Patents

Literature

74results about How to "Achieve low temperature sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of graphene/nano silver epoxy conductive adhesive

ActiveCN102153976AImprove electrical performanceEvenly dispersedEpoxy resin adhesivesElectrically-conducting adhesivesOrganic solventEpoxy matrix

The invention discloses a preparation method of a graphene / nano silver epoxy conductive adhesive, which comprises the following steps: (1) mixing graphite, promoter and organic solvent, then carrying out ultrasonic treatment at 20-50 DEG C for 3-6 hours, standing for 12 hours, centrifuging, and distilling; (2) dissolving epoxy resin and precursor in organic solvent, stirring at 20-50 DEG C for 5-30 minutes, adding a graphene solution to continue reacting for 10-40 minutes, distilling, and carrying out ultrasonic treatment for 5-20 minutes; and (3) adding silver sheets into the graphene-nano silver epoxy resin compound, and carrying out ultrasonic treatment to react at 20-60 DEG C for 30-120 minutes so as to obtain the graphene / nano silver epoxy conductive adhesive. The graphene / nano silver epoxy conductive adhesive disclosed by the invention ensures that the graphene-nano silver compound can be uniformly dispersed in the epoxy matrix, and avoids the problem that the prepared graphene conglobates when the epoxy resin is added, thereby being beneficial to realizing the low-temperature sintering of the nano silver and improving the conductivity and adhesive strength of the conductiveadhesive.

Owner:SOUTH CHINA UNIV OF TECH

Manufacturing method of light rare earth-copper alloy NdFeB magnet with grain boundary being low melting point

InactiveCN104952607AEliminate high temperature tempering heat treatmentSimple processInorganic material magnetismInductances/transformers/magnets manufactureRare earthIngot

The invention provides a manufacturing method of a light rare earth-copper alloy NdFeB magnet with the grain boundary being a low melting point and belongs to the field of rare earth permanent magnetic materials. According to the manufacturing steps, a NdFeB main alloy ingot with the near stoichiometric proportion being 2:14:1 is smashed into 3-5 micron powder particles, light rare earth-copper alloy powder with the weight fraction being 3-8% and the average particle size being 0.1-3 microns is added in the powder particles, the light rare earth-copper alloy powder and the power particles are evenly mixed, magnetic field compression, isostatic pressing and sintering densification are performed, and the product is obtained after thermal treatment. The light rare earth-copper alloy is both a liquid phase sintering additive and a grain boundary phase, and the light rare earth-copper alloy and the 2:14:1 main phase have good wettability. The manufacturing method has the advantages that the light rare earth-copper alloy is evenly distributed on the grain boundary of the 2:14:1 main phase, the exchange coupling effect between grains of the 2:14:1 main phase is effectively hindered, high coercive force can be acquired easily, meanwhile, low-temperature sintering can be achieved, high-temperature tempering thermal treatment is omitted, the process is simplified, and energy is saved.

Owner:UNIV OF SCI & TECH BEIJING

Low-temperature sintered hybrid conductive silver paste for chip package and preparation method thereof

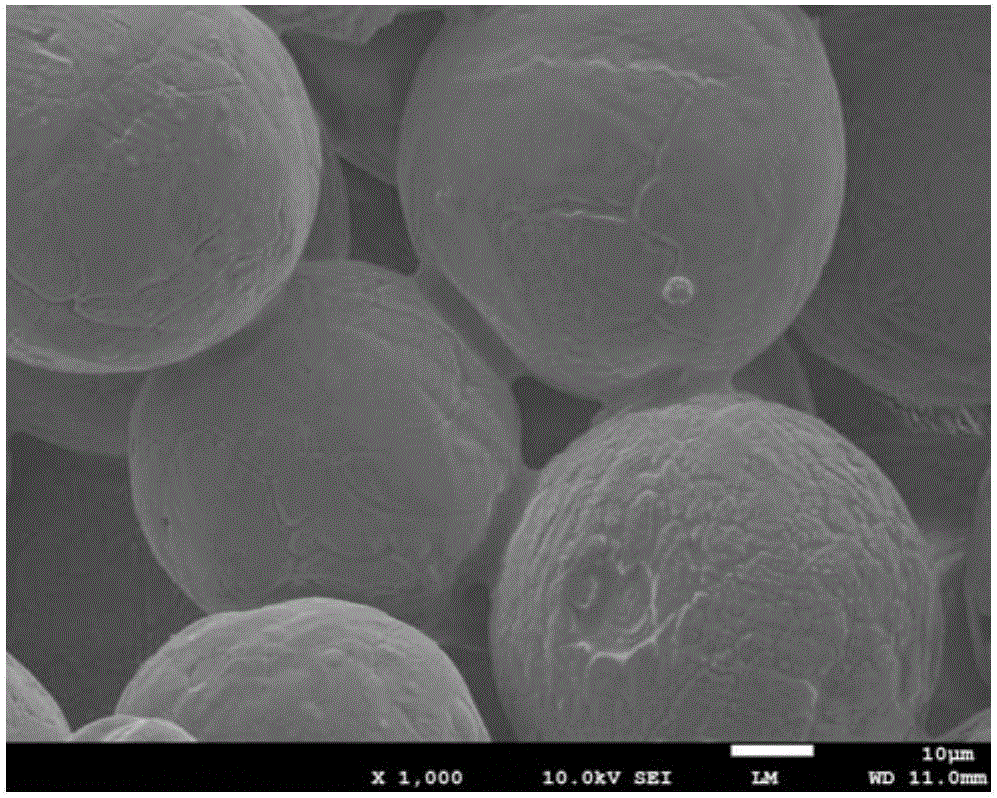

ActiveCN107221373AFully dispersedAchieve low temperature sinteringNon-conductive material with dispersed conductive materialCable/conductor manufactureWater basedMicron scale

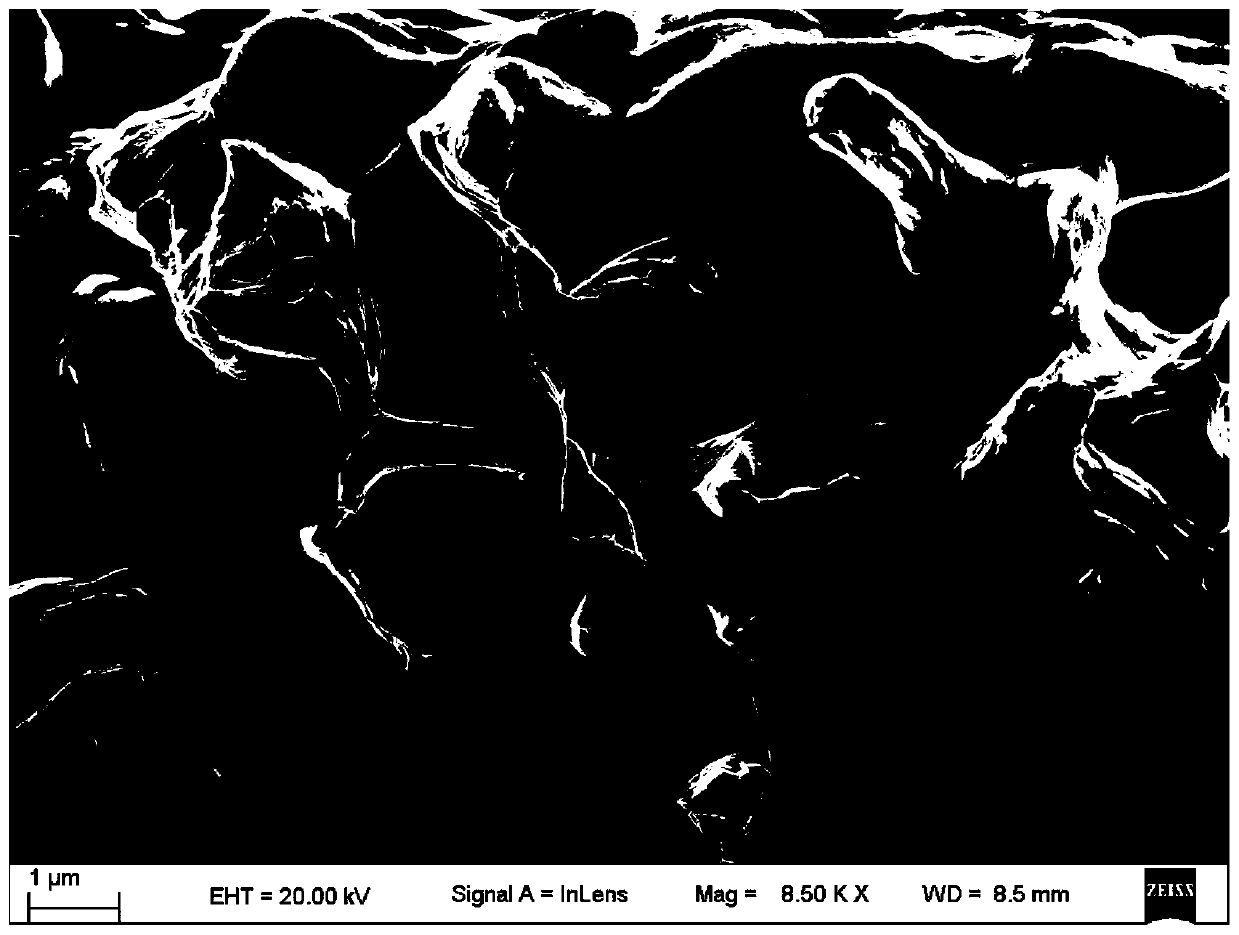

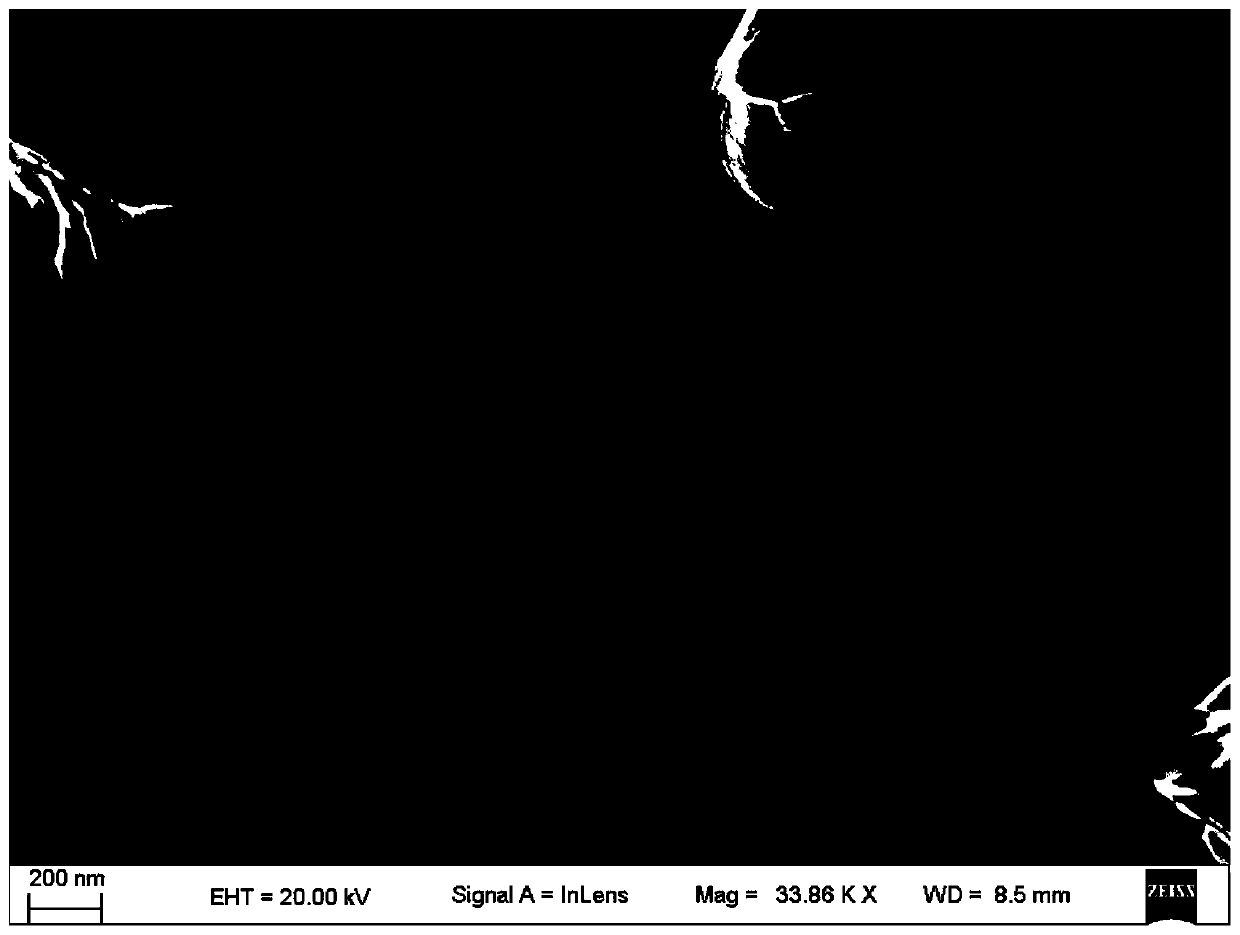

The invention discloses low-temperature sintered hybrid conductive silver paste for chip package and a preparation method thereof. The low-temperature sintered hybrid conductive silver paste comprises 50-95wt% of conductive silver powders and 5-50wt% of organic carrier. The conductive silver powders contain 20-60wt% of micrometer-scale flake silver powders, 5-40wt% of submicron-scale spherical silver powders and 20-60 wt% of nano-scale spherical silver powders. The organic carrier contains 3 to 30 wt% of binder, 40 to 97.9 wt% of solvent and 0.01 to 30 wt% of other additives. The surface modification of the micron-scale silver powders and the submicron-scale silver powders can adapt the decomposition temperature of a modified surface dispersant to that of a water-based ionic dispersant of such type, so as to realize the low-temperature sintering of hybrid silver paste.

Owner:SOUTH CHINA UNIV OF TECH

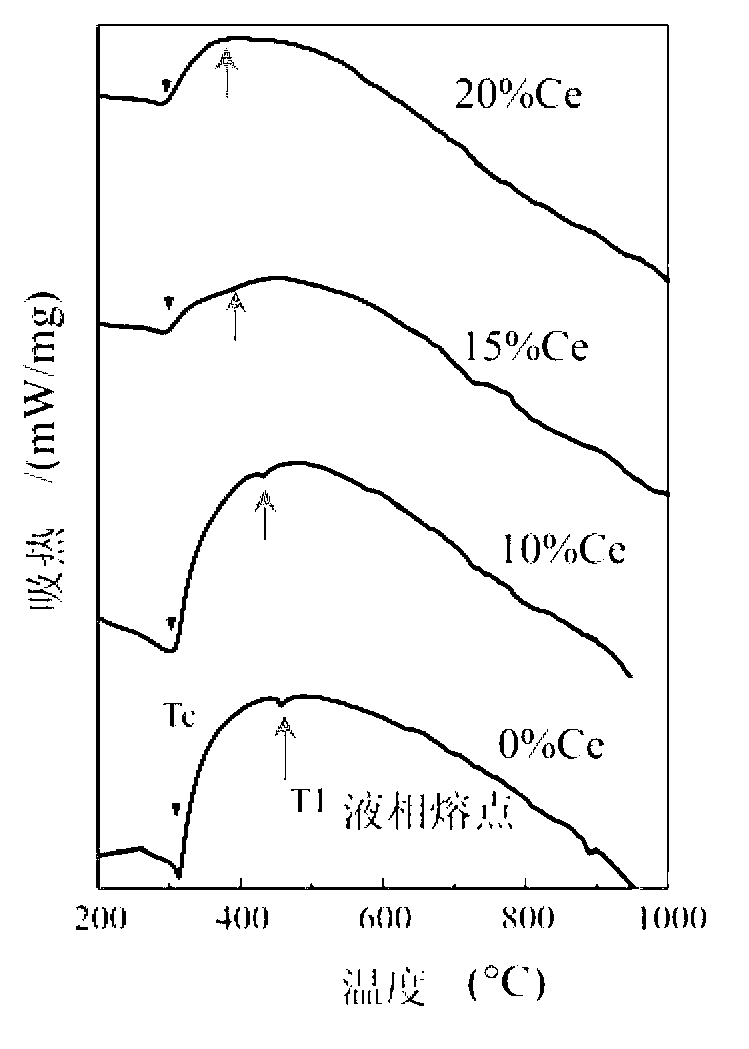

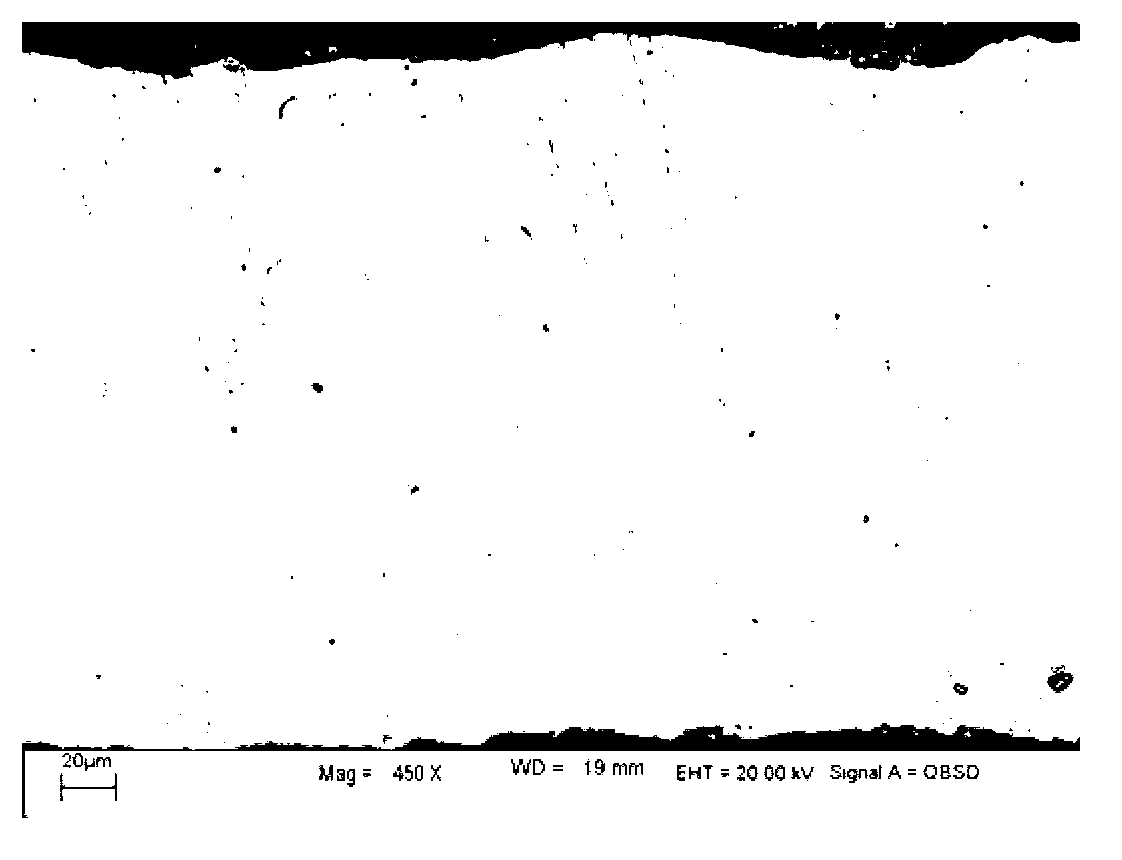

Cerium-containing low-melting-point rare-earth permanent magnet liquid phase alloy and production method of permanent magnet comprising same

ActiveCN103280290AReduce entryImprove remanenceMagnetic liquidsInductances/transformers/magnets manufactureCeriumRare earth

The invention relates to the technical field of rare-earth permanent magnet materials, in particular to cerium-containing low-melting-point rare-earth permanent magnet liquid phase alloy, a permanent magnet comprising the liquid phase alloy and a production method of the permanent magnet. According to mass percent, the chemical formula of the liquid phase alloy is that (Cex,Nd1-x)y-Mz-Fe100-y-z, wherein 0.1<=x<=1.0, 0.04<=y<=0.9, 0<=z<=5, M is one or several of Co, Al, Cu, Ga, Nb, Mo, Ti, Zr and V. The liquid phase alloy is added in an alloy or rapid hardening mode, cerium elements entering the principal phase can be reduced and the residual magnetism can be improved by aid of scientific and reasonable composition design, the sintering temperature of the neodymium iron boron magnet can be reduced through the low-melting-point liquid phase, and therefore low-temperature sintering is achieved, and reducing of the crystal grain dimension of the magnet is benefited. The microstructure of the liquid phase is controlled through the oxygen content so that the liquid phase is ensured to be of a cerium-containing face-centered cubic structure with high coercivity, further the coercivity of the magnet is improved, and good combination property can be obtained.

Owner:CENT IRON & STEEL RES INST

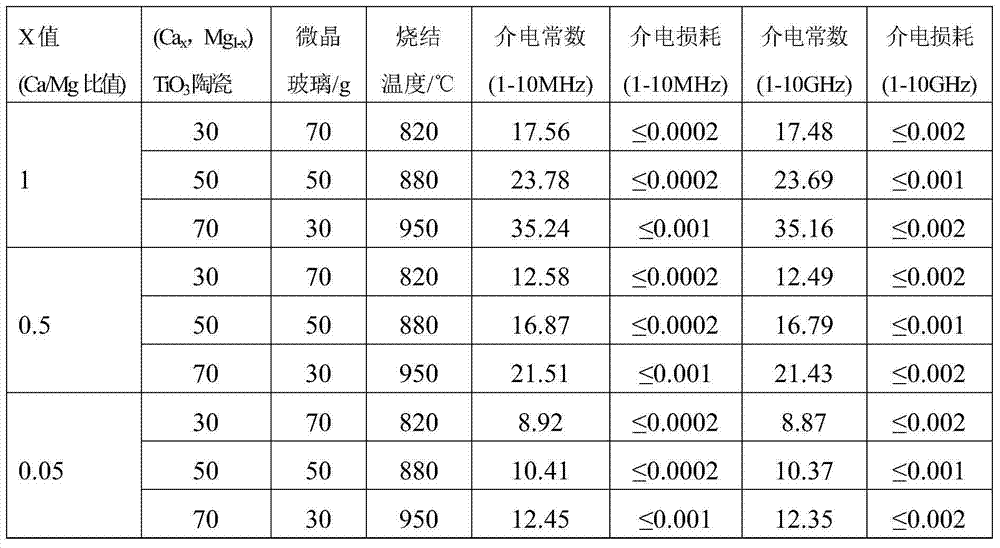

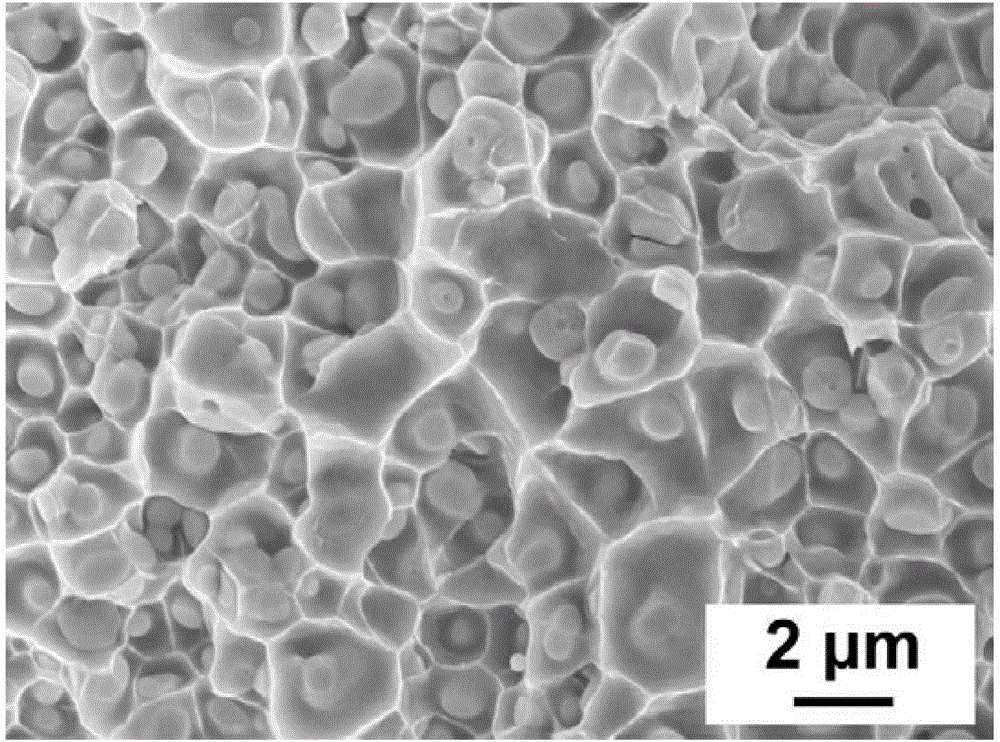

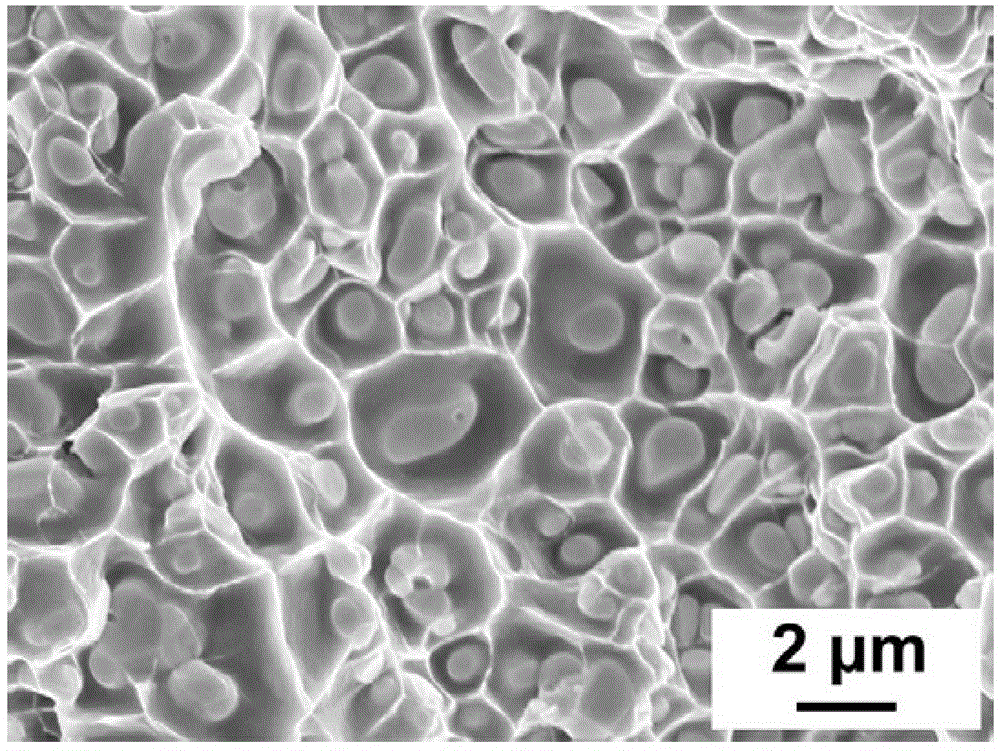

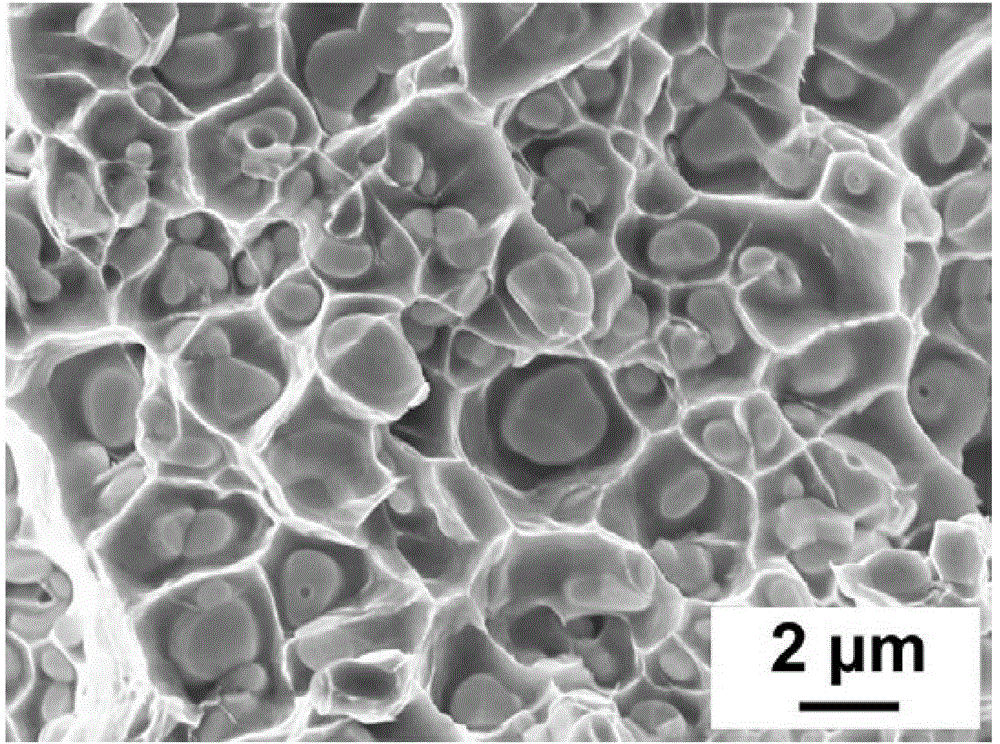

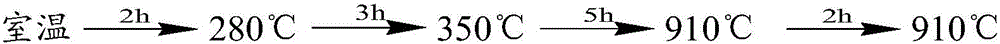

Low-temperature sintered lead-free microwave dielectric ceramic and preparation method thereof

ActiveCN104774005ALower sintering temperatureAchieve low temperature sinteringMicrowaveDielectric loss

The invention provides low-temperature sintered lead-free microwave dielectric ceramic and a preparation method thereof. By adopting the method, continuous adjustable dielectric constant is realized by regulating the Mg / Ca ratio of [Cax, Mg(1-x)]TiO3 powder which serves as a base material; low-temperature sintering of the ceramic material at 800-900 DEG C is realized by adding CaO-Al2O3-B2O3-SiO2 microcrystalline glass. The method comprises the following steps: firstly, synthesizing [Cax, Mg(1-x)]TiO3 ceramic powder, and synthesizing CaO-Al2O3-B2O3-SiO2 microcrystalline glass; then, performing ball-milling, dosing, tape-casting, molding and batching out, sintering and annealing to obtain a low-consumption multi-layer ceramic dielectric material with excellent performance. According to the method, the microcrystalline glass / ceramic green-compact is molded by adopting thick film tape-casting, and multiple layers of the green compact are laminated and subjected to low-temperature sintering to prepare a ceramic substrate, so that the dielectric loss can be reduced, the dielectric constant is adjustable in a range of 9-35, tan delta is less than 0.0002 under 10MHz, and tan delta is less than 0.0015 under 1-10GHz; low-temperature sintering is realized, and industrial production can be realized by combining with an Ag-Pd electrode.

Owner:LUOYANG INST OF SCI & TECH

Method for preparing tungsten-copper alloy by low-temperature sintering of tungsten skeleton

ActiveCN103981389ALow impurity contentAchieve low temperature sinteringHydrogen atmosphereTube furnace

The invention discloses a method for preparing tungsten-copper alloy by low-temperature sintering of a tungsten skeleton. The method comprises the steps of carrying out wet grinding on tungsten powder of which the purity is 99.9% and the particle size is 1-7 mum and WOx powder which accounts for 5%-20% of the total mass of the powder and of which the particle size is 1-15 mum, uniformly mixing, drying and sieving, carrying out isostatic pressing on the mixed powder to obtain a green compact, sintering the green compact to obtain the tungsten skeleton, calculating the copper infiltration amount, cutting a copper plate of which the purity is greater than 99.5% into copper sheets with the same surface size as that of the tungsten skeleton, placing the copper sheets on the tungsten skeleton, feeding into a tubular furnace, heating to 1200-1400 DEG C under hydrogen atmosphere and carrying out copper infiltration. The content of copper in the tungsten-copper alloy is 15wt%-40wt%, and the balance is tungsten; the tungsten-copper alloy has more than 98% of density and the tungsten-copper alloy is suitable for being used as an electrical contact and electrode material, an electronic packaging material, a high-temperature sweating materials and the like.

Owner:XIAMEN UNIV OF TECH

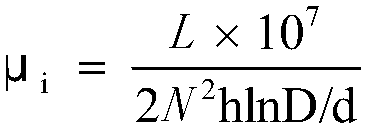

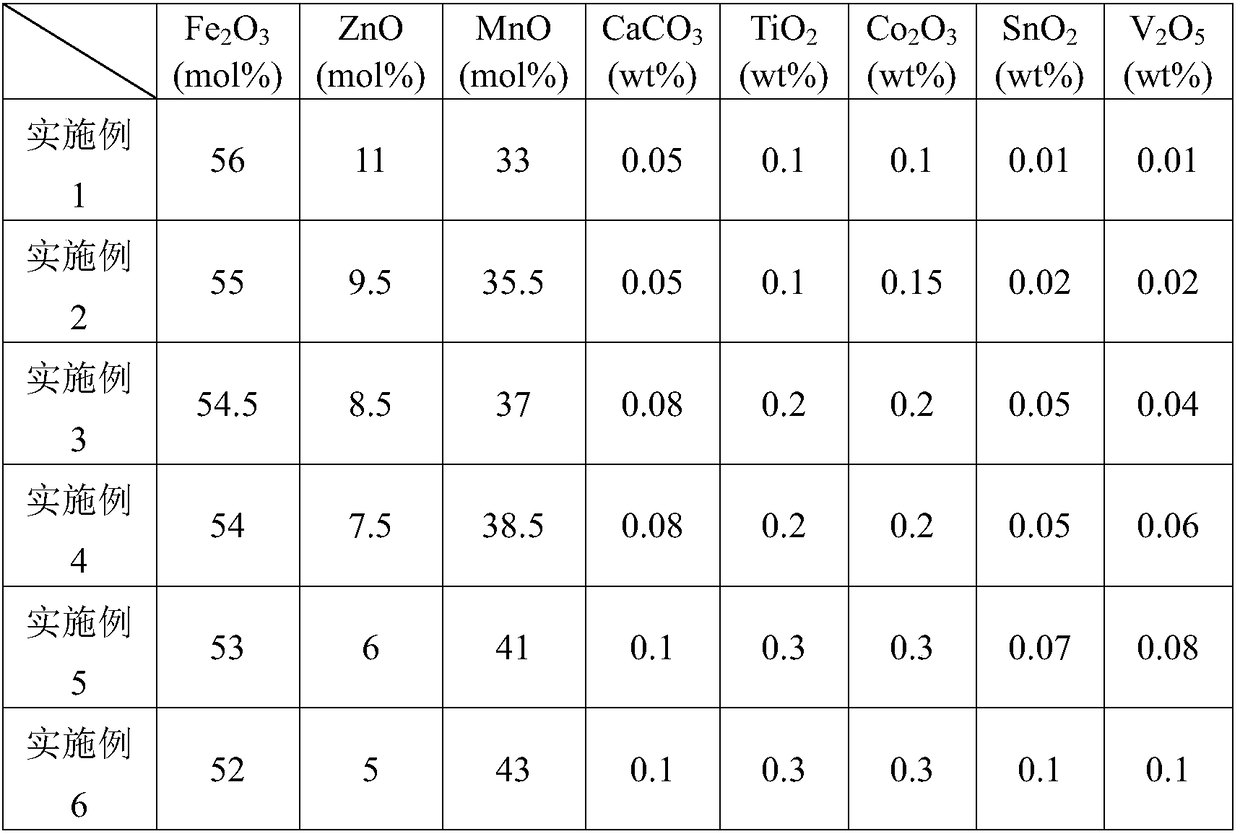

MnZn power ferrite for MHz-level switching mode power supply and preparation method of MnZn power ferrite

ActiveCN108424136AReduce lossReduce power lossInorganic material magnetismInductances/transformers/magnets manufactureDopantElectronic materials

The invention relates to a MnZn power ferrite for a MHz-level switching mode power supply and a preparation method of the MnZn power ferrite and relates to the electronic material technology. The ferrite is prepared from a main material and a dopant. The main material comprises in molar percentage of oxide as follows: 52mol%-56mol% of Fe2O3, 5mol%-11mol% of ZnO and 33mol%-43mol% of MnO; the dopantcomprises in molar percentage of oxide as follows: 0.05wt%-0.1wt% of CaCO3, 0.1wt%-0.3wt% of TiO2, 0.1wt%-0.3wt% of Co2O3, 0.01wt%-0.1wt% of SnO2 and 0.01wt%-0.1wt% of V2O5. The loss of the materialat high MHz frequency is effectively reduced, and the power loss is lower in the wideband range of 0.5-3 MHz and in the temperature range of 25-100 DEG C. Meanwhile, the preparation method has the advantages of being low in sintering temperature, energy-saving and environmentally friendly.

Owner:江西尚朋电子科技有限公司

Preparation method of sintered NdFeB magnet with high coercivity

InactiveCN108389711ALow melting pointReduce magnetismInductances/transformers/magnets manufactureMagnetic materialsRare earthPermeation

The invention discloses a preparation method of a sintered NdFeB magnet with high coercivity. The sintered NdFeB magnet is prepared by taking NdFeB alloy with a positive ratio being 2:14:1 as main alloy and taking rare-earth dysprosium / terbium-copper / aluminum / nickel alloy as auxiliary alloy and by a dual-alloy method, wherein the rare-earth dysprosium / terbium-copper / aluminum / nickel alloy is a liquid-phase sintering additive, is also a grain boundary phase and has favorable wettability with the main phase having the positive ratio being 2:14:1, the rare-earth dysprosium / terbium-copper / aluminum / nickel alloy used as the grain boundary phase is uniformly distributed at a grain boundary of the main phase having the positive ratio being 2:14:1, on one hand, an exchange coupling effect among crystal grains of the main phase is effectively prevented; and on the other hand, Dy / Tb permeations occurs around the crystal grains, the coercivity can be improved, and meanwhile, the residual magnetismand the magnetic energy product are not remarkably reduced.

Owner:NINGBO ZHAOBAO MAGNET

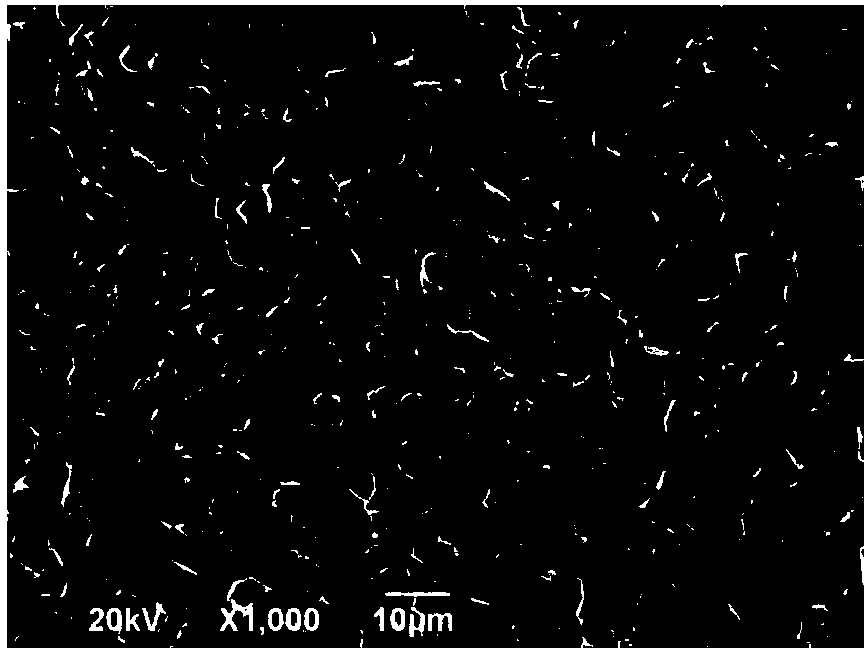

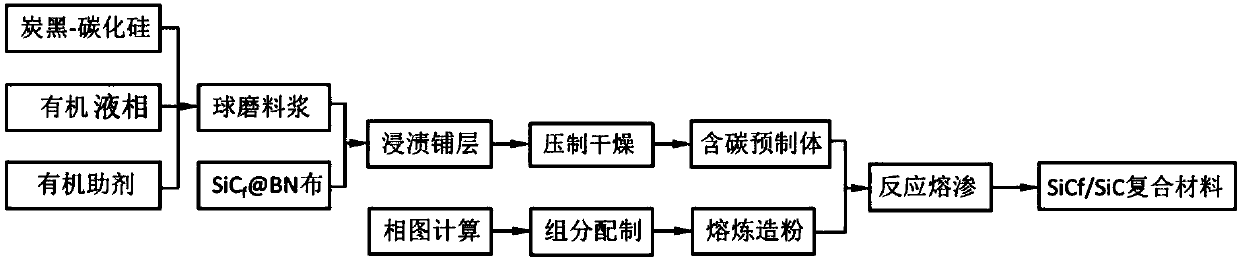

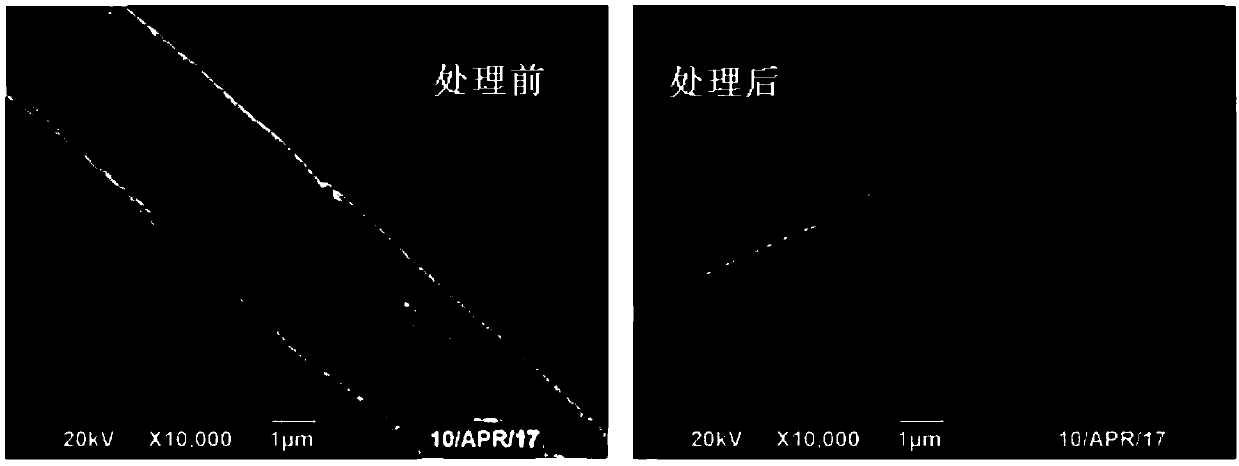

Modified SiCf/SiC composite material and preparation method thereof

The invention discloses a modified SiCf / SiC composite material and a preparation method thereof. The preparation method comprises the following steps: 1) by taking carbon black and silicon carbide powder as solid phases, mixing with a liquid phase, adding additives, performing ball-milling mixing and vacuum ultrasonic degassing so as to obtain dipping slurry; 2) putting a silicon carbide fiber into the dipping slurry, performing vacuum dipping, performing overlapping pressing, and drying so as to obtain a carbon-containing preform, wherein the silicon carbide fiber has a boron nitride interface phase; 3) performing calculation simulation on a binary phase diagram of silicon and metals, and performing high-temperature smelting and powder making so as to obtain low-melting point alloy powder; and 4) wrapping the carbon-containing preform with the low-melting point alloy powder, and performing reaction infiltration, thereby obtaining the modified SiCf / SiC composite material. By adopting the preparation method, the sintering temperature of the modified SiCf / SiC composite material is effectively reduced, the melting points of free silicon and alloys in the composite material are increased, the mechanical properties are improved, the service life of the modified SiCf / SiC composite material is further prolonged, the mechanical properties of the modified SiCf / SiC composite material areimproved, the production energy consumption is reduced, and the production cost is lowered.

Owner:CHINA BUILDING MATERIALS ACAD

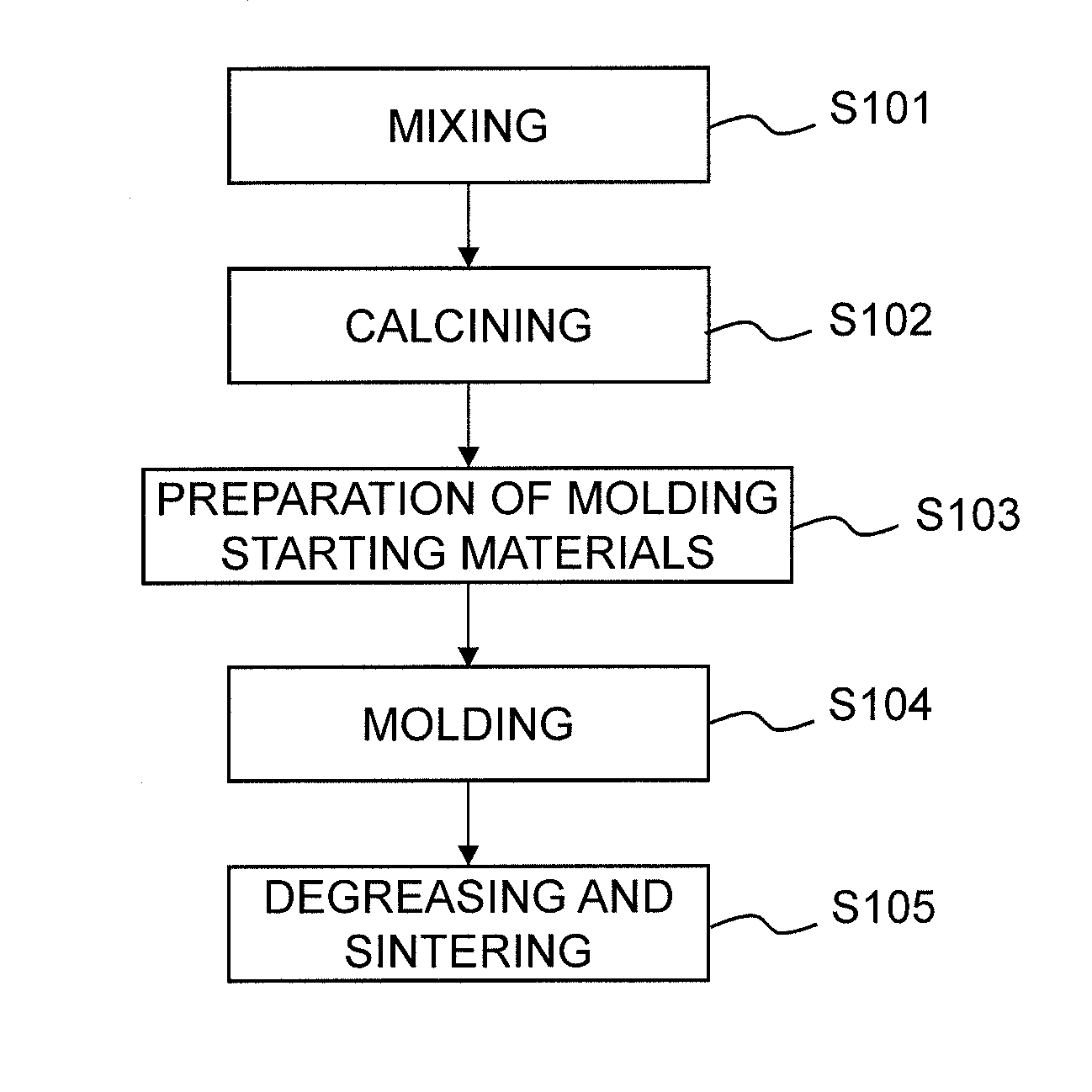

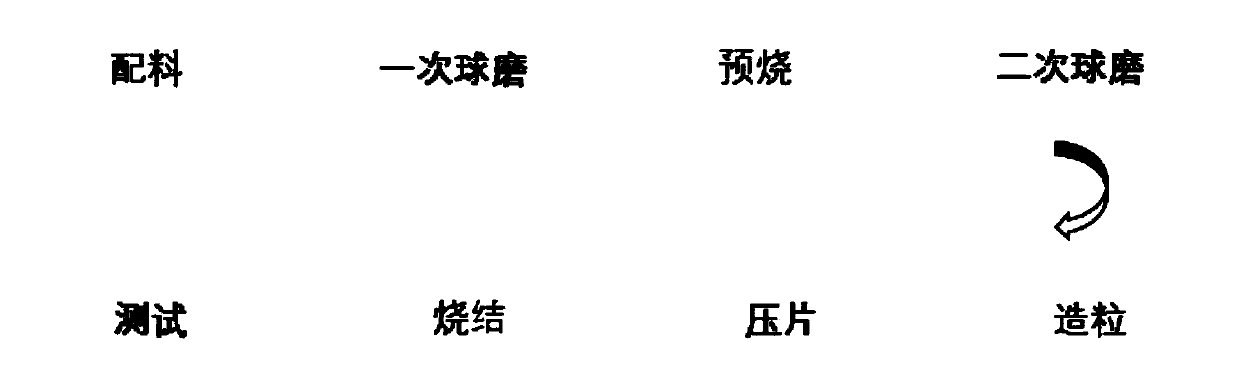

High-thermal-conductivity aluminum nitride ceramic and preparation method thereof

The invention relates to the technical field of ceramic materials, and provides a high-thermal-conductivity aluminum nitride ceramic and a preparation method thereof, wherein the preparation method comprises the following steps: (1) carrying out primary ball milling; (2) calcining; (3) carrying out secondary ball milling; (4) carrying out vacuum defoaming; (5) carrying out tape casting; (6) carrying out isostatic compaction; (7) discharging glue; and (8) carrying out hot pressed sintering. The thermal conductivity of the obtained aluminum nitride ceramic is 200-230 W / (m*K), the bending strength is 470-540 MPa, the volume density is 3.3-3.5 g / cm, and the problem that existing aluminum nitride ceramic only has outstanding performance in one aspect of thermal conductivity, strength and the like and cannot give consideration to performance in all aspects at the same time is solved.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

Lead-free glass powder for preparing solar cell silver paste and application of lead-free glass powder

InactiveCN110021450AImprove photoelectric conversion efficiencyReduce energy consumptionNon-conductive material with dispersed conductive materialPhotovoltaic energy generationEnvironmental resistanceElectron

The invention discloses lead-free glass powder for preparing solar cell silver paste and application of the lead-free glass powder. The lead-free glass powder does not contain lead and comprises 10-70wt% of precious metal, 0-60wt% of lead-free metal oxide and 5-65wt% of non-metal oxide. The lead-free glass powder and the solar cell silver paste do not contain the lead and are safe and environmental-friendly; moreover, the lead-free glass powder is low in softening point, low-temperature sintering can be achieved when the lead-free glass powder is used as the solar cell silver paste, the lead-free glass powder effectively reacts with a silicon nitride anti-reflection layer, a large amount of silver particles are reduced at a silver silicon interface, favorable ohmic contact is formed, electrons in N-type silicon are more easily collected by a silver grid line, so that the photoelectric conversion efficiency of the cell is improved. The glass powder and the solar cell silver paste lay afoundation for preparation the solar cell with low energy consumption, environmental friendliness and the safety.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

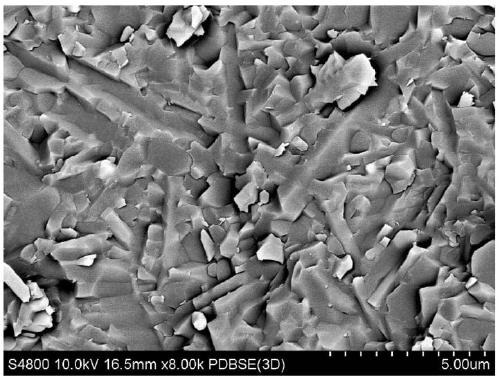

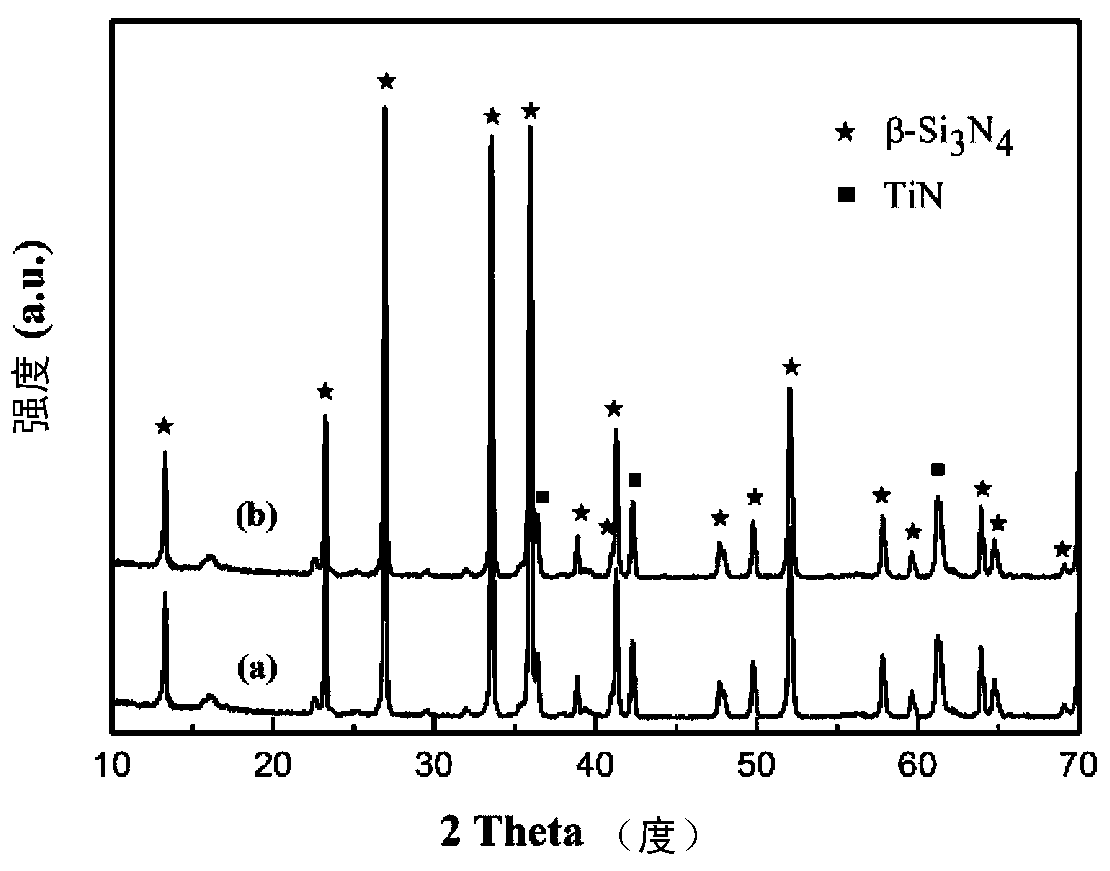

Method for preparing high-heat-conductivity silicon nitride ceramic through normal pressure sintering

The invention relates to a method for preparing high-heat-conductivity silicon nitride ceramic through normal pressure sintering. The method includes the steps that with the total material mass being100%, 95-70% of silicon nitride powder and 5-30% of sintering aids are evenly mixed to obtain ceramic mixed powder, and the sintering aids are a mixture with TiO2 as a main sintering aid and at leastone of Y2O3, Sc2O3, Sm2O3, Lu2O3, Er2O3, MgO, Mg2Si and MgSiN2 as an auxiliary sintering aid; the obtained ceramic mixed powder is molded to obtain a ceramic biscuit; the obtained ceramic biscuit is subjected to normal pressure sintering under 1600-1800 DEG C, so that dense silicon nitride ceramic is obtained. The method can be used for obtaining the dense silicon nitride ceramic with a certain heat conductivity level and excellent mechanical properties.

Owner:浙江多面体新材料有限公司

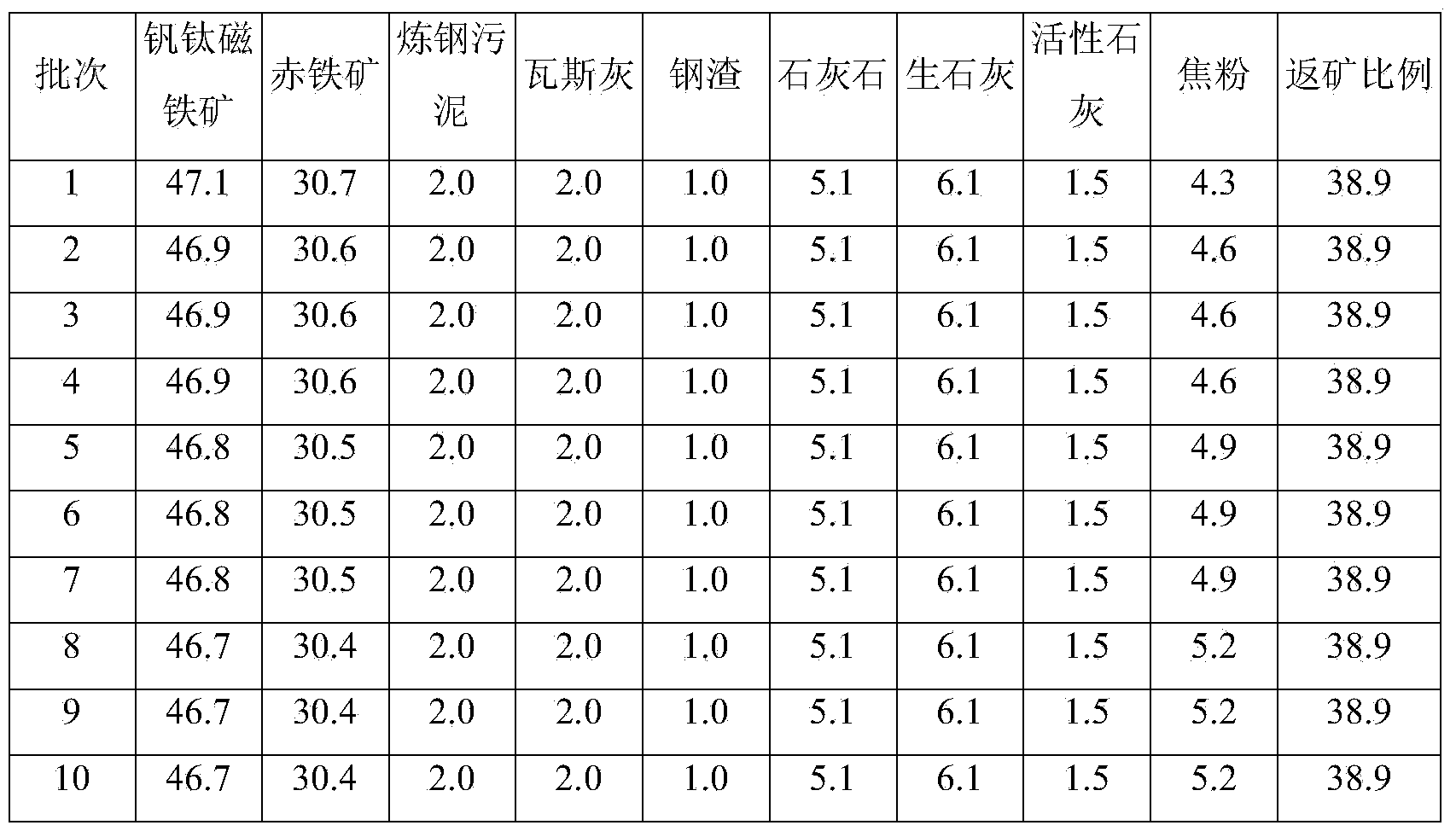

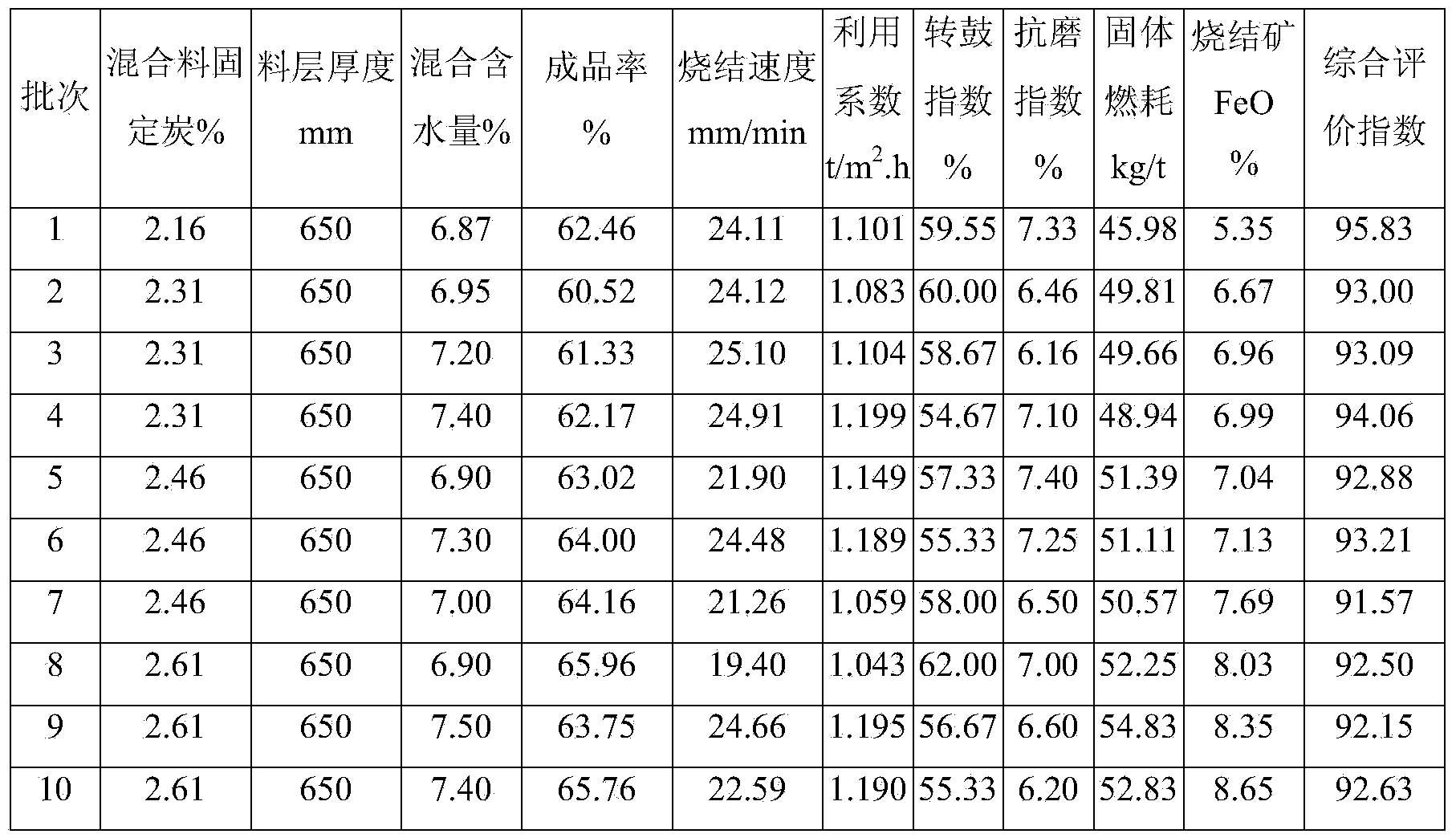

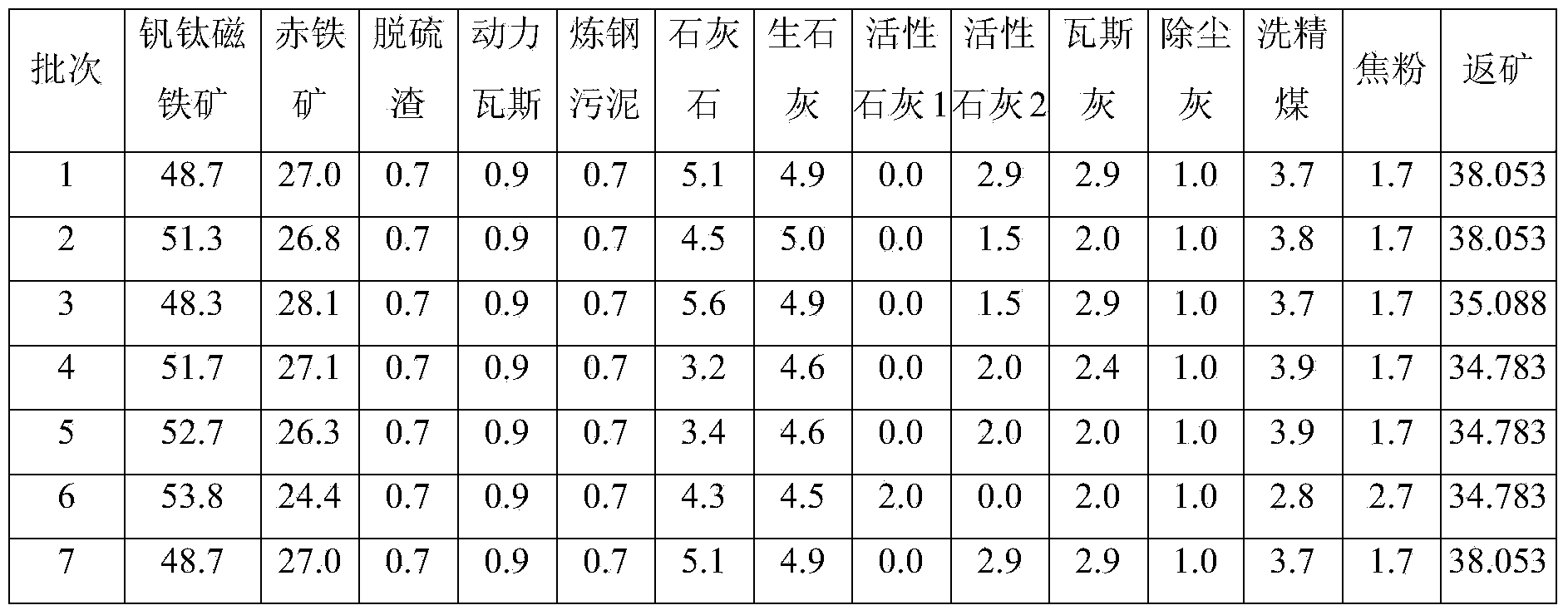

Iron ore low-carbon sintering method

ActiveCN104313308AIncrease incomeReduce the amount of carbonProcess efficiency improvementIronstoneMagnetite

The invention belongs to the field of steel smelting, and particularly relates to an iron ore low-carbon sintering method which is low in sintering energy consumption. According to the technical scheme, the iron ore low-carbon sintering method includes the steps that iron ore, fuel and a fluxing agent are distributed and mixed to form a mixture for sintering, wherein magnetite in the iron ore is not smaller than 50% by mass, non-magnetite m1 is greater than 0 but smaller than or equal to 40%, metallurgy waste m2 is greater than or equal to 0 but smaller than or equal to 10%, the non-magnetite is at least one of hematite, limonite and siderite, and the metallurgy waste is iron waste mainly composed of Fe and FeO. According to the method, raw material constitutes of the mixture and technical parameters are adjusted, so that non-carbon heat input is increased, carbon content is reduced, and sintering energy consumption is reduced.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

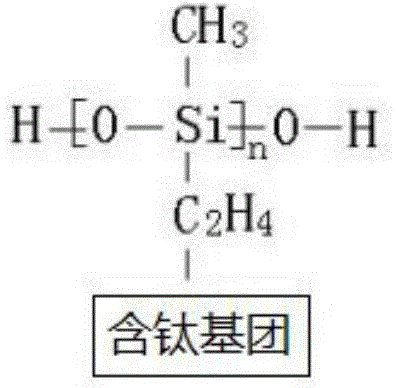

Low-temperature composite high-heat-conductivity ceramic material and preparation method thereof

InactiveCN105565786AIncreased strength and compactnessUniform and stable physical and chemical propertiesPhenyl groupTitanium

The invention provides a low-temperature composite high-heat-conductivity ceramic material which is composed of the following components in parts by weight: 60-70 parts of modified polysiloxane, 30-40 parts of aluminum oxide-aluminum nitride mixed powder and 1-3 parts of coupling agent. The molecular formula of the modified polysiloxane is [RnSiO[4-n / 2]]n, wherein R is the modified part which is a titanium-containing group or phenyl group. The invention also provides a preparation method of the low-temperature composite high-heat-conductivity ceramic material, which comprises the following steps: mixing all the raw materials together, grinding, sintering, and carrying out dry-process powder ball milling to obtain the required ceramic material. The ceramic material has the advantages of high heat conductivity coefficient, high / low-temperature resistance, chemical corrosion resistance, high formability, simple technique, high production efficiency and the like.

Owner:GUANGDONG REAL FAITH LIGHTING TECH

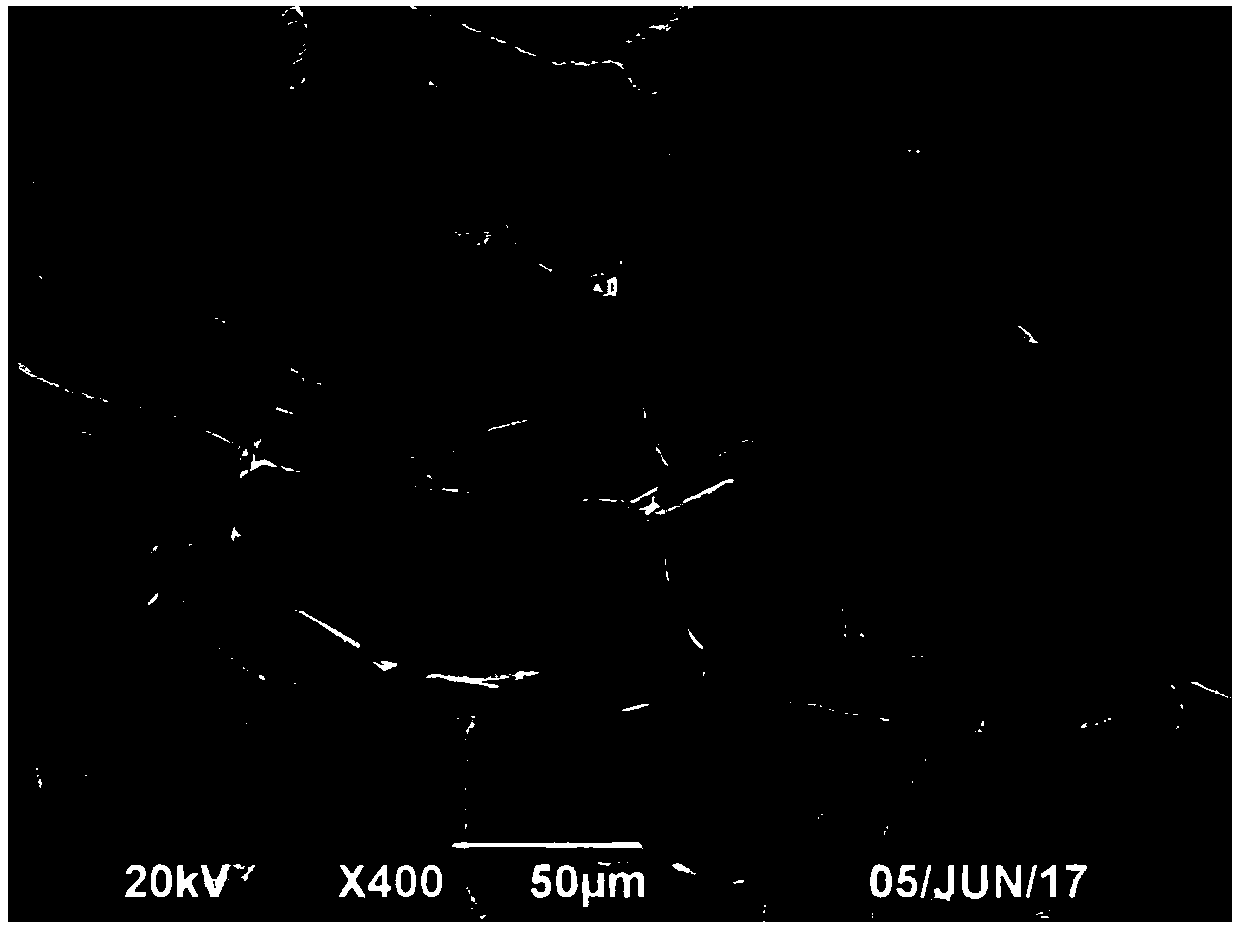

High-hydrophobicity silicon carbide foam ceramic as well as preparation method and application thereof

ActiveCN107857593AHigh porosityLower surface energyOther chemical processesAlkali metal oxides/hydroxidesAdsorption kineticHigh surface

The invention discloses high-hydrophobicity silicon carbide foam ceramic as well as a preparation method and application thereof. The high-hydrophobicity silicon carbide foam ceramic is prepared fromsubstrate silicon carbide foam ceramic, and polydopamine and a long-chain alkyl amine molecule or fluorine-containing molecule covering layer at the surface, wherein the polydopamine is a bottom layerof a covering layer; the long-chain alkyl amine molecules or fluorine-containing molecules are the surface layer of the covering layer. The prepared silicon carbide foam ceramic is of a three-dimensional network communicated structure; the porosity is high; the size is controllable; the cost is low; the industrial production requirements are met; hyperbranched liquid-state polycarbosilane is usedas a bonding agent for preparing the silicon carbide foam ceramic; the low-temperature sintering is realized; the ceramic yield is high. The three-dimensional porous silicon carbide foam ceramic is used; due to large surface area and high surface roughness, relatively good adsorption kinetics are realized in the adsorption process; the adsorption equilibrium can be fast reached; macroporous structures and micropores can be used as oil storage spaces, so that wide application prospects are realized in the aspect of oil adsorption agents.

Owner:CENT SOUTH UNIV

Preparation method for nanometer conductive ink

The invention relates to a preparation method for nanometer conductive ink, and particularly relates to a preparation method for a novel nanometer metal conductive ink which is low in production cost, good in stability and excellent in electrical conductivity, and has a core-shell structure. The nanometer conductive ink is simple in process, short in process time, and suitable for mass production.

Owner:侯李明

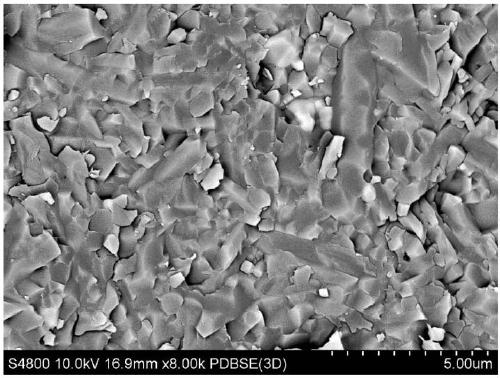

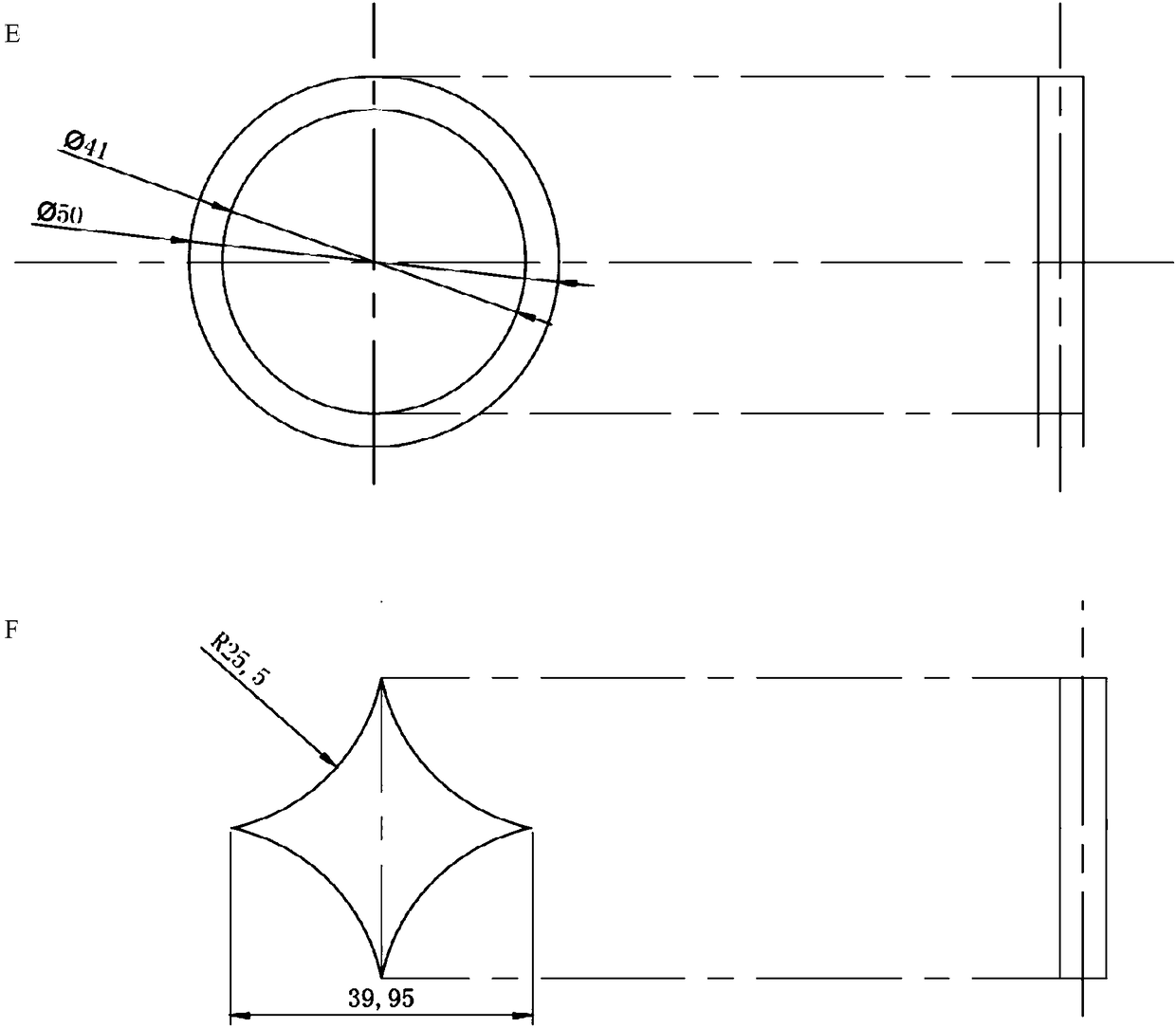

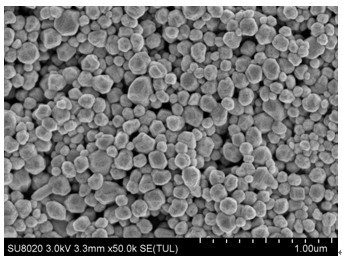

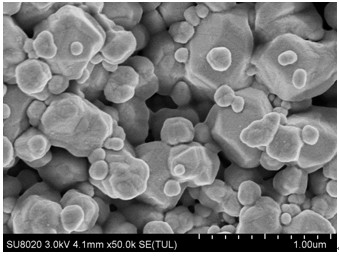

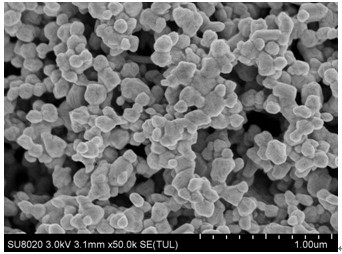

COG dielectric ceramic material for low-temperature sintering thin-media multilayer ceramic capacitor

The invention discloses a low-temperature sintering thin-media nickel electrode dielectric ceramic material. The compositions of the dielectric ceramic material comprise a principal component and additives, wherein the principal component is (Ca1-xSrx)zZryO3, wherein x is more than or equal to 0.2 and less than or equal to 0.4, y is more than or equal to 0.90 and less than or equal to 1.0, and Z is more than or equal to 0.985 and less than or equal to 1.003; the additives are at least two or more compounds of Al2O3, MnCO3, MgO, TiO2, SiO2, BaCO3 and ZnO. The material is in line with COG characteristics of American EIA (Electronic Industries Association) standard, is small in particles, uniform in size distribution, good in dispersibility, and favorable in dielectric property. The material is low in sintering temperature, and uniform and compact in grain sizes when being used for manufacturing a multilayer ceramic capacitor, can realize the thickness of a dielectric layer to be less than 5mum, and is favorable in matching with a nickel internal electrode.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

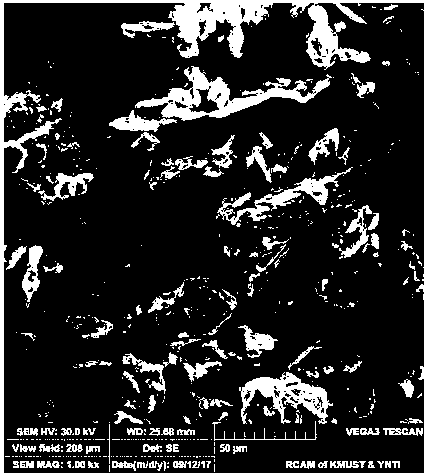

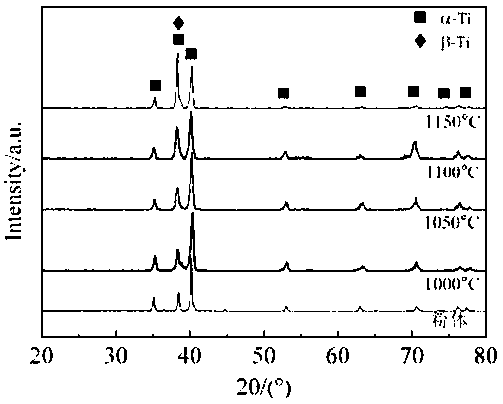

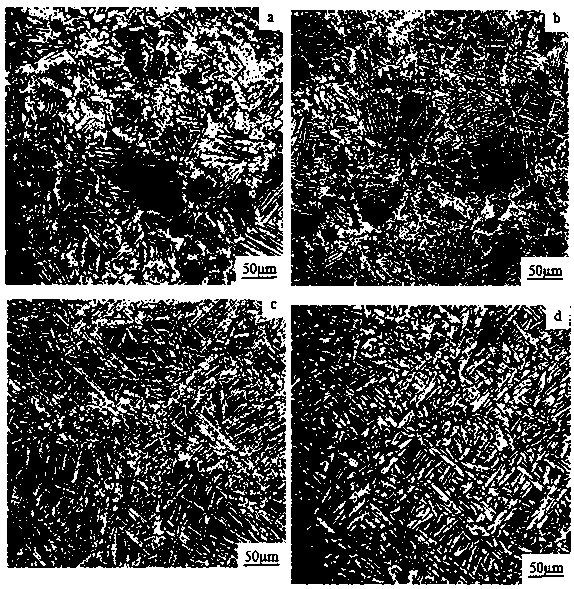

Preparation method of titanium, aluminum, niobium, zirconium and molybdenum alloy

The invention discloses a preparation method of a titanium, aluminum, niobium, zirconium and molybdenum alloy, and belongs to the technical field of preparation of titanium alloys. The method comprises the following steps: weighing Ti, Al, Nb, Zr and Mo metal powder according to certain proportions, mixing the metal powder, performing intermittent dry type ball grinding through a ball grinder to obtain mixed powder, putting the obtained mixed powder into a graphite mold, prepressing the mixed powder, placing the graphite mold into a discharge plasma sintering furnace, applying axial pressure of 10 to 50 MPa for sintering under the condition that the vacuum degree is 2 to 8 Pa, heating the mixed powder in a multi-stage heating mode to 1,000 to 1,150 DEG C, preserving the heat for 3 to 8 min, cooling the mixture to room temperature, and demolding the mixture, thus obtaining the titanium, aluminum, niobium, zirconium and molybdenum alloy material. The titanium, aluminum, niobium, zirconium and molybdenum alloy prepared by the method disclosed by the invention has the advantages of uniform component, high compactness, high intensity, high plasticity and the like; and in addition, the method is easy to operate, short in time, energy-saving and environmentally friendly and has a good popularization value.

Owner:KUNMING UNIV OF SCI & TECH

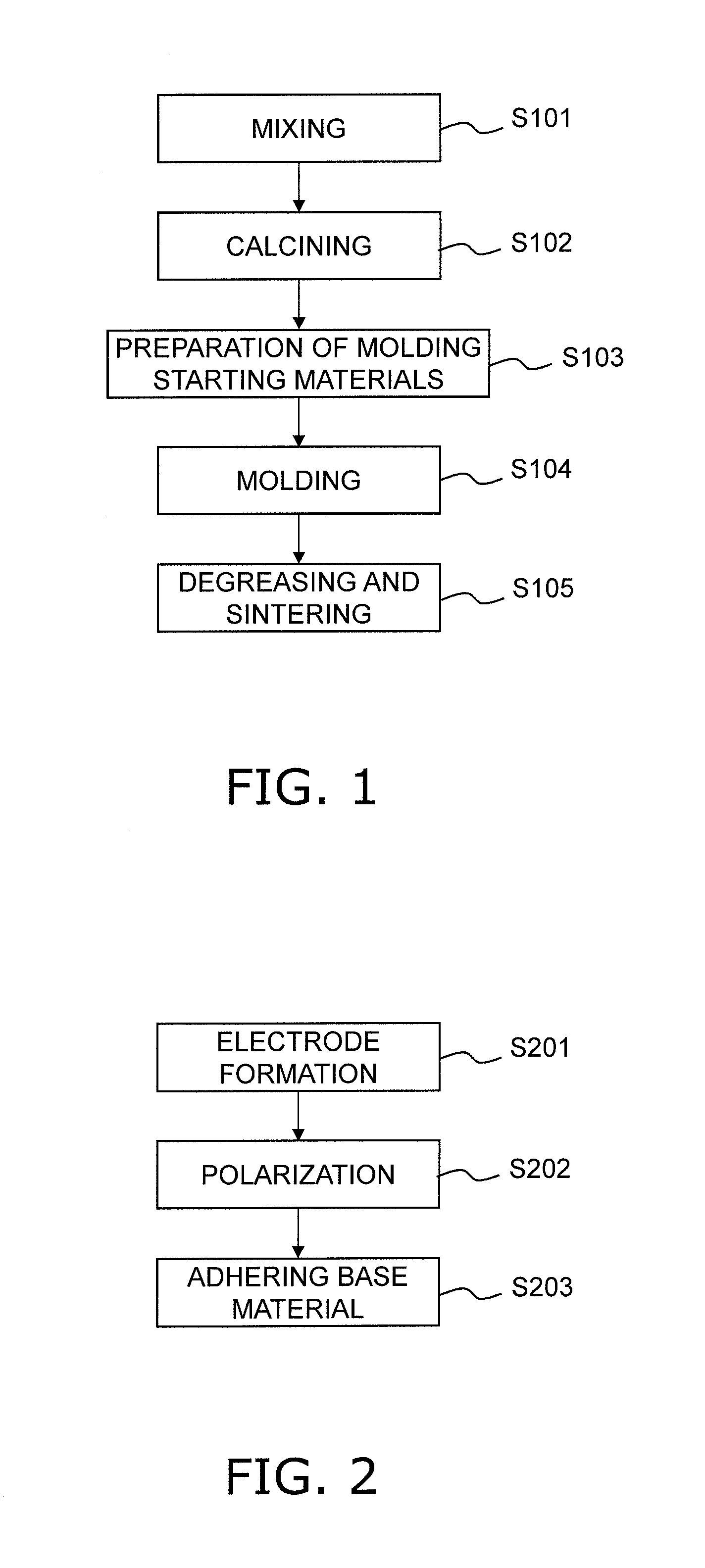

Piezoelectric/electrostrictive material, piezoelectric/electrostrictive body, and resonance driving device

ActiveUS20160293832A1Achieve low temperature sinteringConstant gainPiezoelectric/electrostrictive device manufacture/assemblyCeramic layered productsComposite materialElectrostriction

A piezoelectric / electrostrictive material is composed of Mn and a compound of Pb(Zn, Nb)O3—Pb(Ni, Nb)O3—Pb(Zr, Ti)O3. A ratio of a molar amount of Mn relative to a sum of respective molar amounts of Ni, Zn, Ti, Zr, Nb and Mn is at least 0.001 to no more than 0.015. A ratio of a molar amount of Nb relative to a sum of respective molar amounts of Ni and Zn is at least 2.007 to no more than 2.125.

Owner:NGK INSULATORS LTD

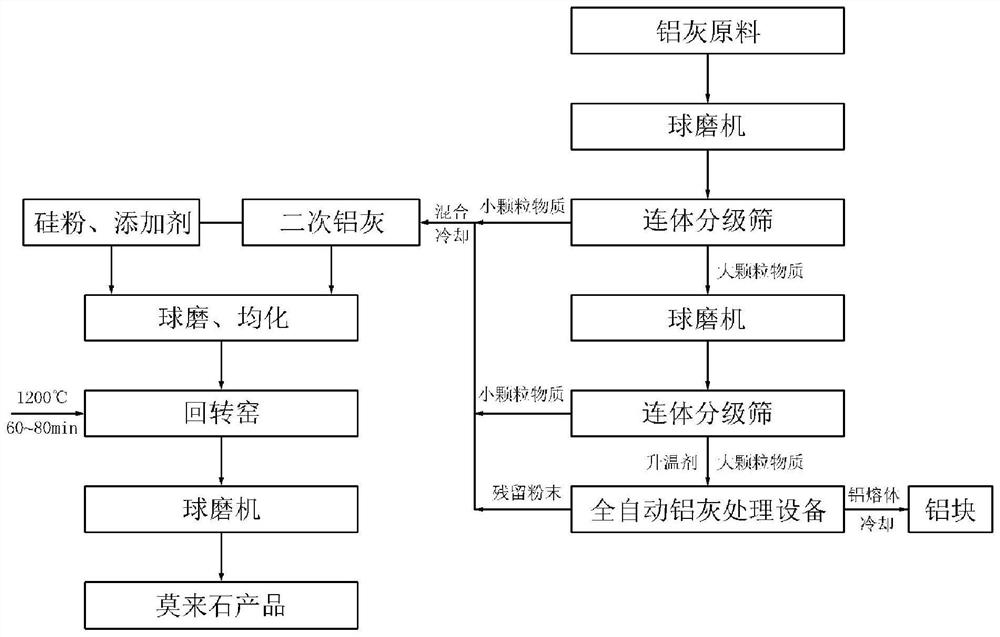

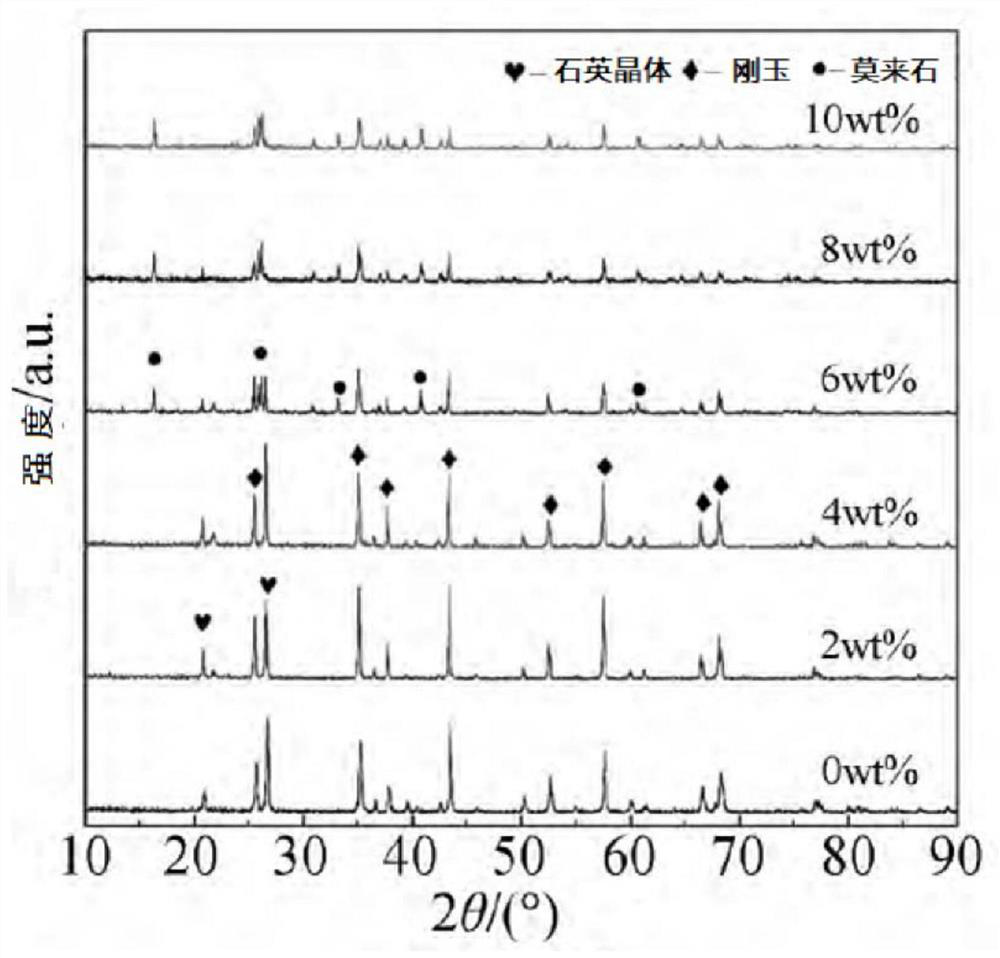

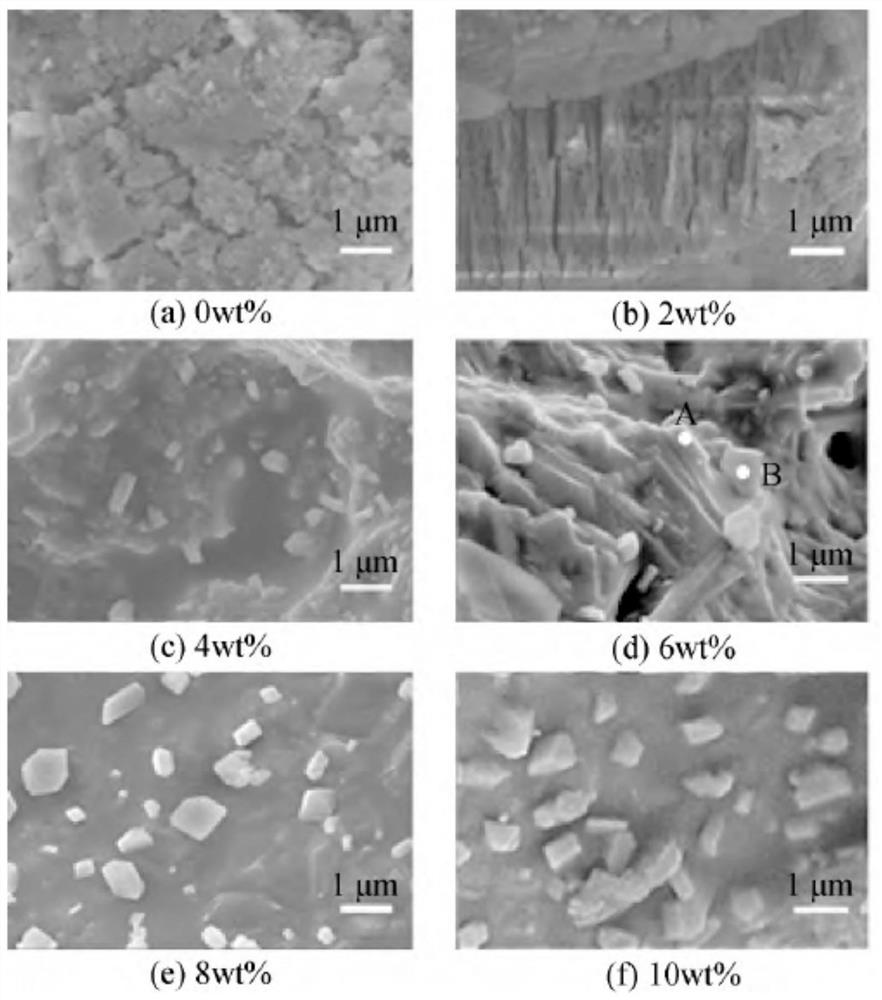

Method for preparing mullite from aluminum ash

ActiveCN113105222AEasy to recycleImprove resource recoveryProcess efficiency improvementMulliteMixed materials

The invention belongs to the technical field of preparation of mullite by using oxide as a base material, and discloses a method for preparing mullite by using aluminum ash. The method comprises the following steps: adding a heating agent into an aluminum ash raw material, and stir-frying the aluminum ash raw material and the heating agent, so that the aluminum ash raw material is in a high-temperature state, and aluminum elementary substances form an aluminum melt and are gradually collected; exporting and cooling the collected aluminum melt to form aluminum blocks, wherein secondary aluminum ash powder is left; adding silicon powder and an additive into the secondary aluminum ash powder, uniformly mixing to form a mixed material, and carrying out ball milling on the mixed material; and introducing the ball-milled mixed material into a rotary kiln, and sintering to generate mullite, wherein the used additive is a mixture of manganese dioxide and zinc oxide. According to the method for preparing mullite by using aluminum ash, provided by the invention, the aluminum ash can be subjected to harmless and resourceful treatment, so that the influence on the ecological environment is reduced, and meanwhile, resource reutilization is completed.

Owner:重庆丰淼生态环境科技有限责任公司

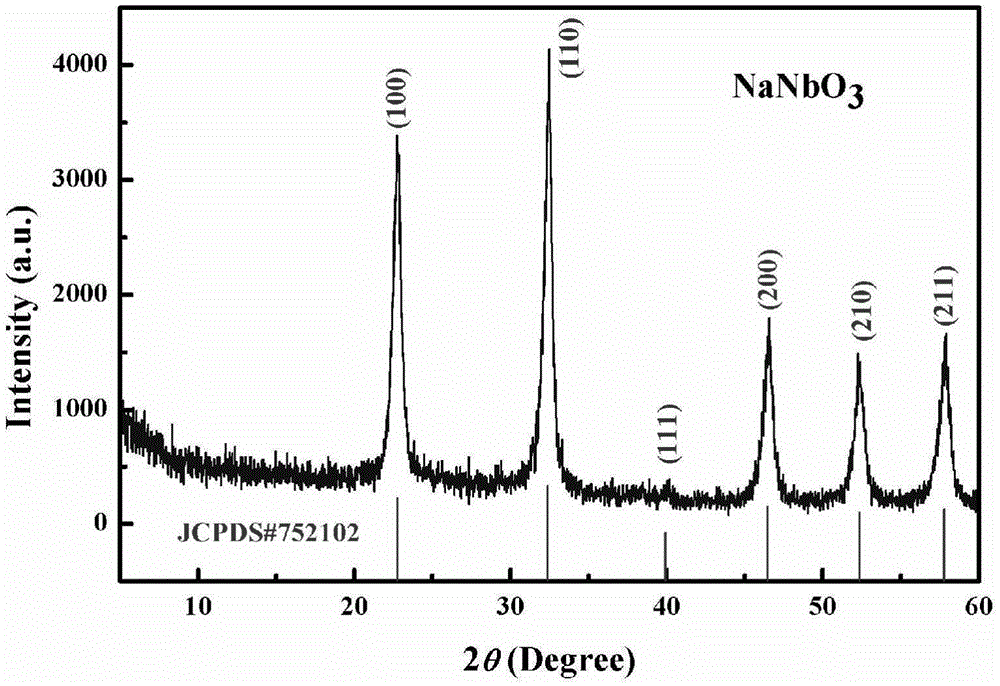

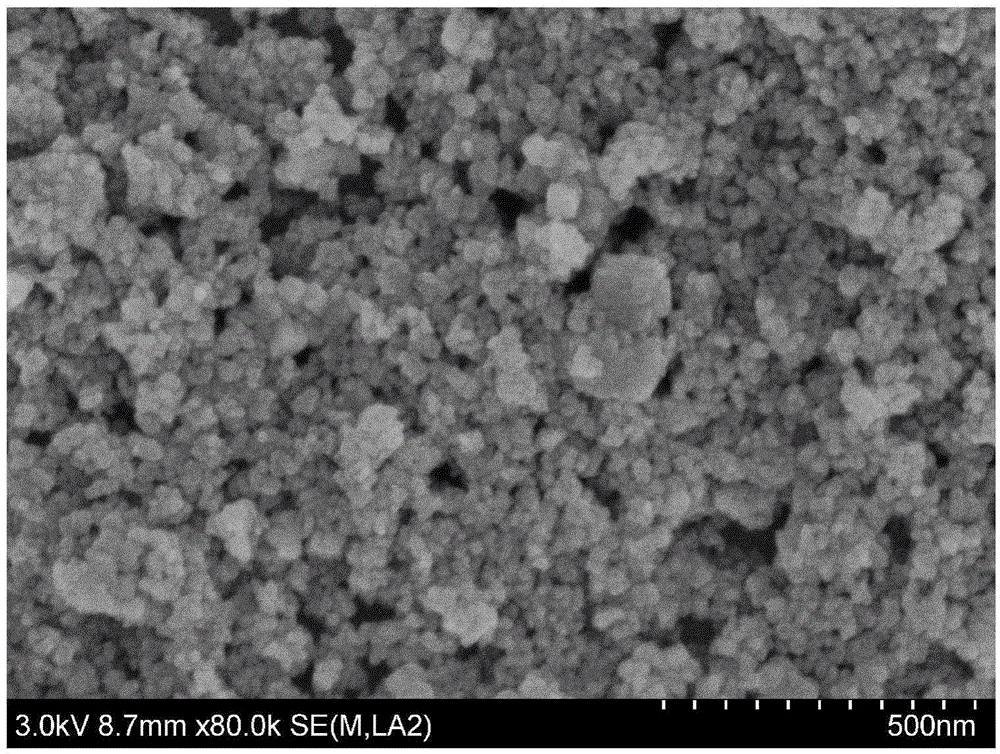

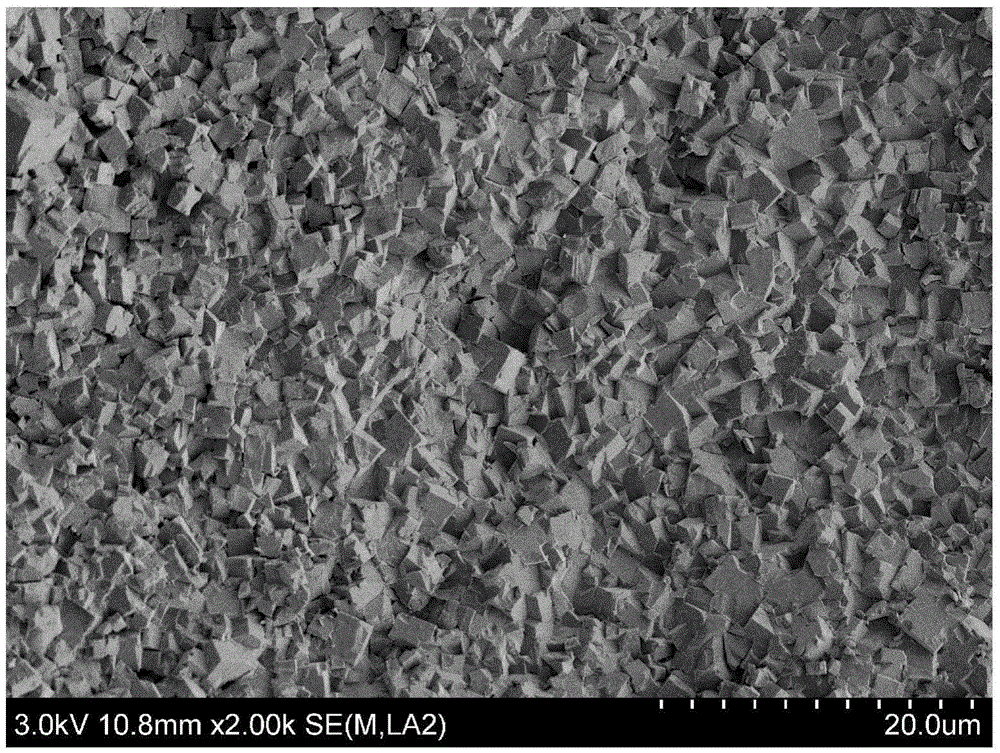

Preparation method of high-performance sodium niobate dielectric ceramic powder

The invention discloses a method for synthesizing cubic phase sodium niobate dielectric ceramic powder under the low-temperature solvothermal condition. The method comprises the steps of weighing organic solvent to prepare a reaction solution, adding niobium pentaoxide, conducting a hydrothermal reaction and washing and drying. The sodium niobate powder prepared through the method has the advantages that a cubic phase structure and the nanoscale size are achieved, and the sintering activity is high; meanwhile, lattice expansion is produced along with the phase change in the sintering process, low-temperature sintering can be achieved, the densification degree is high, and the room-temperature dielectric constant is significantly enhanced. A low-temperature rapid synthetic method of cubic phase sodium niobate nano powder is provided, and meanwhile a new idea is provided for solving the problem of sodium niobate base function ceramic sintering densification.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

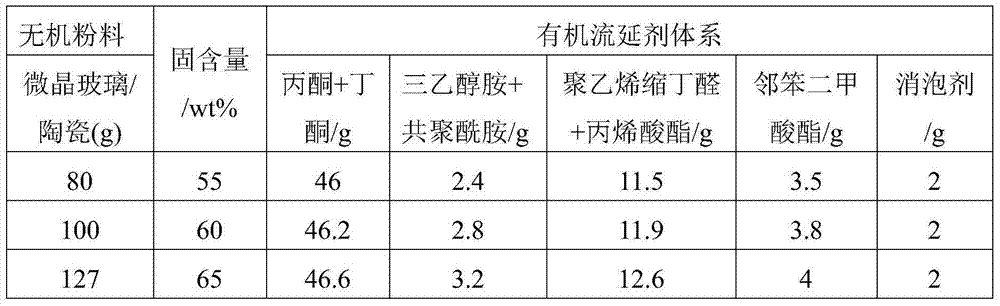

Low-temperature sintering thick film paste applied to PI films and preparation method of low-temperature sintering thick film paste

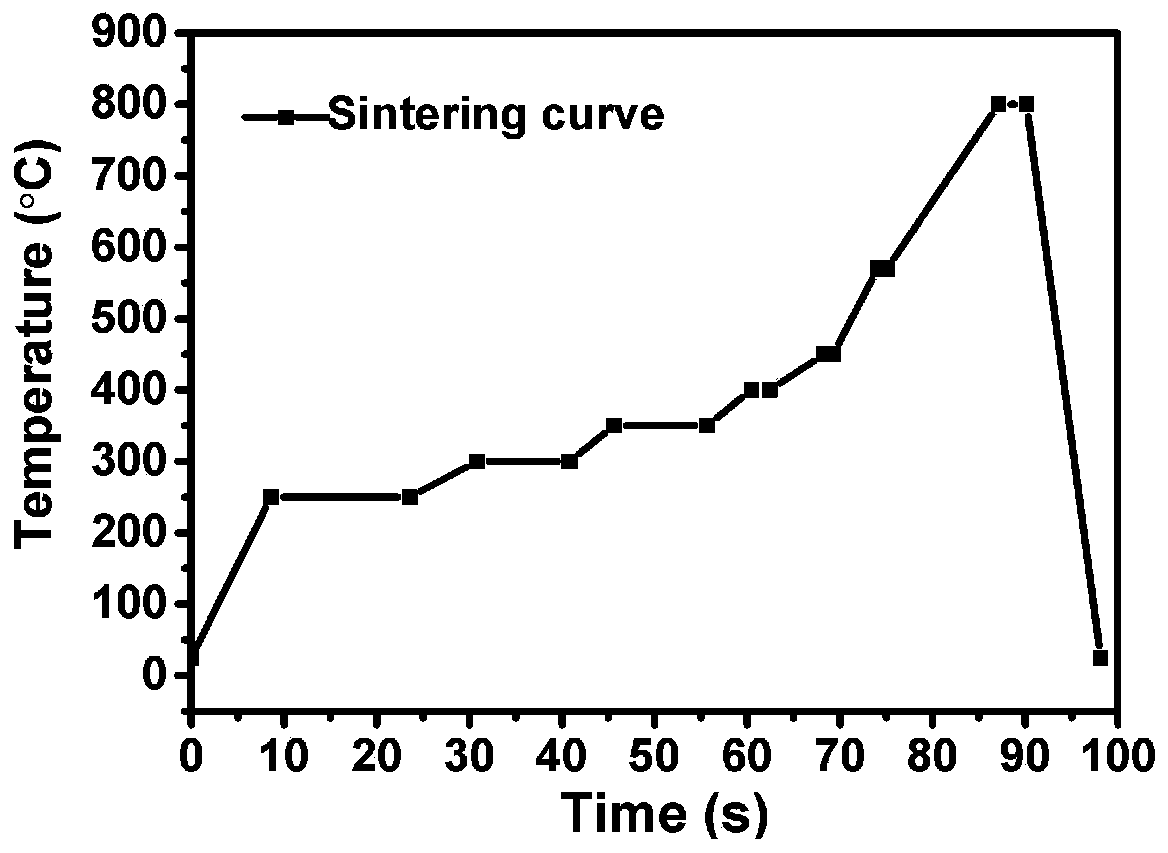

InactiveCN105869706ALower sintering temperatureAchieve low temperature sinteringNon-conductive material with dispersed conductive materialCable/conductor manufactureSolventDefoaming Agents

The invention discloses a low-temperature sintering thick film paste applied to PI films and a preparation method of low-temperature sintering thick film paste. The thick film paste is prepared from a bonding phase, an organic carrier, lanthanum oxide or yttrium oxide and high-purity nano-silver powder. The bonding phase is prepared from Bi2O3, SiO2 and Al2O3, the organic carrier is prepared from a solvent mixture, a thickening agent, a thixotropic agent and a defoaming agent, and the solvent mixture is prepared by mixing a solvent and PVB. The thick film paste has the advantages of being low in sintering temperature and resistance value, short in sintering time, large in adhesion force and good in weldability. The preparation method includes the steps that firstly, the bonding phase is prepared; secondly, the organic carrier is prepared; thirdly, the bonding phase, the organic carrier, the high-purity nano-silver powder and lanthanum oxide or yttrium oxide are mixed and ground, and the thick film paste is obtained after screening. The thick film paste can be effectively produced and prepared with the preparation method.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

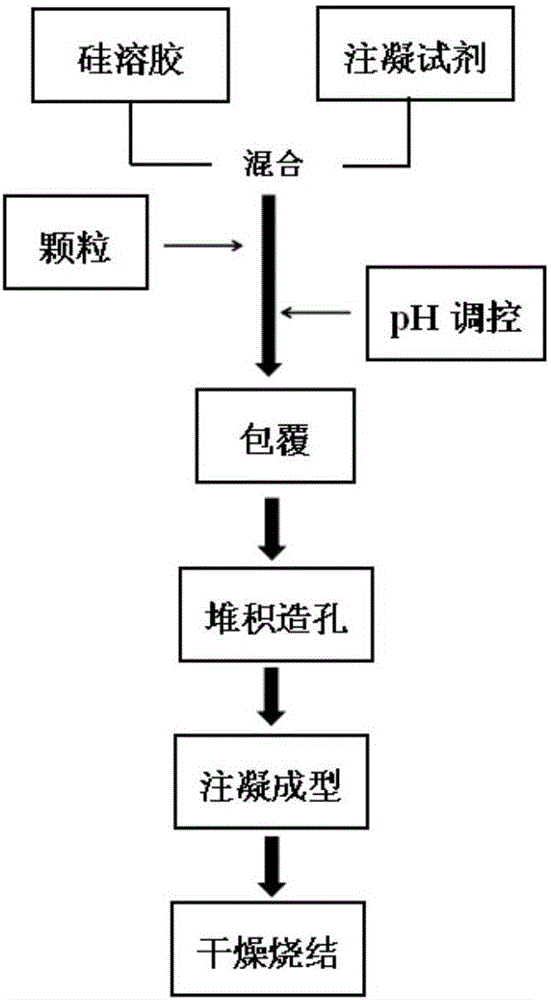

Method of preparing porous ceramic through low-temperature sintering

ActiveCN105906365ADoes not affect pore structureImprove permeabilityCeramicwareCeramic sinteringNeck parts

The invention discloses a method of preparing porous ceramic through low-temperature sintering. In the invention, a method of coating ceramic particles with silicon sol is employed to achieve surface modification of the particles, so that a ceramic powder, which is difficult to sinter, can be subjected to surface fusion at a low temperature, thereby promoting sintering mass transmission among the particles and forming a high-strength neck part. A typical preparation method includes the steps of: 1) dissolving a gel-casting reagent, comprising an organic monomer, MBAM, (NH4)2S2O4 and TEMED in the silicon sol having certain concentration to prepare a pre-mixed liquid; 2) adding raw material particles to the pre-mixed liquid, and controlling the pH to coat the particles; 3) performing stacked pore forming to the particles, and performing polymerization and curing through a reaction at a certain temperature to form a green body; and 4) drying and low-temperature-sintering the green body to form the porous ceramic. The low-temperature ceramic sintering technology not only is free of damage on pore structures but also is simple in process. The porous ceramic can be used in the field of high temperature separation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

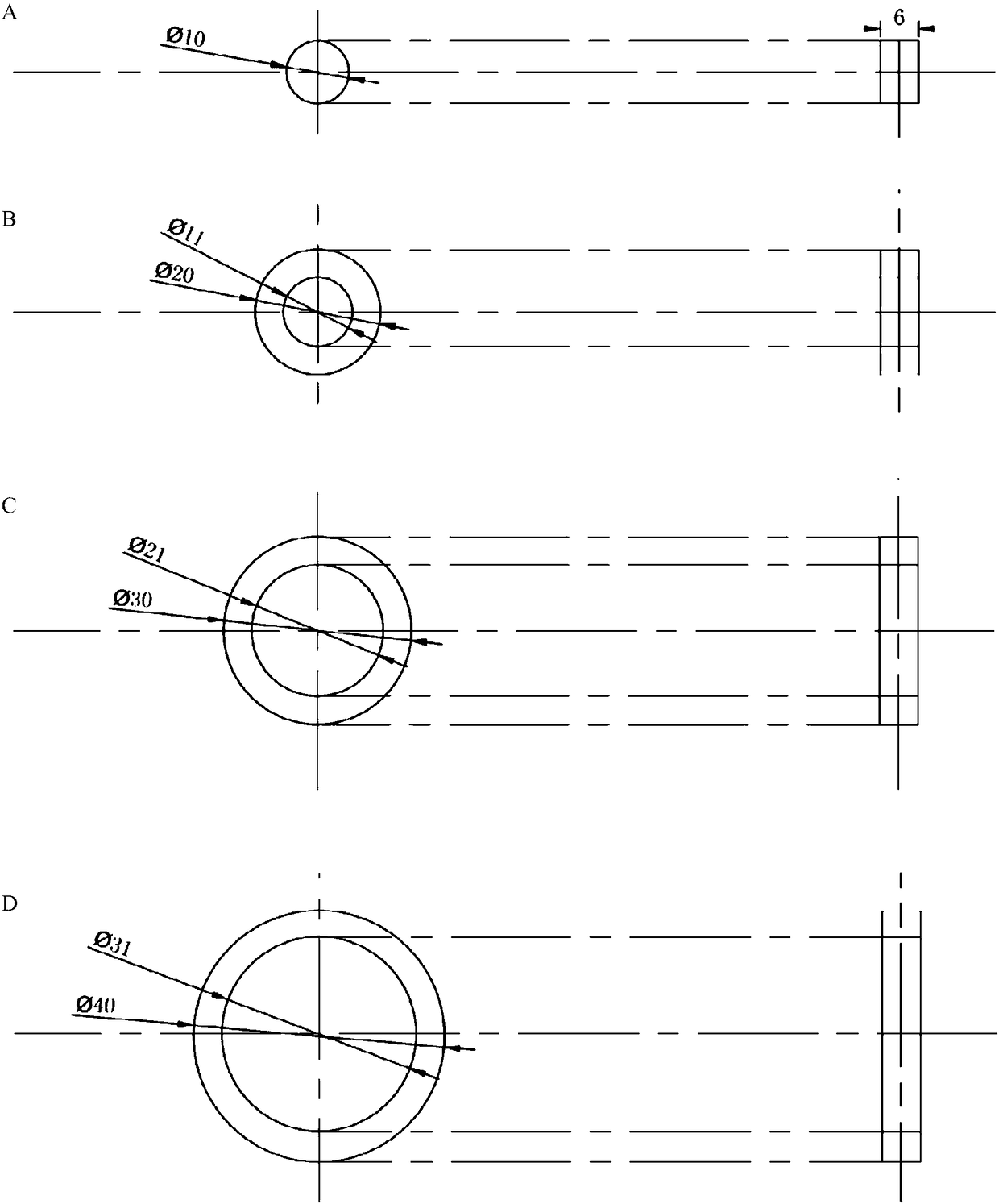

Bulletproof ceramic chip with cyclic structure and bulletproof target plate as well as preparation methods of bulletproof ceramic chip and bulletproof target plate

The invention discloses a bulletproof ceramic chip with a cyclic structure and a bulletproof target plate as well as preparation methods of the bulletproof ceramic chip and the bulletproof target plate. The bulletproof ceramic chip is circular and is formed by nesting a central ceramic circular plate and multiple groups of rings, wherein the inner diameters of the multiple groups of rings are sequentially increased. The bulletproof target plate comprises the bulletproof ceramic chip with the cyclic structure and a PE back plate; the bulletproof ceramic chips are uniformly distributed on the PEback plate. According to the bulletproof ceramic chip disclosed by the invention, a cyclic structural design is introduced, so that the bulletproof performance of the bulletproof ceramic chip can beimproved; a certain amount of TiO2 and MgO powder is introduced into an Al2O3 powder so as to achieve low-temperature sintering; a certain amount of 3Y-ZrO2 is introduced so as to achieve the toughness; due to the existence of filling powder among the rings, the ceramic chip, ceramic rings and special parts can be bonded by sintering and the production efficiency of the bulletproof plate is favorably improved; the preparation methods disclosed by the invention have the characteristics of abundant raw material powder sources, low cost, simple production process and stable product quality.

Owner:HUNAN ZHONGTAI SPECIAL EQUIP

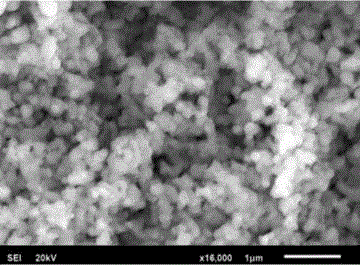

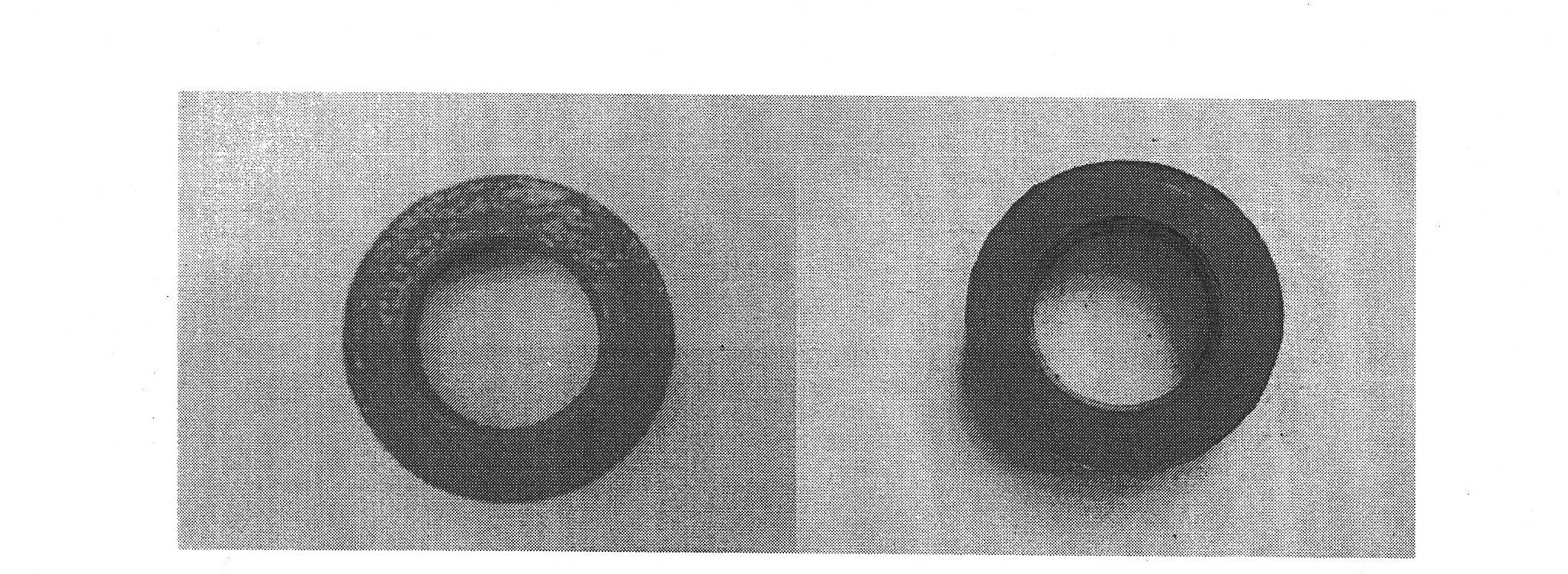

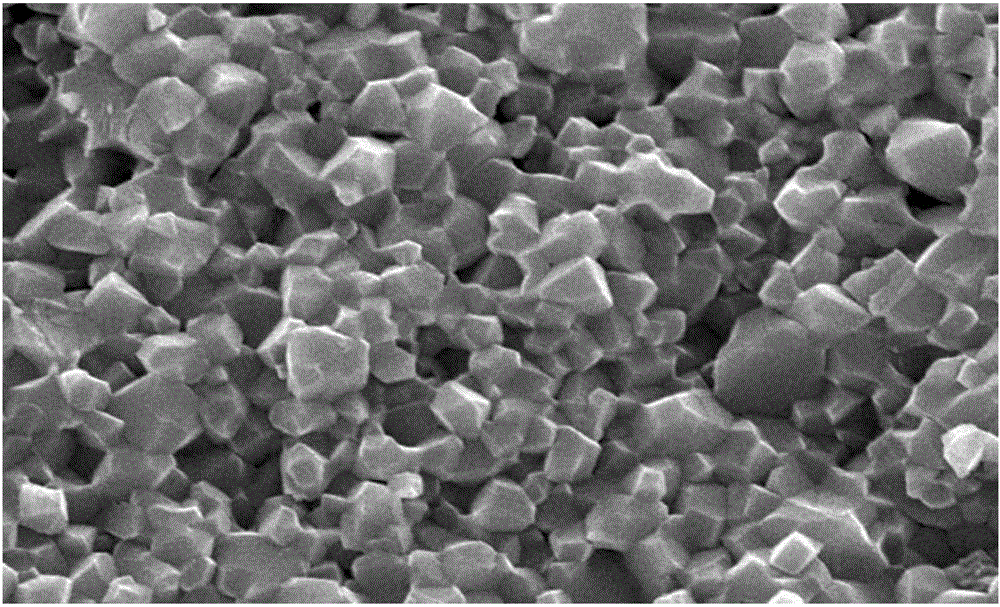

Method for preparing V2O5-adding NiCuZn ferrites

The invention relates to a method for preparing V2O5-adding NiCuZn ferrites, which is characterized in that a ferrite precursor is synthesized in a four-mouth flask under the conditions of water bath, electric heating, stirring, water-cycling condensation and argon protection by using nickel sulfate hydrate, copper sulfate hydrate, zinc sulfate hydrate and ferrous sulphate hydrate as raw materials, using ammonium oxalate as precipitating agent, using polyvinyl alcohol as dispersant, using ethanol as detergent, using vanadium oxide as sintering agent and using argon as protective gas. The particular steps are as follows: preparing blended solution firstly; filtering, washing and drying so as to obtain precursor powder; calcining the precursor powder at a temperature of 800 DEG C; then adding vanadium oxide as sintering agent and deionized water into the precursor powder; carrying out ball-milling on the obtained mixture; pressing the mixture subjected to ball-milling into circular cake-shaped products; finally, carrying out low-temperature sintering on the circular cake-shaped products at a temperature of 870 DEG C so as to obtain the final product. The preparation method is advanced, and grains are uniform and stable in chemical and physical properties, therefore, the preparation method is an ideal method for preparing the NiCuZn ferrites.

Owner:ZHONGBEI UNIV

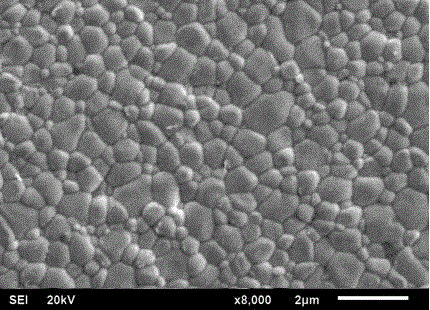

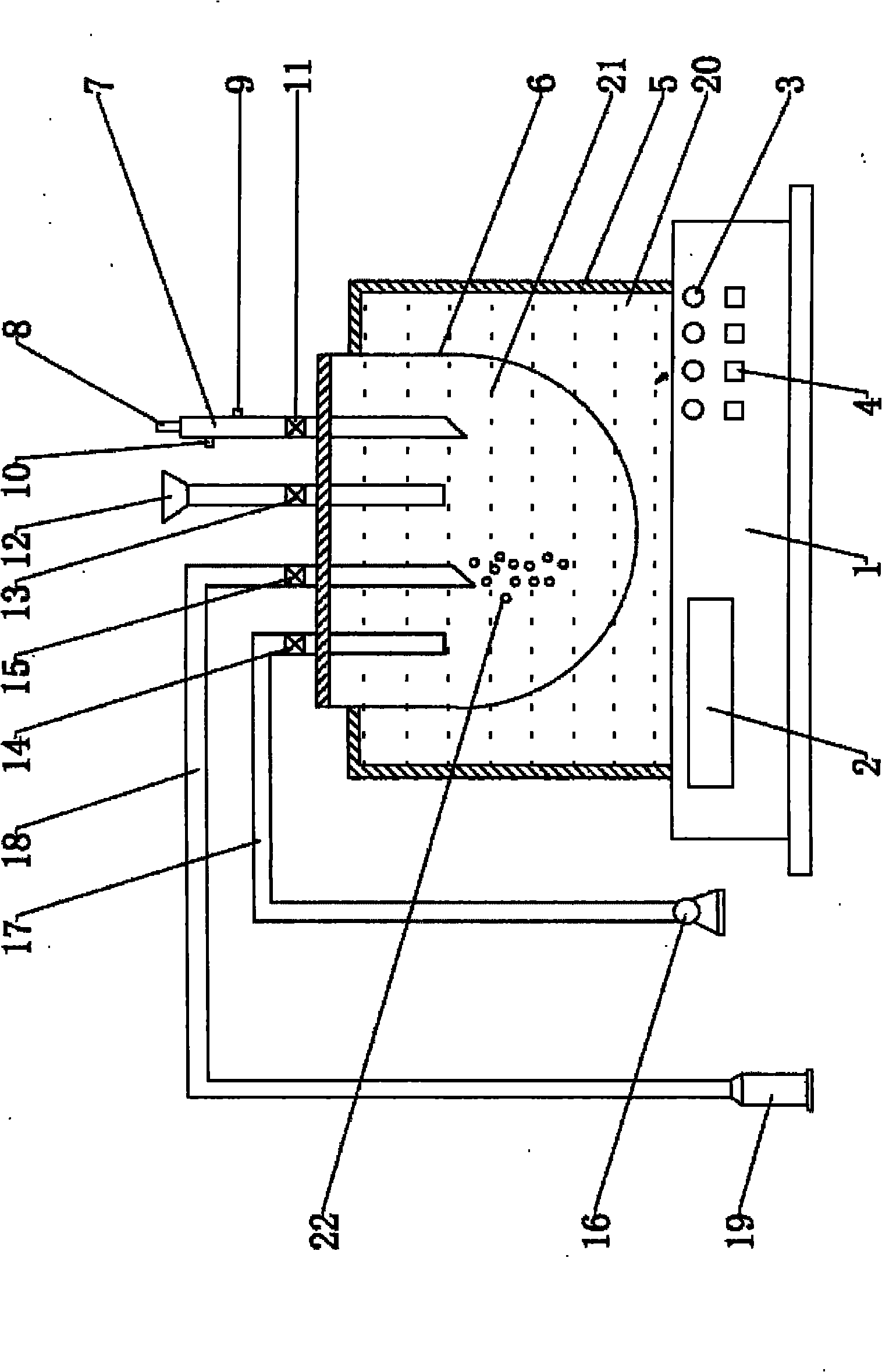

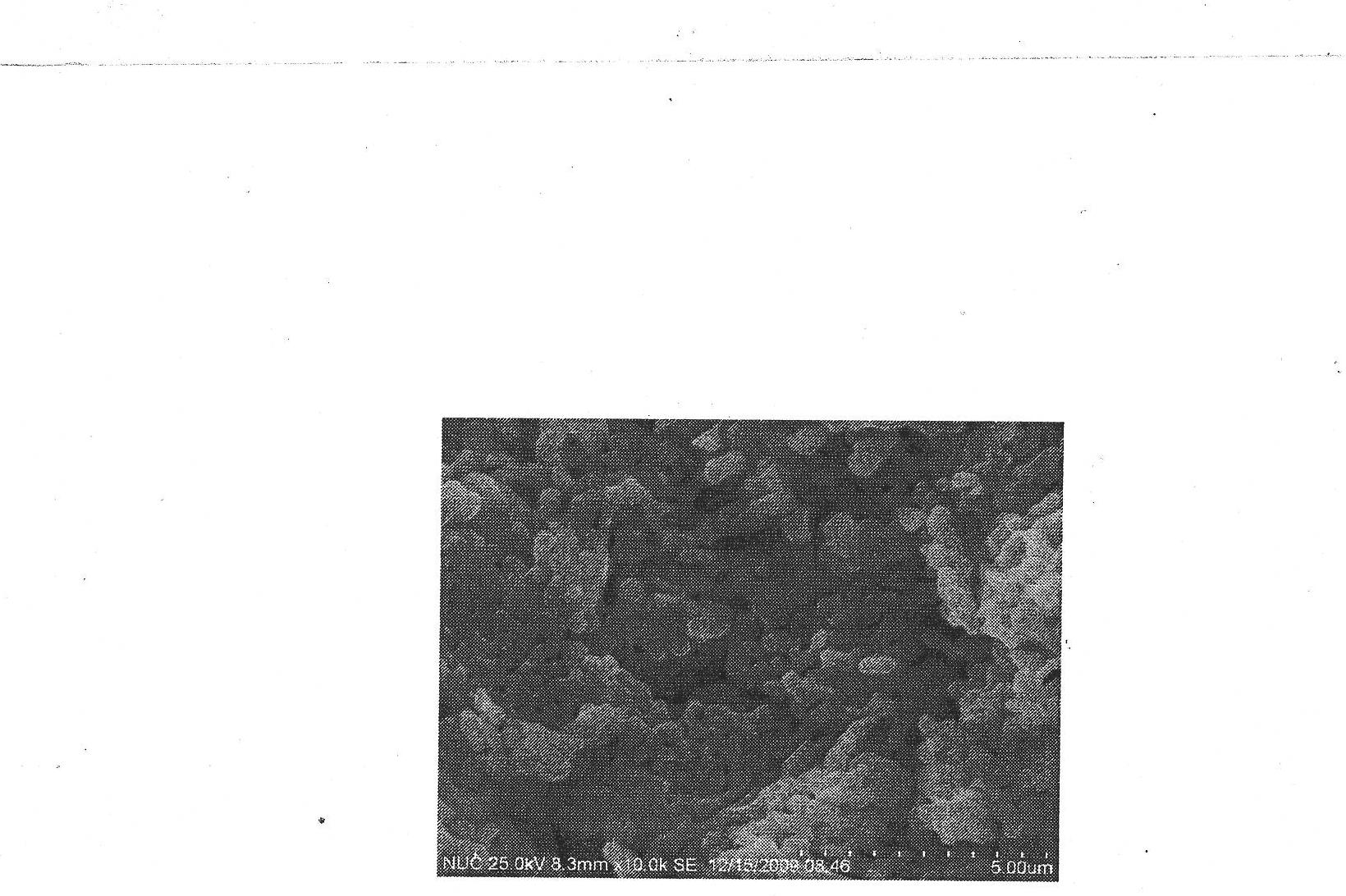

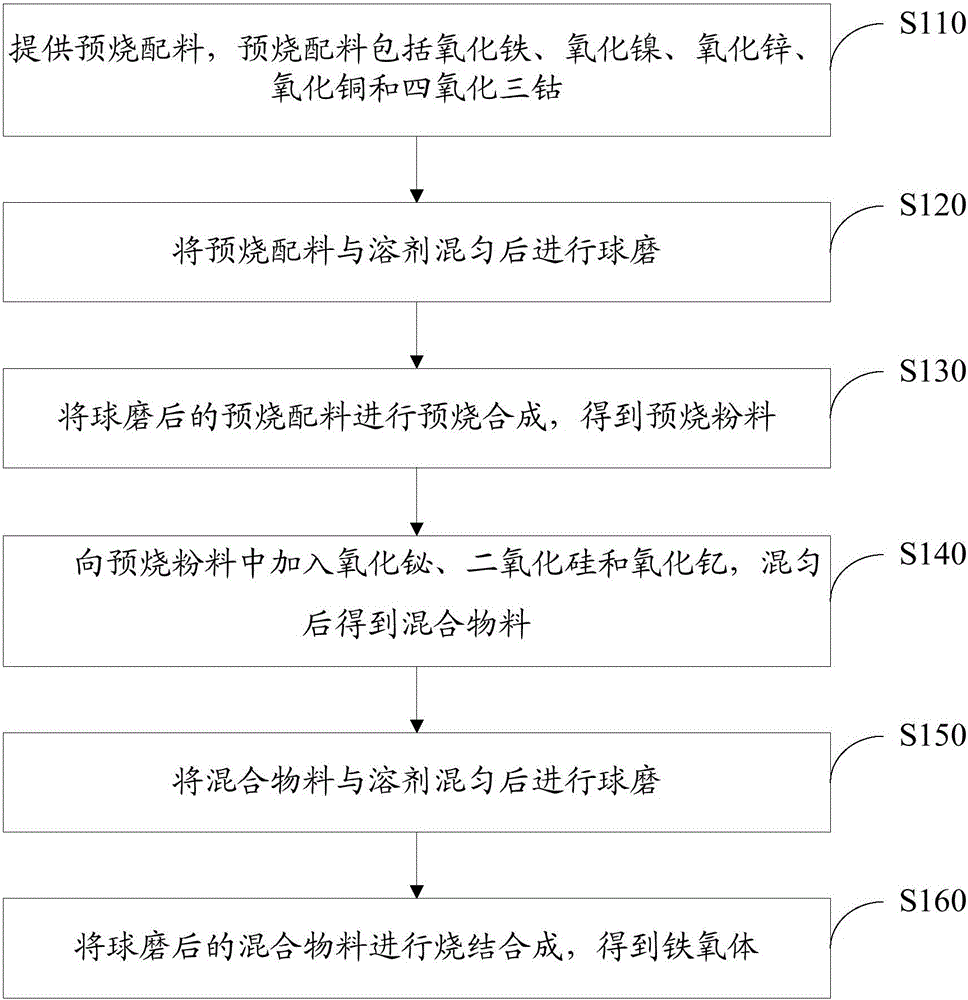

Preparation method for ferrite, ferrite and inductor

ActiveCN105777098AMagnet grains are small and uniformIncrease impactTransformers/inductances magnetic coresCopper oxideGrain structure

The invention discloses a preparation method for a ferrite, the ferrite prepared by the method and an inductor which comprises the ferrite. A crystal grain structure is formed by adding raw materials in batches and ball-milling, pre-sintering and synthesizing the main materials, such as iron oxide, nickel oxide, zinc oxide, copper oxide and cobaltosic oxide. Later, bismuth oxide, silicon dioxide and yttrium oxide are added into a pre-sintered powder material; the yttrium oxide can enter the pre-sintered and synthesized zinc oxide crystal grains, so that the density of the ferrite is improved, and the current impact resistance of the ferrite is improved. The prepared ferrite crystal grains are small; the crystal grain uniformity is high; the magnetic conductance change rate is low. According to the inductor which comprises the ferrite, the inductance value of the inductor is reduced slightly along with the increase of a superimposed current.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Method and application for extracting silicon dioxide to prepare ceramic filter packing in red mud

InactiveCN106116510AImprove economyAct as a fluxWater contaminantsTreatment involving filtrationRare-earth elementWater baths

The invention provides a method and application for extracting silicon dioxide to prepare ceramic filter packing and relates to a preparation method and application of the ceramic filter packing with an aim to solve problems about resource utilization of the silicon dioxide in the red mud and treatment of ammonia nitrogen in tap water. The method includes 1), two-stage acid leaching, namely firstly adopting diluted hydrochloric acid to leach most of metallic oxide in the red mud, and using concentrated sulphuric acid to leach titanium and rare earth elements in the red mud till silicon dioxide powder is remained; 2), material mixing, namely adding bentonite, pulverized coal, limestone and sodium carbonate into the extracted silicon dioxide, mixing prior to ball milling to obtain mixed powder; 3), preparing, namely adding the mixed powder into a polyvinyl alcohol solution prior to stirring into the muddy state in water bath and hand-rubbing into spherical granules. The characteristics that the silicon dioxide in the red mud is high in content and good in chemical stability are taken as the main foundation, so that the ceramic filter packing good in porosity, high in intensity and appropriate for water treatment is prepared. The ceramic filter packing is used for removal of the ammonia nitrogen in the tap water.

Owner:HEILONGJIANG UNIV

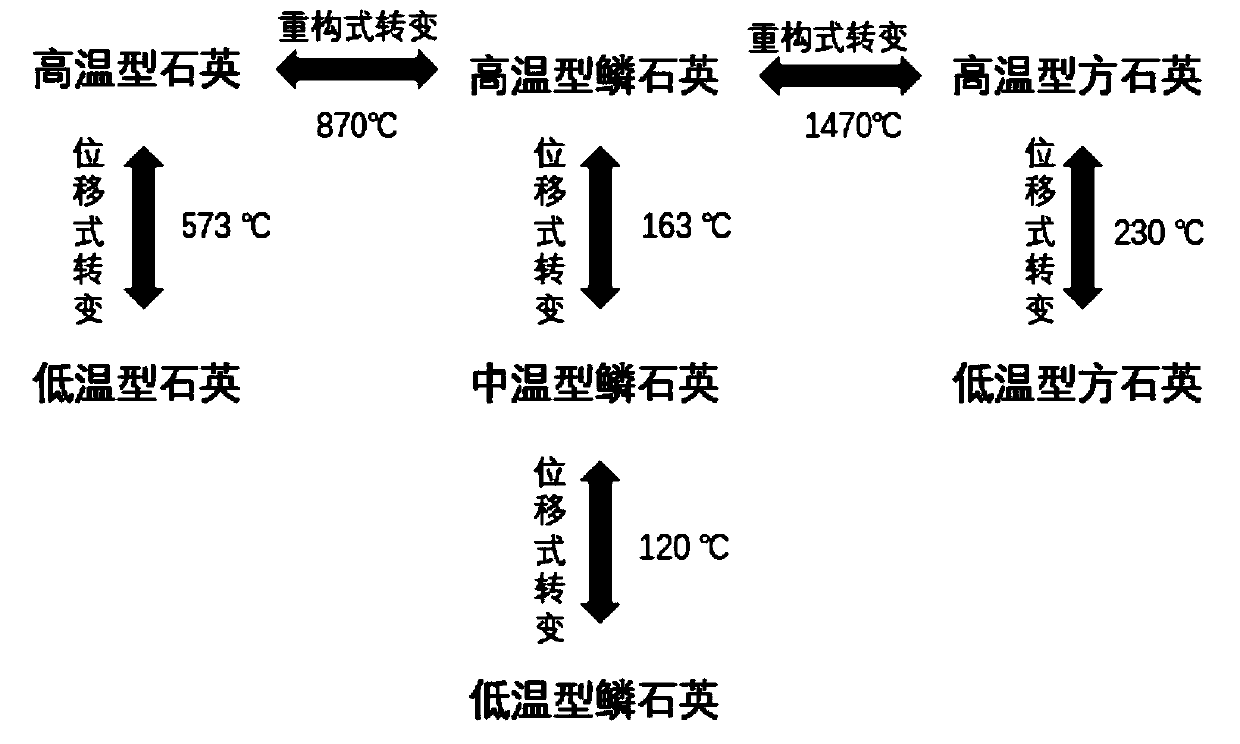

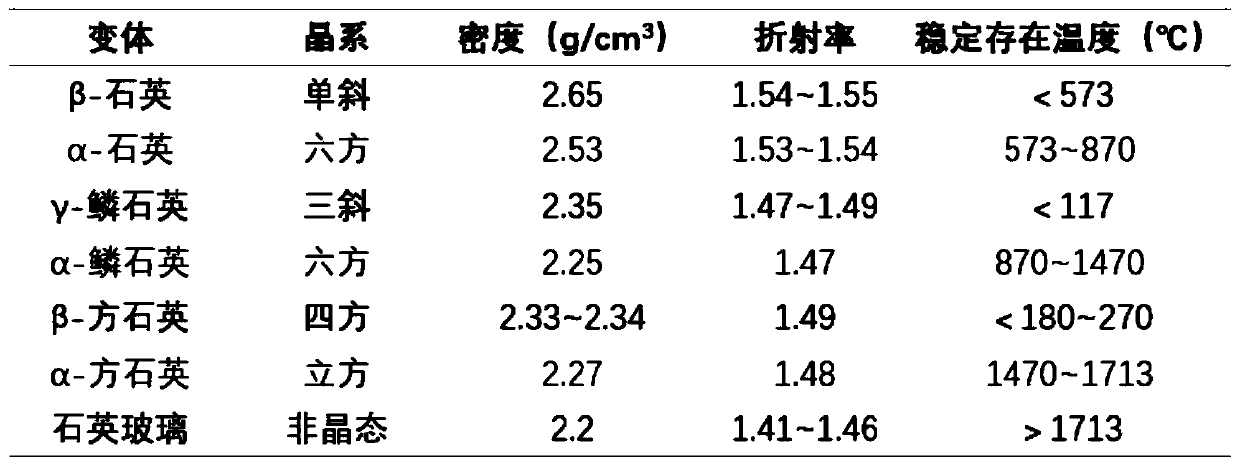

Ultra-low dielectric LTCC microwave ceramic material and preparation method thereof

InactiveCN110903078APromote growthEasy to implement transmissionMicrowave substrateComposite ceramic

The invention belongs to the field of electronic ceramic materials and manufacturing thereof, and relates to an ultra-low dielectric LTCC microwave ceramic material and a preparation method thereof. The ultra-low dielectric LTCC microwave ceramic material provided by the invention is a SiO2-Li2TiO3 composite ceramic taking SiO2 as a main crystal phase, wherein the sintering temperature is 850-900DEG C; the dielectric constant epsilon r is 4.5-5.1; the quality factor Q * f value ranges from 18500 GHz to 26000 GHz; the resonance frequency temperature coefficient tau f ranges from -4.5 ppm / DEG Cto 5 ppm / DEG C; the molecular formula is xSiO2-(1-x)Li2TiO3-yLBSCA(Li2O-B2O3-SiO2-CaO-Al2O3)glass, x is more than or equal to 0.9 and less than or equal to 0.95 molar ratio, y is more than or equal to 4wt% and less than or equal to 8wt% by mass, and the ultra-low dielectric LTCC microwave ceramic material is prepared by a solid phase method. The ultra-low dielectric LTCC microwave ceramic material is simple in manufacturing process, can be produced in batches, and can be widely applied to LTCC microwave substrates, laminated microwave devices and modules when being used as an LTCC microwave dielectric substrate or device material; the low dielectric constant corresponds to the short signal delay time, and the signal transmission speed can be improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

Nano-silver particle mixed conductive ink doped with organic silver and preparation method thereof

Nano-silver particle mixed conductive ink doped with organic silver and a preparation method thereof are disclosed. The advantage of low-temperature reduction (sintering) of organic silver precursor ink is utilized, the organic silver precursor ink is doped into nano-silver particle conductive ink to prepare mixed ink. On one hand, compared with the organic silver precursor ink, the mixed ink hasreduced requirements on storage conditions; on the other hand, compared with the traditional nano-silver particle type ink, the mixed ink has lowered sintering temperature, and can achieve room-temperature or low-temperature sintering, so that the device preparation process is simplified, and the selection range of a substrate material is widened. Nano-silver particles are generated in situ in thedrying process of patterns prepared by the mixed ink, so that the content of silver in the ink can be greatly reduced, and the cost of the ink is reduced.

Owner:JIAXING UNIV

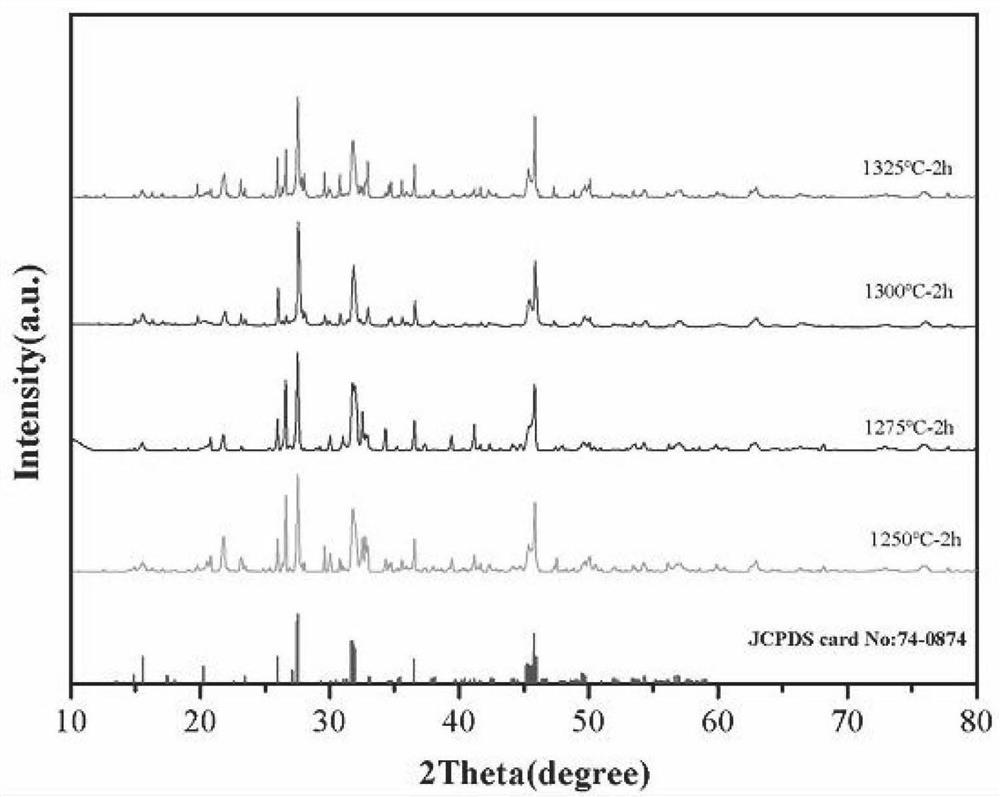

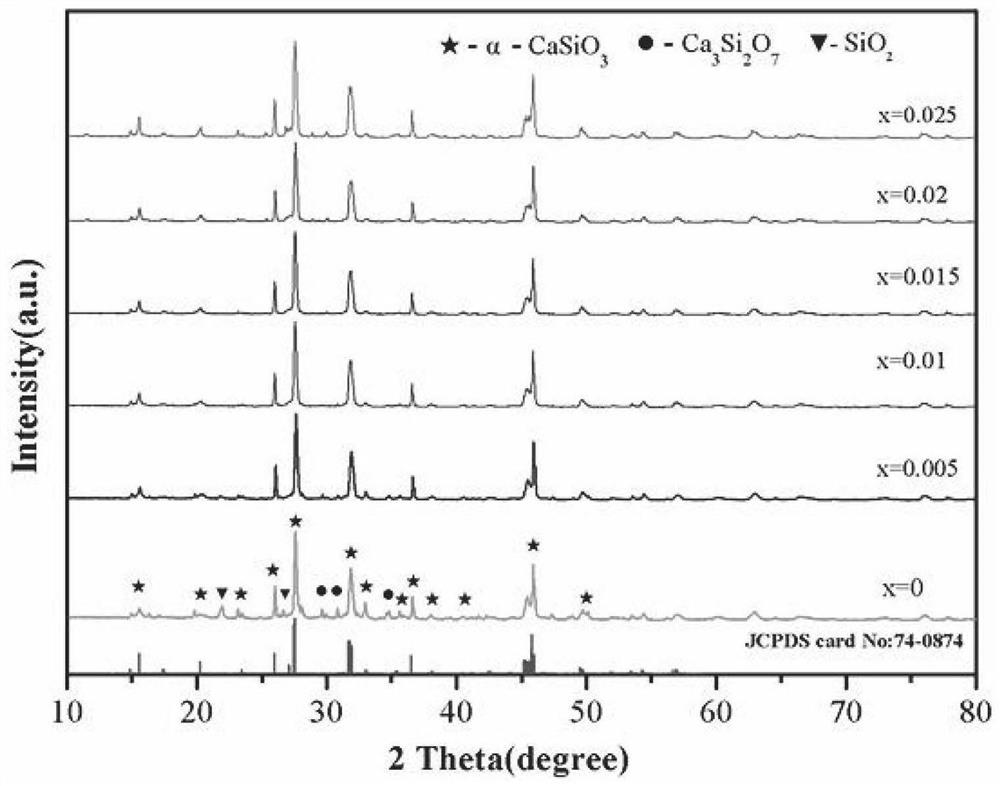

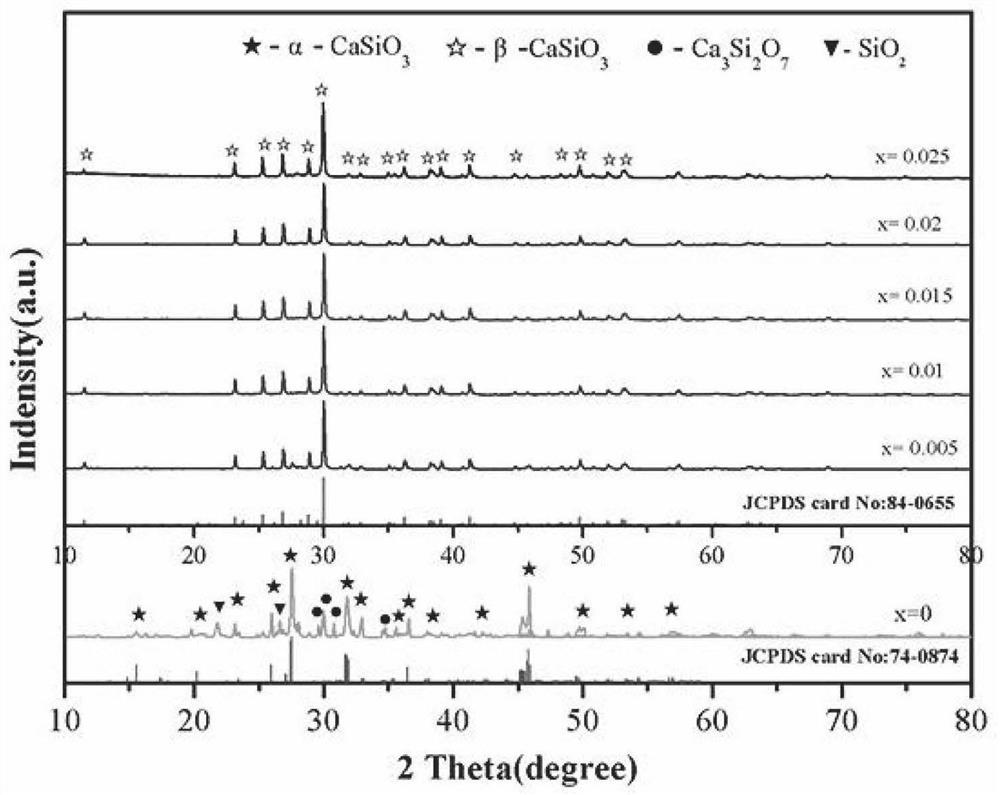

Copper ion doped calcium silicate microwave dielectric ceramic and preparation method thereof

The invention relates to the technical field of electronic ceramic materials, and provides a copper ion doped calcium silicate microwave dielectric ceramic and a preparation method thereof. Copper ions are doped in calcium silicate microwave dielectric ceramic, generation of impure phases in calcined powder can be inhibited by controlling the proper doping amount of the copper ions, pure-phase alpha-CaSiO3 powder (a triclinic system, and a space group is C1) is obtained, and then single-phase beta-CaSiO3 ceramic (a monoclinic system, and a space group is P21 / a) is obtained through sintering. The obtained copper ion doped calcium silicate microwave dielectric ceramic is high in density and excellent in microwave dielectric property, and has a relatively high quality constant and a relatively low dielectric constant. Besides, by doping copper ions, the sintering temperature range of the ceramic is widened, the sintering temperature of a traditional solid-phase synthesis method is 1300 DEG C or above, while the sintering temperature of the preparation method provided by the invention is only 1050 DEG C or above, low-temperature co-firing can be realized, and actual production is facilitated.

Owner:昆明贵研新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com