Intelligent locating full-automatic bolt loosening and tightening machine

An intelligent positioning and fully automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor cost, high labor intensity, and many hidden dangers, and achieve a high degree of automation, high safety factor, and reduced The effect of labor intensity and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

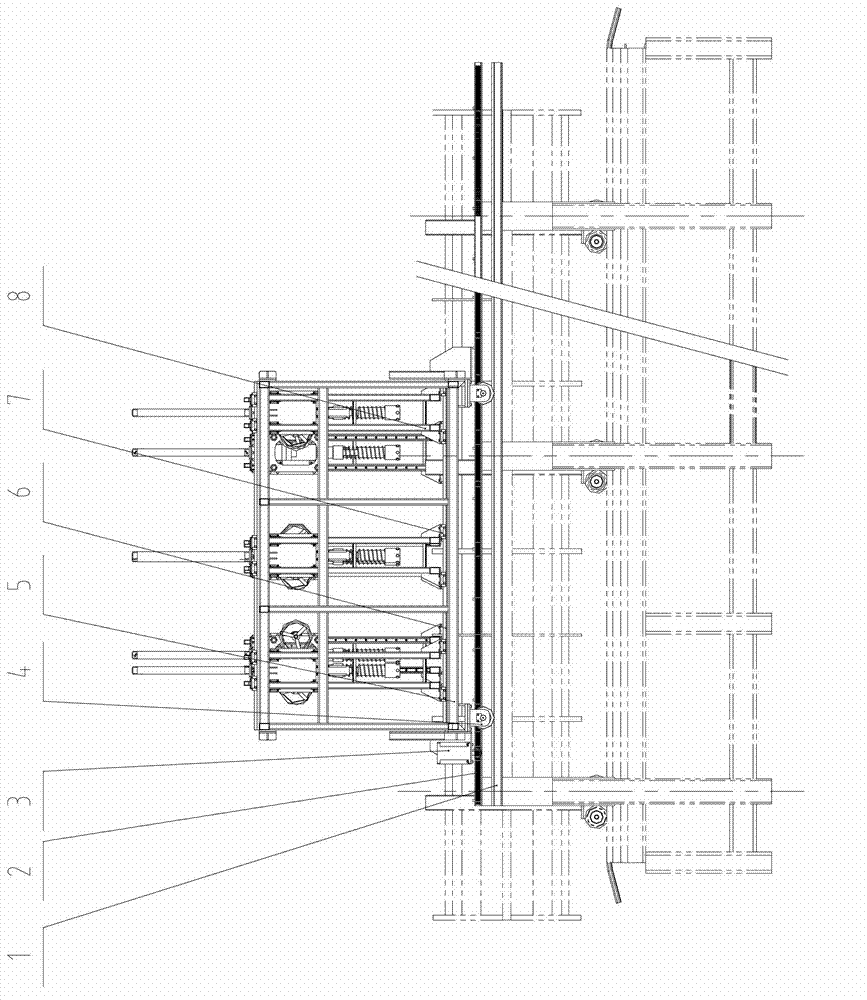

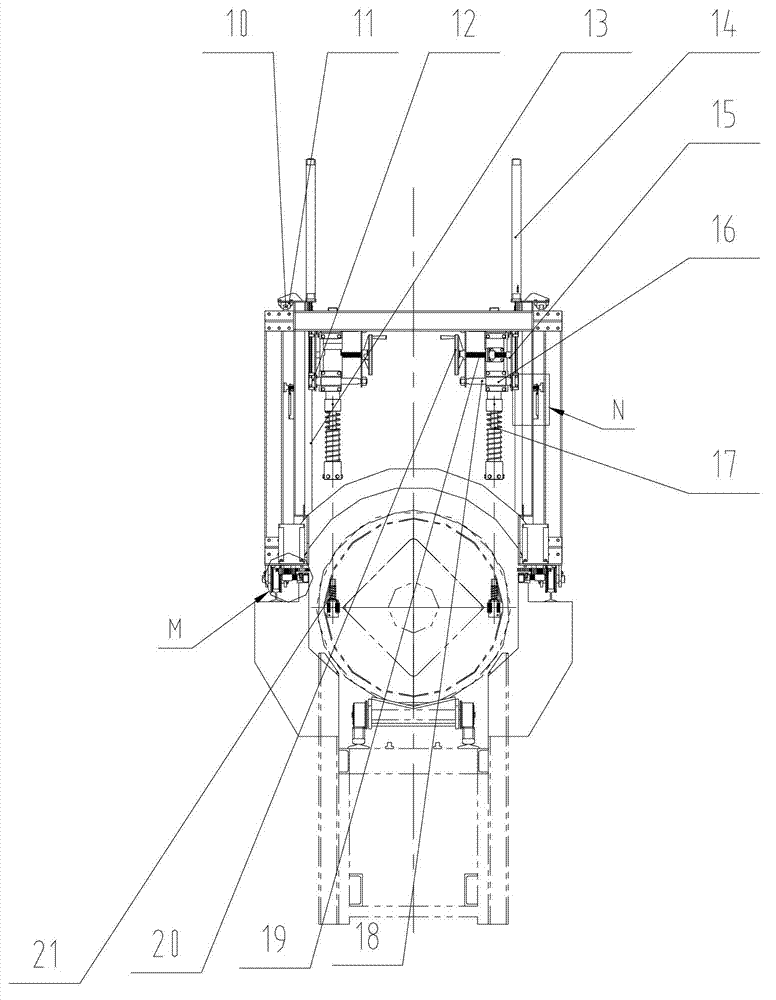

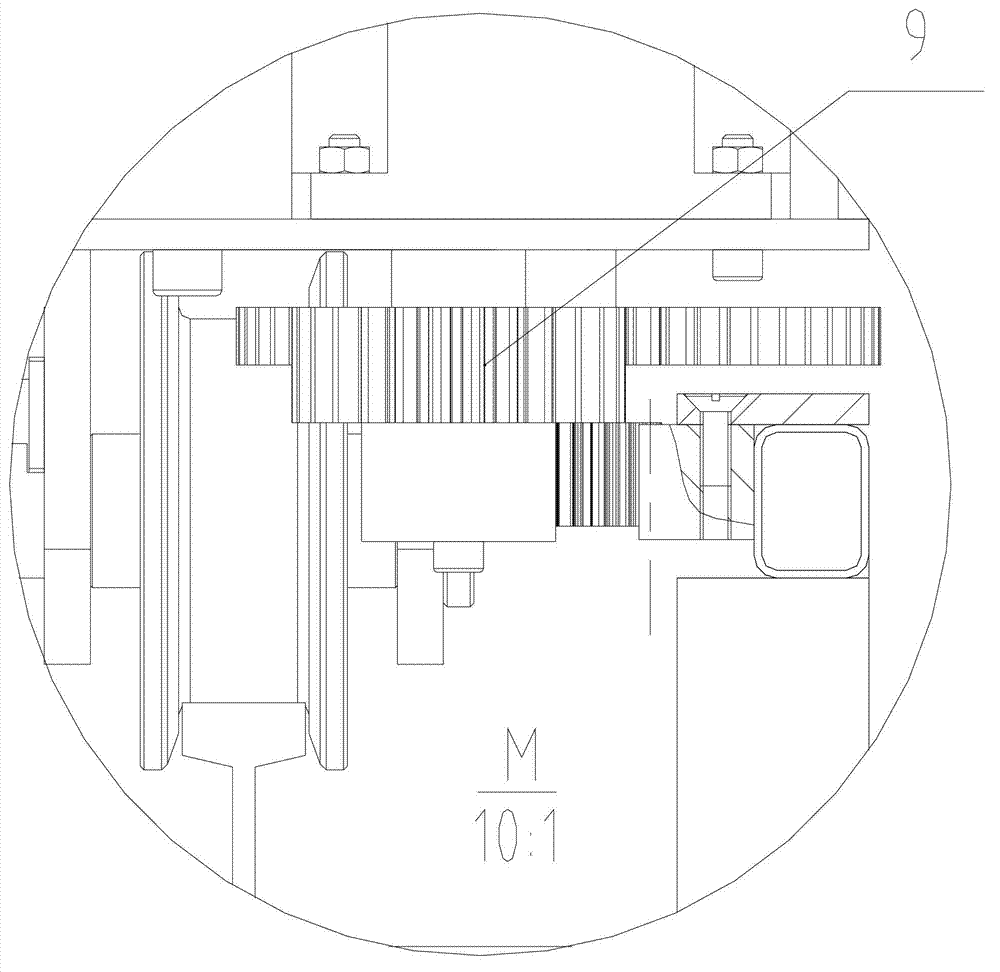

[0020] Embodiment 1: as Figure 1 to Figure 4 As shown, an intelligent positioning automatic bolt tightening machine includes a trolley frame 5, a trolley frame walking drive device, a walking light rail 1, and a PLC controller; the trolley frame 5 is installed on the traveling light rail 1 and travels through the trolley frame The driving device reciprocates left and right on the walking light rail 1. Wherein the trolley frame walking driving device comprises a traveling motor 3, a traveling rack 2, a traveling wheel 4, and a traveling gear 9. The traveling wheel 4 is installed under the trolley frame 5, and the trolley frame 5 is installed on the walking light rail 1 through the traveling wheel 4. On; the travel motor 3 is connected with the travel gear 9 through the travel rack 2, and the travel wheel 4 is connected with the travel rack 2.

[0021] On the trolley frame 5 and on both sides of the mould, at least one wind gun frame 8 and at least one wind gun frame walking d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com