Patents

Literature

426 results about "Nickel(II) chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel(II) chloride (or just nickel chloride), is the chemical compound NiCl₂. The anhydrous salt is yellow, but the more familiar hydrate NiCl₂·6H₂O is green. Nickel(II) chloride, in various forms, is the most important source of nickel for chemical synthesis. The nickel chlorides are deliquescent, absorbing moisture from the air to form a solution. Nickel salts have been shown to be carcinogenic to the lungs and nasal passages in cases of long-term inhalation exposure.

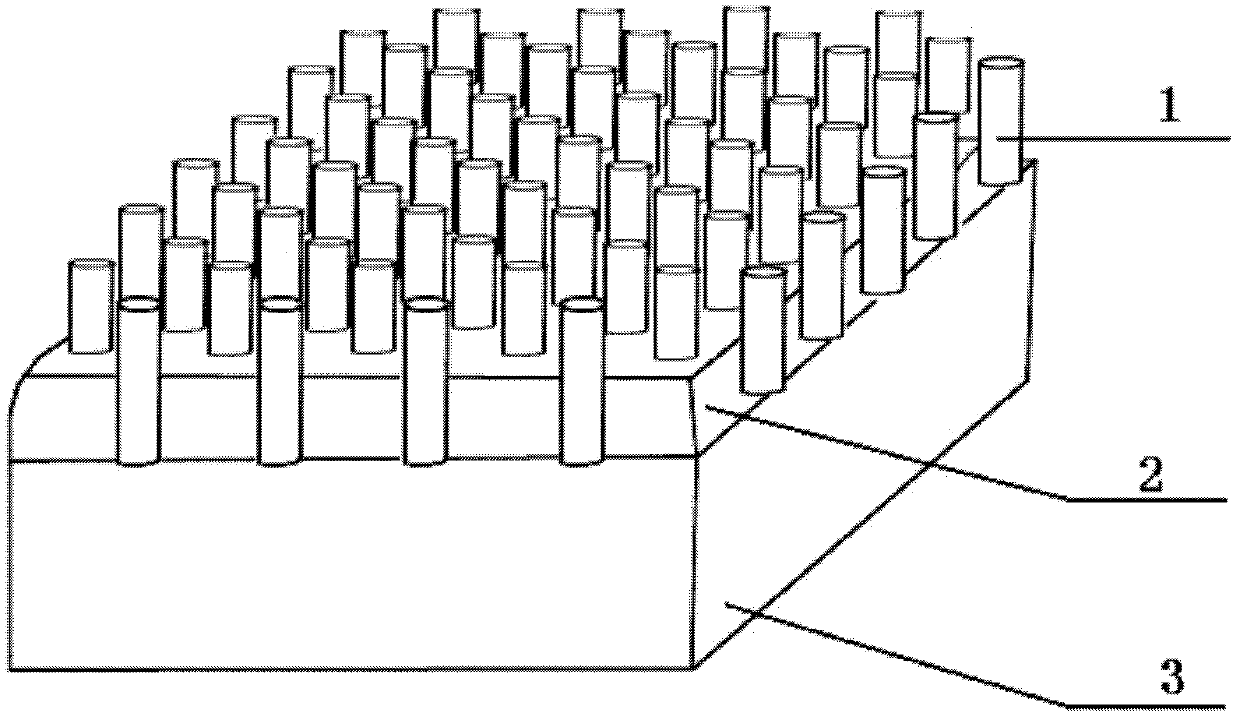

Ni-Mn layered double hydroxide@nickel foam@carbon three-dimensional hierarchically-structured electrode material and preparation method thereof

InactiveCN105655152AGood flexibilityLow reaction temperatureHybrid capacitor electrodesCell electrodesReaction temperatureCarbonization

The invention discloses a Ni-Mn layered double hydroxide@nickel foam@carbon three-dimensional hierarchically-structured electrode material and a preparation method thereof. The preparation method comprises the following steps: firstly carrying out one-step hydrothermal treatment by respectively taking nickel chloride hexahydrate, anhydrous manganese chloride and nickel foam as a nickel source, a manganese source and a substrate, so as to obtain Ni-Mn LDH@NF; and coating Ni-Mn LDH@NF by virtue of glucose or graphene as a carbon source, and carrying out hydrothermal treatment, so as to obtain Ni-Mn LDH@NF@C. According to the preparation method, by virtue of a stepwise hydrothermal-drying method, the preparation process and the required equipment are simple, raw material sources are rich, the reaction temperature is relatively low, the high temperature carbonization is not needed, and the large-scale production is easy to realize; and the Ni-Mn LDH@NF@C composite material is good in thermal stability, high in crystalline degree, large in specific surface area and strong in shape controllability and is one of ideal energy source materials.

Owner:SHANGHAI INST OF TECH

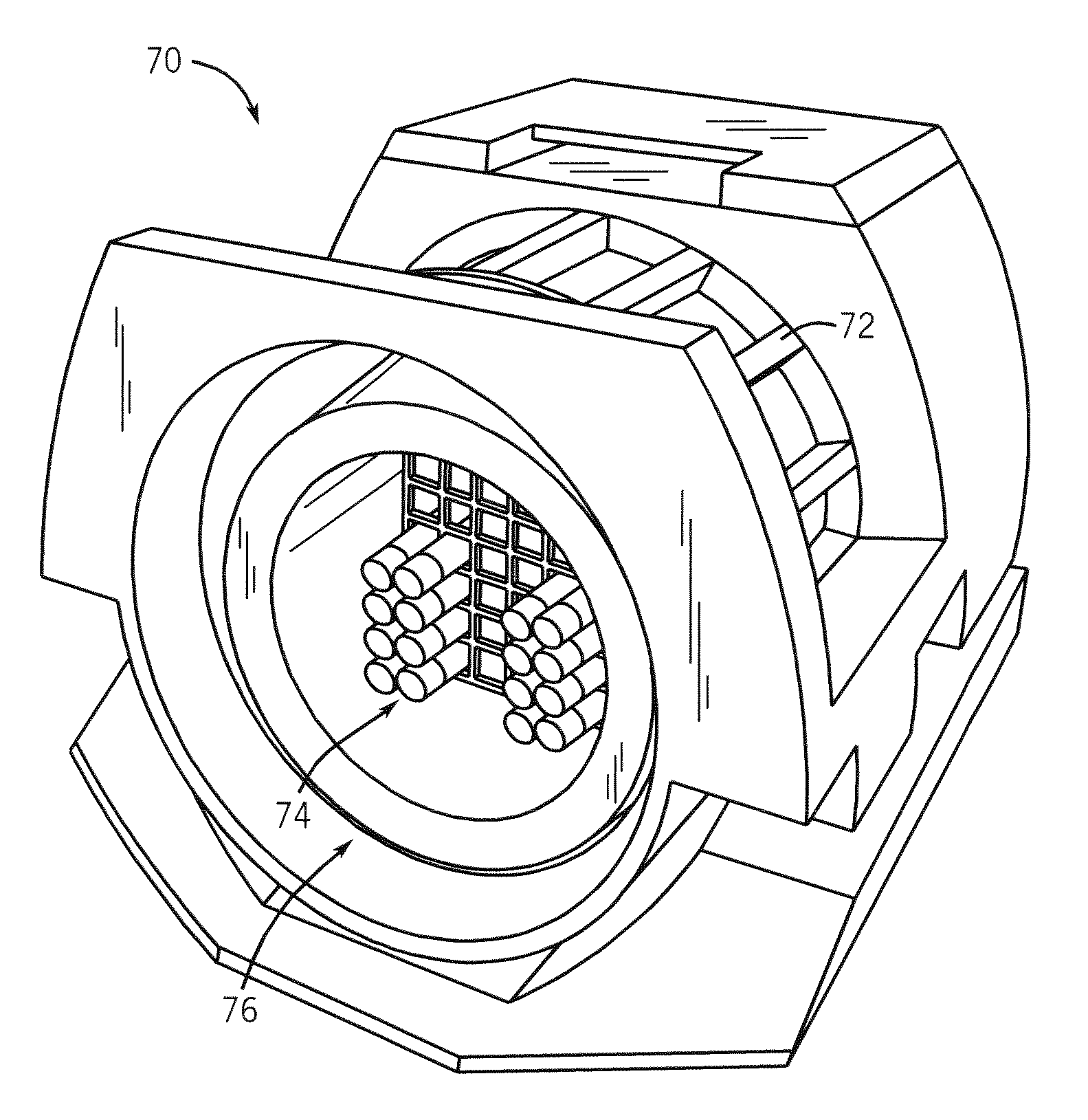

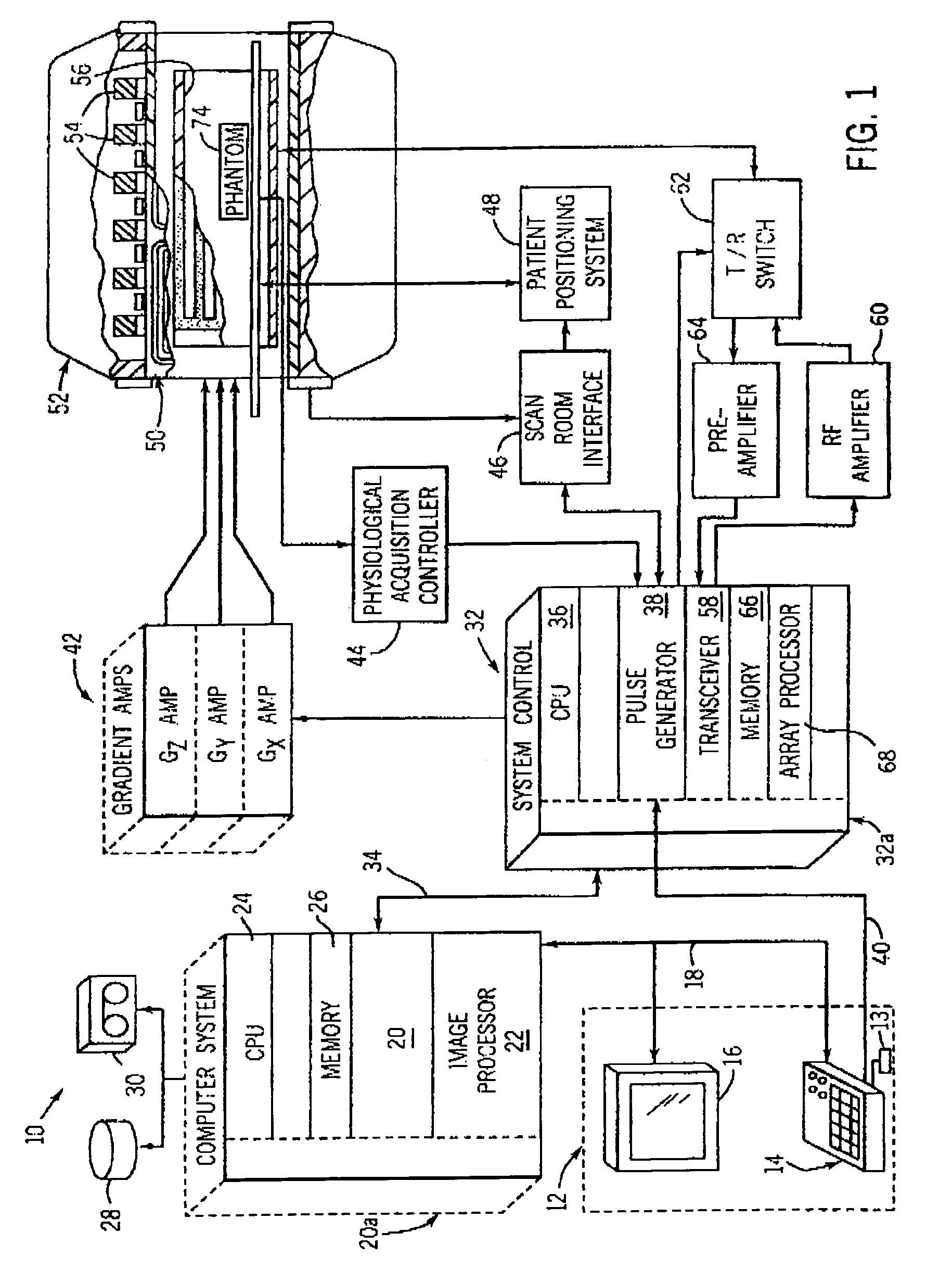

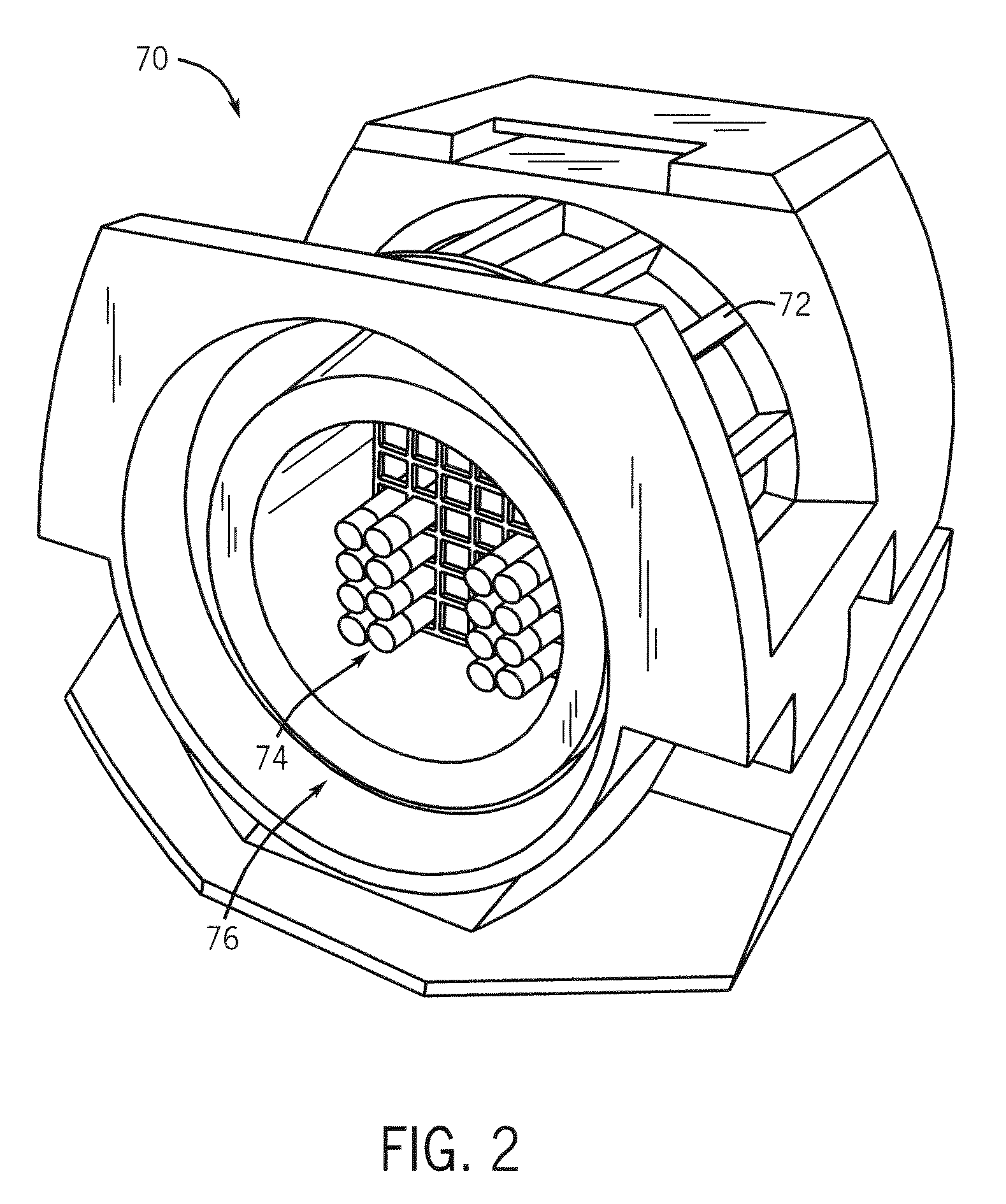

Apparatus to simulate MR properties of human brain for MR applications evaluation

InactiveUS6965235B1Increase contrastImproves white matterMagnetic measurementsElectric/magnetic detectionVolumetric Mass DensityT1 weighted

A system and method for mimicking a human brain for MR imaging at various magnetic field strengths is disclosed. A phantom is constructed of a structure having a number of sections. A first section contains a mixture of nickel chloride, agarose gel powder, potassium sorbate, deuterium oxide, and water such that the T1, T2, and proton density values of the first section mimic white matter of the human brain. A second section contains different amounts of the same components such that the T1, T2, and proton density values of the second section mimic gray matter of the human brain. As such, when the phantom is scanned in an MR imaging machine, an optimized flip angle for T1-weighted imaging to improve contrast between white matter and gray matter of the human brain that takes into account proton density differences therebetween can be determined.

Owner:GENERAL ELECTRIC CO

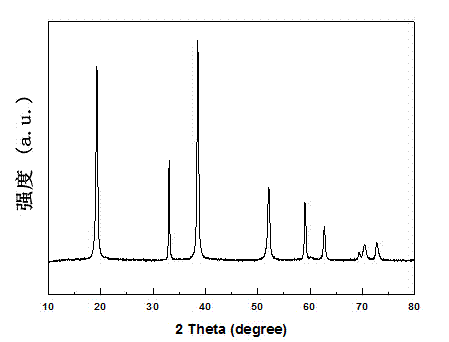

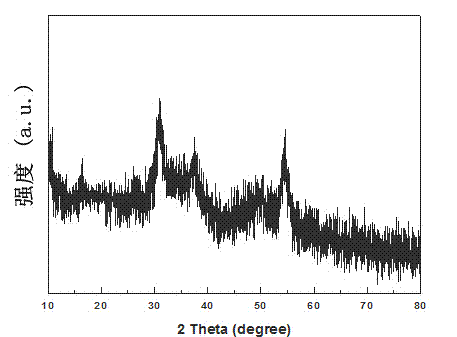

New method for two-step process preparation of nickel sulfide

InactiveCN104261490ASimple production processReaction conditions are easy to controlNickel sulfidesSODIUM SULFIDE NONAHYDRATEHigh pressure

The invention relates to a new method for two-step process preparation of nickel sulfide. The new method comprises the following steps: transferring a water and urea mixed solution of nickel chloride or a water, ammonia water and ethylene glycol mixed solution of nickel chloride into a high-pressure kettle, performing heating reaction at the temperature of 120-160 DEG C for 8-16h, filtering and washing a generated nickel hydroxide precipitate, and drying to prepare a nickel hydroxide precursor; and then dispersing into ethylene glycol, performing ultrasonic dispersion, adding sodium sulfide nonahydrate, transferring into a reactor, performing reflux reaction at the temperature of 160 DEG C for 12-24h, filtering, washing, and performing vacuum drying for 10-12h to prepare nickel sulfide. The new method provided by the invention has the advantages of simple production process, easiness in control of reaction conditions, no need of using a template agent and a surfactant, environmental friendliness and good consistency of the obtained product, is conductive to production of nickel sulfide, and has important practical significance.

Owner:XUZHOU NORMAL UNIVERSITY

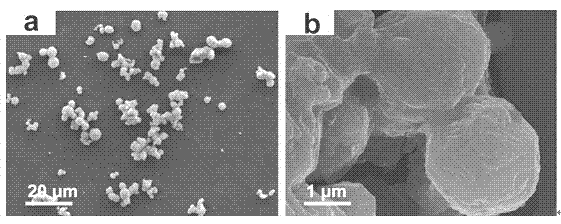

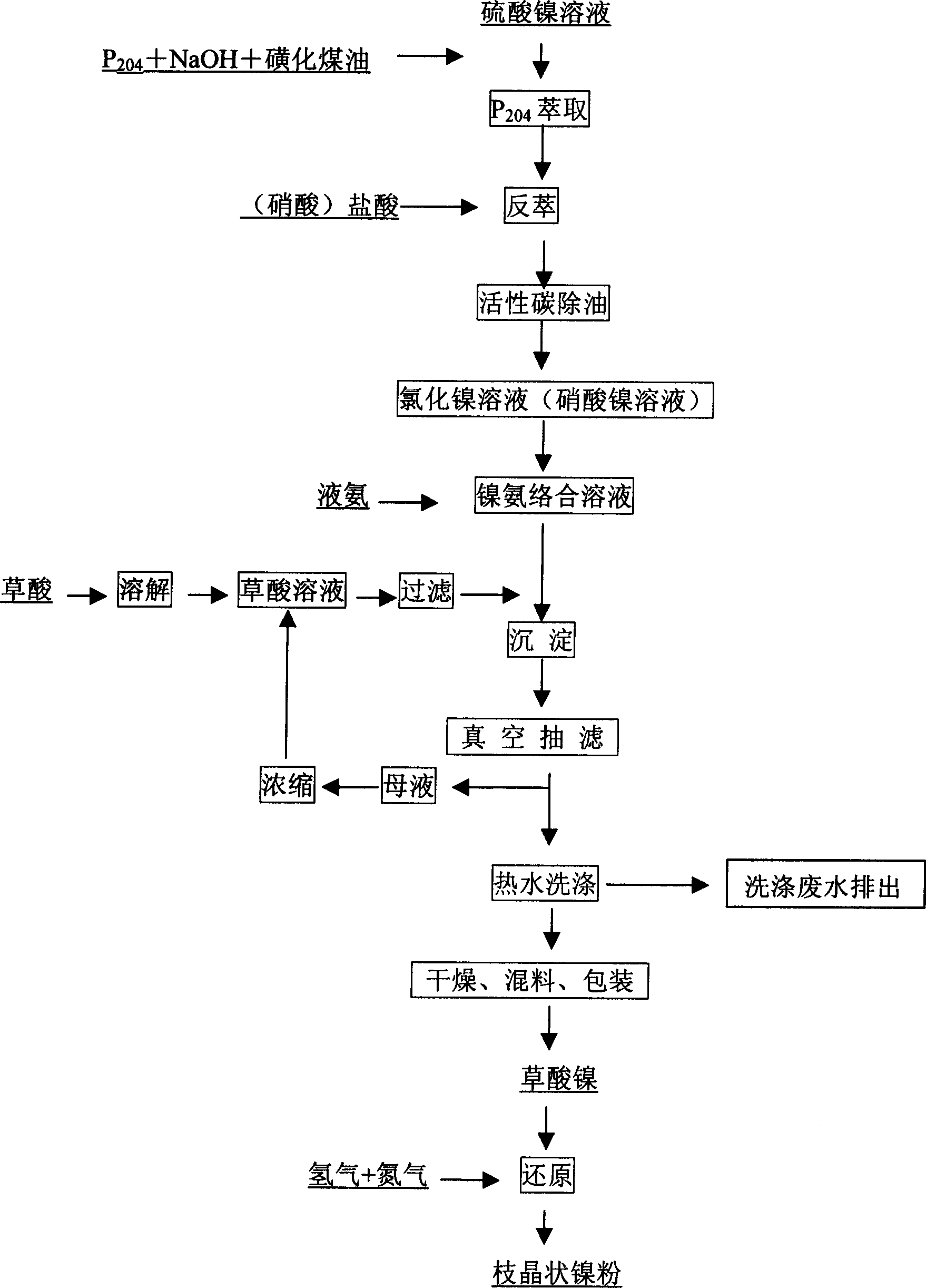

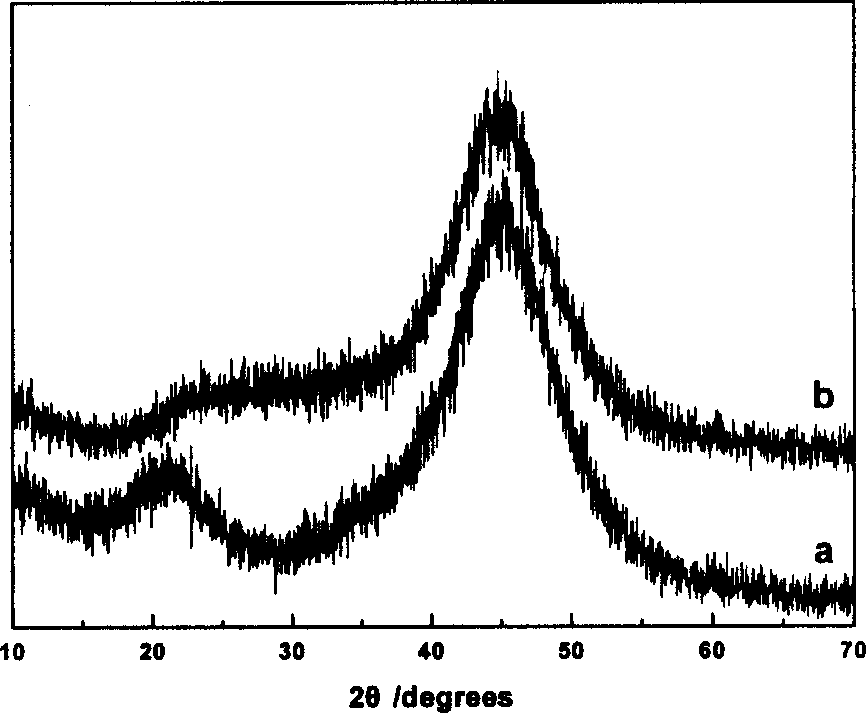

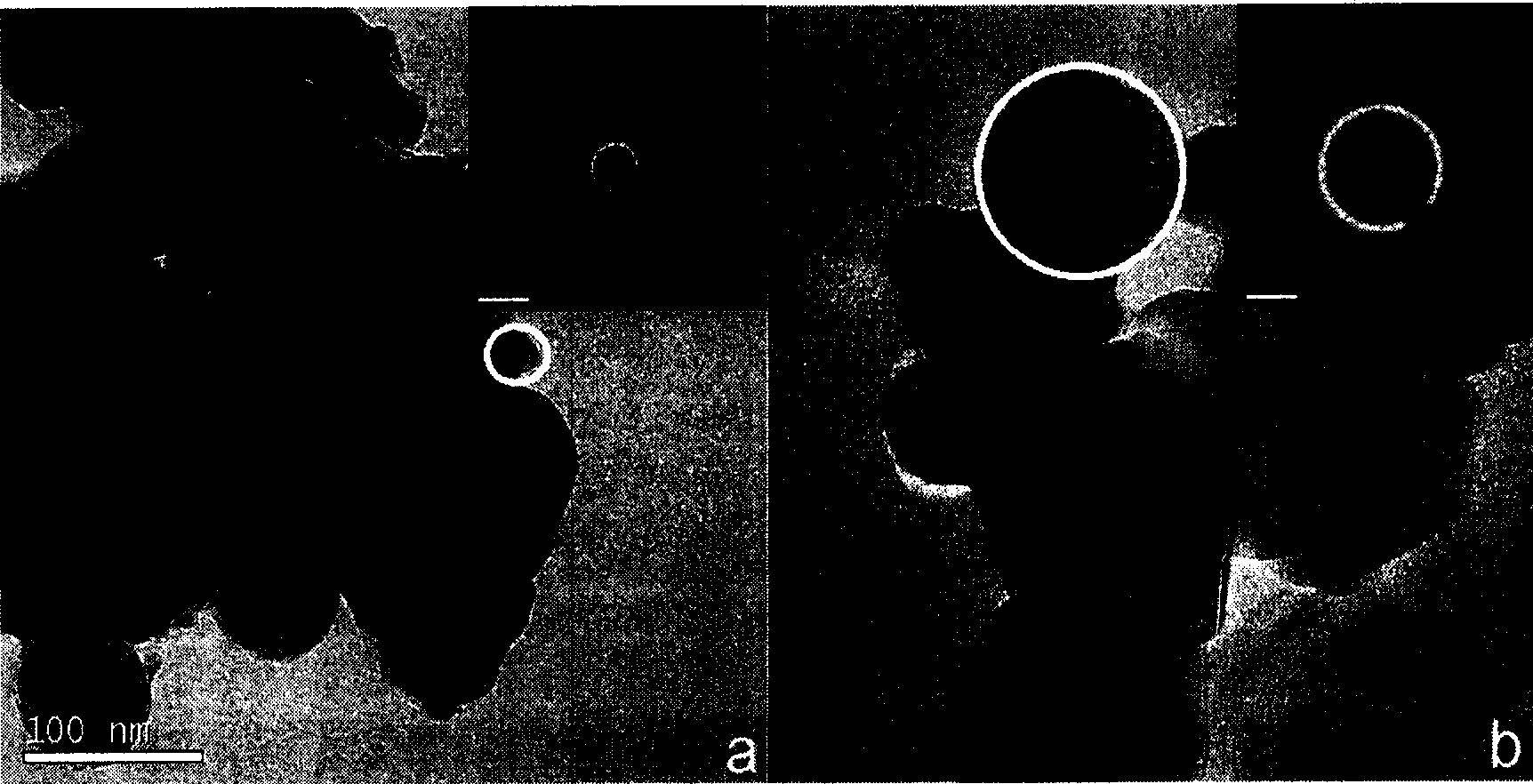

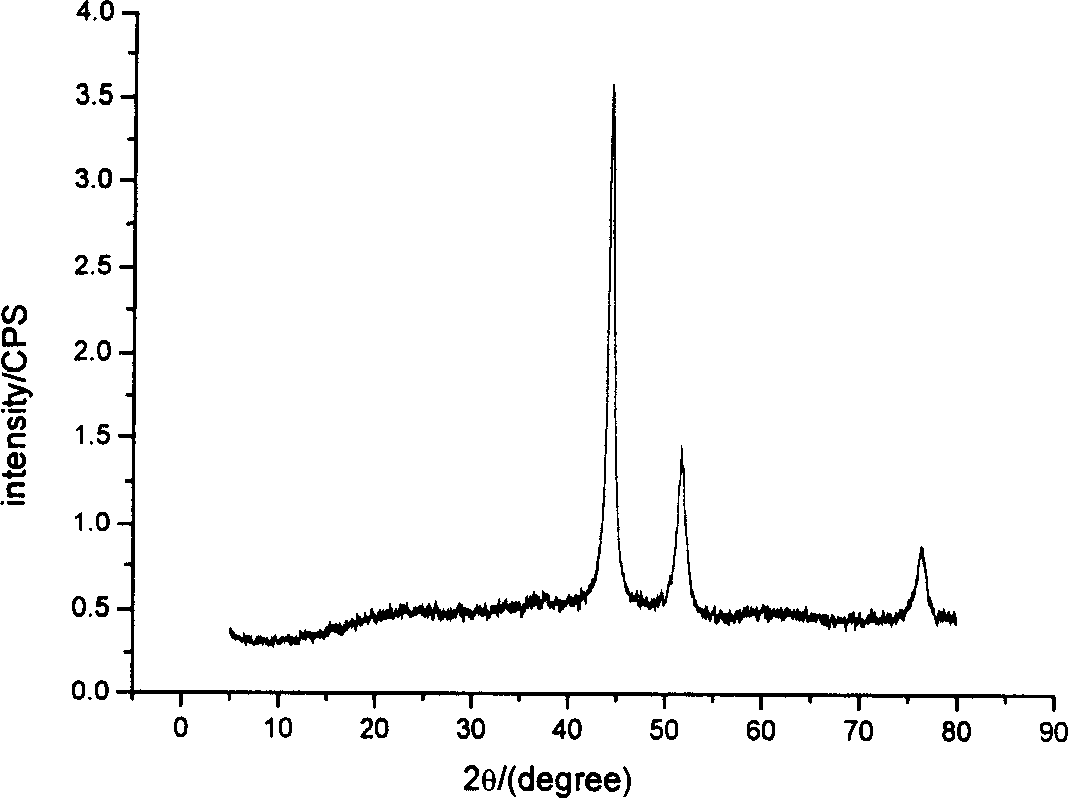

Production method of dentritic morphology nickel powder

A process for preparing the dendritic Ni powder includes such steps as extracting of nickel sulfate solution to become the solution of nickel chloride (or nitrate), preparing nickel-ammonia complex solution, depositing in oxalic acid solution to obtain nickel oxalate, vacuum fitlering, washing, drying, reducing by the mixture of H2 and N2, and pulverizing.

Owner:JINCHUAN GROUP LIMITED

Method for preparing NiB non-crystalline alloy catalyst with the aid of microwave

InactiveCN1792440ACluster size controllableGood dispersionCatalyst carriersHydrocarbon by hydrogenationChemical platingIron(II) chloride

A microwave aided process for preparing the catalyst of non-crystalline NiB alloy suitable for catalytic hydro-reaction with high catalytic active features that the chemical reduction and chemical plating in microwave field is used, KBH4 is used as reducer, its primary salt is chosen from nickel sulfate, nickel acetate, etc, its secondary salt is chosen from cobalt chloride, iron chloride, etc, its carrier is chosen from oxide, molecular sieve, etc, its solvent is chosen from water, tetrahydrofuran, etc and the complex agent, stabilizer and additive is used.

Owner:NANKAI UNIV

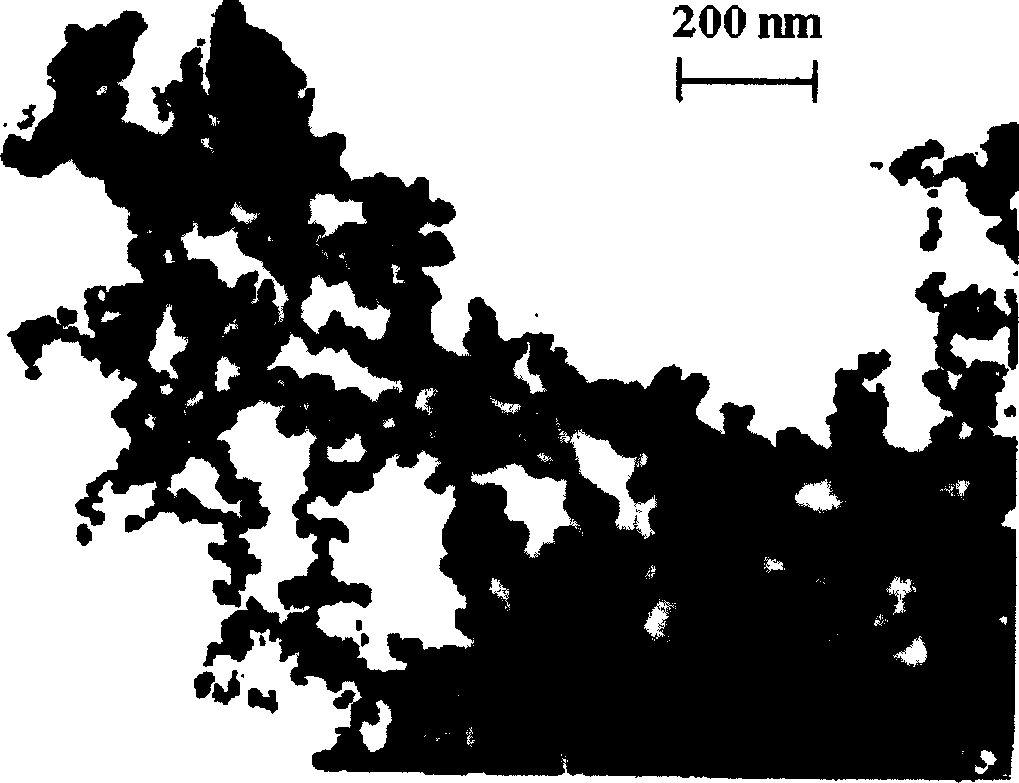

Method for preparing nano nickel powder

InactiveCN102179527AUniform and stable growthReduce pollutionNanotechnologyMaterials scienceReducing agent

The invention provides a method for preparing nano nickel powder. The method comprises the following steps of: mixing nickel nitrate, nickel sulfate or nickel chloride and NaOH or KOH, and dissolving in deionized water to prepare deionized solution; adding surfactant into the solution to obtain stable and uniform Ni(OH)2 colloid; mixing the Ni(OH)2 colloid, a reducing agent NaBH4, or N2H4.H2O, and adding catalyst to prepare Ni(OH)2 size; placing the Ni(OH)2 size into a fluidized bed reactor at the temperature of between 50 and 120 DEG C, and reducing for 1 to 30 minutes, and cooling and suction-filtering to obtain the nickel powder with the grain size of between 20 and 100nm; and desalting the residual reaction liquid and then returning to the fluidized bed reactor. The process can run stably and continuously, is low in energy consumption, is environment-friendly, and achieves zero emission, and the industrial water can be recycled.

Owner:湖南省娄底维亚科技有限公司

Sulfamic acid nickel plating solution and method

The invention relates to a nickel sulfamate electroplating solution which comprises nickel sulfamate, boric acid and nickelous chloride. A formed nickel-plated layer which has favorable stability and is continuous and complete without pinholes, bubble shedding and residual stress is formed after a metal surface is plated by the electroplating solution. The smoothness and the brightness of the obtained plated layer are improved after a certain amount of brightener is added to the electroplating solution so that the metal surface is smoother and more attractive.

Owner:嘉兴中科亚美合金技术有限责任公司

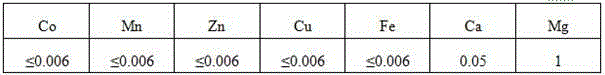

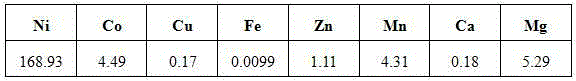

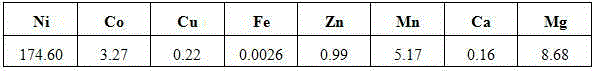

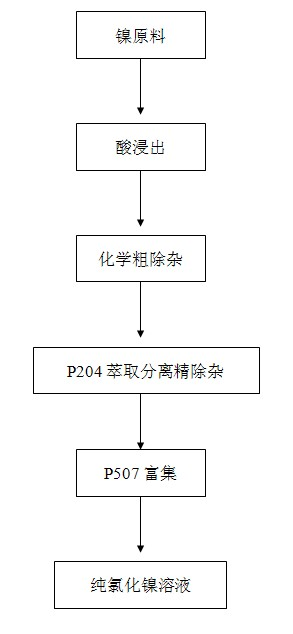

Method of removing impurities out of nickel chloride leachate

The invention discloses a method of removing impurities out of nickel chloride leachate. The method comprises the following steps: in a sequence of extracting metals by using an extraction agent p-507, adding sulfonated kerosene serving as a diluent into p-507; then, sequentially reacting with a NaOH solution and a nickel chloride solution or a nickel sulfate solution; after reaction, carrying out phase separation; and finally, obtaining the extraction agent with the organic nickel load being 14.09-14.43g / L. According to the method disclosed by the invention, p-507 is converted into the extraction agent with the organic nickel load being 14.09-14.43g / L. The extraction agent can further separate impurities such as cobalt, copper, zinc, manganese, calcium and magnesium from the nickel chloride leachate. The nickel chloride extracted by the extraction agent satisfies the production requirements of electroplating-grade nickel chloride products. The method disclosed by the invention is simple, reliable and strongly operable in process and has good removal effect on impurities such as cobalt, copper, zinc, manganese, calcium and magnesium, does not introduce other impurities, expands a novel process of producing electroplating-grade nickel chloride products by nickel cobalt hydroxide raw materials, and has a good economic value.

Owner:金川集团镍盐有限公司

Method for preparing nickel base alloy surface composite plating

The invention relates to a preparation method of a composite plating layer used on the surface of nickel-based alloy, which comprises the following steps: 1) degreasing is carried out; 2) water washing is carried out; 3) acid washing is carried out; a passive film on the surface is pre-removed; activation in hydrochloric acid is carried out; the passive film on the surface of the nickel-based alloy is pre-removed; the concentration of the hydrochloric acid is 20 percent to 36 percent; and the time for activation is 1min to 10min; 4) the removal of the passive film on the surface and the pre-plating of nickel are carried out; activation in a solution containing nickel dichloride and the hydrochloric acid and the cathode electro-deposition of the nickel are carried out; time for activation is 1min to 4min; the content of the nickel dichloride is 120g / l to 480g / l; the content of the hydrochloric acid with the concentration of 20 percent to 36 percent is 60ml / l to 350ml / l; current density is 1A / dm<2> to 10A / dm<2>; and the thickness of a nickel plating layer is less than or equal to 0.1 micron; 5) water washing is carried out; and 6) nano copper-tin is prepared; an electro-deposition method is applied to prepare a nano copper-tin plating layer on the coupling surface of a nickel-based alloy oil bushing. The preparation method carries out the pre-plating of nickel on the coupling surface of the nickel-based alloy oil bushing at first and then plates a copper-tin alloy, thereby improving the anti-sticking performance of a connector of the oil bushing and meeting the requirement for completeness of the oil bushing in the aspect of screwing on and screwing off repeatedly.

Owner:BAOSHAN IRON & STEEL CO LTD

Rare earth-nickel-cobalt-boron multi-element alloy anticorrosion and wear-resistant plating, electroplating liquid and preparation method of electroplating liquid

The invention provides a rare earth-nickel-cobalt-boron multi-element alloy anticorrosion and wear-resistant plating, an electroplating liquid and a preparation method of the electroplating liquid. The plating is of an amorphous mingled nanocrystalline structure, and the microhardness of the plating is HV700-HV1300; and the plating comprises the following components by weight percent: 1wt%-40wt% of cobalt, 0.1wt%-1.5wt% of boron and the balance of nickel and trace rare earth. The electroplating liquid comprises the following components: 180-250g / L of nickel sulfate, 20-50g / L of cobalt sulfate, 30-60g / L of nickel chloride, 2-4g / L of dimethylamine-borane, 30-50g / L of boric acid, 0.001-2g / L of rare earth, 3-5g / L of sodium tartrate, 10-30g / L of sodium citrate or citric acid, and deionzied water which is added to achieve a metered / constant volume. The preparation method of the electroplating liquid comprises the following steps: dissolving nickel sulfate, cobalt sulfate, boric acid and nickel chloride with the deionized water and regulating the pH value; and adding sodium citrate or citric acid, sodium tartrate, rare earth and dimethylamine-borane for the constant volume and sufficiently stirring. The preparation method of electroplating liquid is simple to operate, is high in current efficiency and energy-saving and environmentally-friendly; and the plating is of the amorphous mingled nanocrystalline structure, and has bright, smooth and flaw-free appearance, extremely low porosity, high hardness and good anticorrosion and wear-resistant properties and comprehensive mechanical properties.

Owner:黄激扬

Purification method of cobalt nickel hydroxide hydrochloric acid leaching solution

ActiveCN104073633AImprove qualityReduce usageProcess efficiency improvementPregnant leach solutionSulfate radicals

The invention discloses a purification method of a cobalt nickel hydroxide hydrochloric acid leaching solution. The purification method mainly comprises the following processing steps: I. dissolving and leaching a cobalt nickel hydroxide raw material produced by laterite-nickel ore transformation through industrial concentrated hydrochloric acid; II. adding barium chloride to a leaching solution and implementing sulfate radical removal operation; filter-pressing the solution and reserving the solution as an extracting pre-solution for later use; III. preparing an organic phase at ratio of 25% to 75% of P5O7 to sulfonated kerosene; saponifying the prepared organic phase in a soda soap kettle; reacting the saponified organic phase with a pure nickel chloride solution to obtain nickel soap; and IV. extracting the nickel chloride extracting pre-solution obtained from the step II through the P507 nickel soap, wherein the extracting solution obtained is a finished pure nickel chloride solution. The production process disclosed by the invention is safe and the extracting solution produced is better in component; and moreover, the purification method is short in technological process and more effective in process control.

Owner:JINCHUAN GROUP LIMITED

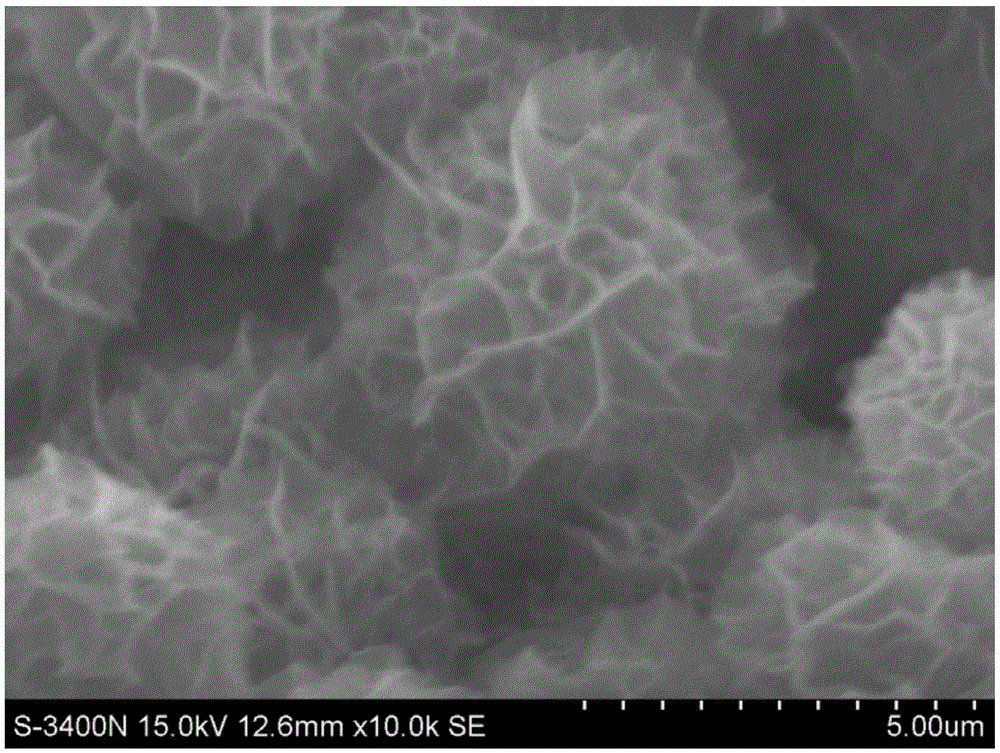

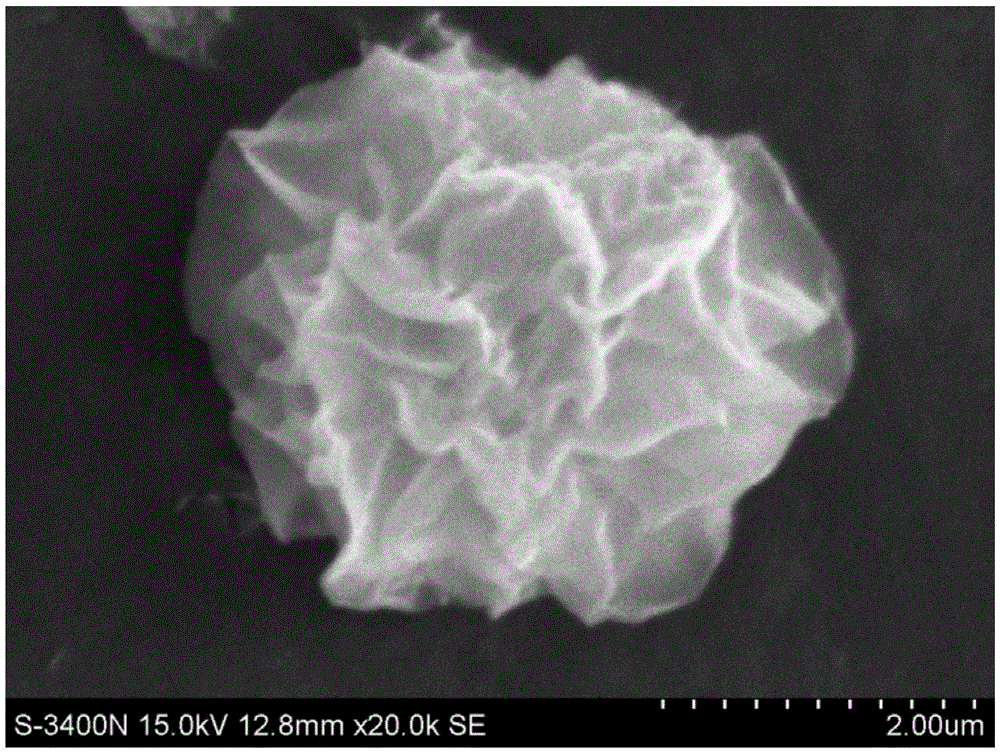

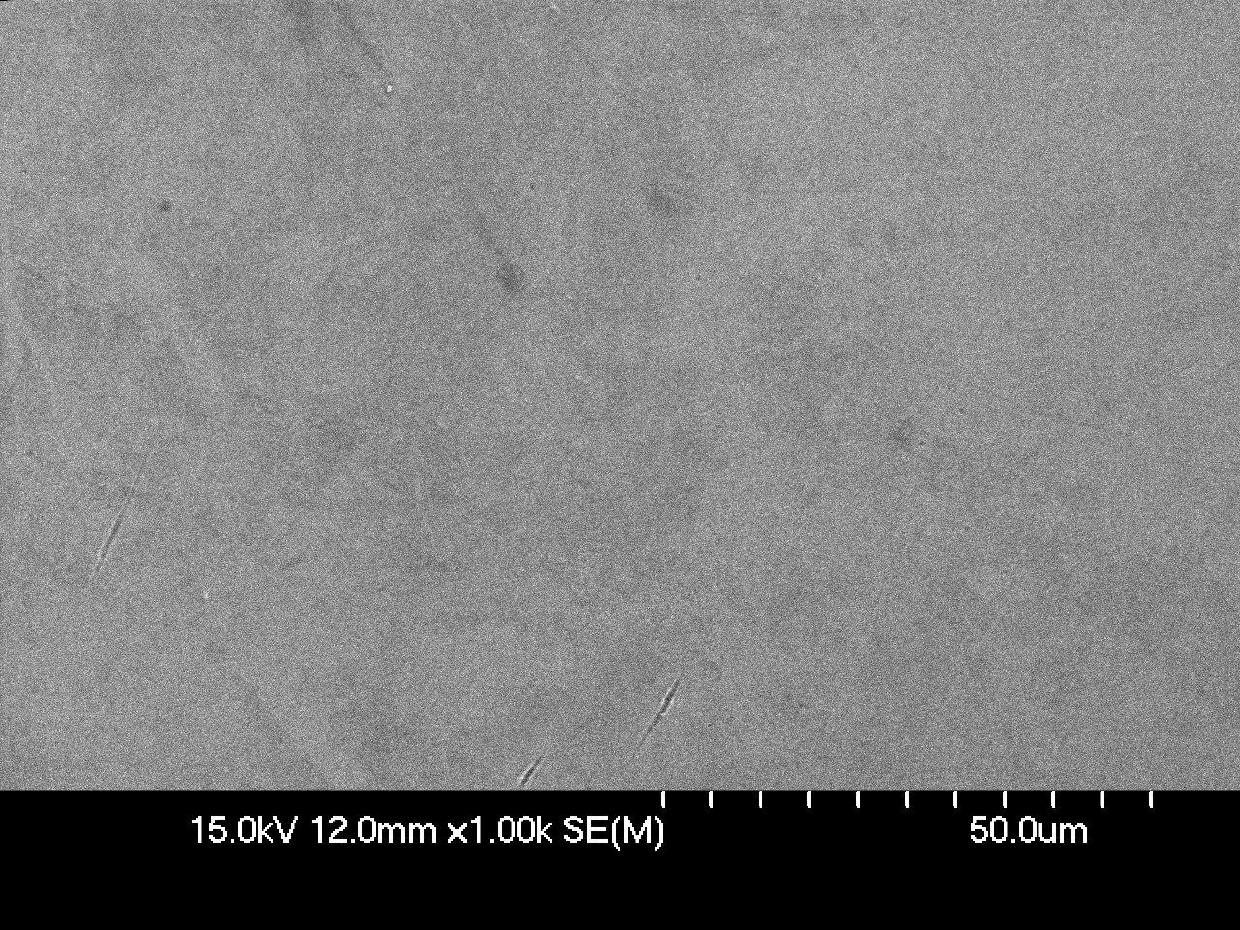

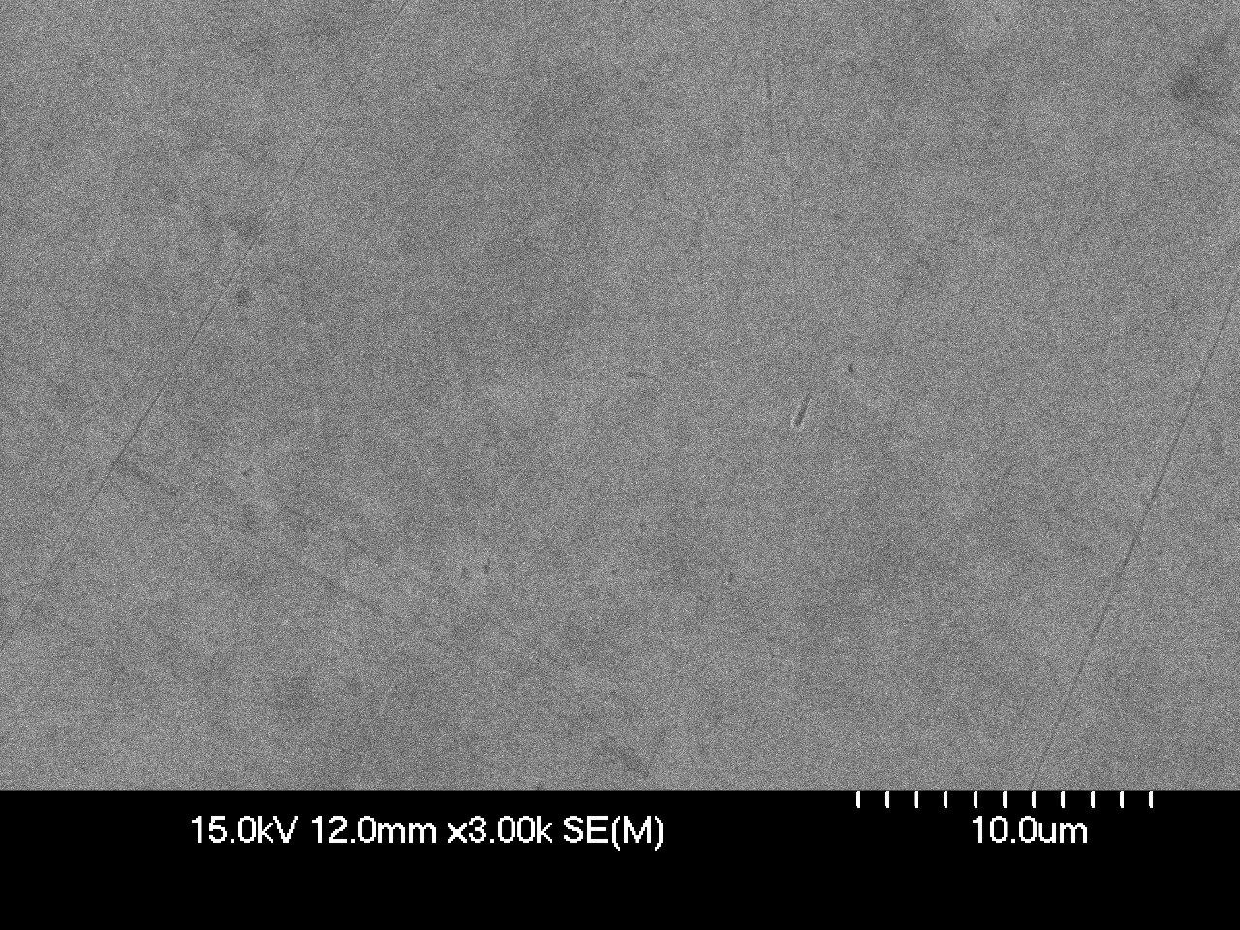

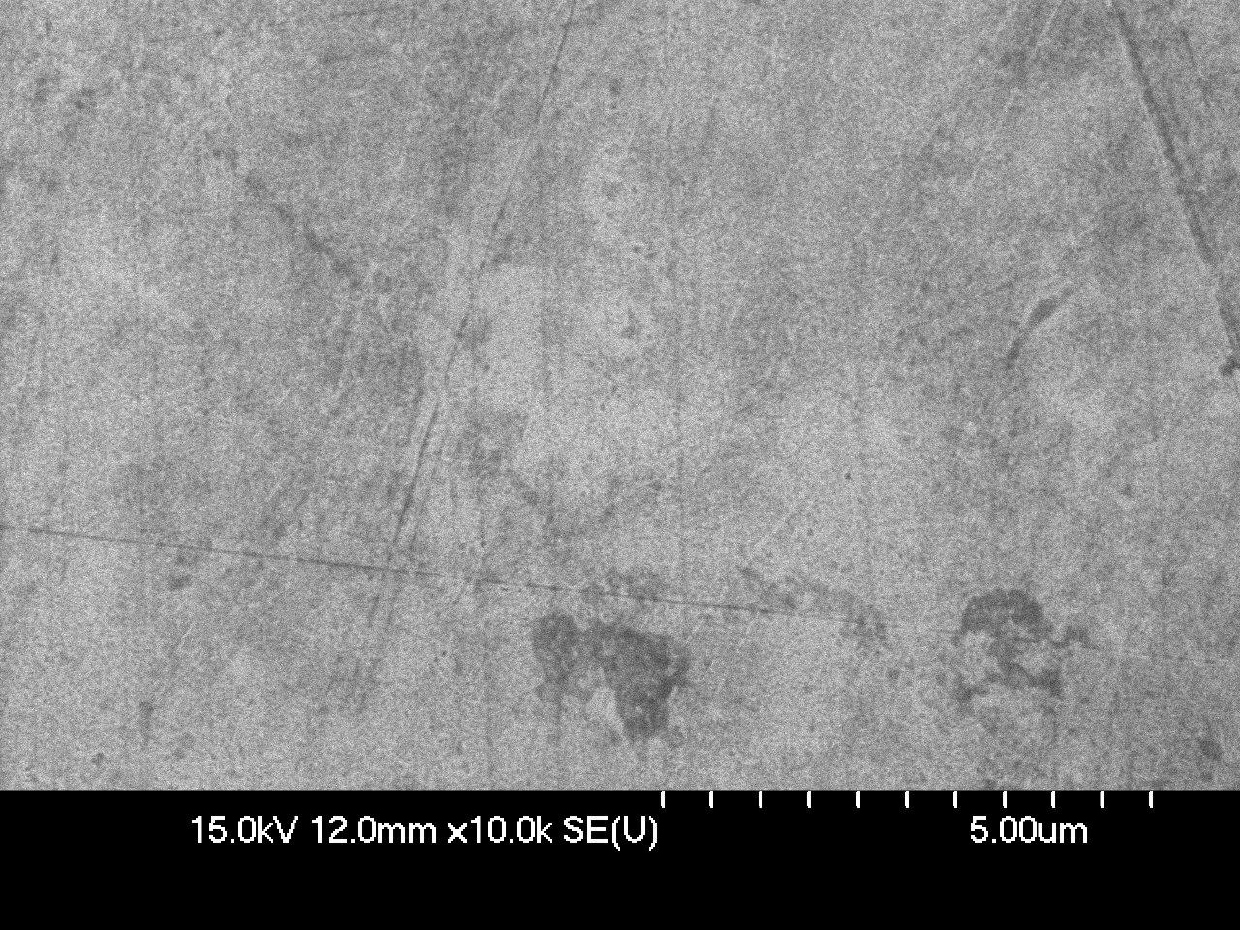

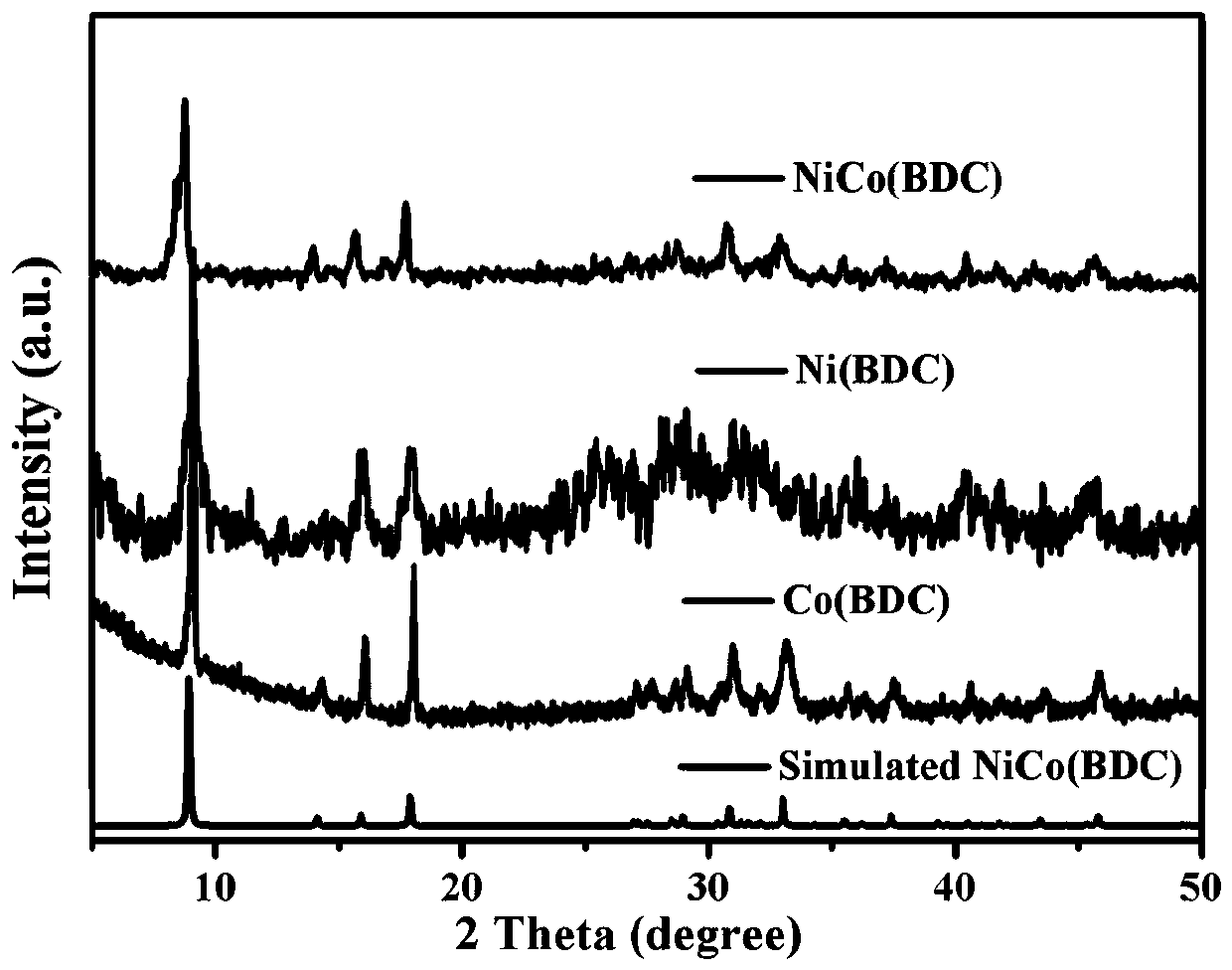

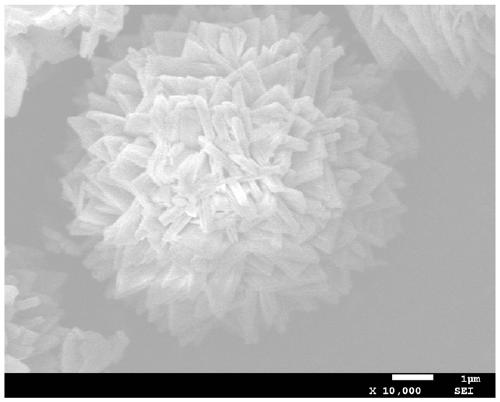

A preparing method and application of a three-dimensional nanoflower metal-organic framework material

ActiveCN109553779AThe synthesis method is simpleLow priceHybrid capacitor electrodesHybrid/EDL manufactureMetal-organic frameworkTerephthalic acid

The invention belongs to a metal-organic framework material, and discloses a composite nanometer metal-organic framework material which has a spherical three-dimensional nanoflower structure and whichis formed by self-assembling of metal ions and an organic component, and application of the material in super-capacitor performance. A one-step synthesis technique is adopted, and self-assembling ofa terephthalic acid organic ligand, cobalt chloride and nickel chloride in a mixture solution consisting of N,N-dimethyl formamide, ethanol and water is utilized to obtain the metal-organic frameworkspherical nanoflower structure with uniform distribution dimension and size and with a diameter of 7-12 [mu]m. Similar nanometer materials can be synthesized by the method. In addition, the metal-organic framework material has a high number of active sites and has good electrical conductivity, so that the metal-organic framework material has good super-capacitor performance.

Owner:CHINA THREE GORGES UNIV

Satin nickel solution and nickel plating process thereof

The invention discloses a satin nickel solution and a nickel plating process thereof. The formula of the satin nickel solution comprises the following components in proportion by weight and volume: 280g / L-380g / L of nickel sulfate, 42g / L-58g / L of nickel chloride, 31g / L-38g / L of boric acid, 3ml / L-7ml / L of a brightener, 8ml / L-15ml / L of a surfactant, 1ml / L-5ml / L of a softening agent, 2ml / L-4ml / L of a walking agent, and 0.2g / L-10g / L of water soluble fiber, wherein the length of the water soluble fiber is 2mm-4mm. For guaranteeing the nickel plating effect of the satin nickel solution, the nickel plating process comprises the following steps: (1) polishing the surface of the to-be-nickel plated material by virtue of 500-1000-mesh sand, so as to increase the specific surface area and roughness of the surface of the to-be-nickel plated material and the adhesive force of a satin nickel plated layer; and (2) carrying out surface nickel plating by taking the to-be-nickel plated material as a cathode and a nickel plate as an anode, so as to guarantee the use effects of the brightener, the surfactant, the softening agent, the walking agent and the water soluble fiber, wherein the temperature is controlled at 42-48 DEG C, the pH value is controlled at 3-5, and the electric current density is controlled at 3A / dm<2>-8A / dm<2>.

Owner:YIDONG ELECTRONICS CHANGSHU

Production for nanometer nickel powder

A process for preparing the Ni nanoparticles includes such steps as adding the solution of sodium borohydride to the alcohol solution of nickel chloride, reacting, adding the pasty mixture of sodium hydroxide and hydrazine hydrate, reacting, separating the product, washing and drying. Its advantages are high purity, uniform and controllable granuality, and high specific surface area.

Owner:NANJING UNIV

Extraction purification method of cobalt nickel hydroxide hydrochloric acid leaching solution

ActiveCN104313323AImprove removal efficiencyMeet production requirementsProcess efficiency improvementKeroseneHydrometallurgy

The invention relates to the technical field of non-ferrous metal smelting hydrometallurgy and discloses an extraction purification method of cobalt nickel hydroxide hydrochloric acid leaching solution. The extraction purification process of the cobalt nickel hydroxide hydrochloric acid leaching solution comprises five links of soda saponifying, nickel saponifying, extraction purifying, organic load nickel washing and reverse extracting. P507 is selected from chloride media to be used as an extraction agent, a megilp (or sulfonated kerosene) is used as a diluting agent, the extraction agent and the diluting agent are used as organic phase, and the flow ratio of the organic phase to water phase is controlled according to different combining capacities of various metal ion extraction agents so that impurity metal ions in the solution are combined with the organic phase to be separated from garget metal Ni ions, and metal ions of Co, Cu, Ca, Mg, Mn, Zn and Fe in the cobalt nickel hydroxide hydrochloric acid leaching solution are further removed so that the cobalt nickel hydroxide hydrochloric acid leaching solution is deeply purified. The extraction purification method provided by the invention is simple in process flow and high in impurity removal efficiency, and the quality of prepared nickel chloride solution meets production requirements of an electroplating grade nickel chloride product.

Owner:JINCHUAN GROUP LIMITED

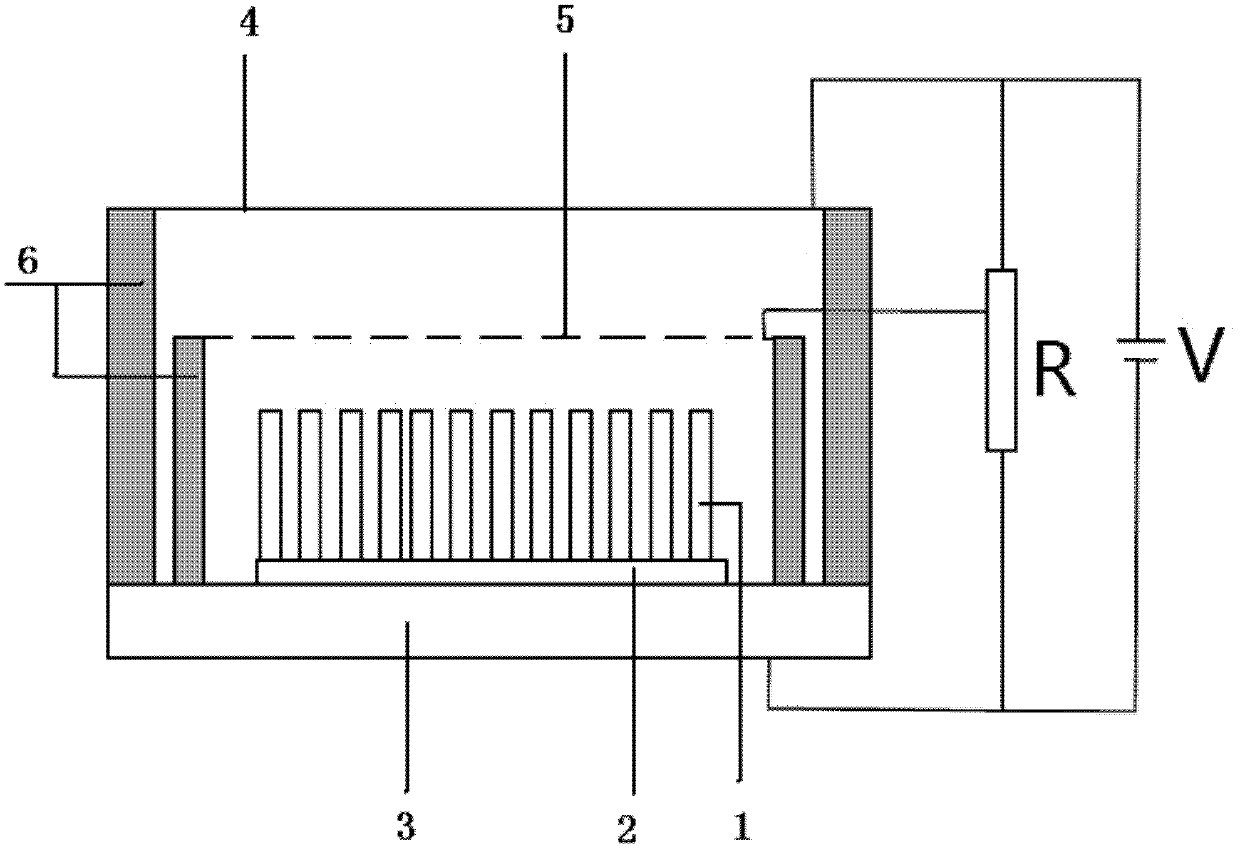

Preparation method of carbon nanotube field emission cathode

ActiveCN102386042AReduce hole diameterHigh aspect ratioCold cathode manufacturePhosphoric acidEvaporation

The invention relates to a preparation method of a carbon nanotube field emission cathode and belongs to the field of nanomaterial preparation and application. The method comprises the following steps of: preparing a porous anodized aluminum template by secondary anodic oxidation process, soaking the template in a nickel chloride or cobalt chloride solution, taking out and air-drying to obtain a template (2); preparing carbon nanotubes in the pores of the template (2) by chemical vapor deposition process to obtain a template (3); adding dropwise a phosphoric acid solution to the surface on which the carbon nanotubes are not deposited to obtain a template (4); forming a silver coating on a stainless steel substrate by evaporation and then sticking the carbon nanotube-grown surface of the template (4) onto the silver coating, to produce the carbon nanotube field emission cathode. The pressure reduction method is adopted in the late stage of the preparation of the porous anodized aluminum template, so as to reduce the diameters of the pores at the bottom of the porous anodized aluminum template and thus to increase the length-diameter ratio of the carbon nanotubes and improve the field emission characteristics of the carbon nanotube field emission cathode.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

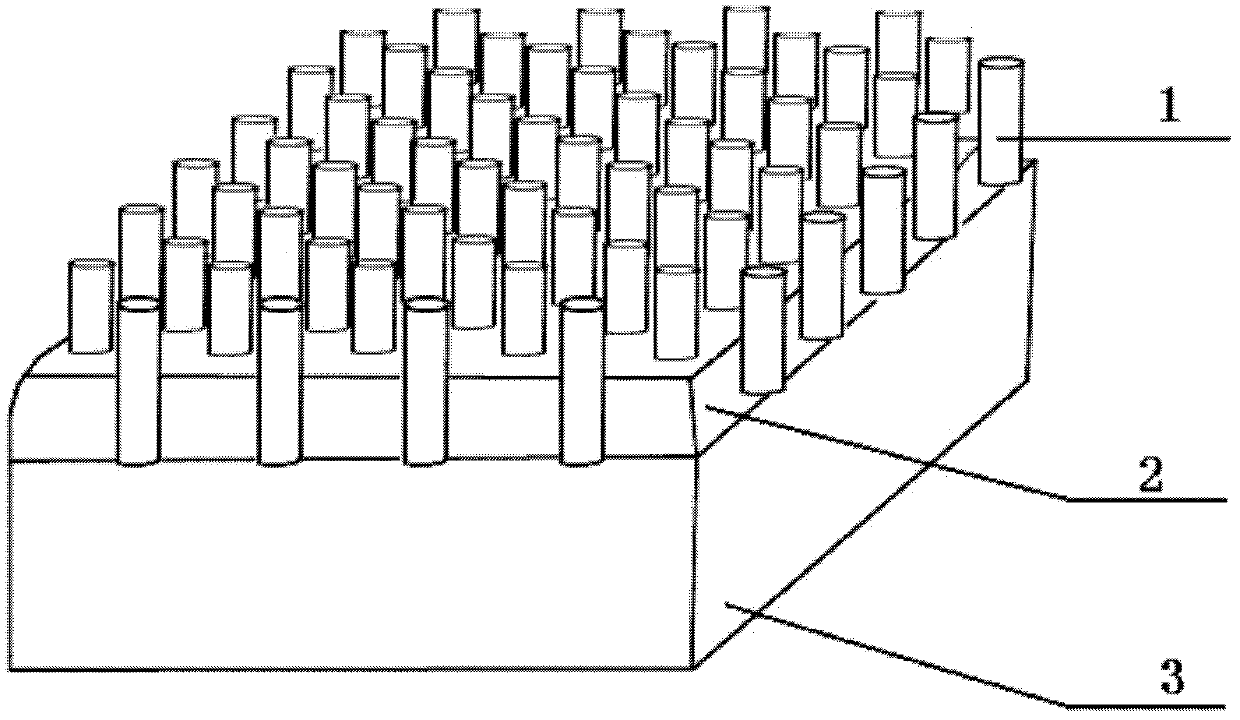

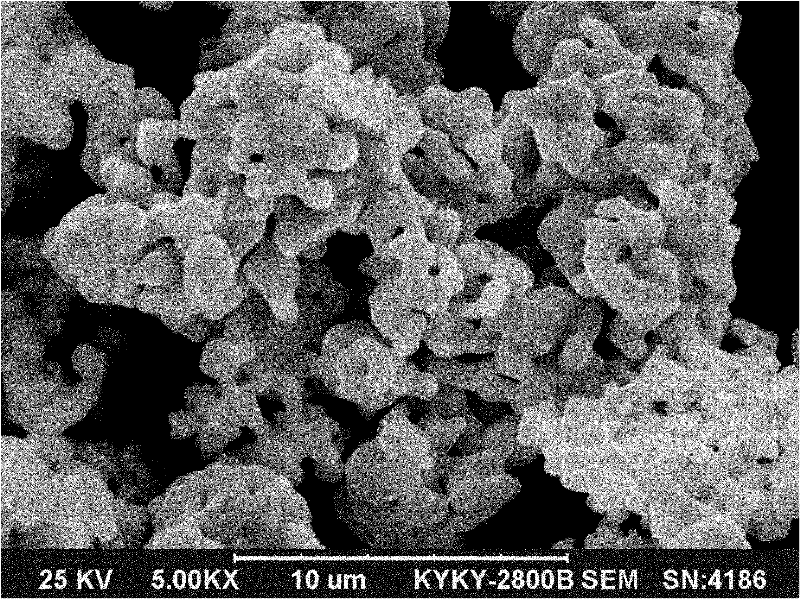

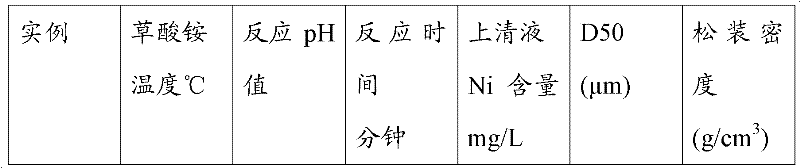

Nickel powder with large furnace safety supervision system (FSSS) particle size and preparation method thereof

ActiveCN102649161ALarge particle sizeHigh purityTransportation and packagingMetal-working apparatusOxalateApplication areas

The invention is suitable for the technical field of metallurgy and provides nickel powder with large furnace safety supervision system (FSSS) particle size and a preparation method thereof. The preparation method of the nickel powder comprises the following steps that: ammonium oxalate and nickel chloride react for 10 to 30 minutes under the conditions that the temperature is 50 to 60 DEG C and the pH value is 1.5 to 3.0 so as to obtain nickel-oxalate precipitates; the operations of flashing, drying and crushing are carried out on the nickel-oxalate precipitates so as to obtain a nickel-oxalate precursor; the treatment of reducing is carried out on the nickel-oxalate precursor under the condition that the temperature is 450 to 550 DEG C so as to obtain a nickel powder precursor; and the operation of turbine crushing is carried out on the nickel powder precursor, and then the operation of airflow crushing is carried out so as to obtain the nickel powder. The nickel powder prepared by the preparation method provided by the invention has large FSSS particle size, small D50 particle size, narrow particle-size distribution and high purity and is in a porous class spherical pattern, the performance approaches to the T123 carboxylic nickel powder of the INCO company, and the requirement of performance of powder metallurgy and the like can be met. The nickel powder has extensive application field. The preparation method provided by the invention is simple to operate, has low requirement to equipment and high production benefit, is friendly to the environment and is very suitable for industrialized production.

Owner:JINGMEN GEM NEW MATERIAL +1

Nickel-contained materials abstraction and type-reverting production method of nickel salt

InactiveCN101139112AReduce demandRelieve production pressureNickel halidesNickel ammonia complexesNickel saltSulfamic acid

An extraction and transformation method to produce nickel salt with material containing nickel relates to an extraction and transformation technology with nickel salt medium solution in the preparation process of nickel salt products, in particular to the preparation of nickelous chloride and nickel sulfamic acid. The present invention is characterized in that the nickel salt solution after purified is extracted by P204 extracting agent and the main metal nickel is led into an organic phase and then the organic phase is back extracted by various acid solution. The nickel is transferred into outer nickel salt solution and then produced to other nickel salt products after the procedures of depth decontamination, evaporating and crystallization. The present invention can enlarge the material range of nickel salt products, greatly improve working environment and save production cost.

Owner:JINCHUAN GROUP LIMITED

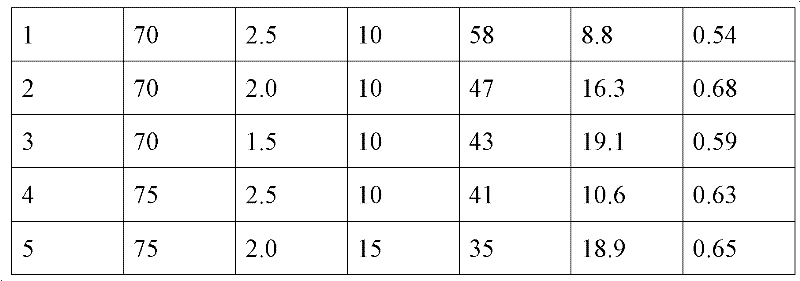

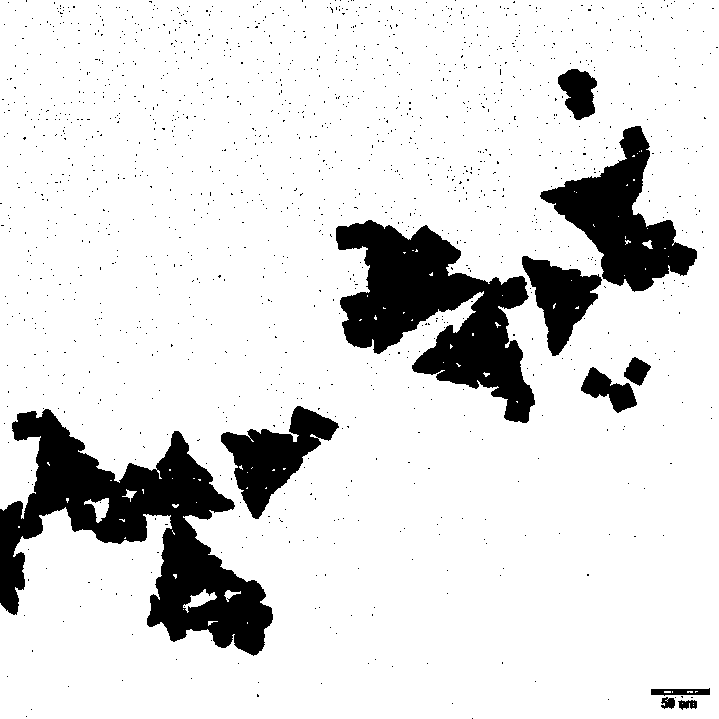

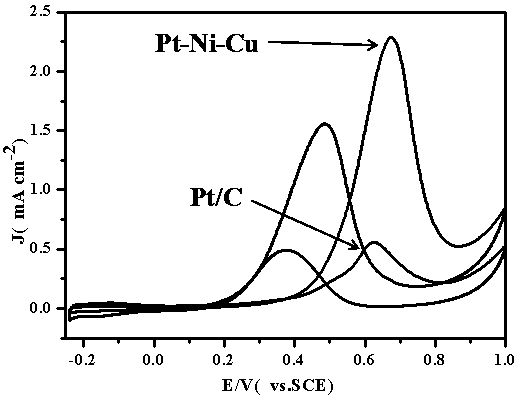

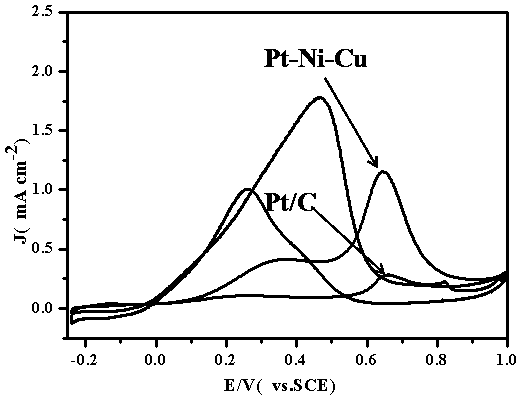

Method for preparing dendritic Pt-Ni-Cu alloy nano-particles

InactiveCN108786845AHigh selectivityHigh active site densityMaterial nanotechnologyCell electrodesAlloyReducing agent

The invention discloses a method for preparing dendritic Pt-Ni-Cu alloy nano-particles. Chloroplatinic acid, copper chloride and nickel chloride are taken as raw materials, glycine and methyl are taken as double reducing agents, polyvinylpyrrolidone is taken as a protective agent and stabilizer, dendritic Pt-Ni-Cu alloy nano-particles with higher selectivity are prepared, and the preparation method is green and clean. The step atoms of the obtained dendritic Pt-Ni-Cu alloy nano-particles are many, the active site density is high, excellent methyl and formic acid electrochemical activities areshown, and the dendritic Pt-Ni-Cu alloy nano-particles have a wide application prospect.

Owner:UNIV OF JINAN

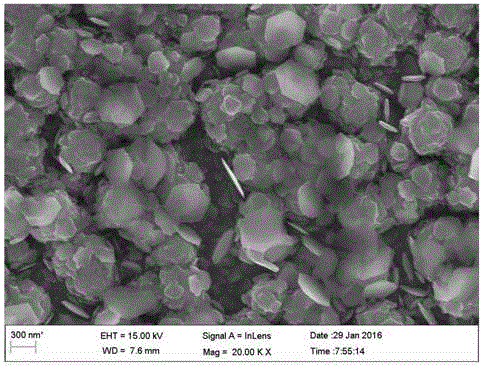

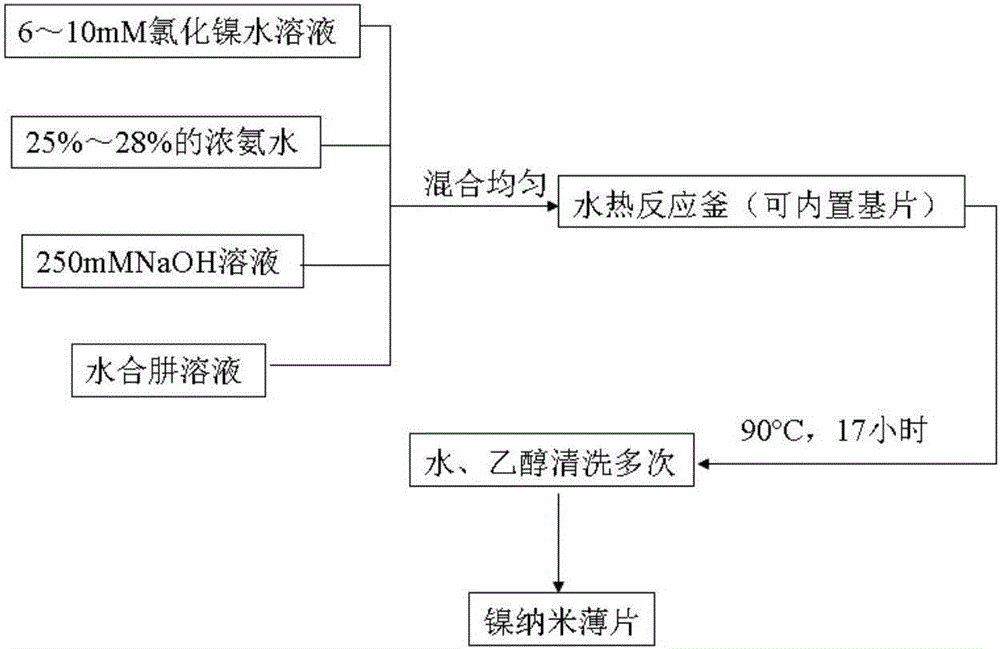

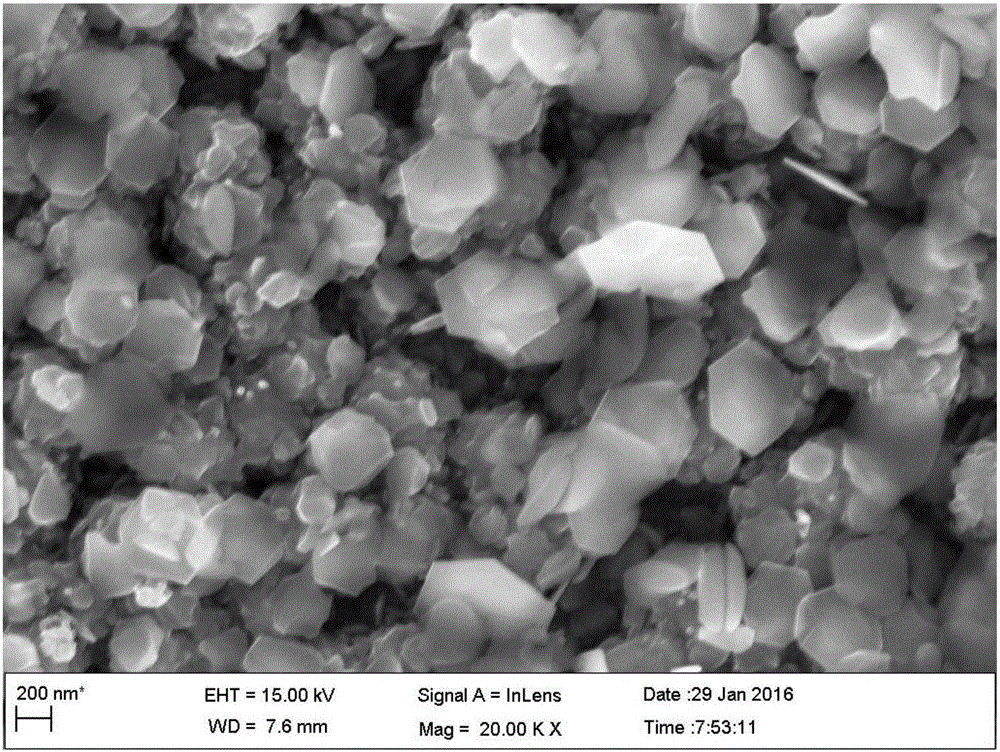

Preparation method of metal nanosheets

InactiveCN106735304ALarge horizontal sizeIncreasing the thicknessTransportation and packagingMetal-working apparatusActive agentChemistry

The invention discloses a preparation method of metal nanosheets. The preparation method comprises the steps that 1, strong ammonia water is added into a nickel chloride solution, a NaOH solution is added, a hydrazine hydrate solution is added, the solutions are stirred and mixed to be uniform, and a mixed solution is obtained; 2, a substrate can be placed in a lining of a hydrothermal reaction kettle, the mixed solution is transferred into the lining of the hydrothermal reaction kettle, the hydrothermal reaction kettle is sealed, the constant temperature ranging from 80 DEG C to 120 DEG C is kept for 12-24 hours, and crude nickel nanosheets or crude nickel nanosheets growing on the substrate are obtained; 3, the crude nickel nanosheets are repeatedly cleaned multiple times in pure water and ethyl alcohol, drying is conducted, and the nickel nanosheets are obtained. According to the preparation method, the nickel metal nanosheets are obtained through spontaneous growth by means of a mild organic surfactant-free method, the thickness of the nickel metal nanosheets can be controlled to be 10 nanometers or below, the prepared nickel nanosheets are high in quality, the surfaces of the nickel nanosheets are not covered with active agents, and the nickel nanosheets are low in cost and suitable for mass production.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Composition for repairing surfaces of metallic rubbing pairs and preparation thereof

InactiveCN101412943AReduce repair costsReduce difficultyAdditivesRestorative materialPhysical chemistry

The invention provides a composition for restoring the surface of a metallic rubbing pair and a preparation method thereof, and relates to the composition for restoring the surface of the metallic rubbing pair and the preparation method thereof. The invention solves the problem that the restoring film formed by the prior restoring material has limited thickness which can not reach over 0.5 millimeter and can not effectively control the clearance between the metallic rubbing pair. The composition consists of nickelous chloride powder, aluminum powder, nickel powder, ferric oxide powder, silicon dioxide powder, a powder suspending agent, a surface modifier and mineral lubricating oil. The preparation method is to put the nickelous chloride powder, the aluminum powder, the nickel powder, the ferric oxide powder, the silicon dioxide powder, the powder suspending agent, the surface modifier and the mineral lubricating oil in a high-speed viscolizer to be homogenized for 30 to 40 minutes. The composition for restoring the surface of the metallic rubbing pair and the preparation method thereof realize restoring modification to the surface of the metallic rubbing pair of which a restoration layer reaches 1.5 millimeters, and effectively control the clearance between the metallic rubbing pair.

Owner:三亚圣龙新材料开发有限公司

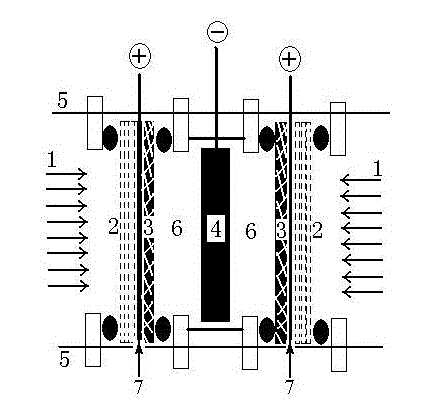

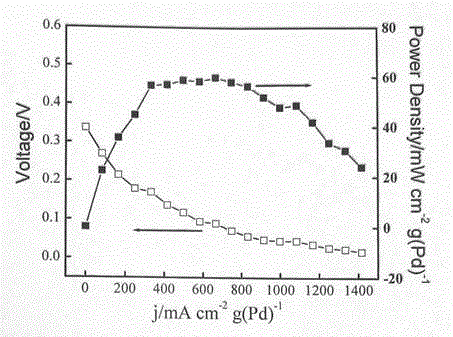

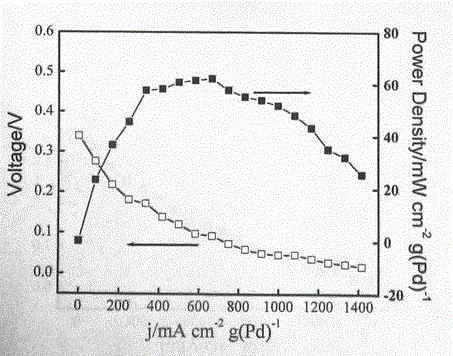

Maskless direct alcohol fuel cell and preparation method thereof

InactiveCN102916209AImprove electrocatalytic activityImprove performanceFinal product manufactureCell electrodesNano catalystElectrolytic agent

The invention discloses a maskless direct alcohol fuel cell and a preparation method thereof. The main content disclosed by the invention comprises the steps of (1) firstly, restoring palladium chloride and nickel chloride by sodium borohydride reductant by adjusting the pH value of mixed solution of the palladium chloride, the nickel chloride and a multi-wall carbon nano tube, preparing PdNi nano-catalyst particles (PdNi / MWCNT) loaded by the multi-wall carbon nano tube; (2) taking ethanol as a solvent, preparing AgCo catalyst particles (AgCo / MWCNT) loaded by the multi-wall carbon nano tube by a hydrothermal method; (3) preparing an anode sheet from the PdNi / MWCNT particles, and preparing the gas diffusion electrode from the AgCo / MWCNT particles, and (4) forming the maskless direct alcohol fuel cell by the anode and the gas diffusion electrode, wherein the electrolyte is sodium hydroxide solution containing alcohol. The maskless direct alcohol fuel cell disclosed by the invention adopts non-platinum metal (palladium-nickel or silver-cobalt) as an electrode material, and is strong in electrocatalytic activity, and stable in performance; the ion exchange membrane is not used, and the battery cost is greatly reduced.

Owner:HUNAN UNIV OF SCI & TECH

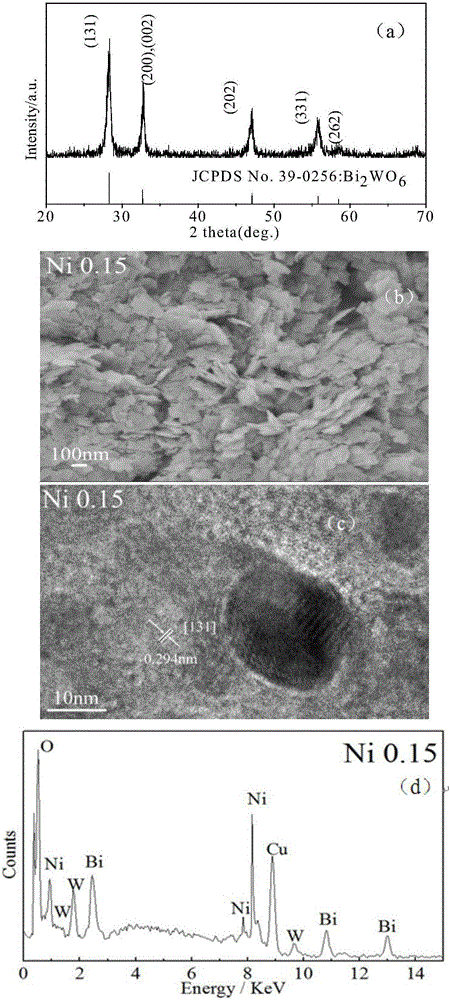

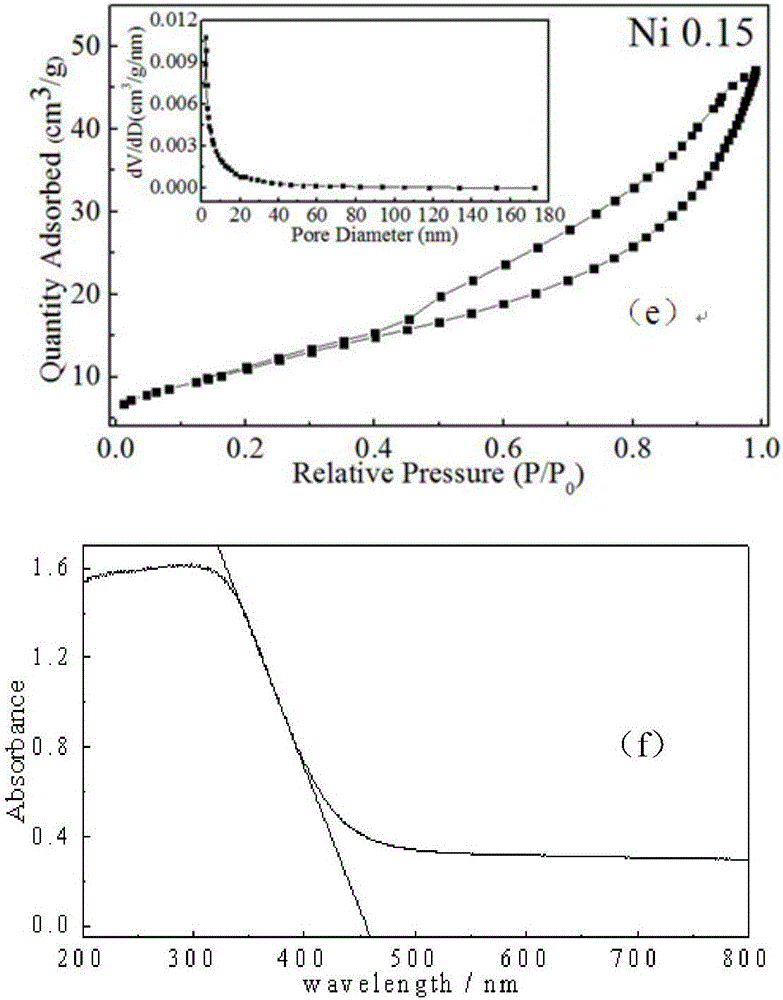

Nickel doped nanometer bismuth tungstate visible-light photocatalyst, and preparation and application thereof

InactiveCN106622271AImprove adsorption capacityImprove photocatalytic abilityWater/sewage treatment by irradiationWater treatment compoundsOrganic dyeTungstate

The invention belongs to the field of environmental photocatalysis research, and specifically discloses a nickel doped nanometer bismuth tungstate visible-light photocatalyst, and a preparation method and an application thereof. The nickel doped nanometer bismuth tungstate visible-light photocatalyst comprises nickel and tungsten with a mol ratio of 1: 20 to 1: 2. The preparation method comprises the following concrete steps: preparing a sodium tungstate aqueous solution, adding nickel chloride tetrahydrate and bismuth nitrate into the sodium tungstate aqueous solution, carrying out a reaction so as to form a precursor, transferring the precursor into a hydrothermal reactor with a polytetrafluoroethylene liner, then carrying out a reaction, and subjecting a reaction product to washing, centrifugation and drying so as to obtain a Ni-Bi2WO6 catalyst. The catalyst provided by the invention has good specific surface adsorption performance, and can realize highly-efficient catalytic degradation of organic dyes in water under visible light.

Owner:JINAN UNIVERSITY

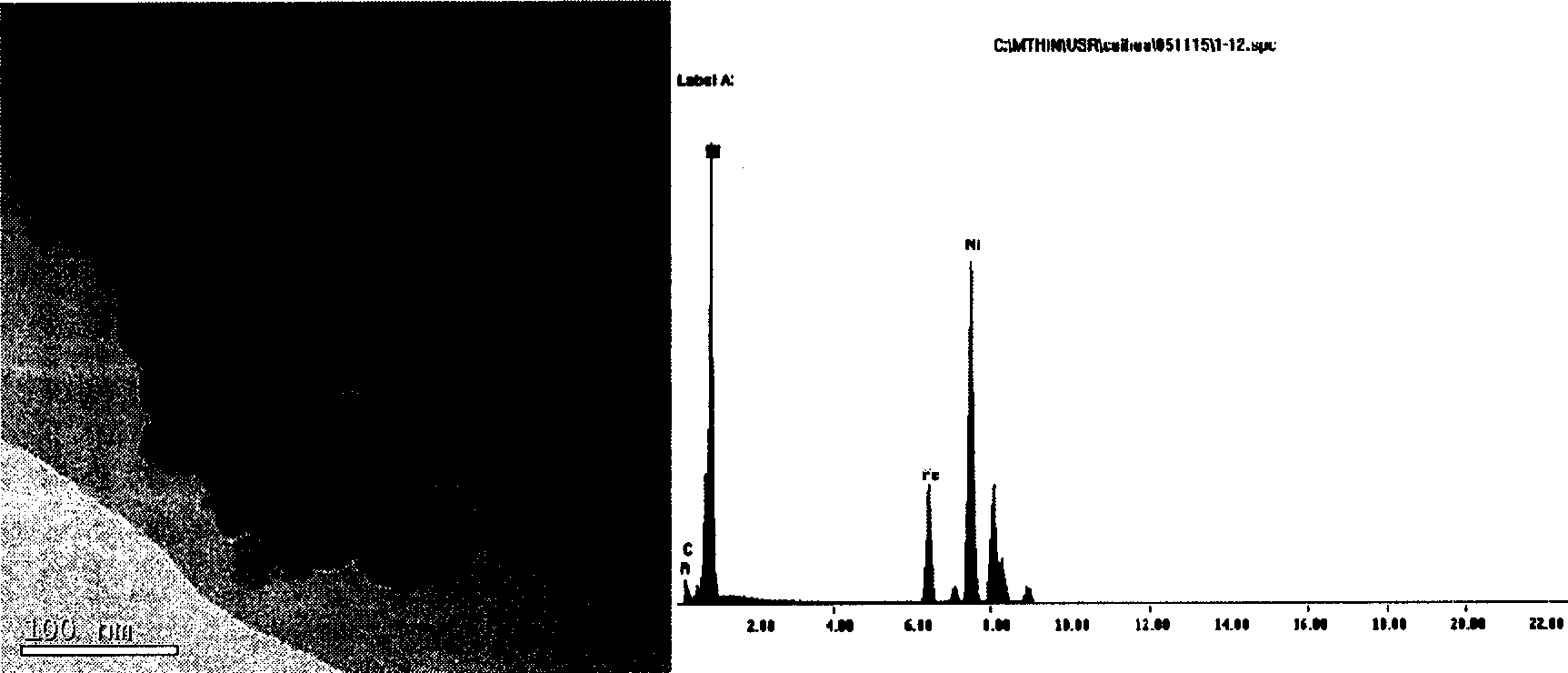

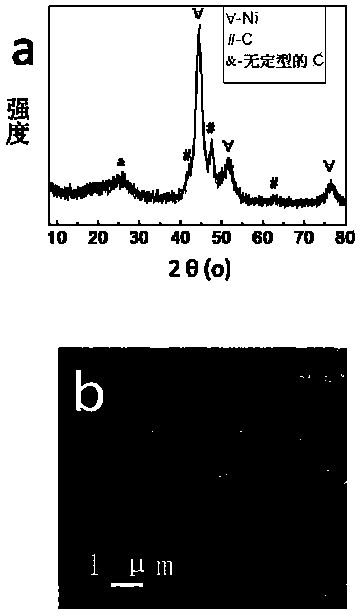

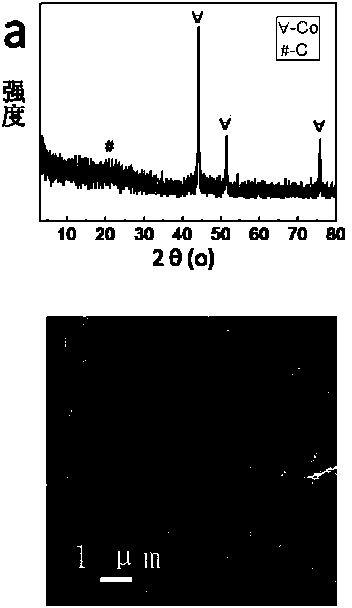

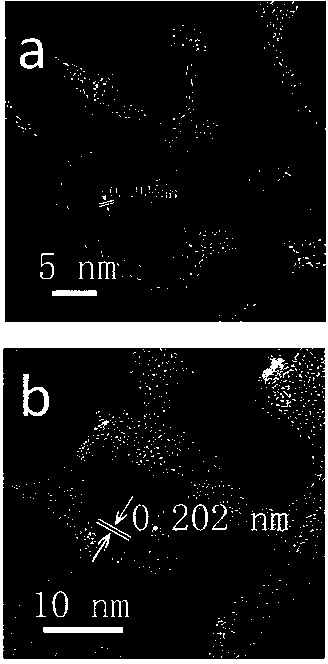

Method for preparing Ni@C or Co@C core-shell nanoparticles

InactiveCN104209514ALarge specific surface areaNarrow pore size distributionMaterial nanotechnologyPtru catalystHeat conservation

The invention relates to a method for preparing Ni@C or Co@C core-shell nanoparticles. The method comprises the steps: (1) adding nickel chloride or cobalt chloride into an isopropanol aqueous solution, adding nitrilotriacetic acid, and stirring for 1 hour at room temperature, so as to obtain a mixed solution; (2) transferring the mixed solution to a reactor, placing the reactor into an air-blasting drying oven, carrying out heat preservation for 6 hours at the temperature of 180 DEG C, cooling, then, separating a product, cleaning and drying in vacuum, so as to obtain a precursor; (3) putting the precursor into a tubular furnace, heating to the temperature of 500-600 DEG C at the heating rate of 2 DEG C / min, and carrying out heat preservation for 2 hours, thereby obtaining a black product, namely the Ni@C or Co@C core-shell nanoparticles. The method has the advantages that the method is simple in process, low in energy consumption, low in cost and free from environmental pollution, and the in-situ synthesis of the Ni@C or Co@C core-shell nanoparticles is realized; the prepared core-shell nanoparticles have porous structures and are larger in specific surface area and narrower in pore size distribution, thereby being a promising catalyst or energy storage material.

Owner:NANKAI UNIV

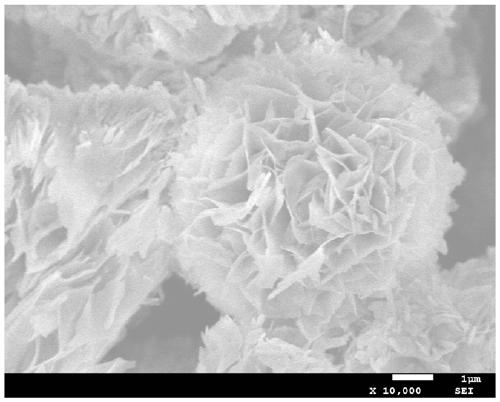

Preparation method for flower-shaped nickel-cobalt-manganese lithium ion battery positive material

The invention discloses a preparation method for a flower-shaped nickel-cobalt-manganese lithium ion battery positive material. The preparation method comprises the steps of preparing a solution withurea as a precipitant, sodium dodecyl sulfate as a surfactant, nickel chloride as a nickel source, cobalt chloride as a cobalt source, manganese chloride as a manganese source, and deionized water asa solvent; adding the solution into a high-pressure reaction kettle for hydrothermal reaction; separating solid from liquid after reaction, and then washing to obtain a flower-shaped nickel-rich precursor; adding the washed product into a co-precipitation reaction kettle, slowly adding the manganese-cobalt solution and the precipitant to react, so as to enable cobalt and manganese elements to slowly settle on the surface of the solid to wrap the flower-shaped precursor; washing and drying, then mixing the wrapped precursor with a lithium source, calcining under a condition of introducing oxygen, so as to obtain lithium ion battery positive material nickel-cobalt-manganese. The preparation method has the advantages of synthesizing the nickel-cobalt-manganese precursor through hydrothermal reaction, ensuring that nickel, cobalt and manganese elements are distributed uniformly in an atomic level compared with conventional solid phase mixing, and preventing element segregation.

Owner:NANCHANG HANGKONG UNIVERSITY

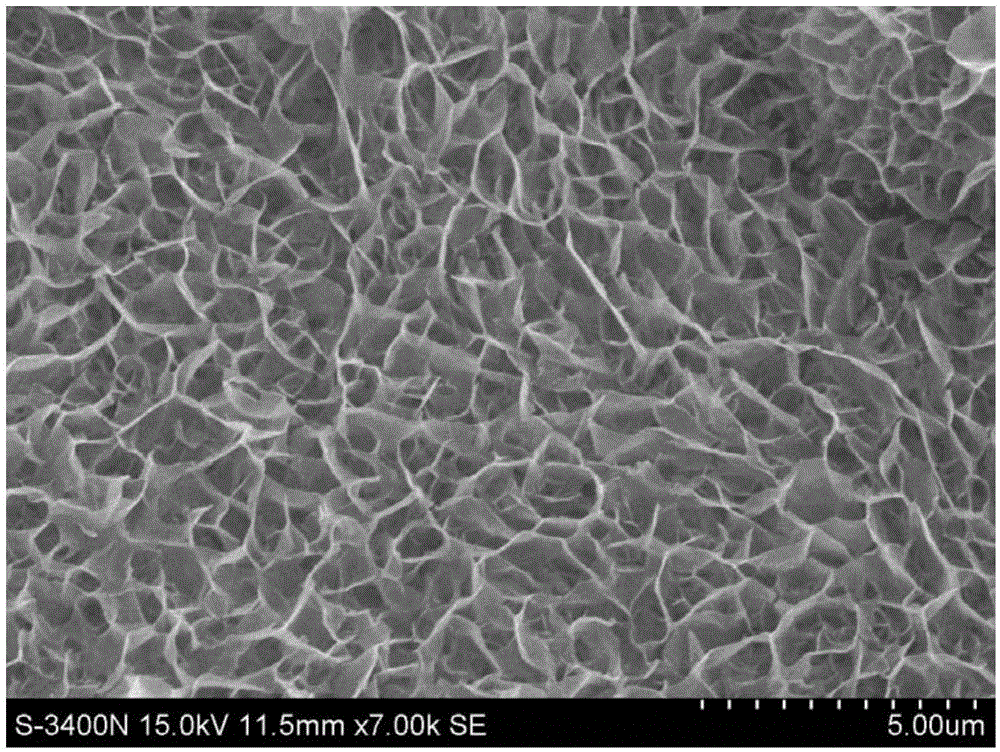

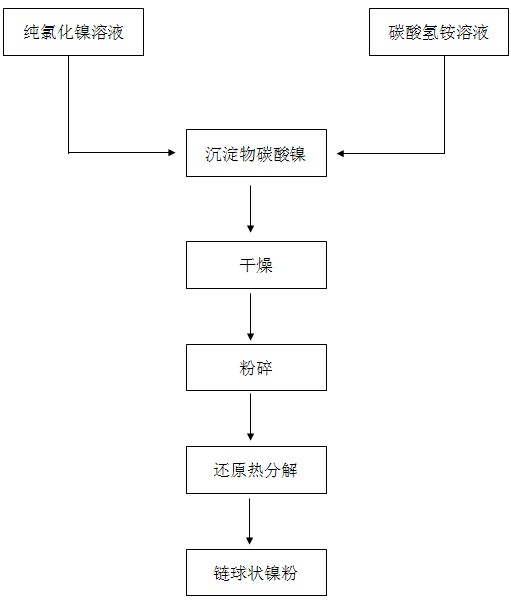

Method for preparing submicron hammer ball superfine nickel powder

InactiveCN102091789AConform to international ROHS standardReduce carbon contentHazardous substanceIron removal

The invention discloses a method for preparing submicron hammer ball superfine nickel powder, which comprises the following steps of: 1) preparing pure nickel chloride solution; 2) preparing nickel carbonate solution; 3) drying; 4) crushing; and 5) performing reductive thermal decomposition. In the method, the pure nickel chloride solution is used as a raw material, and precipitation reaction is adopted; iron removal with an amarillite method, rough removal of calcium and magnesium with sodium fluoride, secondary extraction and separation and superfine crushing are performed; the reaction is performed under the reductive atmosphere of hydrogen and nitrogen; and the final product has low carbon content and meets the current low-carbon environmentally-friendly requirements. The product accords with international restriction of hazardous substances (ROHS) standards of electronic and electric products, and the production process has no toxicity or pollution and is environmentally-friendly. The removal rate of the calcium and the magnesium reaches 95 percent, the purity of the nickel powder reaches 99.8 percent, the apparent density is low and is 0.5 to 0.6g / cm<3>, and the granular submicron hammer ball superfine nickel powder can meet the requirements of many fields.

Owner:DANYANG QIUJING ALLOY STEEL

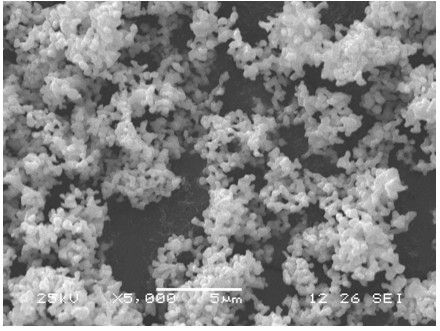

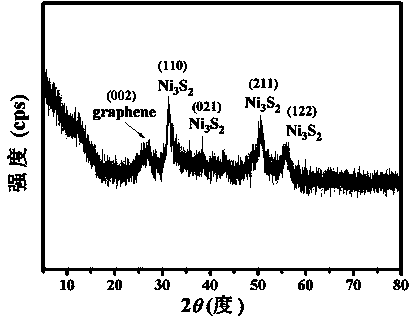

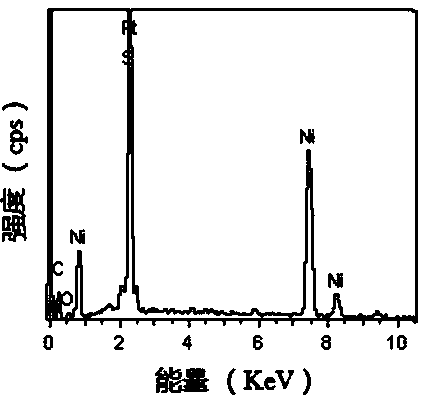

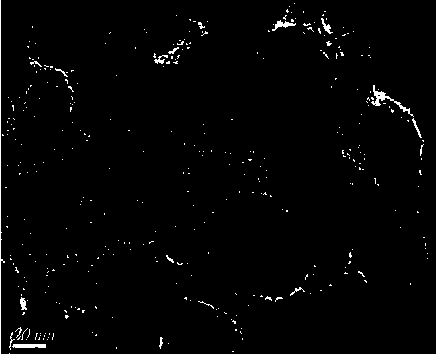

Method for preparing carbon-coated Ni3S2/graphene composite material for supercapacitor electrode

InactiveCN104240971AImprove conductivityAvoid reunionHybrid/EDL manufactureCarbon coatingCapacitance

The invention relates to a method for preparing a carbon-coated Ni3S2 / graphene composite material for a supercapacitor electrode and belongs to the field of preparation of nanometer composite materials. The method comprises the steps that graphite oxide, glucose, a certain amount of nickel chloride and thiourea are dissolved in a mixed solution of water and ethyl alcohol through ultrasound, ammonium hydroxide is added to the mixed solution under the condition of stirring, the mixed solution reacts for six to twelve hours in a reaction still at the temperature of 180 DEG C, sediment is collected, and then the carbon-coated Ni3S2 / graphene composite material is obtained. According to the carbon-coated Ni3S2 / graphene composite material, Ni3S2 nanometer particles are all coated with carbon shells, the carbon-coated Ni3S2 particles are all attached to a graphene sheet, and a high-uniformity structure is obtained; due to carbon coating, the Ni3S2 particles can be protected against oxidation, and the conductivity and the specific surface area of the material can be improved through graphene; the composite material has excellent capacitive performance, and hopefully the composite material is used as a supercapacitor electrode material.

Owner:JIANGSU UNIV

High-magnetic micro-particle-size nano magnetic beads and preparation method thereof

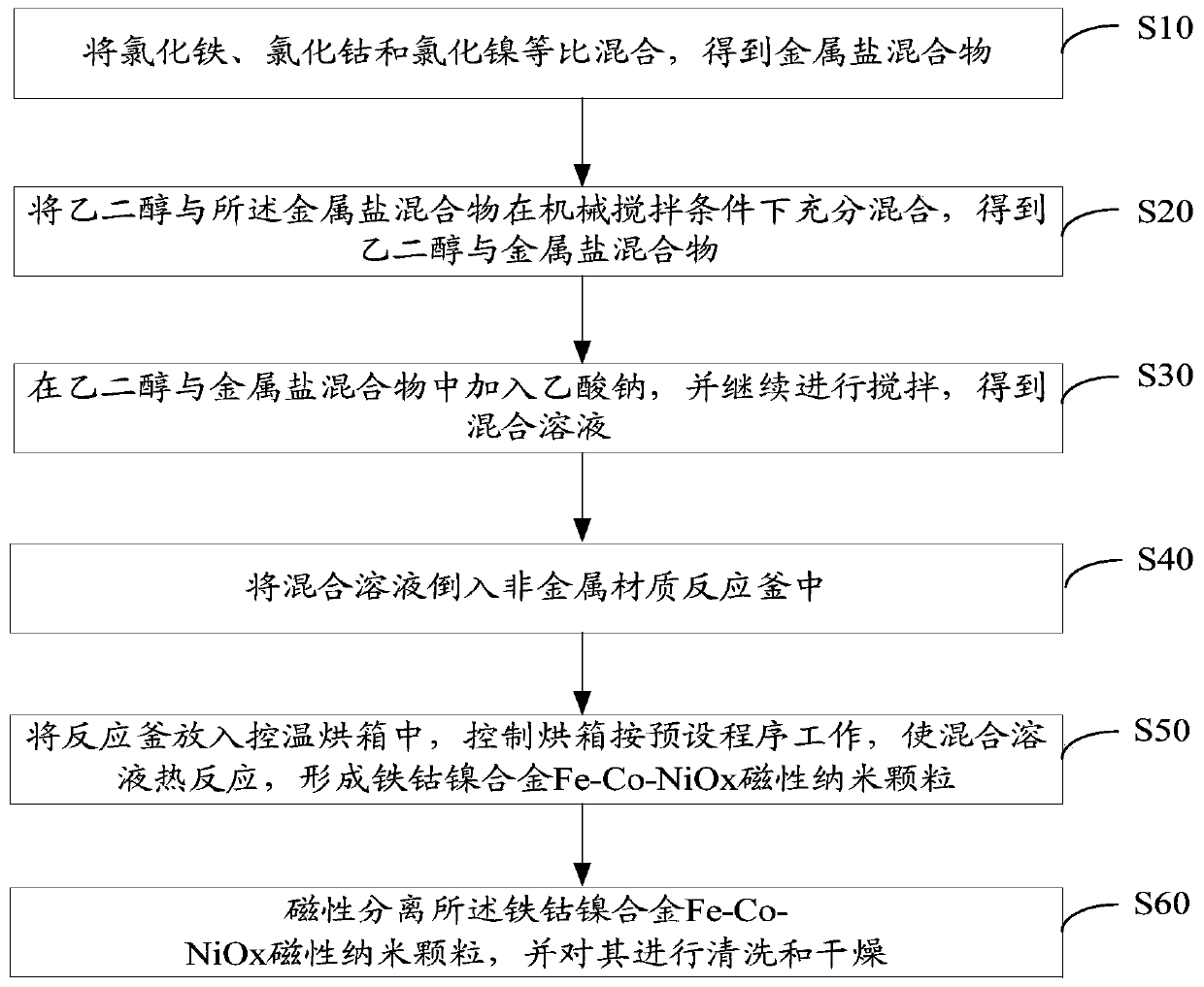

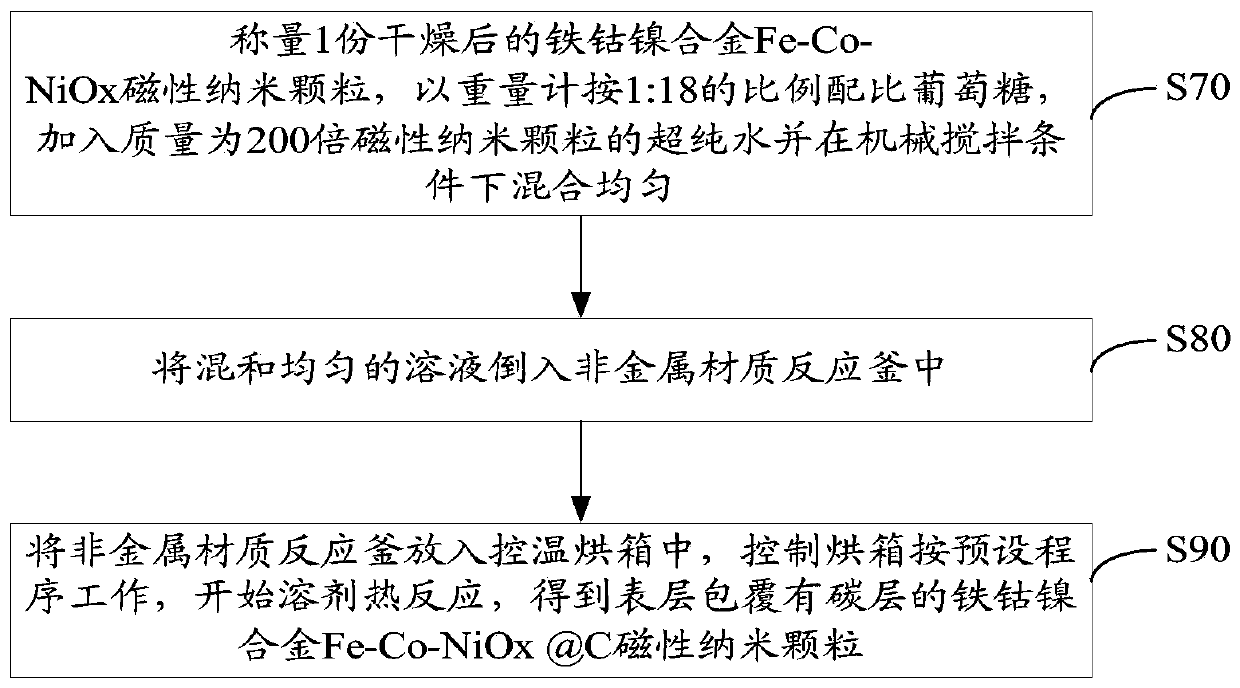

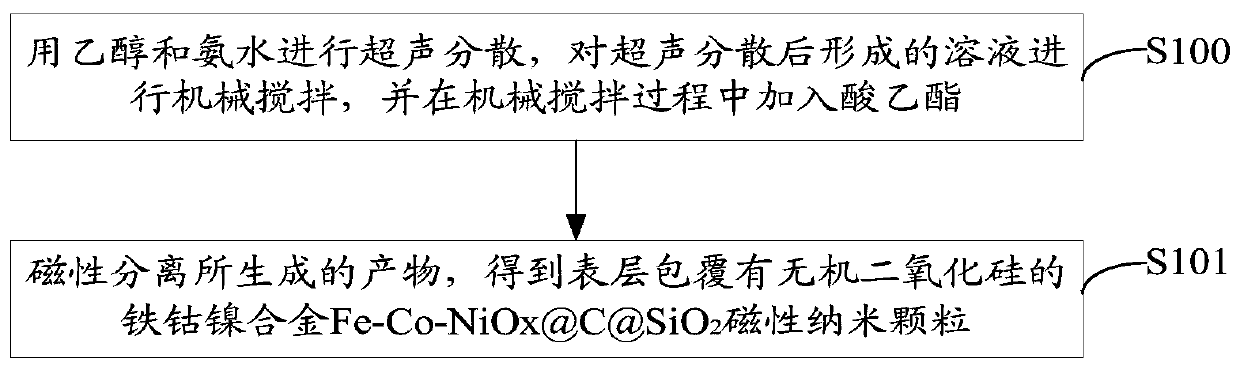

ActiveCN110038533ACapable of strong magnetic responseSmall and uniform particle sizeIon-exchange process apparatusOther chemical processesSodium acetateCarbon layer

The invention discloses a preparation method of high-magnetic micro-particle-size nano magnetic beads. The preparation method comprises the following steps: mixing iron chloride, cobalt chloride and nickel chloride in an equal ratio to obtain a metal salt mixture; mixing ethylene glycol with the metal salt mixture sufficiently under the condition of mechanical stirring to obtain a mixture of the ethylene glycol and metal salt; adding sodium acetate into the mixture of the ethylene glycol and the metal salt, and continuing to stir to obtain a mixed solution; pouring the mixed solution into a non-metallic reaction kettle; placing the reaction kettle in a temperature-controlled oven, and controlling the oven to operate according to a preset procedure to make the mixed solution be subjected toa thermal reaction to form iron-cobalt-nickel alloy Fe-Co-NiOx magnetic nanoparticles; magnetically separating the iron-cobalt-nickel alloy Fe-Co-NiOx magnetic nanoparticles, and washing and drying;coating the surface layers of the iron-cobalt-nickel alloy Fe-Co-NiOx magnetic nanoparticles with a carbon layer and a silicon dioxide layer sequentially, and covalently grafting polyethylene glycol onto an outermost layer. The preparation method disclosed by the invention solves the technical problems of relatively large particle size, wide distribution range, small specific surface area and lowmagnetic response of magnetic beads in the prior art.

Owner:艾铂图生物(江苏)有限公司

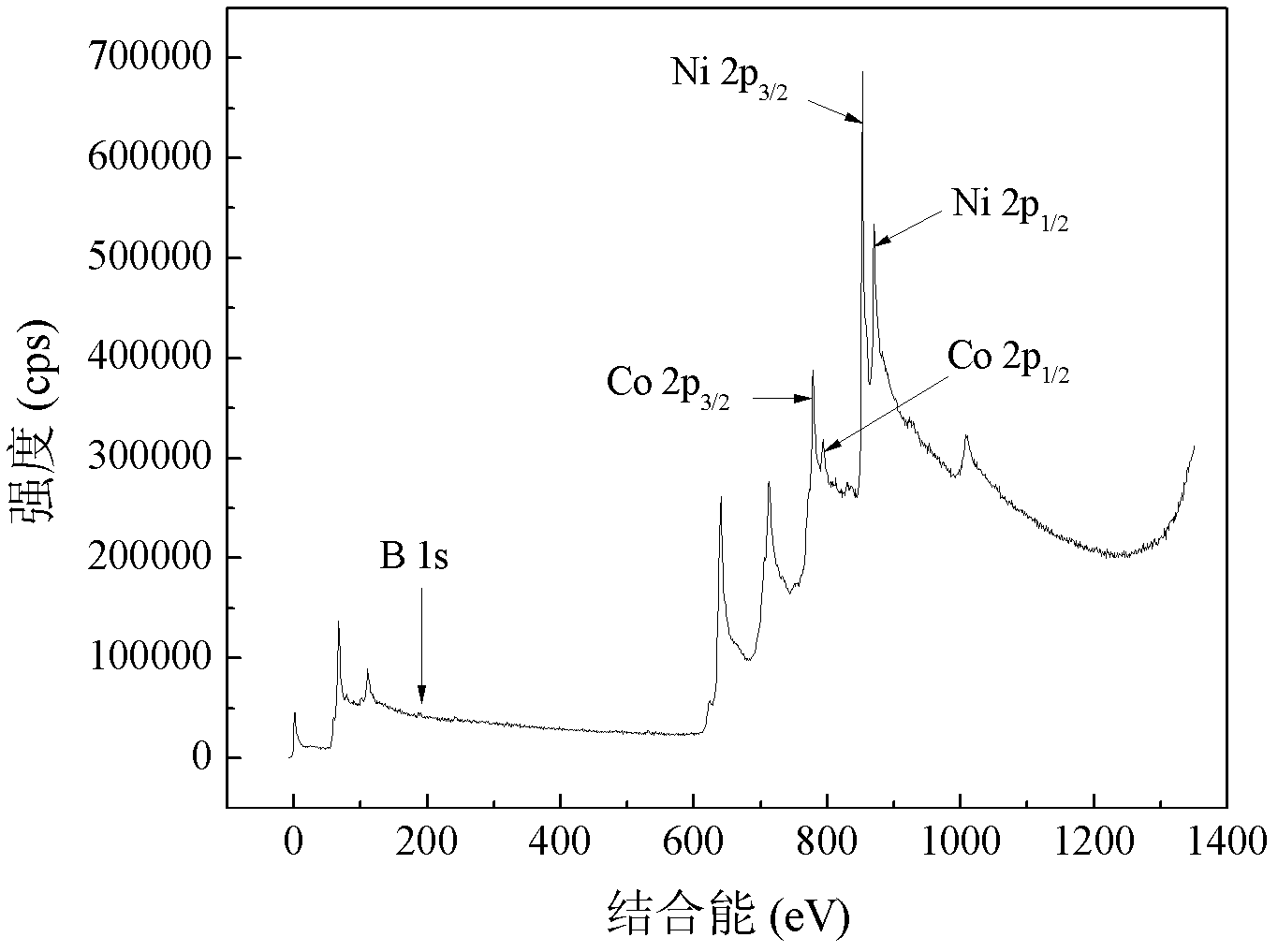

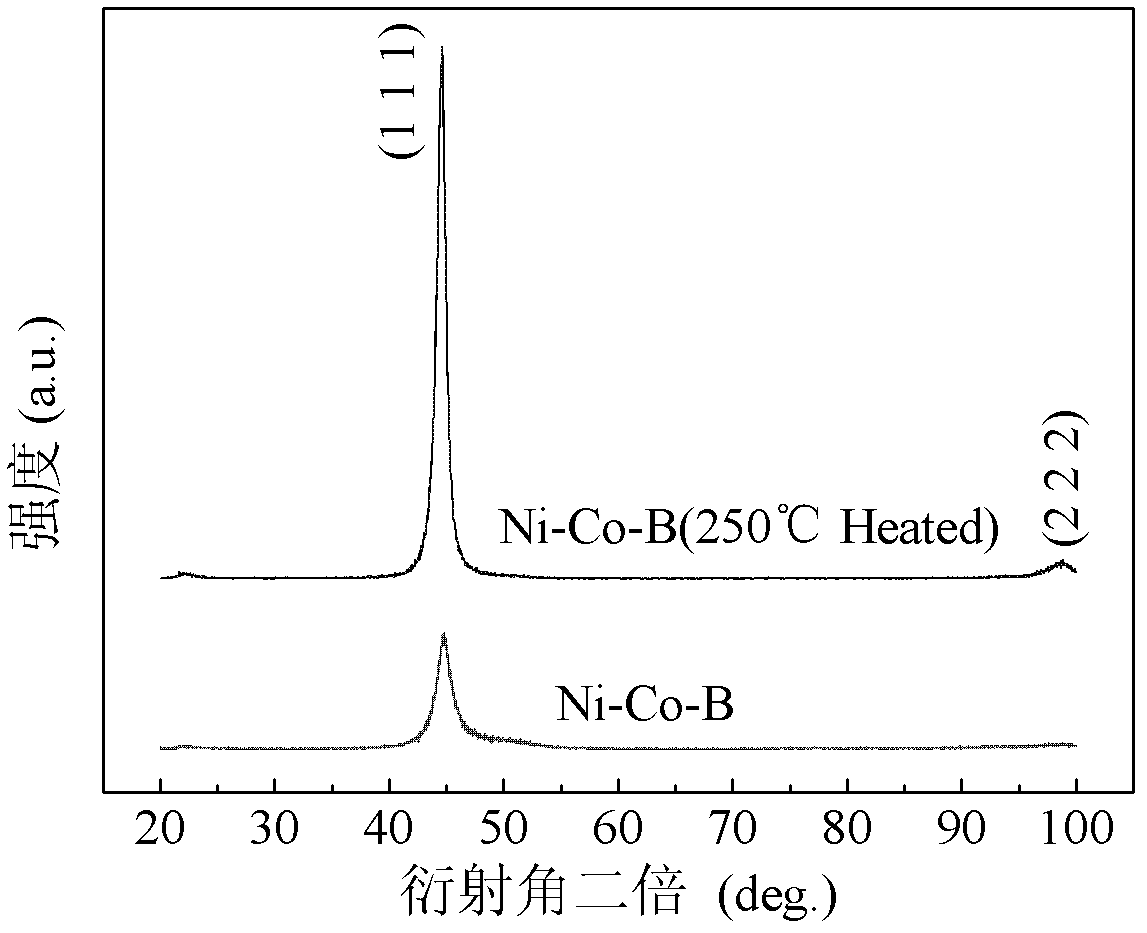

Electric deposition preparation method of Ni-Co-B alloy substituted hard chromium plating

The invention provides an electric deposition preparation method of a Ni-Co-B alloy substituted hard chromium plating, relating to a preparation method of the Ni-Co-B alloy substituted hard chromium plating. The method 1 comprises the following steps of: taking nickel salt, cobalt salt, nickel chloride, boric acid, amine boride, NI3<#> fast high-level nickel-plating glazing agent A and lauryl sodium sulfate; preparing an alloy plating solution; and plating a processed plated part. The method 2 comprises the following steps of: taking nickel chloride, cobalt salt, boric acid, amine boride, NI3<#> fast high-level nickel-plating glazing agent A and lauryl sodium sulfate; preparing an alloy plating solution; and plating a processed plated part. In the invention, a Ni-Co-B alloy plating with uniform brightness, hardness of 770-800HV50 as well as good corrosion resistance and bonding force is obtained at a deposition rate higher than 60mu m / h. In the plating process, the cathode current efficiency is higher than 96%; and after the plating is subjected to heat treatment at 150-400 DEG C for 1-3 hours, the hardness of the plating can be increased to 1055-1108HV50.

Owner:HARBIN INST OF TECH +1

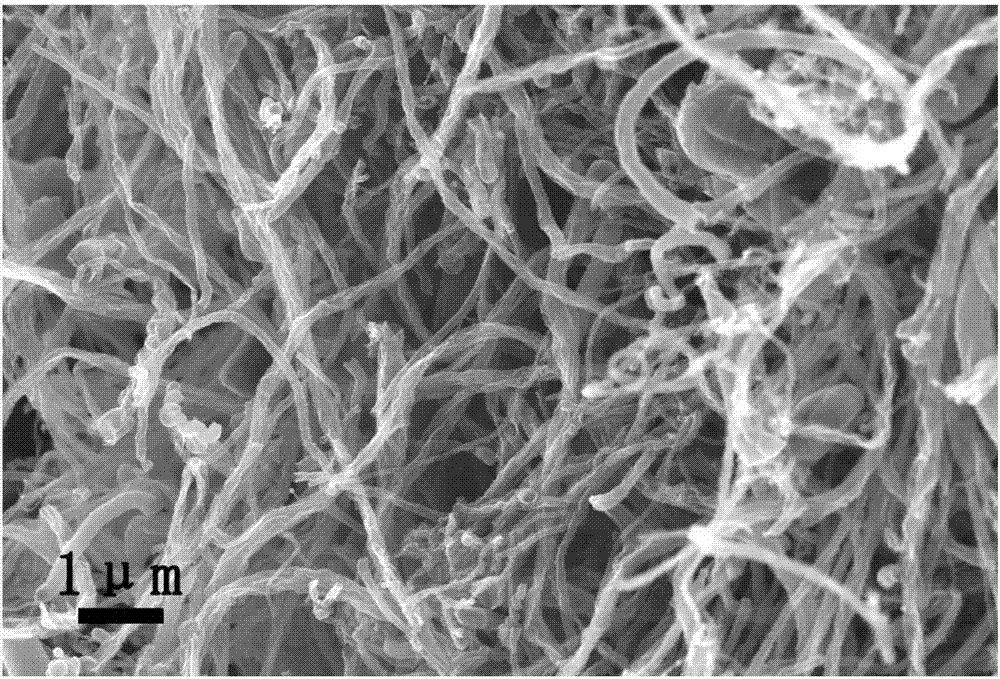

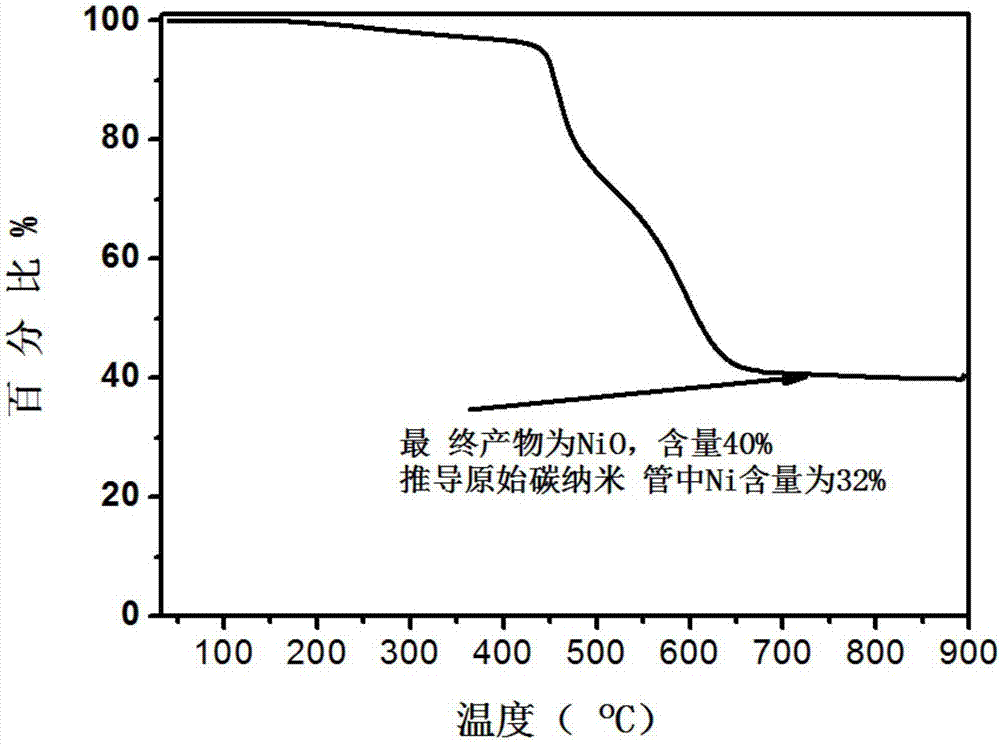

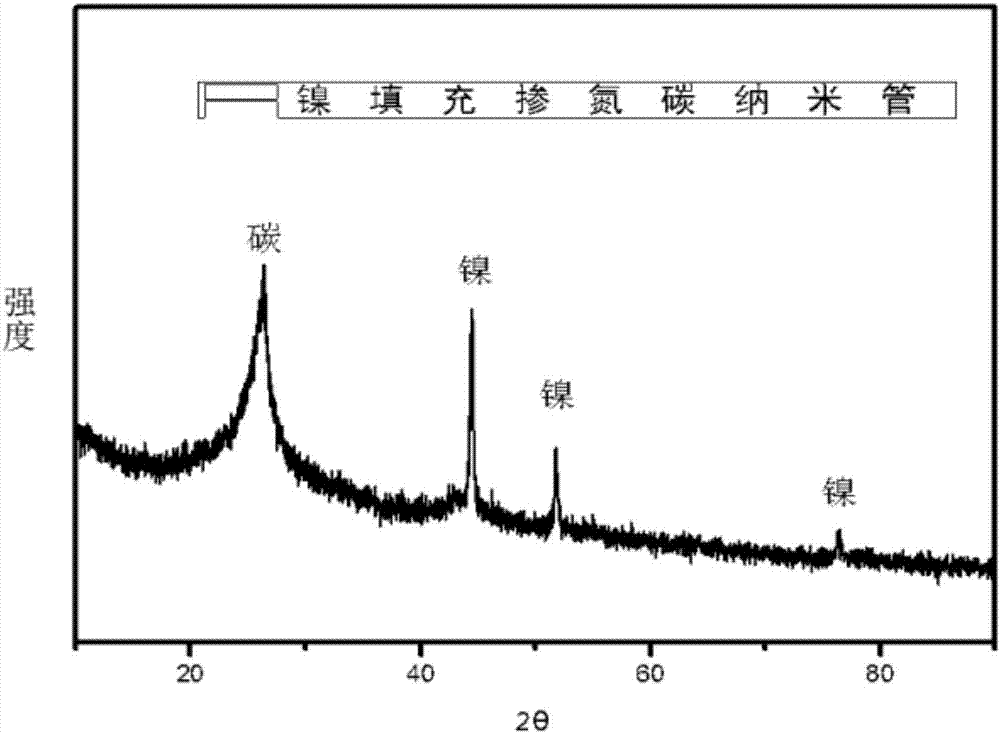

Nickel-filled nitrogen-doped carbon nanotubes as well as preparation method and application thereof

ActiveCN107570192AImprove fill rateMaximum Oxygen Reduction Peak CurrentCatalyst activation/preparationFilling rateNitrogen doped

The invention relates to nickel-filled nitrogen-doped carbon nanotubes as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) adding nickelchloride and a carbon and nitrogen source into a dispersant, uniformly stirring, performing ultrasonic treatment, drying and grinding to obtain mixed powder, wherein the carbon and nitrogen source isone or more of tripolycyanamide, dicyanamide and cyanamide; (2) calcining the mixed powder obtained in the step 1 in an inert gas atmosphere, and then performing acid treatment to obtain the nickel-filled nitrogen-doped carbon nanotubes. The invention further provides the nickel-filled nitrogen-doped according to the preparation method and application of the carbon nanotubes. According to the preparation method, the nickel-filled nitrogen-doped carbon nanotubes are prepared through groundbreaking simple high-temperature pyrolysis of a mixture of the nickel chloride and the carbon and nitrogensource; compared with a single nickel-filled carbon nanotube preparation method, the preparation method provided by the invention has the advantages as follows: the filling rate of nickel is greatly improved, and doping of nitrogen also greatly improves the electrochemical performance of the carbon nanotubes; the nickel-filled nitrogen-doped carbon nanotubes have a wide application prospect.

Owner:DONGGUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com