Percussive drilling construction process for diaphragm wall passing through rock-filled layer in reclamation area

An underground diaphragm wall and construction technology technology, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve problems such as low construction work efficiency, and achieve the effects of reducing comprehensive construction costs, good quality of grooves, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

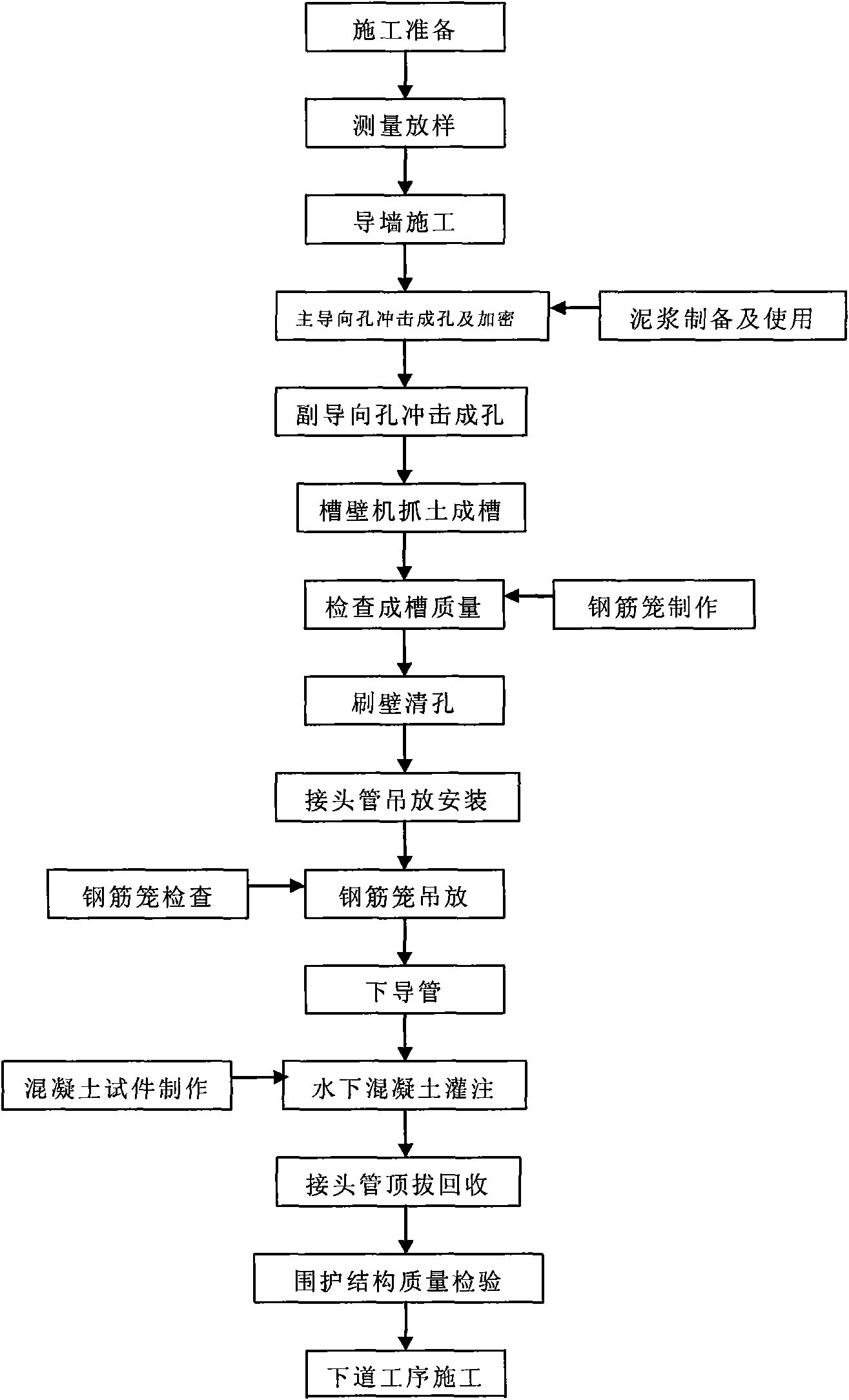

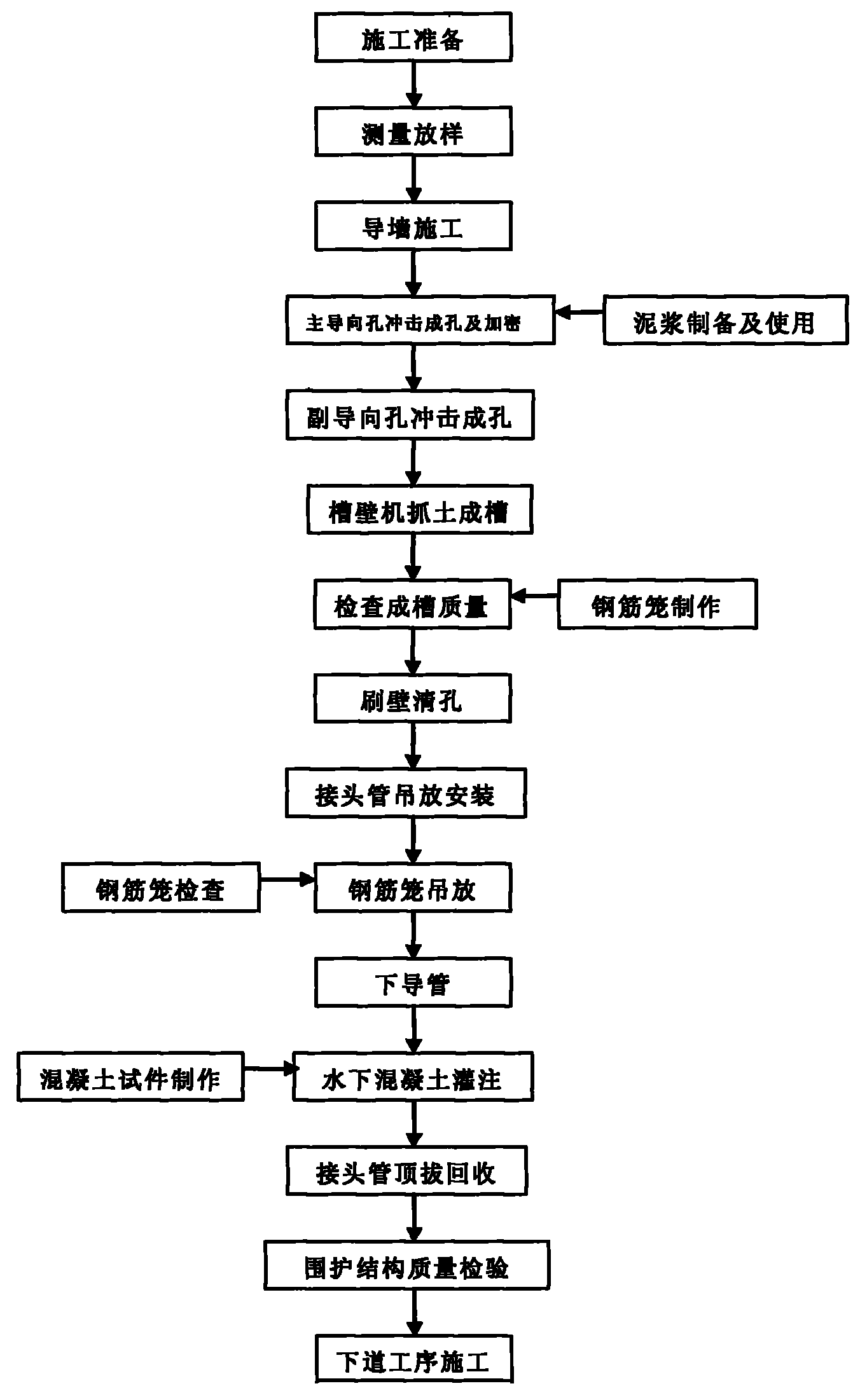

Method used

Image

Examples

Embodiment

[0035] Measure and set out, accurately measure and set the position of the guide wall, and carry out the construction of the guide wall. After the guide wall is accepted, use the instrument to determine the framing line of the underground continuous wall. After the punching pile machine and the slotting machine are in place, first check whether the grab is parallel to the guide wall, and check the punching of the CZ-30 impact pile machine. Whether the center line of the hammer and the grab of the GB24 full hydraulic groove wall machine coincides with the center axis of the guide wall.

[0036] After the slot section is positioned, the positions of the main guide hole and the auxiliary guide hole are determined according to the length of each unit slot section. After the position of the guide hole is determined, first use the impact pile driver to continuously impact the main guide hole where the joint pipe is placed from the top surface of the diaphragm wall to a depth of 0.5m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com