Method for producing bacterial protein by treating fatty acid wastewater with photosynthetic bacteria

A technology of photosynthetic bacteria and bacterial protein, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problem of long treatment time of fatty acid wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

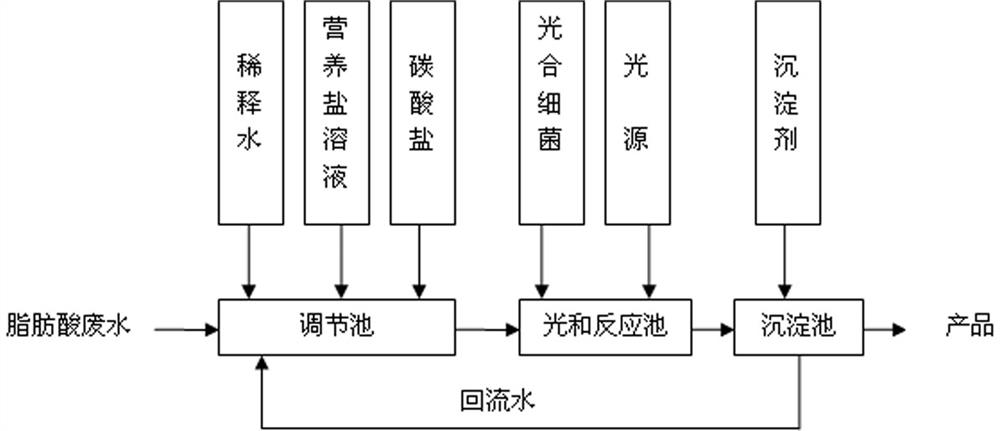

[0022] The photosynthetic bacteria process the fatty acid wastewater to produce the cell protein method, comprising the following steps:

[0023] (1) Domestication of photosynthetic bacteria: select domesticated halophilic photosynthetic bacteria liquid;

[0024] (2) Wastewater treatment: the sulfate content of fatty acid production wastewater is 35%, dilute 1L of fatty acid wastewater by 10 times, add 1% nutrient salt solution of treated water volume, the nutrient salt solution is composed of EDTA (0.5g / L), CaCl 2 ·H 2 O (0.5g / L), ZnSO 4 ·7H 2 O (0.05g / L), FeSO 4 ·7H 2 O (0.9g / L), KCl (0.2g / L), CoCl 2 ·6H 2 O (0.09g / L), MgCl 2 ·6H 2 O (0.6g / L); Control the pH value of waste water with potassium carbonate at 8, inoculate photosynthetic bacteria, at 30 ℃ of culture temperature, under the irradiation of 40W incandescent lamp, cultivate after 3 days, add magnesium chloride solution 0.001g according to every liter of waste water, The bacterial protein is separated, and t...

Embodiment 2

[0027] The photosynthetic bacteria process the fatty acid wastewater to produce the cell protein method, comprising the following steps:

[0028] (1) Domestication of photosynthetic bacteria: select the mixed bacterial solution of domesticated photosynthetic bacteria and domesticated halophilic photosynthetic bacteria,

[0029] (2) Wastewater treatment: the sulfate content of fatty acid production wastewater is 30%, dilute 1L of fatty acid wastewater by 5 times, add 4% nutrient salt solution of treated water volume, and the nutrient salt solution is composed of EDTA (1.3g / L), CaCl 2 ·H 2 O (0.05g / L), ZnSO 4 ·7H 2 O (0.50g / L), FeSO 4 ·7H 2 O (0.2g / L), KCl (0.8g / L), CoCl 2 ·6H 2 O (0.01g / L), MgCl 2 ·6H 2 O (1.9g / L); use calcium carbonate to control the pH value of wastewater at 7.5, inoculate photosynthetic bacteria, and cultivate at a temperature of 30°C under sunlight (all sunny days) for 5 days, then add zinc sulfate per liter of wastewater 0.002 g of the solution, ...

Embodiment 3

[0032] The photosynthetic bacteria process the fatty acid wastewater to produce the cell protein method, comprising the following steps:

[0033] (1) Domestication of photosynthetic bacteria: select domesticated halophilic photosynthetic bacteria liquid;

[0034] (2) Wastewater treatment: the sulfate content of fatty acid production wastewater is 25%, dilute 1L of fatty acid wastewater by 2 times, and add 5% nutrient salt solution of treated water volume, the nutrient salt solution is composed of EDTA (0.8 / L), CaCl 2 ·H 2 O (0.2g / L), ZnSO 4 ·7H 2 O (0.3g / L), FeSO 4 ·7H 2 O (0.7g / L), KCl (0.6g / L), CoCl 2 ·6H 2 O (0.05g / L), MgCl 2 ·6H 2O (0.95g / L); Control the pH value of waste water with sodium carbonate at 7.5, inoculate photosynthetic bacteria, at 20 ℃ of cultivation temperature, under the irradiation of 40W fluorescent lamp, cultivate after 5 days, add aluminum sulfate solution 0.005g according to every liter of waste water, The bacterial protein is separated, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com