Electromagnetic type active vibration absorber

An electromagnetic and shock absorber technology, applied in the direction of shock absorbers, shock absorber-spring combinations, shock absorbers, etc., can solve the problem of inability to achieve low-frequency vibration and broadband vibration with good vibration reduction effect and increase the structural complexity of the shock absorber , Reduce structural reliability and other issues, to achieve the effect of increasing the effective magnetic area, improving the utilization rate of magnetic energy, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

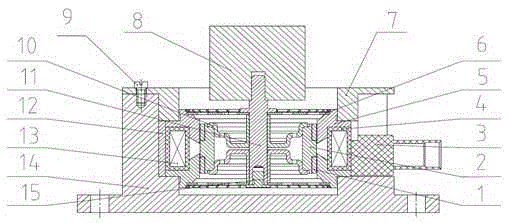

[0022] Such as figure 1 As shown, the electromagnetic active vibration absorber of the present invention includes a permanent magnet 1, a skeleton 2, an enameled coil 13, an insulating sealing shell 4, a wiring port 3, a shaft hub 10, a push rod 11, a screw 15, a metal spring 6, a cover plate 5, Shell 12, mounting base 14, fixed end cover 7, sealing screw 9, quality block 8. According to the working principle, the structure of the electromagnetic active vibration absorber of the present invention can be roughly divided into three parts: the mover, the stator, and the installation foundation. , mass block 8; the stator part includes enameled coil 13, insulating sealing shell 4, wiring port 3, cover plate 5, shell 12; installation base includes installation base 14, fixed end cover 7, sealing screw 9.

[0023] Install two hubs 10 with central holes on both ends of the inner ring of the ring frame 2, and use magnet glue to evenly bond the tile-shaped permanent magnet 1 to the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com