A method for preparing a g-C3N4/carbon quantum dot composite electrode

A technology of carbon quantum dots and composite electrodes, which is applied in the field of preparation of g-C3N4/carbon quantum dot composite electrodes, can solve the problems of limited application, weak electron transfer ability and non-conductivity, and achieves simple preparation method and increased electron transfer rate. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1.1. Preparation of ethanol solution of carbon quantum dots

[0021] Adding carbon quantum dots to ethanol is prepared into a carbon quantum dot ethanol solution with a mass percentage concentration of carbon quantum dots of 30%;

[0022] 1.2. Preparation of g-C 3 N 4 / Carbon quantum dot composite material

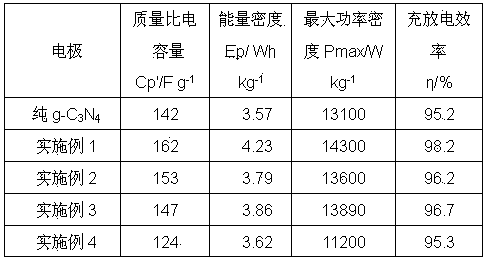

[0023] Mix 1 g of urea with 1 g of carbon quantum dot ethanol solution with a concentration of 30%, disperse it in a 45W ultrasonic wave for 5 min, transfer it to a crucible, and gradually raise the temperature to 550 °C in a muffle furnace for 2 h and then lower it to room temperature to obtain a powdery substance. The product was obtained after trituration with ethanol and filtration. The product was mixed with pure C of uncomplexed carbon quantum dots 3 N 4 Transmission electron microscopy characterization (TEM) was performed. figure 1 is pure C 3 N 4 TEM, it can be seen from the figure that C 3 N 4 Wrinkled sheet structure with nanoscale thickness clo...

Embodiment 2

[0027] 1.1. Preparation of ethanol solution of carbon quantum dots

[0028] Carbon quantum dots are added to ethanol to be prepared with carbon quantum dots mass percentage concentration 32% carbon quantum dots ethanol solution;

[0029] 1.2. Preparation of g-C 3 N 4 / Carbon quantum dot composite material

[0030] Mix 1 g of urea with 1.2 g of carbon quantum dot ethanol solution with a concentration of 32%, disperse it in a crucible with 55W ultrasonic wave for 30 min, and gradually raise the temperature to 350°C in a muffle furnace for 1 h and then lower it to room temperature to obtain a powdery substance. G-C is obtained after grinding and filtering with ethanol 3 N 4 / Carbon quantum dot composites.

[0031] With prepared g-C 3 N 4 The carbon quantum dot electrode material was assembled into a button-type supercapacitor according to the same method as in Example 1, and an electrochemical workstation was used to test its cyclic voltammetry, AC impedance, and constan...

Embodiment 3

[0033] 1.1. Preparation of ethanol solution of carbon quantum dots

[0034] Carbon quantum dots are added to ethanol to be prepared into a carbon quantum dot ethanol solution with a carbon quantum dot mass percentage concentration of 28%;

[0035] 1.2. Preparation of g-C 3 N 4 / Carbon quantum dot composite material

[0036] Mix 1g of urea with 1.5g of carbon quantum dot ethanol solution with a concentration of 28%, disperse it with 50W ultrasonic wave for 20 minutes, transfer it to a crucible, and gradually raise the temperature to 600°C in a muffle furnace for 1.5 hours and then lower it to room temperature to obtain a powdery substance. Add ethanol to grind and filter to get g-C 3 N 4 / Carbon quantum dot composites.

[0037] With prepared g-C 3 N 4 The carbon quantum dot electrode material was assembled into a button-type supercapacitor according to the same method as in Example 1, and an electrochemical workstation was used to test its cyclic voltammetry, AC impeda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com