Rare earth-nickel-cobalt-boron multi-element alloy anticorrosion and wear-resistant plating, electroplating liquid and preparation method of electroplating liquid

A multi-alloy, anti-corrosion and wear-resistant technology, applied in the field of metal surface treatment, can solve the problems of high internal stress, easy cracking, high energy consumption, etc., to achieve high current efficiency, reduce internal stress, and increase corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

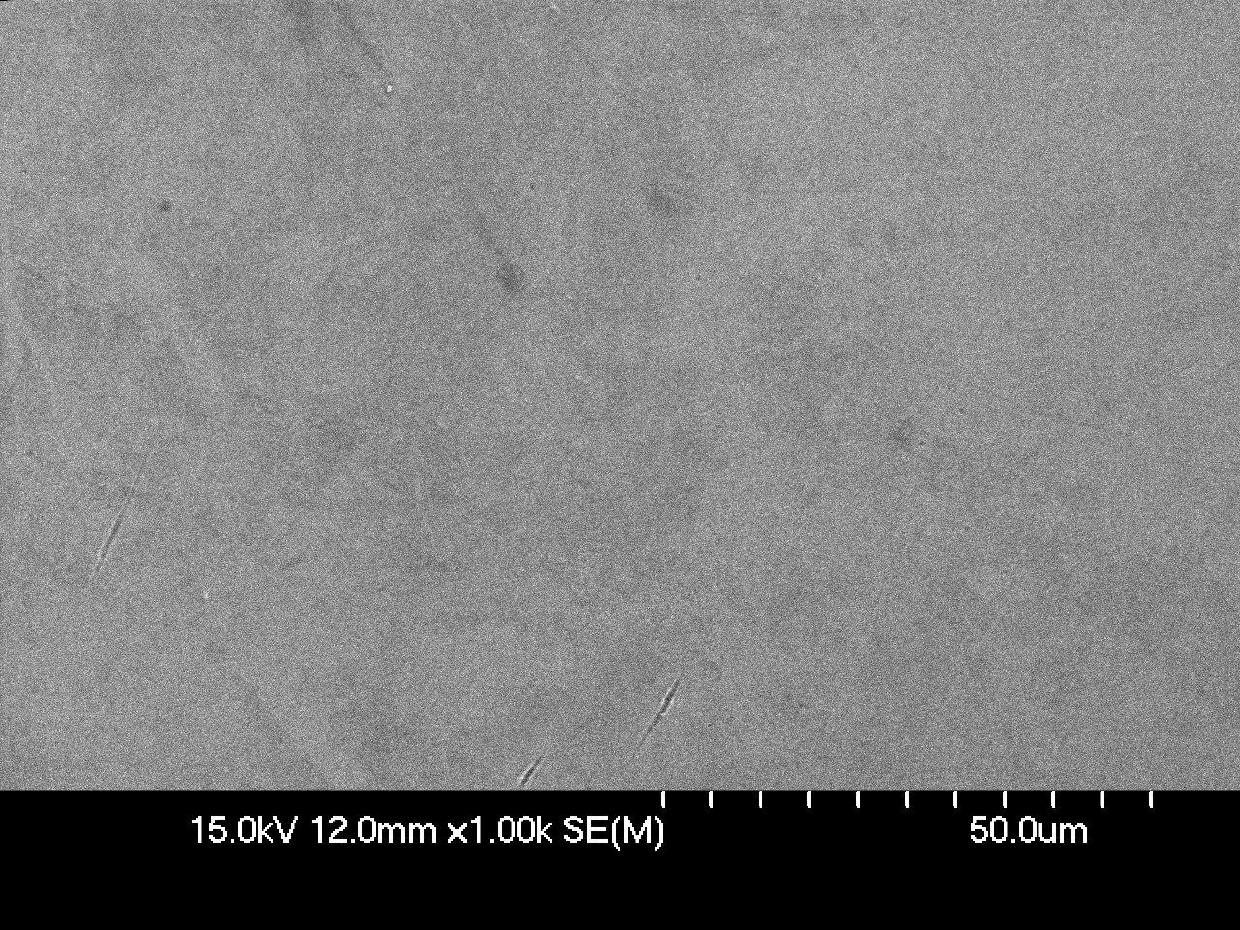

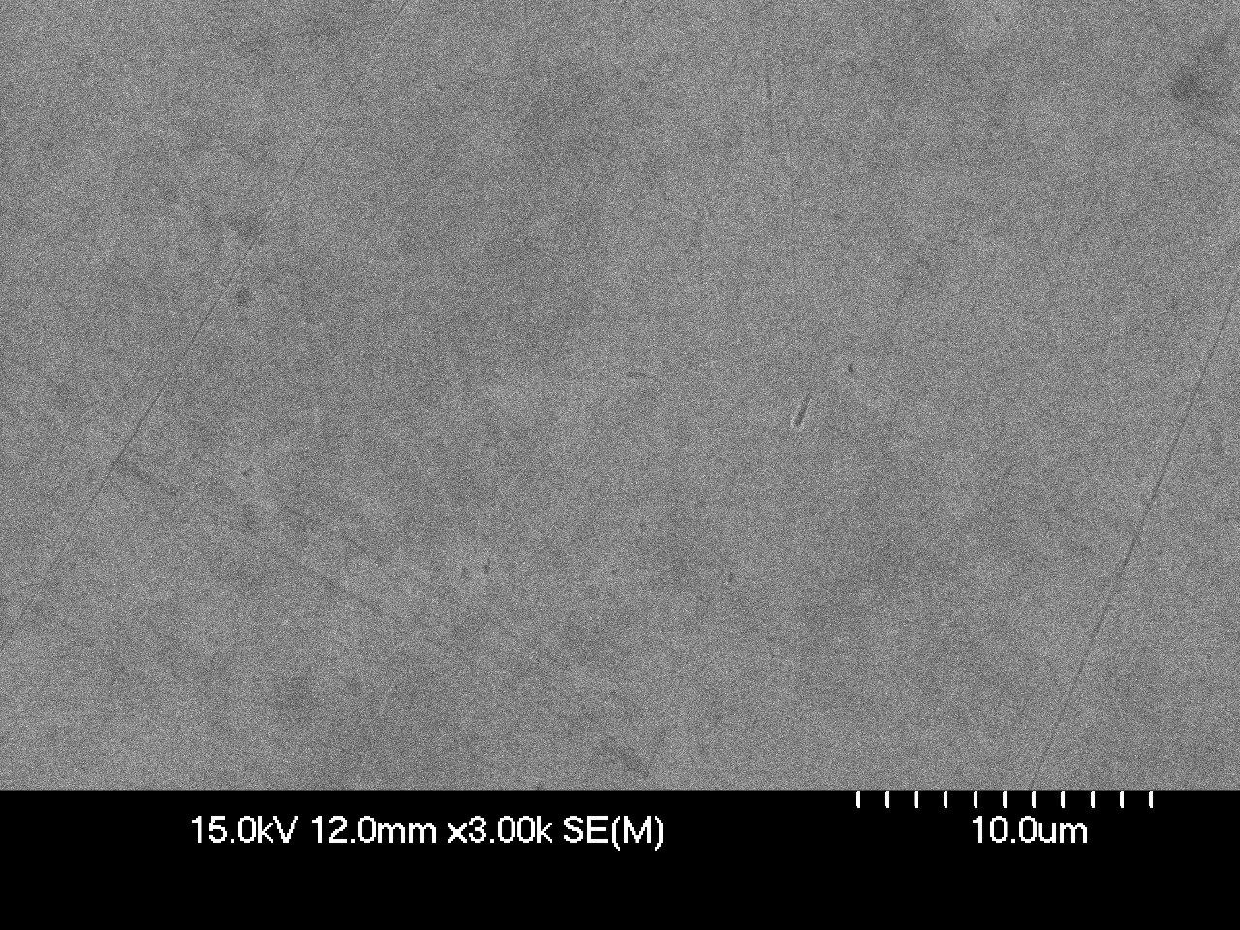

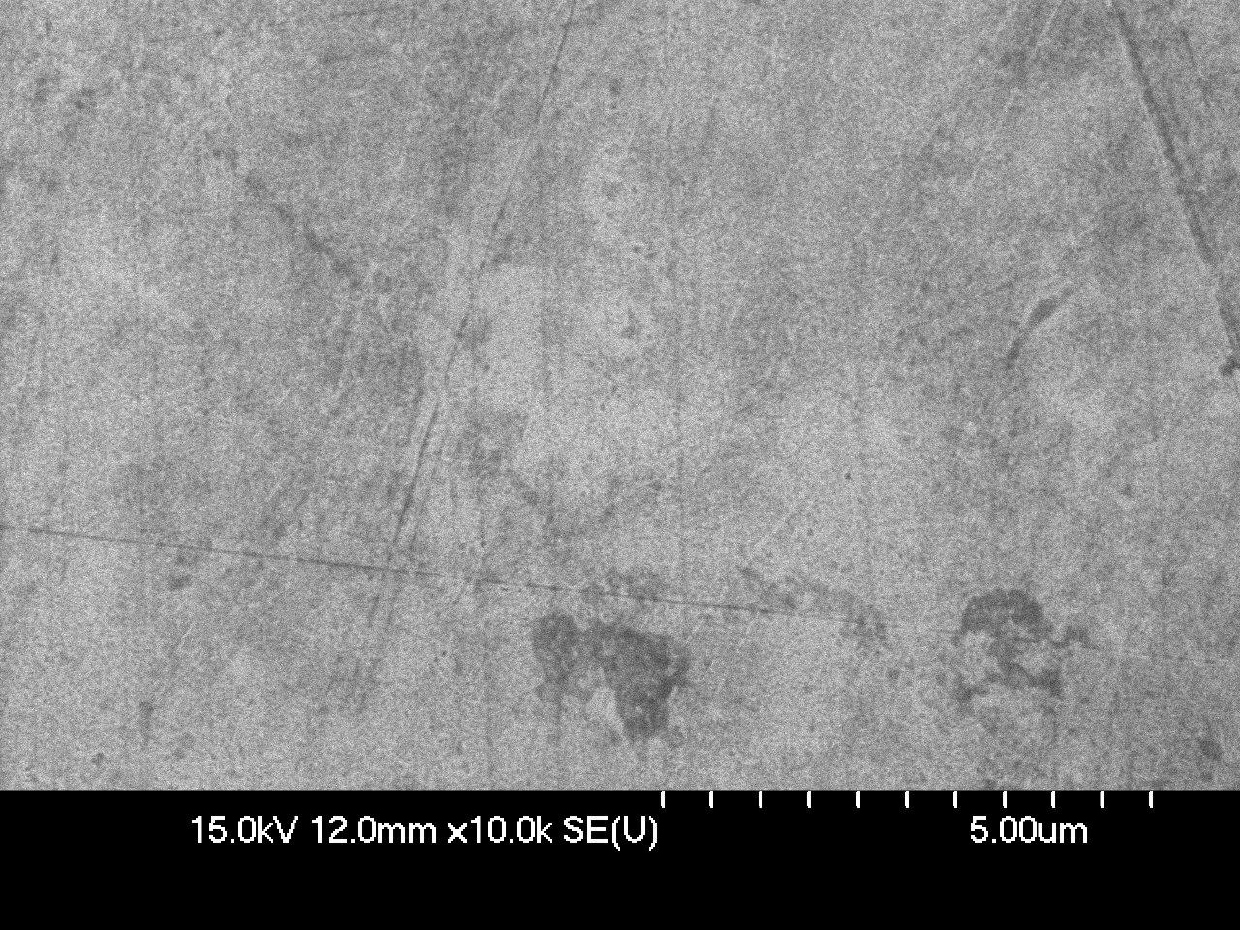

Image

Examples

Embodiment 1

[0030] Heat 650ml of deionized water to 50°C-60°C, add 250g of nickel sulfate, 20g of cobalt sulfate, 50g of boric acid and 30g of nickel chloride, stir well until completely dissolved; adjust the resulting solution to PH=4 with 10% sulfuric acid , add 30 g of sodium citrate and 3 g of sodium tartrate, and stir well to obtain mixed solution I; take 0.1 g of lanthanum trioxide, first use deionized water to make a paste of rare earth, and then fully stir with 20% hydrochloric acid until the solution is clear , add to the mixed solution I, stir well to prepare the mixed solution II; take 2g of dimethylamine borane, adjust the pH to 10 with 50% ammonia water, add it to the mixed solution II, add deionized water to 1L, and stir well , to prepare a lanthanum-nickel-cobalt-boron multi-alloy anti-corrosion and wear-resistant electroplating solution.

[0031] Plating method:

[0032] 1. Carbon steel workpiece 50×50×1.2mm plated parts pretreatment: manual rust removal—water washing—oil...

Embodiment 2

[0044] Heat 650ml of deionized water to 50-60°C, add 200g of nickel sulfate, 30g of cobalt sulfate, 40g of boric acid and 40g of nickel chloride, stir well until completely dissolved; adjust the resulting solution to PH=5 with 50% ammonia water, Add 20g of citric acid and 4g of sodium tartrate, and stir well to obtain mixed solution I; take 0.5g of lanthanum trioxide, first use deionized water to make the rare earth into a paste, then fully stir with 20% hydrochloric acid until the solution is clear, add In the mixed solution I, stir well to prepare the mixed solution II; take 3g of dimethylamine borane, adjust the pH to 10 with 50% ammonia water, add it to the mixed solution II, fill up with deionized water to 1L, and stir well, A lanthanum-nickel-cobalt-boron multi-element alloy anti-corrosion and wear-resistant electroplating solution is prepared.

[0045] Plating is carried out in the same way as in Example 1. After testing, the coating contains 25wt% cobalt, 0.6wt% boron,...

Embodiment 3

[0047] Heat 650ml of deionized water to 50-60°C, add 220g of nickel sulfate, 40g of cobalt sulfate, 40g of boric acid and 50g of nickel chloride, stir well until completely dissolved; adjust the resulting solution to PH=5 with 50% ammonia water, Add 20g of citric acid and 4g of sodium tartrate, and stir well to obtain mixed solution I; take 1g of samarium trioxide, use deionized water to make a paste of rare earth, then fully stir with 20% sulfuric acid until the solution is clear, and add mixed solution In Ⅰ, stir thoroughly to prepare mixed solution II; take 4g of dimethylamine borane, adjust the pH to 10 with 50% ammonia water, add it to mixed solution II, fill up with deionized water to 1L, and stir well to obtain Samarium-nickel-cobalt-boron multi-alloy anti-corrosion and wear-resistant electroplating solution.

[0048]Plating is carried out in the same way as in Example 1. After testing, the coating contains 30wt% cobalt, 0.9wt% boron, and the remainder is nickel and a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com