Bulletproof ceramic chip with cyclic structure and bulletproof target plate as well as preparation methods of bulletproof ceramic chip and bulletproof target plate

A ring-shaped structure and ceramic sheet technology, which is applied to the structure of armor plates, targets, and offensive equipment, can solve the problems of complex molding and sintering processes, high requirements for production equipment, and unfavorable mass production, so as to improve production efficiency. Low cost and the effect of prolonging the crack growth path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1 Preparation of a bulletproof ceramic sheet with ring structure

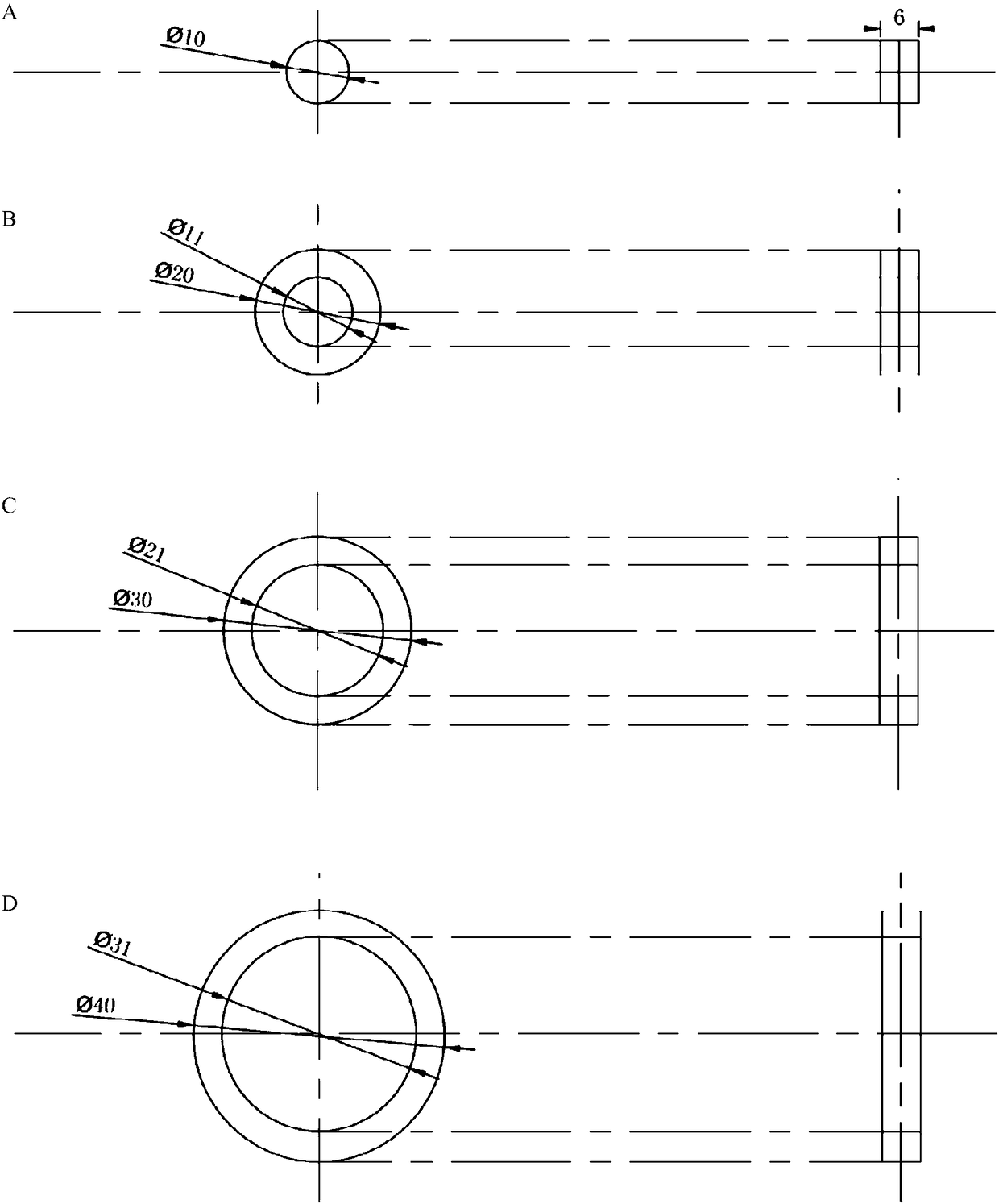

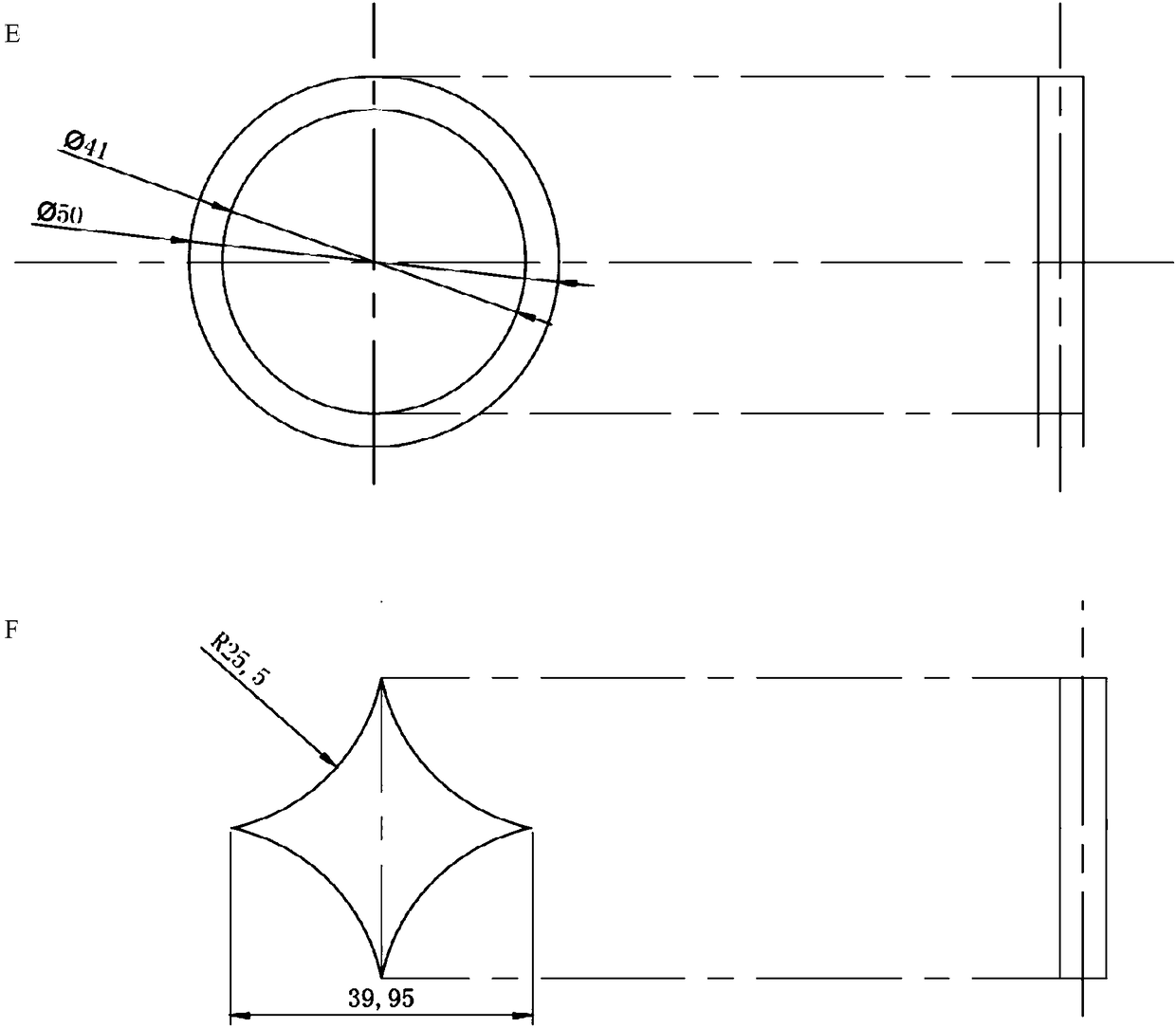

[0071] In this embodiment, the bulletproof ceramic sheet with a ring structure is circular, and is formed by nesting a central ceramic disc and multiple sets of rings, and the inner diameters of the multiple sets of rings increase sequentially. The bulletproof ceramic sheet with a ring structure A preparation method comprising the steps of:

[0072] (1) Al 2 o 3 Powder (alumina, purity 99.0%, particle size 2-5μm), TiO 2 Powder (titanium dioxide, purity 99.5%, particle size 2-5μm) and 3Y-ZrO 2 The powder (triyttrium-stabilized zirconia, with a purity of 99.0%, and a particle size of 2 to 5 μm) was weighed according to 97.0:1.0:2.0 (mass ratio) and put into a ball mill jar, and deionized water of the same quality as the powder was added, Use corundum balls as the grinding medium for wet grinding, the speed of the ball mill is 400 rpm, and the ball milling time is 120 min. After the wet milli...

Embodiment 2

[0078] Embodiment 2 Preparation of a bulletproof ceramic sheet with ring structure

[0079] In this embodiment, the bulletproof ceramic sheet with a ring structure is circular, and is formed by nesting a central ceramic disc and multiple sets of rings, and the inner diameters of the multiple sets of rings increase sequentially. The bulletproof ceramic sheet with a ring structure A preparation method comprising the steps of:

[0080] (1) Al 2 o 3 Powder (alumina, purity 99.0%, particle size 2-5 μm), MgO powder (magnesia, purity 99.5%, particle size 2-5 μm) and 3Y-ZrO 2 The powder (triyttrium-stabilized zirconia, with a purity of 99.0%, and a particle size of 2 to 5 μm) is weighed according to 99.0:0.5:0.5 (mass ratio) and put into a ball mill jar, and deionized water of the same quality as the powder is added, Use corundum balls as the grinding medium for wet grinding, the speed of the ball mill is 400 rpm, and the ball milling time is 120 min. After the wet milling process ...

Embodiment 3

[0086] Embodiment 3 Preparation of a bulletproof ceramic sheet with ring structure

[0087] In this embodiment, the bulletproof ceramic sheet with a ring structure is circular, and is formed by nesting a central ceramic disc and multiple sets of rings, and the inner diameters of the multiple sets of rings increase sequentially. The bulletproof ceramic sheet with a ring structure A preparation method comprising the steps of:

[0088] (1) Al 2 o 3 Powder (alumina, purity 99.0%, particle size 2-5 μm), MgO (magnesium oxide, purity 99.0%, particle size 2-5 μm) and TiO 2 Powder (titanium dioxide, purity 99.5%, particle size 2-5μm) and 3Y-ZrO 2 The powder (triyttrium-stabilized zirconia, with a purity of 99.0%, and a particle size of 2-5 μm) is weighed according to 95.0:0.5:0.5:4.0 (mass ratio) and put into a ball mill jar, and deionized powder of the same quality as the powder is added. Water, use corundum balls as the grinding medium for wet grinding, the speed of the ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com