Standard penetration test device for partitioning rock weathering degree

A standard penetration test and weathering degree technology, which is applied in foundation structure engineering, on-site foundation soil survey, construction, etc., can solve the problems such as the difficulty of delineating the boundary line in the transition zone, and achieve simple structure, easy installation and reading, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

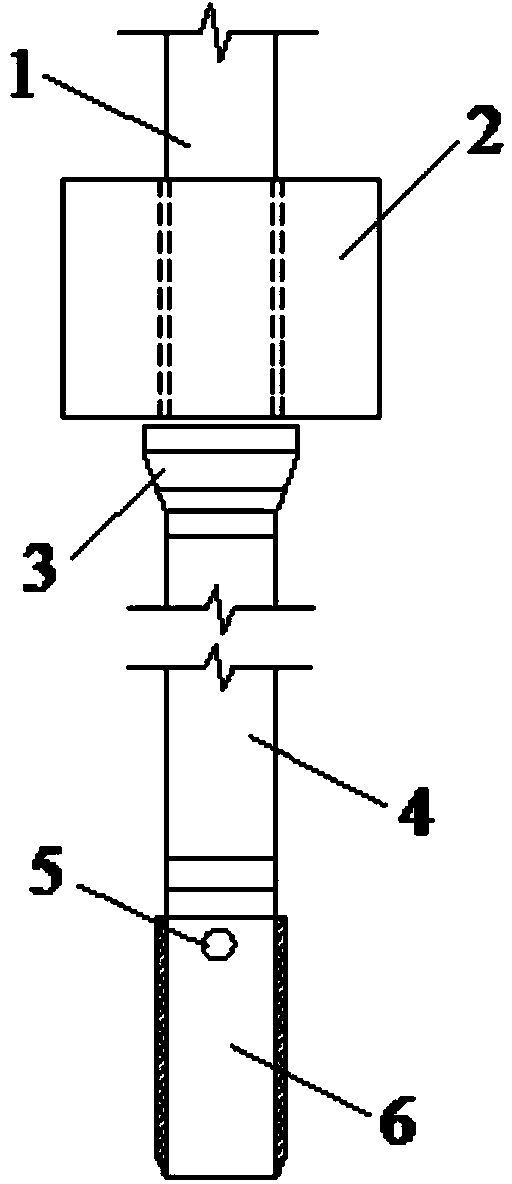

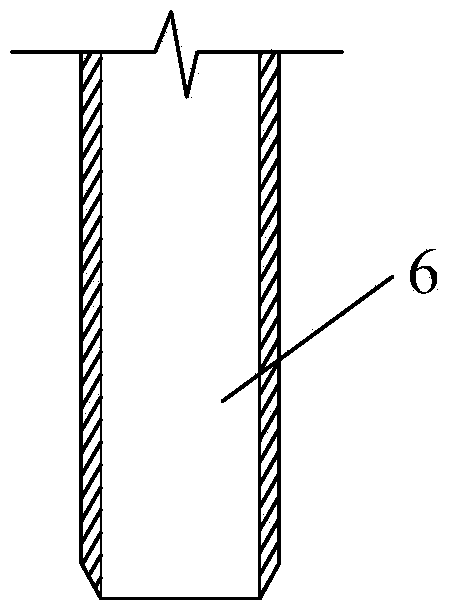

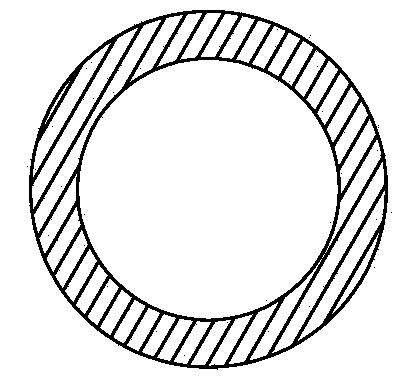

[0018] The main structure of this embodiment includes a guide rod 1, a piercing hammer 2, a hammer pad 3, a probe rod 4, a water outlet 5, and a penetrator 6; the guide rod 1 is embedded in the middle of the piercing hammer 2 for controlling The free fall direction of the piercing hammer 2; the bottom of the piercing hammer 2 with an automatic decoupling device is provided with a hammer pad 3, the piercing hammer 2 can freely fall on the hammer pad 3, and the weight of the piercing hammer 2 is 63.5kg. The drop distance is 76cm; the bottom of the hammer pad 3 is fastened with a screw to form a probe rod 4; the probe rod 4 is provided with a scale line for visually observing the penetration depth, and the diameter of the probe rod 4 is 42mm; The penetrator 6 with the hollow metal tube structure at the cutting edge and the probe rod 4 are connected and fastened by screws. The penetrator 6 is made of ultra-high-strength alloy steel. The penetrator 6 has a length of 300mm and an inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com