Composite pile as well as construction method and single-pile vertical bearing capacity calculation method thereof

A construction method and technology of combined piles, which are applied in the directions of calculation, computer-aided design, sheet pile wall, etc., can solve the sliding damage of prefabricated piles and cement slurry stones, do not give full play to the advantages of combined piles, and calculate the bearing capacity of single piles. Certainly applicable and other issues, to achieve the effect of expanding the effective pile diameter, increasing the bearing capacity of a single pile, and reliable calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

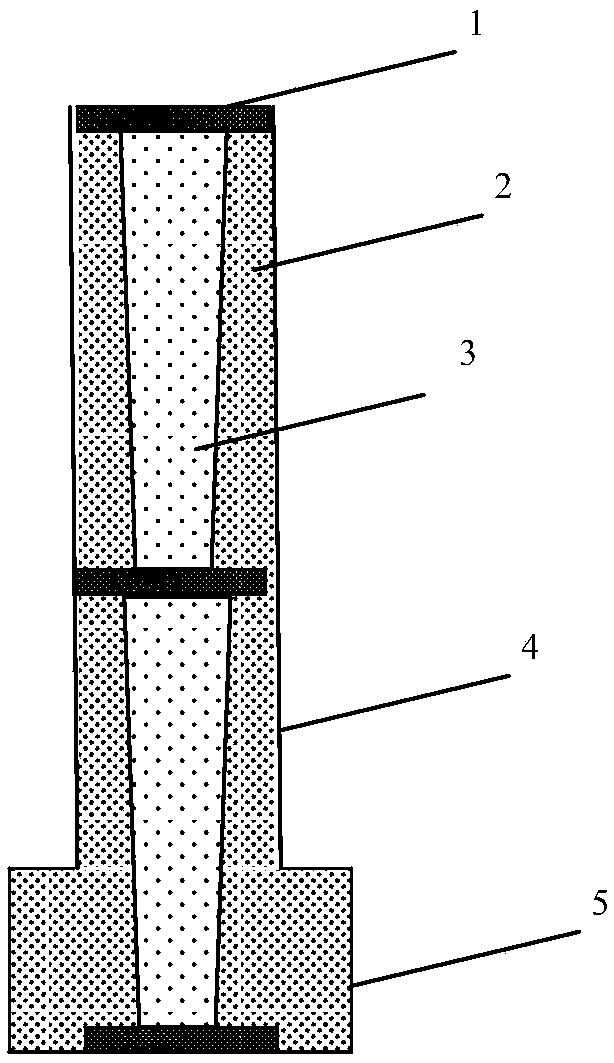

[0083] Such as figure 1 As shown, the pile length of the composite pile is 12m, wherein the length of the non-expansion section is 10m and the diameter is 0.8m, and the length of the expansion section is 2m and the diameter is 1.2m. The prefabricated piles used are PHC pipe piles (hollow piles). The pile length of each prefabricated pile is 6m, the outer diameter of the large section end is 600mm, the outer diameter of the small section is 400mm, and the wall thickness is 125mm.

[0084] The construction of composite piles includes the following steps:

[0085] Drill or dig a hole at the predetermined pile position, the hole depth is 12m, ream the hole within the depth range of 2m above the bottom of the hole to form a reaming section, and inject a small amount of M30 cement slurry into the hole;

[0086] Connect the prefabricated piles of 6m per section to the predetermined pile length of 12m (2 prefabricated piles are enough), and install steel plates at the pile ends, pile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com