Battery string discharging and overturning mechanism

A flipping mechanism and battery technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of poor adsorption of battery strings, high cost, and damage to the surface of battery strings, and achieve reliable adsorption, low cost, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings.

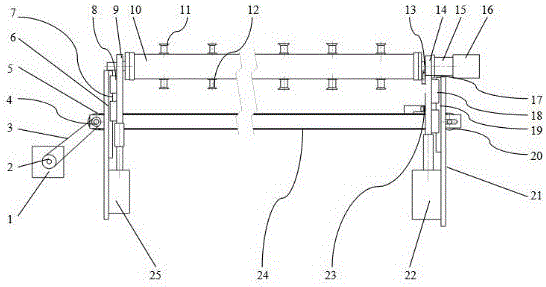

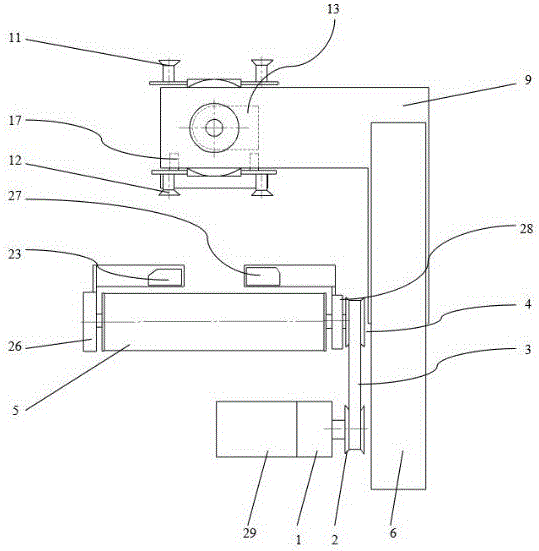

[0017] Such as figure 1 and 2 As shown, a battery string blanking and turning device is mainly composed of a battery string conveying mechanism and a battery string turning mechanism.

[0018] The battery string conveying mechanism includes a reducer 1, a driving synchronous pulley 2, a synchronous belt 3, a driven synchronous pulley 4, a driving pulley 5, a driven pulley 20, a rear sensor 23, a belt 24, and a left pulley mounting plate 26 , front sensor 27, right pulley mounting plate 28 and servo motor 29. Wherein the shafts at both ends of the driving pulley 5 are mounted on the left side pulley mounting plate 26 and the right side pulley mounting plate 28 respectively by bearings, and one end of the driving pulley 5 is equipped with a driven synchronous pulley 4 and both rotate synchronously; The other side of 5 is provided with driven pulley 20, and described driven pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com