Nickel doped nanometer bismuth tungstate visible-light photocatalyst, and preparation and application thereof

A nano-tungsten and catalyst technology, applied in the field of environmental photocatalysis, can solve the problems of lack of independent intellectual property rights, difficult to obtain preparation raw materials, complicated preparation steps, etc., and achieve the effects of easy implementation, mild preparation conditions, and simple preparation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

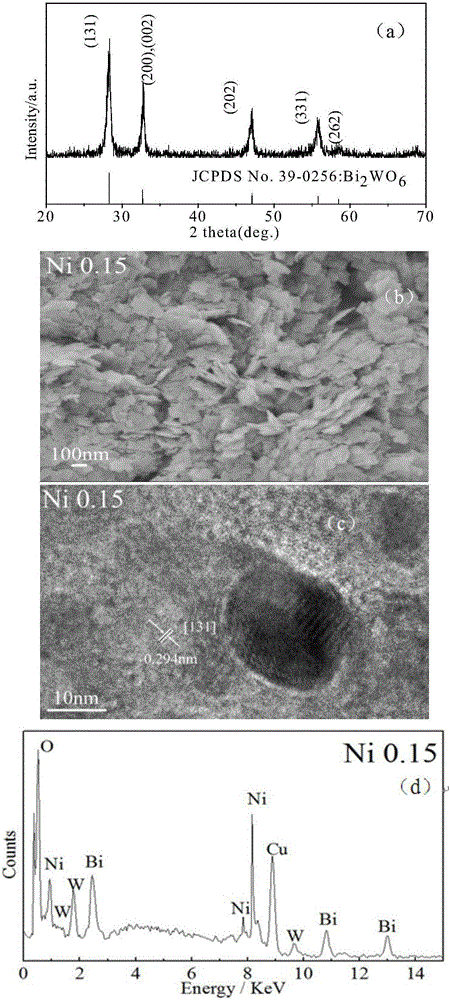

[0033] One, a kind of nickel-doped nano bismuth tungstate (Ni-Bi 2 WO 6 ) The preparation method of visible light catalyst, concrete steps are as follows:

[0034] (1) 1mmol sodium tungstate (Na 2 WO 4 2H 2 O) dissolved in 45 mL of distilled water, sonicated (100W, 5 min) to obtain Na 2 WO 4 2H 2 O solution;

[0035] (2) Then 0.3mmol nickel chloride (NiCl 2 ·6H2 O) and 2 mmol bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) add Na sequentially 2 WO 4 2H 2 O solution, sonication (100W, 5 min) to obtain a light green suspension, which is the precursor for the preparation of the target material.

[0036] (3) The precursor was transferred to a 100 mL high-temperature and high-pressure hydrothermal reactor with a polytetrafluoroethylene liner, and hydrothermally reacted at 180 °C for 12 h.

[0037] (4) After the reaction kettle was naturally cooled to room temperature, the resulting product was collected, washed 5 times with distilled water, centrifuged (3000r / min, 10min), and ...

Embodiment 2

[0045] In order to compare the effect of nickel-tungsten molar ratio (Ni / W) on the performance of nickel-doped nano-bismuth tungstate visible light catalysts, by changing the amount of nickel chloride added (ie 0, 0.1, 0.3, 1, 1.5mmol), and according to The steps in Example 1 were simultaneously prepared to obtain nickel-doped nano-bismuth tungstate visible light with undoped nickel (Ni / W=0) and nickel-tungsten molar ratios of 1:20, 3:20, 1:2, and 3:4, respectively. catalyst.

Embodiment 3

[0047] Ni-Bi 2 WO 6 Adsorption of organic dye (rhodamine B) by visible light catalyst and visible light catalytic degradation test, the specific steps are as follows:

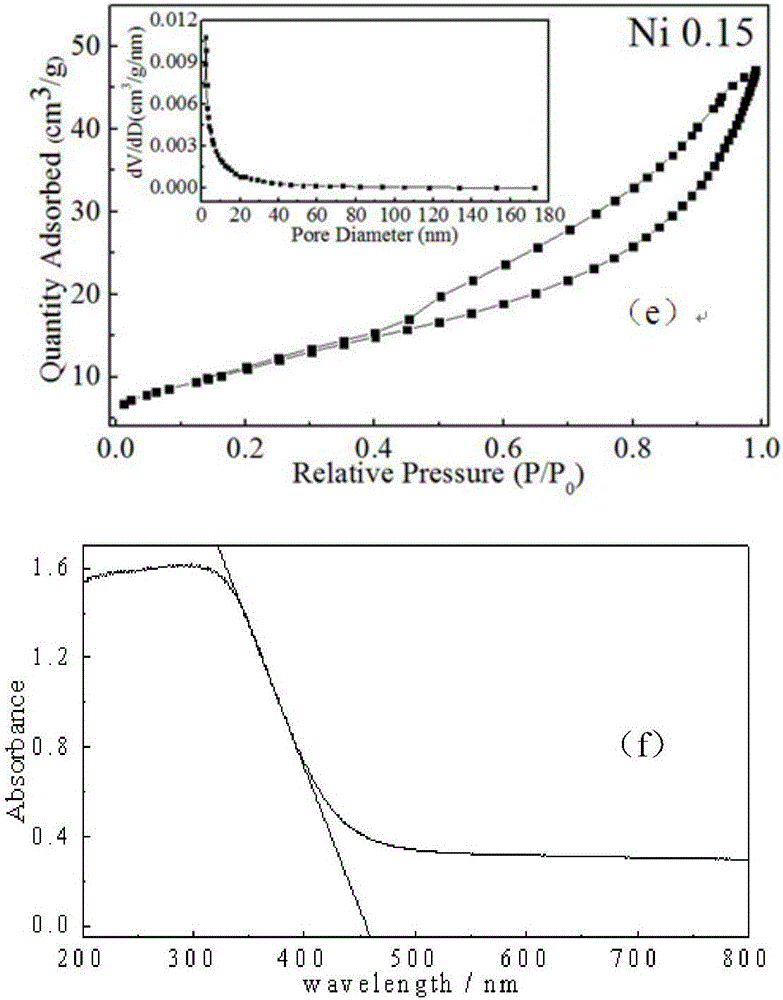

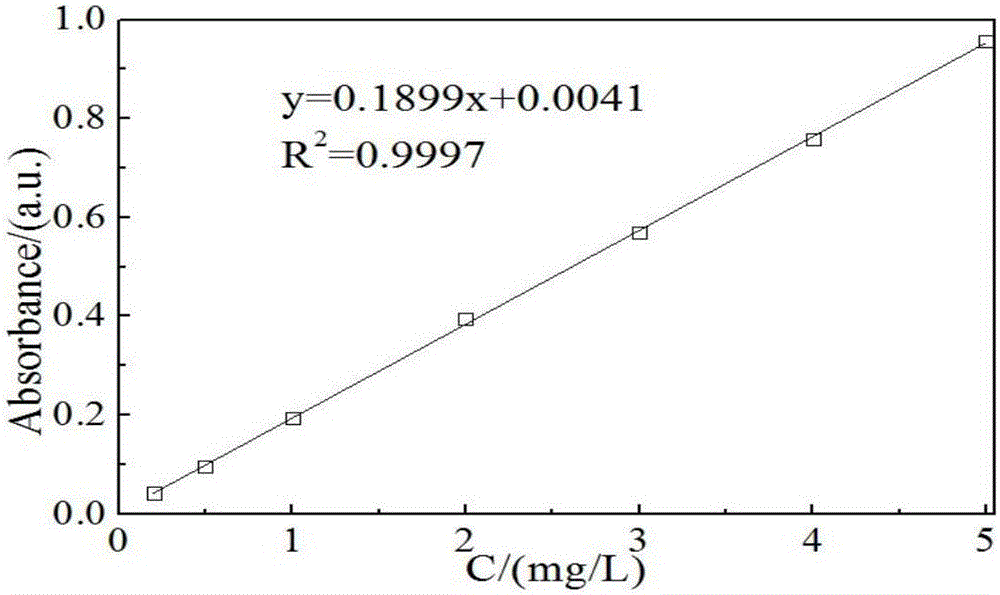

[0048] Prepare 300 mL of rhodamine B solution (15 mg / L), and disperse 0.3 g of photocatalyst (Ni / W=0.15, ie 3:20) in the solution (so that the solubility of the prepared catalyst in the solution is 1 g / L) , the adsorption experiment was carried out under the condition of magnetic stirring (200r / min) in the dark, and the experiment time was 120min. Samples were taken every 10 min, passed through a 0.22 μm filter membrane, and the absorbance of the filtrate was detected at λ=554 nm with a TU-1810 / 1810S UV-visible spectrophotometer, and according to the standard working curve of rhodamine B solution ( figure 2 ) to find its concentration in the filtrate. Take time (t) as the abscissa, and the adsorption rate (the ratio of the concentration of rhodamine B in the filtrate to its initial concentration at a certai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com