Nickel oxide supported sulfur phosphorus doped graphene composite electrocatalyst and preparation method thereof

A graphene composite and electrocatalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of expensive Pt-based electrode materials, few active sites of electrode materials, nanomaterials, poor electrode Conductivity and other issues, to achieve the effect of low material price, high production efficiency, and not easy to fall off and separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

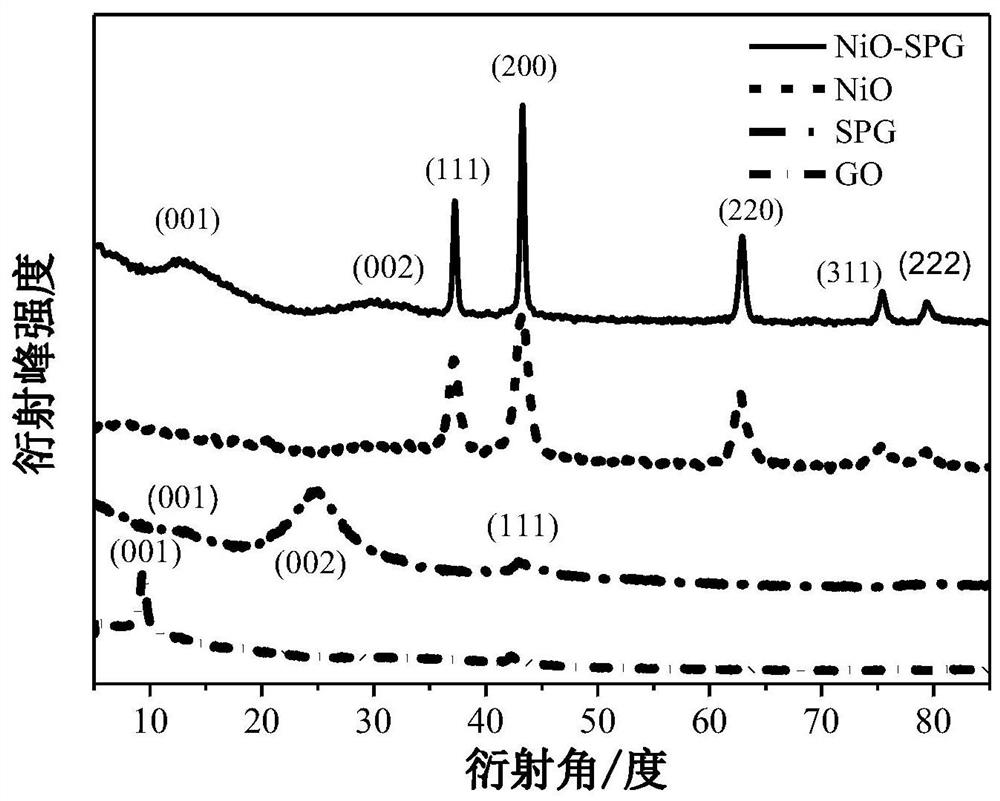

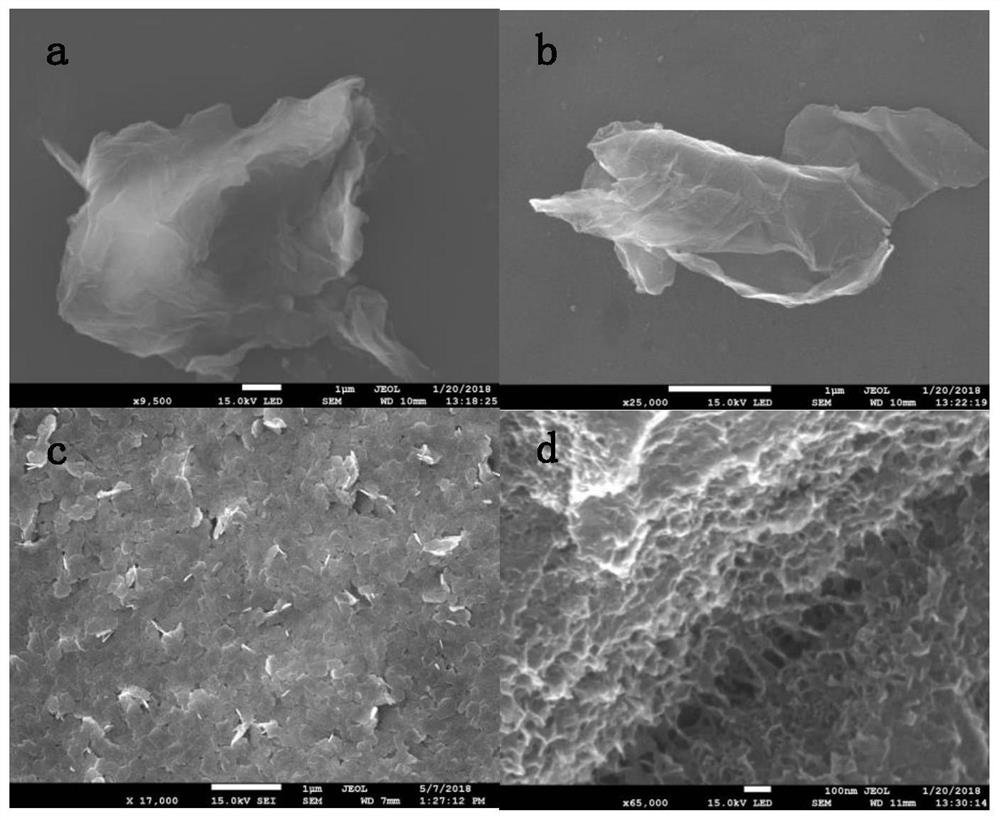

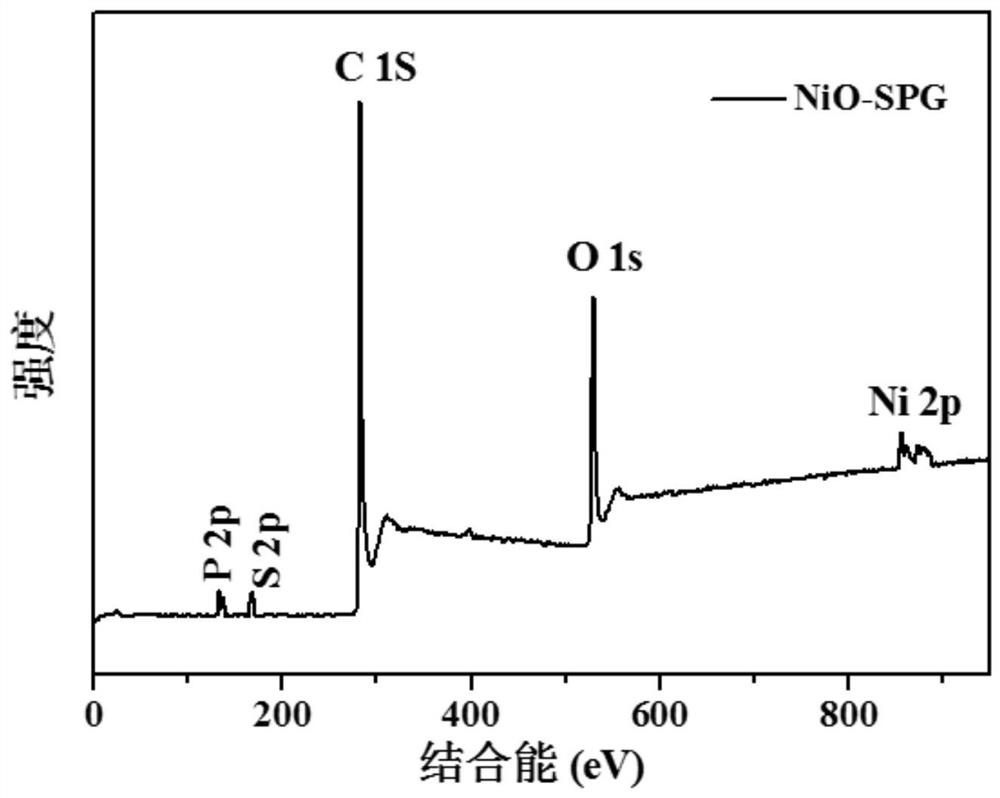

[0034] The preparation method of nickel oxide loaded sulfur phosphorus doped graphene composite electrocatalyst comprises the following steps:

[0035] Step (1): 40 mg of graphene oxide, 2 mL of phosphoric acid, and 2 mL of sulfuric acid were uniformly mixed in 40 mL of aqueous solution, and ultrasonically dispersed for 3 hours to obtain a uniformly mixed mixture A;

[0036] Step (2): Transfer the mixed solution A to a polytetrafluoroethylene-lined hydrothermal kettle for hydrothermal reaction. The temperature of the hydrothermal reaction is 160° C., and the hydrothermal reaction is carried out for 12 hours to obtain a suspension, which is filtered, Wash with water and ethanol respectively, and dry in a vacuum oven at 60°C to obtain sulfur-phosphorus-doped graphene;

[0037] Step (3): Dissolve 0.0005mol of nickel chloride hexahydrate in 30mL of ethanol, stir fully to dissolve completely, and slowly add 2mL of ammonia solution under continuous stirring to obtain light blue solu...

Embodiment 2

[0045] The preparation method of nickel oxide loaded sulfur phosphorus doped graphene composite electrocatalyst comprises the following steps:

[0046] (1) Mix 40 mg of graphene oxide, 3 mL of phosphoric acid, and 4 mL of sulfuric acid in 40 mL of aqueous solution, and ultrasonically disperse for 3 hours to obtain a uniformly mixed mixture A;

[0047] (2) Transfer the mixed liquid A to a polytetrafluoroethylene-lined hydrothermal kettle for hydrothermal reaction. The temperature of the hydrothermal reaction is 185°C, and the hydrothermal reaction takes 13 hours to obtain a suspension, which is filtered, water and ethanol Washing separately and drying in a vacuum oven at 60°C to obtain sulfur-phosphorus-doped graphene;

[0048] (3) Dissolve 0.0006mol of nickel chloride hexahydrate in 40mL of ethanol, stir fully to dissolve it completely, and slowly add 6mL of ammonia solution under continuous stirring to obtain light blue solution B;

[0049] (4) Add sulfur and phosphorus dope...

Embodiment 3

[0056] The preparation method of nickel oxide loaded sulfur phosphorus doped graphene composite electrocatalyst comprises the following steps:

[0057] (1) Mix 40mg of graphene oxide, 1mL of phosphoric acid, and 1mL of sulfuric acid in 40mL of aqueous solution, and ultrasonically disperse for 3 hours to obtain a uniformly mixed mixed solution A;

[0058] (2) Transfer the mixed solution A to a polytetrafluoroethylene-lined hydrothermal kettle for hydrothermal reaction. The temperature of the hydrothermal reaction is 145° C., and the hydrothermal reaction is 8 hours to obtain a suspension, which is filtered, water and Washing with ethanol and drying in a vacuum oven at 60°C to obtain sulfur-phosphorus-doped graphene;

[0059] (3) Dissolve 0.0008mol of nickel chloride hexahydrate in 50mL of ethanol, stir fully to dissolve it completely, and slowly add 8mL of ammonia solution under continuous stirring to obtain light blue solution B;

[0060] (4) Add sulfur and phosphorus doped g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com