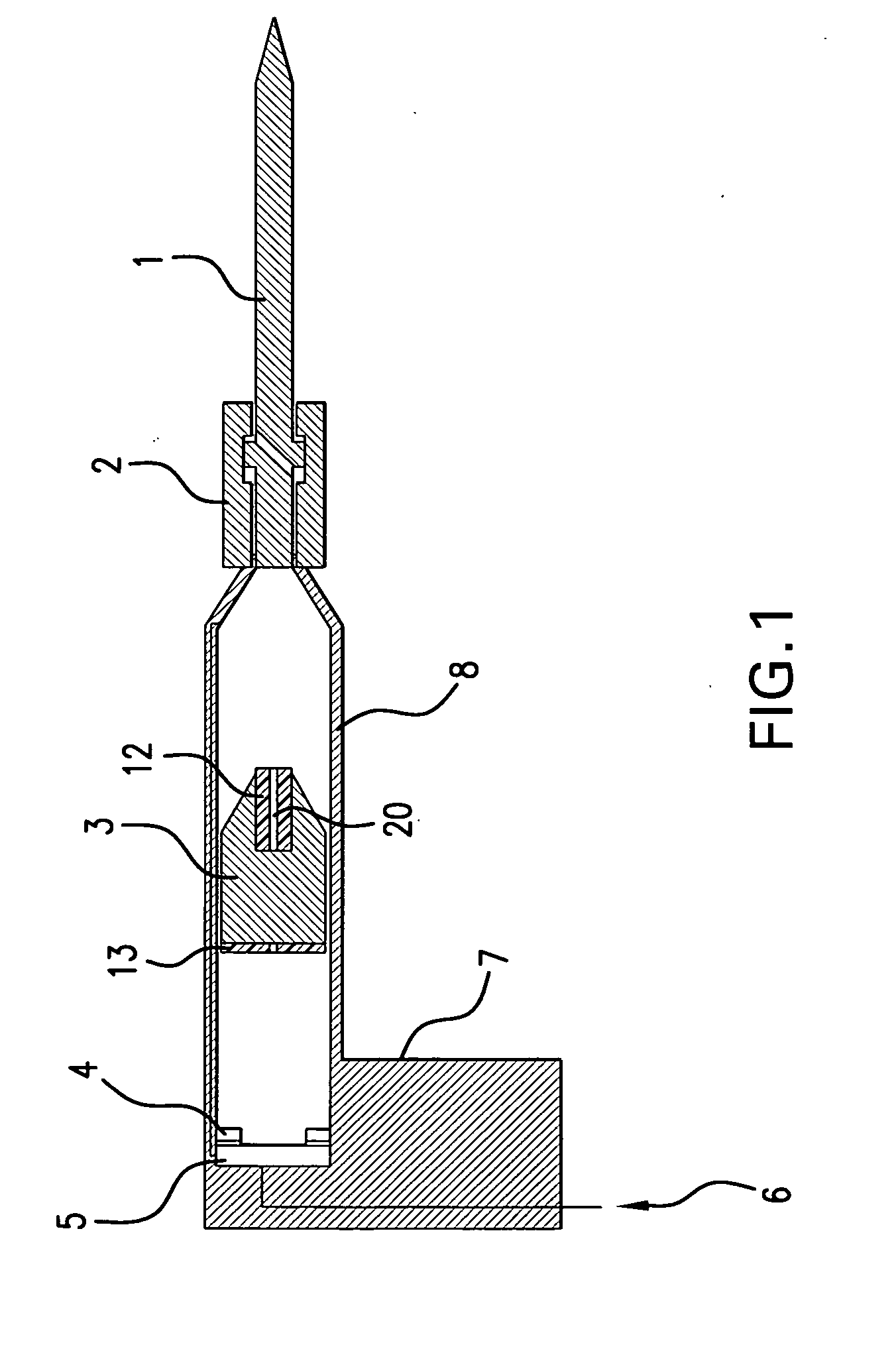

Jackhammer with a lift assist

ActiveUS7694749B2Reduce stepsEasy extractionDrilling rodsReciprocating drilling machinesJackhammerEngineering

The present invention relates to an integrated percussion power tool which contains a percussion mechanism and a lift assist mechanism to reduce the physical demands for its operation by facilitating the lifting and extracting of the percussion power tool. In general, the integrated percussion power tool is a T-shaped machine which has a vertical cylindrical body with two handles, two hand control levers cross the top, and a working tool and a lifting foot on the bottom for engaging with a working surface. The first hand lever is for controlling the operation of the percussion mechanism, whereas the second hand lever is for manipulating the operation of the lift assist mechanism. The percussion mechanism and the lift assist mechanism are both housed in the vertical cylindrical body of the integrated percussion power tool.

Owner:INTEGRATED TOOL SOLUTIONS

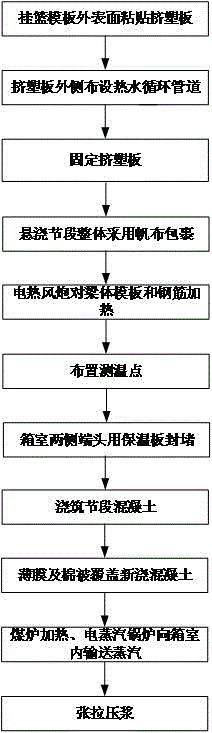

Cast-in-place winter construction method for hanging basket cantilever

ActiveCN106592430AThe method steps are simpleEasy constructionBridge erection/assemblyJackhammerEngineering

The invention discloses a cast-in-place winter construction method for a hanging basket cantilever. The cast-in-place winter construction for the hanging basket cantilever comprises the following specific steps of (1) bonding a flame-retardant extruded sheet on the external surface of a hanging basket template; (2) laying a hot water circulating pipeline on the external side of the flame-retardant extruded sheet; (3) fixing the extruded sheet and the hot water circulating pipeline through spot-welding a reinforcing steel bar on a template vertical and horizontal rib; (4) integrally coating a suspension casting by using a canvas; (5) heating a girder template and the reinforcing steel bar by using an electric heating jackhammer; (6) placing a temperature measuring point; (7) casting segment concrete; (8) covering a cast-in-place beam segment concrete by using a film and a quilt; (9) plugging two cantilever ends of a box girder T-type structure by using fire prevention rock wool boards; (10) heating in a box room by using a coal stove and conveying steam into the box room by using an electric steam generator; and (11) tensioning press mortar. The cast-in-place winter construction method for the hanging basket cantilever has the advantages of simple steps, simple and convenient construction, easily ensured construction quality, good use effect and high practical value.

Owner:CCTEB INFRASTRUCTURE CONSTR CO LTD

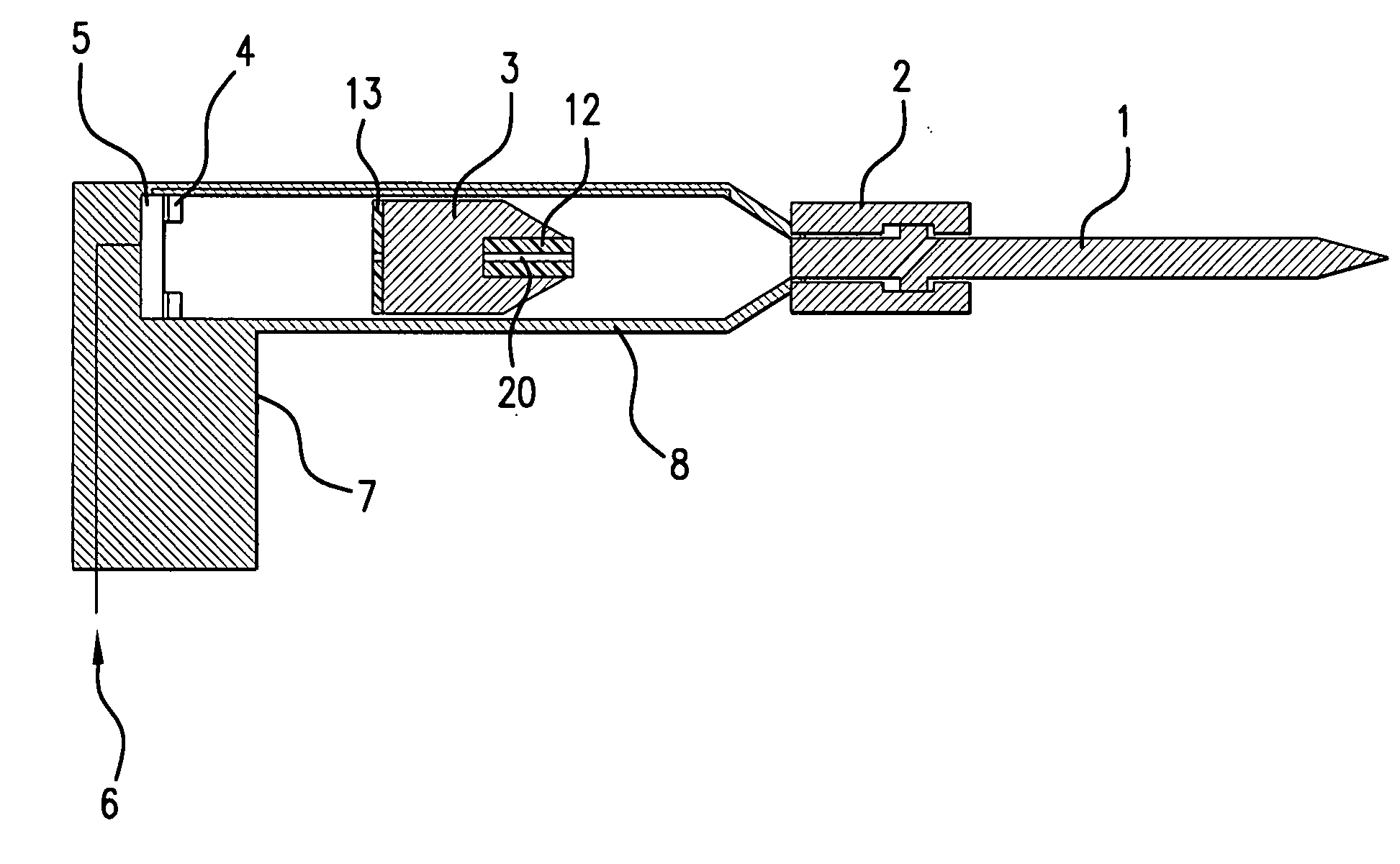

Ultrasonic/sonic jackhammer

The invention provides a novel jackhammer that utilizes ultrasonic and / or sonic vibrations as source of power. It is easy to operate and does not require extensive training, requiring substantially less physical capabilities from the user and thereby increasing the pool of potential operators. An important safety benefit is that it does not fracture resilient or compliant materials such as cable channels and conduits, tubing, plumbing, cabling and other embedded fixtures that may be encountered along the impact path. While the ultrasonic / sonic jackhammer of the invention is able to cut concrete and asphalt, it generates little back-propagated shocks or vibrations onto the mounting fixture, and can be operated from an automatic platform or robotic system.

Owner:CALIFORNIA INST OF TECH

Hand-held ergonomic jackhammer holder for concrete floor chipping, jackhammer and holder assembly, and method of use thereof

InactiveUS20160136799A1Continuous compensationCarriage/perambulator with single axisPortable percussive toolsReciprocating motionJackhammer

A self-adjusting hand-held ergonomic holder for jackhammer for manual use by an operator in chipping a hardened ground surface along a continuously variable chipping strike angle. The holder includes a rigid main frame with an upper load bearing handle and a cradle receiving a pneumatically powered hammer with a reciprocatable elongated pneumatically controlled bit operatively mounted to one end thereof. A coil spring assembly associated with the cradle dampens vibrations generated by the jackhammer. A spring loaded caster member is mounted to the main frame lower portion opposite the jackhammer and providing dynamic continuously variable relative angular chipping tilt of the elongated bit responsive to and acting against the handle bearing load, transversely along the ground surface between a cradle first position, making a generally small acute angle relative to the bearing load downward axis and spaced apart from the caster, and a cradle second position, making a large acute angle relative to the bearing load downward axis and closely proximate the caster.

Owner:R N P IND

Jackhammer with a lift assist

The present invention relates to an integrated percussion power tool which contains a percussion mechanism and a lift assist mechanism to reduce the physical demands for its operation by facilitating the lifting and extracting of the percussion power tool. In general, the integrated percussion power tool is a T-shaped machine which has a vertical cylindrical body with two handles, two hand control levers cross the top, and a working tool and a lifting foot on the bottom for engaging with a working surface. The first hand lever is for controlling the operation of the percussion mechanism, whereas the second hand lever is for manipulating the operation of the lift assist mechanism. The percussion mechanism and the lift assist mechanism are both housed in the vertical cylindrical body of the integrated percussion power tool.

Owner:INTEGRATED TOOL SOLUTIONS

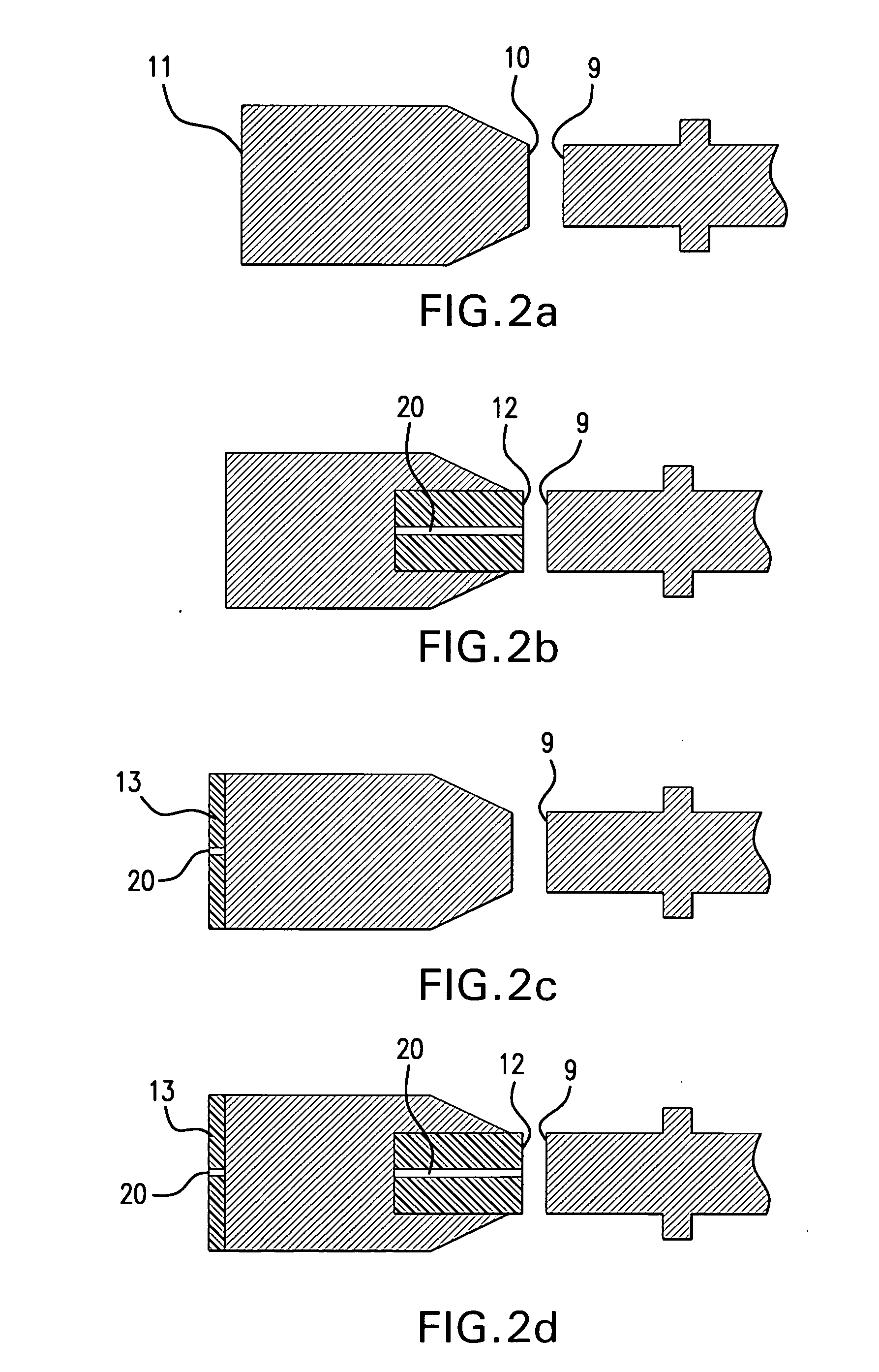

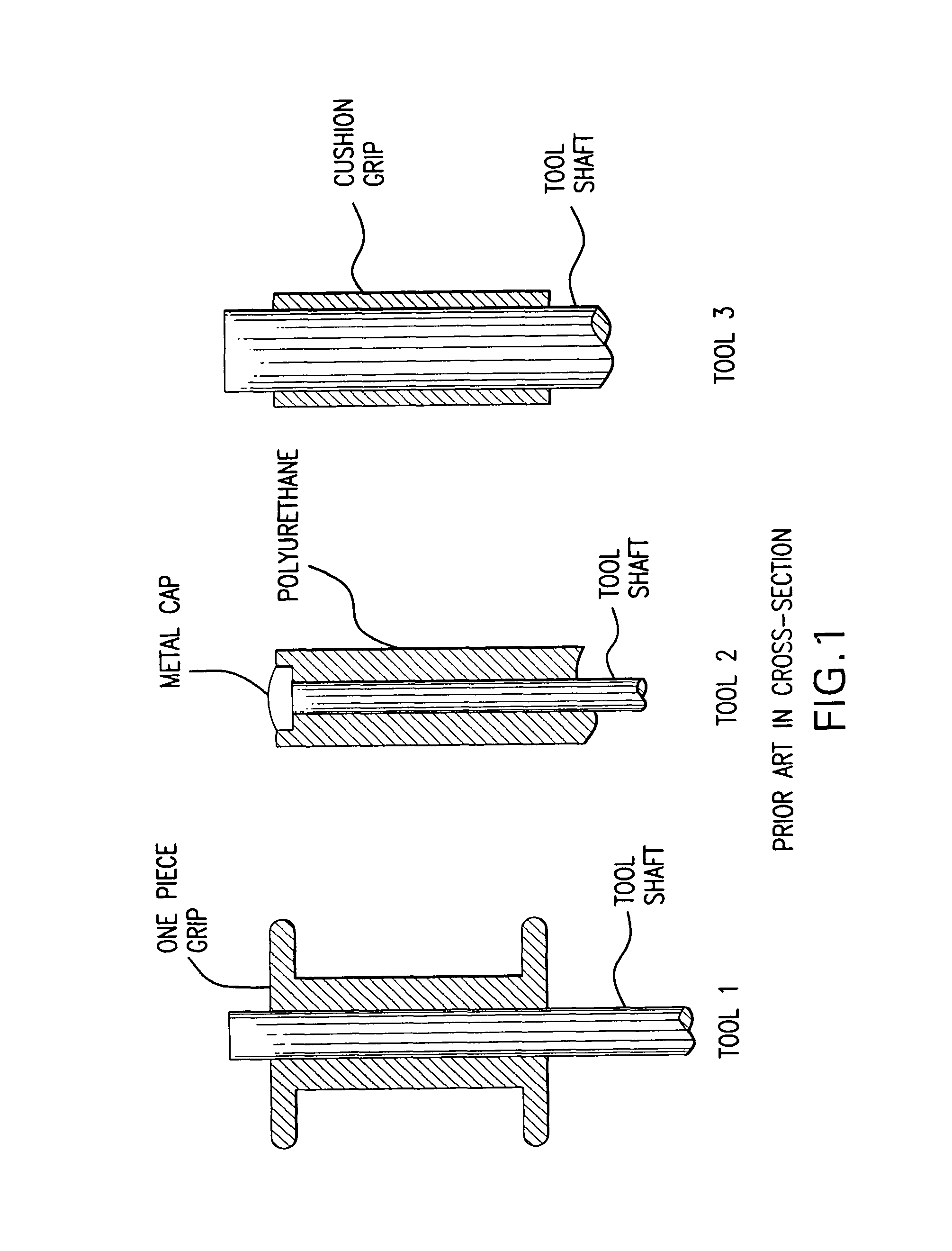

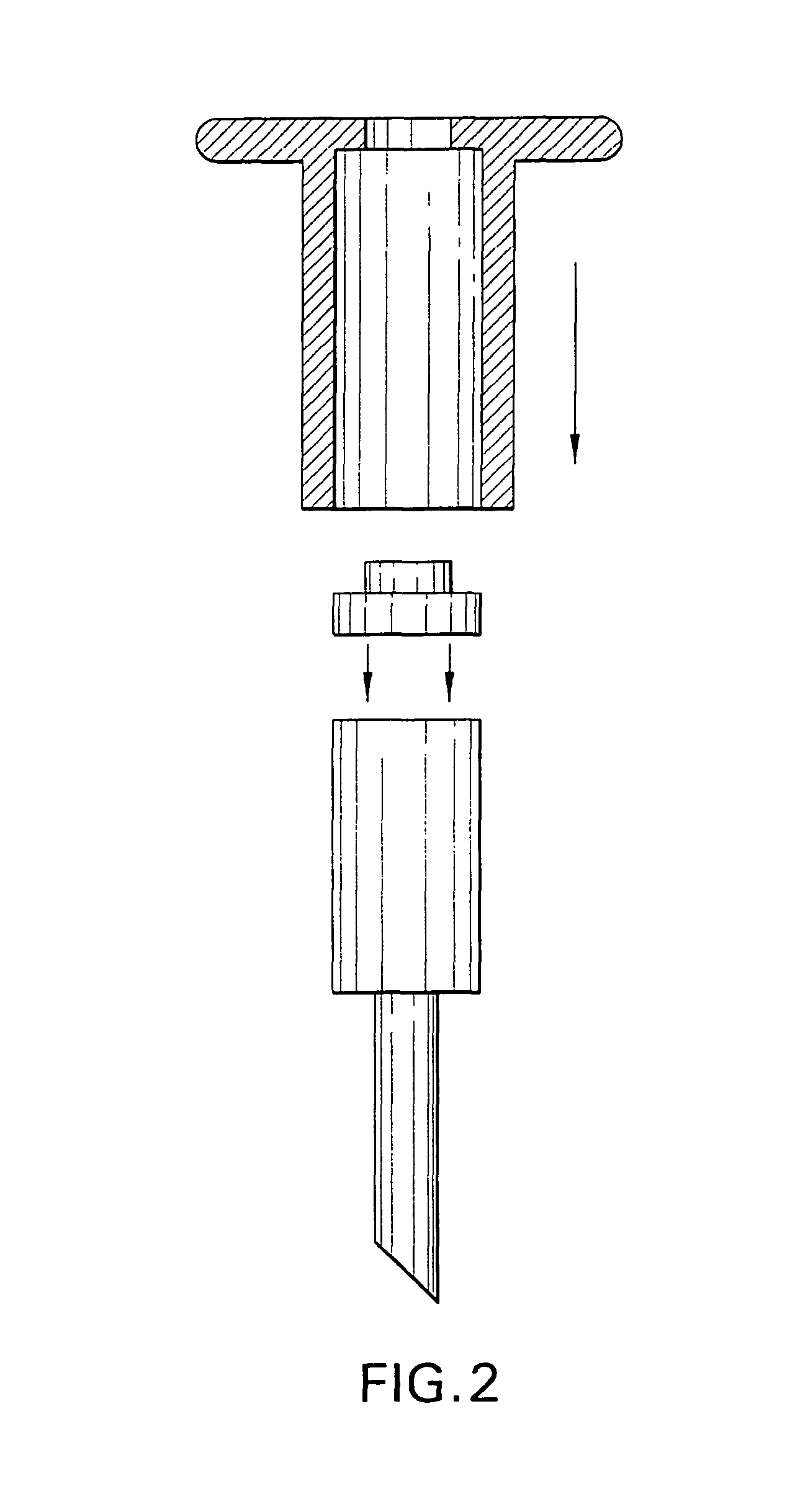

Combination of Impact Tool And Shaped Relatively Lower Modulus Material

InactiveUS20110083870A1Reduce noiseReduce vibrationPortable percussive toolsPortable drilling machinesWork periodChisel

An impacting tool, such as a jackhammer or electric hammer is proposed to be modified by a high modulus polymeric material, or metal of lower relative modulus than surrounding metal such as that of a piston. An interchangeable tool head is proposed to have inserted in a cavity in the impacted end such a high modulus polymeric material. Thus the term relatively lower modulus inclusion (“RLMI”) has been selected for the descriptive term. By using such relatively lower modulus material for an inclusion, which inclusion can be an insert, and modification of the piston or ram or impacting end of the tool, and additionally, if desired, the stop end of the piston or ram, the invention enables reduction of noise and vibration without substantially diminishing impact effectiveness and working time. Additionally, the working end of a cutting or impacting tool can be modified to a sharper angle because of diminished force through such relatively lower modulus inclusion. The edge angle, of for instance a chisel, may be modified to take advantage of mechanical changes resulting from the relatively lower modulus inclusion.

Owner:MCCARTY II H DOWNMAN +3

Anti-spalling combination on an impact tool with an improved holding system

InactiveUS9089962B2Impact can be maintainedEfficient executionHand chiselsHand hammersCircular discJackhammer

The invention is a tool to be struck, or a striking tool, (collectively referred to as an “impact tool”), or alternatively, a cap, that will not suffer metal spall and the attendant dangers of spalling and flying or cutting metal slivers. The preferred mode is on a chisel (wood or cold) or repeated impact tool. The chisel would have a striking end cut square to the shaft. The striking end would be opposite the working end. Other tools such as impact wrenches, jackhammers, wedges, spikes, hammers, mallets or other tools being struck or striking forcibly benefit from the invention by use of a disk insert of polymeric material to alter ergonomic and noise characteristic.

Owner:HARD HAT TECH

Rock drilling jackhammer

The invention relates to a rock drilling jackhammer. The rock drilling jackhammer comprises a steel railway, a first electromagnet assembly, a second electromagnetic assembly, a drill rod, a round-trip servo motor, a linear transmission assembly, a rotating servo motor and a rotating transmission assembly, wherein the first electromagnet assembly, the second electromagnet assembly, the drill rod,the round-trip servo motor, the linear transmission assembly, the rotating servo motor and the rotating transmission assembly are arranged on the steel railway. The drill rod is driven to move and rotate through matching of the servo motors and the electromagnet assemblies to conduct the rock and hole drilling operation, the speed can be adjusted through the servo motors, the noise is small, a power supply is only needed to work, and the rock drilling jackhammer can be installed on a rock drilling truck or a robot to work flexibly.

Owner:广州煌牌自动设备有限公司

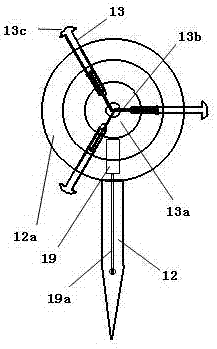

Fire scene automatic panoramic detection robot

PendingCN111298344AEffectively extinguishPrevent the spread of fireFire rescueVertical planeJackhammer

The invention relates to the field of firefighting equipment, in particular to a fire scene automatic panoramic detection robot. The fire scene automatic panoramic detection robot comprises a machinebody. A jackhammer and a spray nozzle are arranged on the machine body. The jackhammer is arranged on the side portion of the spray nozzle, a jackhammer telescopic mechanism is arranged on the jackhammer, the jackhammer telescopic mechanism is used for driving the jackhammer to rotate, when the jackhammer telescopic mechanism works, the jackhammer carries out nodding movement relative to the machine body, a nozzle rotating mechanism and a nozzle angle adjusting mechanism are arranged on the spray nozzle, the nozzle rotating mechanism is used for driving the spray nozzle to rotate on the horizontal plane, the nozzle angle adjusting mechanism is used for driving the nozzle to rotate on the vertical plane, and when the nozzle rotating mechanism and the nozzle angle adjusting mechanism work, the spraying position of the spray nozzle is adjusted. According to the fire scene automatic panoramic detection robot, the corresponding positions of the spray nozzle and the jackhammer can be adjusted according to the positions of fire sources, so that the best spraying effect is achieved, the fire sources are rapidly and effectively extinguished, and fire behaviors are prevented from being increased.

Owner:重庆特斯联智慧科技股份有限公司

Gear and rack type glass cleaning device

InactiveCN108499917ARealize the cleaning workEasy to useFlexible article cleaningCleaning using toolsGear driveGear wheel

The invention relates to a glass cleaning device, in particular to a gear and rack type glass cleaning device, and belongs to the technical field of glass cleaning devices. The gear and rack type glass cleaning device is characterized by comprising a jackhammer, a gear, a rack and a piece of scrubbing cloth, wherein the jackhammer is in drive connection with the gear; the gear is engaged with therack; and the scrubbing cloth is arranged at the lower end of the rack. The jackhammer drives the gear to rotate, the rotary gear drives the rack to vertically move, the vertically moving rack drivesthe scrubbing cloth to vertically move, then cleaning work of glass products is achieved, and the gear and rack type glass cleaning device is convenient to use, easy to machine and manufacture, good in stability and long in service life.

Owner:JIANGSU XINFURUI ENERGY SAVING GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com