A kind of lead-acid battery packaging box automatic reversing side packaging method

A lead-acid battery, automatic reversing technology, applied in the direction of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of overweight, lead-acid battery box stuck, deviation from the conveying track, etc., to achieve interference factors Less, automatic reversing, smooth packing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

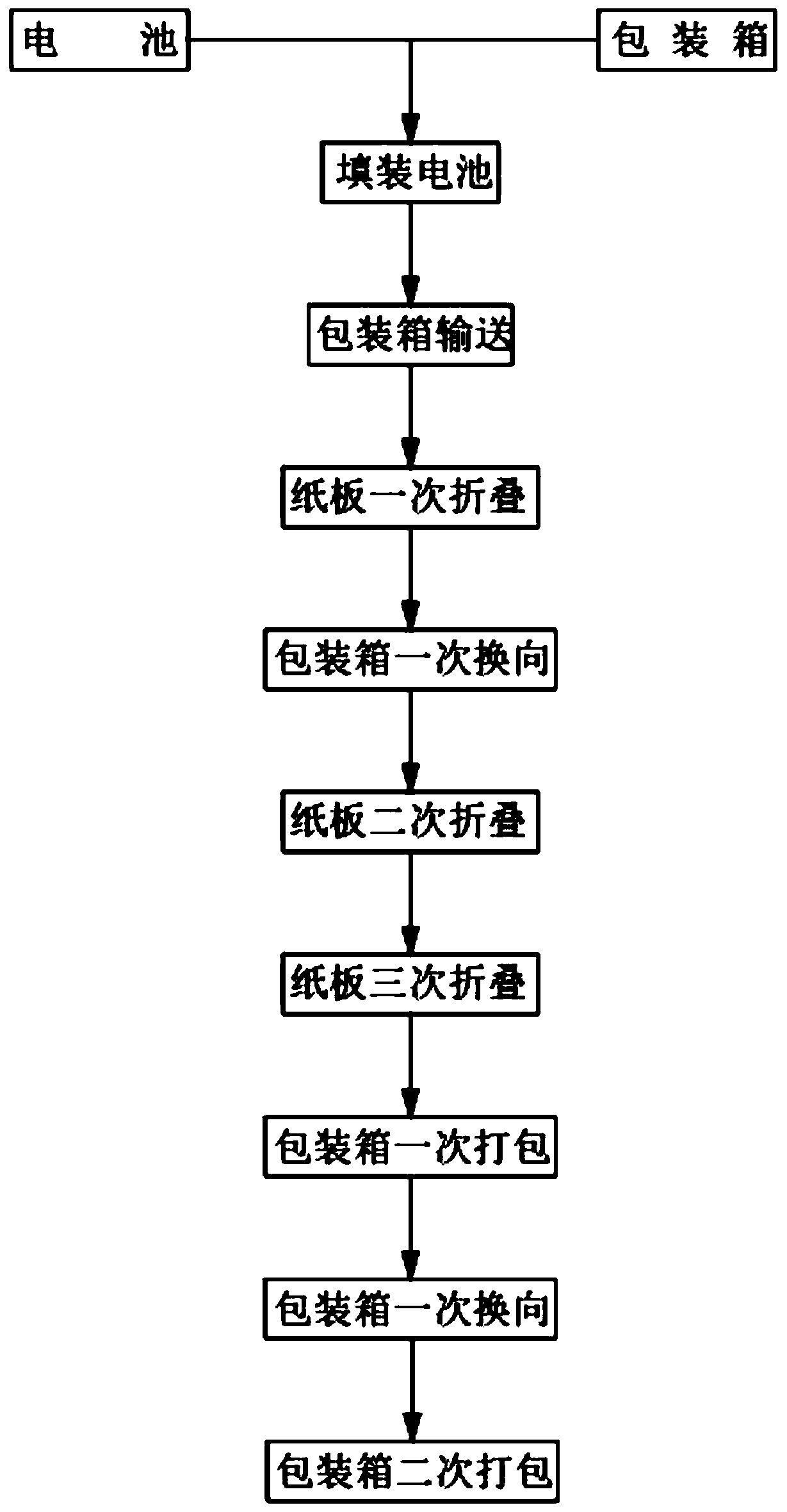

[0055] Such as figure 1 Shown, a kind of lead-acid battery packing box automatic reversing side packing method, comprises the following steps:

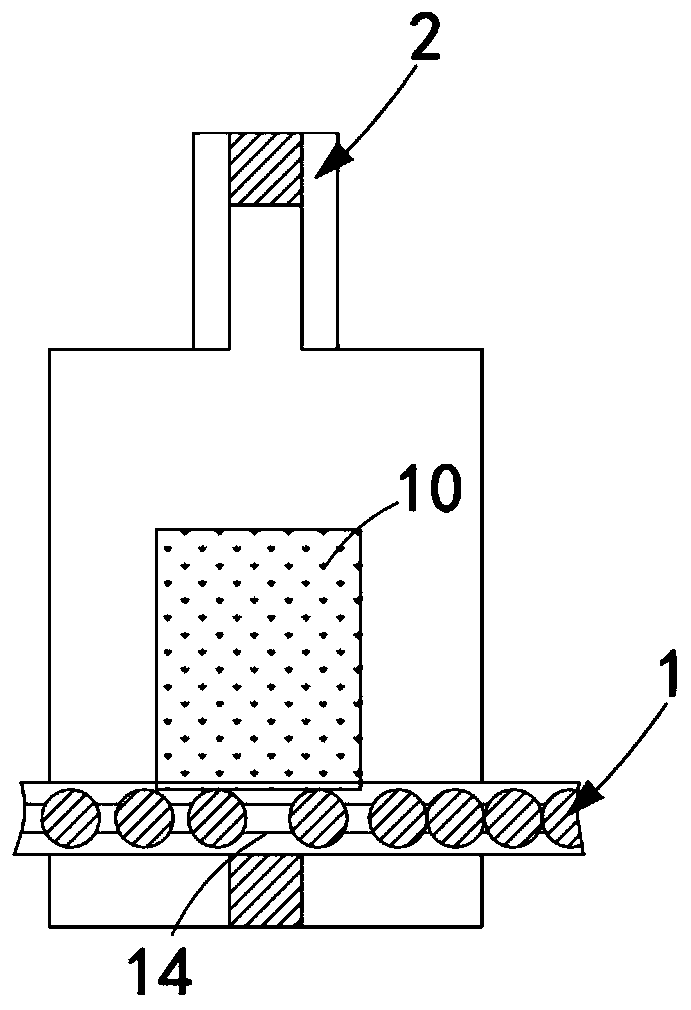

[0056] Step a), filling the batteries, and stacking lead-acid batteries in the lead-acid battery packaging box 10 with the top opened and the bottom glued closed by mechanical or manual means;

[0057] Step b), transporting the packaging box, placing the lead-acid battery packaging box 10 filled with batteries on the packaging conveying line 1, and the lead-acid battery packaging box 10 is transported backward along the conveying direction by the packaging conveying line 1 ;

[0058] Step c), the cardboard is folded once, and the lead-acid battery packaging box 10 is transported to the right below the folding mechanism 4 by the packaging conveying line 1 along the conveying direction, and the top of the lead-acid battery packaging box 10 is in contact with the packaging The first cardboard 101 parallel to the conveying direction of ...

Embodiment 2

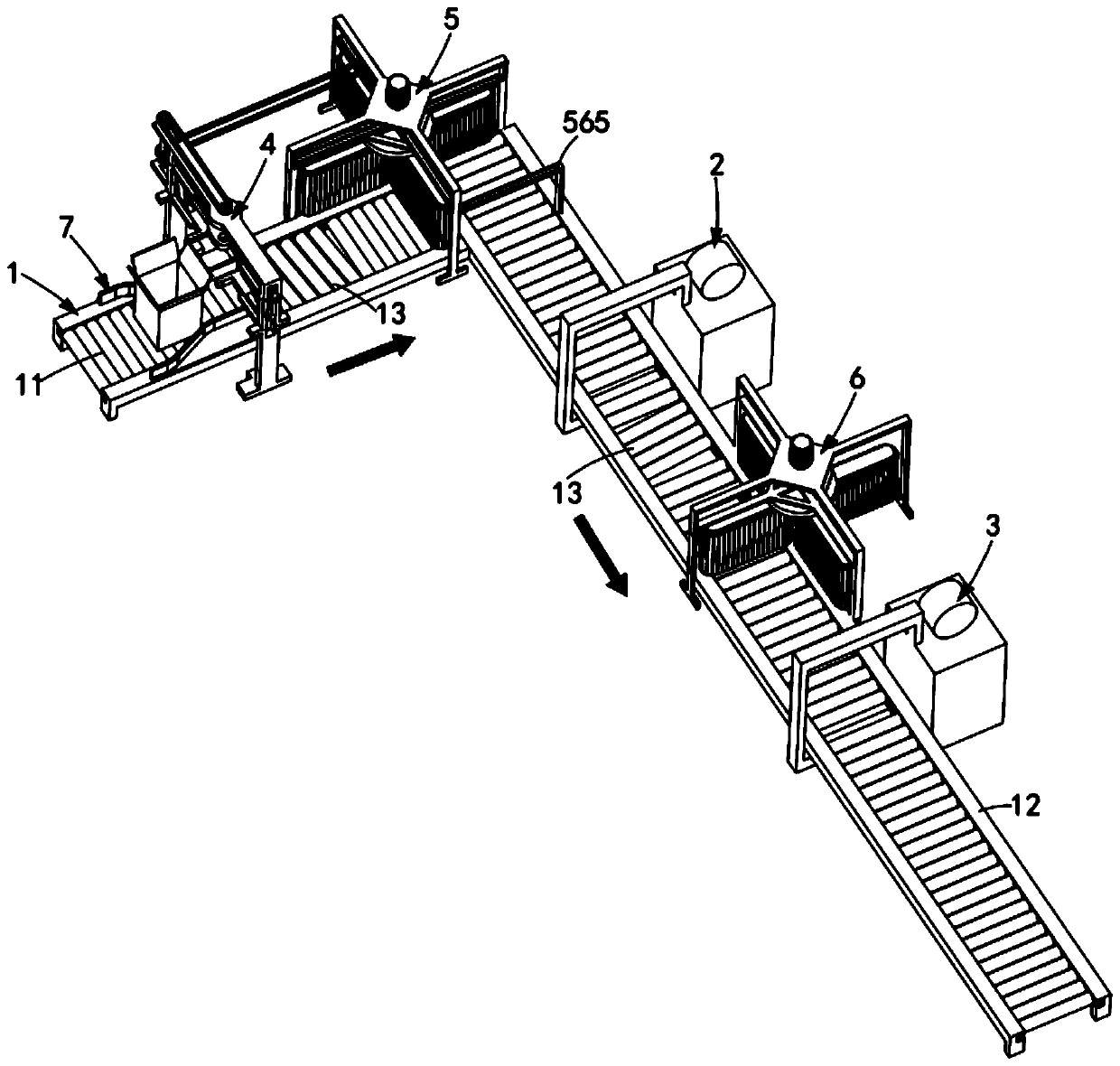

[0071] Referring to Embodiment 1, a method for automatically reversing side packaging of lead-acid battery packaging boxes, the second embodiment of the present invention, a packaging system for automatically reversing side packaging of lead-acid battery packaging boxes, is described.

[0072] Such as figure 2 , image 3 and Figure 9 As shown, a lead-acid battery packaging box automatic reversing side packaging system, which includes a packaging conveyor line 1, the packaging conveyor line 1 is a roller conveyor line, which includes a vertically arranged first conveyor line 11 and a second conveyor line 12 , a first packing machine 2 and a second packing machine 3 are sequentially arranged along the conveying direction of the packing conveying line 1, and also include:

[0073] Turning mechanism 4, described turning mechanism 4 is arranged on the input end of described packaging conveying line 1 along the conveying direction of described packing conveying line 1, and this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com