Intermittent material splashing device

An intermittent, silo technology, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of high market price of induction devices, not suitable for farmers' actual economic needs, complex structure, etc., and achieve simple structure and practicality High, highly automated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

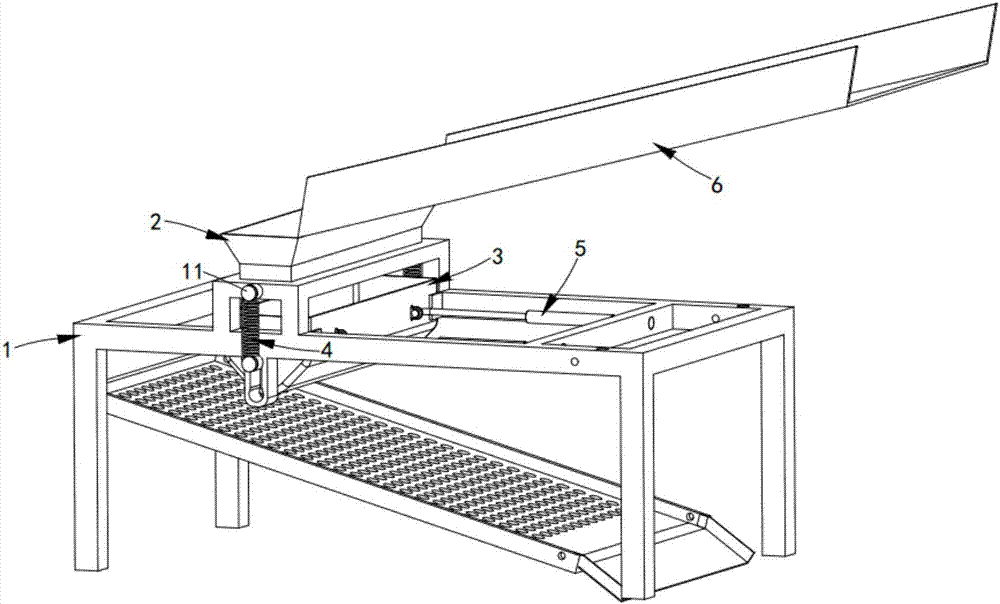

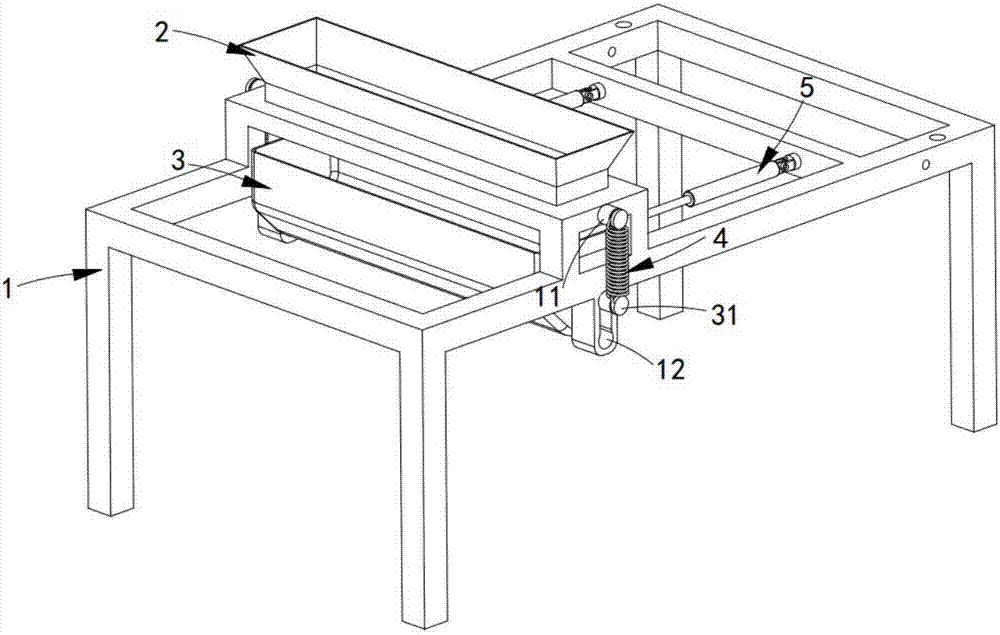

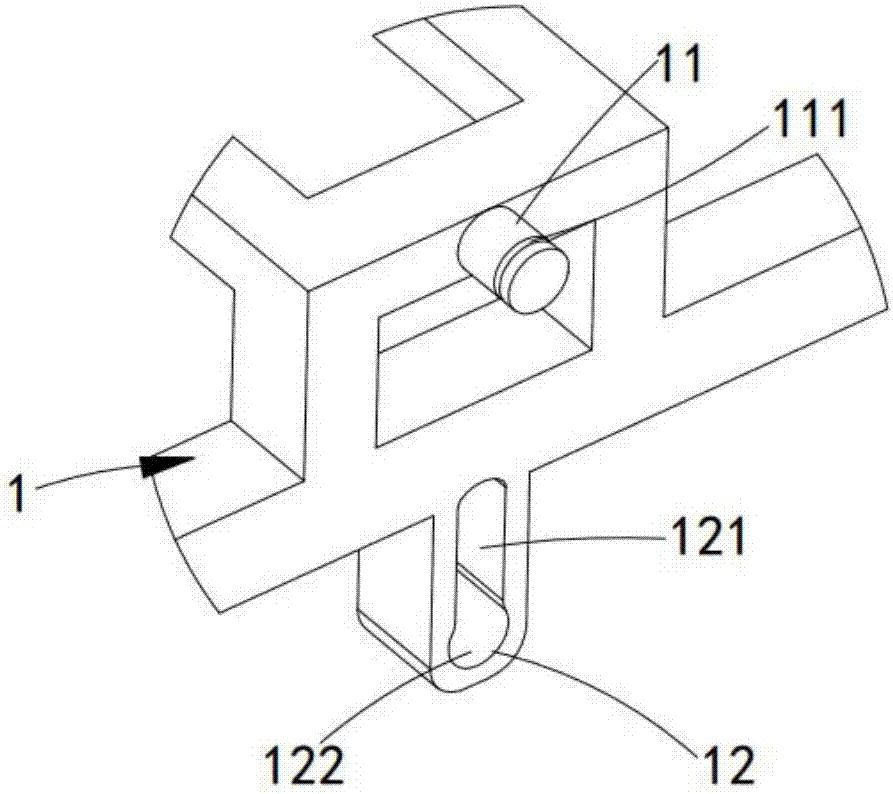

[0041] Such as figure 1 and figure 2 As shown, an intermittent feeding device includes a frame 1, a hopper 2, a silo 3, a buffer spring 4, a reset mechanism 5 and a feeding pipe 6, and connecting rods are arranged symmetrically on both sides of the frame 1 11 and the chute 12, the connecting rod 11 is located directly above the chute 12;

[0042] The hopper 2 is fixedly arranged on the top of the frame 1, its upper and lower ends are both open, and the silo 3 is arranged directly below it, and the feed pipe is arranged on the rear side of the hopper 2 6, and the feeding pipe 6 is correspondingly connected to the receiving hopper 2;

[0043] The feed bin 3 is tapered, with its upper end open, and its two ends are slidingly arranged in the chute 12 through symmetrically arranged guide rods 31, the guide rods 31 being located at the bottom of the feed bin 3;

[0044] The buffer spring 4 is symmetrically arranged on both sides of the frame 1, one end of which is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com