Automatic-water-squeezing mop convenient to use

A self-squeezing water and mop technology, applied in applications, household appliances, carpet cleaning, etc., can solve the problems of inconvenient operation, slow automatic turning and returning of the mop head, affecting work efficiency, etc., to achieve labor-saving operation and convenient water-squeezing operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

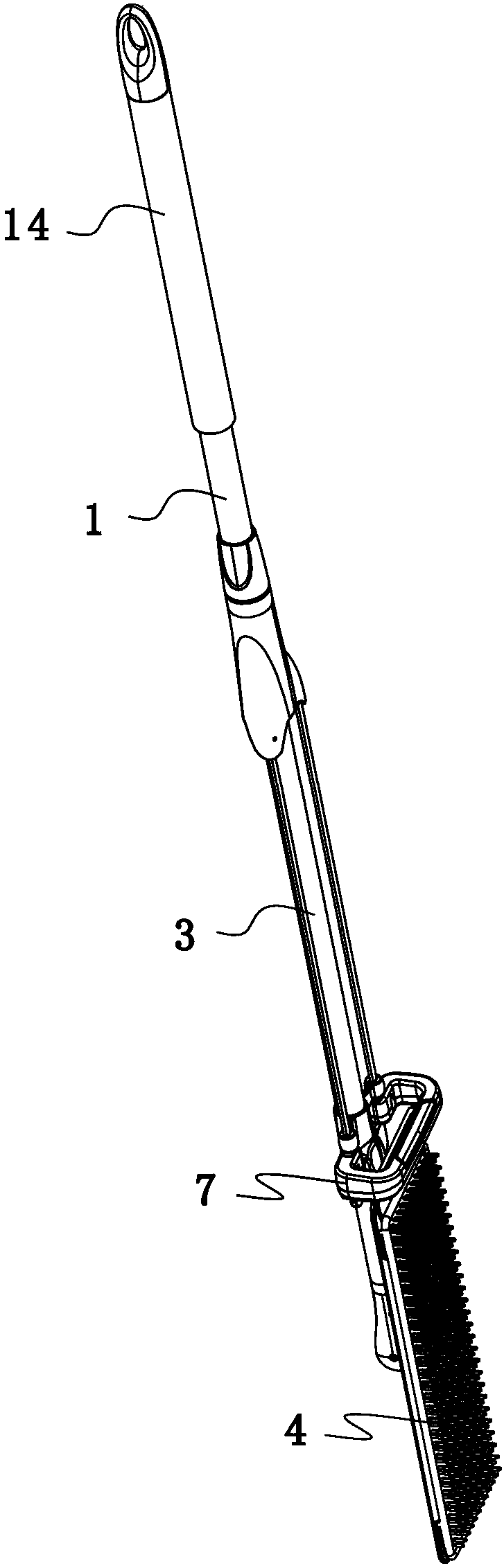

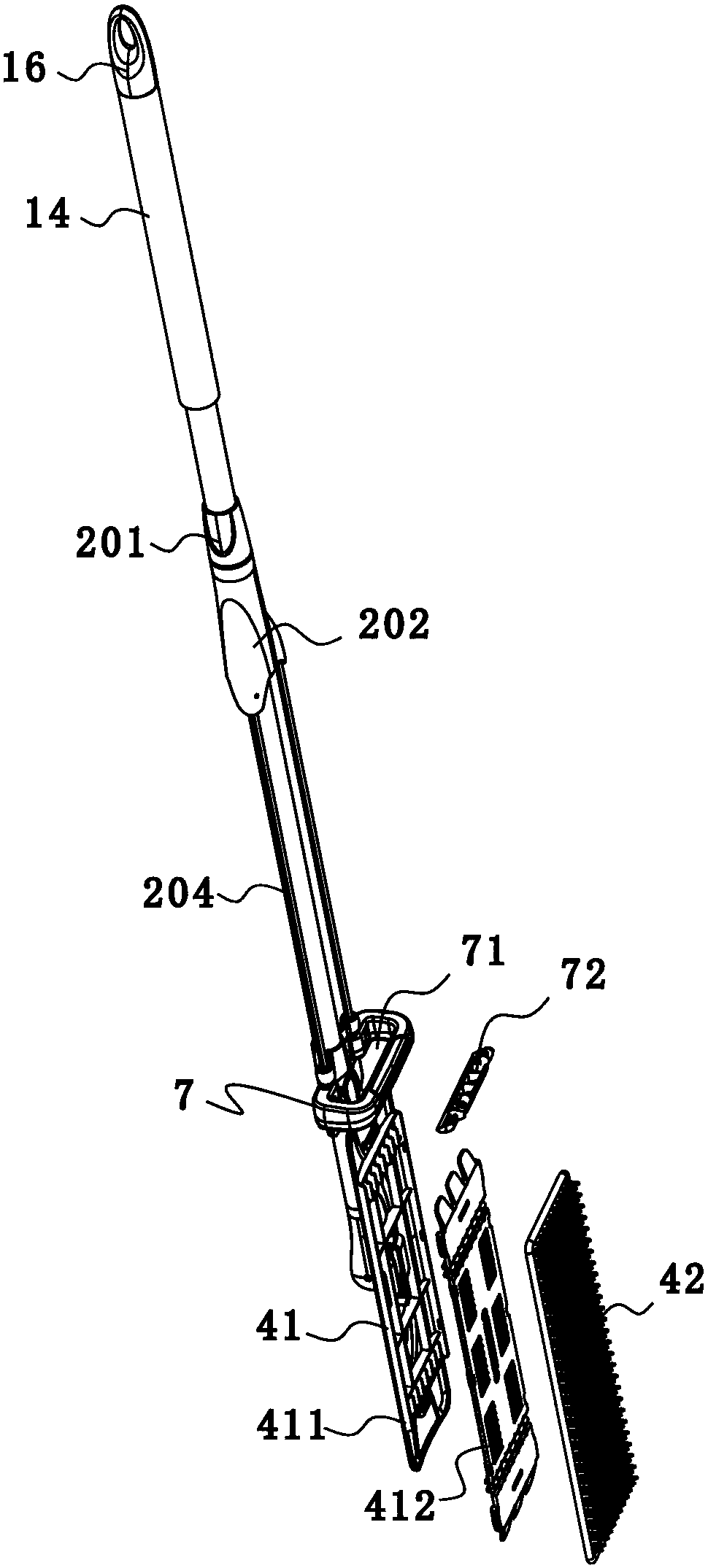

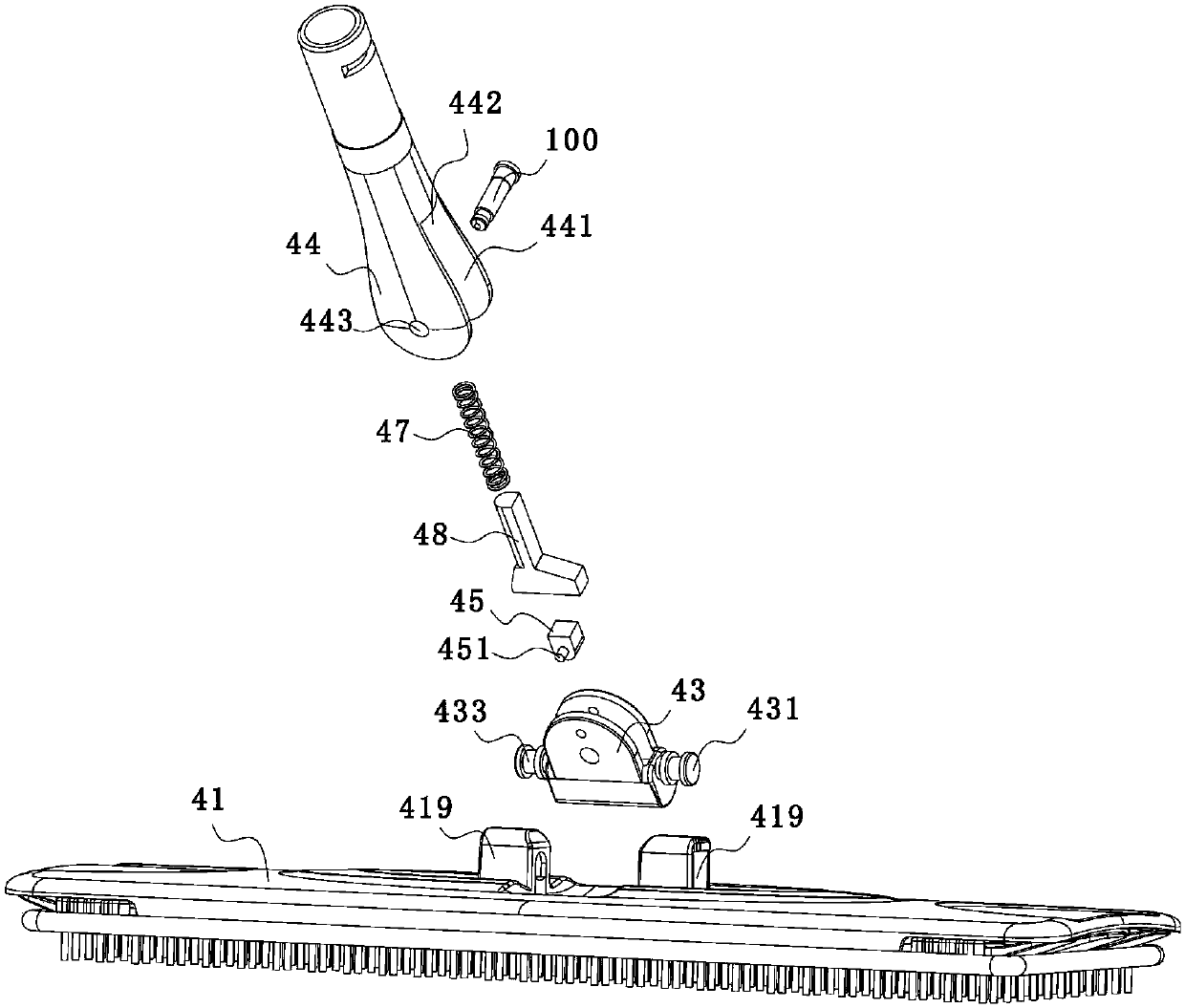

[0042] Such as Figure 17-7 , Shown in 14-22, a kind of self-squeezing water mop comprises a mop head 4, a rolling cover structure and a mop rod, and the rolling cover structure includes a rolling cover 7, which is provided with a perforation 71 for the mop head to pass through The mop rod includes a second rod part 1 and a first rod part 3, the second rod part 1 is movably sleeved outside the first rod part 3, and the second rod part 1 can reciprocate up and down along the first rod part 3 Sliding, the stroke sleeve 7 is connected with the second rod 1, and can move up and down under the drive of the second rod 1; the upper end of the second rod 1 is covered with a soft cover 14, which makes it more comfortable to hold this part; The lower end of the first rod part 3 is movably connected with the mop head 4, and then the mop head 4 can be rotated to a position parallel to the mop rod, and penetrates into the through-hole 71 when the stroke sleeve 7 moves up and down. Further...

Embodiment 2

[0062] Such as Figure 8-11 As shown, the difference between this embodiment and Embodiment 1 is that the contact surface of the adjustment member and the push member is an arc surface, and preferably, the adjustment member is a roller; we set the sliding surface 481 The first positioning part 482 and the second positioning part 483, when the mop is in the state of mopping the floor, the adjustment part 45 cooperates with the first positioning part 482; when the mop is in the cleaning state, the adjustment part 45 and the The second positioning part 483 cooperates, so that the positioning of the mop rod is more firm; specifically, the second positioning part 483 is an arc-shaped slot provided at the lower part of the push piece 45, and the first positioning part 482 is an inclined plane located at the lower end of the push member 45; when the mop rod 5 is perpendicular to the mop head 4, the adjusting member 45 snaps into the first positioning portion 482, thereby effectively ...

Embodiment 3

[0064] Such as Figure 12-14 As shown, the difference between this embodiment and Embodiment 1 is that the connecting member 44 is provided with a positioning structure, the positioning structure includes a moving part 491 and a positioning convex portion 492, and the positioning convex portion 492 is arranged on one of the connecting portions Above; the moving part 491 is a moving block 492 placed in the through cavity and a connecting rod 493 pierced in the moving block, the two ends of the connecting rod protrude to the outer surface of the moving block, and the connecting The part 44 is provided with a hole for the connecting rod to penetrate, so as to realize the fixed connection between the connecting rod 493 and the connecting part 44, so that the moving block 492 is effectively limited in the through cavity of the connecting part; the lower end of the moving part 492 is connected with a Spring 494, the upper end of the moving part stretches out to the through cavity, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com