Lithium-oxygen battery electrode based on metal organic framework material and preparation method of lithium-oxygen battery electrode

A metal-organic framework and oxygen battery technology, which is applied in battery electrodes, fuel cells, fuel cell half-cells and secondary battery-type half-cells, etc., can solve the problems of uneven pore size distribution, chemical reaction termination, and heavy battery performance. In order to avoid problems such as poor reproducibility, the preparation method is simple and the specific capacitance is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

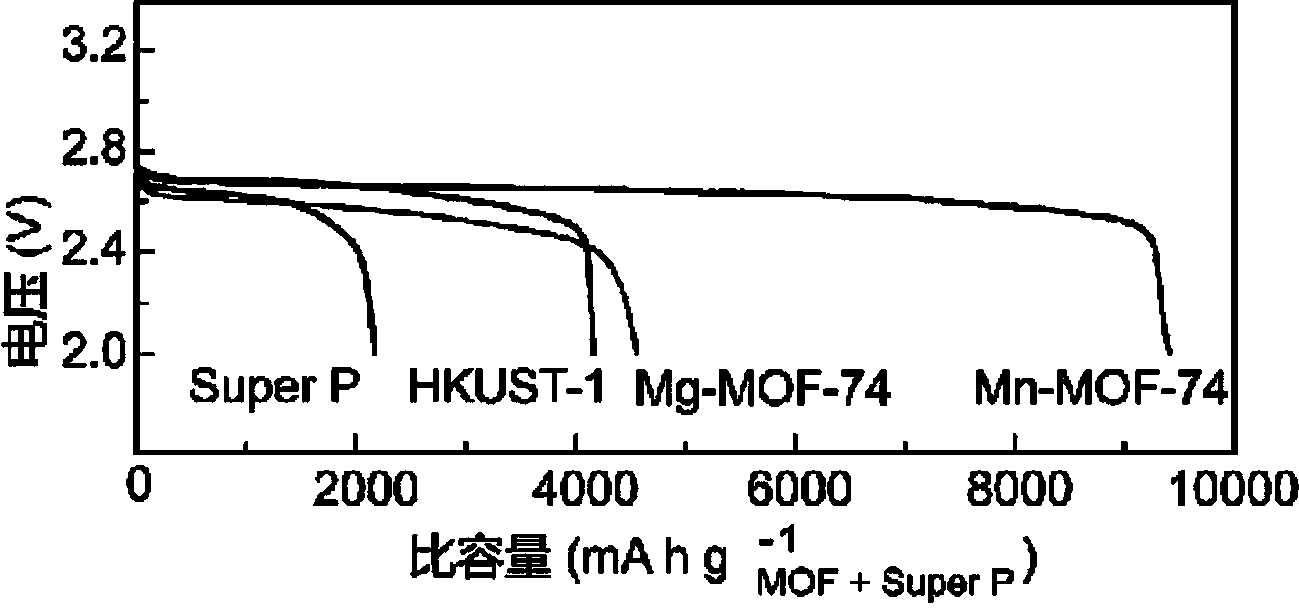

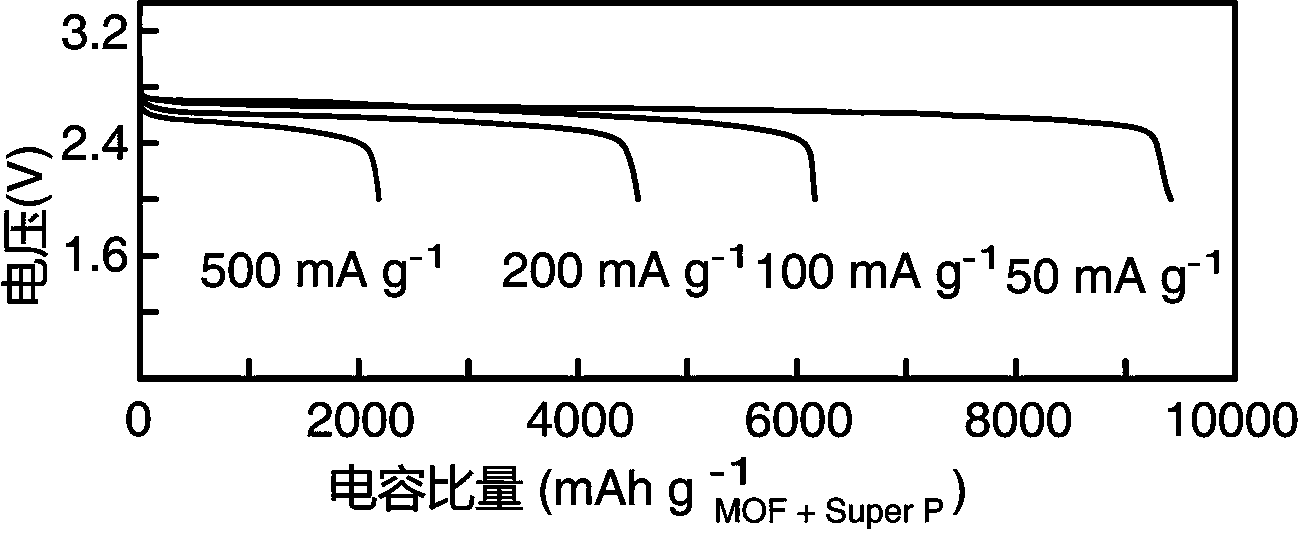

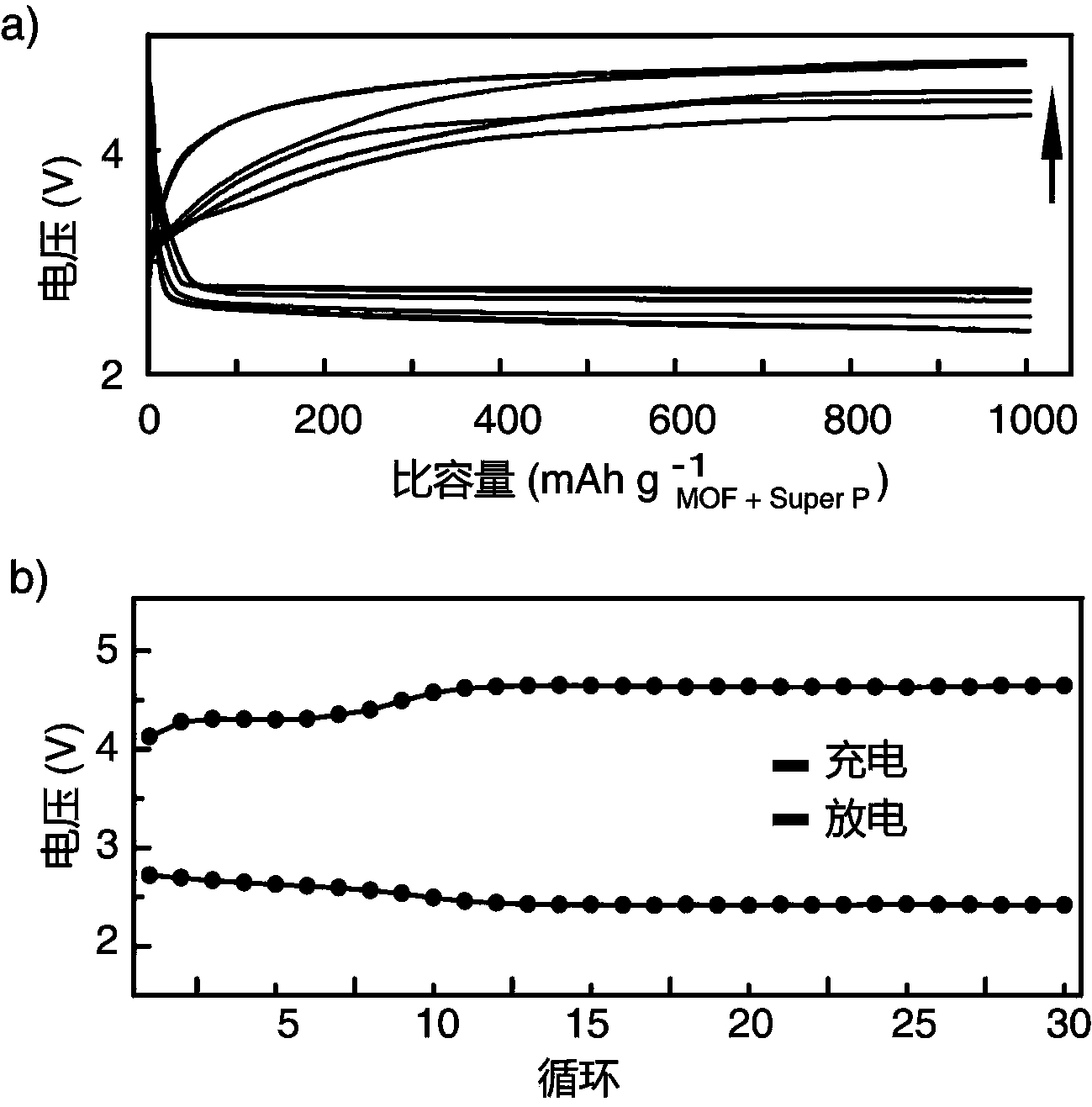

[0033] The present invention is further illustrated by the preparation of the electrode material based on the metal organic framework material Mn-MOF-74 and the performance test of the assembled lithium-oxygen battery:

[0034] 1. Preparation of metal organic framework material Mn-MOF-74 and post-activation treatment process:

[0035] 1.1 Synthesis of Mn-MOF-74:

[0036] Weigh 1098 mg of MnCl 2 4H 2 O and 333 mg of 2,5-dihydroxyterephthalic acid were then dissolved in 150 mL of a mixed solvent of dimethylformamide:ethanol:water=15:1:1 (volume ratio). The obtained clear solution was evenly distributed into six Teflon-lined reaction kettles with a capacity of 50 mL, and the reaction kettles were placed in an oven at 135 °C for 24 hours and then taken out.

[0037] 1.2 Post-processing:

[0038] The synthesized material was taken out from the mother liquor, rinsed three times with dimethylformamide, and soaked with methanol. During the immersion period, the methanol was repla...

Embodiment 2

[0054] The present invention is further illustrated by the preparation of the electrode material based on the metal organic framework material Mg-MOF-74 and the performance test of the assembled lithium-oxygen battery:

[0055] 1. Preparation of metal organic framework material Mg-MOF-74 and post-activation treatment process:

[0056] 1.1 Synthesis of Mg-MOF-74:

[0057] Weigh 466.8 mg of Mg(NO 3 ) 2 ·6H 2 O and 112.4 mg of 2,5-dihydroxyterephthalic acid, then it was dissolved into 51 mL of dimethylformamide: ethanol: water = 15: 1: 1 (volume ratio) in the mixed solvent, obtained The clear solution was evenly distributed into 5 glass reaction vials with a capacity of 25 mL, placed in an oven at 125 °C for 20 hours and then taken out.

[0058] 1.2 Post-processing:

[0059] The synthesized material was taken out from the mother liquor, rinsed three times with dimethylformamide, and soaked with methanol. During the immersion period, the methanol was replaced 3 times a day f...

Embodiment 3

[0071] The present invention is further illustrated by the preparation of the electrode material based on the metal organic framework material HKUST-1 and the performance test of the assembled lithium-oxygen battery:

[0072] 1. Preparation of metal organic framework material HKUST-1 and post-activation treatment process:

[0073] 1.1 Synthesis of HKUST-1:

[0074] Weigh 4000 mg of Cu(NO 3 ) 2 ·3H 2 O and the 1,3,5-trimesic acid of 2000 mg, then it is dissolved in the dimethylformamide of 100 mL: ethanol: in the mixed solvent of water=1:1:1 (volume ratio), obtains The clarified solution was evenly distributed into 10 glass reaction vials with a capacity of 25 mL, placed in an oven at 85 °C for 24 hours and then taken out.

[0075] 1.2 Post-processing:

[0076]The synthesized material was taken out from the mother liquor, rinsed three times with dimethylformamide, and soaked with acetone. During the immersion period, the acetone was replaced 3 times a day for 3 days; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com