Automatic reversing lateral packaging system for lead acid battery packaging box

A lead-acid battery, automatic reversing technology, applied in packaging and other directions, can solve the problems of overweight, lead-acid battery packaging box stuck, deviating from the conveying track, etc., to avoid deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

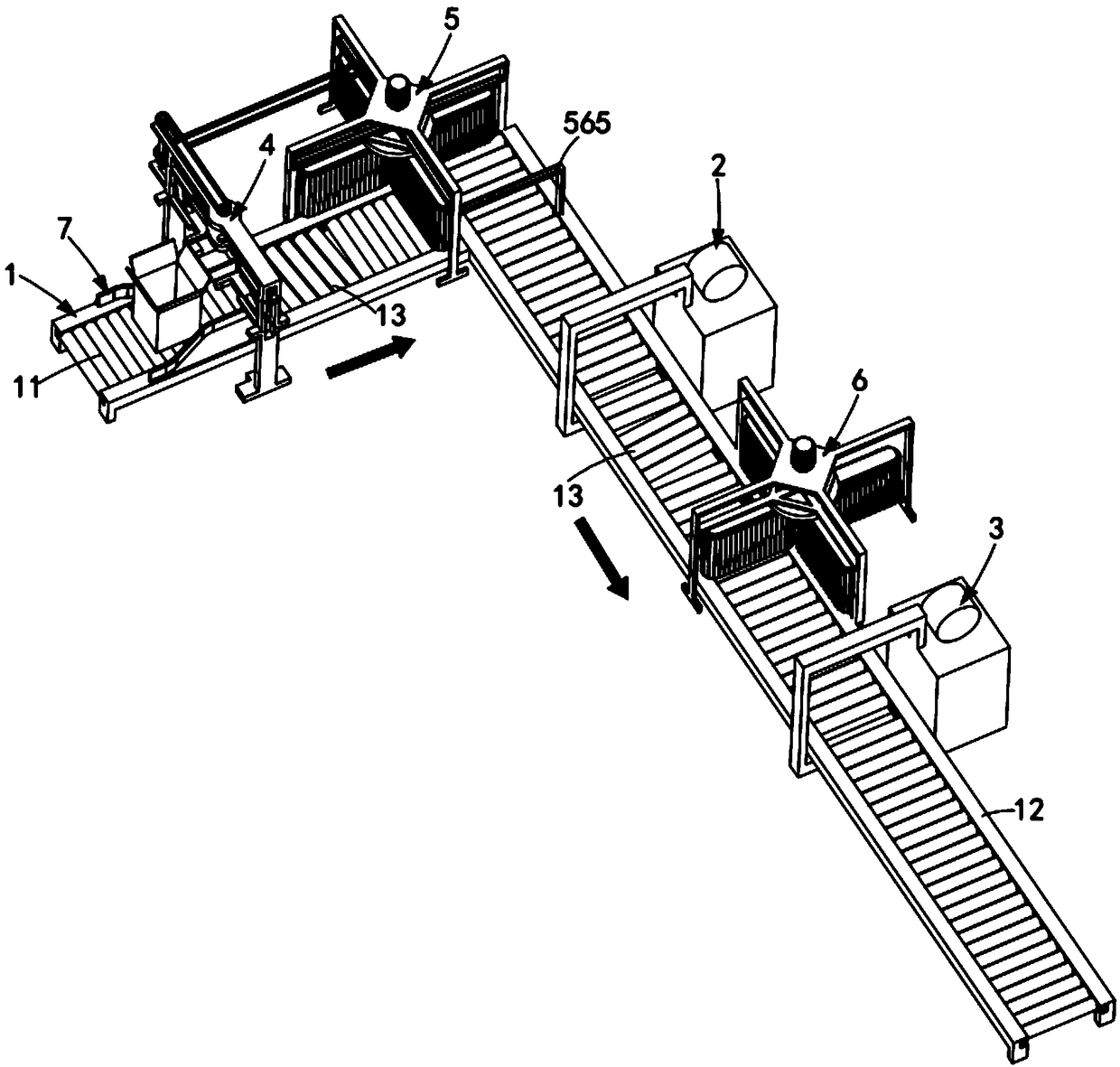

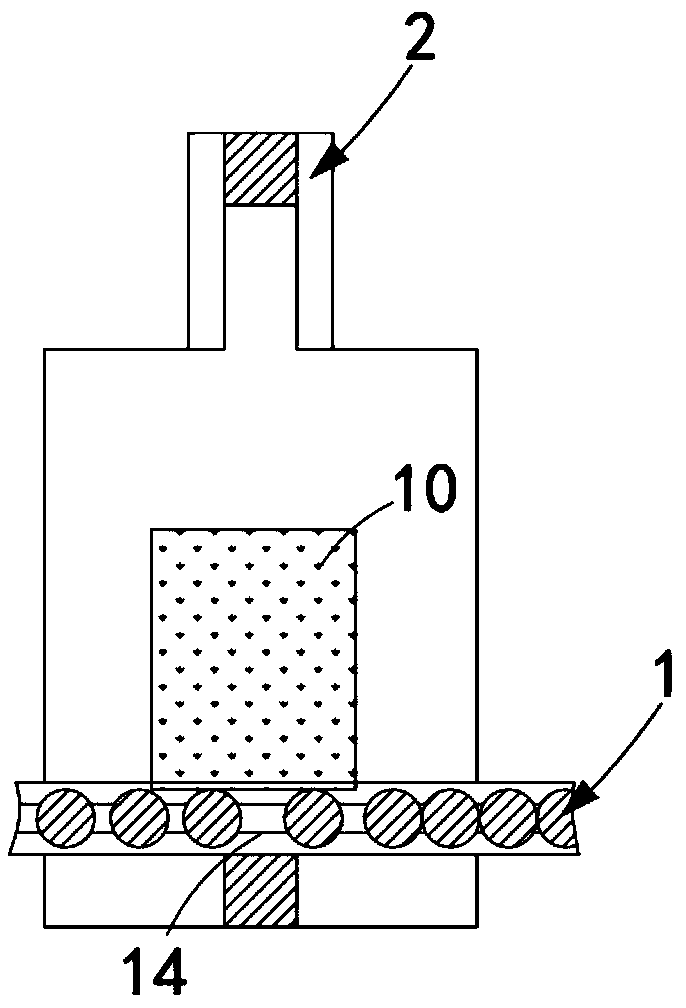

[0072] Such as figure 1 , figure 2 and Figure 8 As shown, a lead-acid battery packaging box automatic reversing side packaging system, which includes a packaging conveyor line 1, the packaging conveyor line 1 is a roller conveyor line, which includes a vertically arranged first conveyor line 11 and a second conveyor line 12 , a first packing machine 2 and a second packing machine 3 are sequentially arranged along the conveying direction of the packing conveying line 1, and also include:

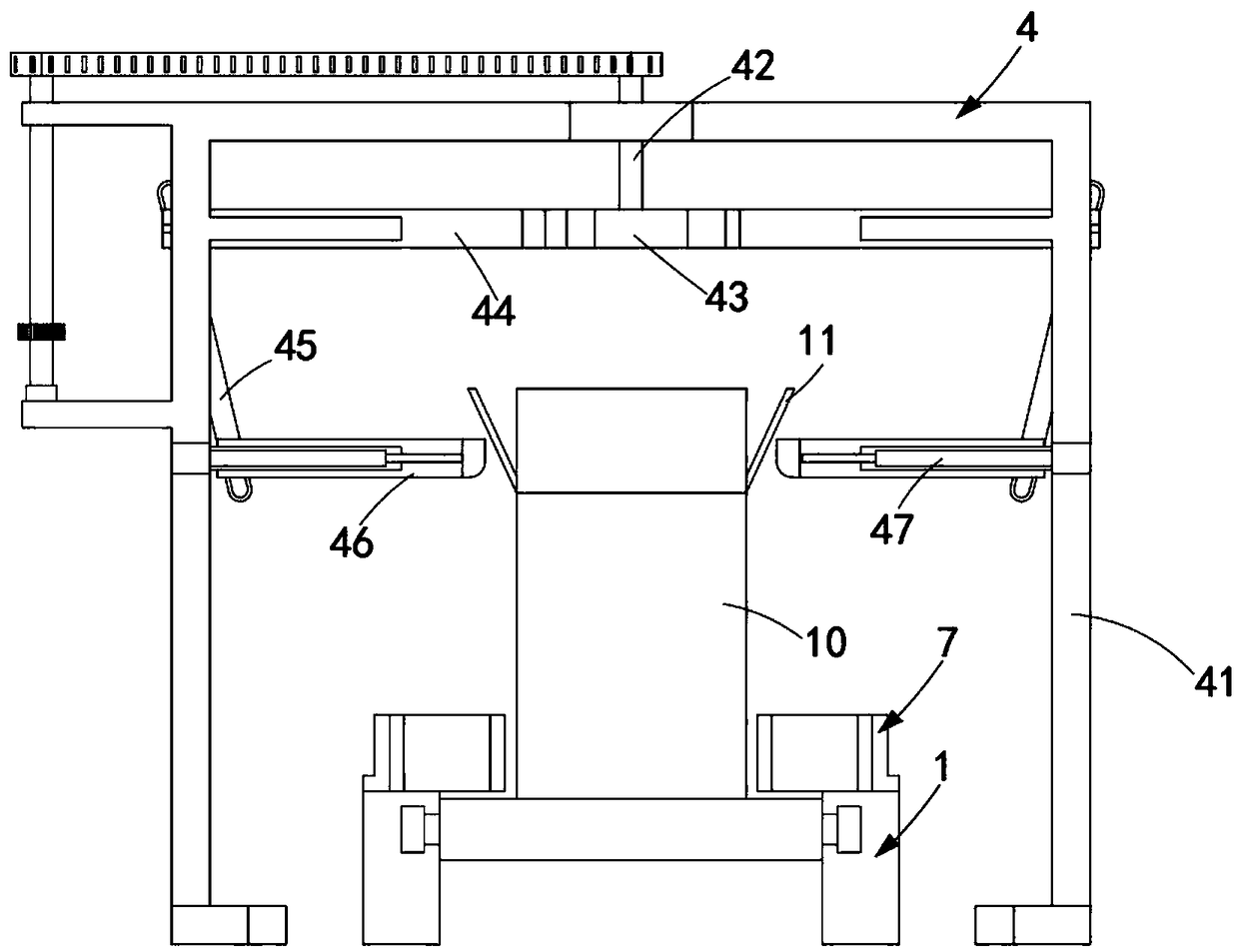

[0073] Turning mechanism 4, described turning mechanism 4 is arranged on the input end of described packaging conveying line 1 along the conveying direction of described packing conveying line 1, and this turning mechanism 4 is to the lead-acid transported on described packing conveying line 1 The first cardboard 101 arranged symmetrically on the top of the battery packaging box 10 is folded;

[0074] The first reversing mechanism 5, the first reversing mechanism 5 is arranged at the con...

Embodiment 2

[0121] Figure 17It is a structural schematic diagram of Embodiment 2 of a lead-acid battery packaging box automatic reversing side packaging system of the present invention; Figure 17 As shown, the parts that are the same as or corresponding to the first embodiment adopt the corresponding reference numerals of the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The second embodiment is similar to the first embodiment. figure 1 The difference of the shown embodiment one is:

[0122] Such as Figure 8 and Figure 17 As shown, a lead-acid battery packaging box automatic reversing side packaging system, the rotation of the rotating shaft 42 is driven by the driving motor in the first reversing mechanism 5 through a rack and pinion transmission, and the driving motor 52 drives the rotation. The reversing shaft 53 rotates, and the reversing shaft 53 is respectively connected with the rotating shaft 42 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com