Preparation method of nickel aminosulfonate solution

A technology of nickel sulfamate and sulfamic acid, which is applied in the field of preparation of nickel sulfamate solution, can solve the problems of large internal stress of the coating, unqualified products, unfriendly environment, etc., and achieves small voltage fluctuations and production process flow Short, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

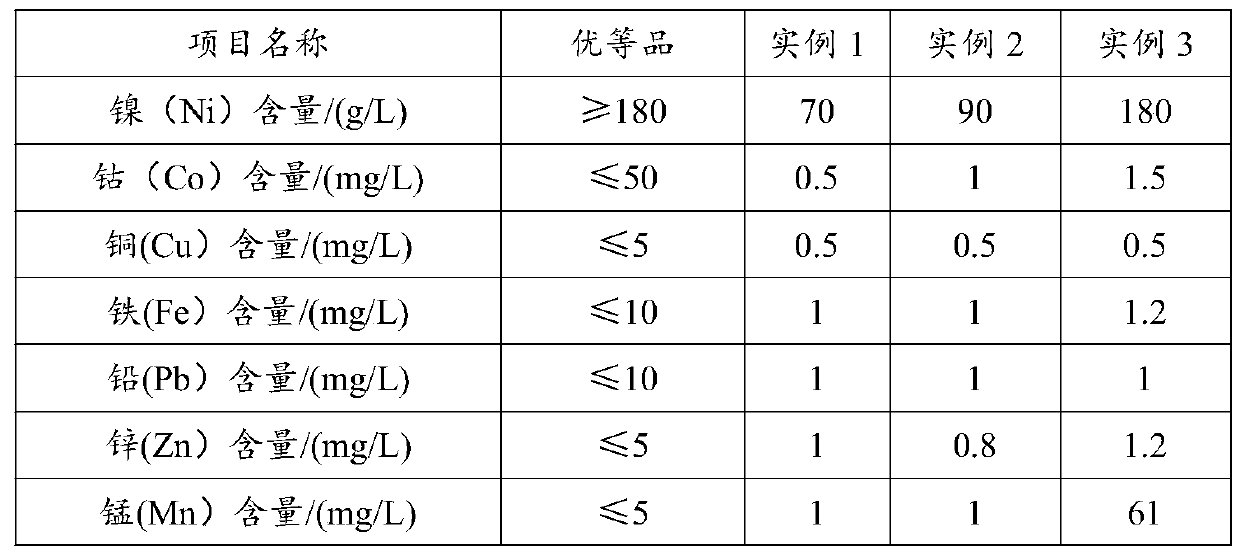

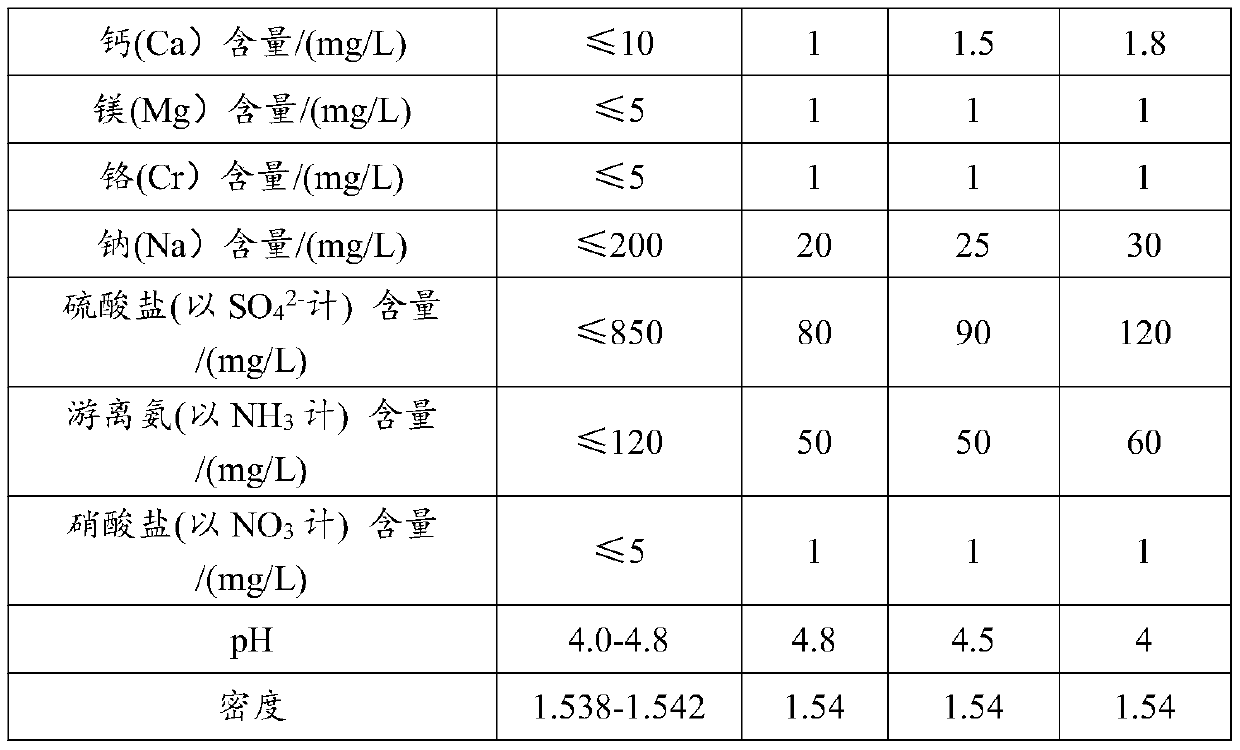

Embodiment 1

[0026] A preparation method of nickel sulfamic acid solution, comprising the following steps:

[0027] S1. Preparation of acidic nickel solution: prepare an acidic nickel solution containing nickel ions with a weight fraction of 8wt% in the first dosing tank;

[0028] S2. the preparation of nickel plate: then the acidic nickel solution prepared described in step S1 is dropped into the first diaphragm electrolyzer, the anode of the first diaphragm electrolyzer described is a titanium plate, and the negative electrode is a nickel plate with a thickness of 3mm. Adopt ion-exchange membrane to separate between the negative and positive electrodes of the first diaphragm electrolyzer described above, then carry out electrolytic deposition for the first time, stop electrolysis after making the thickness of the nickel plate of negative electrode increase to 20mm, then described thickness is 20mm The nickel plate is cleaned and set aside;

[0029] S3. The preparation of sulfamic acid s...

Embodiment 2

[0038] A preparation method of nickel sulfamic acid solution, comprising the following steps:

[0039] S1. Preparation of acidic nickel solution: prepare an acidic nickel solution containing nickel ions with a weight fraction of 5wt% in the first dosing tank;

[0040] S2. the preparation of nickel plate: then the acidic nickel solution prepared described in step S1 is dropped into the first diaphragm electrolyzer, the anode of the first diaphragm electrolyzer is a titanium plate, and the negative electrode is a nickel plate with a thickness of 2mm. Adopt ion-exchange membrane to separate between the positive and negative electrodes of the first diaphragm electrolyzer described above, then carry out electrolytic deposition for the first time, stop electrolysis after making the thickness of the nickel plate of negative electrode increase to 10mm, then described thickness is 10mm The nickel plate is cleaned and set aside;

[0041] S3. Preparation of sulfamic acid solution: prepa...

Embodiment 3

[0050] A kind of preparation method of nickel sulfamate solution comprises the following steps:

[0051] S1. Preparation of acidic nickel solution: prepare an acidic nickel solution containing nickel ions with a weight fraction of 3wt% in the first dosing tank;

[0052] S2. the preparation of nickel plate: then the acidic nickel solution prepared described in step S1 is dropped into the first diaphragm electrolyzer, the anode of the first diaphragm electrolyzer is a titanium plate, and the negative electrode is a nickel plate with a thickness of 2mm. The cathode and anode electrodes of the first diaphragm electrolyzer are separated by an ion exchange membrane, and then the first electrolytic deposition is carried out, so that the thickness of the nickel plate of the cathode is increased to 8mm and then the electrolysis is stopped, and then the thickness is 8mm. The nickel plate is cleaned and set aside;

[0053] S3. Preparation of sulfamic acid solution: prepare a sulfamic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com