Preparation method of nickel molybdate/carbon electrode material and prepared supercapacitor

A technology for supercapacitors and carbon electrodes, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor separators, hybrid capacitor electrodes, etc., can solve the problem of conductivity limiting ion shuttle and electron migration, limiting electrochemical performance development and application prospects and other problems, to achieve excellent rate performance and cycle stability, high specific capacitance, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a preparation method of nickel molybdate / carbon electrode material, the preparation steps are as follows:

[0032] Dissolve 0.1209 g of sodium molybdate dihydrate and 0.1184 g of nickel chloride hexahydrate in 5 mL of water and 3 mL of cyclohexane, respectively. Add nickel chloride Rongfeng dropwise into the sodium molybdate solution, stir the mixed solution for 30 minutes, transfer it to a polytetrafluoroethylene-lined stainless steel autoclave with a capacity of 30ml, and react in a constant temperature blast drying oven at 100°C for 24 hours. Wash with ethanol and distilled water and centrifuge 3 to 5 times, and dry overnight in a constant temperature blast drying oven at 60°C to obtain the precursor electrode material.

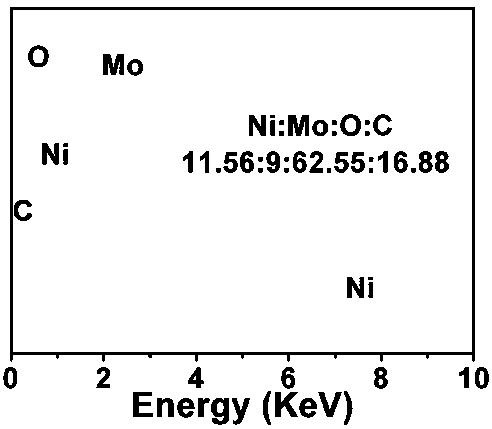

[0033] The precursor electrode material was heated to 600 °C for 2 hours in an inert gas atmosphere, and the heating rate was 5 °C min -1 ,get figure 1 The nickel molybdate / carbon composite electrode material shown.

[00...

Embodiment 2

[0036] This embodiment provides a preparation method of nickel molybdate / carbon electrode material, the preparation steps are as follows:

[0037] Dissolve 0.1209 g of sodium molybdate dihydrate and 0.1184 g of nickel chloride hexahydrate in 5 mL of water and 3 mL of cyclohexane, respectively. Drop the nickel chloride solution into the sodium molybdate solution, stir the mixed solution for 30 minutes, transfer it to a polytetrafluoroethylene-lined stainless steel autoclave with a capacity of 30ml, and react it in a constant temperature blast drying oven at 120°C for 18 hours. Wash with ethanol and distilled water, centrifuge for 3-5 times, and dry overnight in a constant temperature blast drying oven at 60°C to obtain the precursor electrode material.

[0038] The precursor electrode material was heated to 600 °C for 2 hours in an inert gas atmosphere, and the heating rate was 5 °C min -1 ,get figure 1 The nickel molybdate / carbon composite electrode material shown.

Embodiment 3

[0040] This embodiment provides a kind of supercapacitor, and its preparation steps are as follows:

[0041] Preparation of the positive electrode: the nickel molybdate / carbon electrode material, carbon nanotubes, acetylene black and polyvinylidene fluoride prepared in Example 1 were weighed at a mass ratio of 6:2:1:1, and then 5 mL of ethanol was added Disperse and mix to make a slurry, coat it on the nickel foam, then dry, press and other steps to make a positive electrode, the loading capacity of the positive electrode nickel / carbon electrode material is 4 mg / cm 2 ;

[0042] Preparation of negative electrode: Weigh commercial activated carbon and polyvinylidene fluoride at a mass ratio of 8:1, put them into a 10 mL beaker, disperse and mix them to make slurry, coat them on foamed nickel, dry them, and press them into tablets. Negative electrode, the activated carbon loading of the negative electrode is 13mg / cm 2 .

[0043] Assembly of the supercapacitor: Stack the prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com