Mold compounding system adapting to pipe pile molds of multiple specifications

A pipe pile mold, multi-specification technology, applied in the direction of molds, etc., can solve the problems of inability to tighten bolts, stuck, speed errors, etc., and achieve the effect of continuous and uninterrupted production, ensuring accuracy, and ensuring detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is illustrated below in conjunction with accompanying drawing

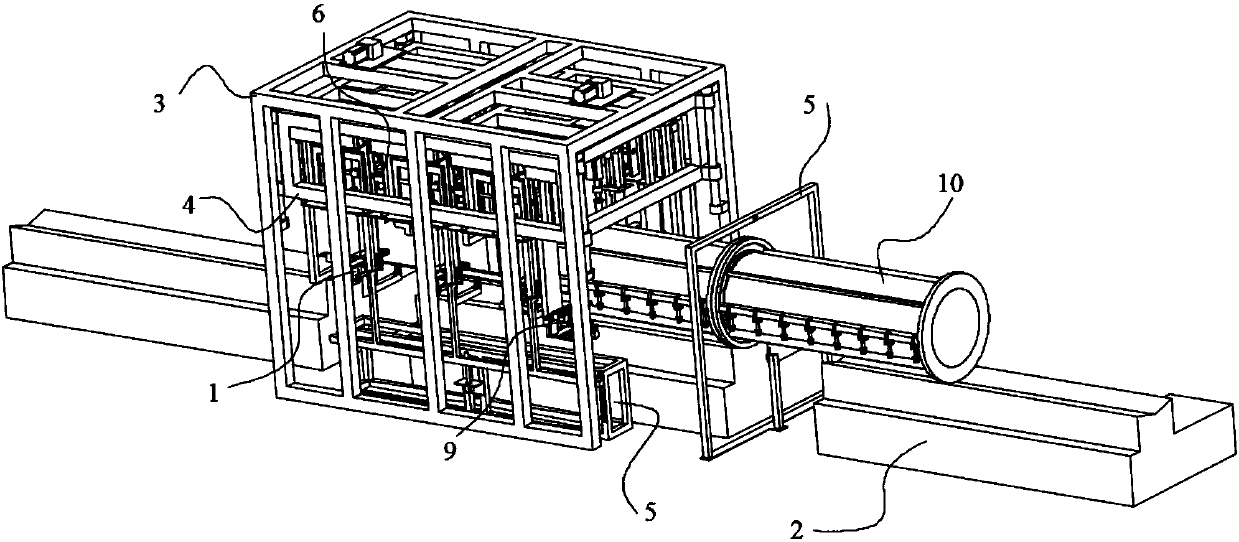

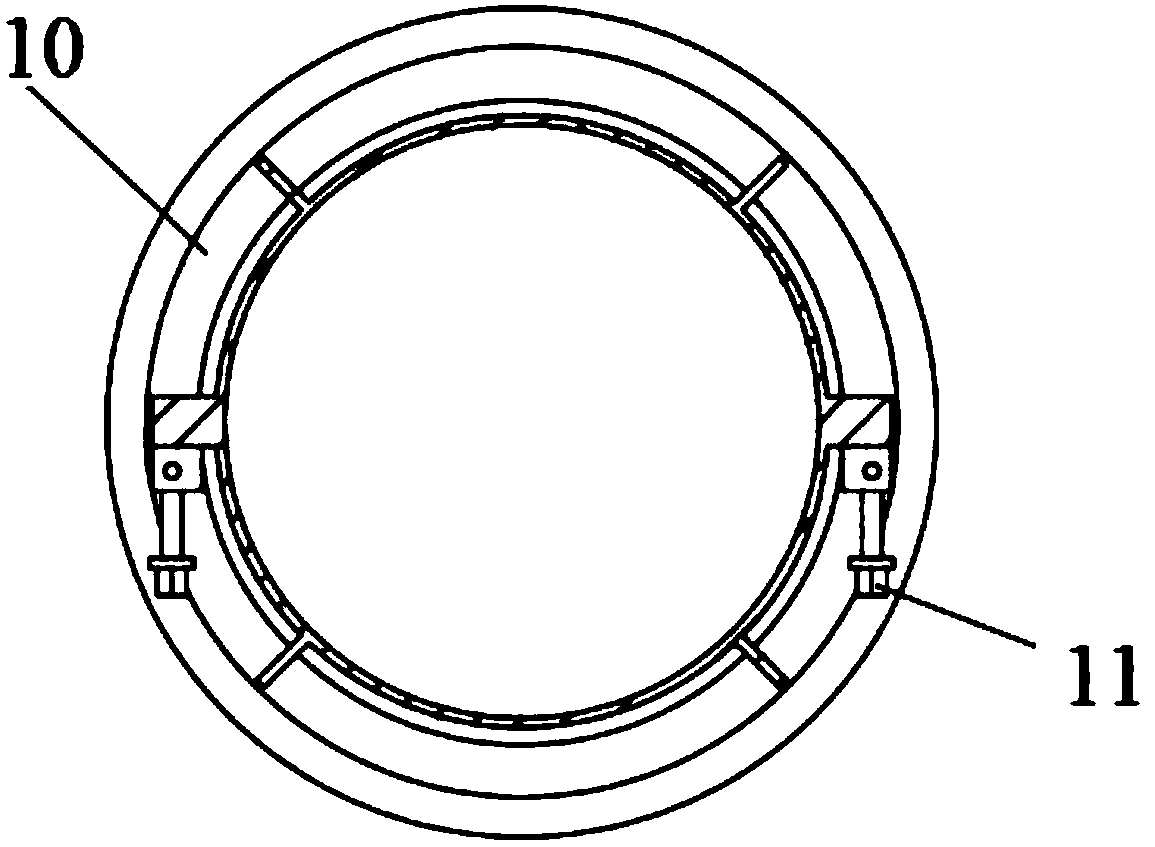

[0042] Such as Figure 1 to Figure 13 As shown, a pipe pile mold clamping system adapting to multiple specifications, including pipe pile mold conveying device 2, outer frame 3, inner frame 4, detection device 5, jackhammer device 6, jackhammer installation rod 7, bolt supporting guide rail 8. Bolt leveling mechanism 9 and bolt righting and positioning mechanism 1,

[0043] The pipe pile mold conveying device 2 is used to convey the pipe pile mold 10 along its axial direction at a constant speed;

[0044] Described outer frame 3 is arranged on the top of pipe pile mold conveying device 2, is used as the support of whole device;

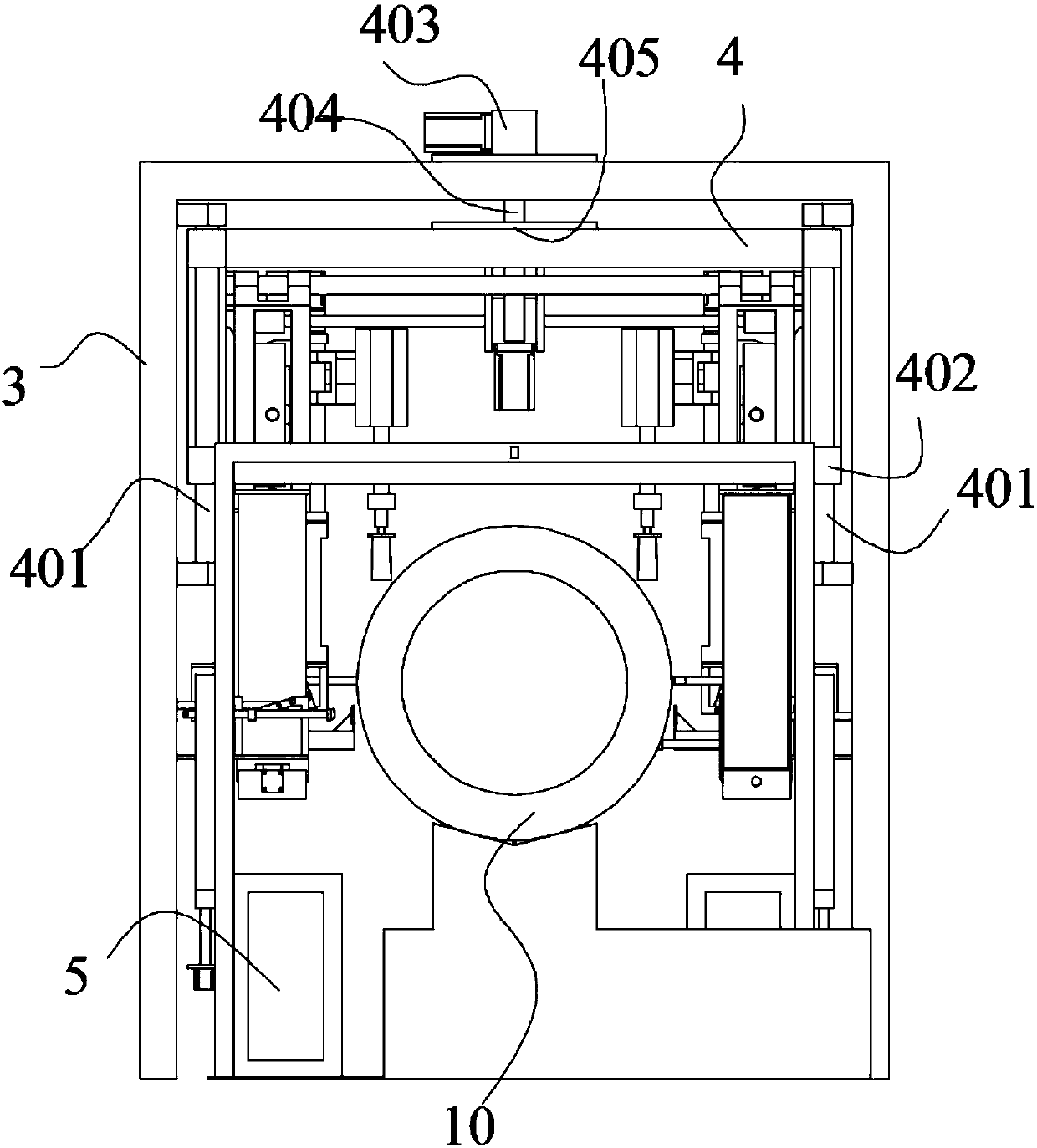

[0045] Such as figure 2 , Figure 12 and 13 As shown, the inner frame 4 is installed inside the outer frame 3 through a lifting mechanism. Specifically, four inner frame guide rods 401 are arranged on the support rods around the outer frame 3, and four i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com