Patents

Literature

58 results about "Nickel sulfate hydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

As a non-caking salt used for nickel plating, each molecule of the nickel sulfate crystal is usually hydrated with six molecules of water.

Nickel-phosphorus chemical precipitation plating layer of aluminium alloy

InactiveCN101638778AExtend your lifeImprove performanceLiquid/solution decomposition chemical coatingSodium acetateGram

The invention relates to a nickel-phosphorus chemical precipitation plating layer of an aluminium alloy, mainly containing the following components in content by weight: 20-30 grams / litre of hexahydrated nickel sulphate, 20-30 grams / litre of sodium hypophosphite, 15-20 grams / litre of sodium acetate, 6-10 grams / litre of butane diacid, 30-50 grams / litre of complexing agents, 20-60 PPM of stabilizingagent and 30-100 PPM of plating midbodies. The nickel-phosphorus chemical precipitation plating layer has the advantages of fast precipitation, well combining force of a plating layer, brightness andcompactness of the plating layer, excellent stable property of tank liquor, long service life, easy maintenance, and the like.

Owner:郑建国 +1

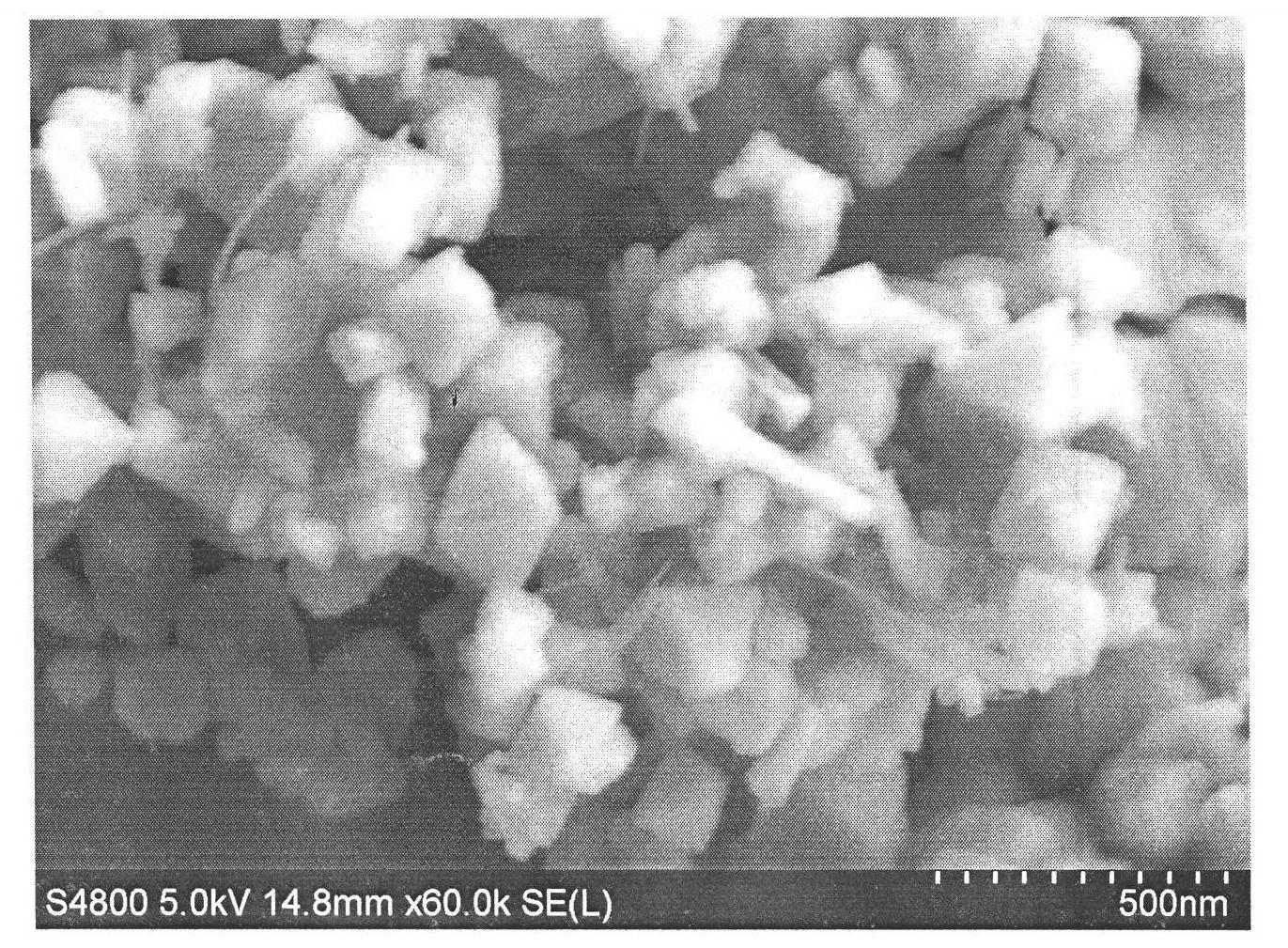

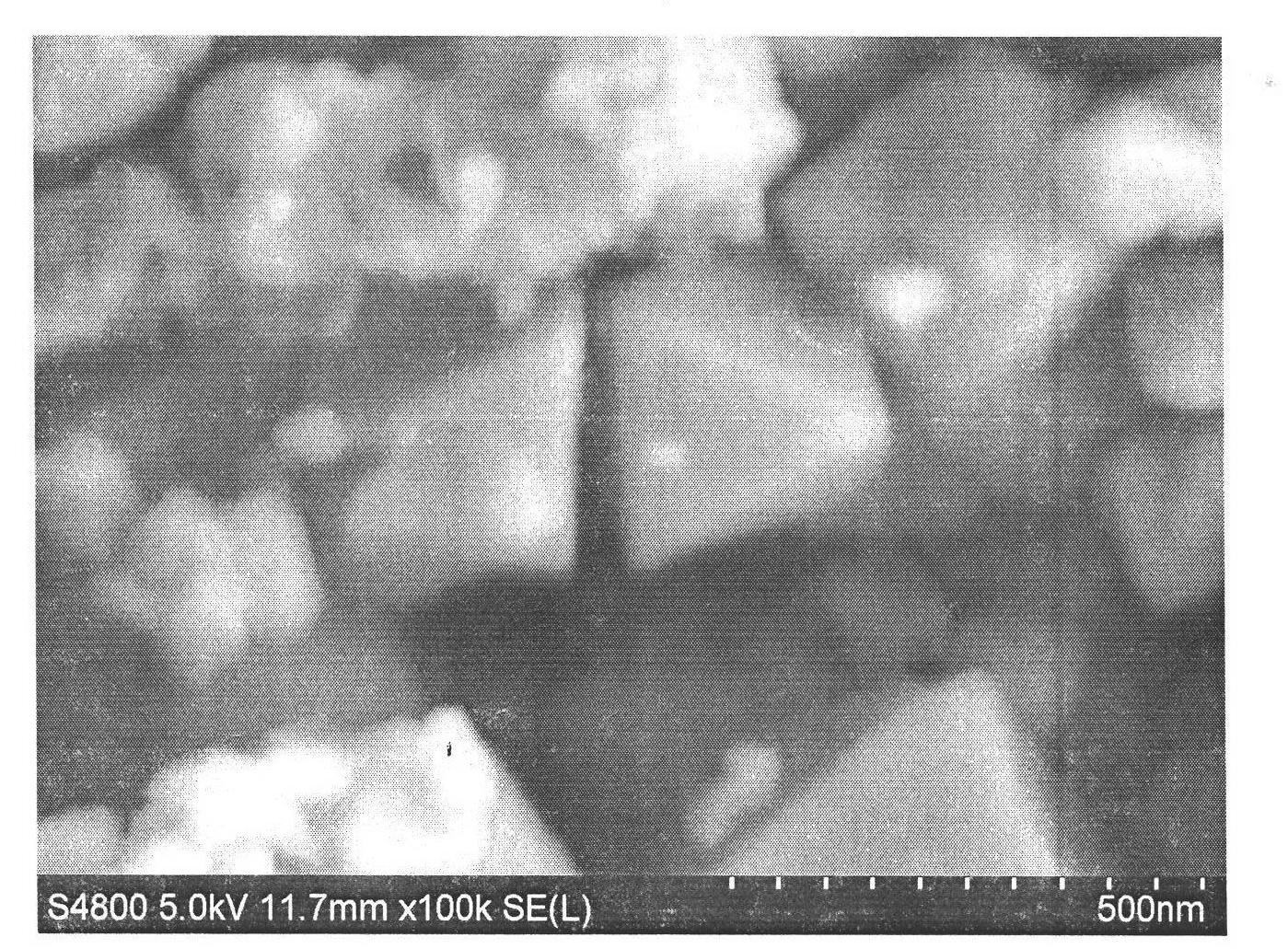

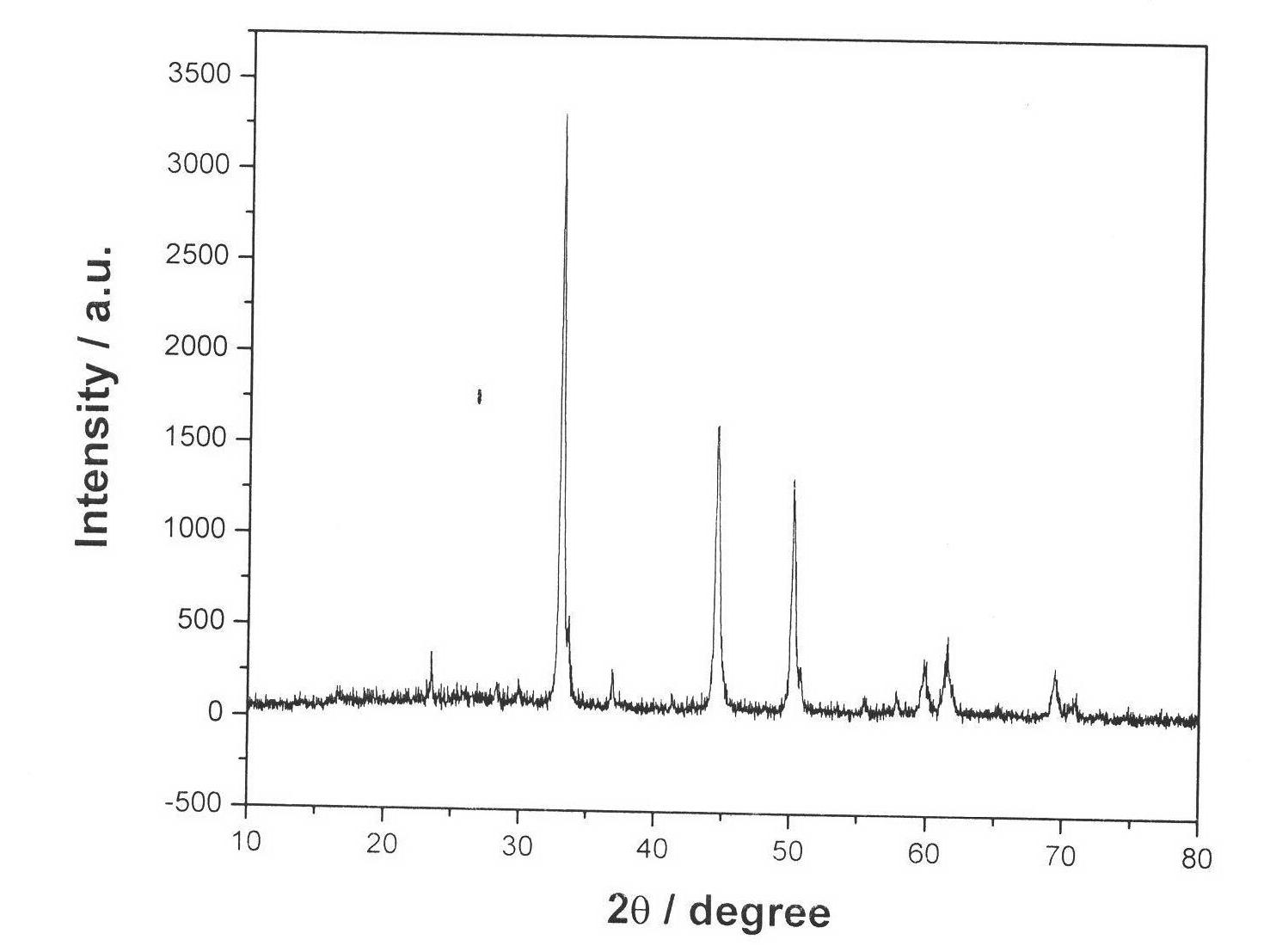

Preparation method of porous nickel oxide/tin dioxide micro/nano spheres

InactiveCN102680539AHigh purity powderPorous pore size distribution is uniformMaterial resistanceTin dioxideMicro nano

The invention discloses a preparation method of porous nickel oxide / tin dioxide micro / nano spheres, which comprises the following steps: stirring tin tetrachloride pentahydrate, nickel sulfate hexahydrate, sodium hydroxide and ammonia water which are used as raw materials, heating, separating, washing, drying and the like to obtain micro / nano spherical hydroxy nickel stannate; and roasting a micro / nano spherical NiSn(OH)6 precursor at high temperature, and cooling to respectively obtain porous micro / nano spherical NiO / SnO2 powder. The micro / nano spherical NiO / SnO2 product prepared by the method disclosed by the invention is light green powder, and has the advantages of large specific area and good product quality. The impedance gas sensing element prepared from the micro / nano spherical NiO / SnO2 powder has high sensitivity, and the sensitivity S value for 100ppm methylbenzene and formaldehyde gases is respectively up to 19.8 and 27.6.

Owner:ANHUI NORMAL UNIV

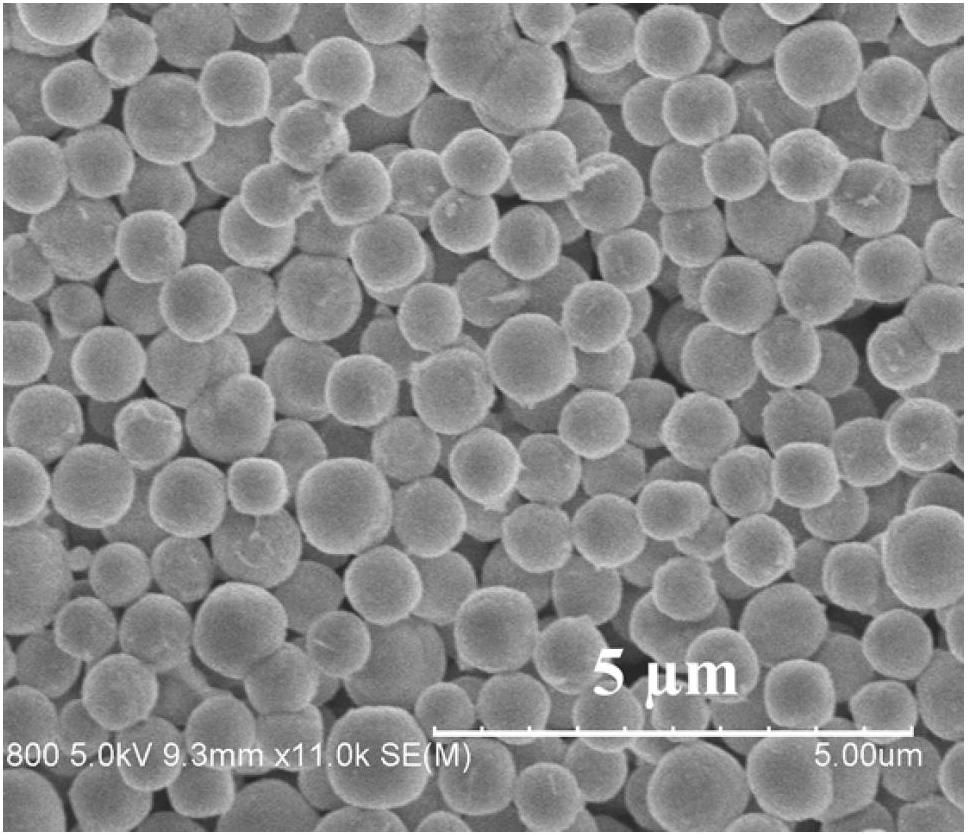

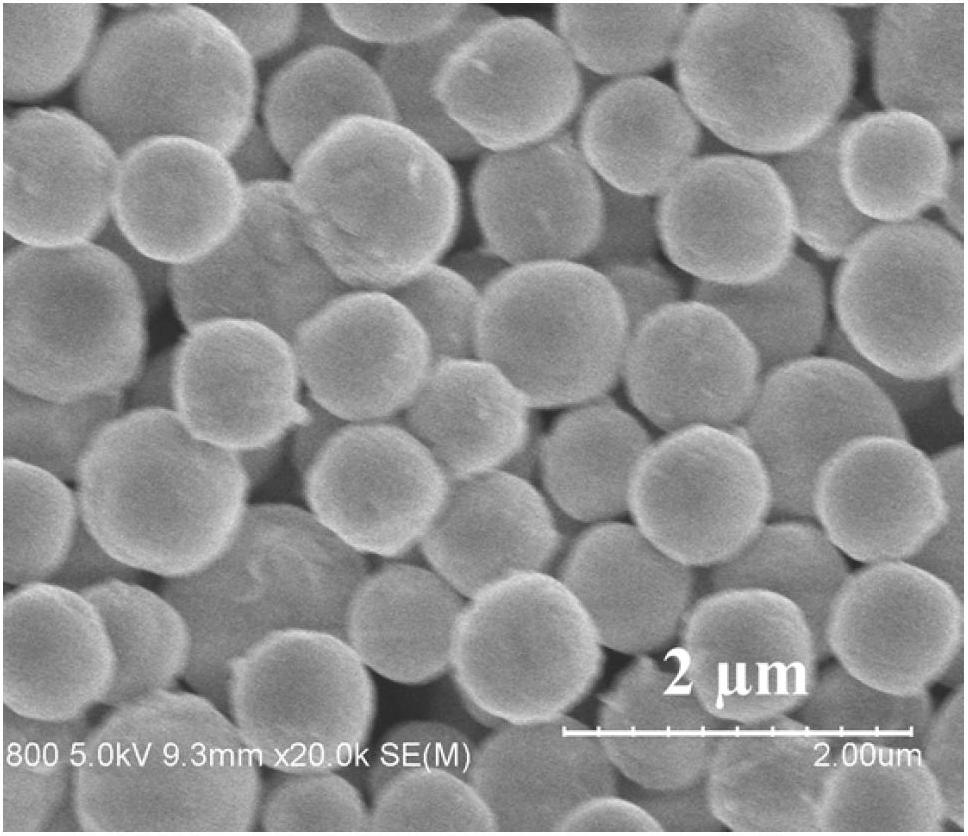

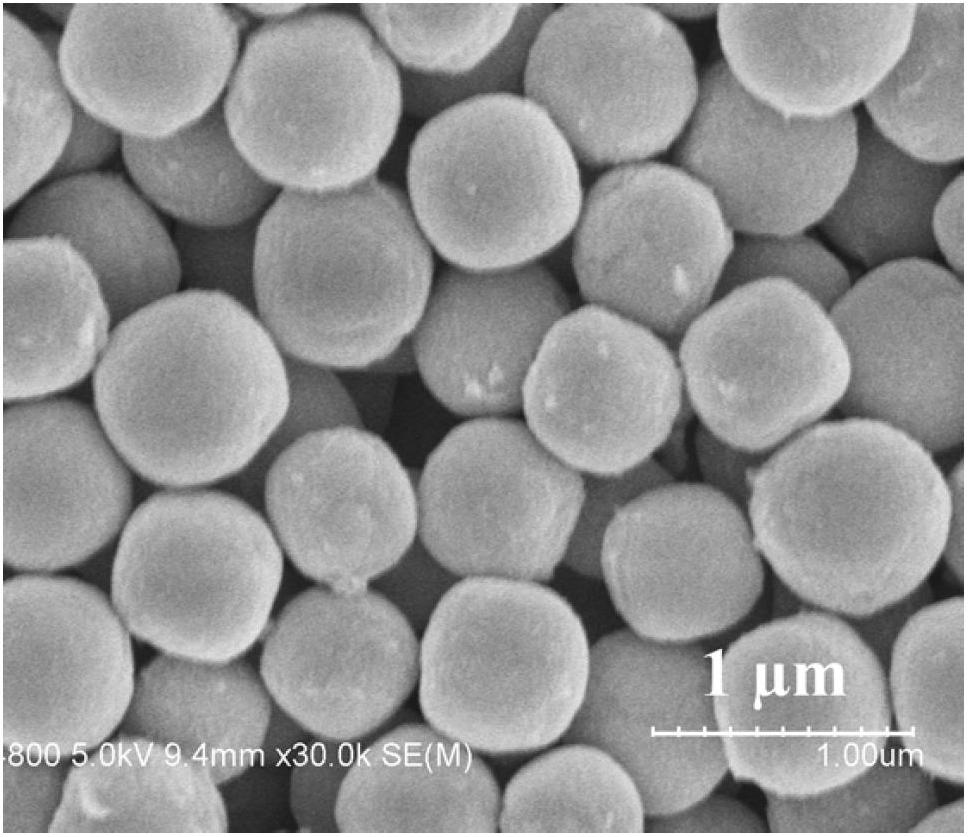

Method for producing surface-activated superfine nickel powder

InactiveCN101797650AGuaranteed purityEasy for industrial implementationActive agentNickel sulfate hydrate

The invention discloses a method for producing surface-activated superfine nickel powder. The process comprises the following steps of: dissolving nickel sulfate hexahydrate in water; reacting the obtained solution with prepared alkaline liquor to produce nickel hydroxide precipitate; adding a certain amount of noble metal ruthenium trichloride into the precipitate so as to activate the surface of a precursor; directly adding nickel hydroxide paste into a pressure container for liquid-phase hydrogen reduction without being filtered and washed, wherein the temperature and pressure for the liquid-phase hydrogen reduction are controlled to be fixed values; performing liquid-solid separation and washing the solid after the reaction is performed for a fixed time; and drying the solid in a baking box and transferring the dried solid into a hydrogen reducing furnace for reduction at the temperature of between 300 and 500 DEG C for a certain time so as to obtain the superfine nickel powder. The method has the advantages that: the conventional high-temperature and high-pressure hydrogen reduction conditions are weakened by adopting a liquid-solid combined reduction method so as to make large-scale industrial production easy; and simultaneously, the noble metal consumption cost is reduced and the average particle diameter of the prepared superfine nickel powder is less than 2 microns because the noble metal ruthenium trichloride is used as an active agent in place of palladium chloride.

Owner:KUNMING INST OF PRECIOUS METALS

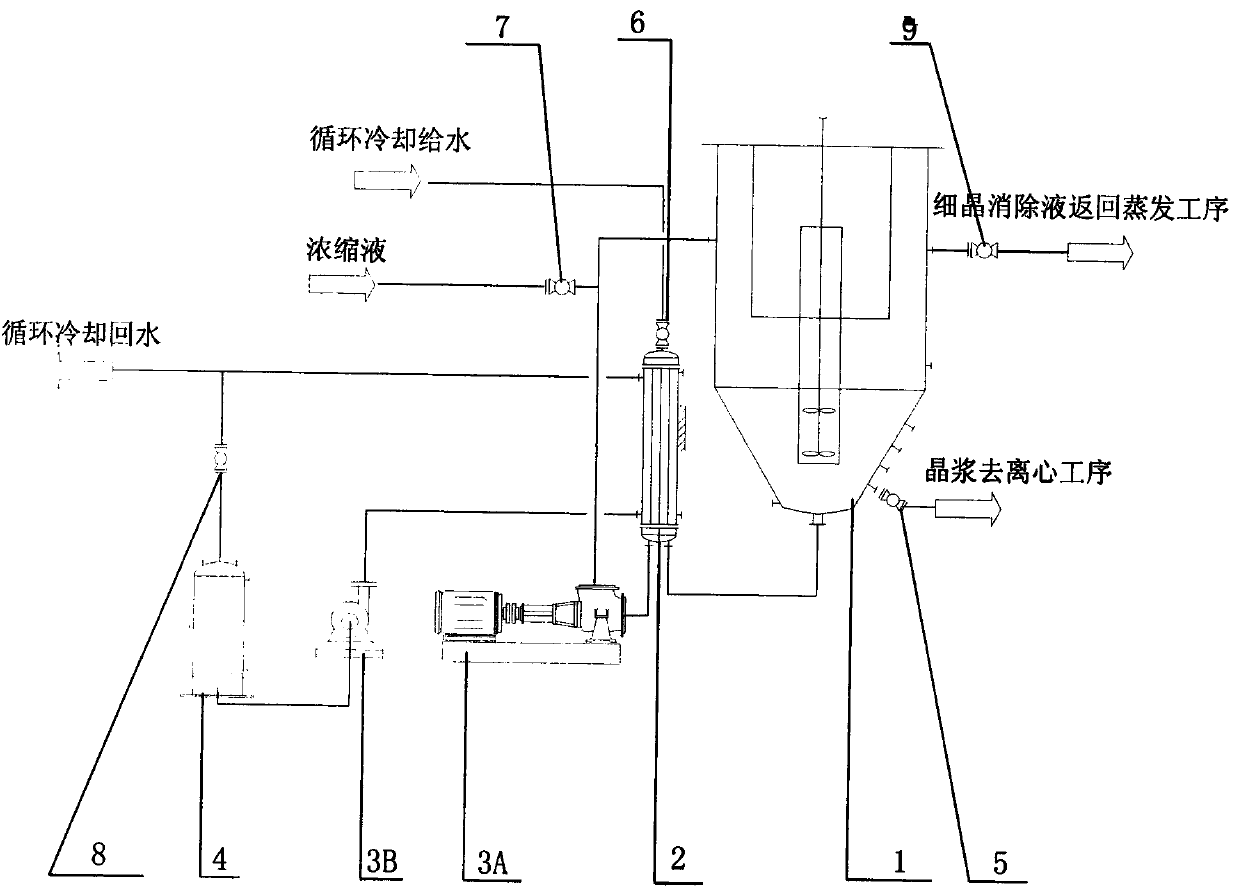

Nickel-cobalt sulfate continuous-crystallizing process

ActiveCN104192917AImprove energy savingRealize continuous productionNickel sulfatesEvaporationSlurry

The invention discloses a nickel sulfate hexahydrate crystal and cobalt sulfate heptahydrate crystal continuous-crystallizing process which comprises the following steps: firstly carrying out MVR evaporation concentration on a high-purity solution produced through an extraction procedure to 30%-39%, and secondly continuously cooling and crystallizing through an improved cooling type internal-circulating continuous crystallizer; continuously discharging crystal slurry from the bottom of the crystallizer for centrifugal solid-liquid separation; and continuously drying a crystal product at low temperature to produce product crystals with large granularity and uniform size distribution, and recovering a mother solution to an evaporation process. Compared with the traditional periodic crystallization process, the nickel sulfate hexahydrate crystal and cobalt sulfate heptahydrate crystal continuous-crystallizing process disclosed by the invention has the advantages of low evaporation energy consumption, fewer crystallization control process parameters, stability in operation, high automation degree, high production efficiency and the like and is easy to control, and operators are reduced.

Owner:ZHEJIANG HUAYOU COBALT

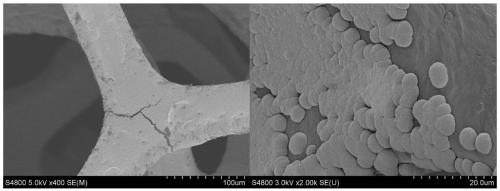

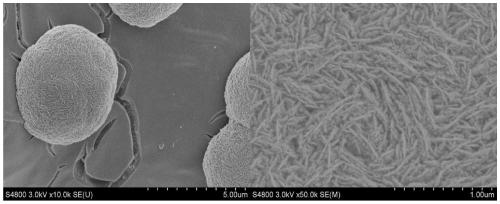

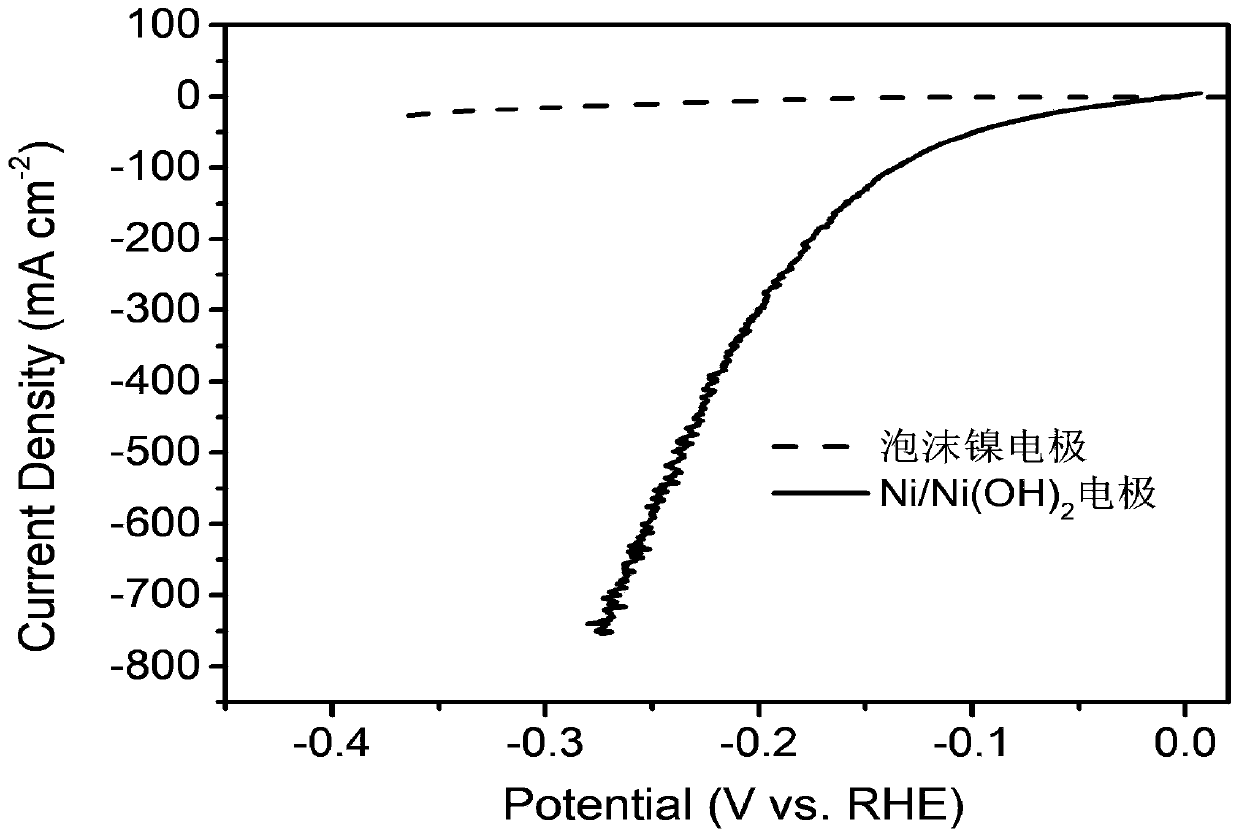

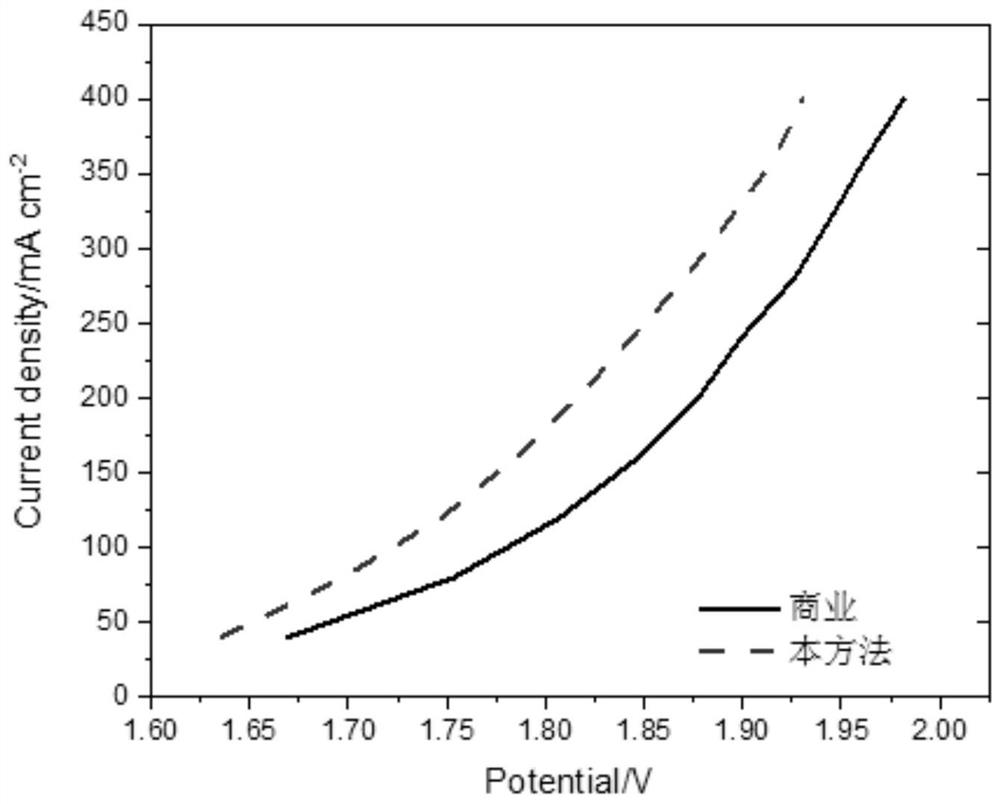

Efficient Ni/Ni(OH)2 hydrogen evolution electrode and preparation method thereof

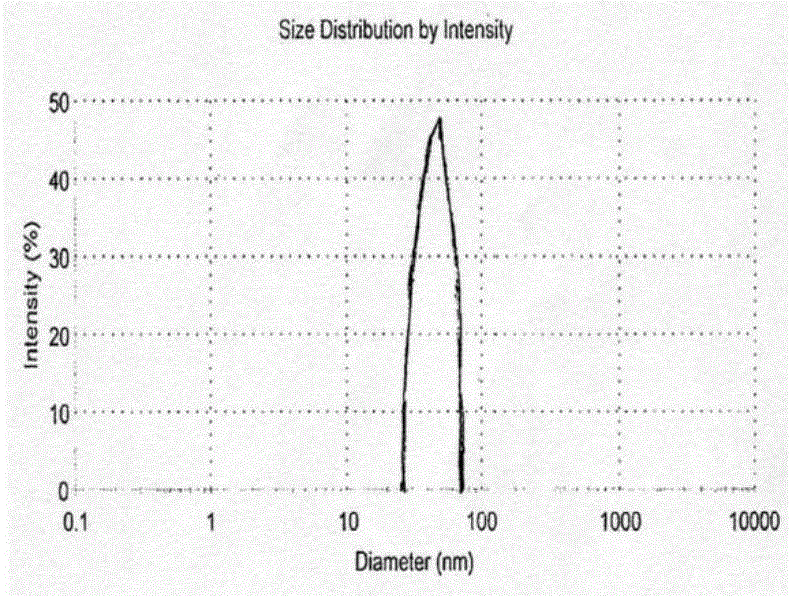

ActiveCN110129825ALarge specific surface areaCatalytic hydrogen evolution activity is highAnodisationElectrolytic inorganic material coatingNanoparticleNickel sulfate hydrate

The invention relates to an efficient Ni / Ni(OH)2 hydrogen evolution electrode, which is characterized in that nickel sulfate hexahydrate and nickel chloride are adopted as sources of nickel elements,and nickel and hydroxide nanoparticles thereof are uniformly doped into a catalyst layer through a direct-current electrodeposition method in combination with subsequent oxidation-reduction treatment,so that the efficient Ni / Ni(OH)2 hydrogen evolution electrode is prepared. The invention also relates to a preparation method of the high-efficiency Ni / Ni(OH)2 hydrogen evolution electrode, which comprises the following steps: (1) pretreating the conductive substrate; (2) carrying out DC electrodeposition to prepare a catalyst layer formed by stacking nano flaky nickel and hydroxide thereof; and(3) carrying out anodic oxidation treatment to obtain the Ni / Ni(OH)2 hydrogen evolution electrode. The Ni / Ni(OH)2 hydrogen evolution electrode is scientific and reasonable in design and has the advantages of being high in catalytic hydrogen evolution activity, low in cost, low in energy consumption, stable in use, good in electrical conductivity and the like. The invention provides the Ni / Ni(OH)2hydrogen evolution electrode and the preparation method thereof with relatively high innovativeness.

Owner:天津市大陆制氢设备有限公司

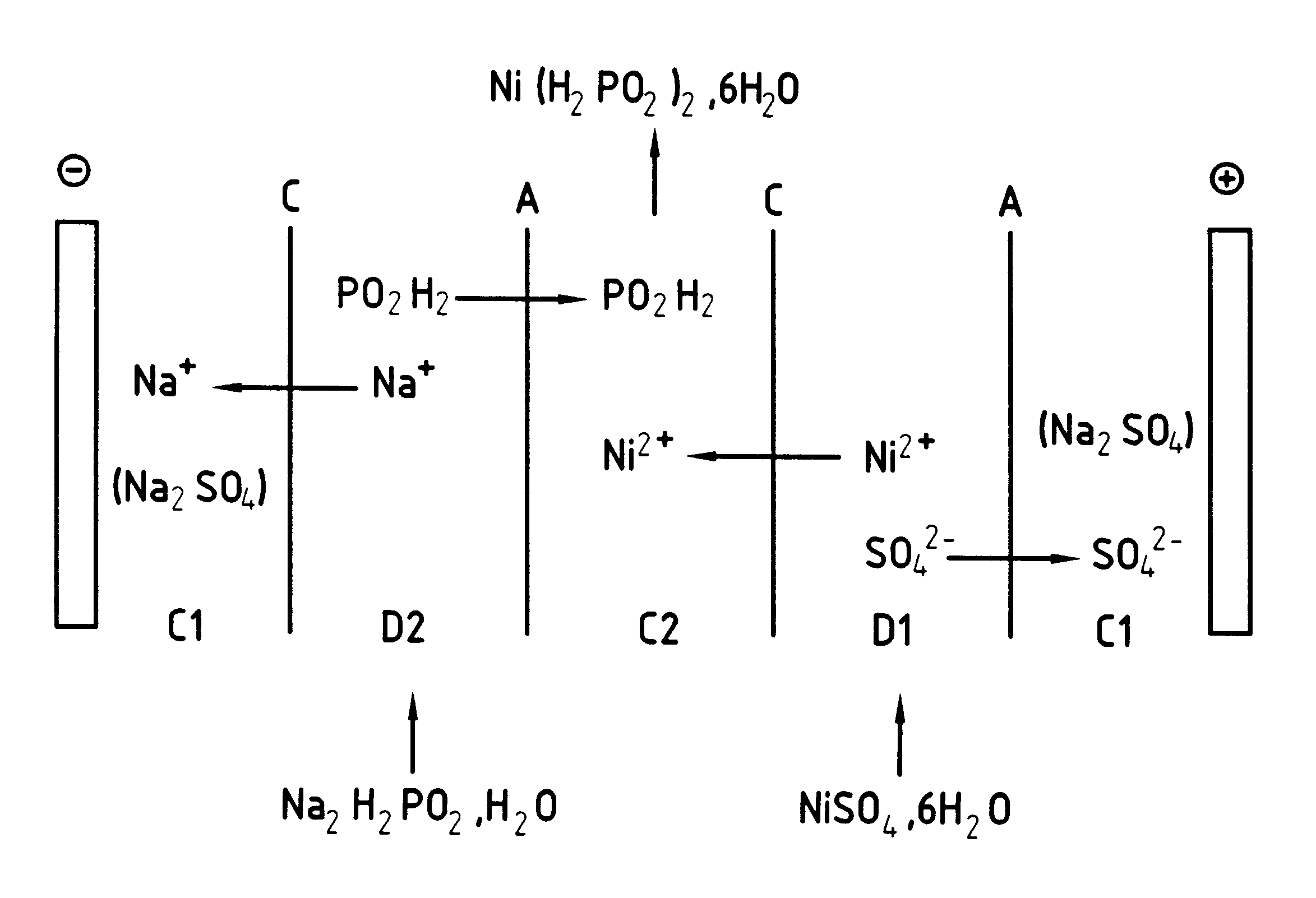

Method of manufacturing nickel hypophosphite by the electro-membrane technique

InactiveUS6200448B1Improve concentrationElectrolysis componentsVolume/mass flow measurementElectricitySulfate

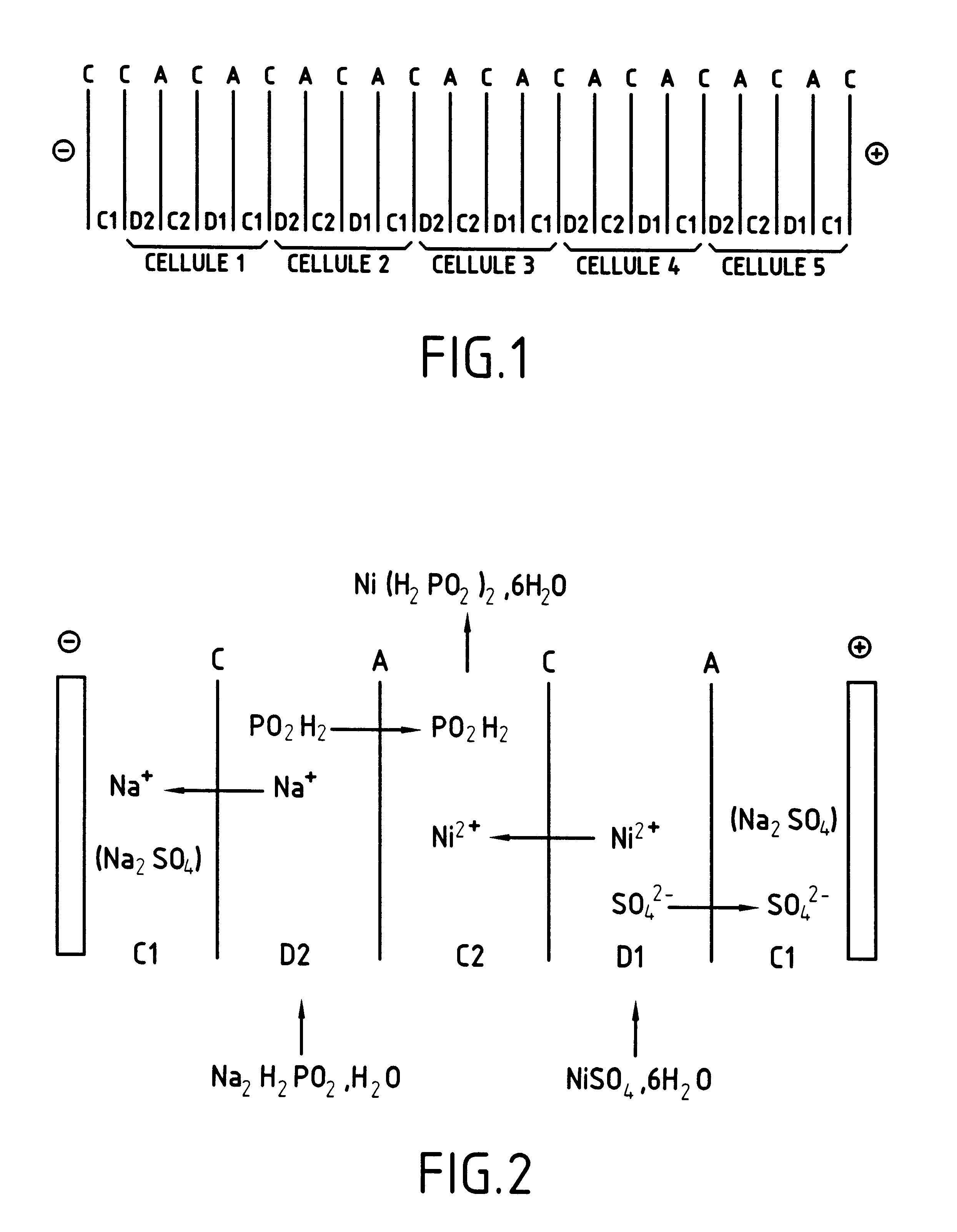

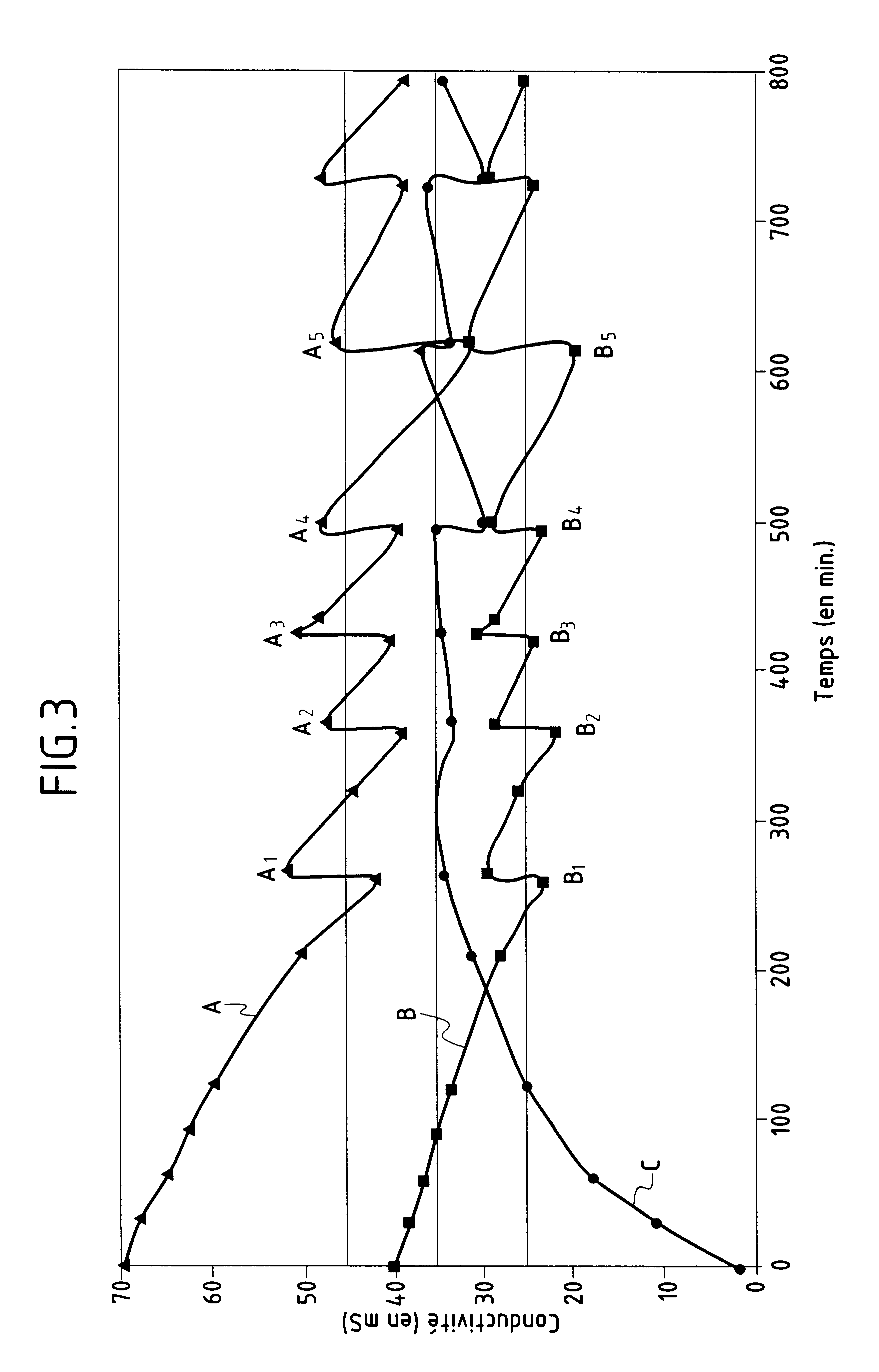

The method of manufacturing nickel hypophosphite from a solution of hexahydrated nickel sulfate and a solution of monohydrated sodium hypophosphite by an electro-membrane technique, consists:a) in introducing respectively the hexahydrated nickel sulfate solution and the monohydrated sodium hypophosphite solution into each of two dilution circuits of four-compartment electrodialysis cells formed by alternating stacks of cationic and anionic homopolar membranes in an electrodialysis apparatus having an anode and a cathode that are insoluble;b) in applying an electrical current from the anode to the cathode without regulating the pH of the solutions contained in the dilution and concentration circuits but regulating the electricity supply, either in voltage or in current; andc) in recovering a hexahydrated nickel hypophosphite solution from one of the concentration circuits.

Owner:ETAB A RICHARD

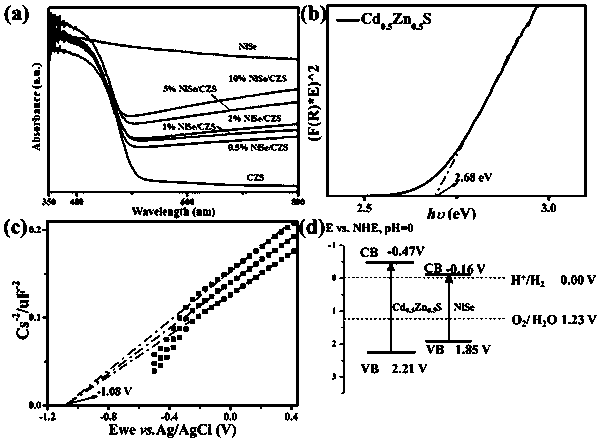

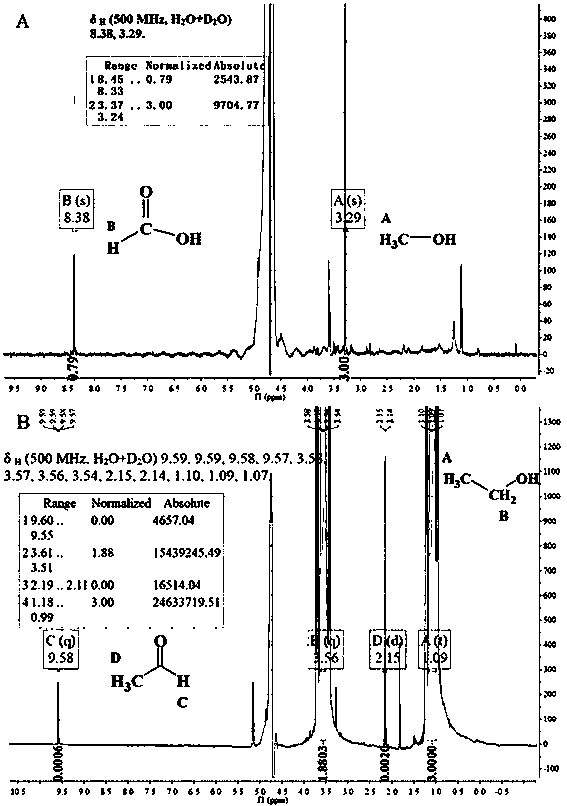

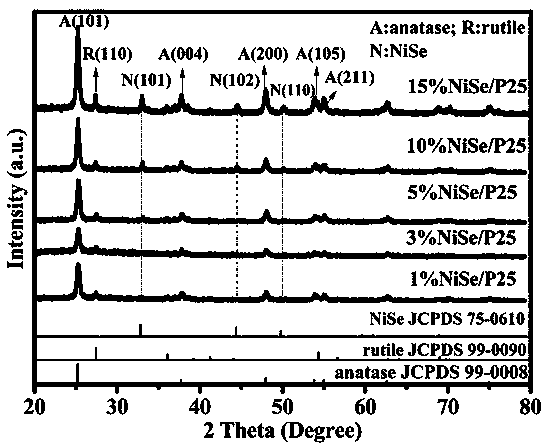

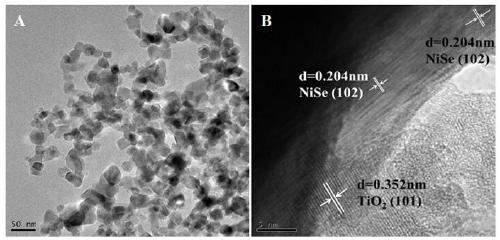

Efficient heterojunction photocatalyst taking NiSe as aid as well as preparation method and application thereof

InactiveCN110075875ASimple thermal reactionEasy to makePhysical/chemical process catalystsHydrogen productionHeterojunctionNickel sulfate hydrate

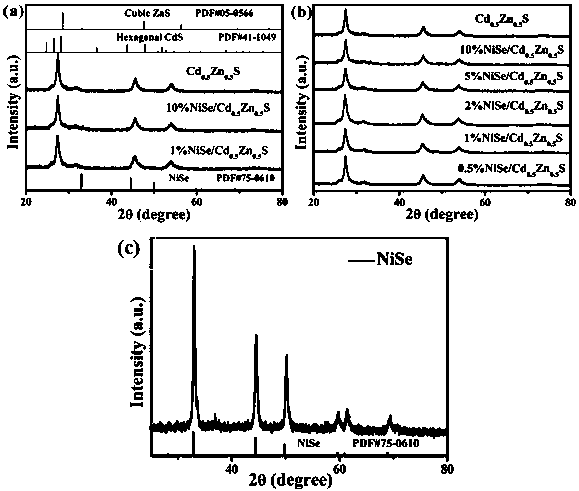

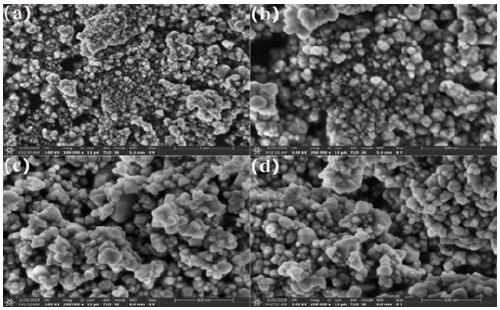

The invention discloses a visible light driven NiSe-based heterojunction photocatalyst for performing efficient photocatalysis on water to perform pyrolysis to produce hydrogen. The heterojunction photocatalyst is prepared by the following steps: preparing Cd0.5Zn0.5S sosoloid by taking cadmium acetate, zinc acetate and thioacetamide as cadmium, zinc and sulfur sources correspondingly and adoptinga precipitation-hydrothermal method; and taking nickel sulfate hexahydrate, sodium selenite and the synthesized Cd0.5Zn0.5S sosoloid as substrates, taking glycol as a solvent and a reducing agent, and synthesizing a NiSe / Cd0.5Zn0.5S heterojunction photocatalyst through a one-step solvent-thermal method. The maximum hydrogen production rate of the heterojunction photocatalyst under visible light reaches 70.3 mmol / h / g, and the activity of the heterojunction photocatalyst is 2.35 times that of pure Cd0.5Zn0.5S sosoloid; furthermore, the preparation method is green, environmentally-friendly, simple to operate and stable in activity, the utilization rate of sunlight, particularly visible light by the photocatalyst is greatly increased, and higher economic benefit can be achieved.

Owner:FUZHOU UNIV

Method for making high-reflectance microprism reflecting film working mould with ultrasound-pulse electroforming

ActiveCN103422128AEasy to adjustControl retroreflection coefficientElectroforming processesPrismDissolution

The invention relates to a microprism, in particular to a method for making a high-reflectance microprism reflecting film working mould with ultrasound-pulse electroforming. Electroforming liquid is prepared, namely hot water is added into an electroforming groove, then nickel sulfate hexahydrate and nickel chloride are added in sequence, hot water is added into a container, then boric acid is added, boiling is carried out, then lauryl sodium sulfate is added, after dissolution, liquid is poured into the electroforming groove, saccharin and 2-butyne-1,4-diol are added into the electroforming groove, then water is injected until the electroforming groove is full, pH is adjusted to 4.2; an anode nickel plate is placed into an anode basket and is connected to a positive electrode, a nickel master mould is connected to a negative electrode, ultrasound power is adjusted to 210-300W, frequency is adjusted to 30-50kHz, pulse current density is adjusted to 1-6A / dm<2>, current frequency is adjusted to 1000Hz, working time ratio of forward currents and backward currents is adjusted to 5:1, duty ratio is adjusted to 10%-30%, electroforming is carried out, and the high-reflectance microprism reflecting film working mould is obtained after cathode demoulding.

Owner:福建跃发光新材料股份有限公司

Preparing method of environment-friendly type stainless steel welding wire not plated with copper

InactiveCN106086975AImprove securityHigh hardnessWelding/cutting media/materialsSoldering mediaCopper platingSodium phosphates

The invention discloses a preparing method of an environment-friendly type stainless steel welding wire not plated with copper and belongs to the technical field of welding wire machining. A degreasing solution is prepared by using sodium hydroxide, sodium carbonate, sodium phosphate dodecahydrate and sodium silicate as raw materials, a low-carbon steel wire is soaked in the degreasing solution for ultrasonic washing after being polished, and the low-carbon steel wire is connected with a power supply with a pure nickel bar, placed in an electroplating solution prepared by mixing nickel sulfate hexahydrate, nickel chloride, titanium dioxide and the like for electroplating, and dried after being fully electroplated so as to obtain the environment-friendly type stainless steel welding wire not plated with copper. The preparing method obviously improves the ductility, toughness and high temperature resistance of the welding wire by electroplating one layer of nickel and titanium dioxide on the surface of the low-carbon steel wire, avoids the problems of environment pollution and physical health hazards, caused in an original welding wire copper plating production process, improves the safety of a welding wire preparing process, and has wide application prospects.

Owner:NINGBO JIANGDONG YONGFENG IND DESIGN

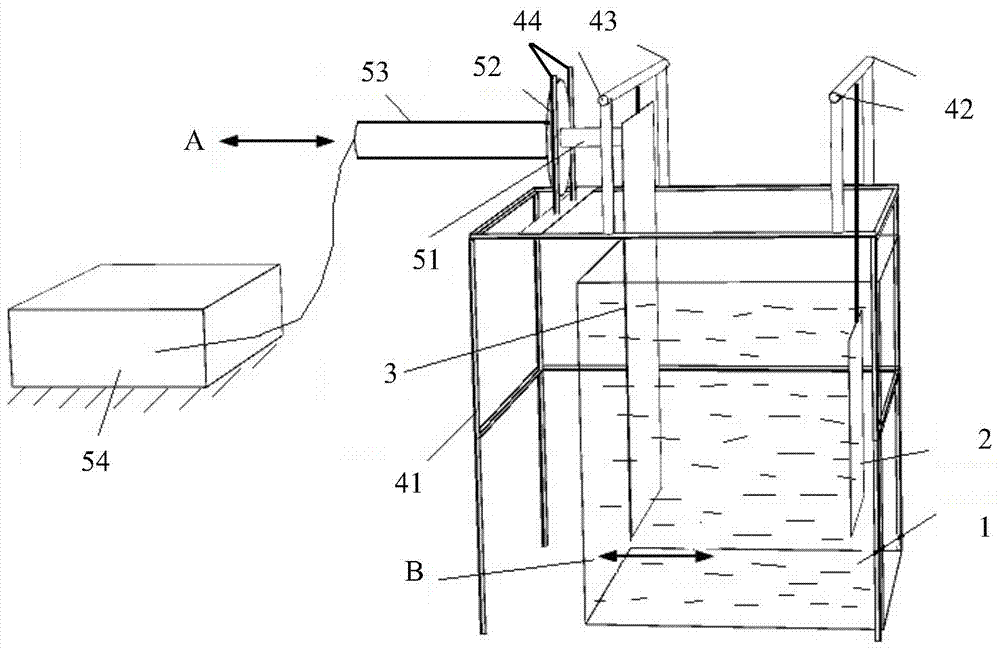

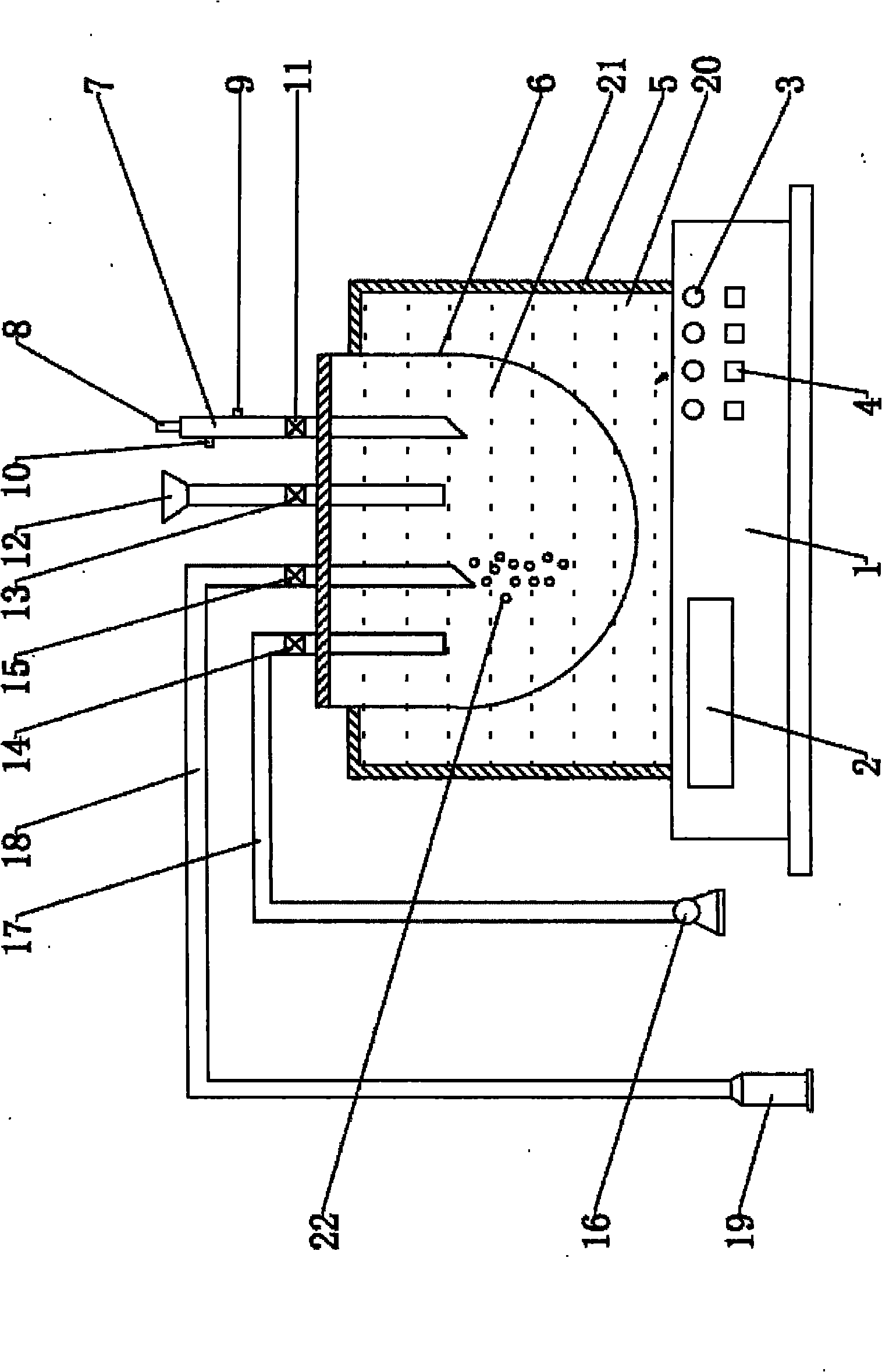

Device and method for making high-reflectance microprism working mold

The invention discloses a device and a method for making a high-reflectance microprism working mold and relates to a microprism. An electroforming groove, an anode, a cathode, a bracket device and an ultrasonic system are arranged on the device, wherein a frame body, an anode, a cathode and a flange fixing rod are arranged on the bracket device; the anode, the cathode and the flange fixing rod are fixedly connected to the top of the frame body; a tool head, a flange, an amplitude-change pole and an ultrasonic power supply are arranged on the ultrasonic system; the front end of the tool head is arranged on the outer side of the cathode; the back end of the tool head is connected with the front end of the amplitude-change pole by virtue of the flange; the back end of the amplitude-change pole is connected with the ultrasonic power supply. The method comprises the following steps: adding water into the electroforming groove, and adding nickel sulfate hexahydrate and nickel chloride in sequence; adding boric acid into hot water, boiling, adding dodecyl sodium sulfate, dissolving, pouring into the electroforming groove, adding saccharin and 1,4-butynediol into the electroforming groove, and filling the electroforming groove with water to obtain an electroforming liquid; putting the anode into an anode basket, connecting a positive pole, connecting a nickel master mold with the cathode, and connecting the upper end of the cathode with the foremost end of the tool head; electroforming, and demolding to obtain the working mold.

Owner:福建跃发光新材料股份有限公司

Heterojunction photocatalyst for hydrogen production and alcohol oxidation by high-efficiency photocatalytic water-cracking

ActiveCN108993546AImproving the hydrogen production performance of photocatalytic water splittingEasy to makePhysical/chemical process catalystsHydrogen productionHeterojunctionLight energy

The invention discloses a heterojunction photocatalyst for hydrogen production and alcohol oxidation by high-efficiency photocatalytic water-cracking, and belongs to the field of photocatalyst preparation and application. According to the invention, nickel sulfate hexahydrate, sodium selenite and titanium dioxide are taken as reactants, glycol is taken as a solvent and a reducing agent, and then aNiSe / TiO2 heterojunction photocatalyst is synthesized according to a one-step solvothermal method. The heterojunction photocatalyst prepared by the invention has a photocatalytic hydrogen productionperformance 9 times higher than that of pure TiO2, and shows good stability in the long-cycle operation. Furthermore, simple alcohols are taken as sacrificial agents, and chemicals of high-value fuel(hydrogen), small molecular acids, aldehydes and the like are prepared through the photocatalytic water cracking under illumination of simulated sunlight. In addition, the heterojunction photocatalystused in the invention is green and simple in preparation method, rich in material sources, low in cost and stable in activity, and combines the small molecular alcohols as the sacrificial agents, sothat economic benefits of photocatalysis and the utilization rate of absorbed light energy can be greatly improved.

Owner:FUZHOU UNIV

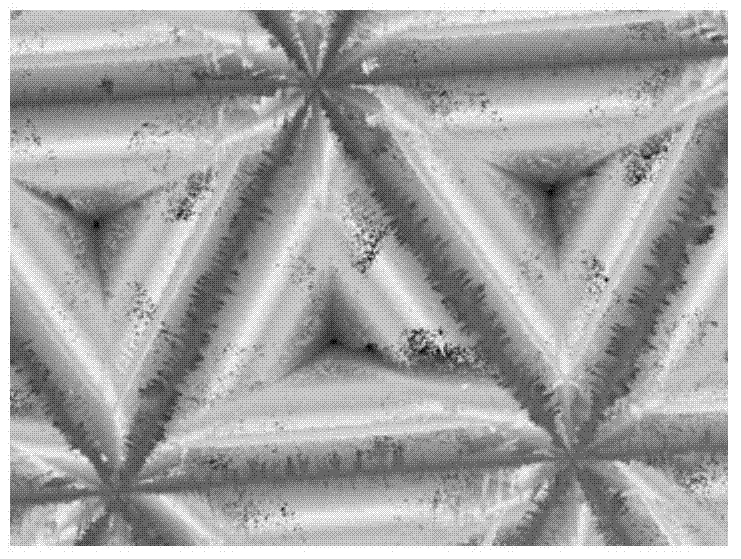

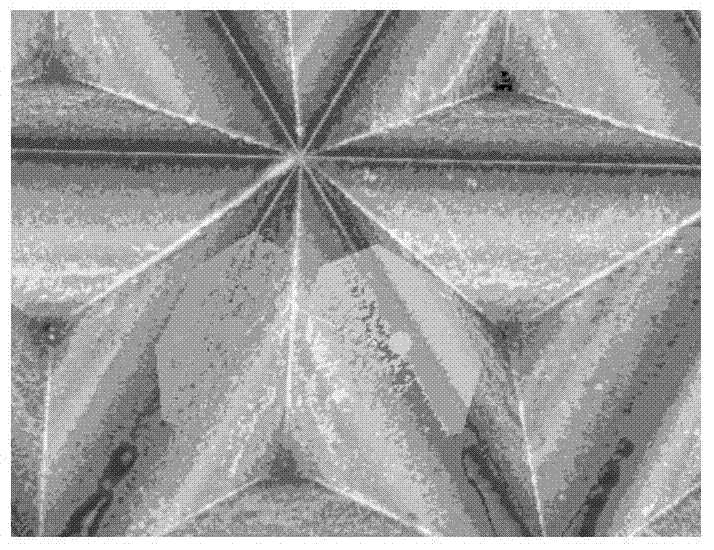

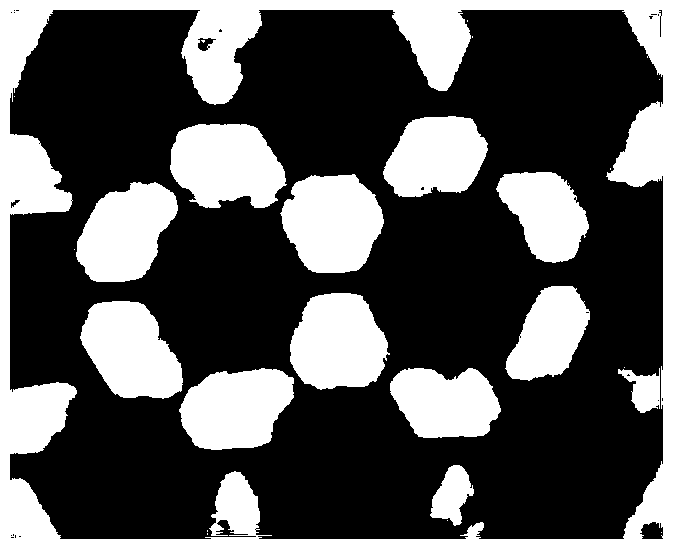

Crystal growth method during alpha-type six hydration nickel sulfate interval crystallization process

The invention discloses a crystal growing method of alpha type hexahydrate nickel sulfate batch crystallization process, which comprises the following steps: allocating a finite density nickel sulfate solution; heating to a finite temperature; stirring to complete dissolve; proceeding cooled crystallization through controlling detemperature rate, stirring rate and adding crystal with a finite quantity and grain size; centrifugalizing the crystalline liquid; getting the crystal; drying under a finite temperature; getting the end product. This product possesses big grain size, even distribution, good crystal system and strong market competitive power.

Owner:GUANGDONG GUANGHUA SCI TECH

High-strength moisture-proof starch glue and preparation method and application method thereof

ActiveCN104449461AImprove bindingImprove moisture resistanceNon-macromolecular adhesive additivesStarch adhesivesOligomerAdhesive

The invention relates to the technical field of adhesives, particularly to a high-strength moisture-proof starch glue and a preparation method and application method thereof. The high-strength moisture-proof starch glue is composed of the raw materials including, by weight part, 100 parts of corn starch, 4-20 parts of phenolic oligomer, 2-10 parts of polylactic acid, 0.5-3 parts of borax, 0.5-5 parts of nickel sulfate hexahydrate, 2-15 parts of sodium peroxide, 1-5 parts of tributyl phosphate and 200-300 parts of water. The h high-strength moisture-proof starch glue is high in bonding strength in humid environments, product bonding stability and moisture-proofness, has anti-mildew effects and avoids environmental pollution when degraded. The preparation method of the h high-strength moisture-proof starch glue is simple and convenient to apply.

Owner:广东省汇林包装科技集团有限公司

Electrolytic copper foil surface treatment method

The invention relates to an electrolytic copper foil surface treatment method. The electrolytic copper foil surface treatment method is characterized by comprising the following steps: (1) preparing a passivation solution from the following chemical components: a main salt sulfate containing 10-80g / L of Zn<2+> and 1.0-10g / L of Ni<2+>, 0.5-2.0g / L of sodium dihydrogen phosphate, 1.0-8g / L of organic corrosion inhibitor 1-phenyl-5-mercaptotetrazole (PMTA), 20-120g / L of buffering agent sodium citrate, and keeping the pH value within the range of 3.5-5.5; and (2) performing the following operation process: adding analytically pure zinc sulfate hydrate and nickel sulfate hydrate for inorganic matter sulfates according to the detection result allocation by use of a metering pump; metering and adding sodium dihydrogen phosphate, the organic corrosion inhibitor and the buffering agent according to the detection result allocation, automatically regulating and controlling the pH value by use of 5% NaOH and 5% dilute sulfuric acid; keeping the current density within the range of 0.2-0.5A / dm<2> and the linear velocity of treating the copper foil within the range of 2-30m / min, performing the subsequent steps of water washing, drying by squeezing, hot air blow-drying and winding.

Owner:雷磊

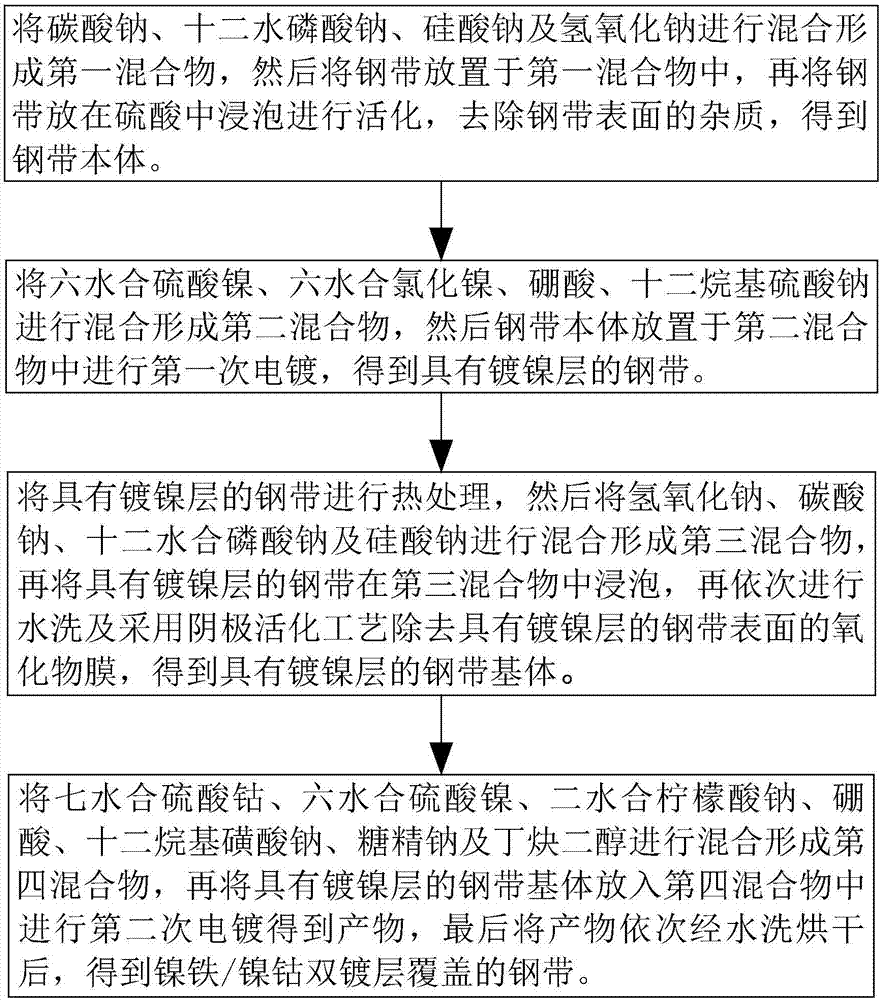

Preparation method of steel strip covered by ferronickel/nickel-cobalt double coatings

A preparation method for a steel strip covered by a nickel-iron / nickel-cobalt double coating, comprising the following steps: Step 1: mixing sodium carbonate, sodium phosphate dodecahydrate, sodium silicate and sodium hydroxide, and placing the steel strip in the first mixture , the steel strip is soaked in sulfuric acid to activate and remove impurities; step 2: nickel sulfate hexahydrate, nickel chloride hexahydrate, boric acid, and sodium lauryl sulfate are mixed, and the steel strip body is placed in the second mixture for the first electroplating; Step 3: heat-treat the steel strip with the nickel-plated layer, mix sodium hydroxide, sodium carbonate, sodium phosphate dodecahydrate and sodium silicate, soak the steel strip with the nickel-plated layer in the third mixture, wash with water and perform cathodic activation process Removing the oxide film of the steel strip with the nickel-plated layer; step 4: mixing cobalt sulfate heptahydrate, nickel sulfate hexahydrate, sodium citrate dihydrate, boric acid, sodium dodecylsulfonate, sodium saccharin and butynediol , the steel strip substrate with the nickel-plated layer is put into the fourth mixture for the second electroplating, and is successively washed and dried.

Owner:SHENZHEN ANDING NEW ENERGY TECH DEV CO LTD

Method for preparing nano nickel selenide with octahedral structure

InactiveCN102583273AGood effectEfficient decompositionChemical industryNanotechnologyHydration reactionActive agent

The invention provides a method for preparing nano nickel selenide with an octahedral structure, and belongs to the technical field of preparation of nano materials. The method is characterized by comprising the following steps of: adding 0.1314 gram of nickel sulfate hexahydrate and 0.0866 gram of sodium selenite into a 25-milliliter high-pressure reaction kettle with a polytetrafluoroethylene lining, adding 20 milliliters of ethylene glycol, stirring for 20 minutes, closing the reaction kettle, putting into a digital display temperature control furnace, and reacting for 24 hours at the temperature of 180 DEG C; and performing three times of centrifugal washing on the obtained sample, drying, and thus obtaining the product. An organic template and a surfactant are not required in the method, and the nano nickel selenide is synthesized in one step and has high yield and the octahedral structure; the method is simple, energy-saving and suitable for industrialized production; and the obtained octahedral nickel selenide has a good catalytic effect on decomposition of hydrazine hydrate.

Owner:ANHUI UNIVERSITY

Supported photocatalyst and preparation method thereof

ActiveCN110302809AEasy transferEnhance photocatalytic hydrogen production activityPhysical/chemical process catalystsHydrogen productionHeterojunctionNickel sulfate hydrate

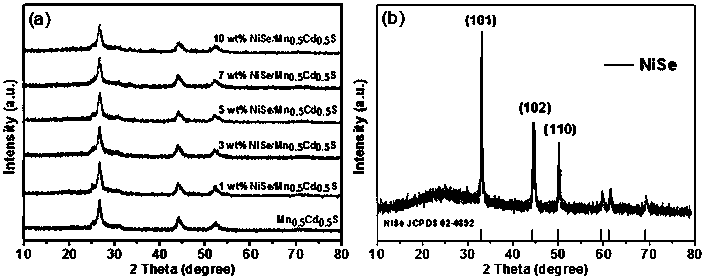

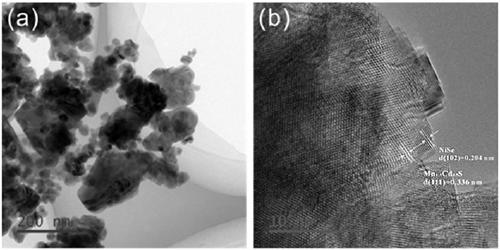

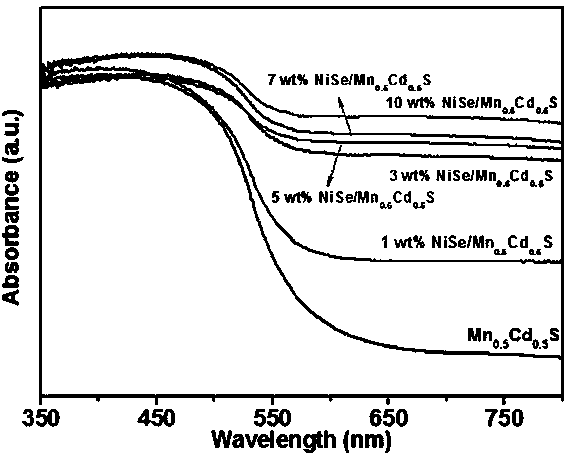

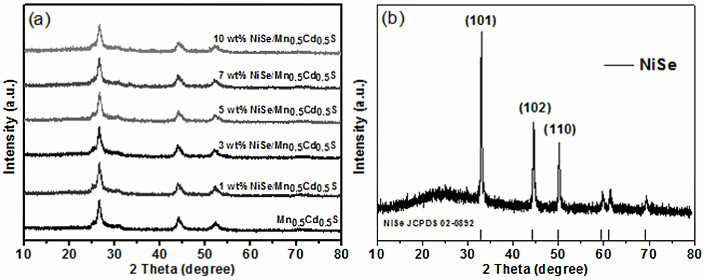

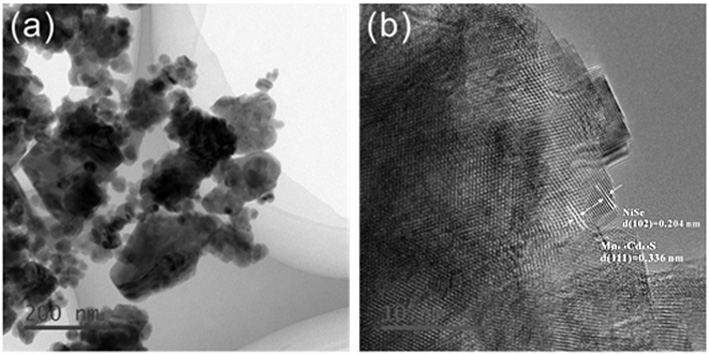

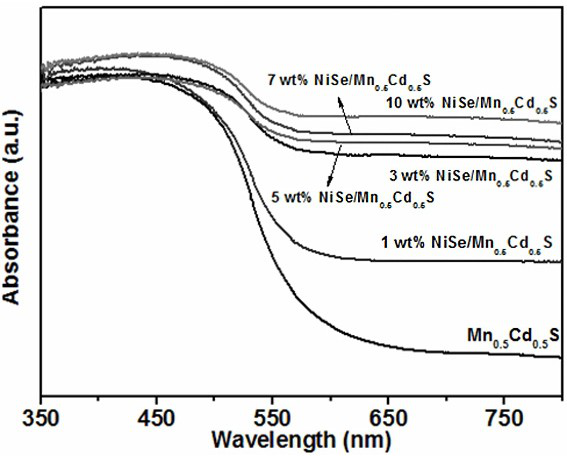

The invention discloses a supported photocatalyst NiSe / Mn0.5Cd0.5S and a preparation method thereof. The supported photocatalyst is prepared by firstly synthesizing a Mn0.5Cd0.5S solid solution by using a gentle one-step hydrothermal method, and by secondly, enabling the solid solution to react with nickel sulfate hexahydrate and sodium selenite. NiSe and Mn0.5Cd0.5S are tightly combined to form heterojunctions in the composite catalyst, migration of photon-generated carriers can be facilitated, combination of photon-generated electron holes is inhibited, and the photocatalysis hydrogen production activity of the Mn0.5Cd0.5S solid solution can be remarkably improved. The novel NiSe / Mn0.5Cd0.5S photocatalyst disclosed by the invention is simple to prepare, can be massively prepared, is highin photocatalysis activity and good in stability, and has wide application prospects in clean energy development.

Owner:FUZHOU UNIV

Waterproof cement slurry resistant to chemical harmful erosion

The invention belongs to the technical field of building materials, in particular to waterproof cement slurry resistant to chemical harmful erosion. The waterproof cement slurry comprises the following raw materials: cement, hydroxy-terminated lactic acid oligomer with a molecular weight of 800-2000, a surface-active substance, a composite filler, glycollic acid, nickel sulfate hexahydrate, starchsodium octenylsuccinates, terpenyl epoxy resin and acrylate emulsion. Compared with the prior art, the waterproof cement slurry disclosed by the invention has the advantages that a powdered flexiblewaterproofing material made from multiple active chemicals is doped into cement, wherein ephedra fiber powder can contribute to improving the flexibility of the cement slurry and effectively improvingthe penetrating function and chemical harmful erosion, and the waterproof cement slurry has ultra-strong penetration capacity and excellent impervious performance, and is high in harmful chemical erosion resistance, capable of automatically and rapidly repairing micro-cracks, safe, environment friendly and excellent in waterproof performance.

Owner:安徽力峰建材科技有限公司

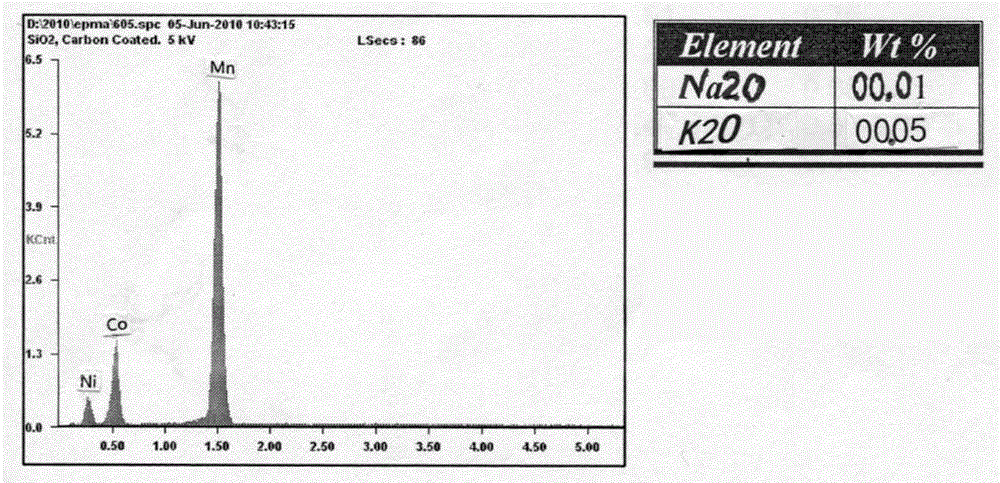

Preparation method for cobalt-manganese-nickel oxides

InactiveCN105140505AEvenly distributed ingredientsImprove uniformityCell electrodesSecondary cellsManganeseNickel sulfate hydrate

The invention discloses a preparation method for cobalt-manganese-nickel oxides. The preparation method comprises steps of separately dissolving industrial products including manganese sulfate monohydrate, cobaltous sulfate heptahydrate and nickel sulfate hexahydrate by hot water, gradually adding a NH4HCO3 solution for performing a neutralization reaction and a precipitation reaction, then continuing to add a KOH solution to react, discharging, filtering, washing by water until SO42-ions disappear, drying, roasting by a high-temperature furnace at the temperature of 820 DEG C for 2-3 hours, ball milling and smashing, stirring and washing by hot water, then filtering, washing, drying and smashing to obtain the cobalt-manganese-nickel oxides. The preparation method is simple, easy to operate, and low in production cost; and the prepared cobalt-manganese-nickel oxides are excellent in product uniformity, stability and electric property, and low in production cost, and can be used for industrial production.

Owner:GUIZHOU ACADEMY OF TESTING & ANALYSIS

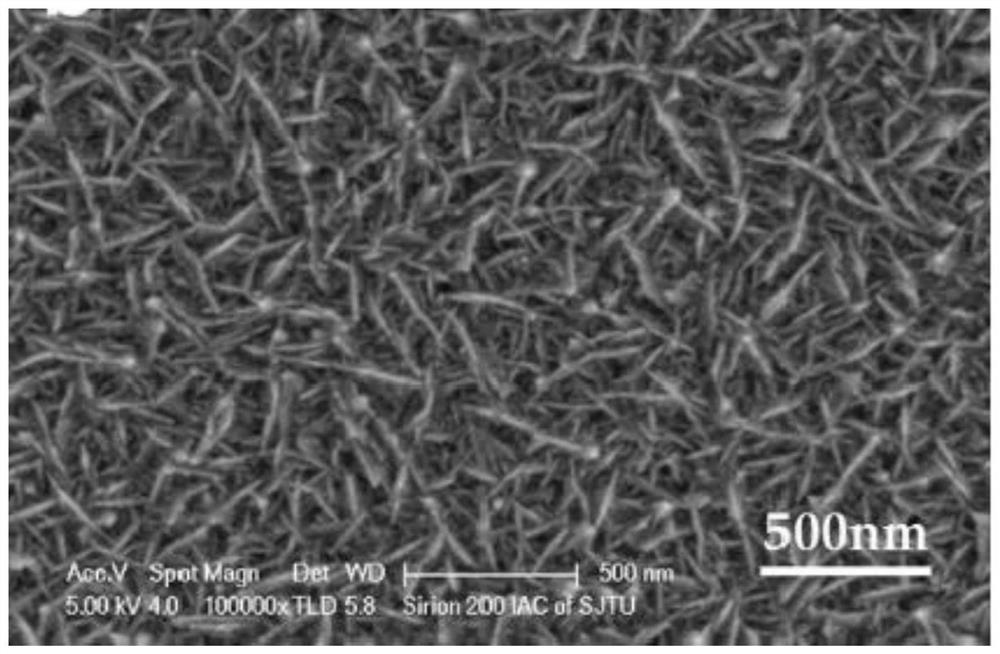

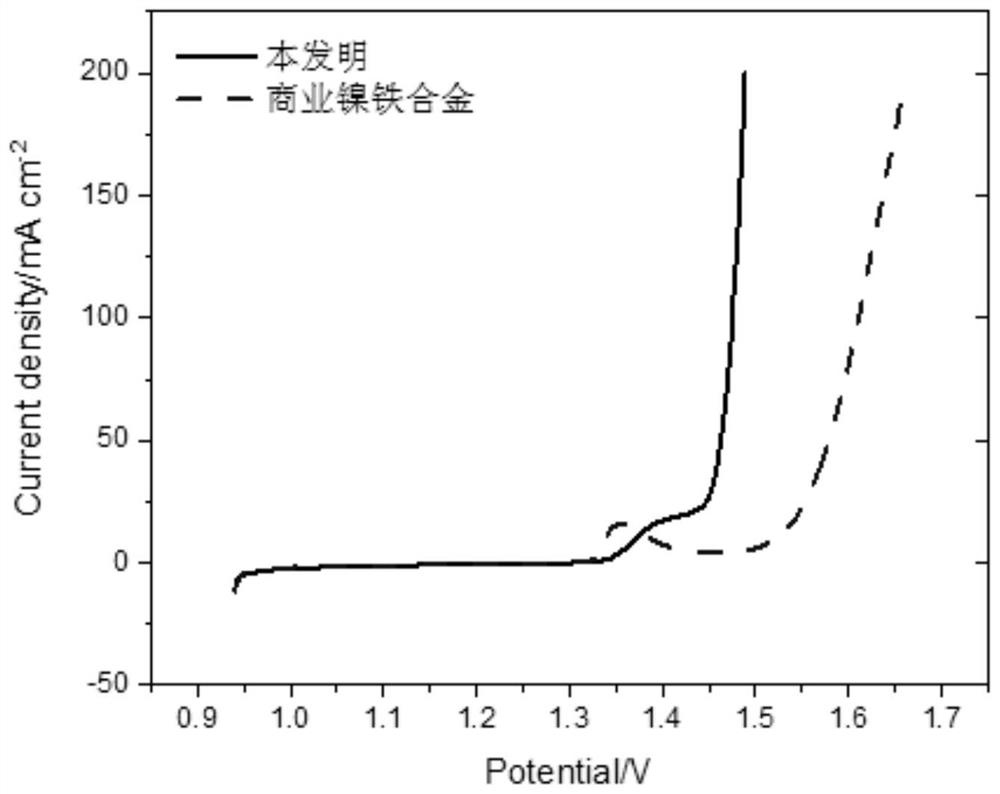

Preparation method of ferronickel catalyst for hydrogen production through water electrolysis

The invention discloses a preparation method of a ferronickel catalyst for hydrogen production by electrolysis of water, which comprises the following steps: (1) adding nickel sulfate hexahydrate and ferrous sulfate heptahydrate into water for dissolving to obtain a dissolved solution; (2) selecting sodium chloride, boric acid, sodium citrate, a benzenesulfinic acid agent, lauryl sodium sulfate and saccharin as regulator raw materials, sequentially adding the regulator raw materials into the dissolved solution, and uniformly mixing to obtain a dark green transparent mixed solution; (3) adjusting the pH value of the mixed solution to 3-3.5 to obtain an electroplating solution; (4) transferring the electroplating solution into an electroplating bath, and raising the temperature to 45-55 DEG C; and (5) selecting a nickel net as a carrier, using an electrochemical workstation, and carrying out electrodeposition by adopting a chronoamperometry to obtain the nickel-iron alloy catalyst. According to the invention, the electrodeposition conditions are controlled, and the composition and morphology structure of the plating layer are regulated and controlled by changing the composition of the plating solution, so that the electrocatalytic performance of the nickel-iron catalyst is accurately controlled, and the catalyst has good catalytic performance and stable performance.

Owner:QINGDAO CHUANGQI XINNENG CATALYSIS TECH CO LTD

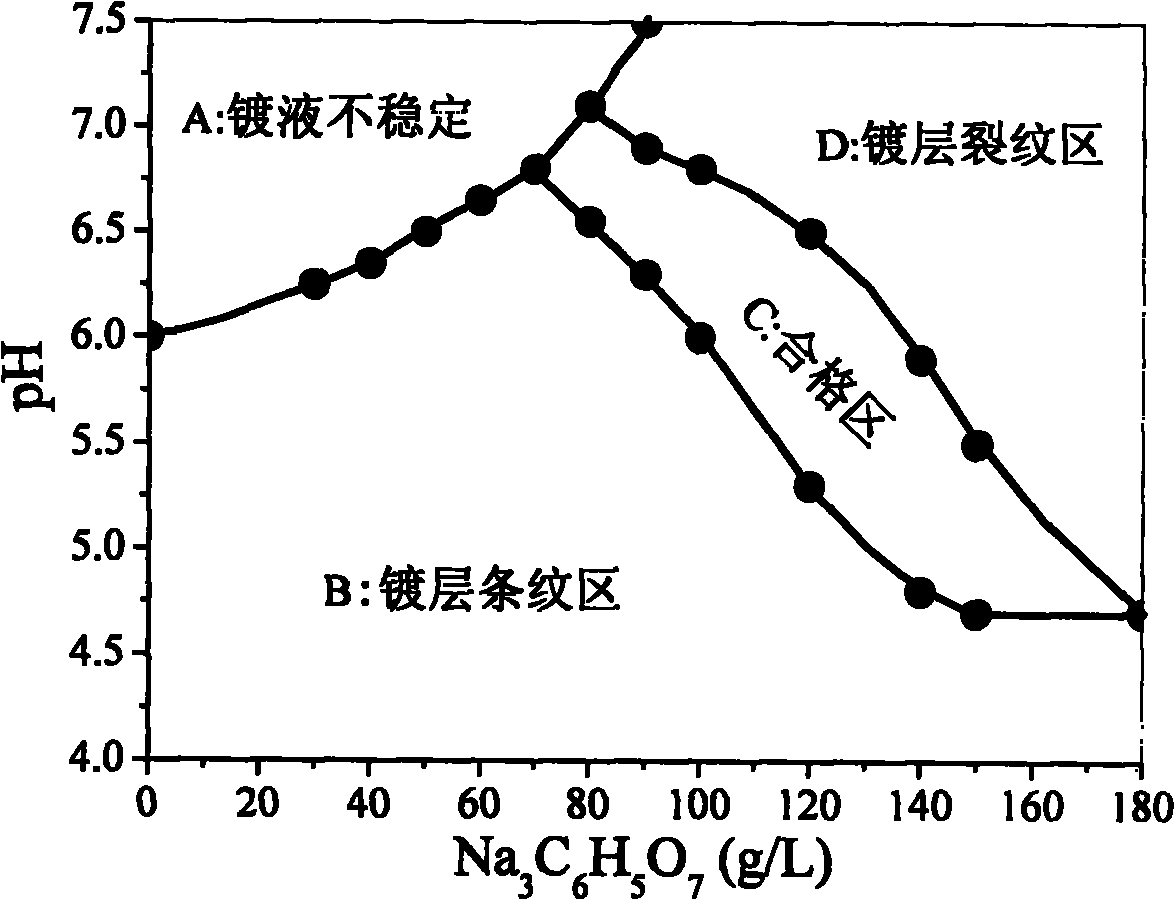

Electrodeposit nickel plating solution for deformation zinc alloy and electrodeposit nickel plating method thereof

ActiveCN101818368ANo pollution in the processNo blistering and peelingZinc alloysNickel sulfate hydrate

The invention discloses electrodeposit nickel plating solution for a deformation zinc alloy and an electrodeposit nickel plating method thereof. The solvent of the electrodeposit nickel plating solution is deionized water, and a solute comprises nickel sulfate hexahydrate (110-130g / L), sodium chloride (10-15g / L), boric acid (30-35g / L) and sodium citrate (80-170g / L). In the electrodeposit nickel plating method, before electrodepositing, the pH value of the electrodeposit nickel plating solution is regulated to 4.8-6.9, the temperature of the electrodeposit nickel plating solution is kept at 20-30 DEG C, and the cathode current density is 0.8-1.5 amperes / dm<2>. The electrodeposit nickel plating solution does not contain prussiates and has the advantages of no pollution and good stability. The cladding surface made by the electrodeposit nickel plating method has no fringes, no cracks when being observed by a metalloscope, and no bubbling or stripping in case of thermal shock at 150 DEG C; and the discolored area on the paste surface does not exceed 10%.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Nano-structure Ni-base composite electroplating solution containing nano Si3N4 particles and preparation method thereof

InactiveCN102051644AShort process flowReduce investmentMaterial nanotechnologyElectrolytic coatingsNickel sulfate hydrateNanostructure

The invention belongs to the technical fields of electrochemistry and metal surface treatment, in particular relates to a nano-structure Ni-base composite electroplating solution containing nano Si3N4 particles and a preparation method thereof. Every 1L of the nano-structure Ni-base composite electroplating water solution containing nano Si3N4 particles comprises 5-12g of the nano Si3N4 particles, 160-220g of nickel sulfate hexahydrate, 42-57g of nickel chloride hexahydrate, 40-55g of boric acid, 1.6-5.0g of lauryl sodium sulfate, 0.1-1.0g of 1,4-butynediol and 0.8-5.0g of brightener, whereinthe nano Si3N4 particles are firstly subjected to surface chemical modification by using a lauryl sodium sulfate solution. A thin-film material produced by using the composite electroplating solutionprovided by the invention has the characteristics of favorable binding force with a substrate, favorable corrosion resistance, higher hardness and favorable wear resistance.

Owner:JIAXING TIANQI NEW MATERIAL TECH

Environment-friendly electroplating formula with cobalt-based ternary alloy replacing hard chromium plating and preparation method thereof

The invention discloses an environment-friendly electroplating formula with cobalt-based ternary alloy replacing hard chromium plating and a preparation method thereof. The environment-friendly electroplating formula with the cobalt-based ternary alloy replacing hard chromium plating includes cobaltous sulfate heptahydrate, nickel sulfate hexahydrate, sodium tungstate dihydrate, citric acid monohydrate and sodium lauryl sulfate. By means of the environment-friendly electroplating formula with the cobalt-based ternary alloy replacing hard chromium plating and the preparation method thereof, the problem of environmental pollution caused by hexavalent chromium is solved, and the technical difficulty on the aspects of hardness and bonding force of a plating layer is overcome.

Owner:SHANGHAI YOUXIANG CHEM CO LTD

Method for preparing high-reflectance working mould of microprism reflecting films by utilizing ultrasonic electroforming

ActiveCN103436922AEasy to adjustControl retroreflection coefficientElectroforming processesNickel sulfate hydrateDiol

The invention provides a method for preparing a high-reflectance working mould of microprism reflecting films by utilizing ultrasonic electroforming, and relates to microprisms. The method comprises the following steps of preparing electroforming solution, namely adding hot water into an electroforming tank, then adding nickel sulfate hexahydrate and nickel chloride in sequence, adding hot water into a container, then adding boric acid, then boiling the mixture, then adding lauryl sodium sulfate, pouring the solution into the electroforming tank after lauryl sodium sulfate is dissolved, adding saccharin and 2-butyne-1,4-diol into the electroforming tank, then injecting water to fully fill the electroforming tank and regulating the pH value to be 4.2; putting an anode nickel sheet into an anode basket, connecting the anode nickel sheet to an anode and connecting a nickel master mould to a cathode to carry out electroforming, and carrying out cathode demoulding to obtain the high-reflectance working mould of the microprism reflecting films. The method has the advantages that the ultrasonic parameters can be conveniently regulated by utilizing an ultrasonic washing machine during production; the coefficient of retroreflection of the microsized working mould of the microprism reflecting films can be controlled by regulating the ultrasonic parameters and the electroforming solution formula.

Owner:福建跃发光新材料股份有限公司

Preparing method of nano-nickel phosphide

InactiveCN106495114ASimple processShorten the production cycleChemical industryNanotechnologyAlcoholCentrifugation

The invention relates to a preparing method of nano-nickel phosphide. The preparing method comprises the steps of adopting nickel sulfate hexahydrate and yellow phosphorous and adding dipotassium phosphate to conduct liquid phase reduction reaction to prepare nano-nickel phosphide sol; conducting microwave heating reaction, centrifugation, ethyl alcohol rinsing and drying to obtain the nano-nickel phosphide. According to the preparing method of the nano-nickel phosphide, the prepared nano-nickel phosphide has an uniform particle size, good dispersibility, and the particle diameter is smaller than 10 nm; meanwhile, a microwave-hydrothermal method is adopted to replace a traditional hydrothermal method so as to obtain the nano-nickel phosphide, and the preparing method of the nano-nickel phosphide is characterized by having a simple technology, a short production cycle, energy conversation and environment protection property, a good safety property and the like.

Owner:青岛丰泽中兴科技服务有限公司

Chromium-nickel alloy electroplating solution and electroplating method

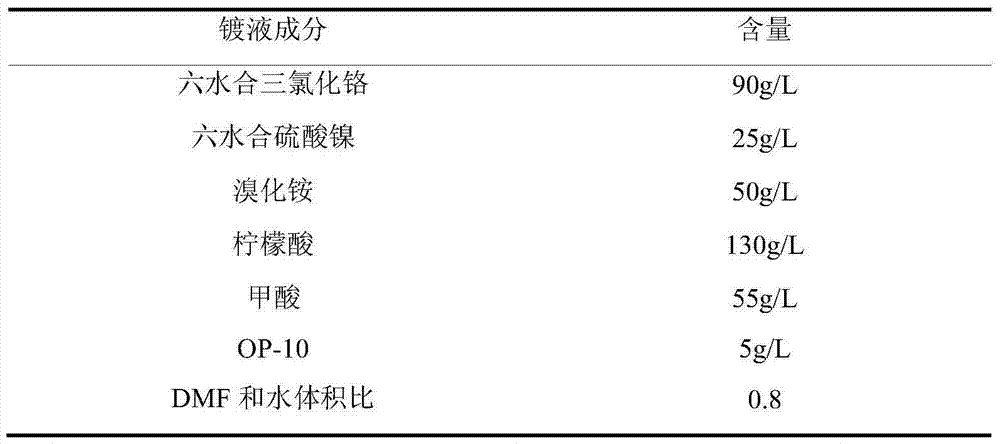

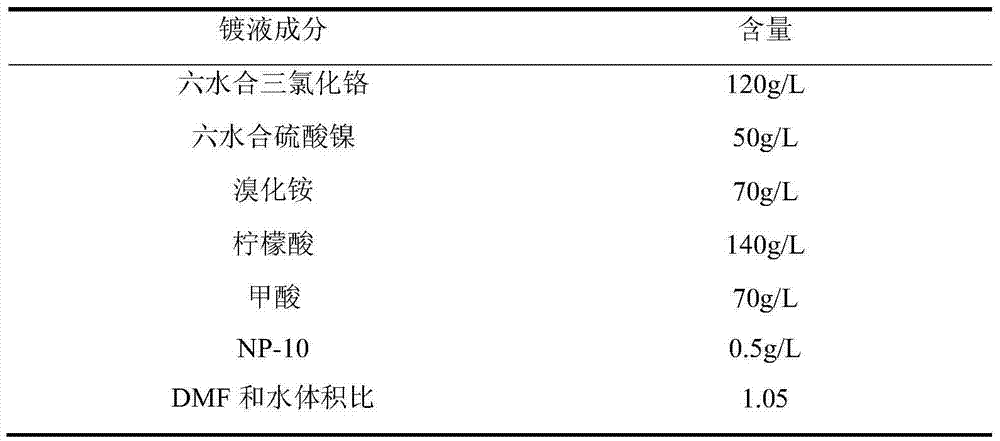

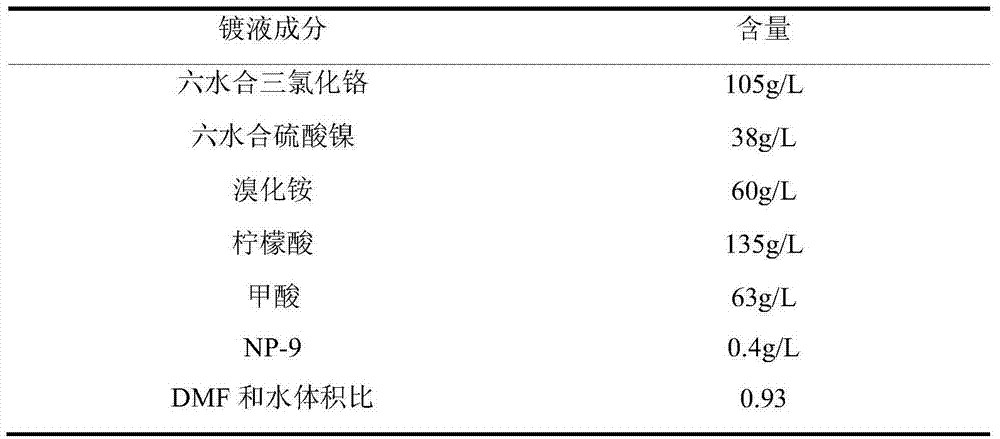

The invention discloses a chromium-nickel alloy electroplating solution and an electroplating method. The chromium-nickel alloy electroplating solution includes: 90-120g / L chromium chloride hexahydrate, 25-50g / L nickel sulfate hexahydrate, 50-70g / L ammonium bromide, 130-140g / L citric acid, 55-70g / L formic acid, 0.3-0.5g / L an emulsifier and the balance a solvent. The solvent is a mixed solution of DMF and water in a volume ratio of (0.8-1.05):1. The chromium-nickel alloy electroplating solution provided by the invention adopts the mixed solution of DMF and water as the solvent of the electroplating solution, citric acid and formic acid are taken as the compound complexing agent, citric acid and formic acid are selected as the buffering agent to replace boric acid, thus simplifying the formula, enhancing the hardness and corrosion resistance of the coating, and improving the dispersion ability and deep plating ability of the electroplating solution.

Owner:WUXI HUAYE IRON & STEEL

Method for preparing V2O5-adding NiCuZn ferrites

The invention relates to a method for preparing V2O5-adding NiCuZn ferrites, which is characterized in that a ferrite precursor is synthesized in a four-mouth flask under the conditions of water bath, electric heating, stirring, water-cycling condensation and argon protection by using nickel sulfate hydrate, copper sulfate hydrate, zinc sulfate hydrate and ferrous sulphate hydrate as raw materials, using ammonium oxalate as precipitating agent, using polyvinyl alcohol as dispersant, using ethanol as detergent, using vanadium oxide as sintering agent and using argon as protective gas. The particular steps are as follows: preparing blended solution firstly; filtering, washing and drying so as to obtain precursor powder; calcining the precursor powder at a temperature of 800 DEG C; then adding vanadium oxide as sintering agent and deionized water into the precursor powder; carrying out ball-milling on the obtained mixture; pressing the mixture subjected to ball-milling into circular cake-shaped products; finally, carrying out low-temperature sintering on the circular cake-shaped products at a temperature of 870 DEG C so as to obtain the final product. The preparation method is advanced, and grains are uniform and stable in chemical and physical properties, therefore, the preparation method is an ideal method for preparing the NiCuZn ferrites.

Owner:ZHONGBEI UNIV

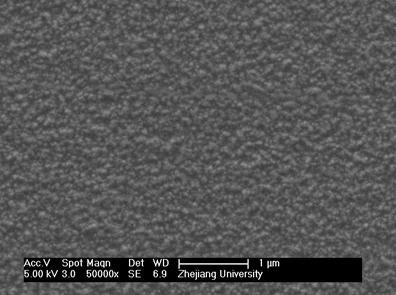

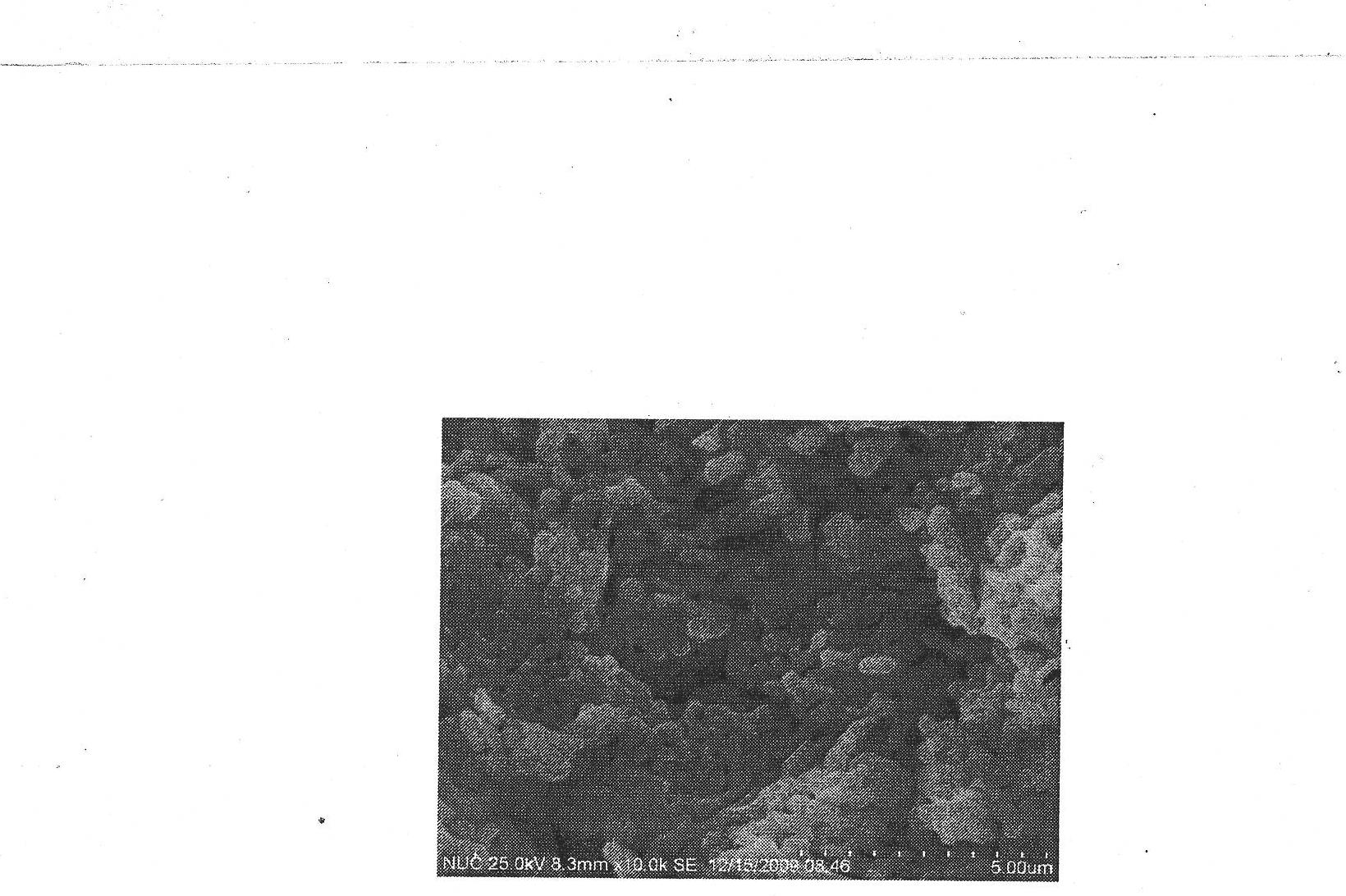

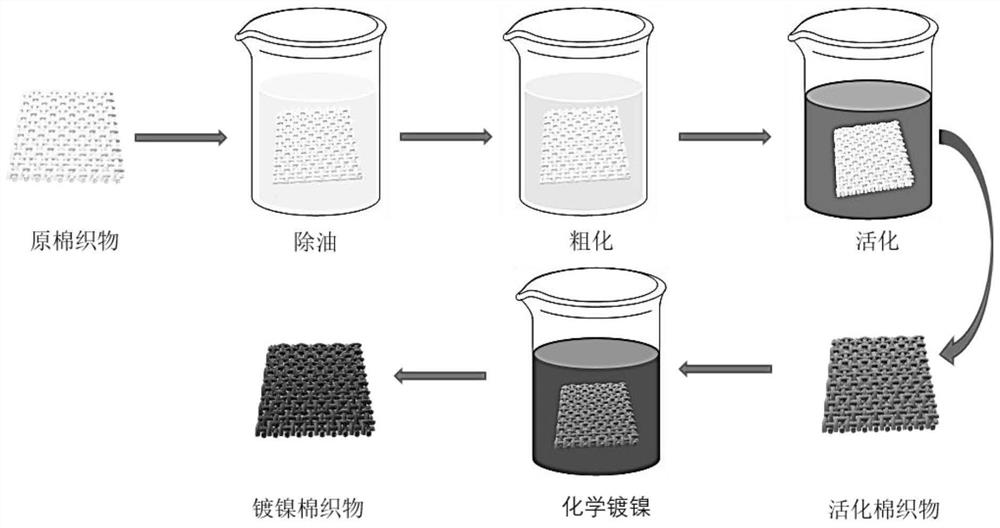

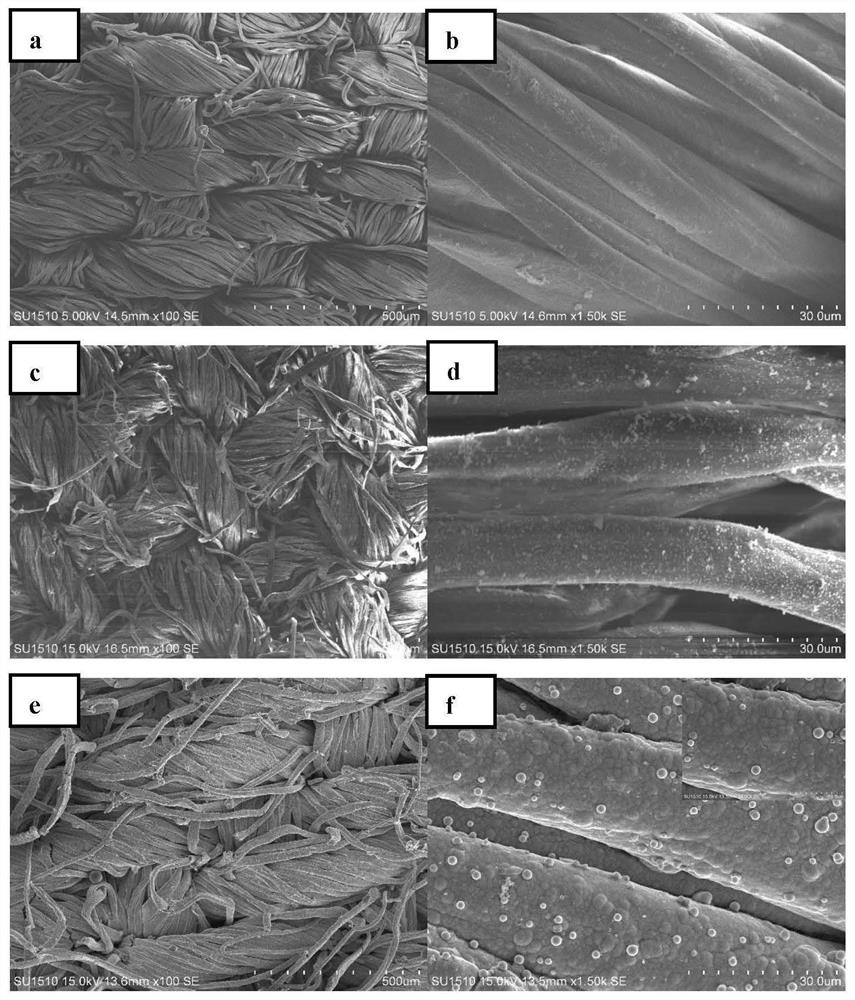

Palladium-free activated nickel-plated conductive cotton fabric and preparation method thereof

InactiveCN111621977ALow priceSimple processPhysical treatmentVegetal fibresNickel sulfate hydrateNickel sulfate hexahydrate

The invention discloses palladium-free activated nickel-plated conductive cotton fabric and a preparation method thereof, and belongs to the field of functional materials. The preparation method of the palladium-free activated nickel-plated conductive cotton fabric comprises the following steps of performing oil removal, coarsening, ultrasonic activation and chemical nickel plating on cotton fabric to obtain the conductive cotton fabric, wherein an activating solution adopted in the ultrasonic activation step comprises the following components: a reducing agent, nickel sulfate hexahydrate andwater, and the mass ratio of reducing agent to nickel sulfate hexahydrate to water is 2:1.5:30. The preparation method of the palladium-free activated nickel-plated conductive cotton fabric is simpleto operate, short in process flow and low in production cost, and the palladium-free activated nickel-plated conductive cotton fabric is endowed with good conductivity on the premise of ensuring uniform nickel plating of the cotton fabric.

Owner:JIANGNAN UNIV

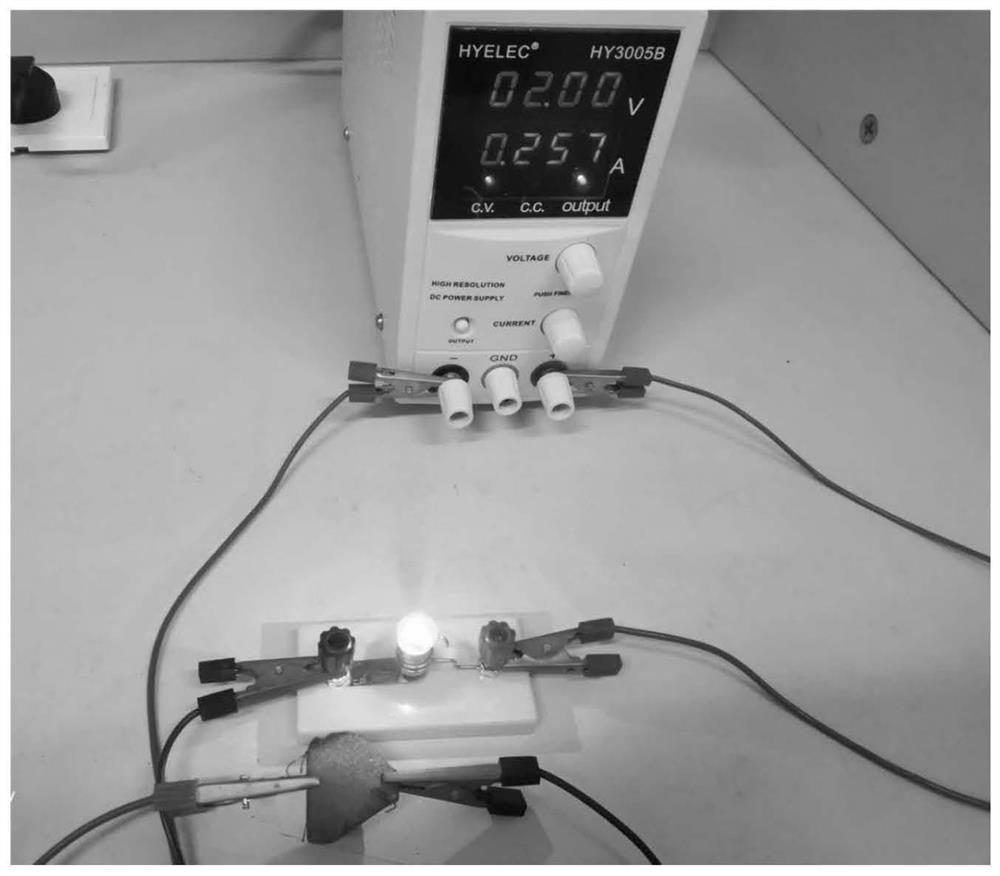

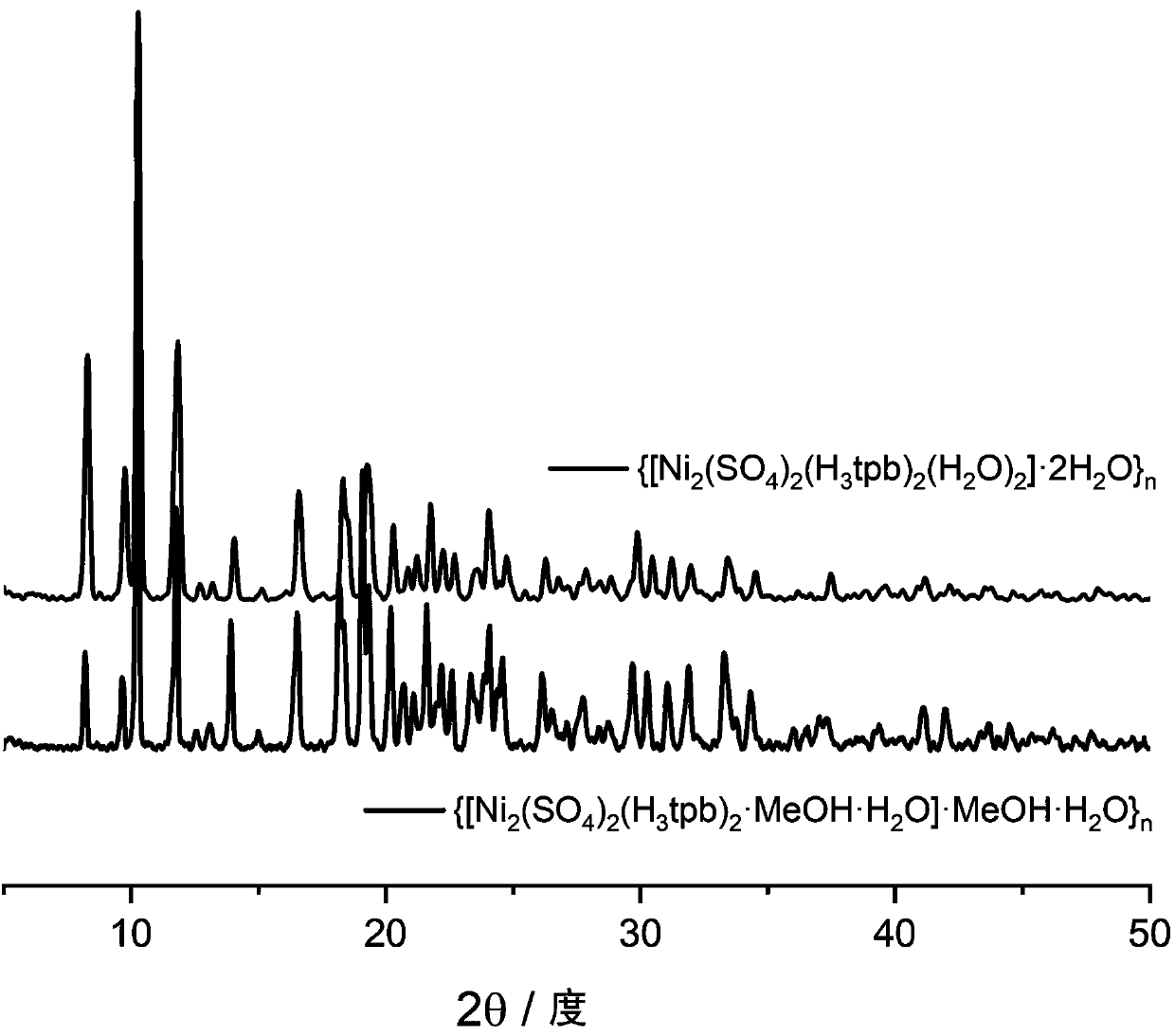

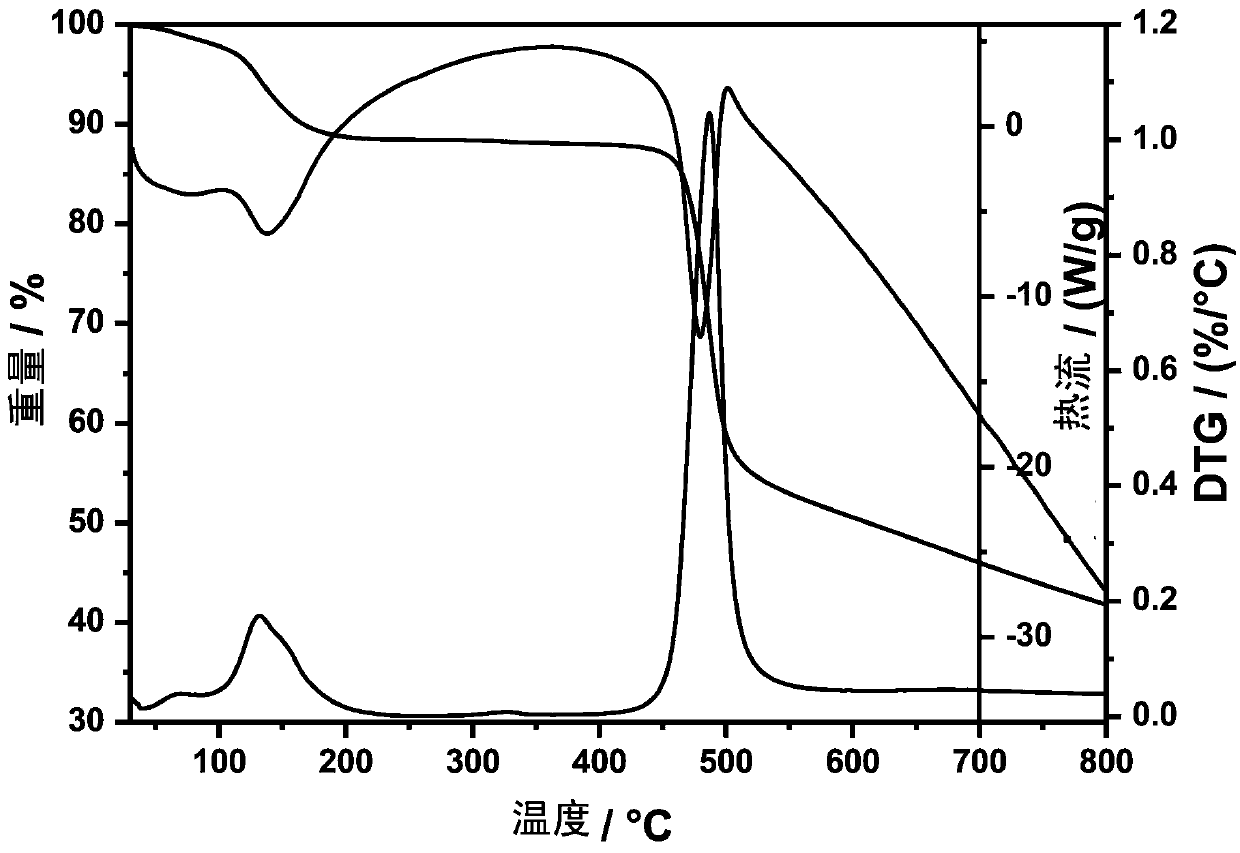

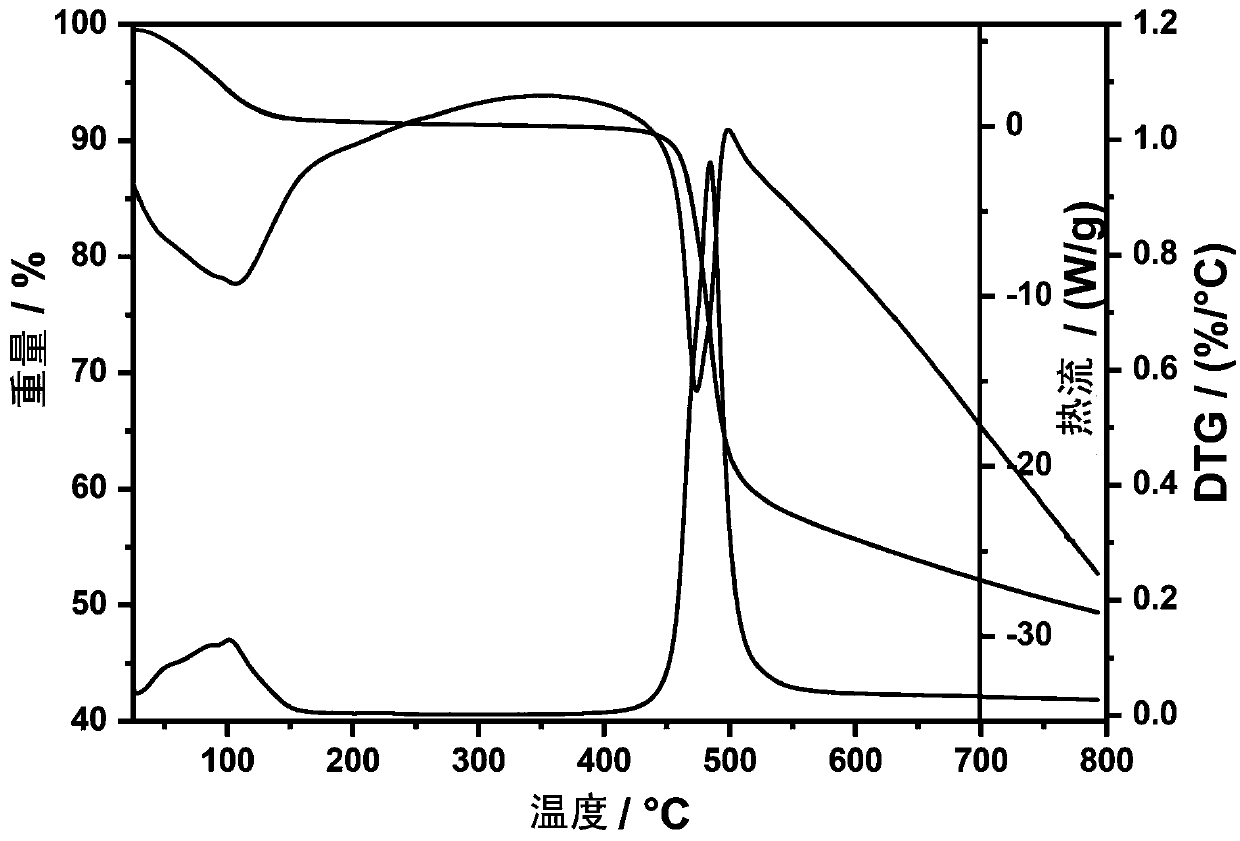

Nickel coordination polymer material with wide-temperature-range reversible thermochromic property and preparation method and application of nickel coordination polymer material

ActiveCN111116929ASimple stepsHigh yieldThermometers using physical/chemical changesTenebresent compositionsBenzenePyrazolylchalcone

The invention discloses a wide-temperature-range reversibly thermochromic coordination polymer material and a preparation method and application thereof. The molecular formula of the coordination polymer material is {[Ni2(SO4)2(H3tpb)2(H2O)2].2H2O}n, wherein H3tpb is 1,3,5-(pyrazolyl)benzene. The coordination polymer material is prepared by adopting a solvothermal method. The specific preparationmethod comprises the following steps: dissolving nickel sulfate heptahydrate and 1,3,5-(pyrazolyl)benzene in a mixed solution of methanol and water, carrying out a solvothermal reaction at 120-180 DEGC for 2-5 days, and carrying out heat treatment on the obtained product to obtain the thermochromic material. According to the preparation method, synthesis steps are simple, and yield is high; and the prepared thermochromic material is good in thermal stability and chemical stability, wide in discoloration temperature range, short in color compounding time, obvious in color change and good in reversibility and can be used for temperature detection.

Owner:NORTHWEST UNIV

A kind of supported photocatalyst and preparation method thereof

ActiveCN110302809BEasy transferEnhance photocatalytic hydrogen production activityPhysical/chemical process catalystsHydrogen productionHeterojunctionHydration reaction

The invention discloses a loaded photocatalyst NiSe / Mn 0.5 Cd 0.5 S and preparation method thereof, it is to adopt mild one-step hydrothermal method to synthesize Mn earlier 0.5 Cd 0.5 S solid solution, and then react it with nickel sulfate hexahydrate and sodium selenite. NiSe and Mn in the composite catalyst 0.5 Cd 0.5 S is closely combined to form a heterojunction, which is beneficial to the migration of photogenerated carriers and inhibits the recombination of photogenerated electrons and holes, making Mn 0.5 Cd 0.5 The photocatalytic hydrogen production activity of S solid solution was significantly improved. The novel NiSe / Mn that the present invention uses 0.5 Cd 0.5 S photocatalyst has the advantages of simple preparation, mass preparation, high photocatalytic activity and good stability, which makes it have broad application prospects in the development of clean energy.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com