Patents

Literature

40 results about "Nickel chloride hydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for Ni-Co/carbon nanotube aerogel catalyst of zinc-air battery

ActiveCN105609790AWide variety of sourcesImprove securityCell electrodesPtru catalystZinc–air battery

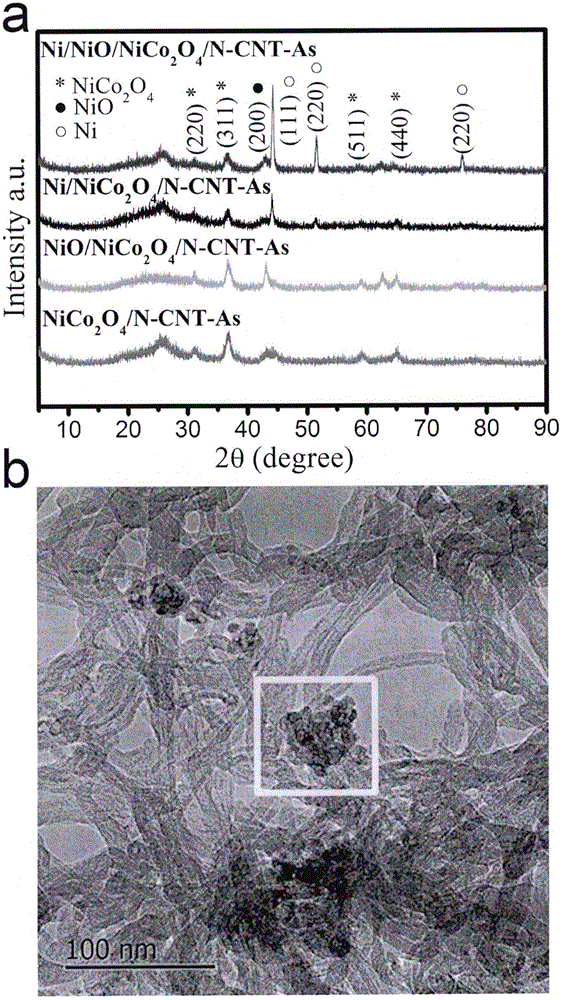

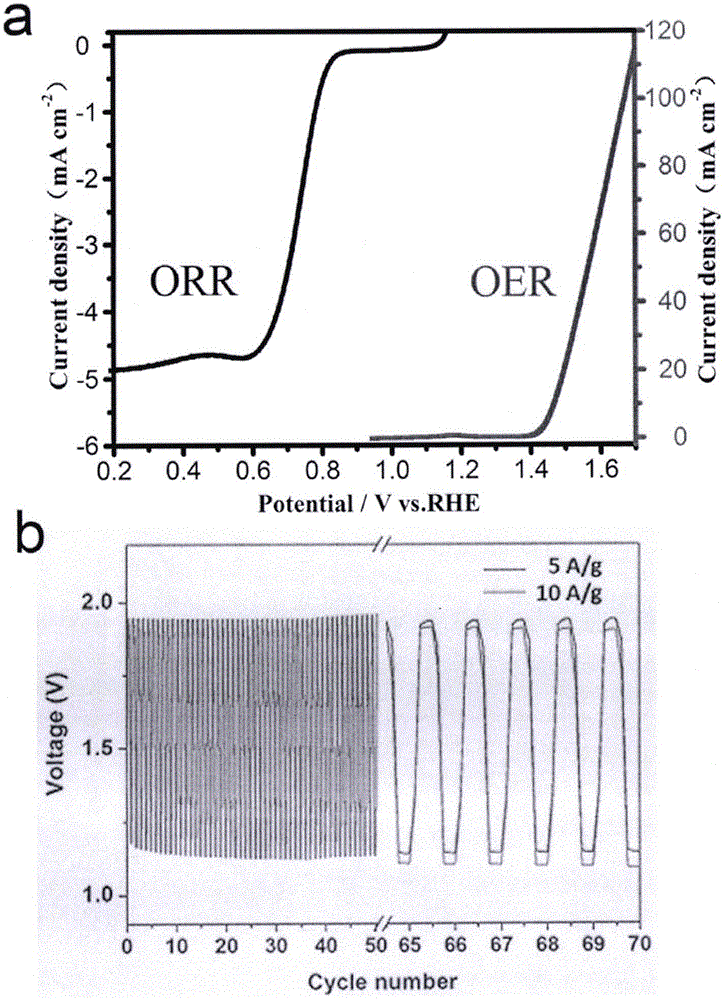

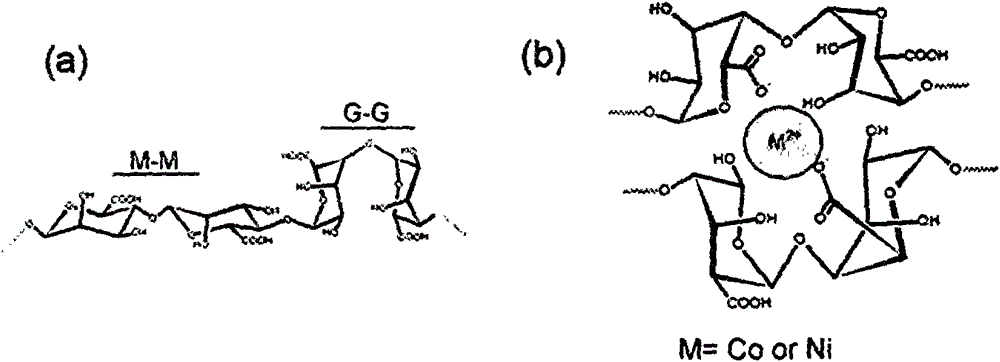

The invention discloses a preparation method for a Ni-Co / carbon nanotube aerogel catalyst of a zinc-air battery, which is used for the field of the zinc-air battery. In the catalyst, the nanometer Ni-Co / carbon nanotube aerogel dual-functional catalyst is successfully prepared by taking sodium alginate, cobalt chloride hexahydrate, nickel chloride hexahydrate and carbon nanotubes as raw materials. The dual-functional catalyst is endowed with excellent oxygen evolution reaction (OER) and oxygen reduction reaction (ORR) catalytic performance, the initial potential of OER is early, the current density of the dual-functional catalyst is large, the initial potential of ORR is early, the limiting current density is large, and the stability is high; and moreover, the charging and discharging voltage difference of the zinc-air battery before and after long circulation test is small, and the energy efficiency after long circulation is high. The preparation method has the advantages of simplicity, rapidness in operation, greenness and environment friendliness, the source of sodium alginate is rich, and the obtained dual-functional catalyst is excellent in performance and is the zinc-air battery catalyst having a very good prospect.

Owner:QINGDAO UNIV

A method for controllable growth of uniform nano nickel chain array induced by magnetic field

The present invention discloses a method for controllable growth of uniform nano nickel chain array induced by magnetic field. NiCl2.6H2O, glycol and hydrazine hydrate are chosen as raw materials. The raw materials react in a stable magnetic field to get a black product. Through centrifugal separation and alcohol wash of the black product, a regularly arranged nickel nano linear array is obtained. Through controlling the reaction temperature of the system and magnetic-field intensity, the present invention may obtain a nickel nano linear array with controllable dimensions, high purity, high length-diameter ratio and high orientation. The preparation method of the present invention is characterized by simple process, easy operation, moderate reaction conditions, energy conservation and environmental friendliness.

Owner:BEIHANG UNIV

Complex catalyst for viscosity reduction of thick oil by hydrothermal catalytic cracking and preparation and application thereof

ActiveCN102019205AFully play the catalytic activityLow viscosityCatalytic crackingOrganic-compounds/hydrides/coordination-complexes catalystsEthylenediamineReduction rate

Owner:PETROCHINA CO LTD +1

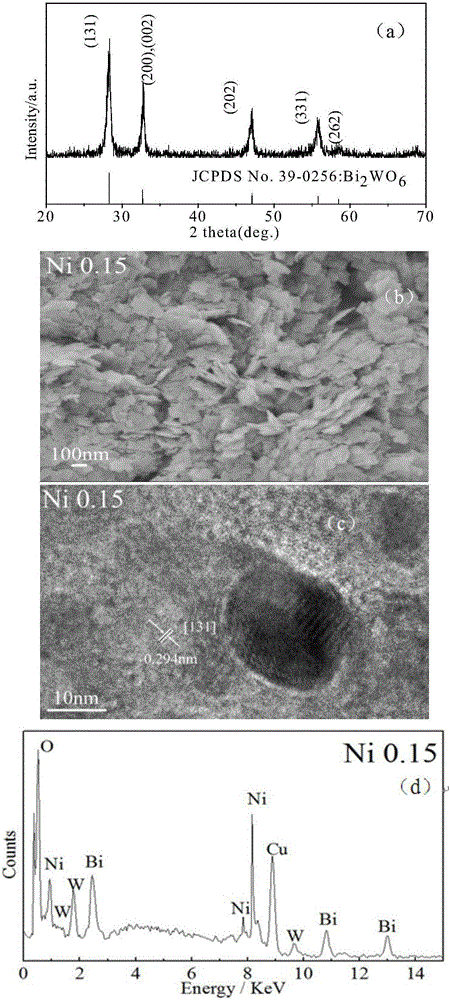

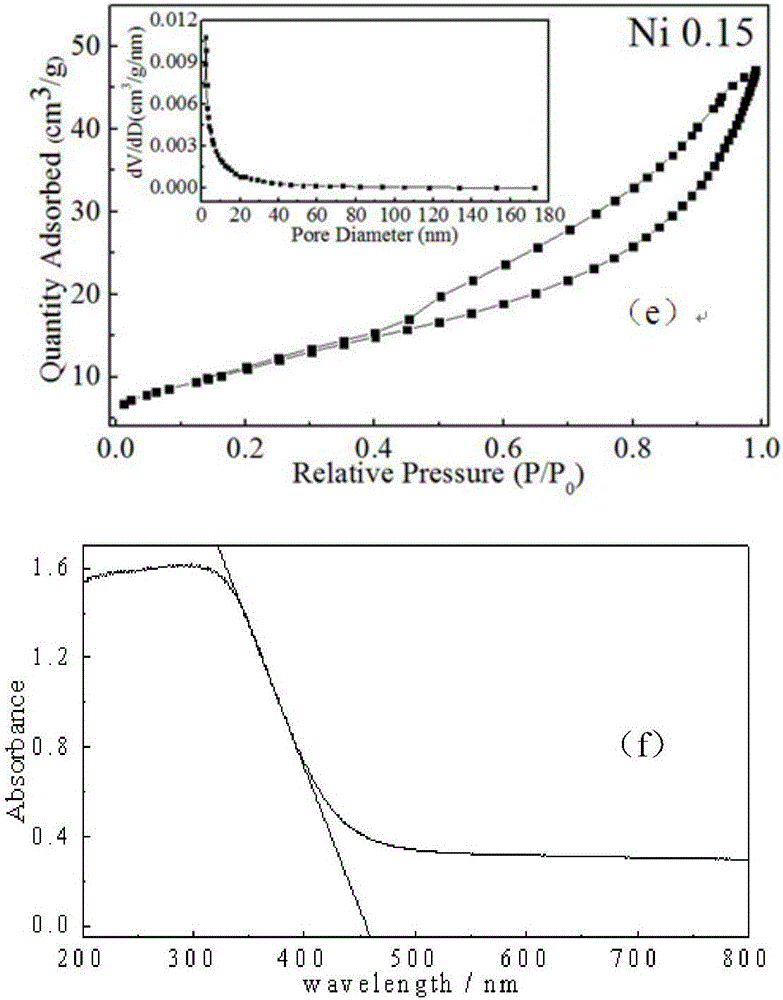

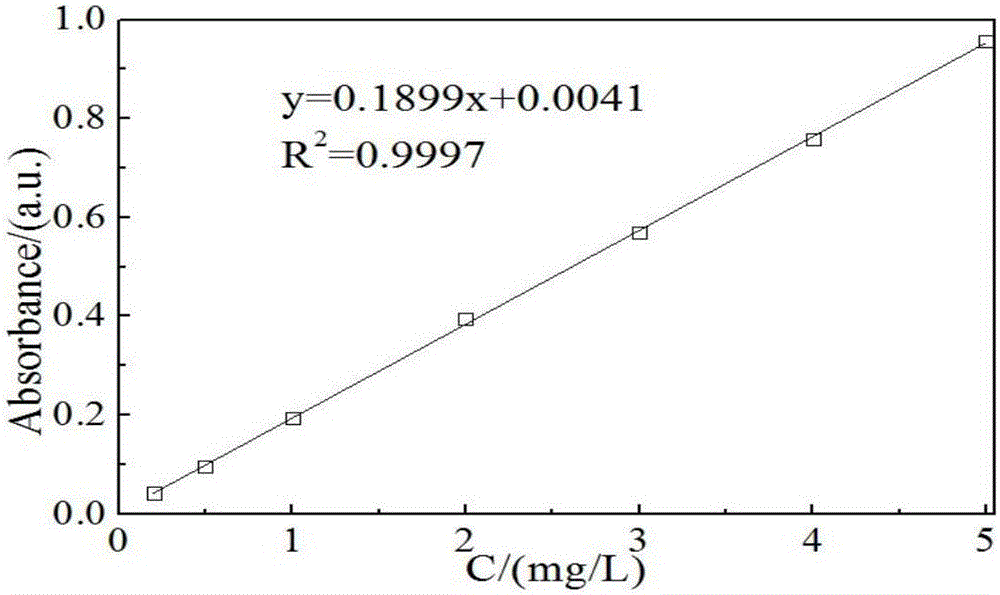

Nickel doped nanometer bismuth tungstate visible-light photocatalyst, and preparation and application thereof

InactiveCN106622271AImprove adsorption capacityImprove photocatalytic abilityWater/sewage treatment by irradiationWater treatment compoundsOrganic dyeTungstate

The invention belongs to the field of environmental photocatalysis research, and specifically discloses a nickel doped nanometer bismuth tungstate visible-light photocatalyst, and a preparation method and an application thereof. The nickel doped nanometer bismuth tungstate visible-light photocatalyst comprises nickel and tungsten with a mol ratio of 1: 20 to 1: 2. The preparation method comprises the following concrete steps: preparing a sodium tungstate aqueous solution, adding nickel chloride tetrahydrate and bismuth nitrate into the sodium tungstate aqueous solution, carrying out a reaction so as to form a precursor, transferring the precursor into a hydrothermal reactor with a polytetrafluoroethylene liner, then carrying out a reaction, and subjecting a reaction product to washing, centrifugation and drying so as to obtain a Ni-Bi2WO6 catalyst. The catalyst provided by the invention has good specific surface adsorption performance, and can realize highly-efficient catalytic degradation of organic dyes in water under visible light.

Owner:JINAN UNIVERSITY

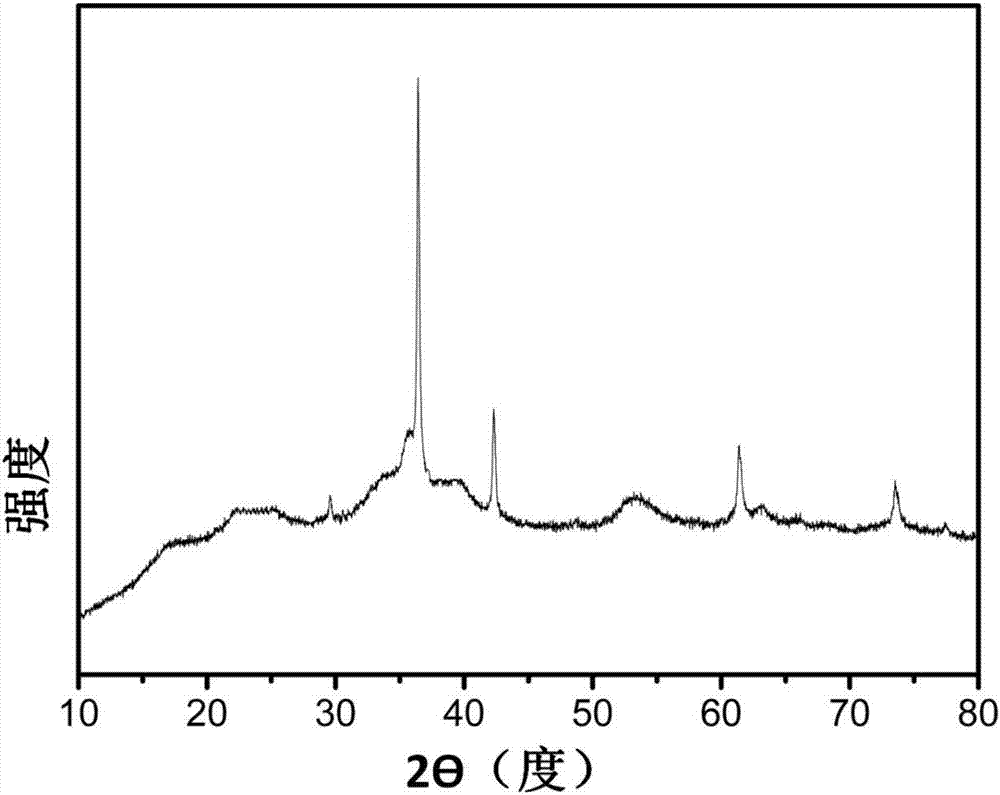

Preparation method and application of NiFe2O4/Cu2O magnetic composite nanometer catalyst

InactiveCN107008331AEnergy efficient and fast adsorptionEnergy Efficient and Fast Adsorption-Photocatalytic RemovalWater/sewage treatment by irradiationWater treatment compoundsNano catalystSodium hydroxide

The invention belongs to the technical field of catalysts, and particularly relates to a preparation method of a NiFe2O4 / Cu2O magnetic composite nanometer catalyst. According to the preparation method, nickel chloride hexahydrate, ferric trichloride hexahydrate, copper acetate hexahydrate, glucose, sodium hydroxide and deionized water are used as raw materials. The preparation method comprises the following steps: firstly preparing a mixed solution by using the nickel chloride hexahydrate and the ferric trichloride hexahydrate, then heating, separating, washing and drying the mixed solution to obtain a magnetic NiFe2O4 nanometer catalyst; secondly, dissolving copper acetate dihydrate in ethylene glycol monomethylether and stirring, adding NiFe2O4 solid powder to the mixed solution, stirring, adding the glucose, separating, washing and drying to obtain a NiFe2O4 / Cu2O magnetic composite nanometer catalyst. The NiFe2O4 / Cu2O magnetic composite nanometer catalyst can remove organic dyestuff in water through adsorption and photocatalysis efficiently and quickly, can be recycled through magnets and meanwhile has the characteristics of simple preparation and repeated use.

Owner:CHANGZHOU UNIV HUAIDE COLLEGE

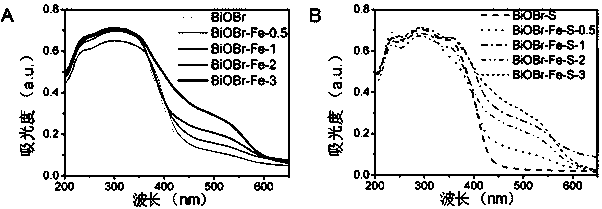

Oxygen vacancy-containing transition metal doped BiOBr nanosheet photocatalyst, preparation method and applications thereof

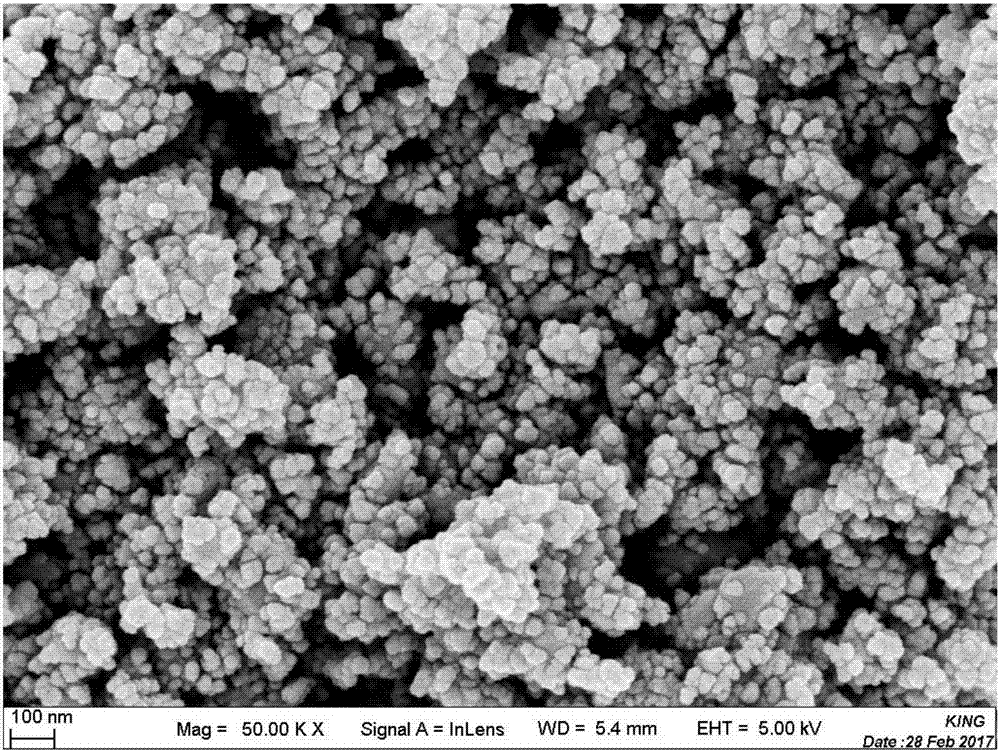

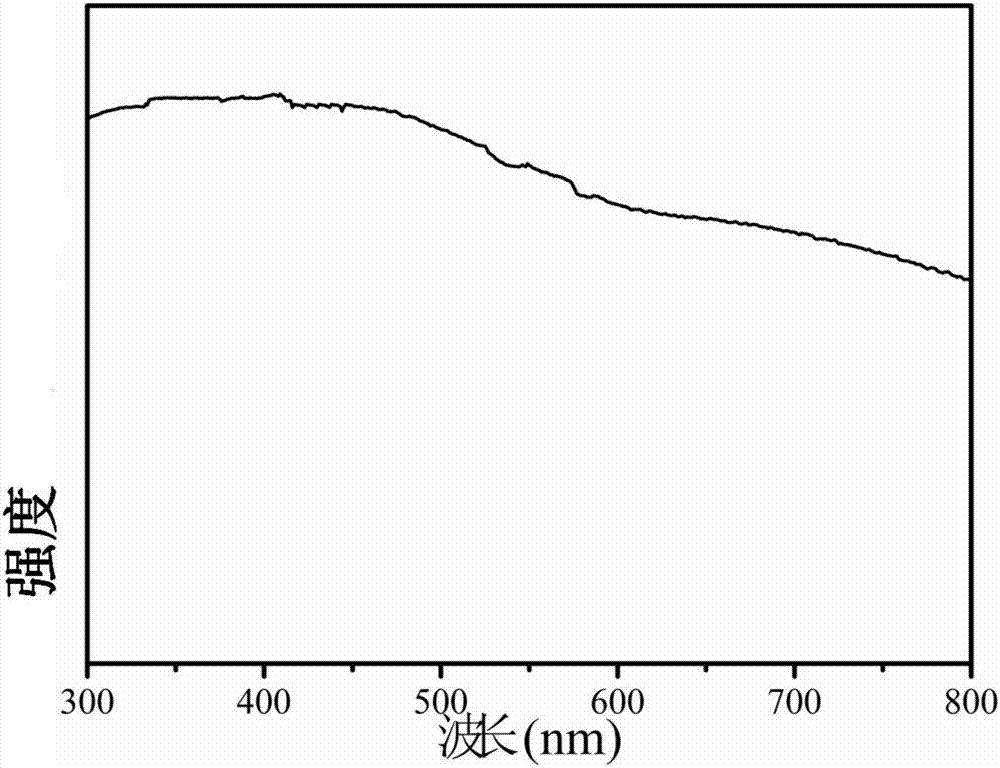

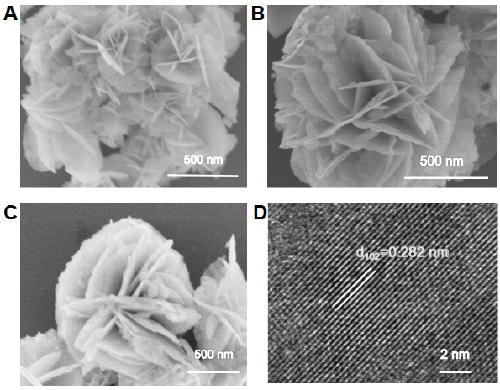

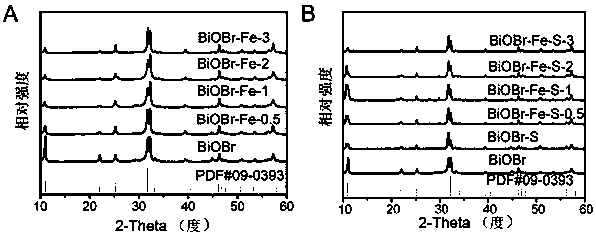

ActiveCN111036243AImprove adsorption capacityEfficient catalytic reduction half-reactionPhysical/chemical process catalystsBulk chemical productionPtru catalystOxygen vacancy

The invention discloses an oxygen-vacancy-containing transition metal (iron, molybdenum and nickel)-doped BiOBr nanosheet photocatalyst and a preparation method thereof, and applications in photocatalytic reduction of nitrogen to produce ammonia. According to the invention, bismuth nitrate pentahydrate, potassium bromide and metal salts (anhydrous ferric chloride, sodium molybdate and nickel chloride dehydrate) are used as raw materials, a transition metal doped BiOBr nanosheet is synthesized through a hydrothermal method, and the transition metal doped BiOBr nanosheet photocatalyst containingoxygen vacancy is obtained through secondary solvothermal method treatment; and the method is simple in preparation process, visible light is used as driving energy, water is used as a reaction solvent, the oxygen-vacancy-containing transition metal doped BiOBr nanosheet is used for photocatalytic reduction of nitrogen to produce ammonia for the first time, and the BiOBr nanosheet photocatalyst has high catalytic activity and is beneficial to sustainable development of environment and energy.

Owner:FUZHOU UNIV

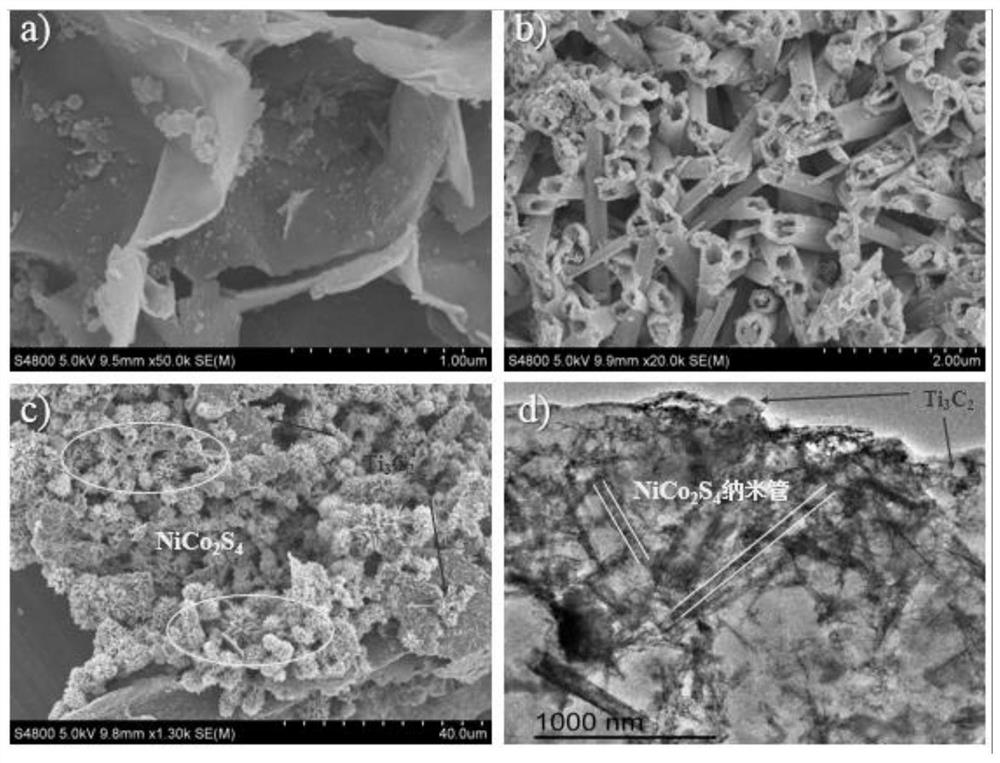

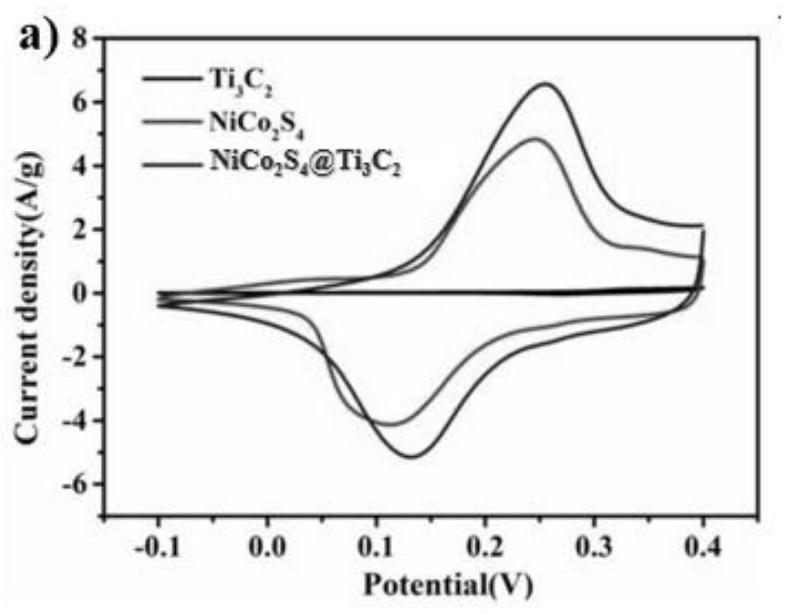

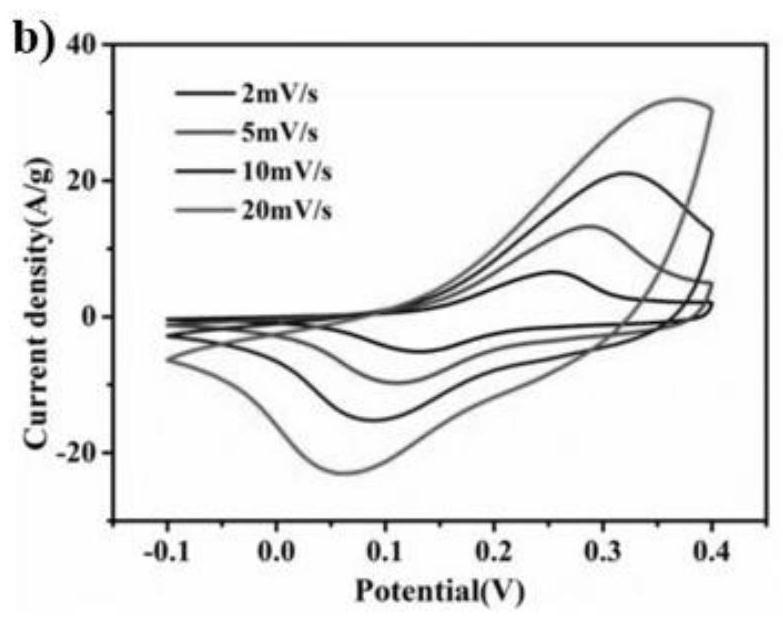

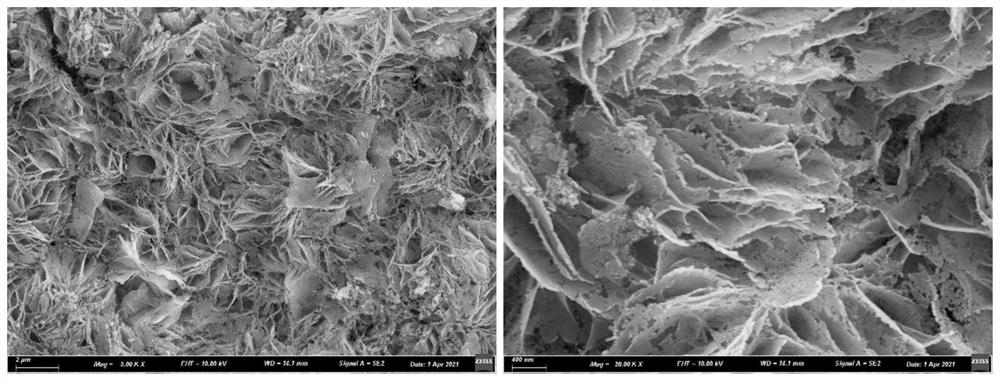

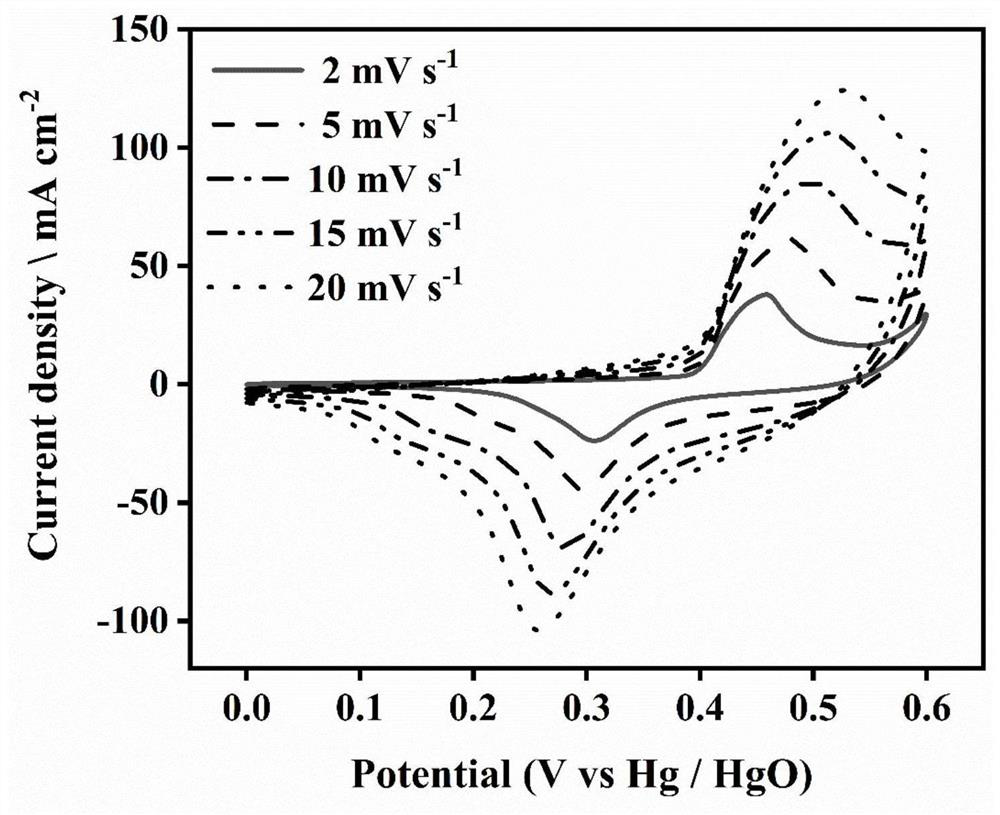

Nanotube NiCo2S4@titanium carbide composite material and preparation method and application thereof

InactiveCN111916288AImprove conductivityHigher theoretical specific capacitanceMaterial nanotechnologyHybrid capacitor electrodesCapacitanceTitanium carbide

The invention discloses a nano tubular NiCo2S4@titanium carbide composite material and a preparation method and application thereof. The nano material takes nickel chloride hexahydrate as a nickel source, takes cobalt chloride hexahydrate as a cobalt source, and employs a two-step hydrothermal method. The method comprises the steps: preparing a nano tubular precursor by a first hydrothermal method, wherein at the moment, the two materials are compounded together by the precursor; vulcanizing the precursor through secondary hydrothermal treatment, wherein the material compounds Ti3C2 of a single sheet layer with hollow tubular NiCo2S4 for the first time to prepare a NiCo2S4@titanium carbide composite material, and the NiCo2S4@titanium carbide composite material is applied to research of electrochemical performance of a supercapacitor, and loading modified Ti3C2 on a NiCo2S4 hollow tube to provide an additional electron transmission path, thereby improving the electron transmission efficiency. Experiments show that compared with a single electrode material, the NiCo2S4 and titanium carbide composite electrode material has more excellent specific capacitance and cycle performance.

Owner:SHAANXI UNIV OF SCI & TECH

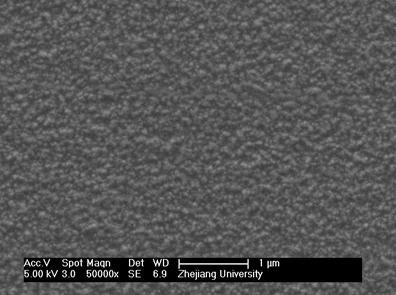

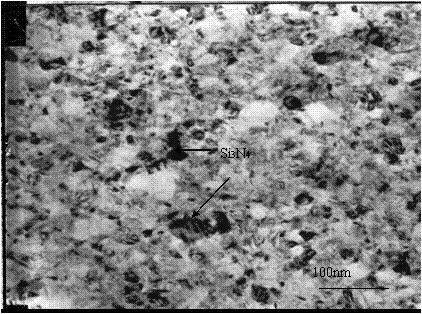

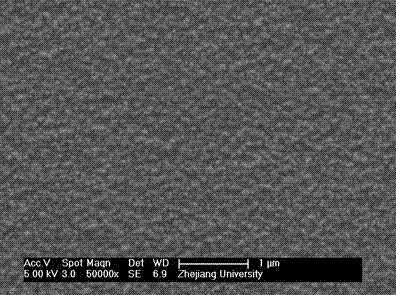

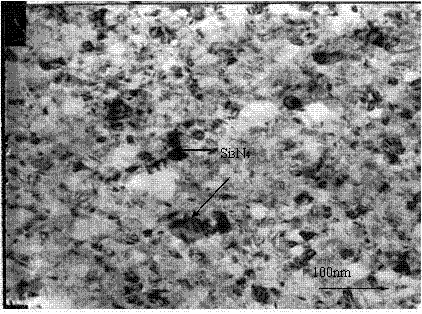

Nano-structure Ni-base composite electroplating solution containing nano Si3N4 particles and preparation method thereof

InactiveCN102051644AShort process flowReduce investmentMaterial nanotechnologyElectrolytic coatingsNickel sulfate hydrateNanostructure

The invention belongs to the technical fields of electrochemistry and metal surface treatment, in particular relates to a nano-structure Ni-base composite electroplating solution containing nano Si3N4 particles and a preparation method thereof. Every 1L of the nano-structure Ni-base composite electroplating water solution containing nano Si3N4 particles comprises 5-12g of the nano Si3N4 particles, 160-220g of nickel sulfate hexahydrate, 42-57g of nickel chloride hexahydrate, 40-55g of boric acid, 1.6-5.0g of lauryl sodium sulfate, 0.1-1.0g of 1,4-butynediol and 0.8-5.0g of brightener, whereinthe nano Si3N4 particles are firstly subjected to surface chemical modification by using a lauryl sodium sulfate solution. A thin-film material produced by using the composite electroplating solutionprovided by the invention has the characteristics of favorable binding force with a substrate, favorable corrosion resistance, higher hardness and favorable wear resistance.

Owner:JIAXING TIANQI NEW MATERIAL TECH

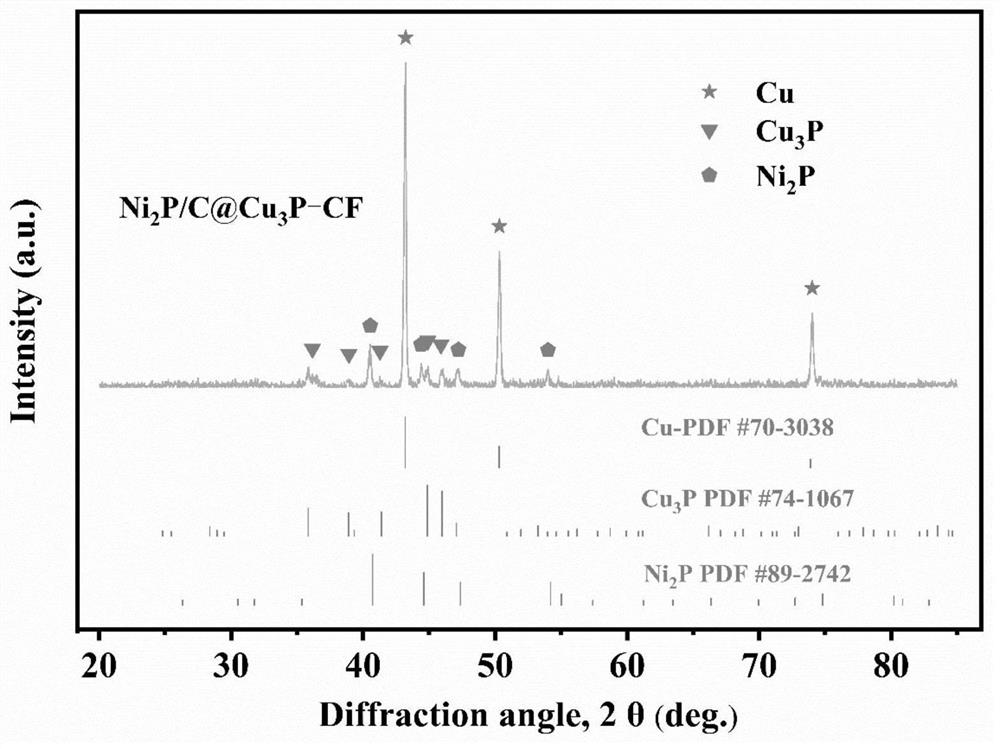

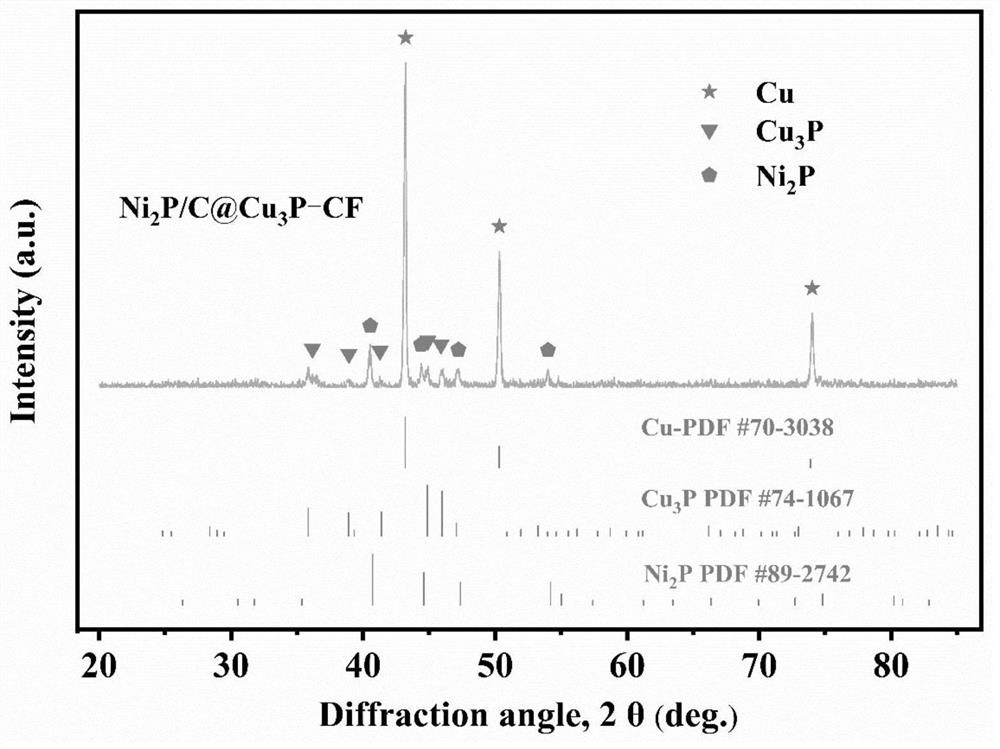

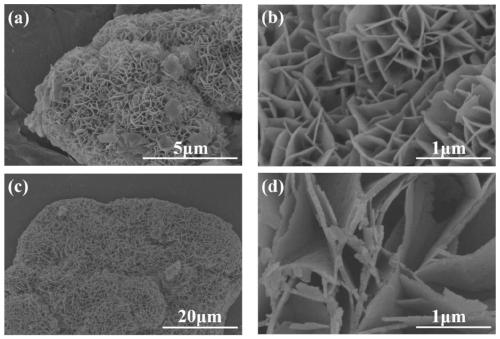

A MOF-derived porous metal phosphide nanosheet array and its application

ActiveCN113299492BExcellent redox reversible performanceImprove hydrophilicityMaterial nanotechnologyHybrid capacitor electrodesPhysical chemistrySupercapacitor

A MOF-derived porous metal phosphide nanosheet array and its application belong to the technical field of MOF-derived supercapacitor materials. Nickel chloride hexahydrate (NiCl 2 ·6H 2 O), terephthalic acid (PTA) and copper foam were reductively phosphated under relatively mild conditions to prepare electrode materials with excellent supercapacitor performance - in situ growth of carbon-coated Ni on foam substrates 2 Porous nanoarrays of P (Ni 2 P / C@substrate). The material has good redox reversible properties.

Owner:BEIJING UNIV OF TECH

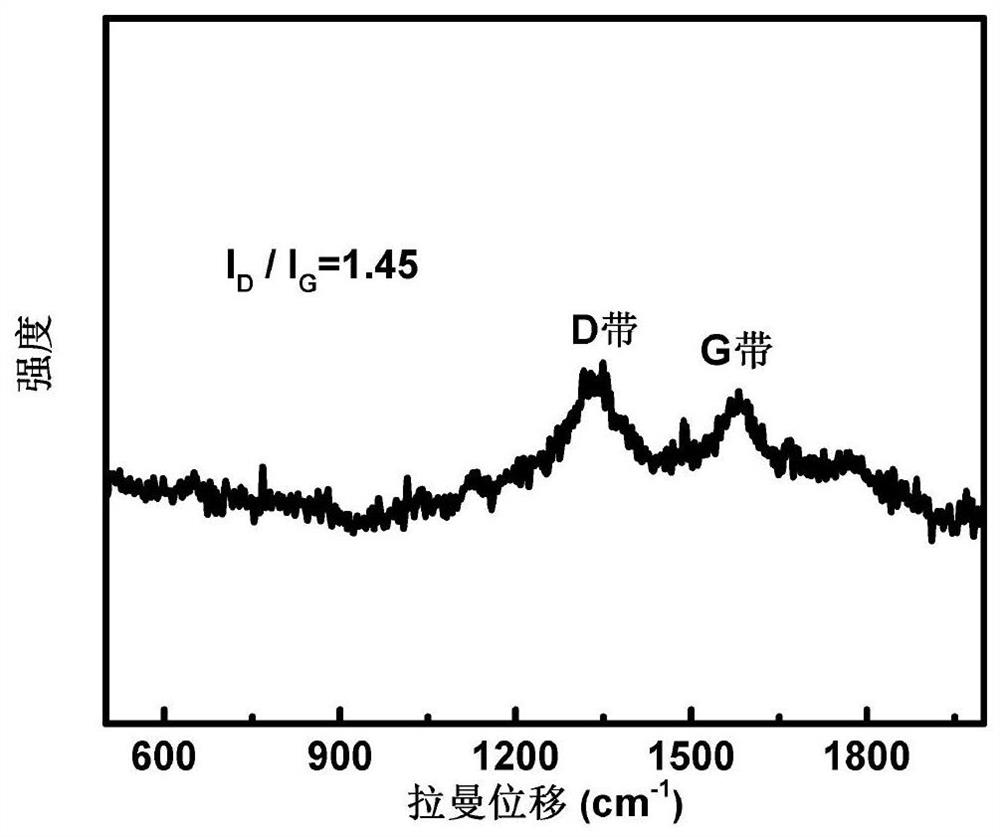

Preparation method of lithium ion battery positive electrode material

InactiveCN112421006AImprove electrochemical performanceSimple structureCell electrodesSecondary cellsCarbon nanotubeLithium-ion battery

The invention relates to a preparation method of a lithium ion battery positive electrode material, and belongs to the technical field of lithium ion battery electrode materials. The method comprisesthe following steps: adding 50mg-200mg of ferric chloride hexahydrate, 5mg-40mg of nickel chloride hexahydrate and 3mg-20mg of carbon nanotubes into a mixed solvent consisting of water and DMF, adding1-5ml of a sodium sulfide solution with the concentration of 0.1 M into the mixed solution, carrying out heating reflux, transferring into a hydrothermal kettle, carrying out hydrothermal reaction toobtain a hydrothermal reaction product, and carrying out microwave plasma treatment. The FeNiS2-CNTs material prepared by the method has good chemical properties, more active sites are exposed due toa relatively large graphitization defect degree, and the preparation method is environment-friendly, simple and convenient for large-scale production.

Owner:江苏大学京江学院

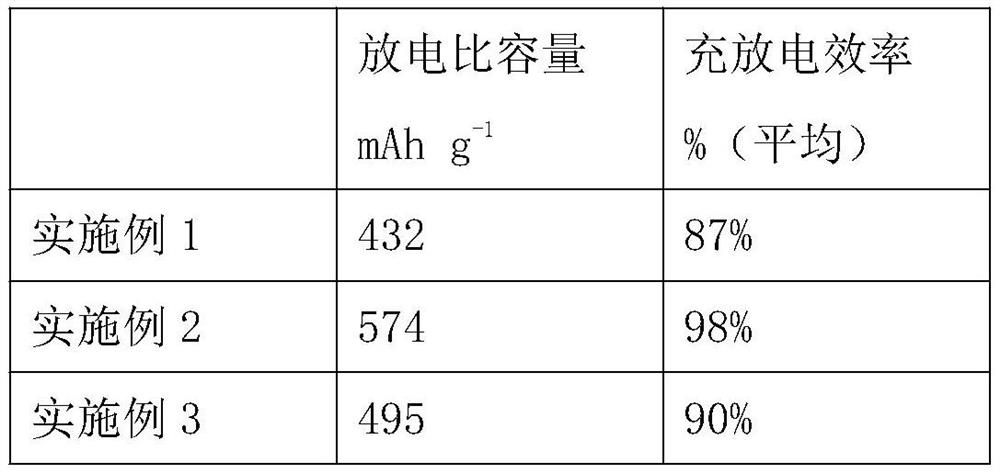

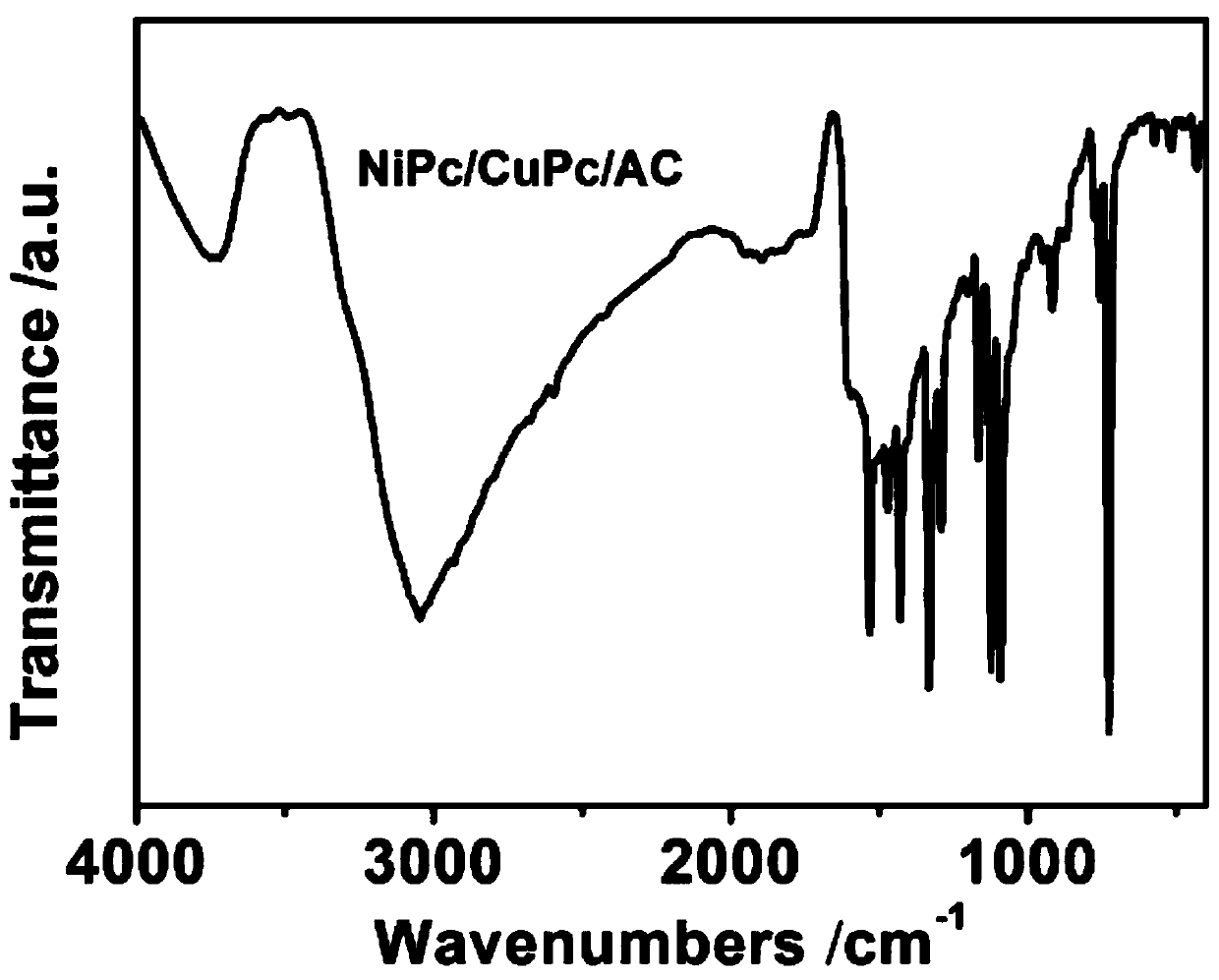

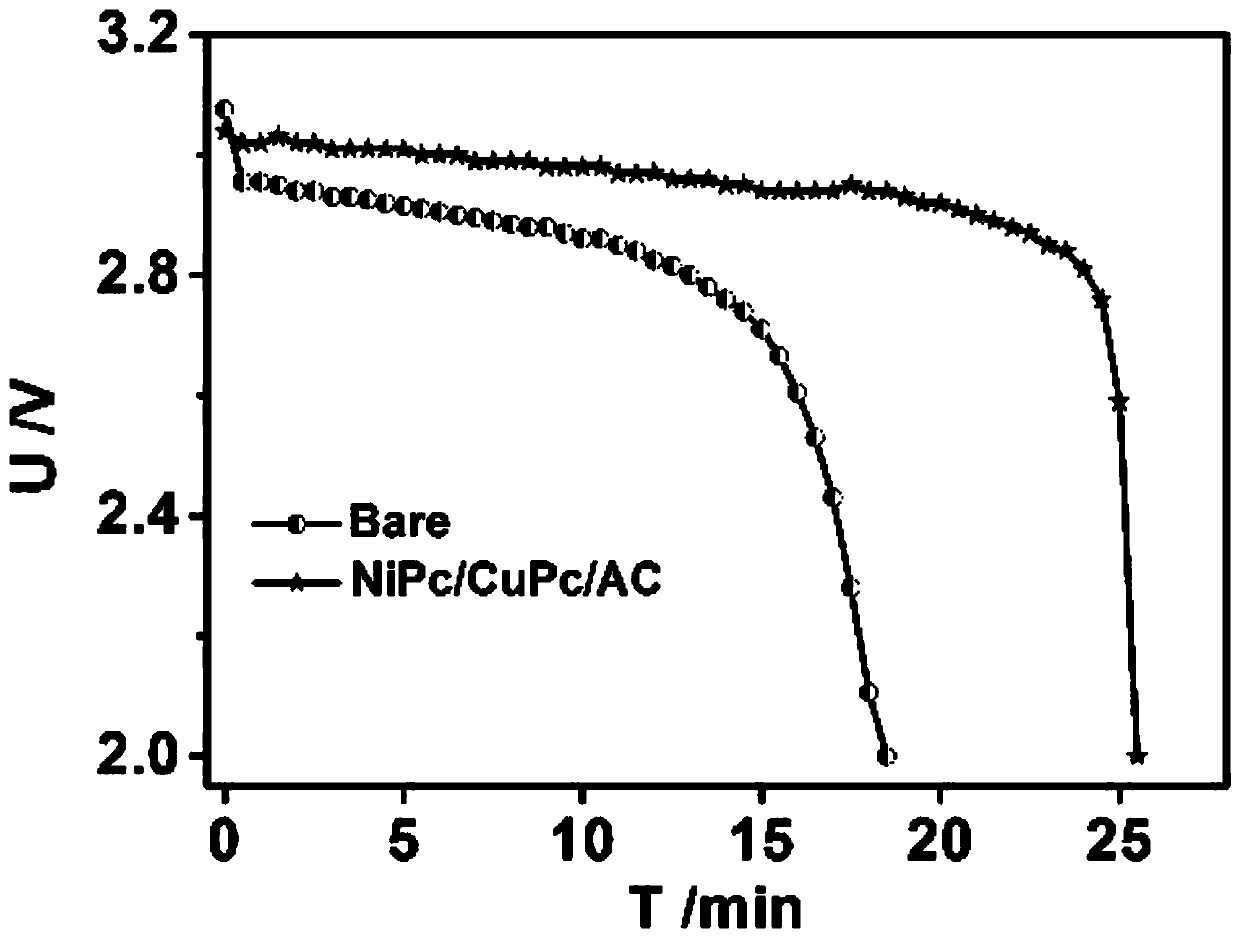

Preparation method of nickel phthalocyanine/copper phthalocyanine/activated carbon Li/SOCl2 battery positive electrode catalytic material

The invention discloses a preparation method of a nickel phthalocyanine / copper phthalocyanine / activated carbon Li / SOCl2 battery positive electrode catalytic material. The method comprises the following steps of respectively grinding and then mixing phthalic anhydride, pitch coke activated carbon, urea, ammonium molybdate tetrahydrate, nickel chloride hexahydrate and copper chloride dihydrate to obtain a mixture; putting the mixture into a crucible, carrying out solid-phase sintering at 110-290 DEG C, and cooling to room temperature to obtain a crude product; and grinding the crude product, purifying and drying to obtain the nickel phthalocyanine / copper phthalocyanine / activated carbon Li / SOCl2 battery positive electrode catalytic material. The prepared positive electrode catalytic materialhas the excellent catalytic performance for the Li / SOCl2 batteries.

Owner:SHAANXI UNIV OF SCI & TECH

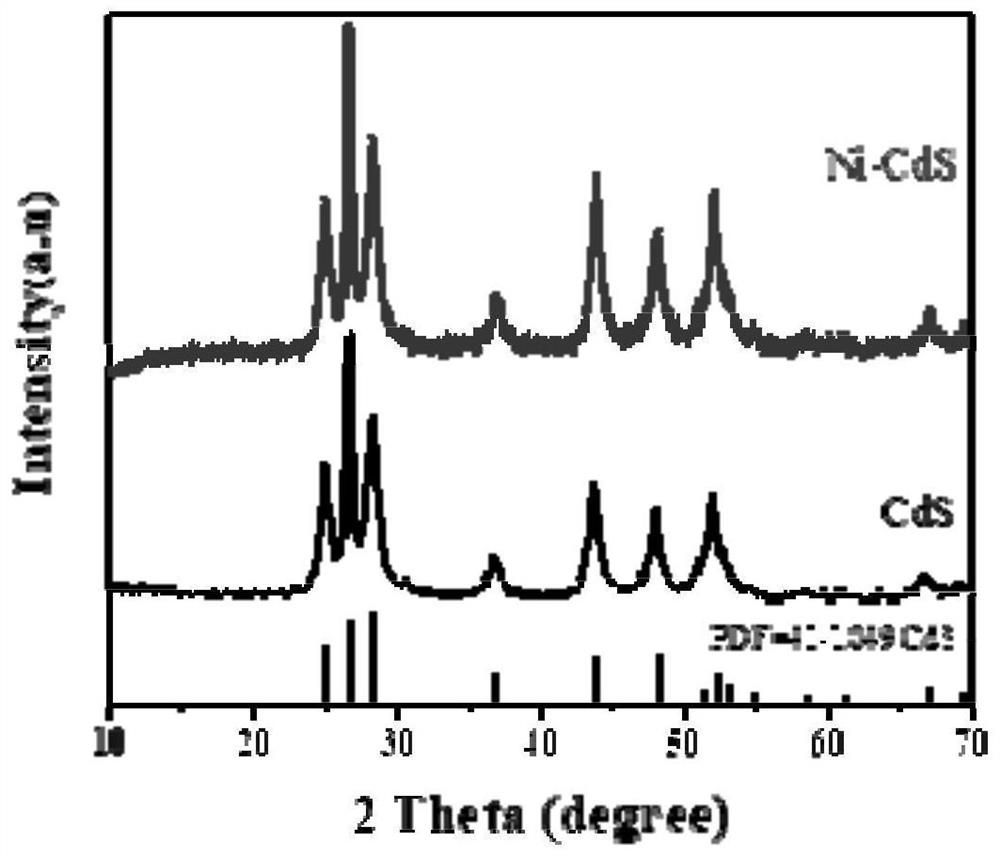

Hydrothermally synthesized Ni-doped CdS composite photocatalyst as well as preparation method and application thereof

InactiveCN114272939AEnhance photocatalytic hydrogen productionImprove conductivityCatalyst activation/preparationHydrogen productionHydration reactionThio-

The invention discloses a hydro-thermally synthesized Ni-doped CdS composite photocatalyst as well as a preparation method and application thereof. The hydro-thermally synthesized Ni-doped CdS composite photocatalyst comprises CdS powder, nickel chloride hexahydrate and urea in a ratio of (1-2): (0.4-1): (10-20). The preparation method comprises the following steps: step 1, weighing cadmium acetate and thioacetamide in a ratio of (0.5-0.8): (0.6-1.2), adding ethylenediamine and ethylene glycol in a ratio of (1-4): 1, and stirring to form a solution A; step 2, carrying out hydrothermal reaction on the solution A, and filtering to obtain CdS powder; step 3, adding CdS powder, nickel chloride hexahydrate and urea into deionized water according to a ratio of (1-2): (0.4-1): (10-20), and stirring to obtain a solution B; and step 4, carrying out hydrothermal reaction on the solution B, filtering and drying to obtain the Ni-doped CdS composite photocatalyst material.

Owner:SHAANXI UNIV OF SCI & TECH

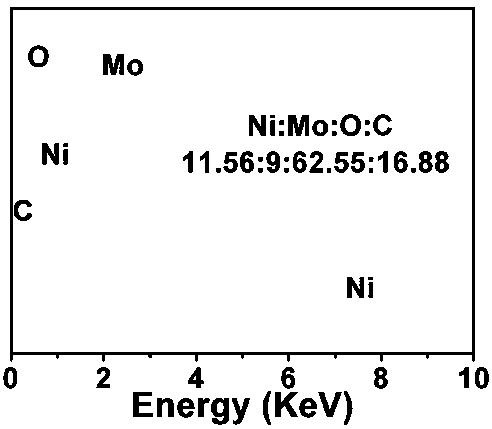

Preparation method of nickel molybdate/carbon electrode material and prepared supercapacitor

InactiveCN110993364AHigh specific capacitanceExcellent rate performanceHybrid capacitor separatorsHybrid capacitor electrolytesCarbon compositesHigh current density

The invention provides a preparation method of a nickel molybdate / carbon electrode material and a prepared supercapacitor. The nickel molybdate / carbon electrode material is a porous one-dimensional electrode material prepared by taking sodium molybdate dehydrate, nickel chloride hexahydrate, deionized water and cyclohexane as raw materials through a solvothermal method and an annealing step, and the preparation method is simple and easy to implement, high in yield and easy to industrially amplify, and has a good application prospect. A supercapacitor prepared from the nickel molybdate / carbon composite electrode material has relatively high specific capacitance, excellent rate capability and cycling stability. And rapid charging and discharging under high current density can be effectivelyrealized. Under the current density of 0.5 Ag<-1>, the capacity of a single electrode is as high as 325.1 F g<-1>. When the current density is increased to 8 A g <-1>, the capacity is still kept at 182.1 F g<-1>, and after 10000 circles of circulation under the current density of 5 A g<-1>, the capacity still reaches 105.8 F g<-1>.

Owner:ZHONGYUAN ENGINEERING COLLEGE

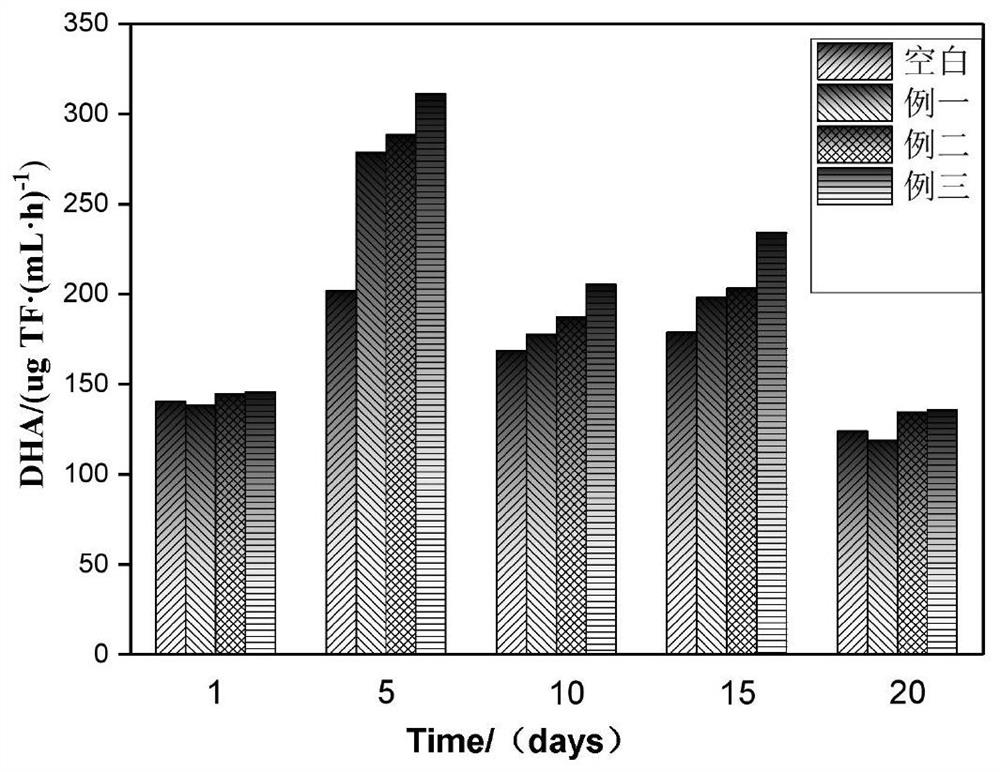

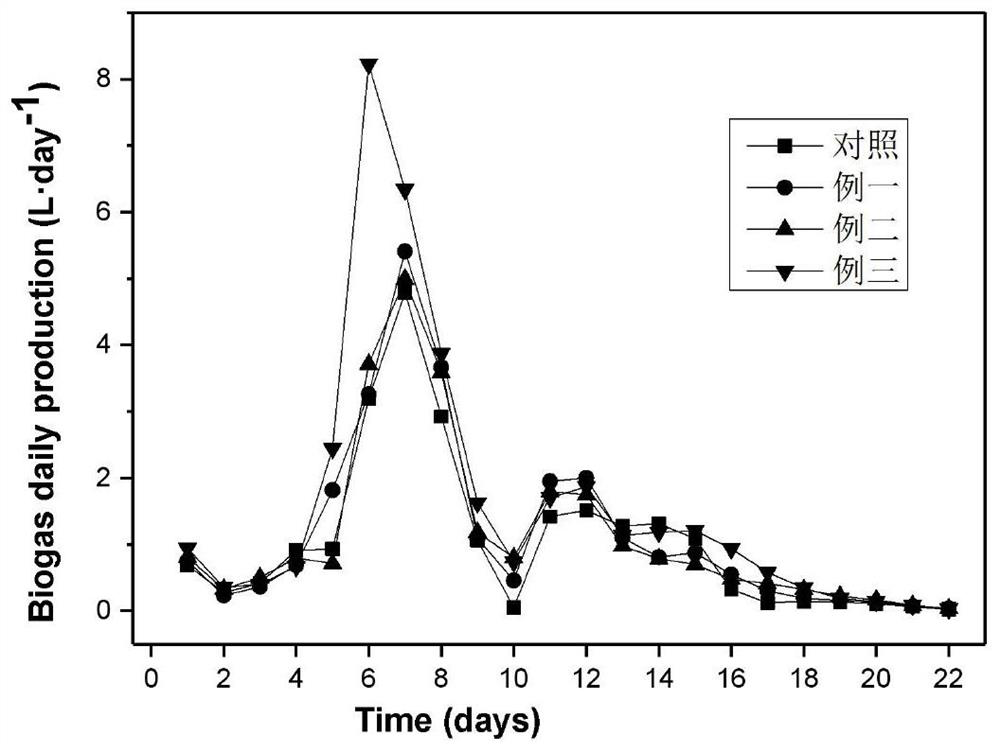

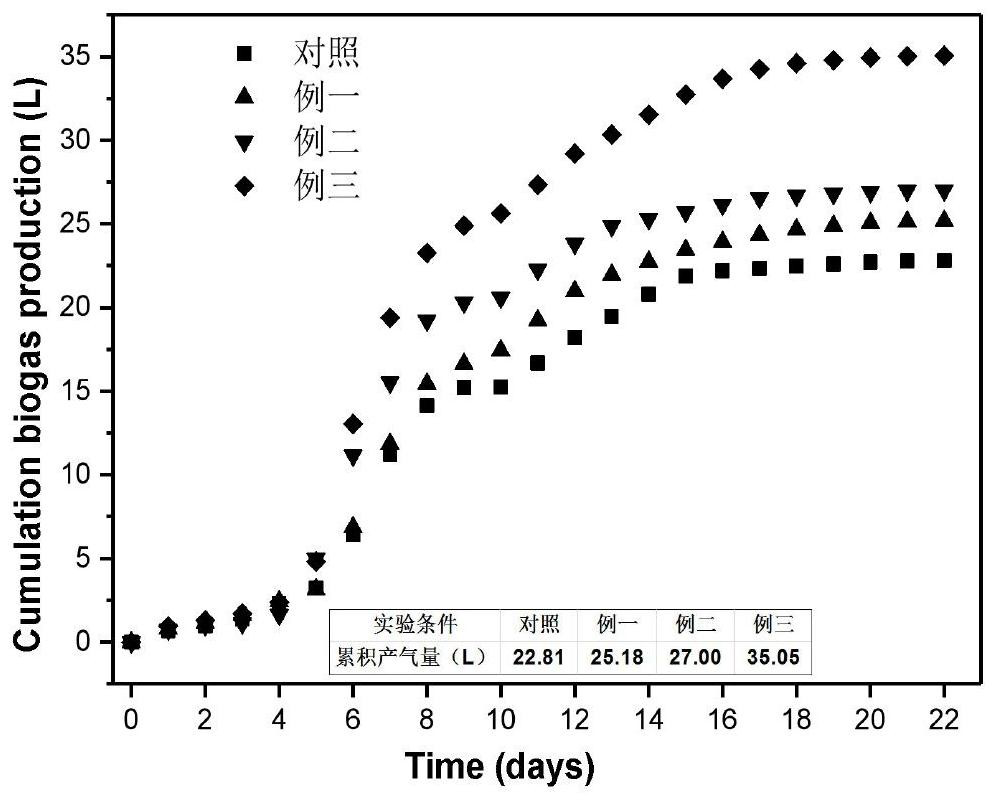

Mixed metal salt formula for increasing biogas yield of cassava vinasse waste liquid through fermentation

ActiveCN111607554AMeet growth needsIncrease growth rateWaste based fuelFermentationDipotassium hydrogen phosphateSodium acetate

The invention belongs to the technical field of carbon-containing waste resource utilization, and particularly relates to a mixed metal salt formula for increasing the biogas yield of cassava vinassewaste liquid through anaerobic fermentation. The mixed metal salt formula is composed of ferrous chloride tetrahydrate, cobalt chloride hexahydrate, nickel chloride hexahydrate, sodium acetate, potassium dihydrogen phosphate, dipotassium hydrogen phosphate, magnesium sulfate, manganese sulfate monohydrate, zinc sulfate monohydrate, calcium chloride and ammonium chloride. The mixed metal salt is added into a fermented liquid to increase the biogas yield of cassava vinasse waste liquid through fermentation, and the formula can promote the rapid growth of anaerobic microorganisms, and increase the concentration and diversity of microorganisms and the biogas yield.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

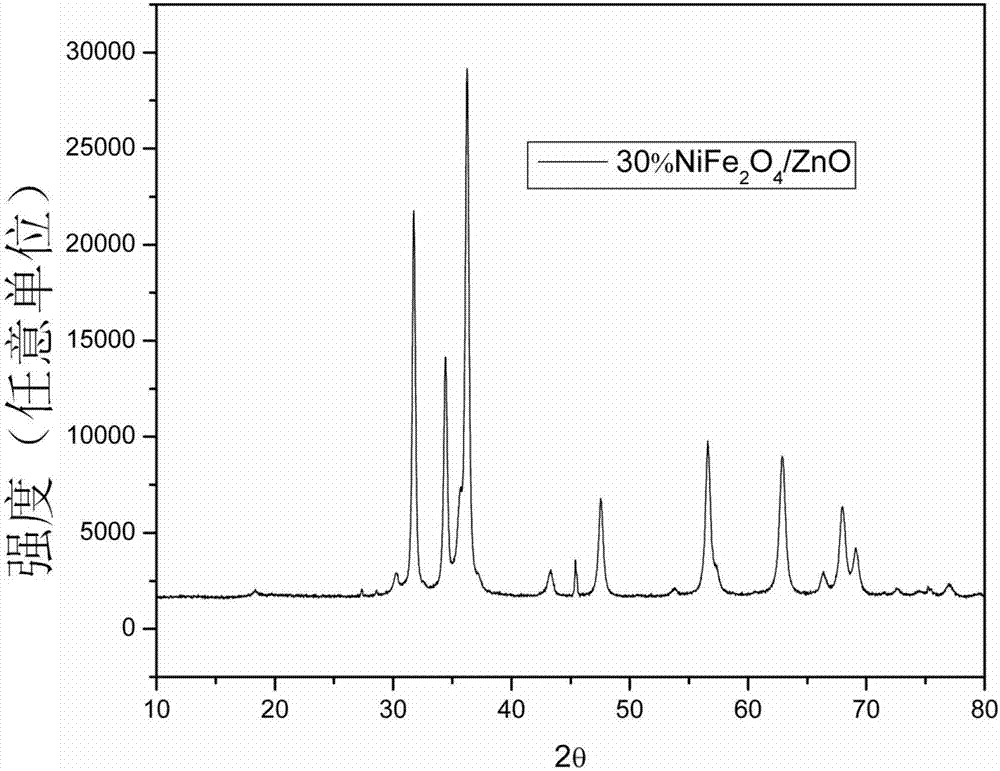

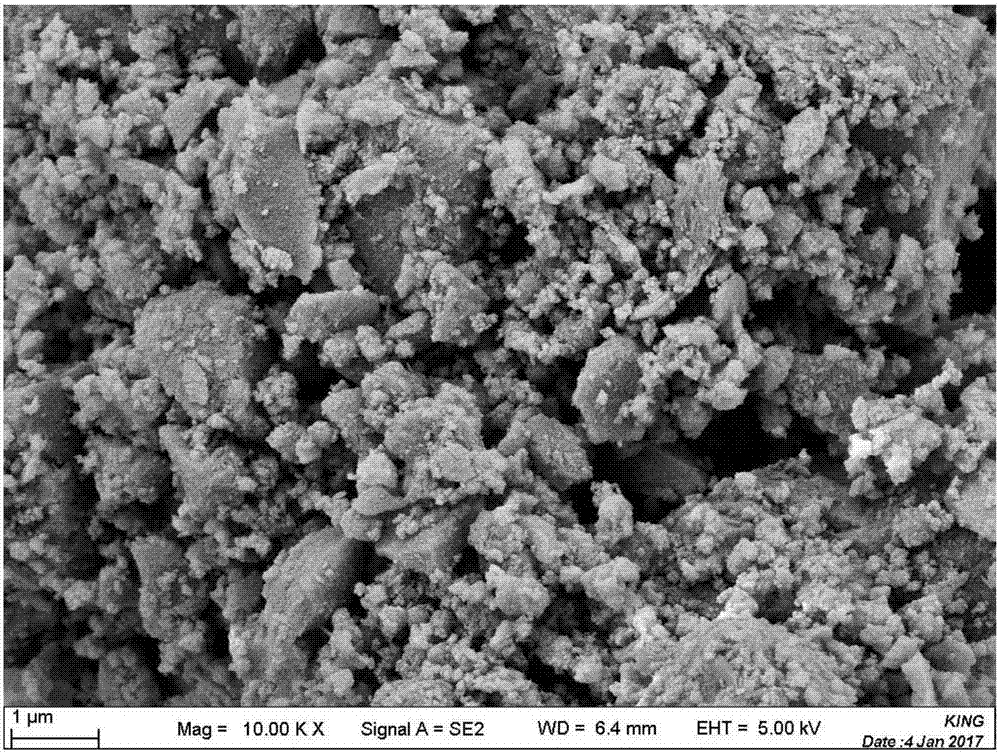

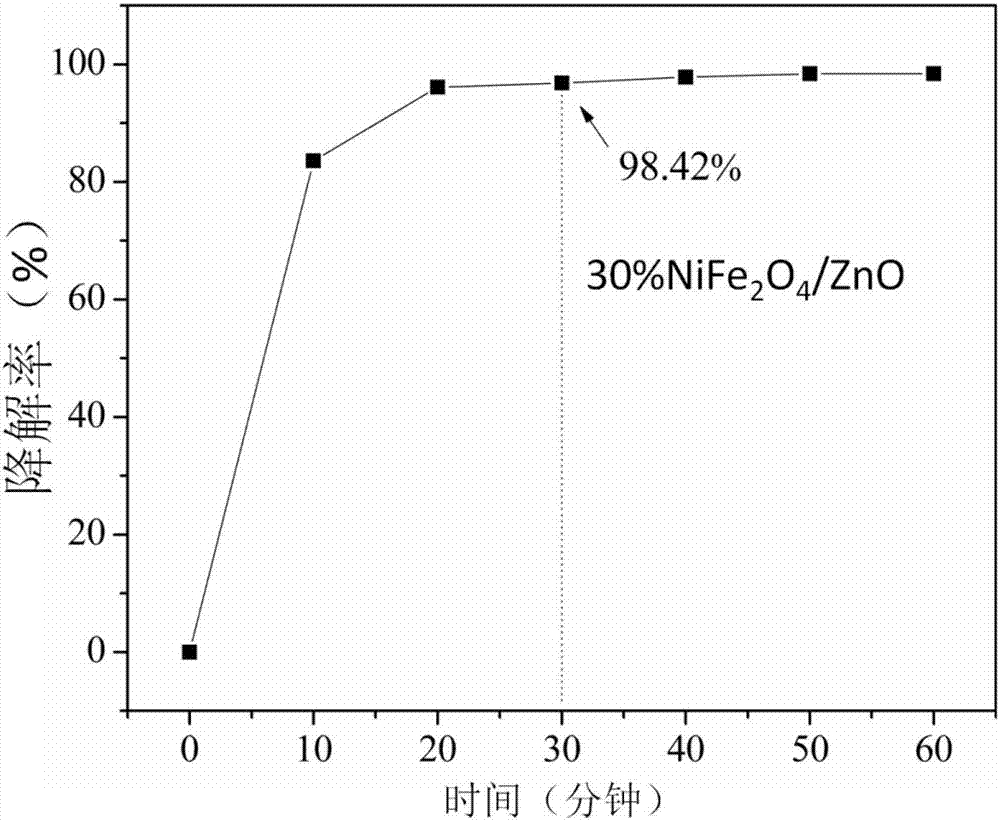

Preparation method and application of magnetic heterogeneous photo-Fenton NiFe2O4/ZnO composite nano material

InactiveCN107008333AEnergy efficient and fast adsorptionEnergy Efficient and Fast Adsorption-Photocatalytic RemovalWater/sewage treatment by irradiationOther chemical processesSemiconductor materialsPtru catalyst

The invention belongs to the technical field of catalysts and particularly relates to a preparation method of a magnetic heterogeneous photo-Fenton NiFe2O4 / ZnO composite nano material. The preparation method using nickel chloride hexahydrate, ferric trichloride hexahydrate, zinc acetate dihydrate, ethylene glycol monomethyl ether, ethanolamine, sodium hydroxide and deionized water as the raw materials includes: preparing the nickel chloride hexahydrate and the ferric trichloride hexahydrate into a mixed solution, and performing heating, separation, washing and drying on the mixed solution to obtain magnetic heterogeneous photo-Fenton NiFe2O4; dissolving the zinc acetate dihydrate into the ethylene glycol monomethyl ether while stirring to obtain a mixed solution, adding NiFe2O4 solid powder into the mixed solution, adding the ethanolamine and a dispersing agent while stirring, heating, separating, washing, and drying to obtain the magnetic heterogeneous photo-Fenton NiFe2O4 / ZnO composite nano semiconductor material. The material can achieve effective and fast absorption-photocatalysis to remove organic dye in water, can be recycled through magnets and is simple to prepare and reusable.

Owner:CHANGZHOU UNIV HUAIDE COLLEGE

MOF-derived porous metal phosphide nanosheet array and application

ActiveCN113299492AExcellent redox reversible performanceImprove hydrophilicityMaterial nanotechnologyHybrid capacitor electrodesSupercapacitorRedox

The invention discloses an MOF-derived porous metal phosphide nanosheet array and application, and belongs to the technical field of MOF derivative supercapacitor materials. Nickel chloride hexahydrate (NiCl2. 6H2O), terephthalic acid (PTA) and foamy copper are subjected to reduction and phosphorization under a relatively mild condition to prepare an electrode material with excellent supercapacitor performance, namely a porous nano array (Ni2P / C@substrate) of carbon-coated Ni2P grown on a foam substrate in situ. The material has good redox reversibility.

Owner:BEIJING UNIV OF TECH

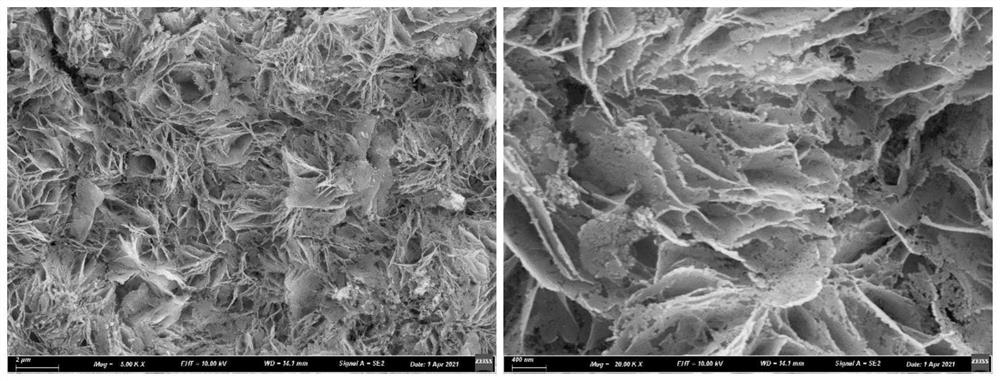

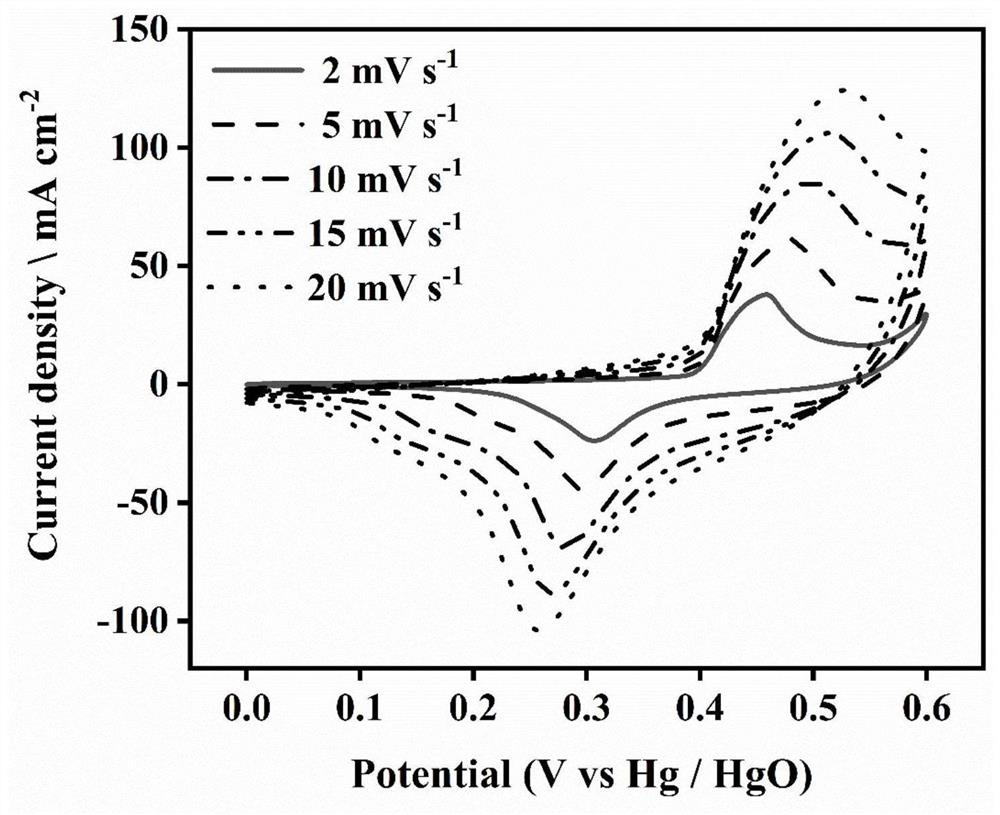

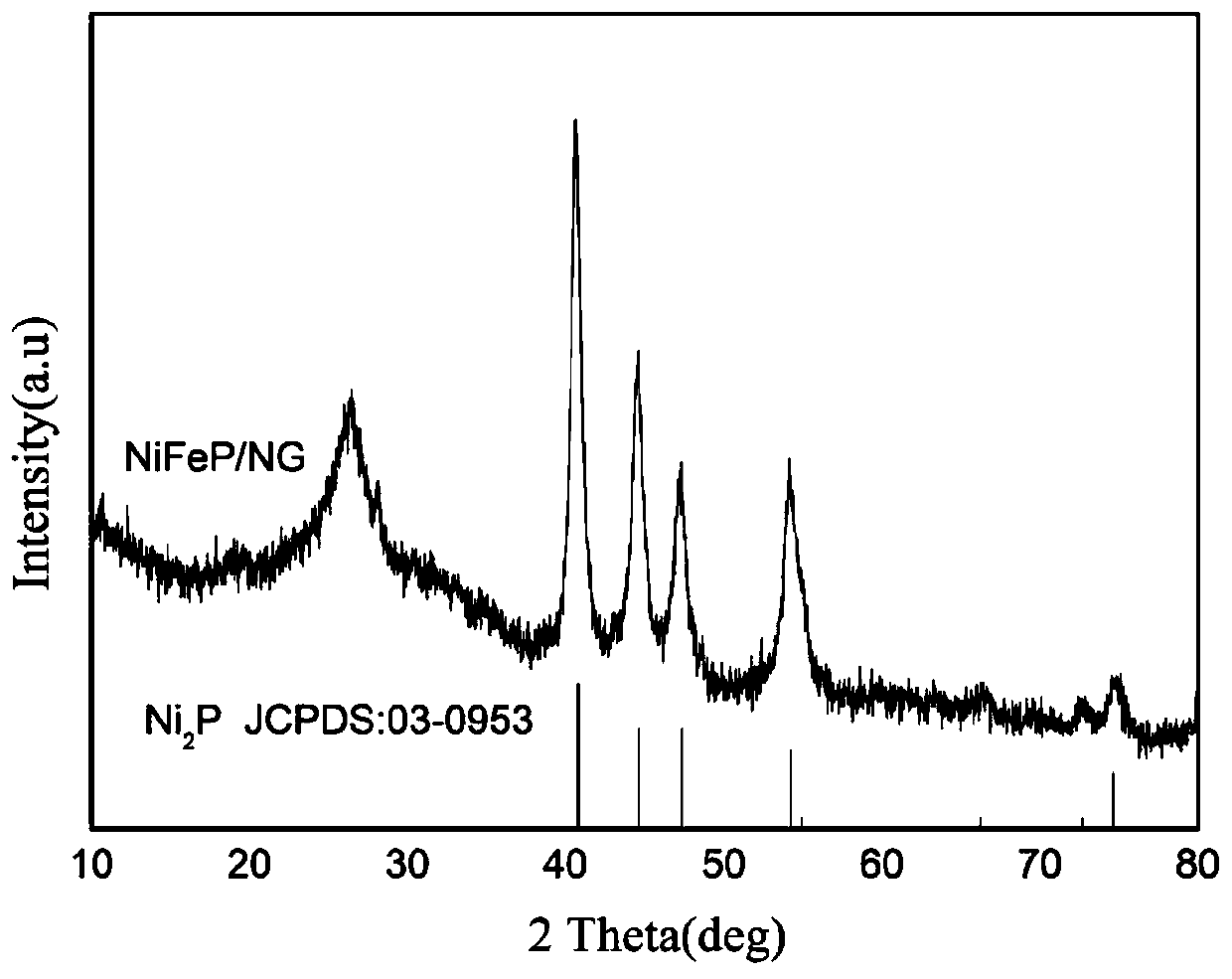

Preparation method of iron-doped nickel phosphide composite nitrogen-doped reduced graphene oxide electro-catalytic material

InactiveCN111068726AEasy to prepareLow costPhysical/chemical process catalystsElectrodesHydration reactionPhysical chemistry

The invention discloses a preparation method of an iron-doped nickel phosphide composite nitrogen-doped reduced graphene oxide electro-catalytic material, and the method comprises the following steps:1) dissolving graphene oxide, carrying out ultrasonic treatment to obtain a uniform graphene oxide solution, adding melamine, stirring, and evaporating to obtain a light black solid; 2) putting the light black solid into a tubular furnace, heating and preserving heat in an inert atmosphere, cooling to room temperature, washing and drying to obtain nitrogen-doped reduced graphene oxide; 3) dissolving the nitrogen-doped reduced graphene oxide in deionized water to obtain a nitrogen-doped reduced graphene oxide solution; 4) adding urea, NH4F, nickel chloride hexahydrate and ferrous sulfate heptahydrate into the nitrogen-doped reduced graphene oxide solution, and uniformly stirring; 5) transferring the solution into a reaction kettle, centrifuging after reaction to obtain a dark green precipitate, washing and drying to obtain a precursor material, and 6) heating the precursor material in an inert atmosphere, keeping the temperature, and cooling to room temperature to obtain the catalyst.The preparation method is simple, low in cost and excellent in catalytic performance.

Owner:ZHEJIANG UNIV

Nickel molybdate nano-catalyst, and preparation method and application thereof

ActiveCN111167465ASolve pollutionSolve energy shortageHydrogenCatalyst activation/preparationPtru catalystMolybdate

The invention discloses a nickel molybdate nano-catalyst, and a preparation method and application thereof. The nickel molybdate nano-catalyst is prepared from ammonium molybdate tetrahydrate, nickelchloride hexahydrate and deionized water as raw materials through a supercritical hydrothermal synthesis method, wherein a mass ratio of the ammonium molybdate tetrahydrate to the nickel chloride hexahydrate is 1.346: 1. The catalyst is suitable for hydrogen production through formaldehyde reforming and has the advantages of high H2 selectivity, long service life, simple regeneration and the like,and high-added-value carbon nanotubes can be separated during catalyst regeneration. The nickel molybdate nano-catalyst can convert the organic pollutant formaldehyde into hydrogen and prepare a large amount of carbon nanotubes at the same time, has the social and economic benefits of being environment-friendly, turning the waste into wealth and the like, and has wide market application prospects.

Owner:南京环福新材料科技有限公司

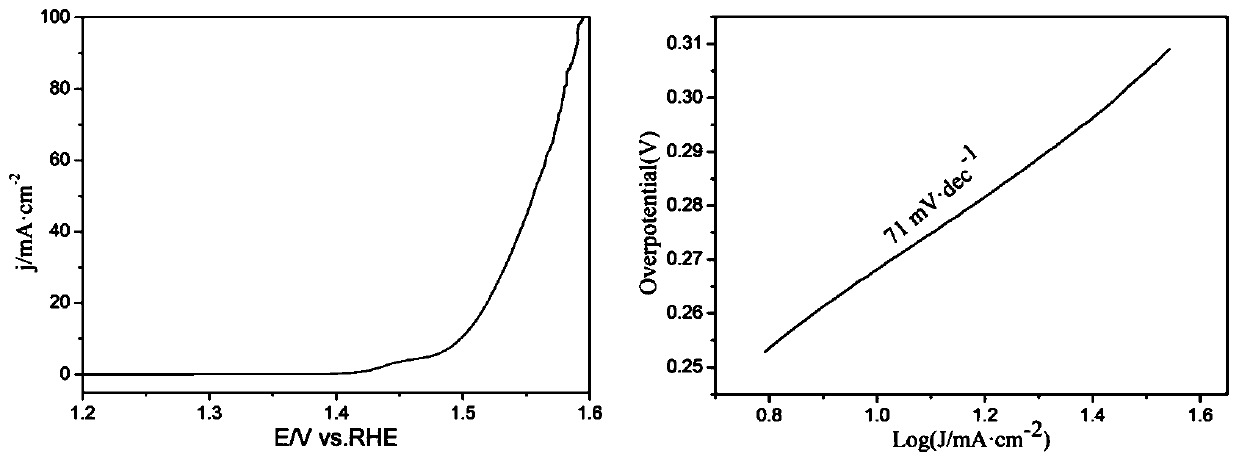

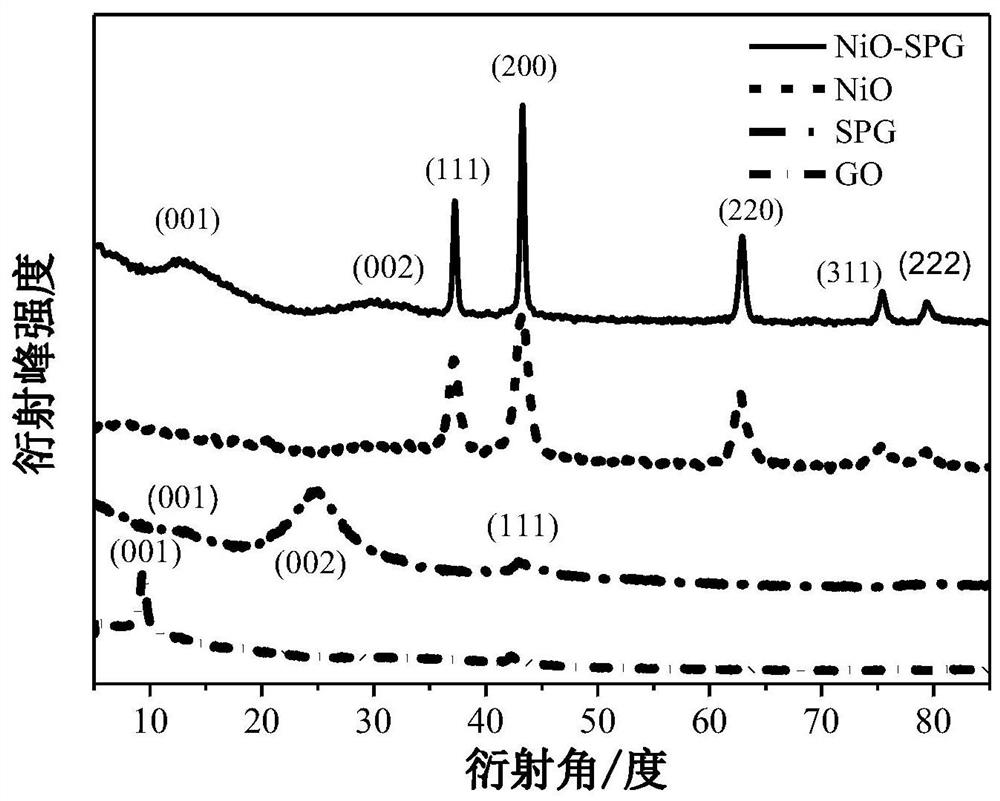

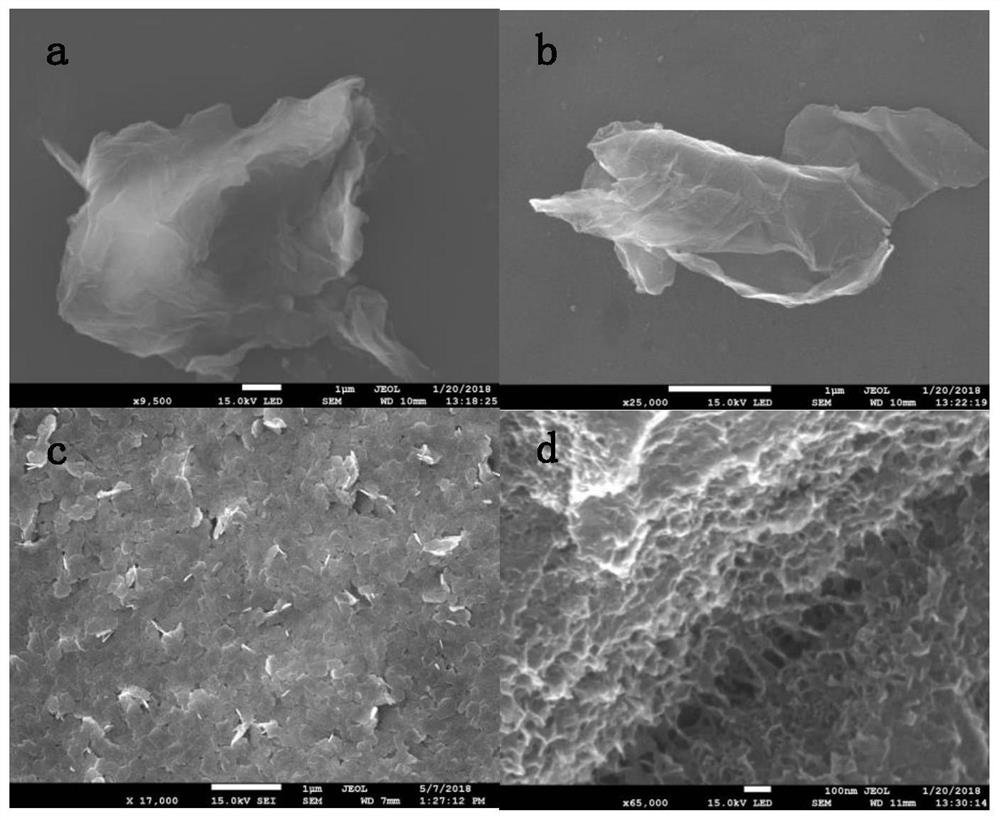

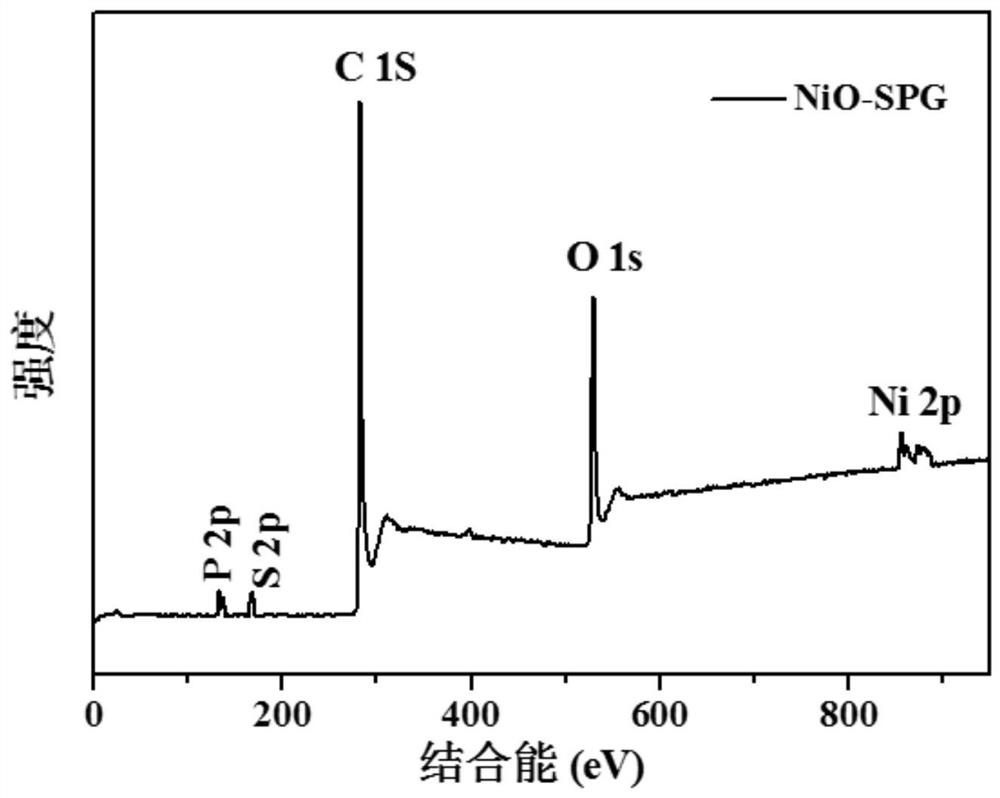

Nickel oxide supported sulfur phosphorus doped graphene composite electrocatalyst and preparation method thereof

ActiveCN109876833BImprove conductivityLarge specific surface areaMaterial nanotechnologyCatalyst activation/preparationHydration reactionDoped graphene

The invention belongs to the category of electrocatalytic hydrogen production catalytic material preparation, in particular to a preparation method of nickel oxide-supported sulfur-phosphorus-doped graphene composite electrocatalyst. Graphene oxide, phosphoric acid and sulfuric acid are uniformly mixed to form an aqueous solution, which is transferred to a hydrothermal kettle Hydrothermal reaction is carried out in the process to obtain sulfur and phosphorus doped graphene; after the sulfur and phosphorus doped graphene, nickel chloride hexahydrate and ethanol are mixed uniformly, hydrothermal is performed on it, and the obtained solution is subjected to suction filtration , washing, and drying to obtain a nickel oxide-supported sulfur-phosphorus-doped graphene composite electrocatalyst. The reaction conditions of the invention are simple, the operation is convenient, and the process flow is short; the prepared nickel oxide nanosheets have good dispersibility, suitable size and uniformity, and have excellent hydrogen evolution performance as an electrocatalytic hydrogen evolution electrode catalyst.

Owner:JIANGSU SOPO GRP +2

Preparation method of supercapacitor electrode material

ActiveCN112735859AGuaranteed stabilityEnough storage spaceHybrid capacitor electrodesHybrid/EDL manufactureElectrochemical responseLamellar crystals

The invention relates to a preparation method of a supercapacitor electrode material, which comprises the following steps: 1, adding nickel chloride hexahydrate and terephthalic acid into a solution containing ethanol, deionized water and N, Ndimethylformamide, and adding triethylamine to form a colloidal suspension; carrying out ultrasonic treatment, centrifugally collecting a product, washing with ethanol, and carrying out vacuum drying to obtain an active material; 2, 1) cutting foamed nickel into rectangles meeting process requirements, cleaning, drying in a drying oven, and weighing; 2) uniformly mixing an active material, conductive carbon black and polyvinylidene fluoride according to the proportion required by the process, and dissolving the mixture in N-methylpyrrolidone to obtain paste; and coating the foamed nickel with a small amount of paste, drying the foamed nickel in a vacuum drying oven to obtain an electrode plate, tabletting and weighing. According to the invention, a layered crystal structure is obtained, layers are connected through terephthalate, and the stability of the material in the electrochemical reaction process provides enough storage space for electrolyte ions.

Owner:CHONGQING UNIV

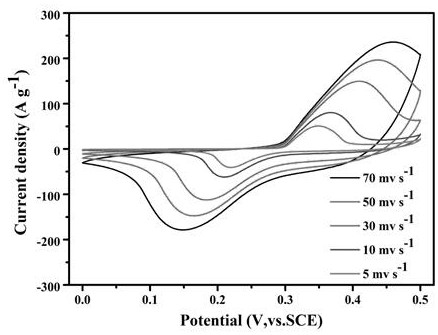

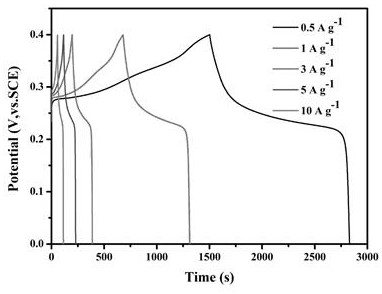

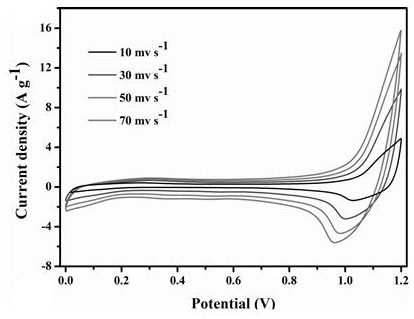

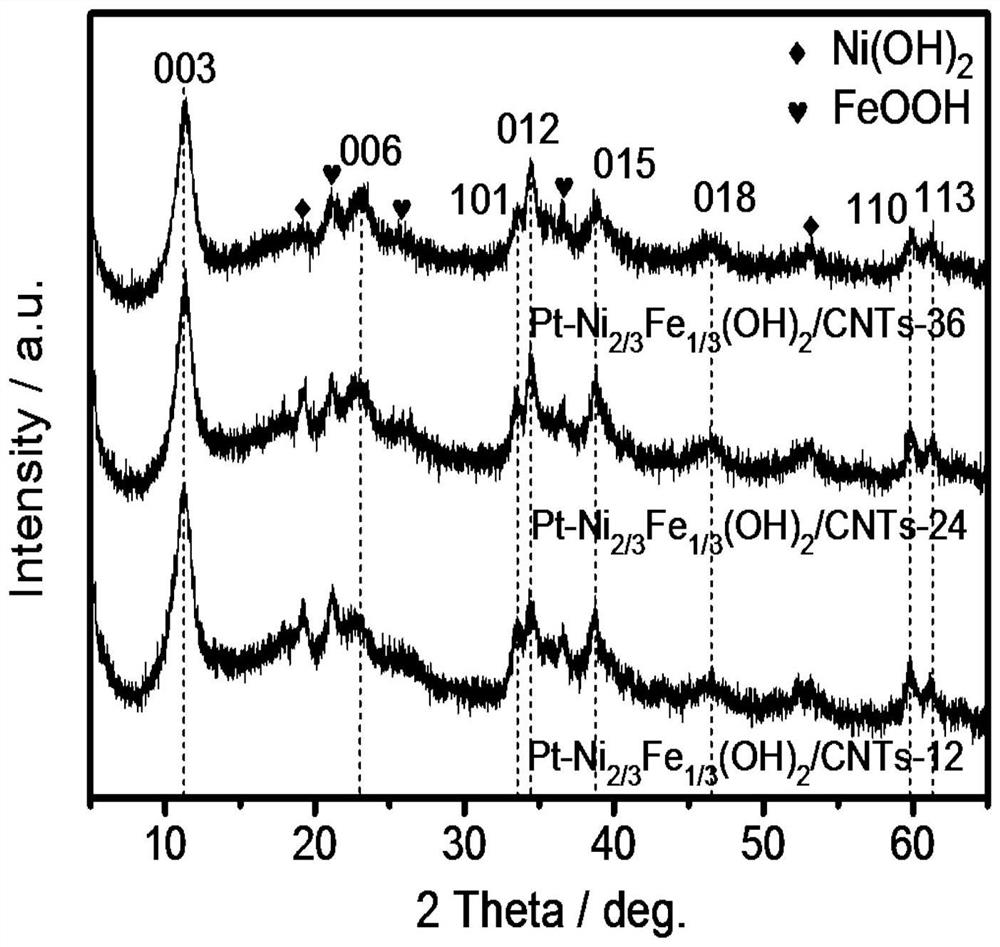

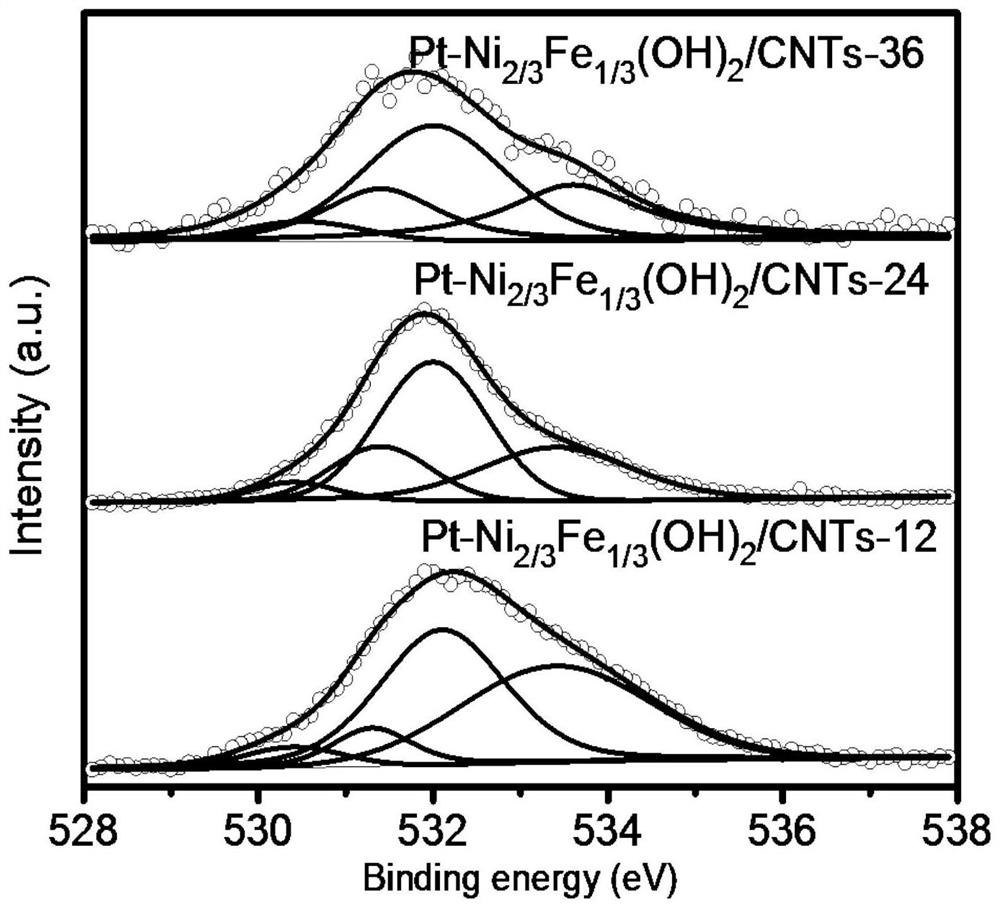

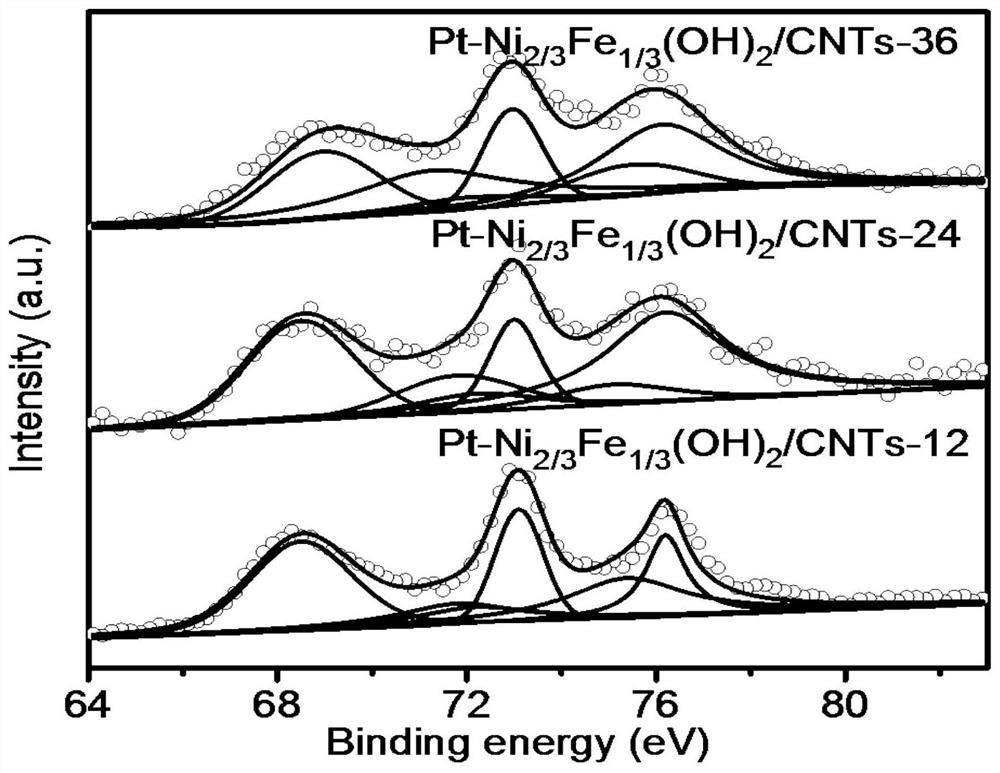

Platinum monatomic catalyst and preparation method and application thereof

The invention provides a platinum monatomic catalyst which is structurally Pt-Ni<x>Fe<1-x>(OH)<2> / CNTs nanosheets, wherein x ranges from 1 / 5 to 1 / 2. The preparation method comprises the following steps of: dissolving carbon nanotubes subjected to oxidation treatment in deionized water without oxygen; dissolving a proper amount of hexamethylenetetramine, ammonium fluoride, nickel chloride hexahydrate and ferrous chloride tetrahydrate into the solution in the step S1, the molar ratio of Ni to Fe in the nickel chloride hexahydrate and the ferrous chloride tetrahydrate being (1-4): 1; reacting the mixed solution in the step S2 in a sealed reaction kettle to obtain a Ni<x>Fe<1-x> (OH)<2> / CNTs catalyst; and adding a proper amount of H2PtCl6. 6H2O into the Ni<x>Fe<1-x> (OH)<2> / CNTs catalyst in the step S3, and oxidizing at room temperature to obtain a platinum monatomic catalyst Pt-Ni<x>Fe<1-x>(OH)<2> / CNTs, the molar ratio of Pt to Fe being 1: (1-4). The platinum monatomic catalyst provided by the invention has the characteristics of high platinum monatom loading capacity, high metal utilization rate, good catalytic activity and the like, and can be widely applied to the fields of electrolysis of water, air batteries and the like. The invention also provides a preparation method of the platinum monatomic catalyst and application of the platinum monatomic catalyst in electrolysis of water.

Owner:ZHENGZHOU UNIV

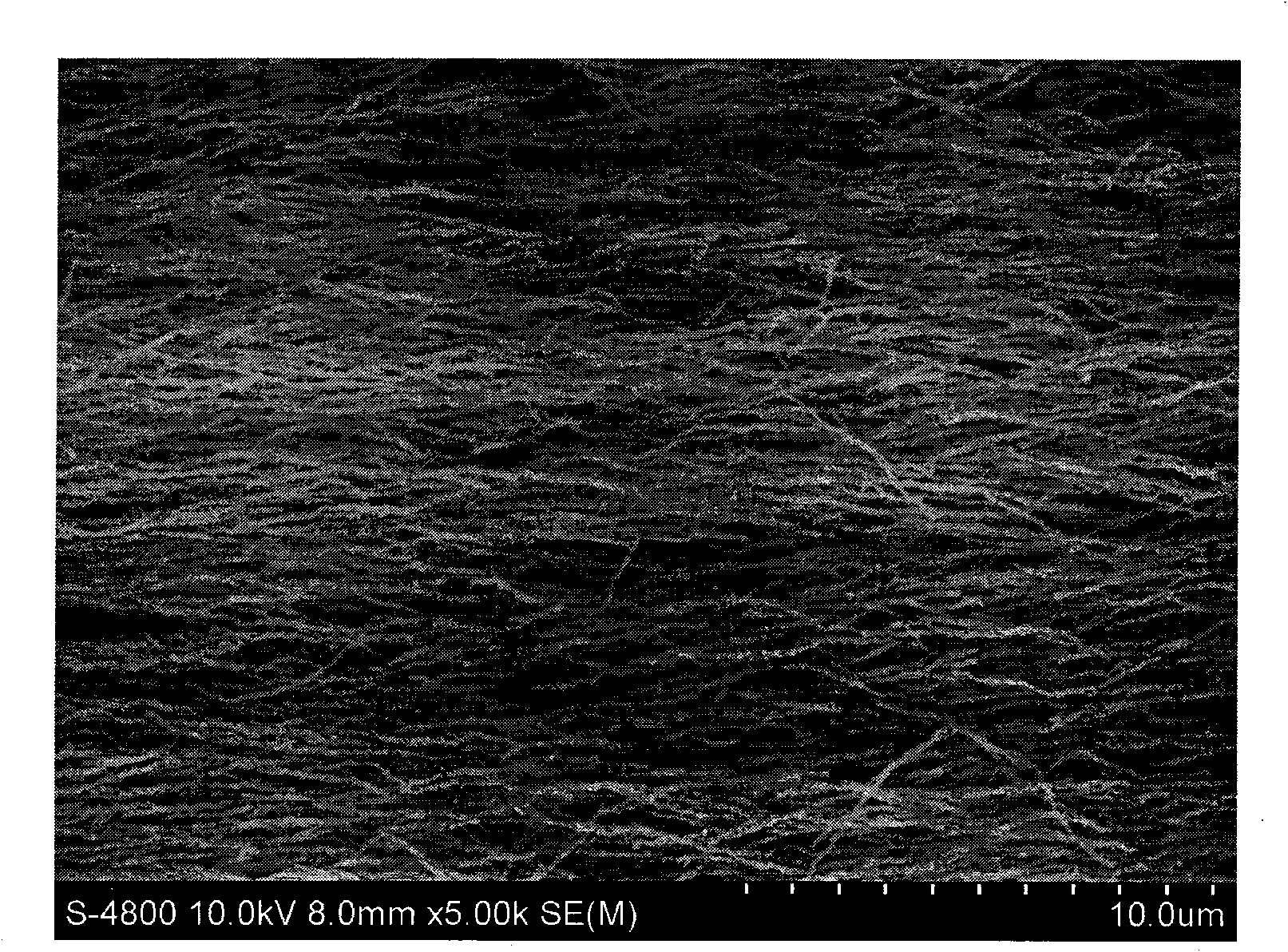

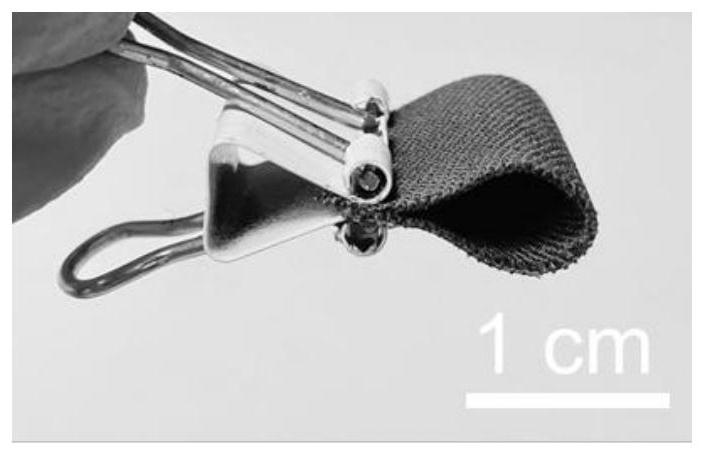

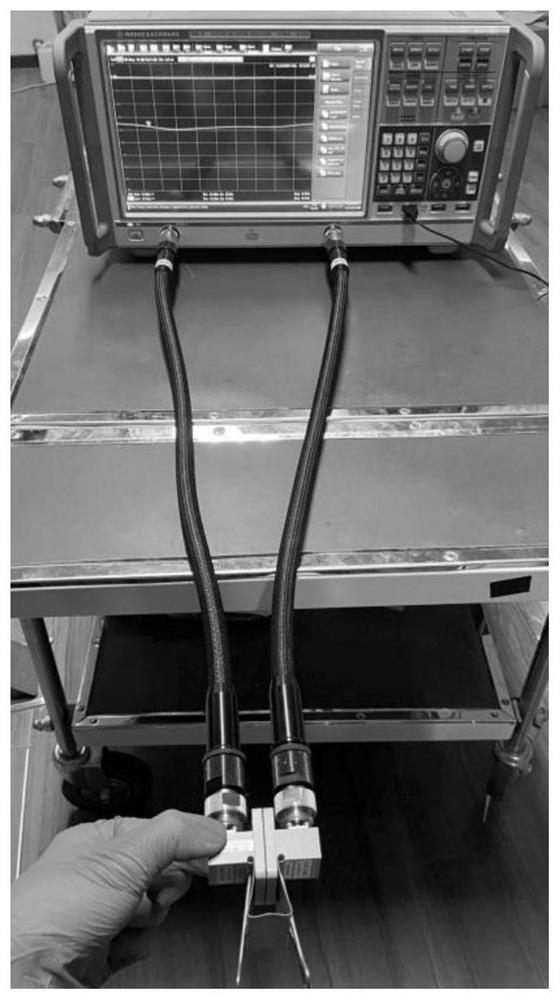

Flexible light and thin carbon cloth composite material with high electromagnetic shielding performance and preparation method thereof

PendingCN114318846ALittle flexibilityLow densityMagnetic/electric field screeningHeating/cooling textile fabricsCyclodextrinNickel chloride hexahydrate

The invention discloses a flexible light and thin carbon cloth composite material with high electromagnetic shielding performance and a preparation method thereof. The flexible light and thin carbon cloth composite material is composed of carbonized cotton fabric and nickel single crystals growing on the carbonized cotton fabric in situ. The preparation method of the flexible light and thin carbon cloth composite material with the high electromagnetic shielding performance comprises the following steps: pretreating a cotton fabric with an alkaline solution, further modifying the surface of the cotton fabric with hydroxypropyl-beta-cyclodextrin, soaking the cotton fabric in a nickel chloride hexahydrate solution, and drying to obtain the flexible light and thin carbon cloth composite material with the high electromagnetic shielding performance. Drying and calcining to prepare the flexible, light and thin carbon cloth composite material with high electromagnetic shielding performance. According to the carbon cloth composite material, the combination of flexibility and high electromagnetic shielding performance is realized, the sheet resistance of the carbon cloth composite material can be as low as 0.6 omega / sq, the density of the carbon cloth composite material is light as 0.7056 g / cm < 3 >, the carbon cloth composite material has excellent conductivity, flexibility and electromagnetic shielding performance, and a new solution strategy is provided for the problem of electromagnetic wave pollution.

Owner:SOUTHEAST UNIV

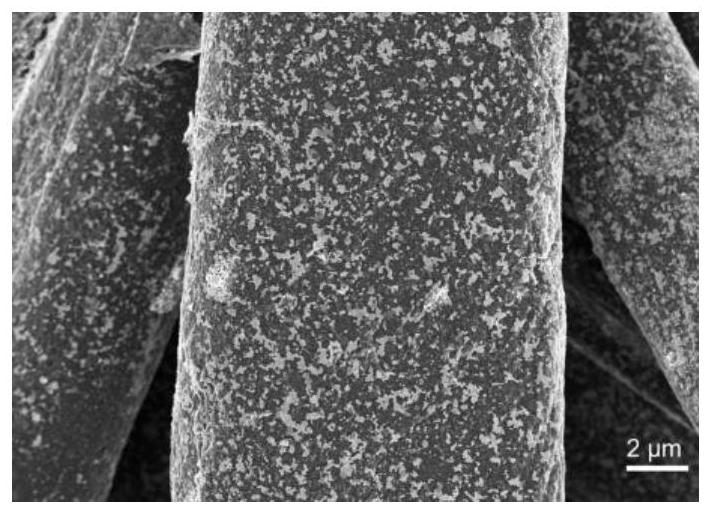

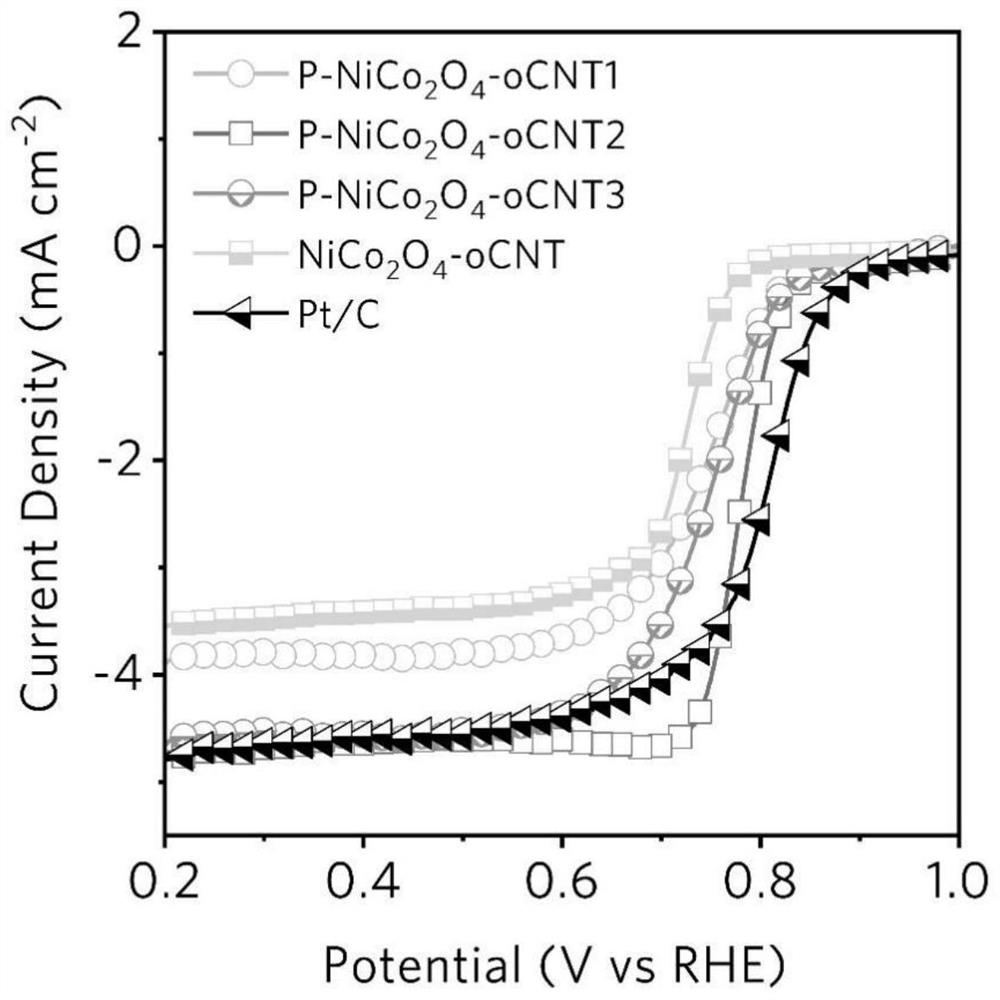

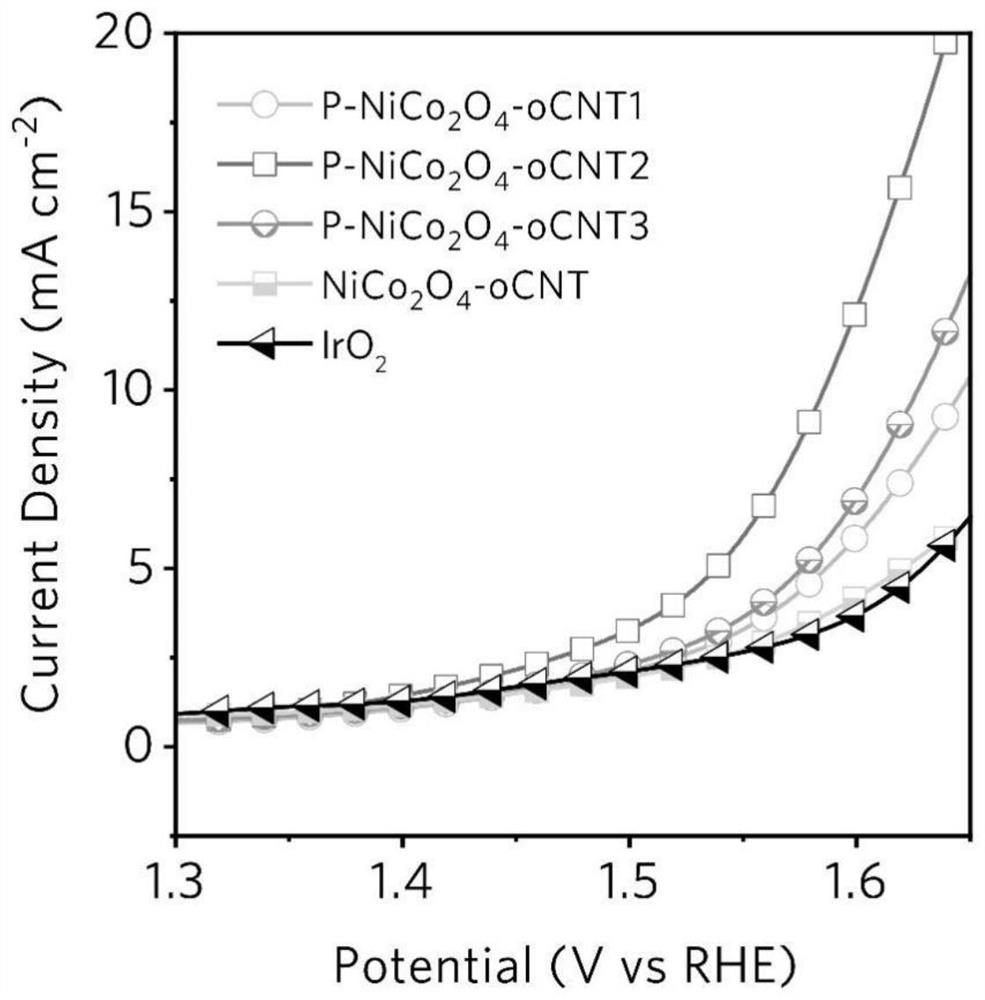

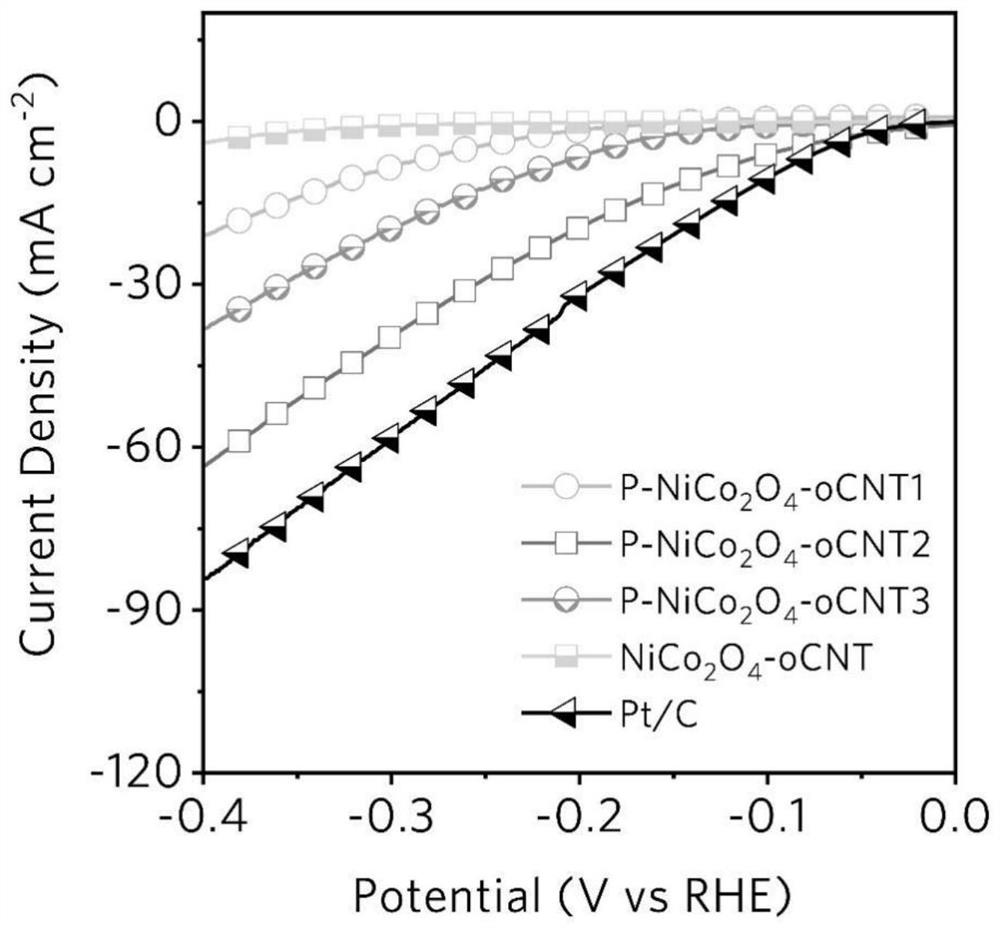

Phosphorus-modified nickel cobaltate-modified carbon nanotube electrode catalyst

The invention discloses a phosphorus-modified nickel cobaltate-modified carbon nanotube electrode catalyst. The preparation method comprises the following steps of mixing cobalt chloride hexahydrate and nickel chloride hexahydrate into an ethanol solution containing ammonia water, adding a hydroxyl carbon nanotube, mixing and dispersing to obtain a precursor mixed solution, carrying out a hydrothermal reaction at 140 DEG C for 16 hours, filtering, washing and drying, and then carrying out heat treatment with sodium hypophosphite at 600 DEG C under the protection of nitrogen for 2 hours to obtain the catalyst. The electrode catalyst disclosed by the invention is based on phosphorus-modified nickel cobaltate nanoparticles with high intrinsic activity loaded on the carbon nanotubes, and has excellent catalytic performance of oxygen reduction, oxygen evolution and hydrogen evolution reaction. The preparation method is simple, low in cost and easy to popularize.

Owner:广州费舍尔人工智能技术有限公司

Nano-structure Ni-base composite electroplating solution containing nano Si3N4 particles and preparation method thereof

InactiveCN102051644BShort process flowReduce investmentMaterial nanotechnologyElectrolytic coatingsNickel sulfate hydrateNanostructure

Owner:JIAXING TIANQI NEW MATERIAL TECH

Complex catalyst for viscosity reduction of thick oil by hydrothermal catalytic cracking and preparation and application thereof

ActiveCN102019205BFully play the catalytic activityLow viscosityCatalytic crackingOrganic-compounds/hydrides/coordination-complexes catalystsEthylenediamineReduction rate

Owner:PETROCHINA CO LTD +1

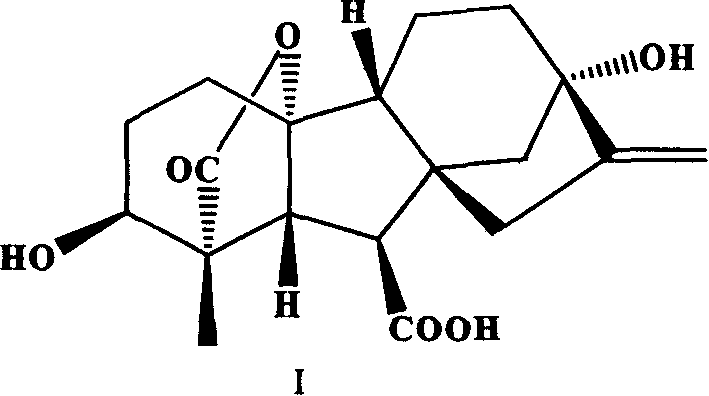

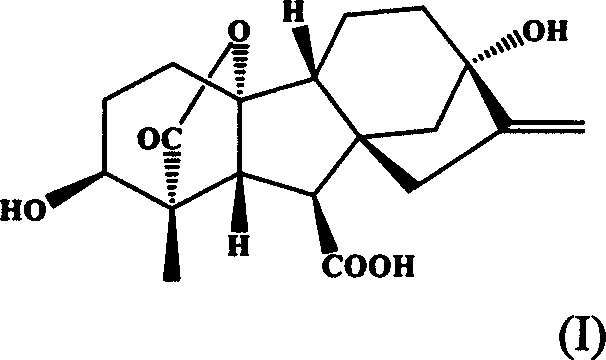

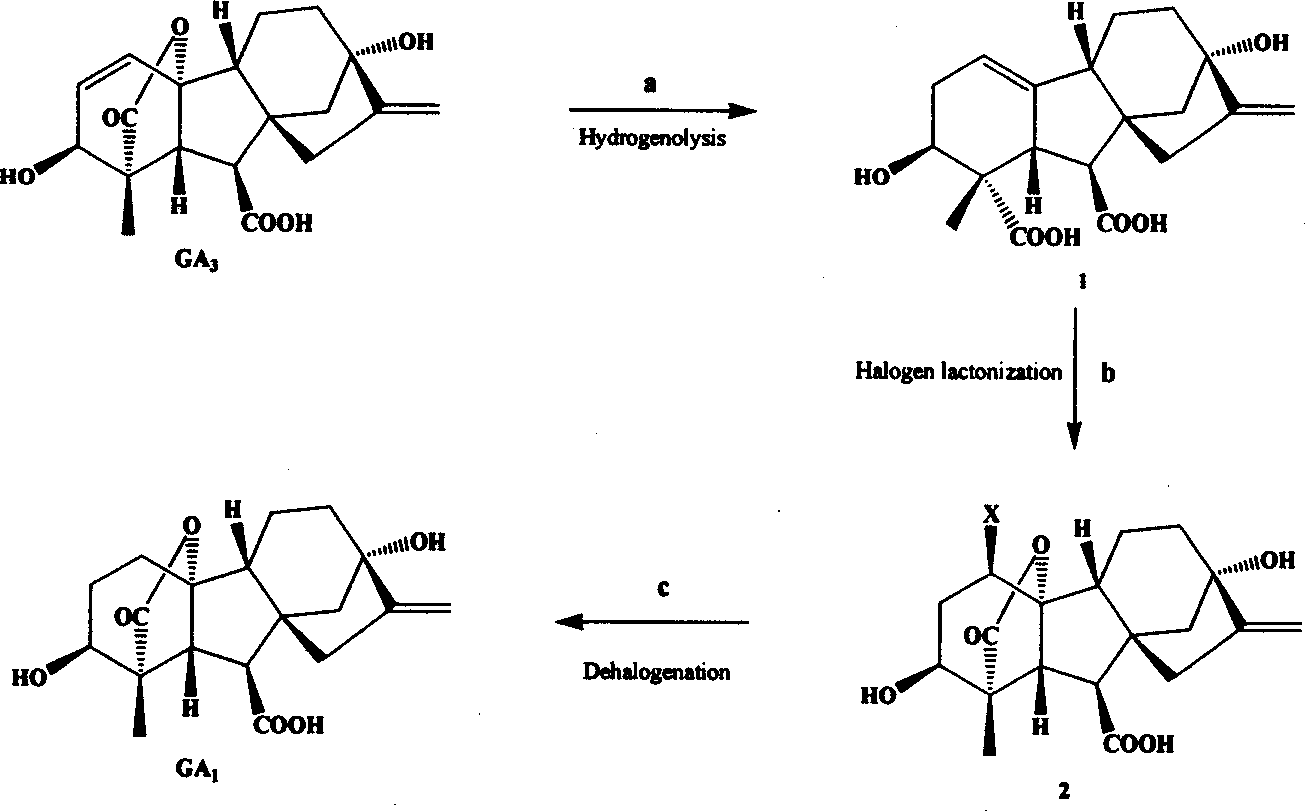

Simple method for preparing gibberellin GA1

The invention surfactant a simple and convenient method for preparing gibberellin GA1 (3beta, 10 alpha, 13 alpha-trihydroxyl-20-decarbonized Gibberella-16-alkene-7, 19-diacid-19, 10 inner ester), using the GA3 produced by industrialized fermenting method as initial raw material, and making a series of easy-to-industrialize chemical reactions to synthesize and obtain the GA1. And the invention dissolves the GA3 in the solvent such as alcohol, adds in organic alkali such as triethylamine and Pt / Pd in a certain proportion as catalyst, feeds hydrogen gas (H2) to make reaction at room temperature, then making halogen inner esterification on the hydrogenated products, and recrystallizes the products of the halogen inner esterification, and then eliminating the halogens from the recrystallized products under the condition of Zn and hydrated nickel chloride (Zn / NiCl2.XH2O) or sodium hydrosulfide so as to obtain the target products GA1. And the invention has the advantages of moderate reacting conditions, lower cost, easy operation, and being adaptive to industrialized production.

Owner:YUNNAN UNIV +1

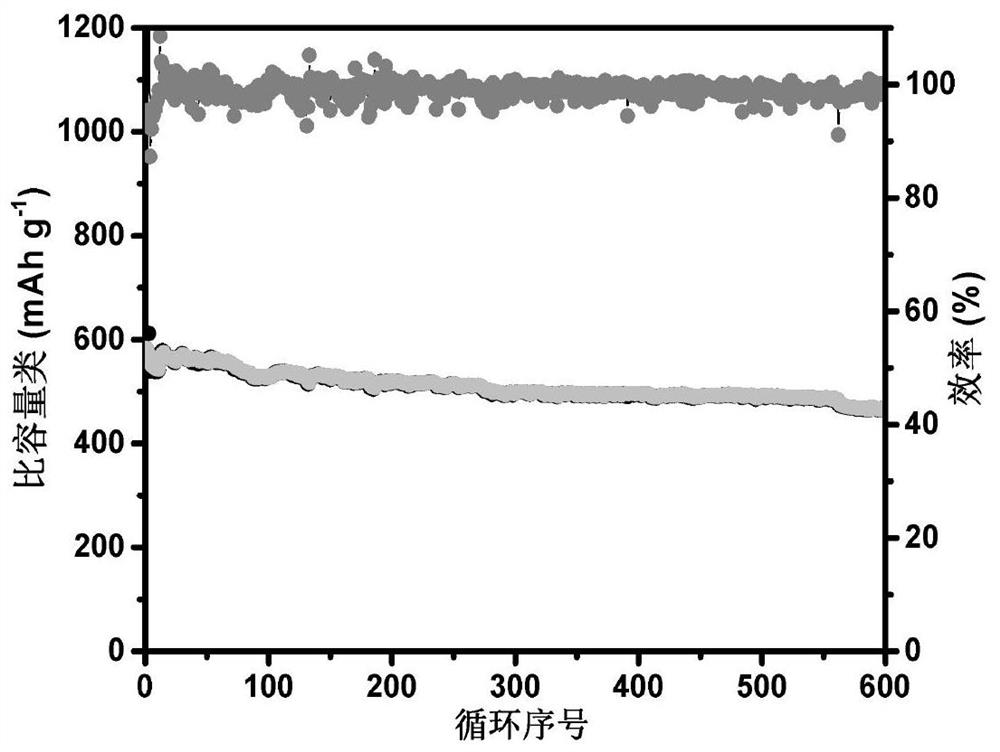

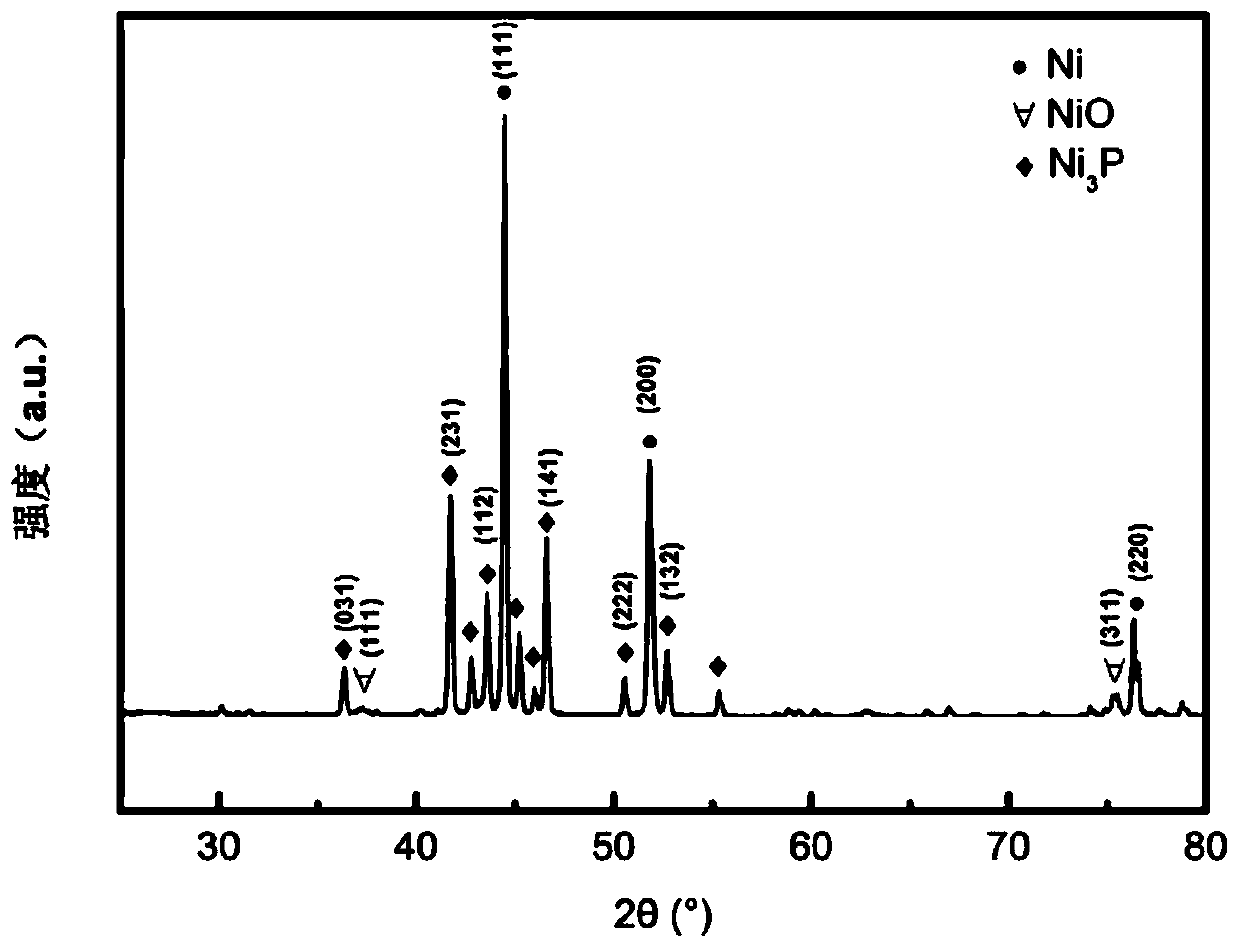

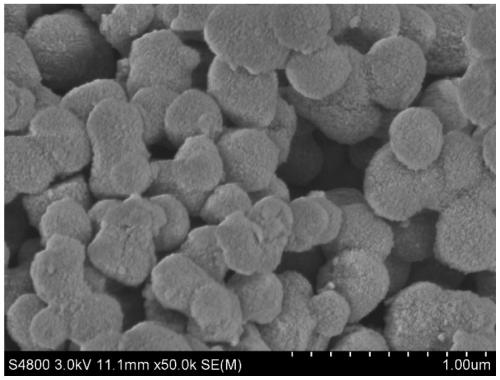

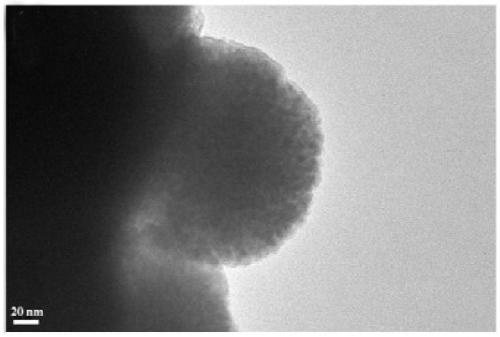

A nickel-phosphorus-oxygen micron-spherical lithium-ion battery negative electrode material and its preparation method and the prepared lithium-ion battery negative electrode

InactiveCN107611352BEasy to makeModerate and controllable conditionsCell electrodesElectrical batteryMicrosphere

The invention discloses a nickel-phosphorus-oxygen micron spherical negative electrode material for a lithium-ion battery, a preparation method of the nickel-phosphorus-oxygen micron spherical negative electrode material and a negative electrode of the lithium-ion battery prepared from the nickel-phosphorus-oxygen micron spherical negative electrode material. The preparation method comprises the following steps of mixing choline chloride and urea, and heating and stirring a mixture to obtain a deep-eutectic solvent; adding a cationic surfactant, carrying out ultrasonic dissolving, sequentiallyadding nickel chloride hexahydrate and sodium dihydrogen phosphate and carrying out ultrasonic dissolving to obtain a reaction precursor solution; and heating and refluxing the reaction precursor solution, cleaning and drying to obtain the nickel-phosphorus-oxygen micron spherical negative electrode material for the lithium-ion battery, wherein main components of the nickel-phosphorus-oxygen micron spherical negative electrode material are Ni, Ni3P and NiO, and a large-size microsphere material of which the particle sizes are 0.2-0.5micron is formed by self-assembling of particles in the preparation process. The nickel-phosphorus-oxygen micron spherical negative electrode material for the lithium-ion battery has excellent electrochemical properties.

Owner:ZOTYE INT AUTOMOBILE TRADING CO LTD

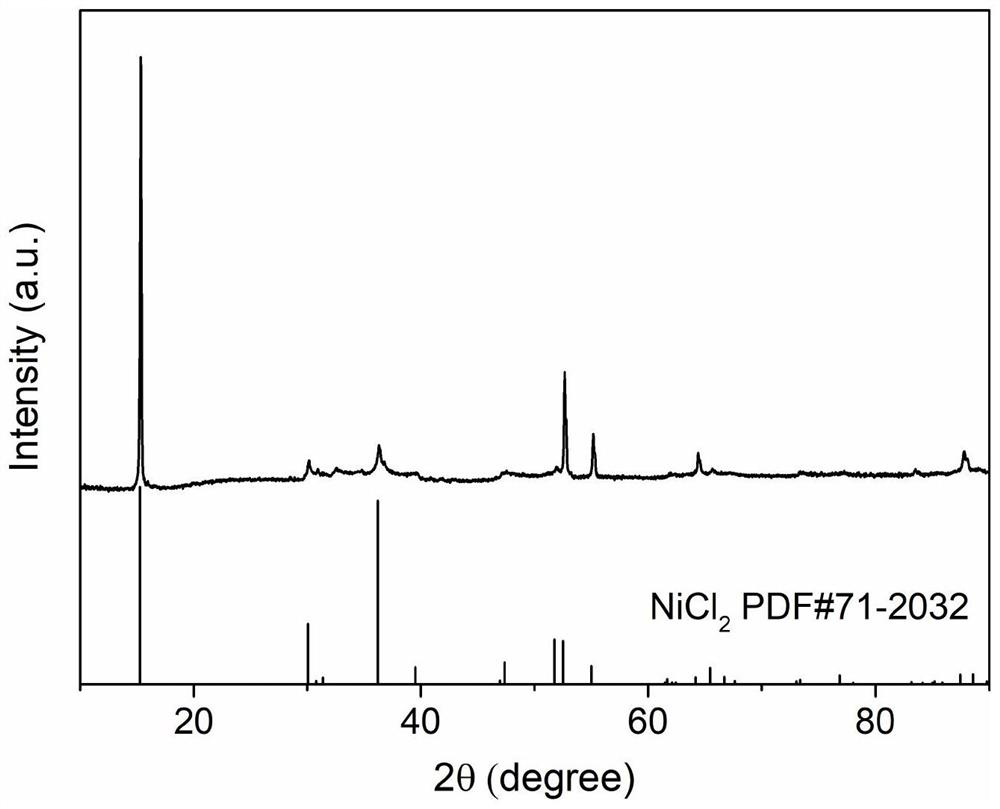

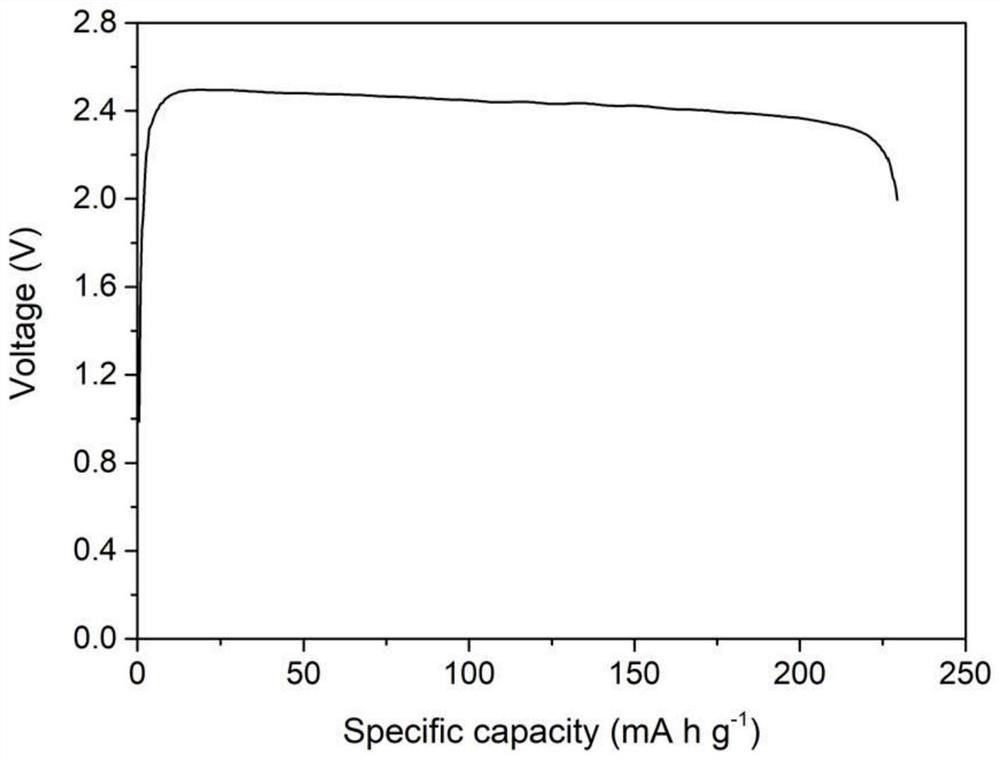

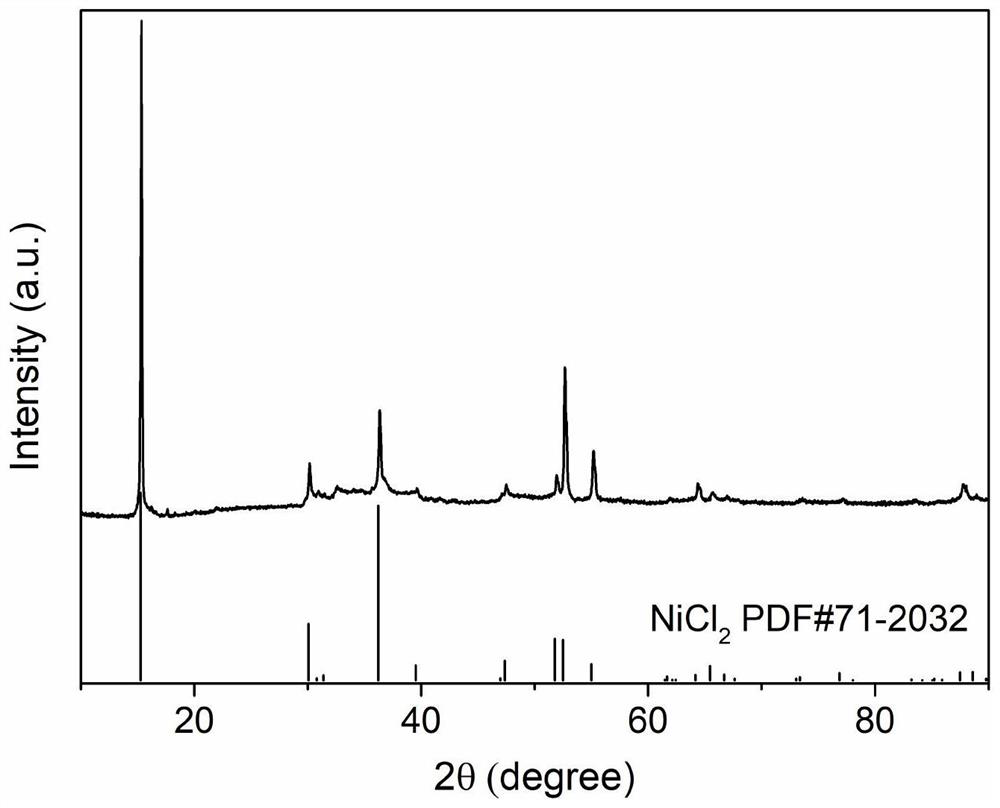

NiCl2 powder synthesized at low temperature and application

PendingCN113955814ALow dehydration temperatureImprove thermal stabilityNickel halidesSodium-ion batteryLithium-ion battery

The invention relates to NiCl2 powder synthesized at low temperature and application, and belongs to the technical field of powder preparation. The NiCl2 powder synthesized at low temperature takes hydrated nickel chloride as a raw material; raw materials and an extraction aid are uniformly mixed in an organic solvent, dried and then calcined at 280-550 DEG C to obtain the product; the extraction aid is chloride of transition metal elements. The pure-phase NiCl2 is prepared under the low-temperature condition for the first time. The related preparation process is short in period, low in energy consumption and low in cost. The designed and prepared product can be applied to at least one of thermal batteries, supercapacitors, lithium ion batteries and sodium ion batteries.

Owner:HUNAN UNIV

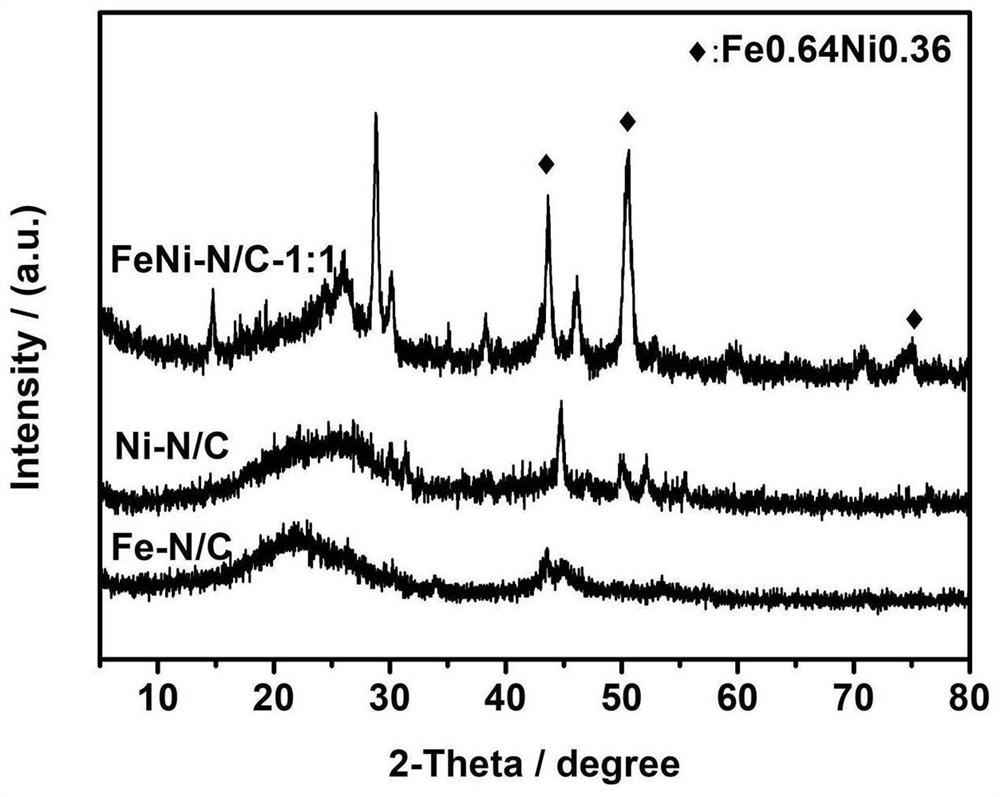

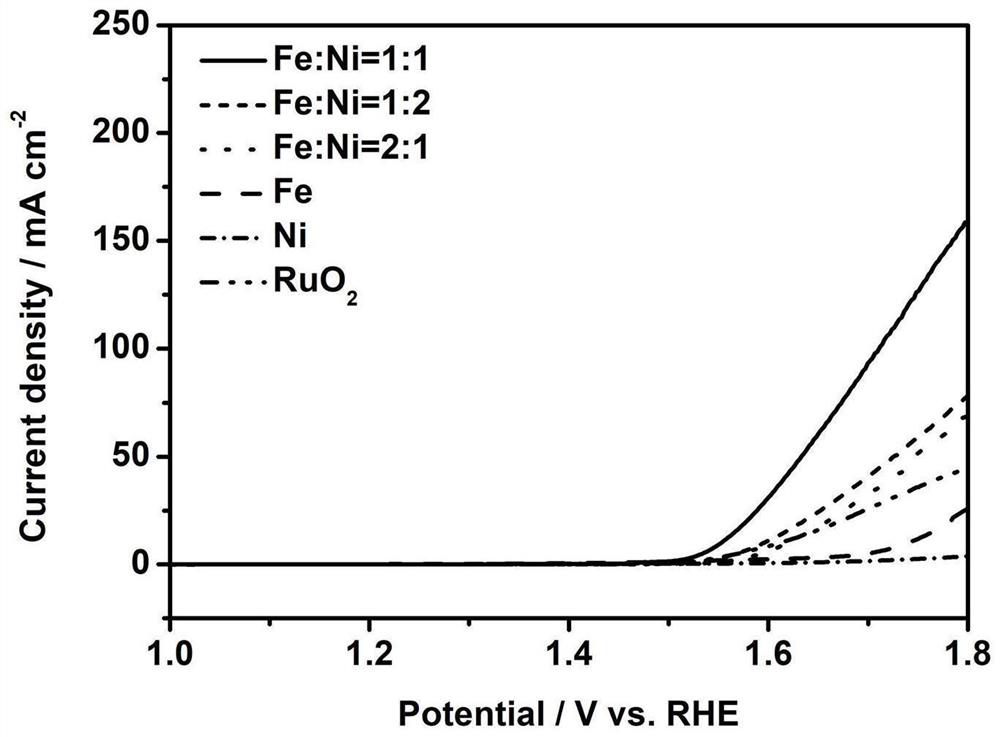

Nickel-doped iron-based bimetallic non-noble metal catalyst and preparation method thereof

InactiveCN113136588AImprove oxygen evolution performanceReduce overpotentialElectrodesPtru catalystElectrolysis

The invention provides a nickel-doped iron-based bimetallic non-noble metal catalyst and a preparation method thereof. According to the non-noble metal-based catalyst, SBA-15 is used as a hard template, sucrose is used as a carbon source, melamine is used as a nitrogen source, ferric chloride hexahydrate is used as an iron source, and nickel chloride hexahydrate is used as a nickel source, and then high-temperature carbonization treatment is performed to obtain the FeNi / N-C catalyst. Compared with single-metal Fe-N / C and Ni-N / C materials, the bimetallic FeNi-N / C material prepared by the preparation method disclosed by the invention plays a synergistic role between iron and nickel bimetals and between the iron and nickel bimetals and a defective carbon material, so that a nickel-doped iron-based bimetallic catalyst has high oxygen evolution performance and even exceeds a commercial RuO2 catalyst. The electrocatalyst has the characteristics of low cost and high performance, which greatly promotes the commercialization process of an electrolytic hydrogen production system.

Owner:XIAN UNIV OF TECH

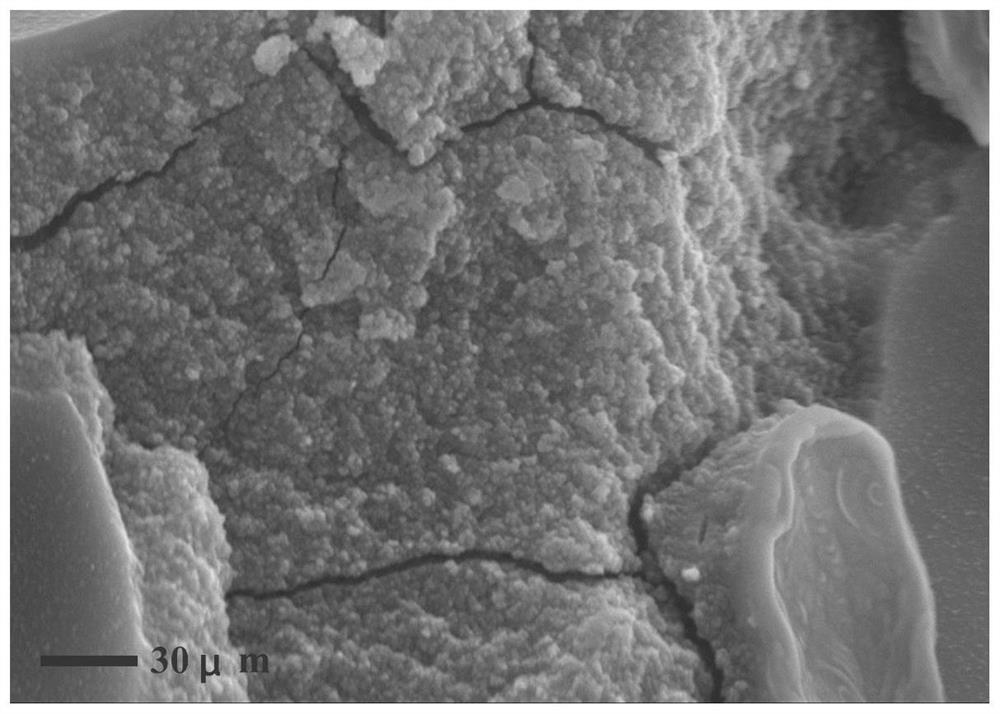

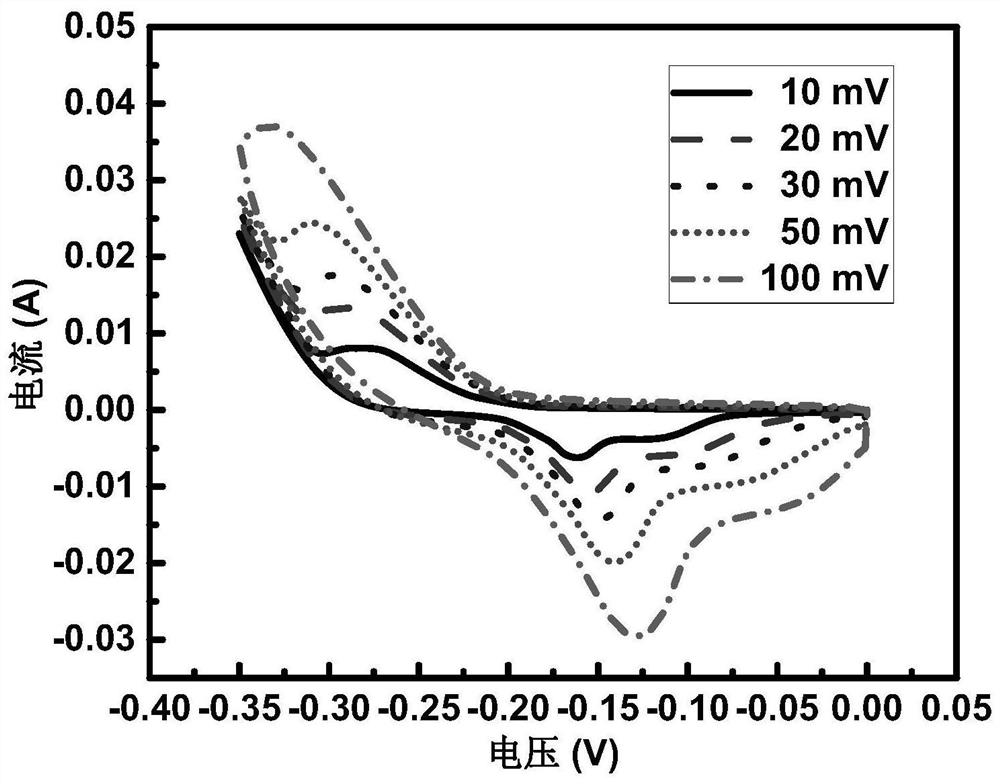

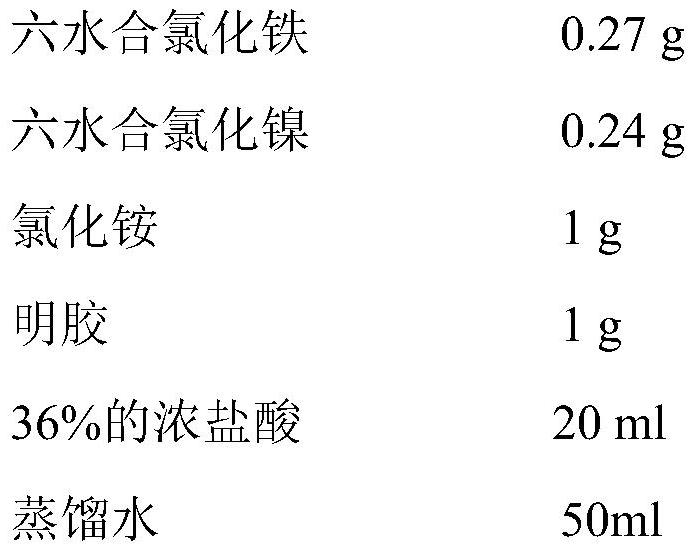

A carbon-doped double metal oxide material and its preparation method

ActiveCN108711621BImprove conductivityImprove charge and discharge performanceMaterial nanotechnologyHybrid capacitor electrodesToxic gasNickel chloride hexahydrate

The invention discloses a carbon-doped double metal oxide material and a preparation method thereof. The preparation method of the present invention comprises the following steps: (1) heating and mixing ferric chloride hexahydrate, nickel chloride hexahydrate, ammonium chloride, gelatin and deionized water and then drying; (2) drying the After drying, the sample is carbonized at a low temperature under an inert atmosphere. After the low-temperature carbonization, the sample is soaked and etched with hydrochloric acid with a concentration of 0.8-2mol / L, and then dried by suction filtration; (3) The dried sample is carbonized at a high temperature under an inert atmosphere. After high-temperature carbonization, the sample was soaked and etched with hydrochloric acid with a concentration of 0.1-0.5mol / L, and then filtered and dried to obtain a carbon-doped double metal oxide material. The invention has low raw material cost and simple preparation method, and the obtained carbon-doped double metal oxide material has high specific surface area and relatively uniform pore size distribution, and has good application prospects in the fields of toxic gas adsorption and lithium batteries.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com