Patents

Literature

60results about How to "Solve the complex preparation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

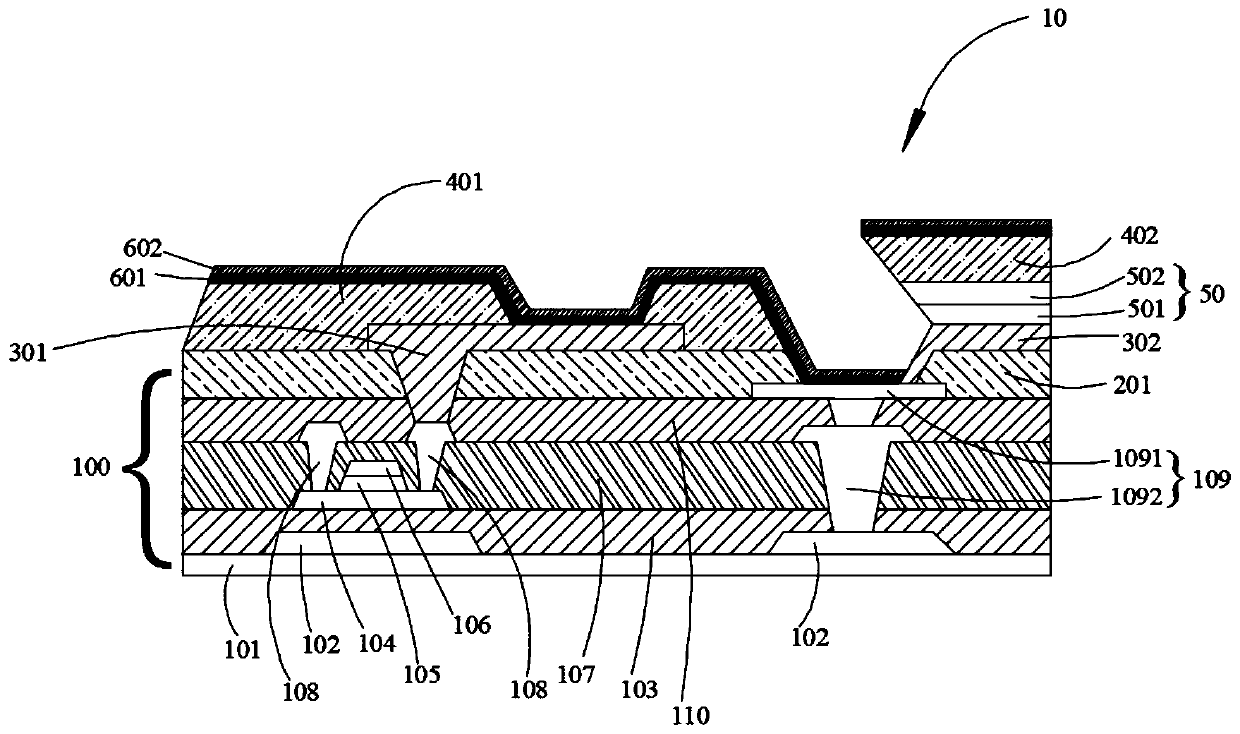

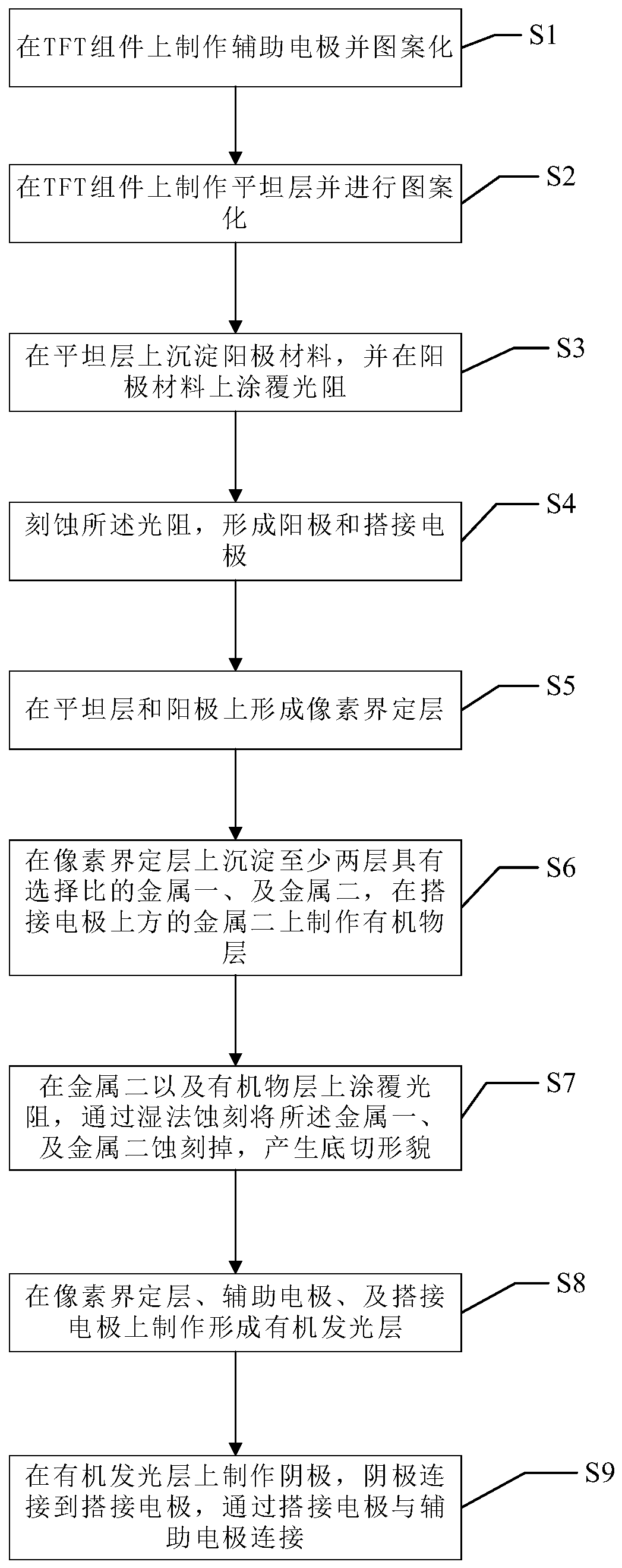

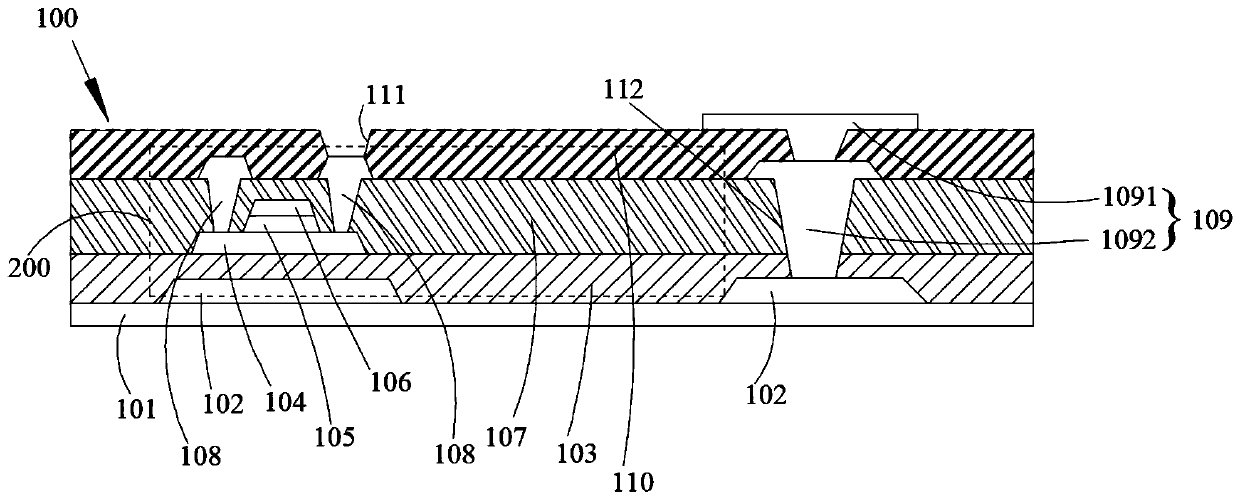

OLED display panel and manufacturing method thereof

ActiveCN110911461ASolve the complex preparation processSimple structureSolid-state devicesSemiconductor/solid-state device manufacturingAuxiliary electrodeMaterials science

The invention provides an OLED display panel and a manufacturing method thereof. The OLED display panel comprises a TFT assembly, an auxiliary electrode, an anode, a lap joint electrode, a metal layer, an organic matter layer, an organic light-emitting layer and a cathode. The lap joint electrode is connected with the auxiliary electrode, and the organic light-emitting layer and the cathode are connected with the auxiliary electrode; and the metal layer and the organic matter layer have undercut structures.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

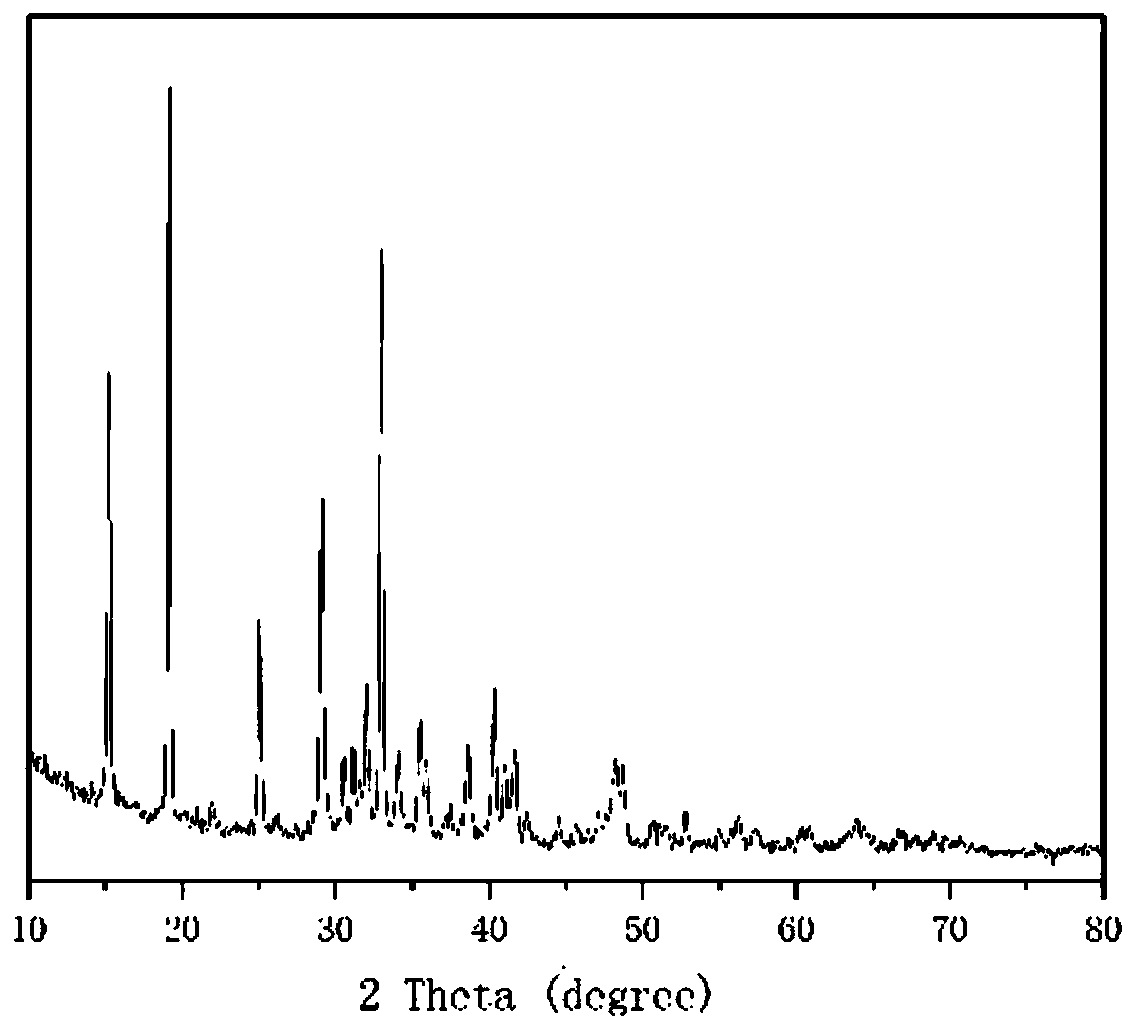

Electrode surface in-situ growth nano ZnO based NO2 sensor

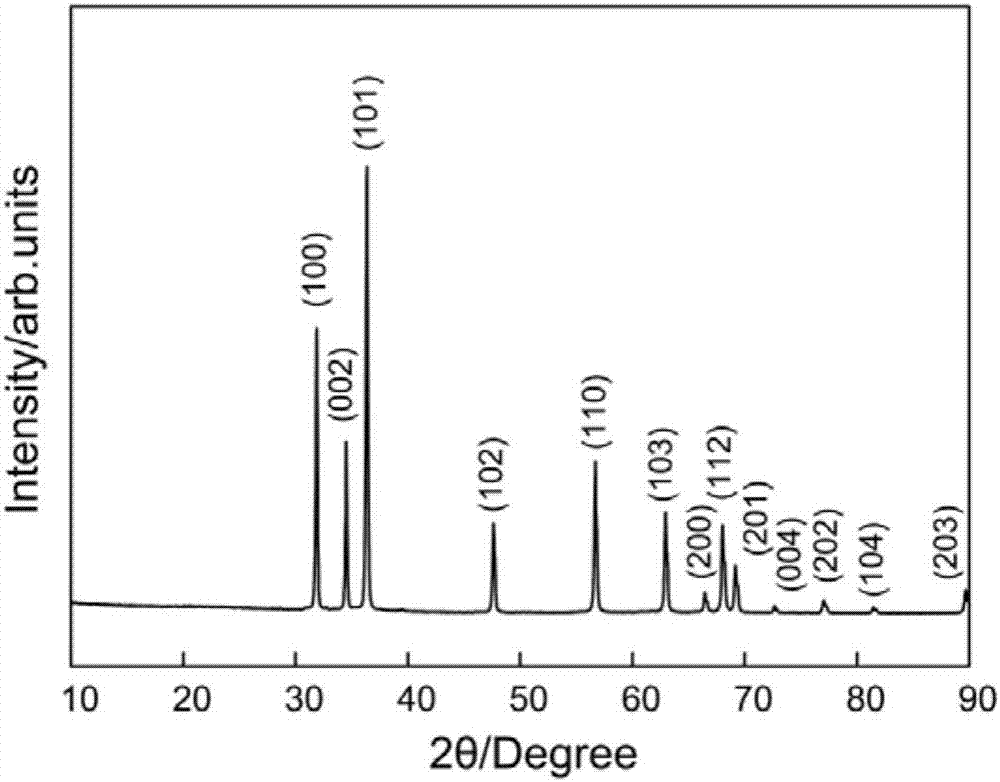

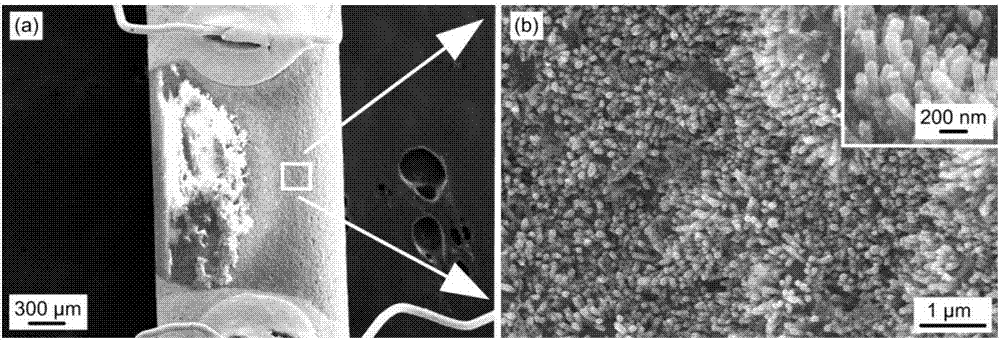

ActiveCN106970117APromote crystallizationHigh aspect ratioMaterial resistanceCrystal structureWurtzite crystal structure

The invention relates to an electrode surface in-situ growth nano ZnO based NO2 sensor and belongs to the technical field of gas sensors of one-dimensional semiconductor metal oxide materials. The electrode surface in-situ growth nano ZnO based NO2 sensor is characterized by being obtained through in-situ growth ZnO nanowire arrays on the electrode elements, a ZnO nanowires are 80-100nm in diameter and 600nm-1umm in length, and the crystal structure of the ZnO nanowires is of the hexagonal-phase wurtzite crystal structure. The gas sensor acquiring maximum sensitivity on NO2 gas in the working temperature of 250DEG C is short in response and recovery time, good in reversibility and selectivity and good in development prospect.

Owner:NORTHEASTERN UNIV

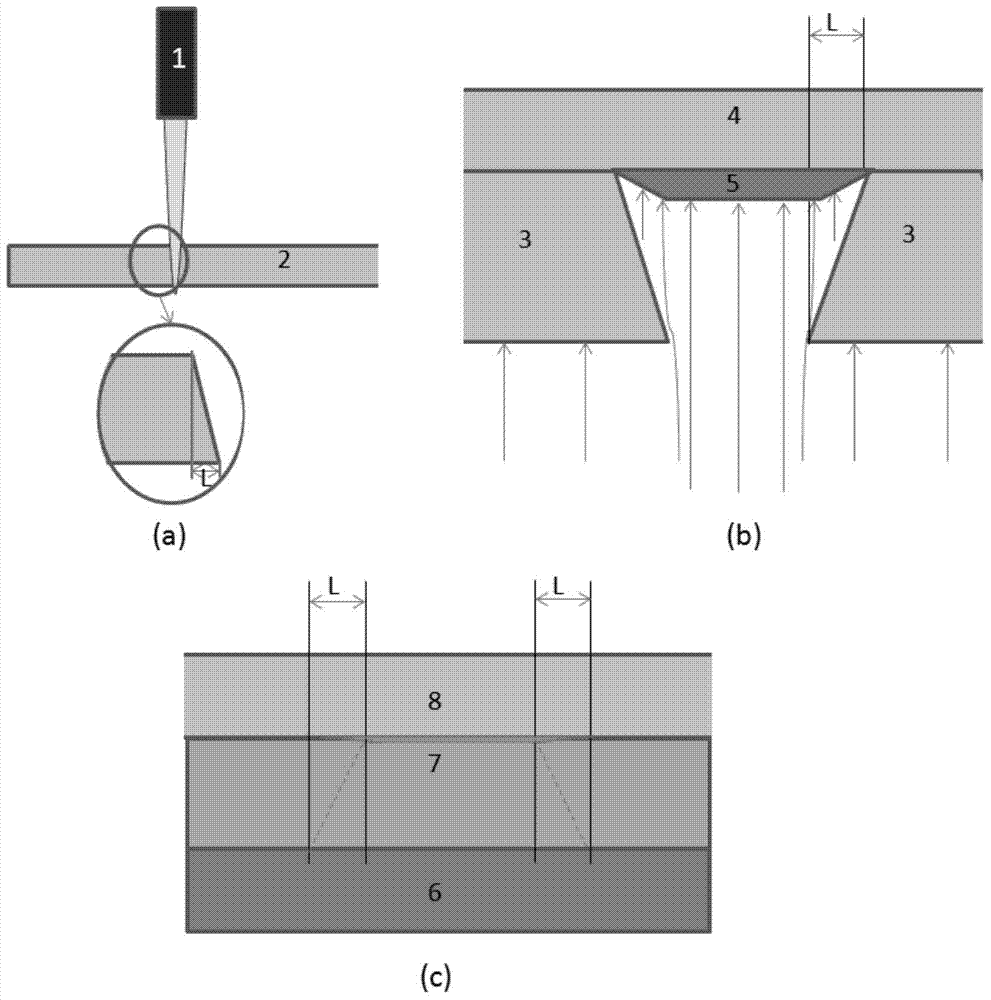

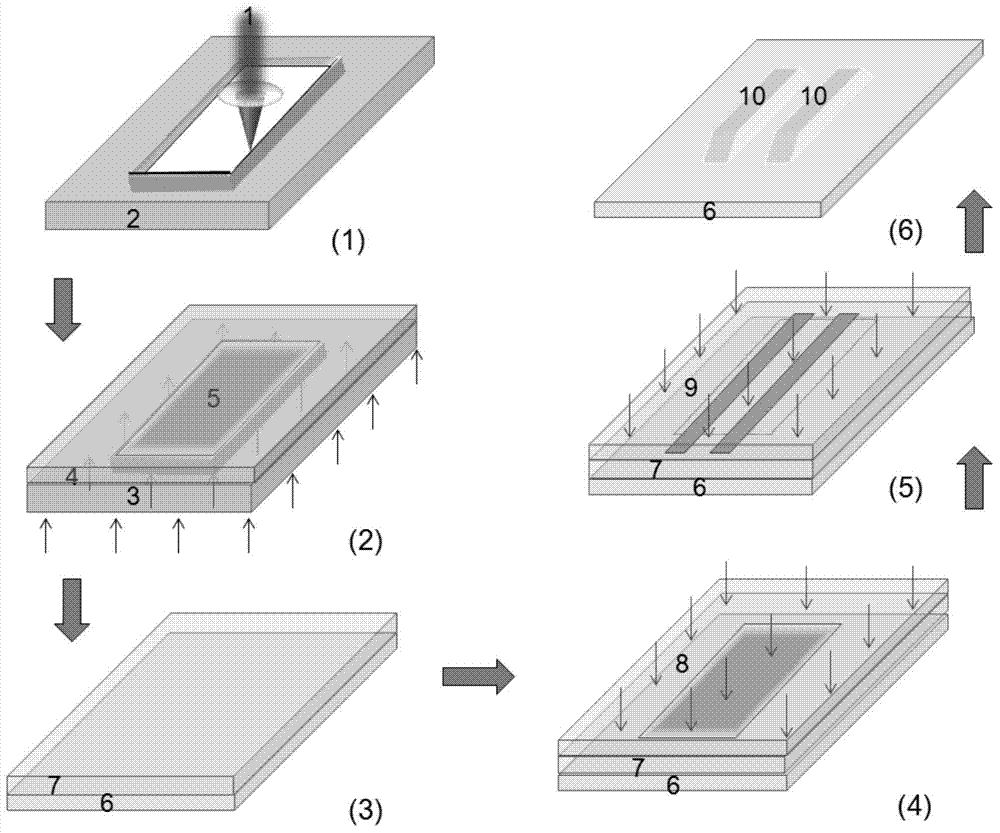

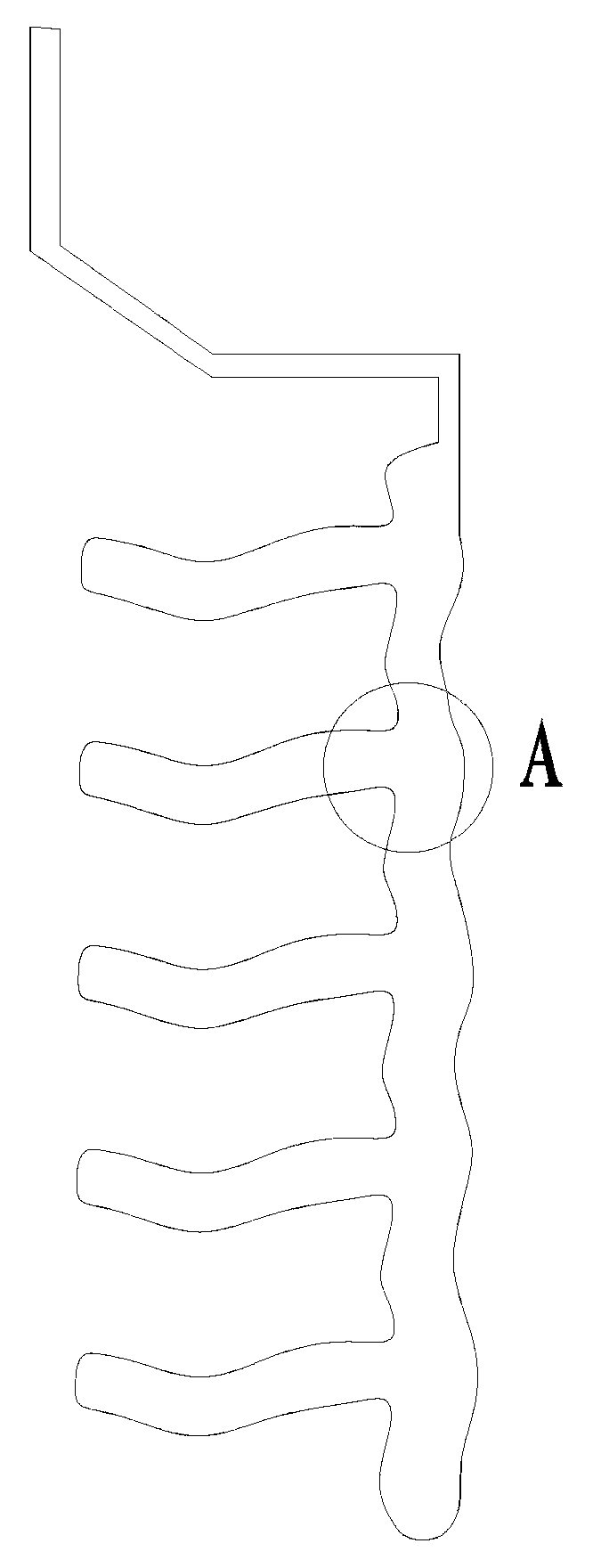

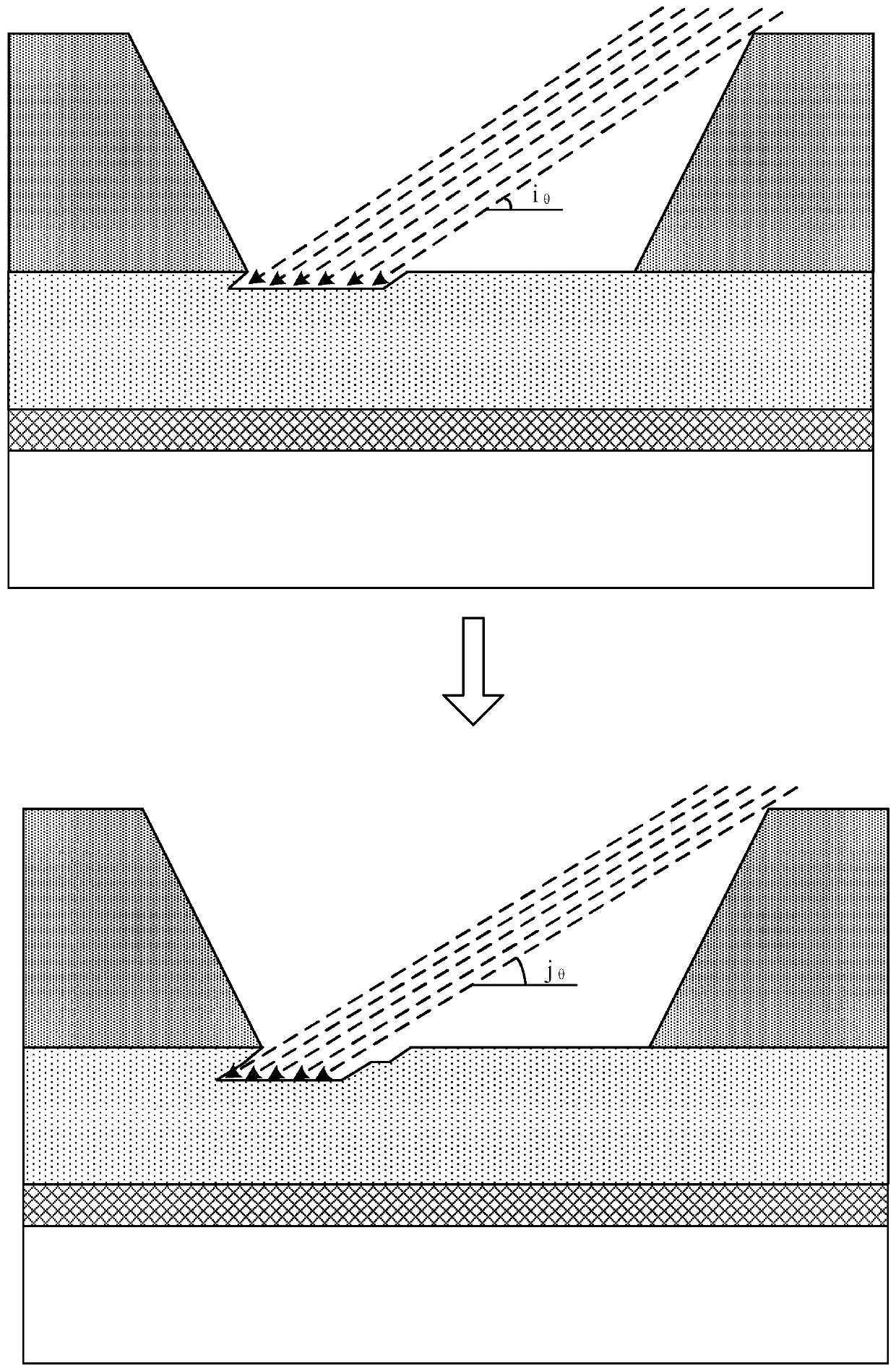

Preparation method of polymer optical waveguide with inclined-surface coupling port

InactiveCN104503024ASolve the complex preparation processLow costPhotomechanical exposure apparatusMicrolithography exposure apparatusChemistryIntegrated devices

The invention relates to a preparation method of a polymer optical waveguide with an inclined-surface coupling port, belongs to the technical field of three-dimensional integration of optical waveguides and particularly relates to a method for preparing a polymer optical waveguide with an inclined-surface coupling port through gray scale lithography in combination with secondary waveguide lithography. The port can be used for the three-dimensional integration of the optical waveguides. The polymer optical waveguide with the inclined-surface coupling port prepared by adopting the preparation method is prepared by adopting laser cutting, gradient evaporation and nano-imprinting, the problem that a preparation process of a gray scale photomask is complex is solved, the device cost is reduced, the length and angle of an inclined surface of the waveguide can be accurately controlled, the inclined surface has good roughness according to wet-process development and the roughness of the inclined surface is smaller than 5nm. The method provided by the invention is suitable for mass production of practically applicable three-dimensional spatial integrated devices of organic polymers and other materials; moreover, when photoresist with special thickness is adopted, the structure provided by the invention can be applied to the preparation of 45-degree optical waveguide reflector inclined surfaces.

Owner:JILIN UNIV

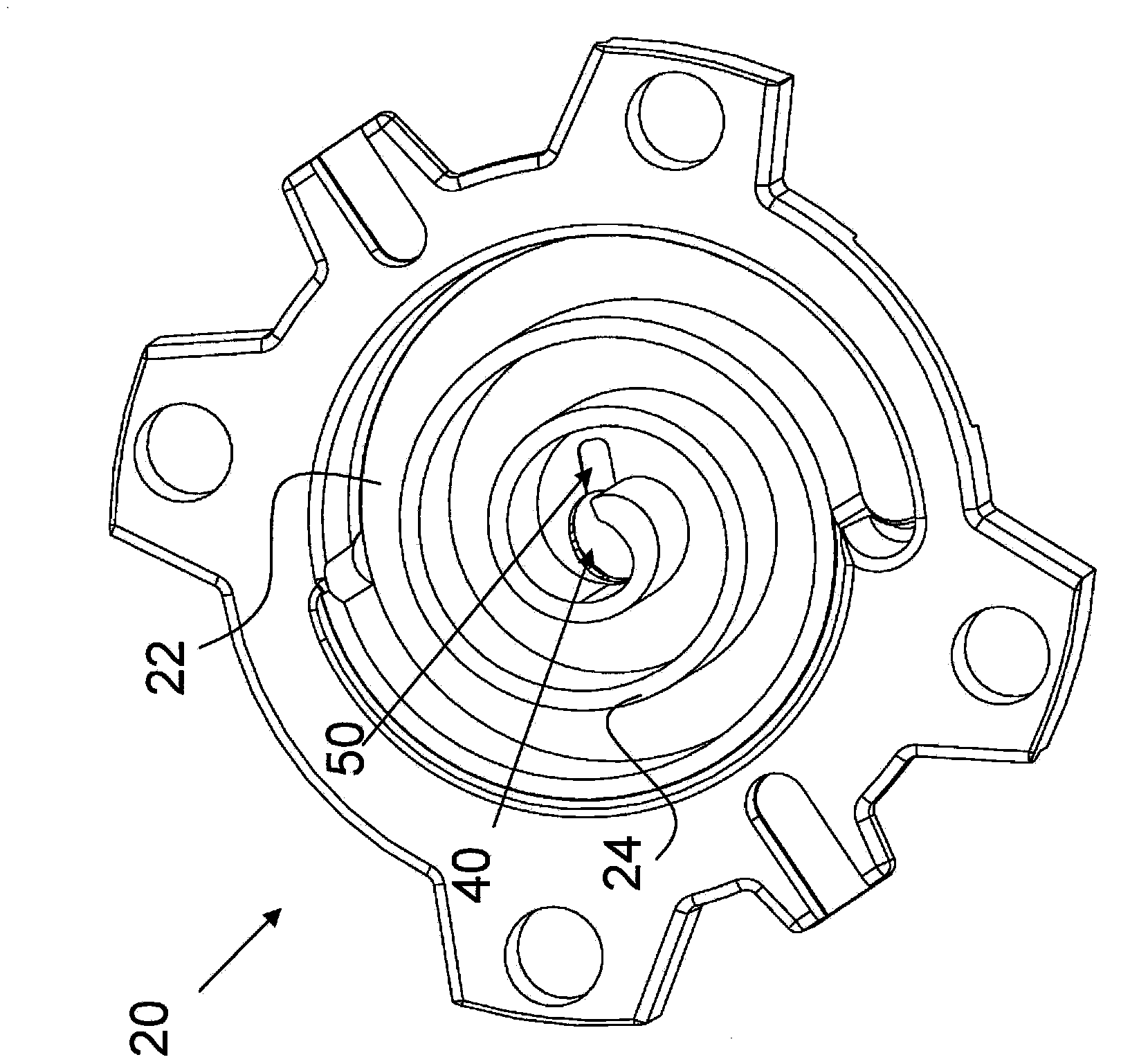

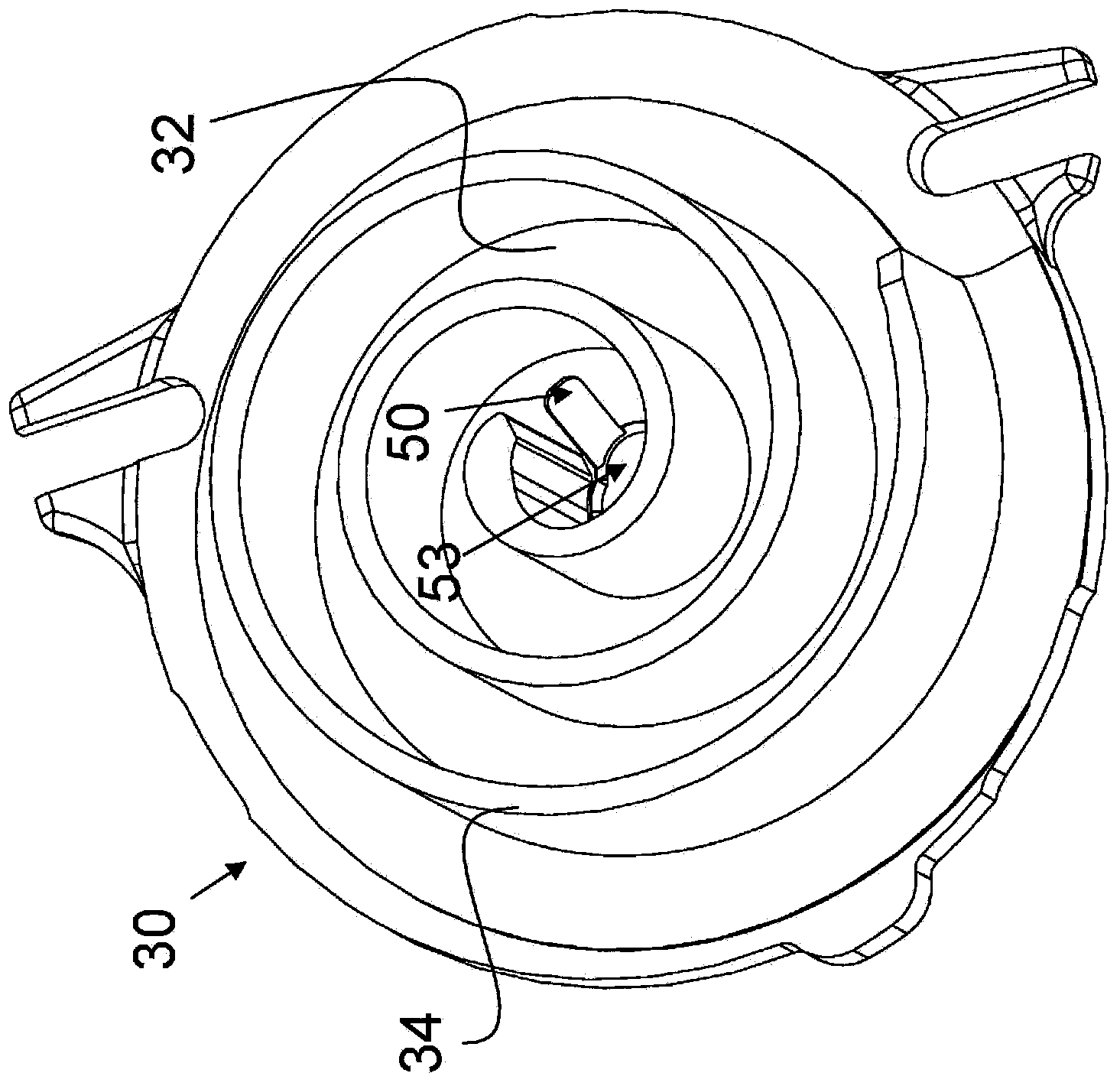

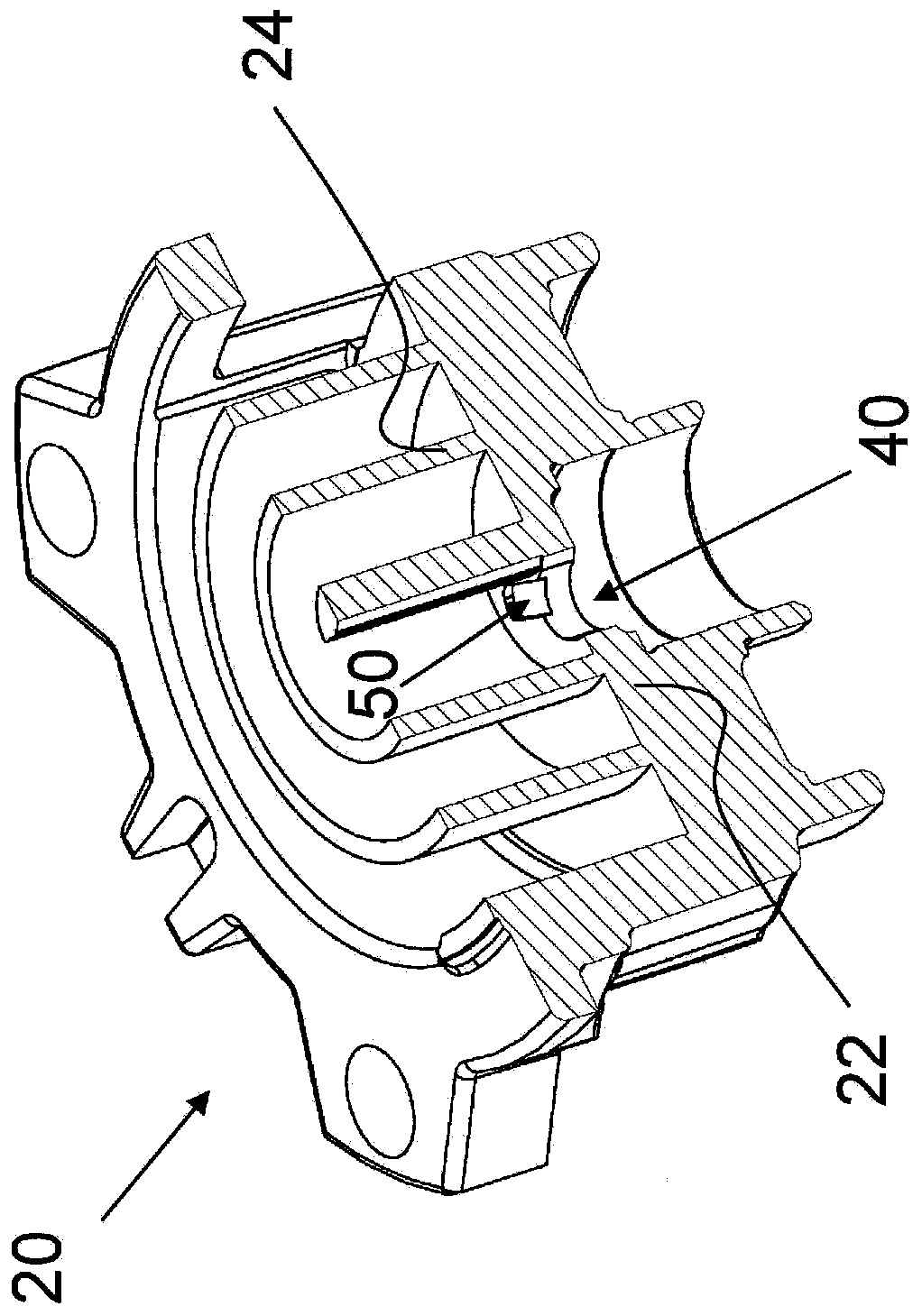

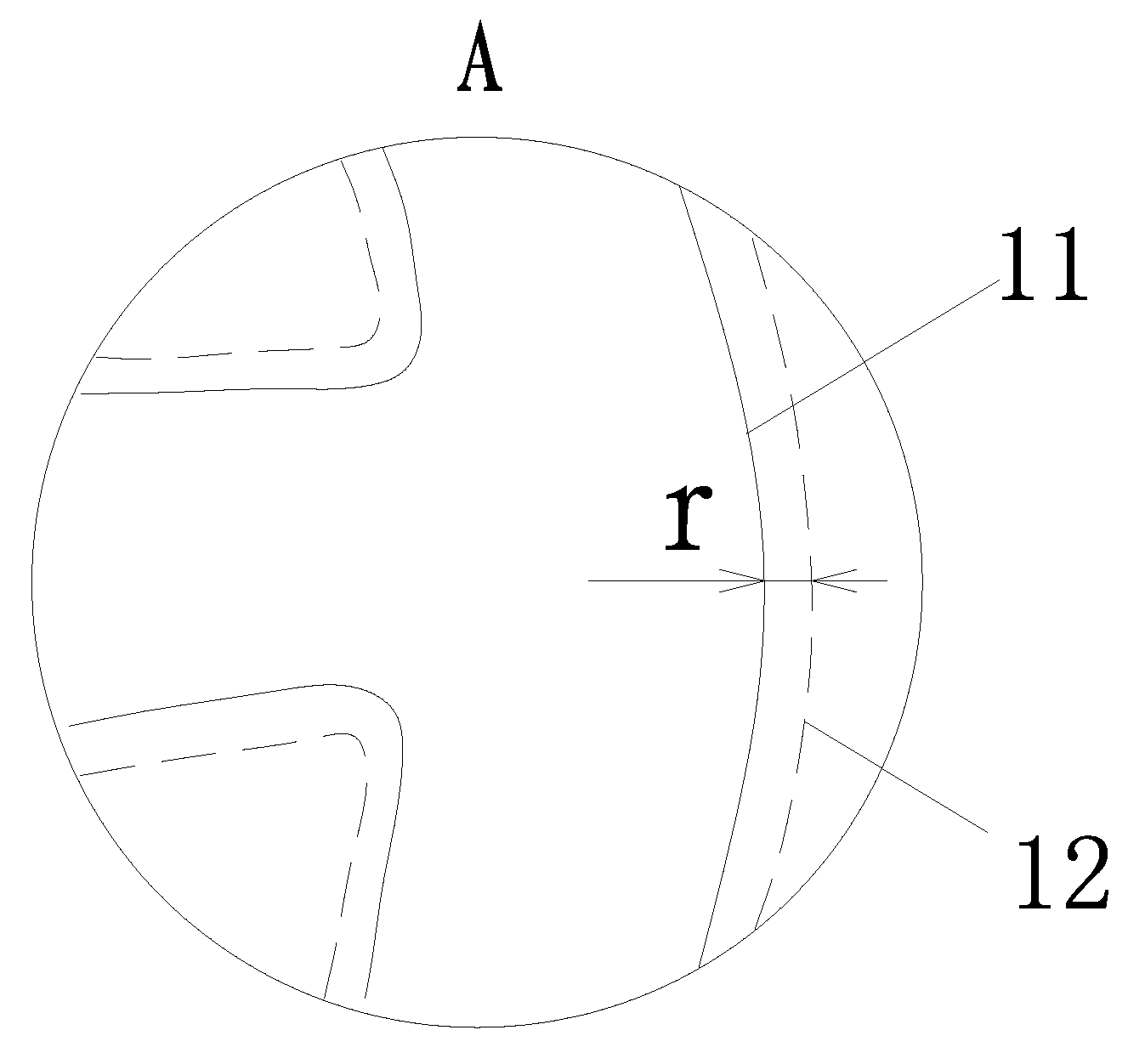

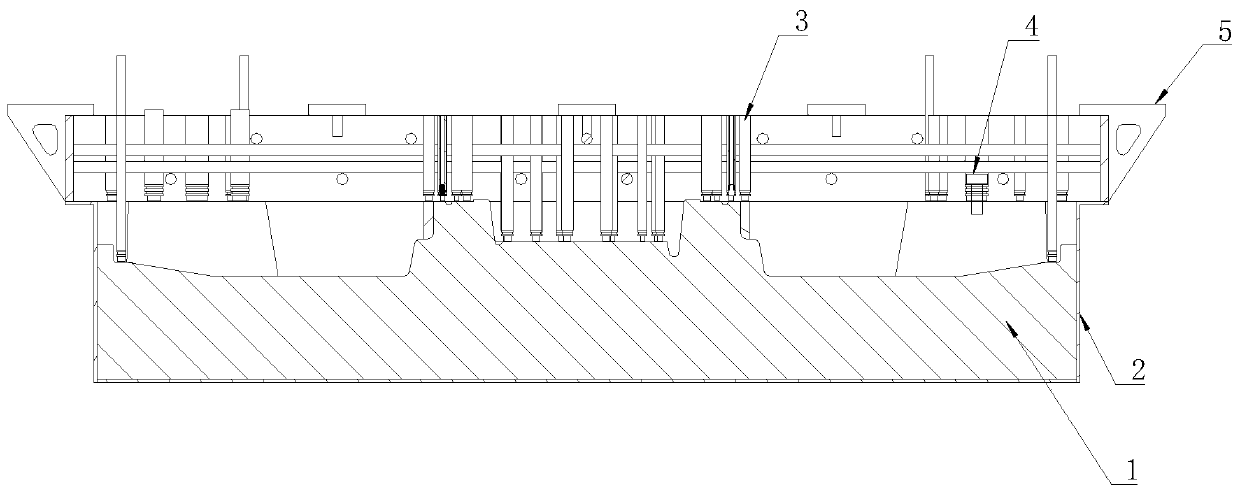

Vortex compressor as well as fixed vortex member and movable vortex member

ActiveCN104235016ASuppresses high noise problemsSuppress noiseRotary piston pumpsRotary piston liquid enginesBusiness efficiencyEngineering

The invention discloses a vortex compressor as well as a fixed vortex member and a movable vortex member. On the one hand, the vortex compressor comprises a compression mechanism, an exhaust port and an emission space, wherein the compression mechanism comprises a fixed vortex member and a movable vortex member, the fixed vortex member comprises a fixed vortex end plate and a fixed vortex roll, the movable vortex member comprises a movable vortex end plate and a movable vortex roll, and the fixed vortex roll and the movable vortex roll are combined together to limit a plurality of compression chambers including first compression chambers and second compression chambers; the exhaust port is suitable for communicating with the first compression chambers; and the emission space is suitable for communicating with the exhaust port. The first compression chambers, the exhaust port and the emission space form a high-pressure area. The vortex compressor also comprises a communicating passage which is set to ensure that at least one of the second compression chambers and the high-pressure area can be communicated with each other before a vortex roll separation point. According to the invention, the pressure of the first / center compression chambers can be changed more gently, so that the problem of high noise can be effectively solved, and the energy efficiency ratio and working stability of the compressor can be improved.

Owner:EMERSON CLIMATE TECH (SUZHOU) CO LTD

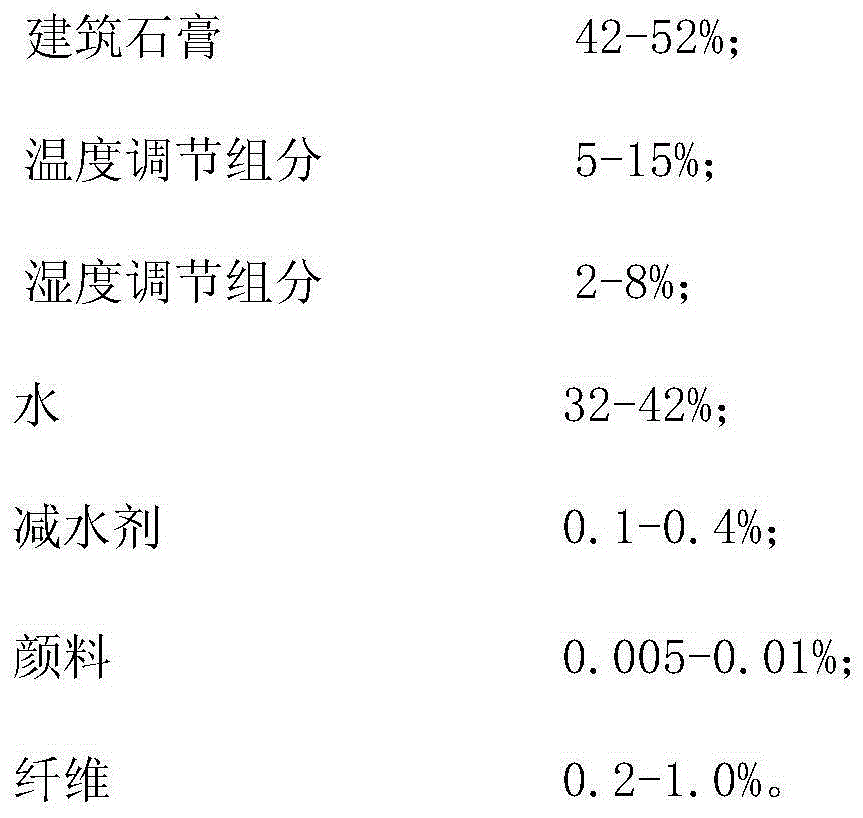

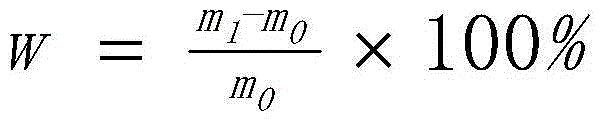

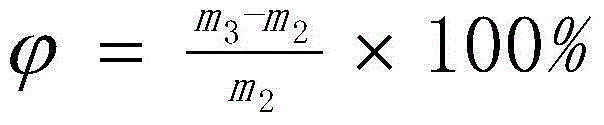

Wall material capable of adjusting indoor environmental temperature and humidity and preparation method of wall material

InactiveCN105218056ASimple preparation processImprove thermophysical propertiesFiberThermal insulation

The invention discloses a wall material capable of adjusting indoor environmental temperature and humidity and a preparation method of the wall material. The wall material is prepared from components in percentage by weight as follows: 42%-52% of building plaster, 5%-15% of temperature adjustment components, 2%-8% of humidity control components, 32%-42% of water, 0.1%-0.4% of water reducing agents, 0.005%-0.01% of pigments and 0.2%-1.0% of fiber. According to the wall material, the preparation process of a functional wall material is optimized, fluctuation of indoor environmental temperature and humidity is reduced, the durability, the anti-permeability, the anti-cracking performance and the fireproof performance of a wall body are improved, and energy consumption is reduced during construction; with the adoption of the temperature adjustment components and the humidity control components, the wall material has the function of indoor environmental temperature and humidity adjustment, the homogeneity of the wall material is guaranteed, and a product has high strength and seldom contracts; the thermal physical performance of the wall material is excellent, the wall body does not require a thermal-insulation layer, and construction procedures are reduced.

Owner:ZHANGZHOU ZHENGBA BUILDING MATERIAL TECH

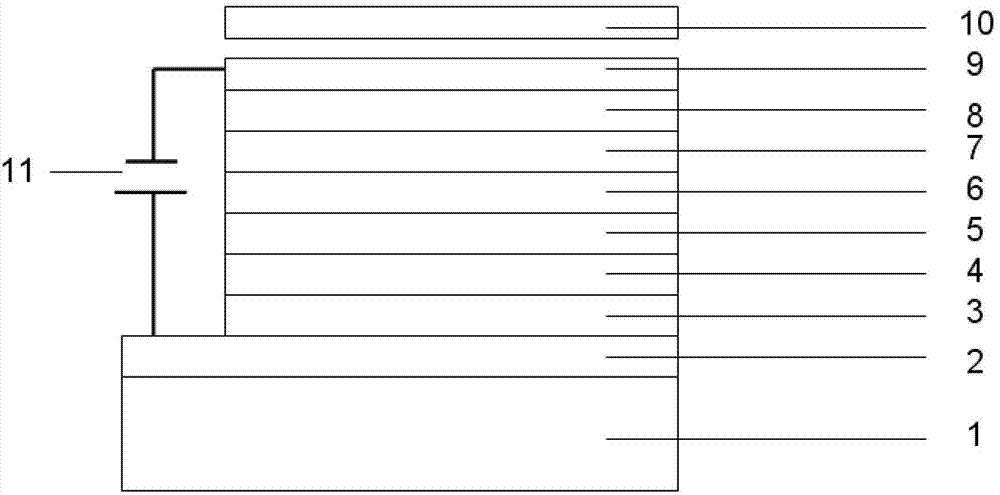

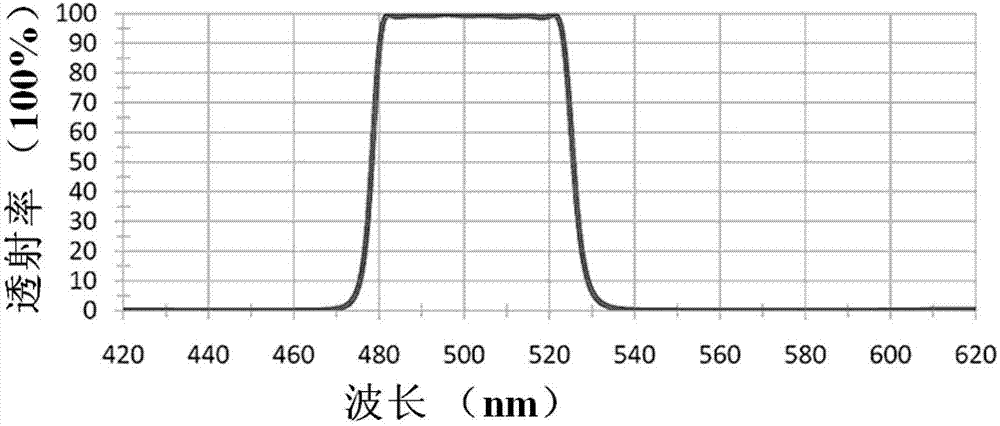

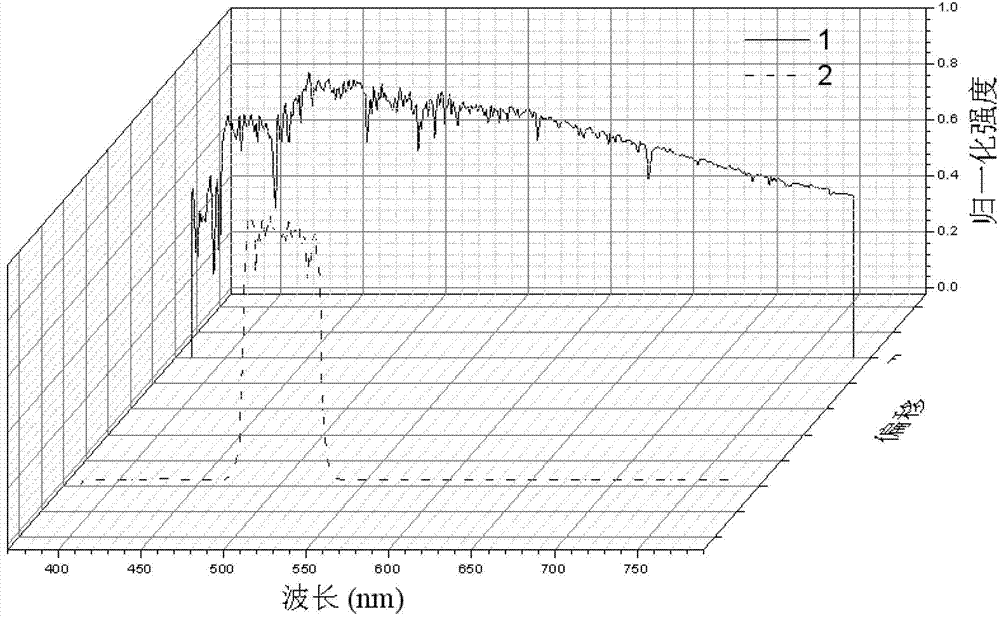

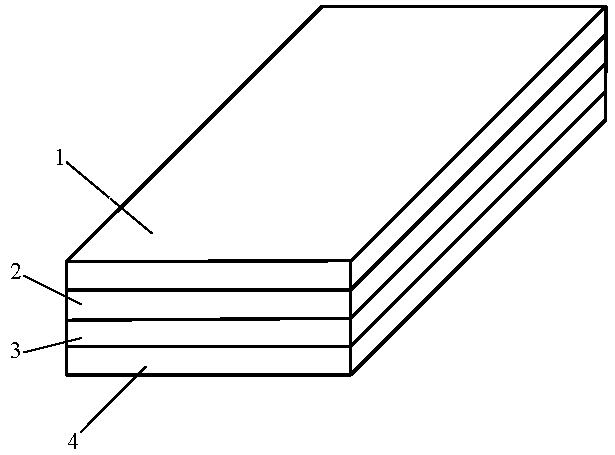

High-contrast organic light-emitting device (OLED) with band-pass filter film and top-emitted green ray

InactiveCN102969454AIncrease contrastImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionBand-pass filter

The invention belongs to the field of organic light-emitting devices (OLED), in particular relates to a high-contrast organic light-emitting device (OLED) with a band-pass filter film and top-emitted green ray. The OLED comprises a substrate, a metal anode, an organic function layer, a metal cathode and the band-pass filter film, wherein the organic function layer sequentially comprises a hole injection layer, a hole transmission layer, an electronic barrier layer, a green ray emission layer, an electronic transmission layer and an electronic injection layer. The filter film introduced can weaken the influence of ambient light to the contrast of display devices, thereby realizing the high-contrast OLED. The high-contrast OLED overcomes the defects that for purpose of realizing high contrast, the original top emission device is complicated in structure and has large process difficulty, and almost has no influence on the efficiency of the device while the contrast is improved. The top emission OLED produced has the advantages of being high in contrast, low in efficiency loss, simple in process and low in cost.

Owner:JILIN UNIV

One glass solution (OGS) capacitive touch screen and manufacturing method thereof

InactiveCN103257774AKeep it thinDiversified inputInput/output processes for data processingProduction lineCapacitance

The invention discloses a one glass solution (OGS) capacitive touch screen which comprises a PET protective film, optical cement, an ITO functional piece and a soft circuit board, wherein the PET protective film, the optical cement and the ITO functional piece are arranged in an up-down overlapping mode, and the soft circuit board is attached to the upper surface or the lower surface of the ITO functional piece. The invention further discloses a manufacturing method of the OGS capacitive touch screen. The manufacturing method of the OGS capacitive touch screen includes the following steps: 1, preparing the PET protective film, and preparing the soft circuit board; 2, converting a functional pattern into a laser path; 3, leading the laser path into a laser device; 4, etching a large-piece ITO plate by using the laser device; 5, dividing the large-piece ITO plate and forming the single ITO functional piece in a splicing and combined mode; 6, connecting the soft circuit board to the ITO functional piece, and carrying out electrical logging on functions; 7, splicing the ITO functional piece and the PET protective film; 8, carrying out the electrical logging on finished products. The OGS capacitive touch screen and the manufacturing method of the OGS capacitive touch screen are rich in color, capable of preparing soft touch screens, simplified in production procedure, less in investment of production lines and environment-friendly in production, and products have higher competitiveness.

Owner:LEAD COMM

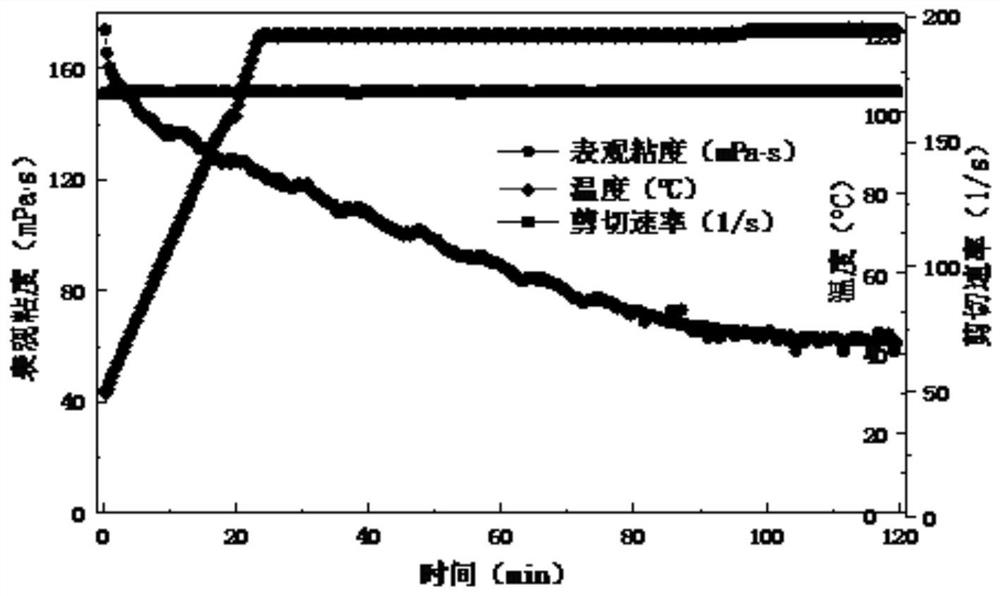

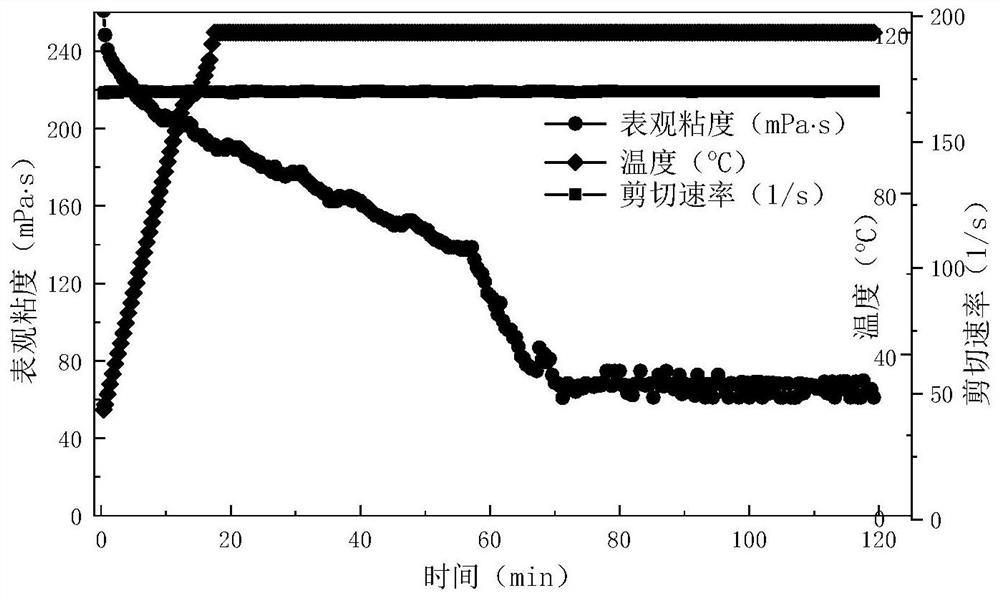

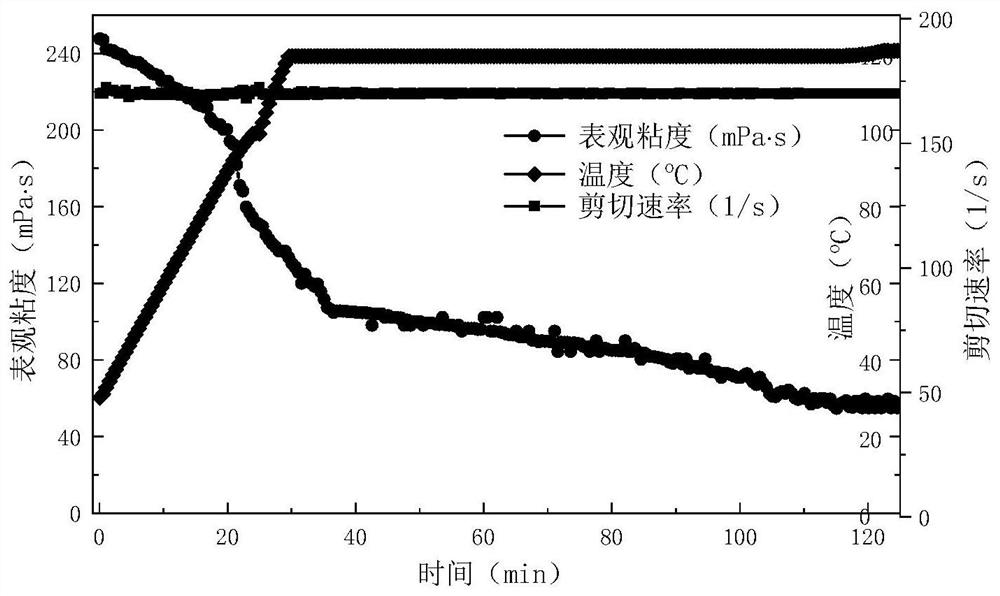

Disulfonic acid group surfactant, clean fracturing fluid and preparation method of clean fracturing fluid

ActiveCN112812076AStrengthen the hydrophobic binding forceRejection tendency weakenedOrganic chemistryDrilling compositionEthanesulfonic acidActive agent

The invention discloses a disulfonic surfactant, a clean fracturing fluid and a preparation method of the disulfonic surfactant. The preparation method comprises: with a low-cost and easily-available long-chain tertiary amine compound and epoxy chloropropane as raw materials, an intermediate A is produced, then the intermediate A and piperazine-N,N'-bis(2-ethanesulfonic acid) sesquicarbonate are further subjected to a quaternization reaction, and the double-tailed disulfonic acid group surfactant is prepared. The disulfonic acid group surfactant has good surface activity reducing capability and is simple to prepare; the clean fracturing fluid using the thickening agent has excellent salt resistance and temperature resistance, and the shear viscosity of the optimal product at 120 DEG C and 170 / s is not less than 60 mPa.s, which is far greater than 25 mPa.s required by field construction of the clean fracturing fluid. The product has a good application prospect in oil field fracturing fluid and recovery efficiency improvement.

Owner:SOUTHWEST PETROLEUM UNIV

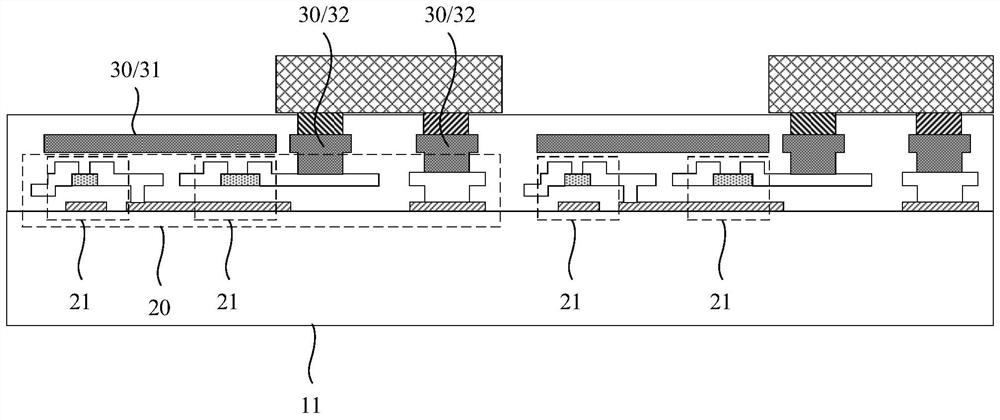

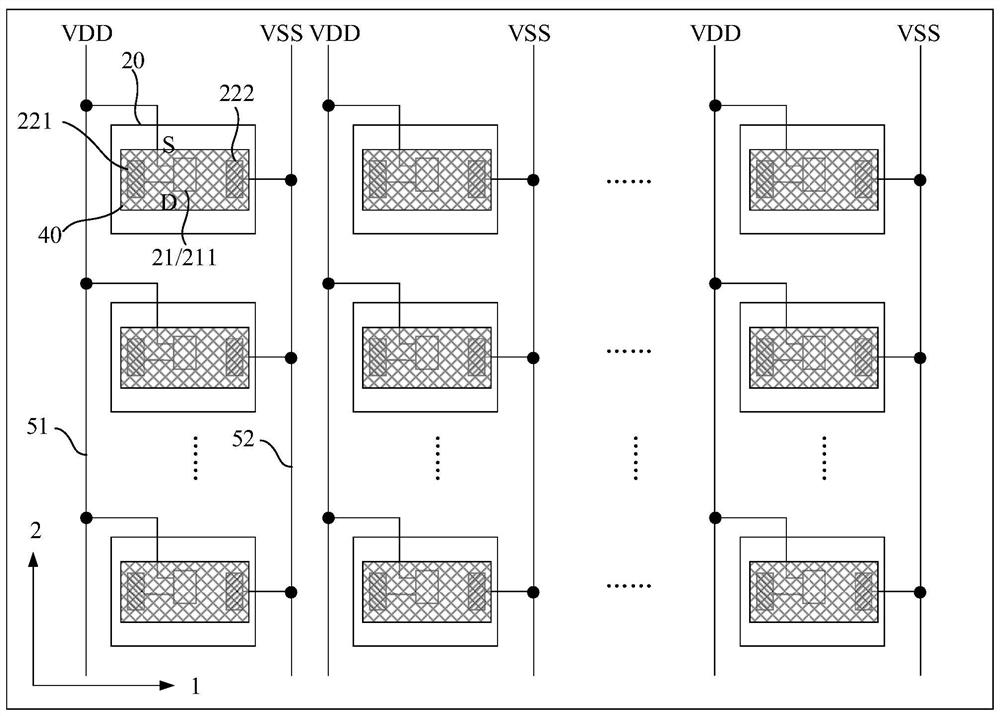

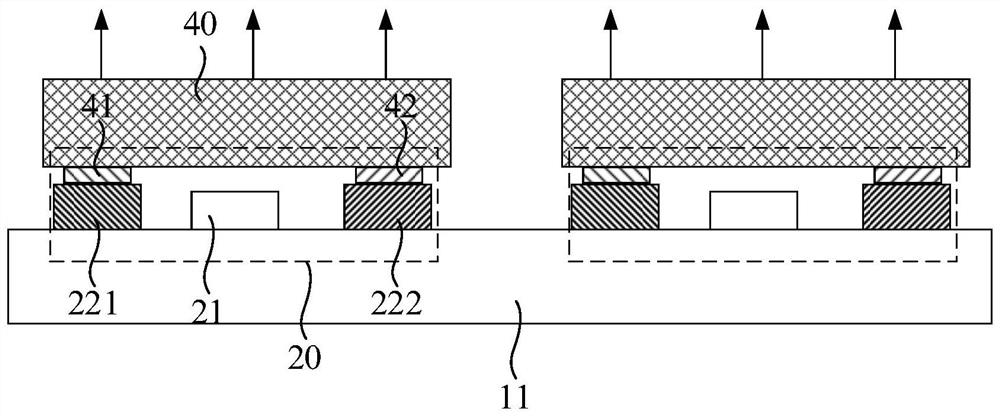

Array substrate, backlight module, display panel, display device and preparation method

ActiveCN111913323ASolve the complex preparation processSimple manufacturing processStatic indicating devicesSemiconductor lamp usageDisplay deviceThin membrane

The embodiment of the invention discloses an array substrate, a backlight module, a display panel, a display device and a preparation method. The array substrate comprises a plurality of driving units. Each driving unit comprises a first electrode, a second electrode and at least one thin film transistor; the first electrode and the second electrode are used for being connected with the anode andthe cathode of a light emitting diode respectively, so that the vertical projection of the light emitting diode on the array substrate can be overlapped with the at least one thin film transistor, andthe thin film transistor is located at the backlight side of the light emitting diode in the light emitting direction of the light emitting diode. The driving unit controls the light-emitting diode to be turned on or off according to the driving signal. According to the embodiment of the invention, the problem that an existing array substrate needs to be additionally provided with a shading layer, so that the preparation process is complex, is solved; the influence of external illumination on the thin film transistor can be avoided, masks and preparation procedures required for preparing theshading layer are saved, the preparation process of the array substrate is simplified, and the manufacturing cost is reduced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

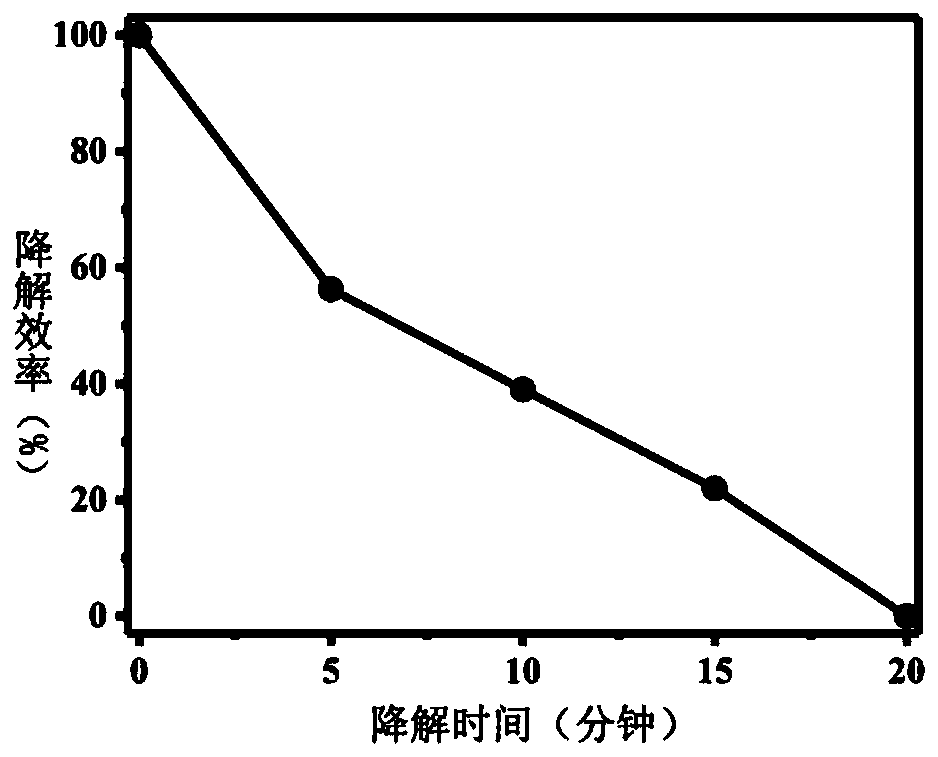

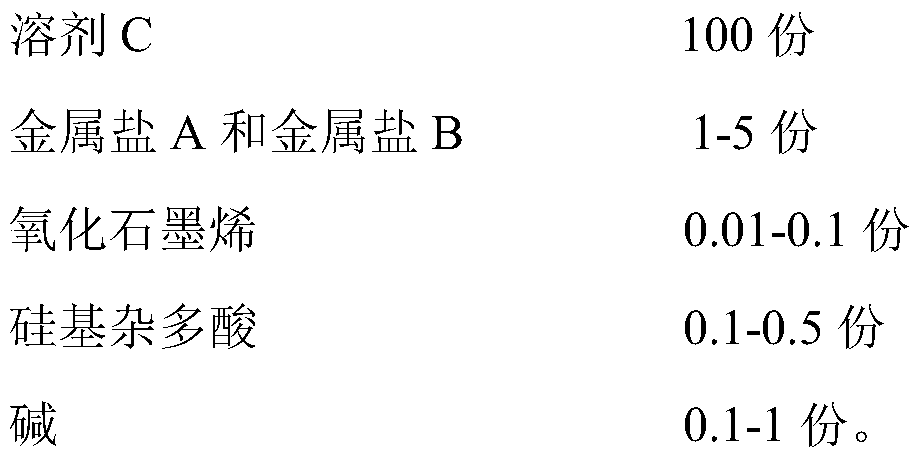

Preparation method of silicon-based heteropolyacid doped magnetic composite membrane material

InactiveCN111437882AEasy to recycleEasy to useWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHeteropoly acidSolvothermal reaction

The invention belongs to the technical field of inorganic material preparation, and particularly relates to a preparation method of a silicon-based heteropolyacid doped magnetic composite membrane material. The preparation method comprises the following steps: (1) adding a metal salt A, a metal salt B and graphene oxide into a solvent C, stirring, adding silicon-based heteropolyacid, and continuing to stir uniformly to obtain a mixed solution; (2) dissolving alkali in the mixed solution, and carrying out solvothermal reaction; and (3) carrying out suction filtration on a product prepared by the solvothermal reaction, and respectively washing and drying with ethanol and water to form a film. The preparation method of the silicon-based heteropolyacid doped magnetic composite membrane material is simple, the composition and the structure are controllable, the thickness of the membrane layer is controllable, the membrane layer has magnetism and is convenient to recycle and use, and the problem that the preparation process of the composite membrane material is complex is solved; the method is simple in process flow, environment-friendly, suitable for large-scale industrial production and wide in application prospect; the prepared silicon-based heteropolyacid doped magnetic composite membrane material is excellent in Fenton performance, recyclable and high in structural stability.

Owner:山东特龙谱新材料有限公司

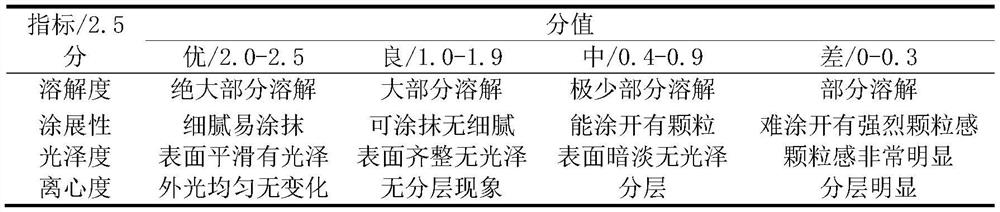

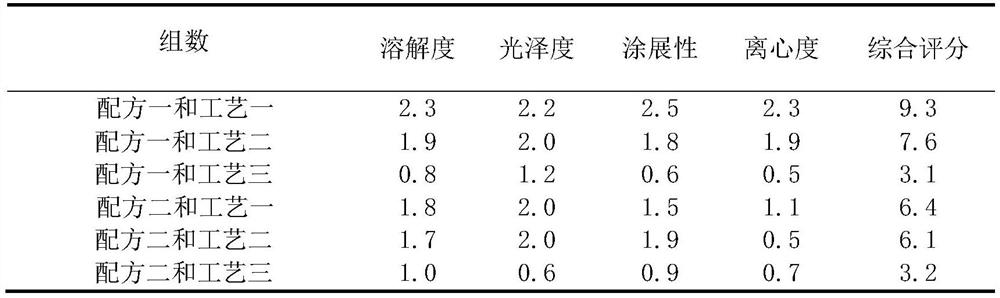

Moisturizing and repairing facial cream and preparation method thereof

ActiveCN112641657ASolve the complex preparation processNo textureCosmetic preparationsToilet preparationsGlycerolPantothenic acid

The invention relates to moisturizing and repairing facial cream and a preparation method thereof. The moisturizing and repairing facial cream is prepared from the following components in percentage by weight: 45-55% of water, 15-25% of caprylic / capric triglyceride, 5-8% of propylene glycol, 2.5-5.5% of cetostearyl oleate, 1.5-3% of sorbitan oleate, 1.5-3% of squalane, 1-3% of tocopheryl acetate, 5-9% of glycerol, 1-2% of avocado tree butter, 1-3% of urea, 0.5-1.5% of sodium hyaluronate, 0.1-0.5% of vitamin B3, 0.1-0.3% of acetyl chitin, 0.05-0.15% of calcium pantothenate, 0.04-0.10% of sodium citrate, 0.005-0.015% of adenosine, 0.005-0.013% of lactic acid and 0.001-0.006% of ceramide 3. The preparation method comprises the following steps of weighing different components to respectively prepare four different mixtures , combining the mixtures, uniformly stirring the mixtures by using a heat collection type magnetic stirrer, and obtaining the moisturizing and repairing facial cream. The moisturizing and repairing facial cream has the advantages of skin repairing, hydrating, moisturizing, whitening, wrinkle resisting and the like, and is simple in preparation process, low in equipment requirement and suitable for industrial production.

Owner:贵州大隆药业有限责任公司

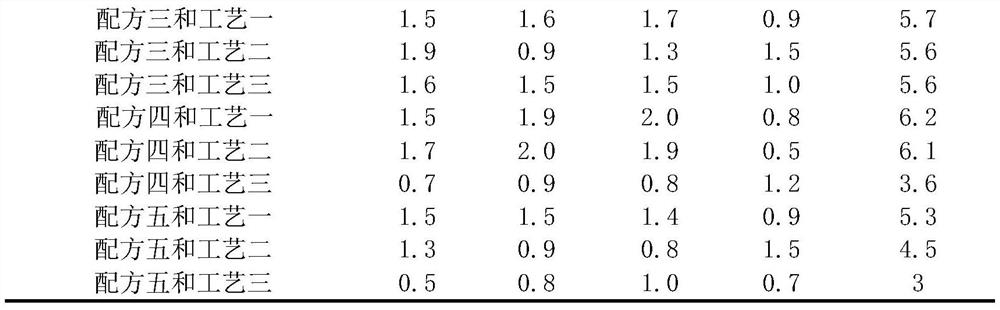

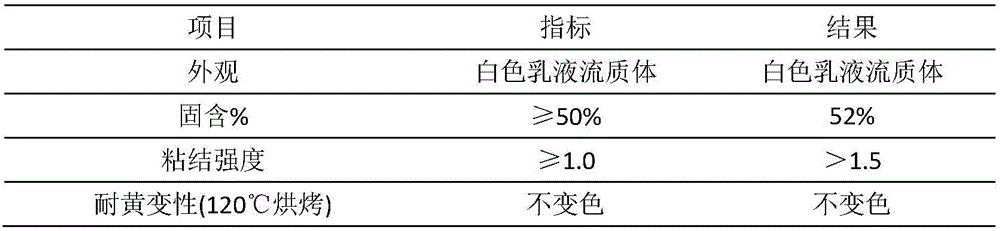

Food packaging adhesive and preparation method thereof,

InactiveCN106047225AImprove stabilitySolve the complex preparation processMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEthylenediamineAdhesive

The invention discloses a food packaging adhesive and a preparation method thereof, wherein the food packaging adhesive comprises, by weight, 400-500 parts of deionized water, 15-50 parts of polyvinyl alcohol, 120-300 parts of vinyl acetate, 80-150 parts of butyl acrylate, 80-120 parts of methyl methacrylate, 2-8 parts of a silane coupling agent, 3-15 parts of an anionic emulsifier, 3-12 parts of a nonionic emulsifier, 3-8 parts of a sodium salt chelating agent, 2 parts of a defoamer, an initiator having the amount of 0.1-0.2 wt% of the total amount of the monomer, and 0-5 parts of a preservative, wherein the sodium salt chelating agent is one selected from ethylenediaminetetraacetic acid disodium salt, ethylenediaminetetraacetic acid tetrasodium salt, and hydroxyethyl ethylenediamine triacetic acid trisodium salt. According to the present invention, the food packaging adhesive has characteristics of high adhesion strength and good stability, has advantages of rapid adhesion, simple use method, easily-available raw materials and low preparation cost, and is the environmental protection and convenient use food packaging adhesive.

Owner:FOSHAN CITY YONGHENGDA NEW MATERIAL TECH CO LTD

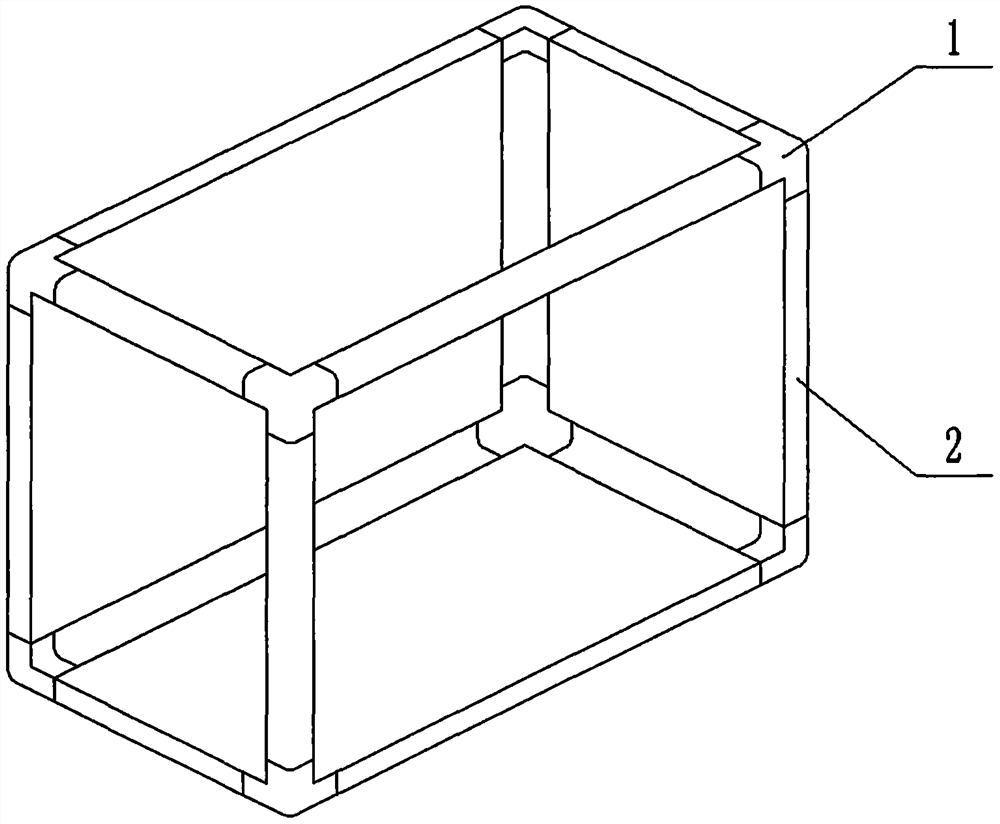

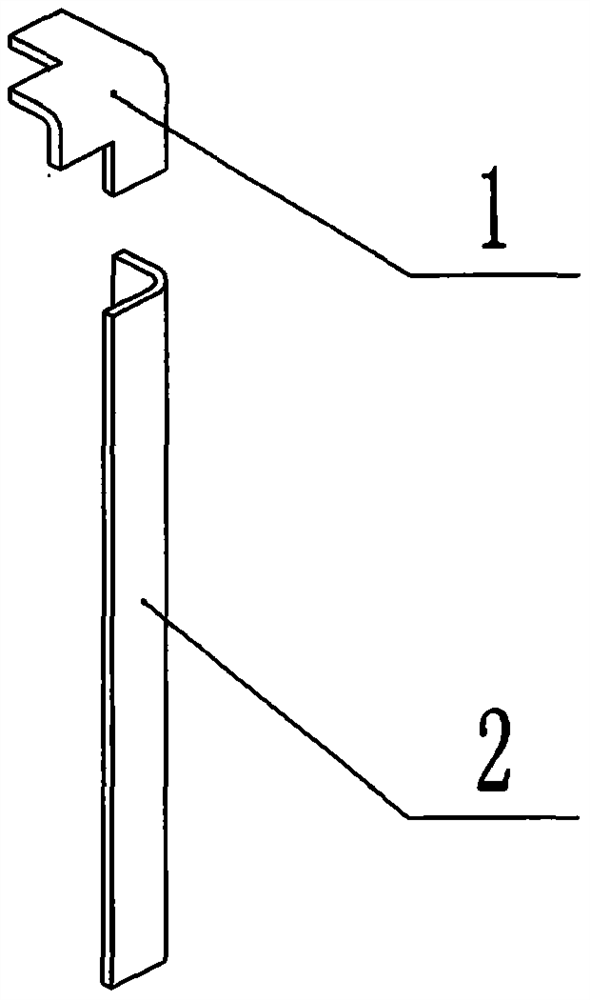

Metal frame structure and manufacturing method thereof

PendingCN112975275AAccurate docking and high precisionNice appearanceConstructions elementsBatch productionManufacturing engineering

The invention belongs to the field of machining and particularly relates to a metal frame structure and a manufacturing method thereof. In order to solve the problems that the existing metal frame structure manufacturing process is complex, the working intensity is high, the sharp corner potential safety hazards exist, the production efficiency is low, and the environmental pollution is high, the invention provides a metal frame structure and a manufacturing method thereof. The metal frame structure is simple in process, attractive in appearance, free of sharp corner potential safety hazards, low in environmental pollution and high in production efficiency. The metal frame structure is specifically formed by butting and splicing eight vertex angle connectors and frame beams. The vertex angle connectors are precision stamping parts or precision castings with vertex angles and edges which are in circular arc transition. During manufacturing, only the vertex angle connectors need to be welded to the butted inner surfaces of the frame beams; the process is simple and is easy to operate; polishing is not needed or only a small amount of polishing and finishing are needed; the dust pollution is avoided; the production efficiency is obviously improved; and the method is widely used for machining and manufacturing various box bodies, table bodies and frame structural bodies, is applied to small-batch and large-batch production, and has wide application and popularization prospects.

Owner:TIANSHUI GREATWALL ELECTRIC CRANE CONTROLLER

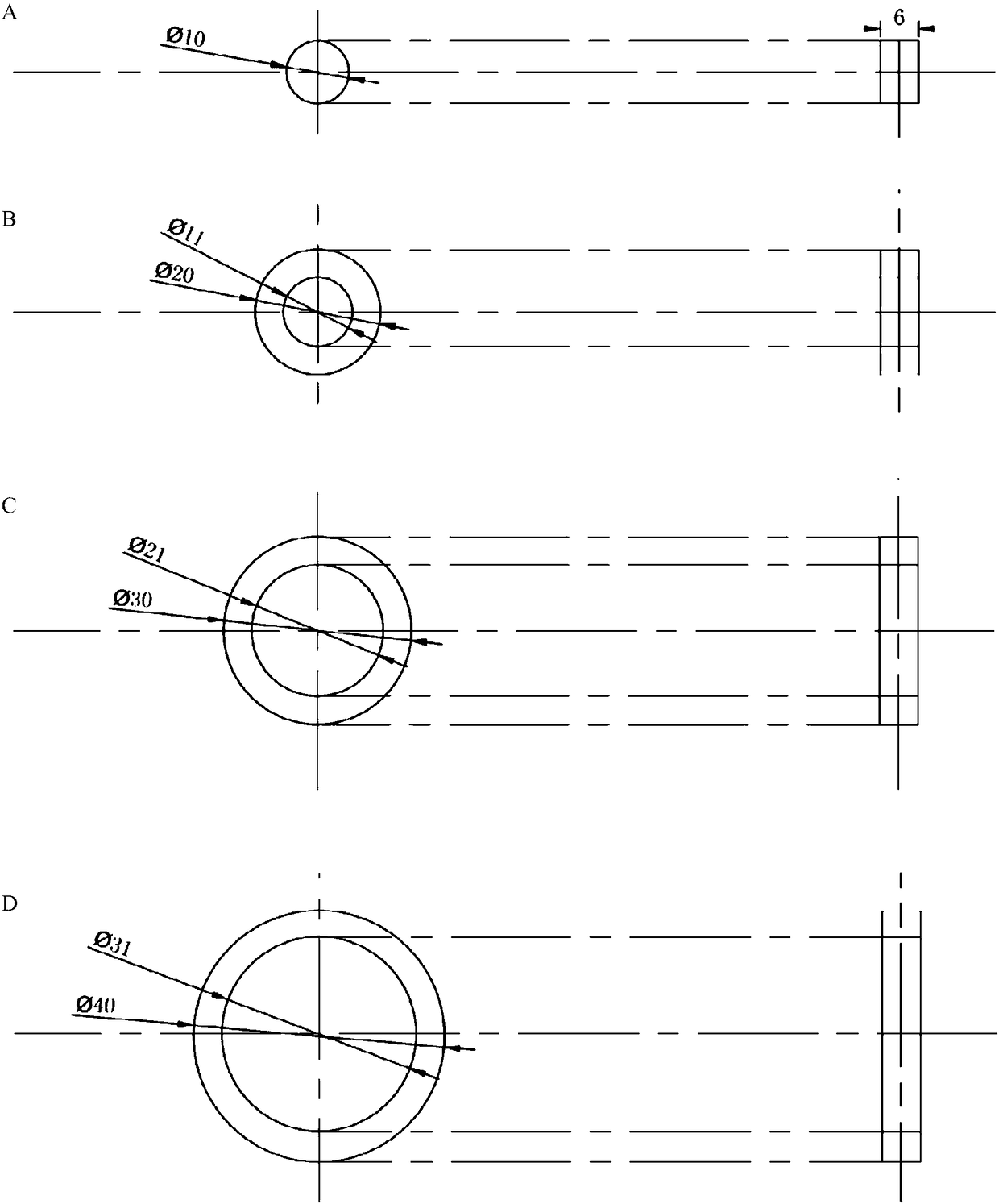

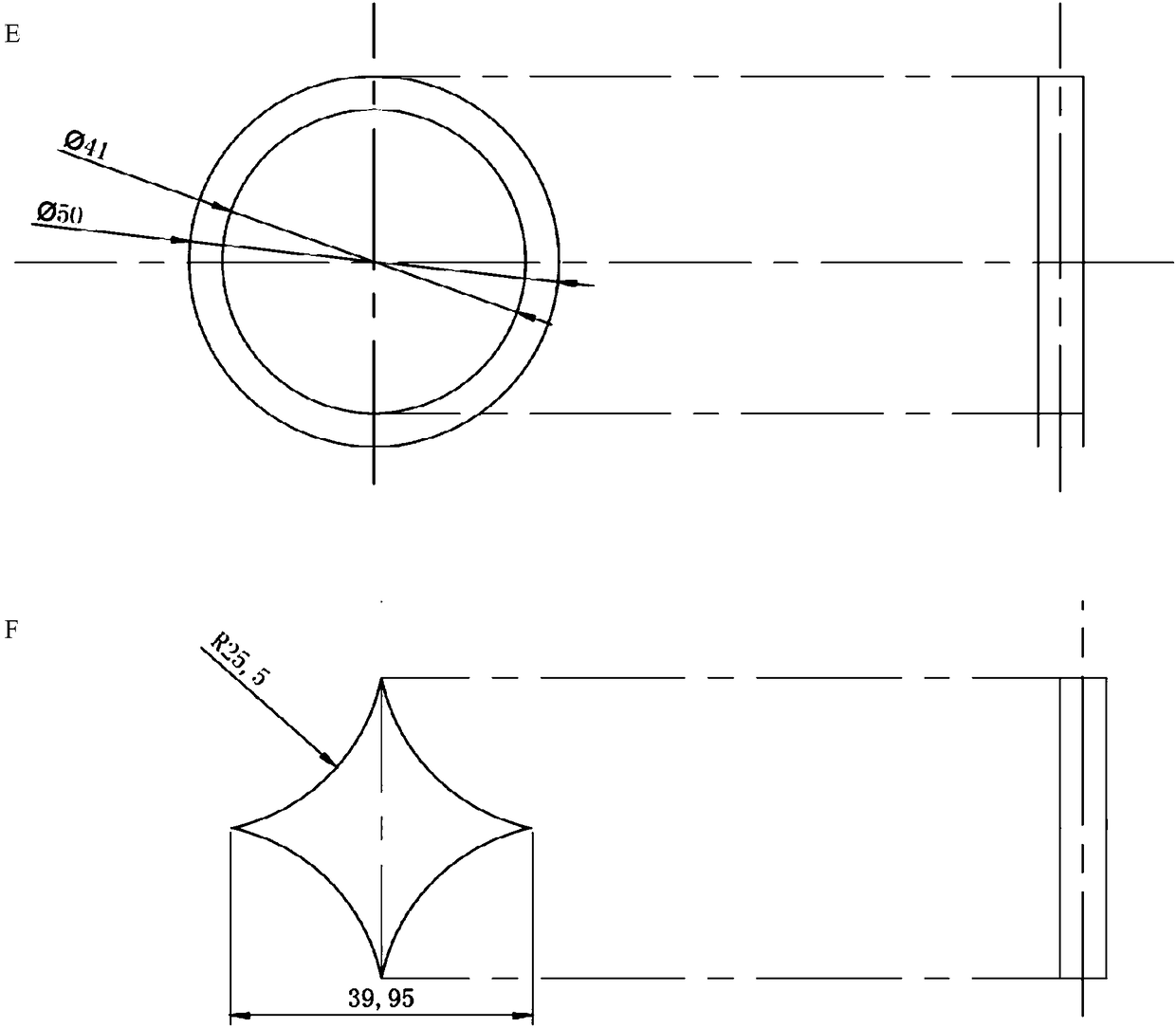

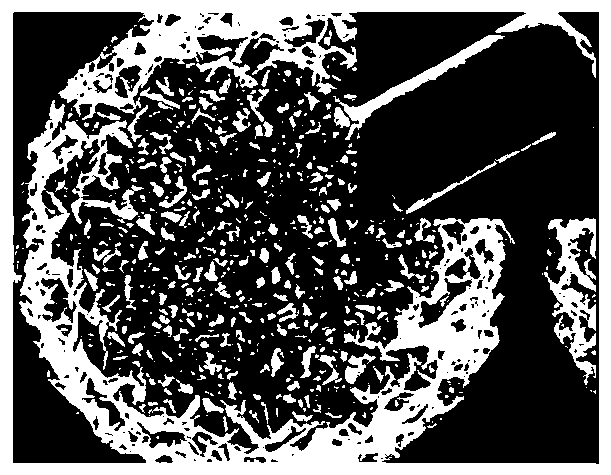

Bulletproof ceramic chip with cyclic structure and bulletproof target plate as well as preparation methods of bulletproof ceramic chip and bulletproof target plate

The invention discloses a bulletproof ceramic chip with a cyclic structure and a bulletproof target plate as well as preparation methods of the bulletproof ceramic chip and the bulletproof target plate. The bulletproof ceramic chip is circular and is formed by nesting a central ceramic circular plate and multiple groups of rings, wherein the inner diameters of the multiple groups of rings are sequentially increased. The bulletproof target plate comprises the bulletproof ceramic chip with the cyclic structure and a PE back plate; the bulletproof ceramic chips are uniformly distributed on the PEback plate. According to the bulletproof ceramic chip disclosed by the invention, a cyclic structural design is introduced, so that the bulletproof performance of the bulletproof ceramic chip can beimproved; a certain amount of TiO2 and MgO powder is introduced into an Al2O3 powder so as to achieve low-temperature sintering; a certain amount of 3Y-ZrO2 is introduced so as to achieve the toughness; due to the existence of filling powder among the rings, the ceramic chip, ceramic rings and special parts can be bonded by sintering and the production efficiency of the bulletproof plate is favorably improved; the preparation methods disclosed by the invention have the characteristics of abundant raw material powder sources, low cost, simple production process and stable product quality.

Owner:HUNAN ZHONGTAI SPECIAL EQUIP

Mold-duplicating preparation process for mineral casting

The invention discloses a mold-duplicating preparation process for a mineral casting and relates to the technical field of molds. The preparation process comprises the following steps: performing surface dressing on a product that requires rolling over; locking an original product mold surrounding plate with a product in situ to form a rolling-over surrounding plate; casting a mineral casting material between the original product mold surrounding plate and the rolling-over surrounding plate; and performing demolding after the mineral casting material is cured to obtain a product female mold. The shortcomings of long mold manufacture period and high mold-opening cost are overcome. Sufficient mold support is provided for quick mass production.

Owner:福建振丰矿物新材料有限公司

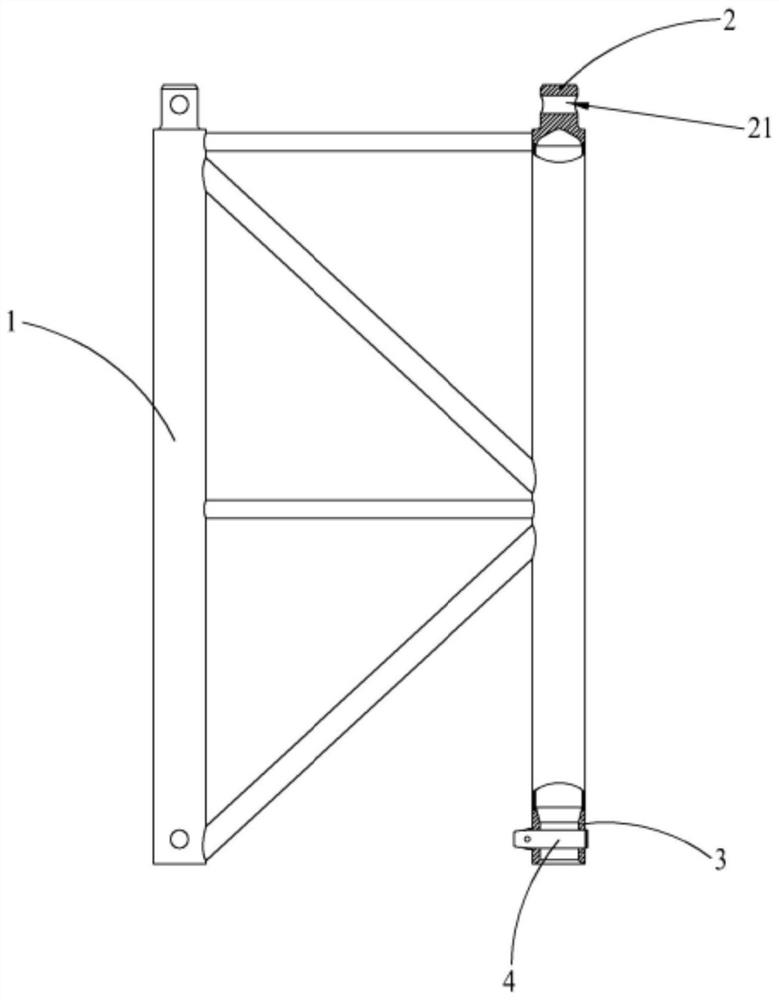

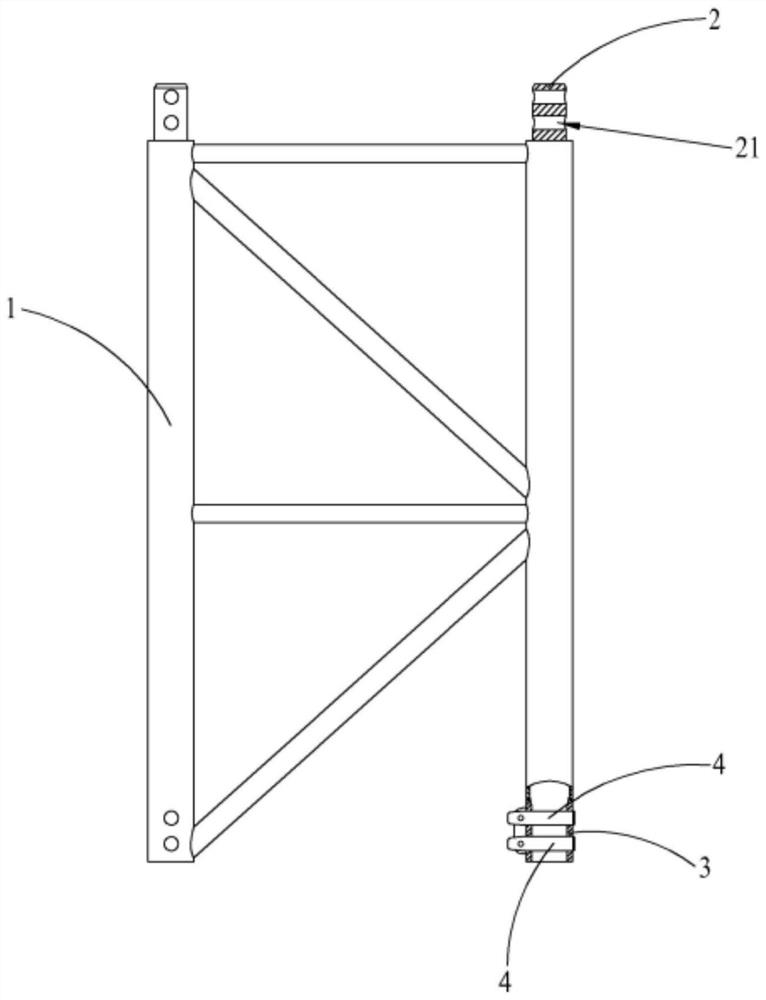

Standard knot device and tower crane

PendingCN114408770ASolve the complex preparation processLayout restrictionsBoltsRod connectionsStructural engineeringTower crane

The invention provides a standard knot device and a tower crane, the standard knot device comprises a main chord member body, a male joint, a female joint and a pin shaft body, the male joint is arranged at the first end of the main chord member body, the male joint is provided with a first plug pin hole which is through in the radial direction, the female joint is a hollow circular pipe and is connected with the second end of the main chord member body, and the pin shaft body is arranged in the first plug pin hole; the outer diameter of the female joint is equal to the outer diameter of the main chord member body, the inner diameter of the female joint is smaller than the inner diameter of the main chord member body, a second bolt hole is formed in the female joint in a radial penetrating mode, and the female joint is arranged on the male joint of another adjacent standard knot device in a sleeving mode; the pin shaft body is used for being arranged in the first plug pin hole and the second plug pin hole in a penetrating mode to connect the two adjacent standard knot devices, a reinforcing plate on the outer side of the female connector is omitted, the problem that the manufacturing process of the reinforcing plate is complex is fundamentally solved, arrangement of idler wheels of a climbing frame is not limited, and therefore design of a climbing system is facilitated.

Owner:HUNAN ZOOMLION CONSTR HOISTING MASCH CO LTD

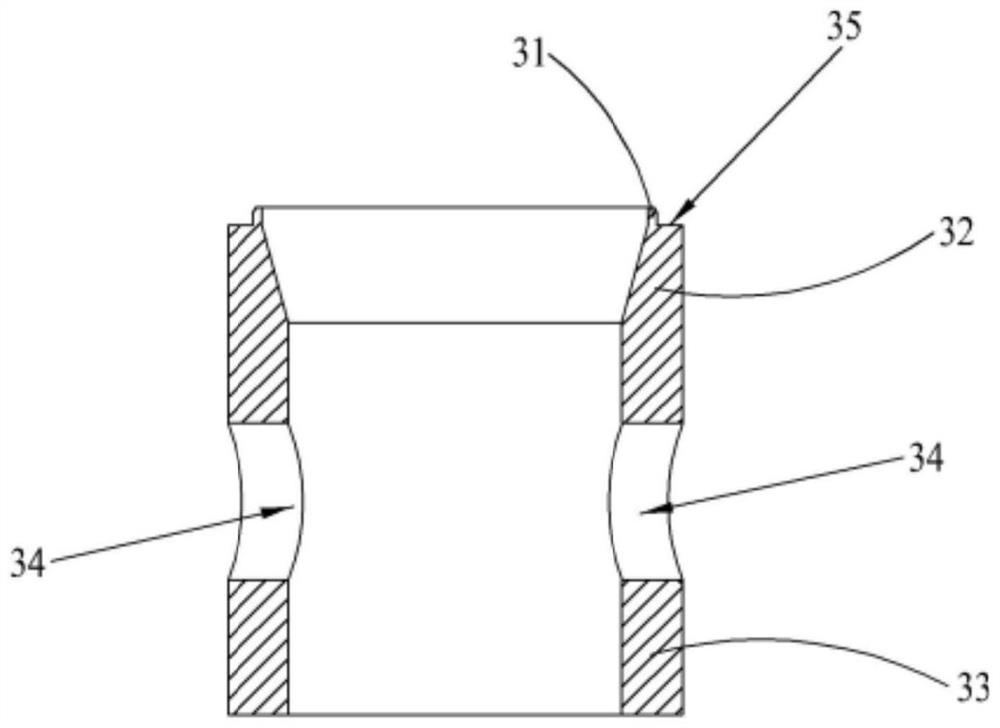

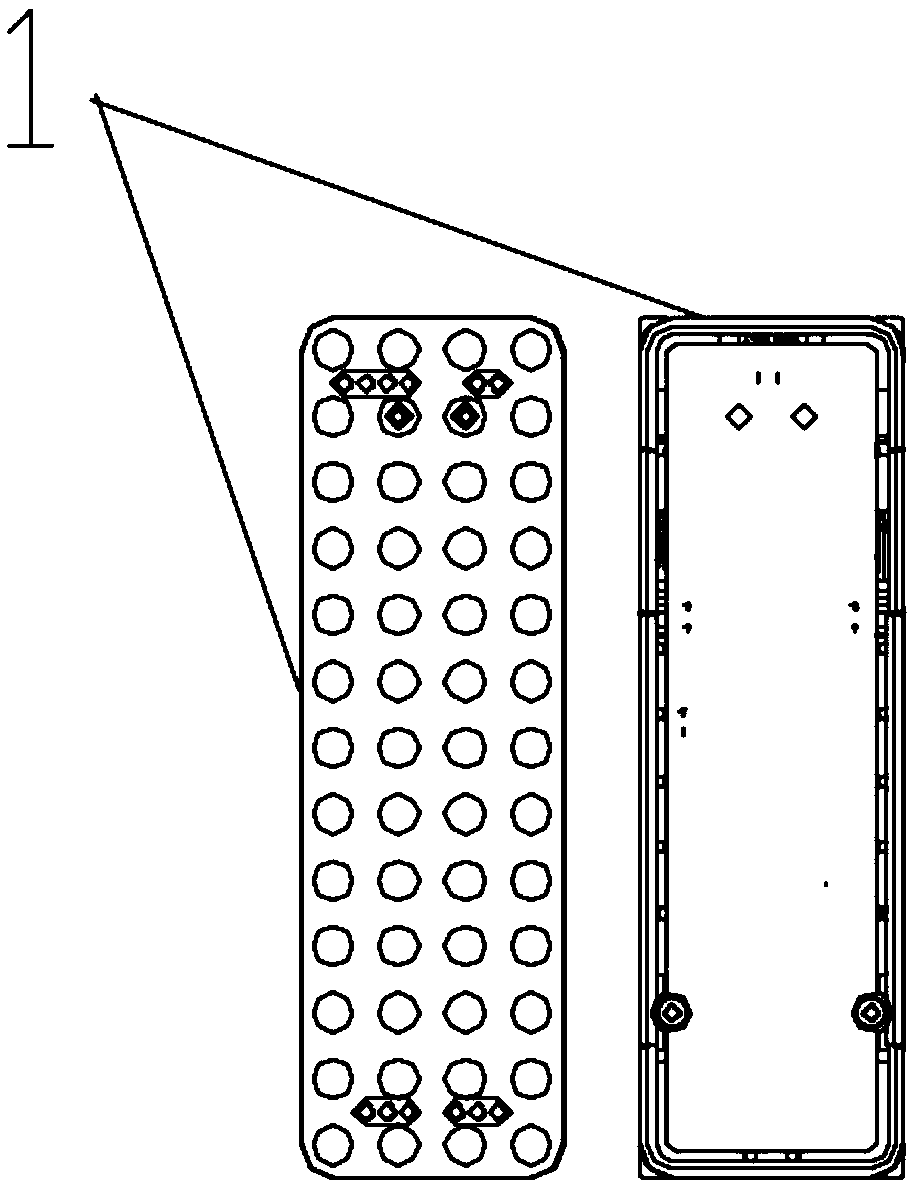

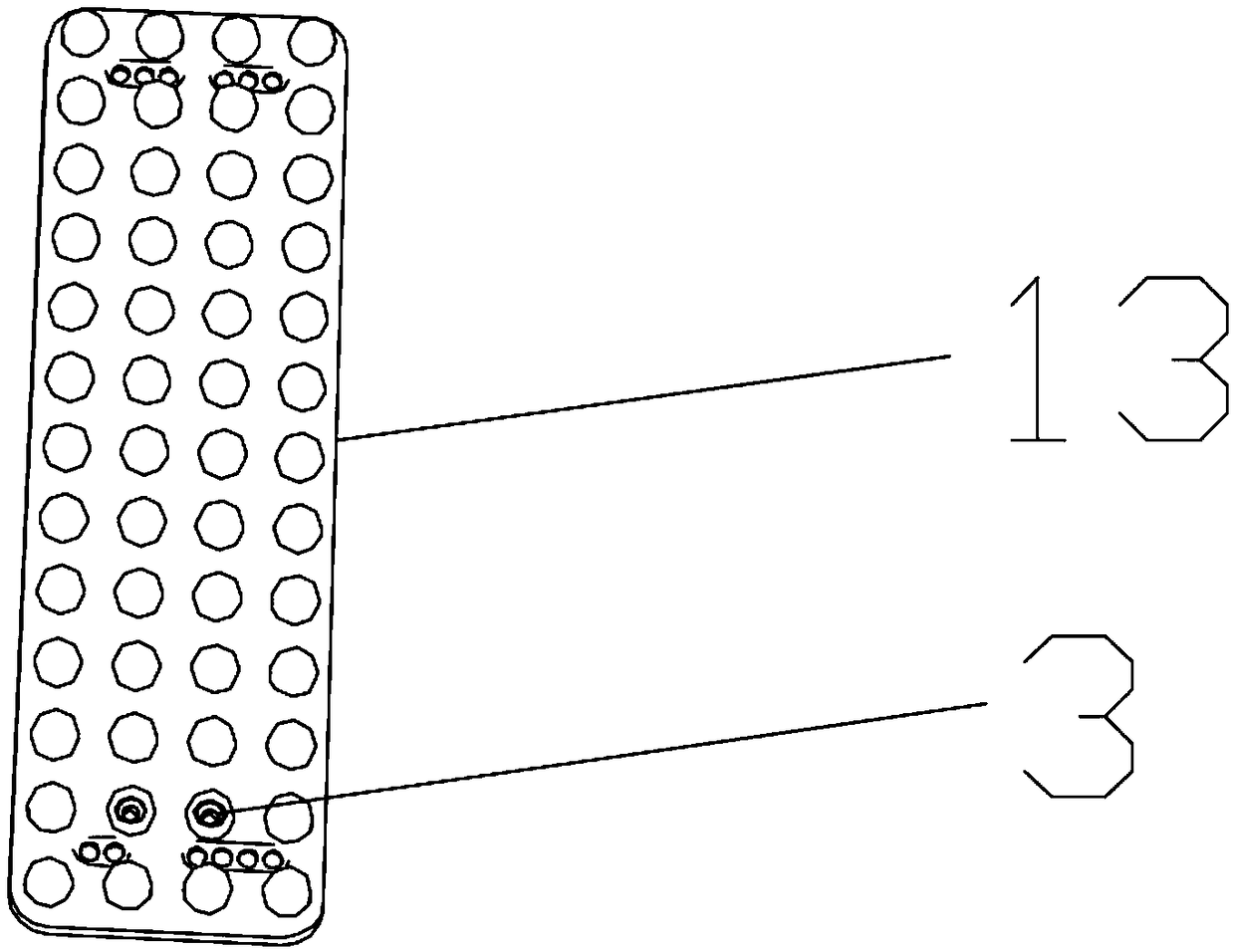

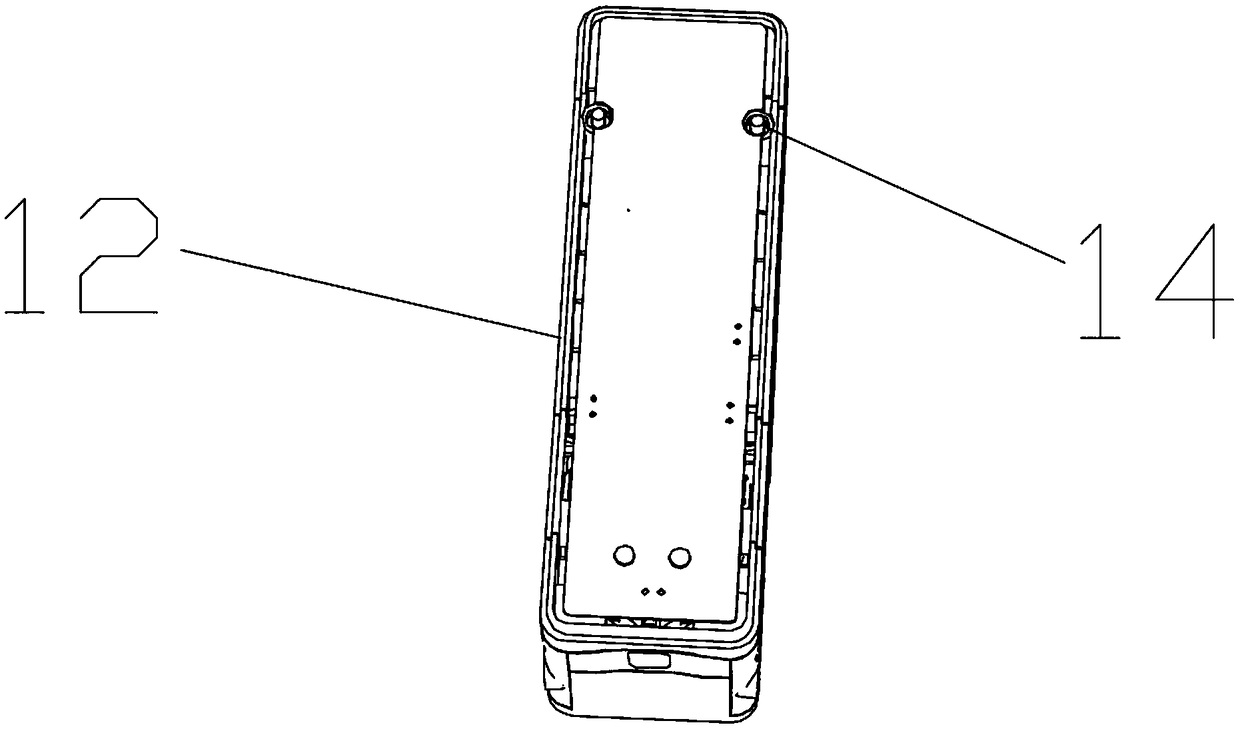

Connecting method of electronic building blocks and combination body of electronic building blocks

The invention discloses a connecting method of electronic building blocks. The connecting method comprises the following steps: (1) preparing a basic module of each electronic building block with thefunction of a basic circuit and the basic circuit of the basic module, and arranging the basic circuit in the basic module, wherein two or more electric connecting points are preset on the basic module of each electronic building block and the basic circuit of the basic module; (2) preparing a branch circuit module of each electronic building block and a branch circuit of the branch circuit module, and arranging metal elastic contacts at the bottom of the branch circuit module of each electronic building block, wherein the metal elastic contacts are connected with the branch circuit through lines; (3) arranging circular-truncated-cone-shaped concave-convex structures on the upper end face of the basic module of each electronic building block, arranging concave holes in any adjacent circular-truncated-cone-shaped concave-convex structures, and arranging the electric connecting points of the basic module of each electronic building block in the concave holes; and (4) cascading the electronic building blocks in a direct insertion manner so that a combination body of the electronic building blocks is formed, and meanwhile, connecting the metal elastic contacts and the electric connecting points in the concave holes, so that the combination body of the electronic building blocks and the function circuit of the combination body are formed.

Owner:GUANGZHOU TUDAO INFORMATION TECHNOLONY CO LTD

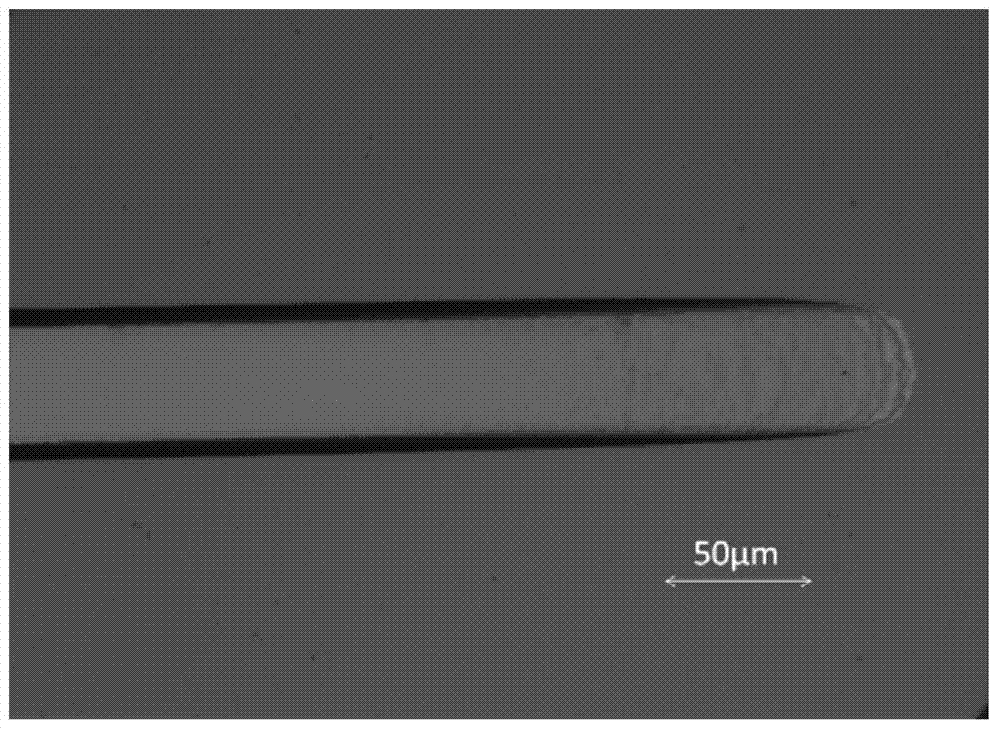

Preparation method of microelectrode diaphragm

InactiveCN110143569ASolve the complex preparation processSimple processDecorative surface effectsLaminating printed circuit boardsBiological bodyMicroelectrode

The invention provides a preparation method of a microelectrode membrane, belongs to the technical field of bioelectrodes, and can overcome the defect of low contact tightness between a microelectrodeformed by an existing microelectrode membrane preparation method and a living body. The preparation method of the microelectrode diaphragm comprises the following steps: forming at least one groove on a temporary substrate; forming a microelectrode implanted crystal in the groove; growing a microelectrode in the groove by utilizing the microelectrode implanted crystal to form the microelectrode;contacting the first substrate with one side of the temporary substrate with the groove; the microelectrode is separated from the temporary substrate to transfer the microelectrode onto the first substrate.

Owner:BOE TECH GRP CO LTD

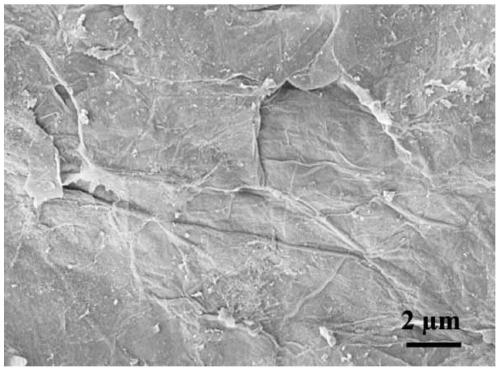

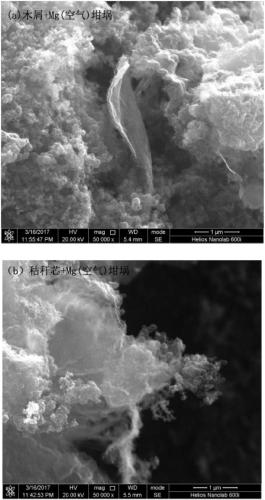

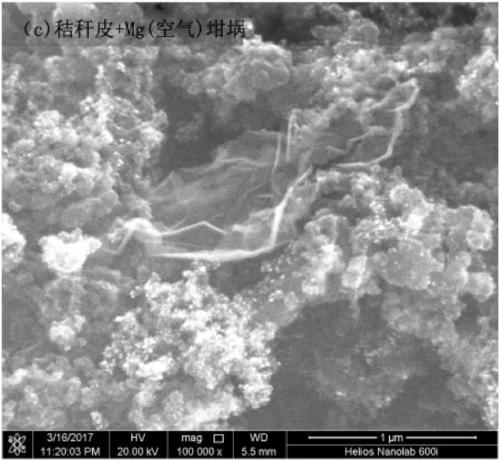

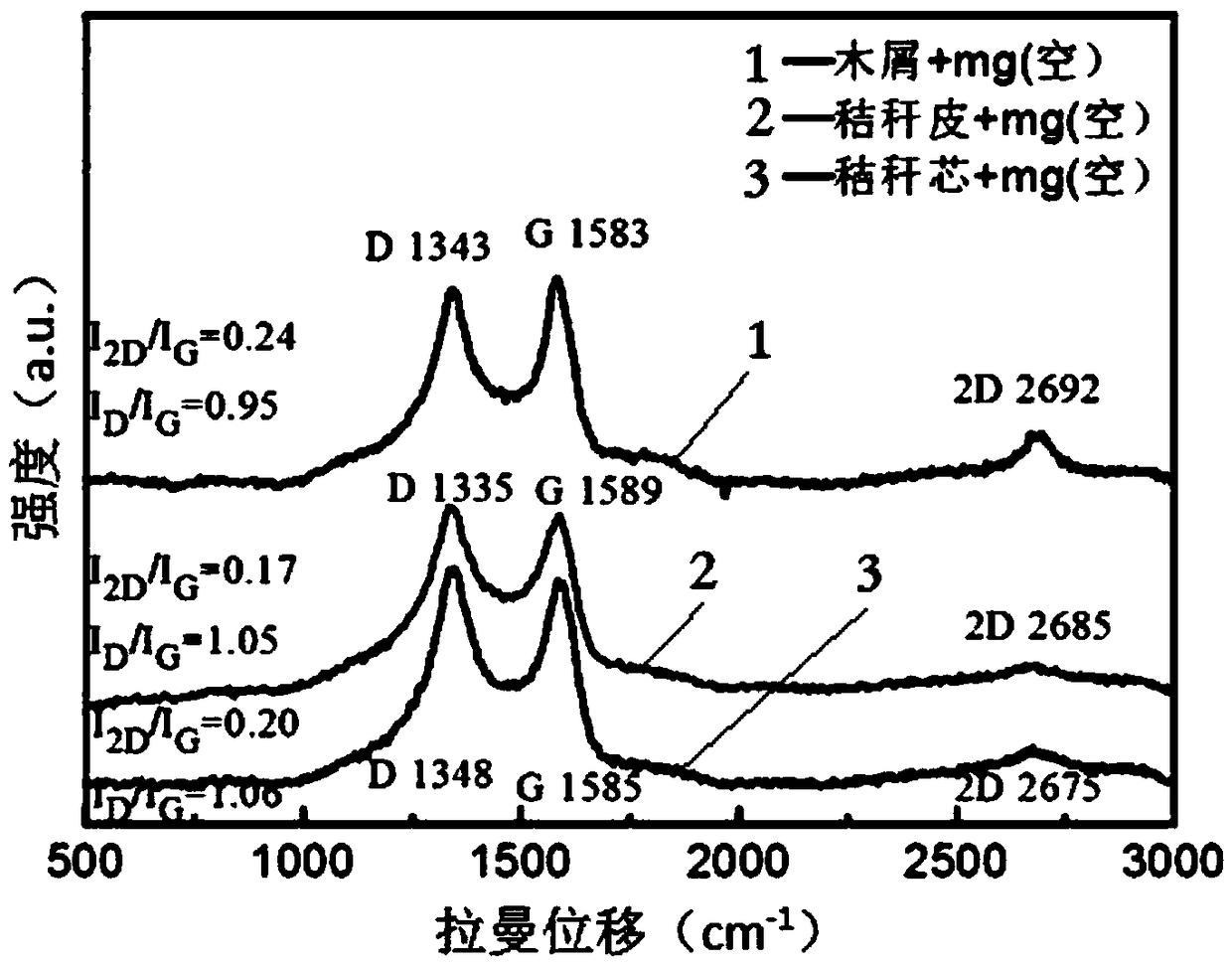

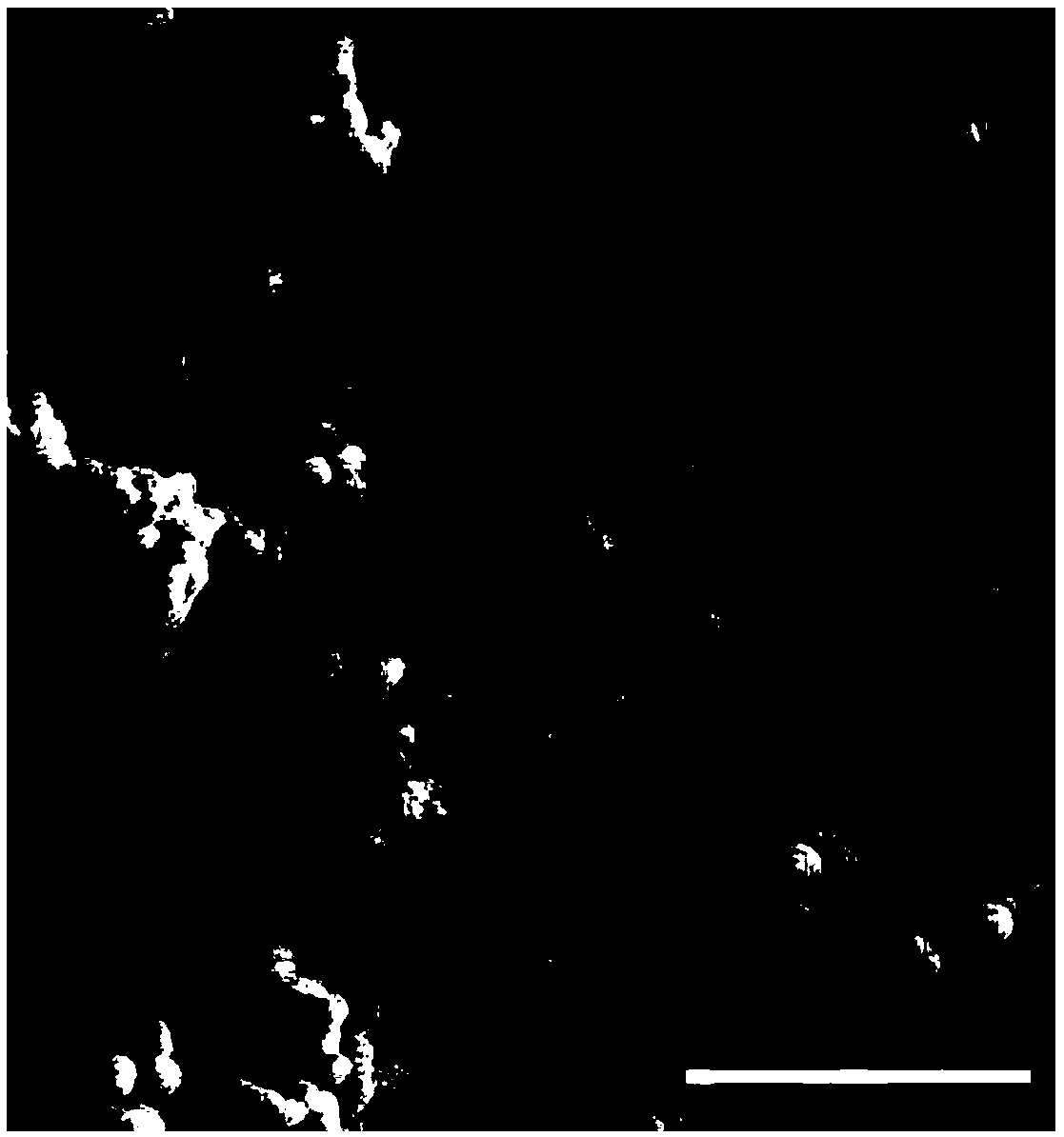

Preparation method for synthesizing graphene through biomass burning and application thereof

ActiveCN109319765ASolve the complex preparation processSimple process equipment and operationHybrid capacitor electrodesGrapheneCvd grapheneBiomass

The invention provides a preparation method for synthesizing graphene through biomass burning and application thereof, and relates to the field of solid waste treatment and the technical field of chemical synthesis. The graphene is prepared from biomass by a combustion synthesis method; the prepared graphene can be applied as a supercapacitor material. Common biomass with low utilization value innature is subjected to resource utilization for preparing the graphene; the production cost for industrially synthesizing the graphene is reduced, so that important potential application is realized in the fields of catalysts, composite materials, electrochemistry and the like. The process is simple; the raw materials are cheap; the equipment requirements and the operation are very simple; the mass production can be easily performed; the reasonable resource utilization method of biomass materials is added.

Owner:HARBIN INST OF TECH

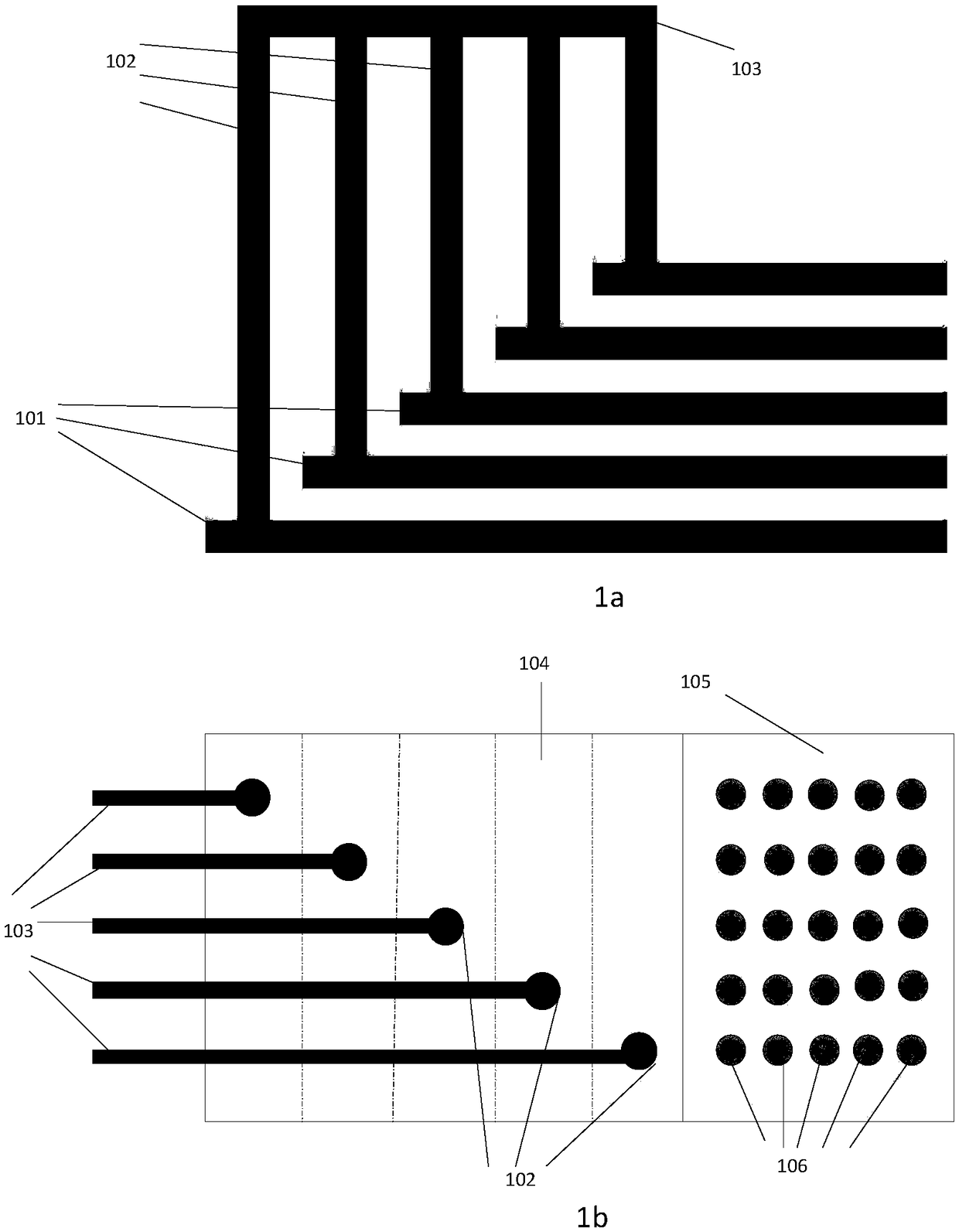

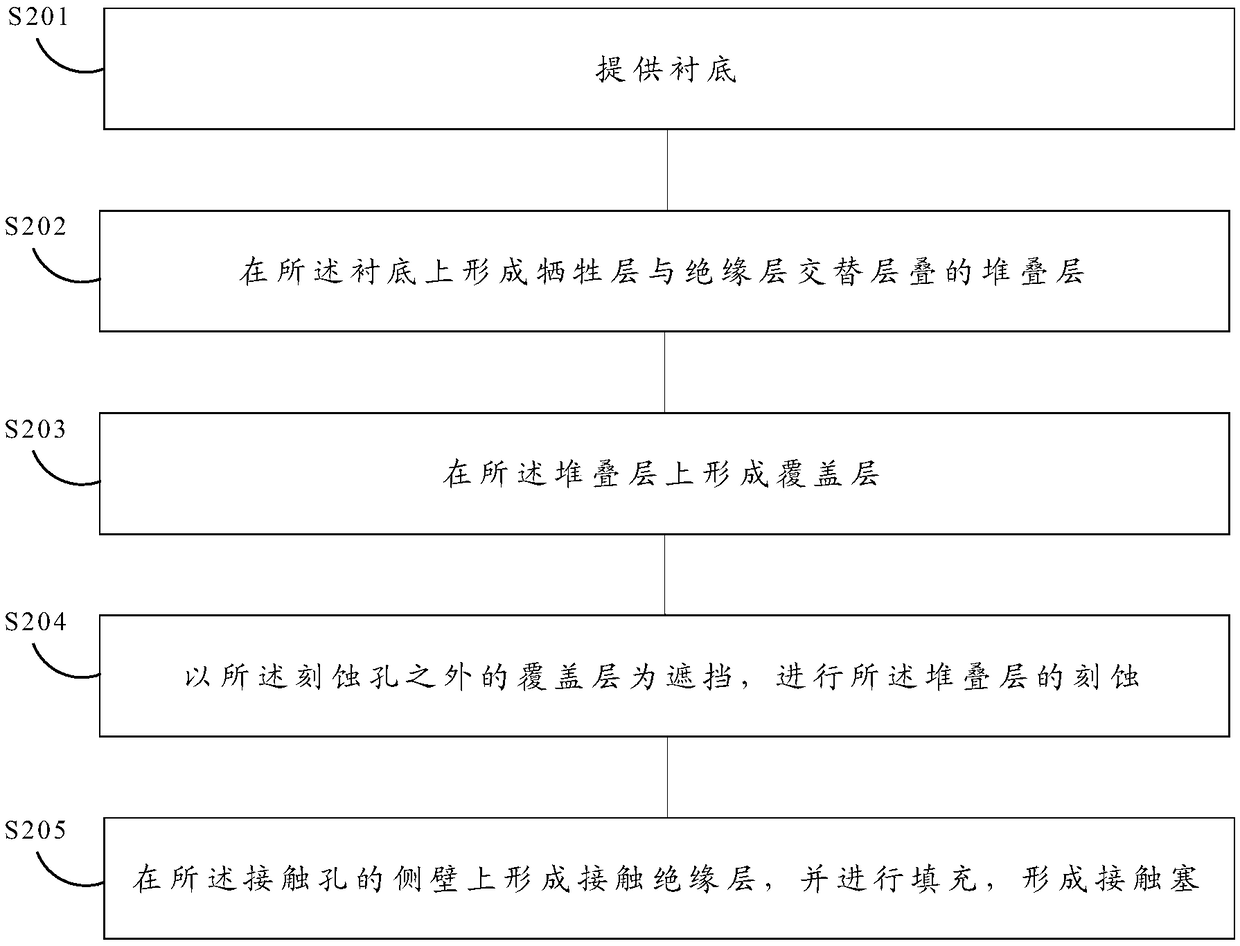

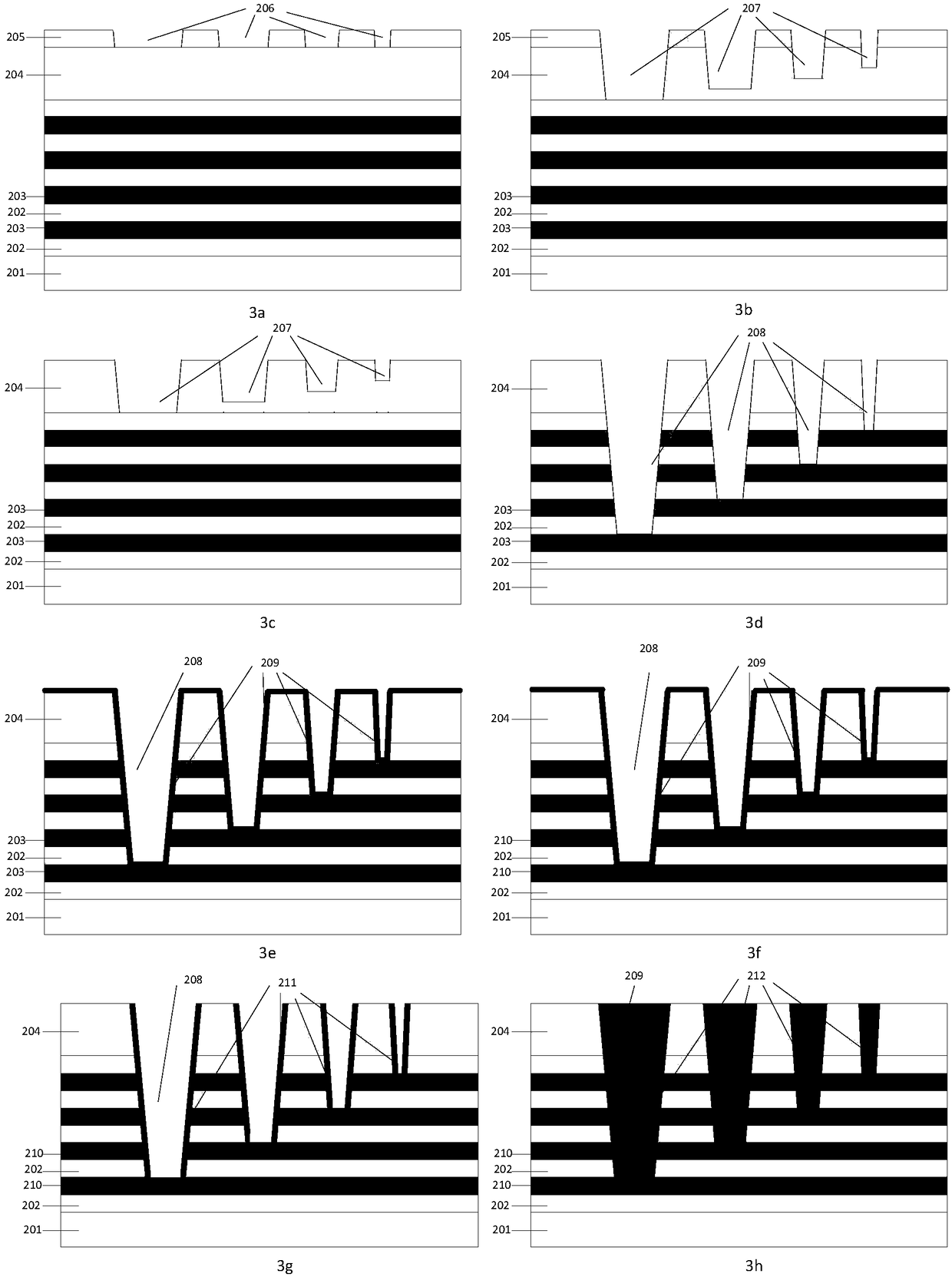

A kind of 3d NAND storage device and its manufacturing method

The present invention provides a method for manufacturing a 3D NAND storage device. By forming a stacked layer alternately stacked with sacrificial layers and insulating layers on a substrate, a channel hole and a storage device in the channel hole are formed in the first region of the stacked layer. layer, forming a covering layer on the stacked layer, wherein etching holes with different apertures are formed in the covering layer in the second region, and the covering layer is used as a shield to etch the stacked layer to form a contact hole under the etching hole, Different contact holes stop at different sacrificial layers. During the etching process, the larger the diameter of the etching hole, the greater the etching rate of the underlying stacked layer, so that the contact hole under the larger etching hole can have a deeper hole depth, thus achieving different depths of contact. The holes are etched to form contact holes corresponding to different sacrificial layers. For storage devices with multiple stacked layers, the complex manufacturing process and high cost caused by etching multi-layer steps are avoided, the area required for the device is reduced, and the yield rate of the wafer is improved.

Owner:YANGTZE MEMORY TECH CO LTD

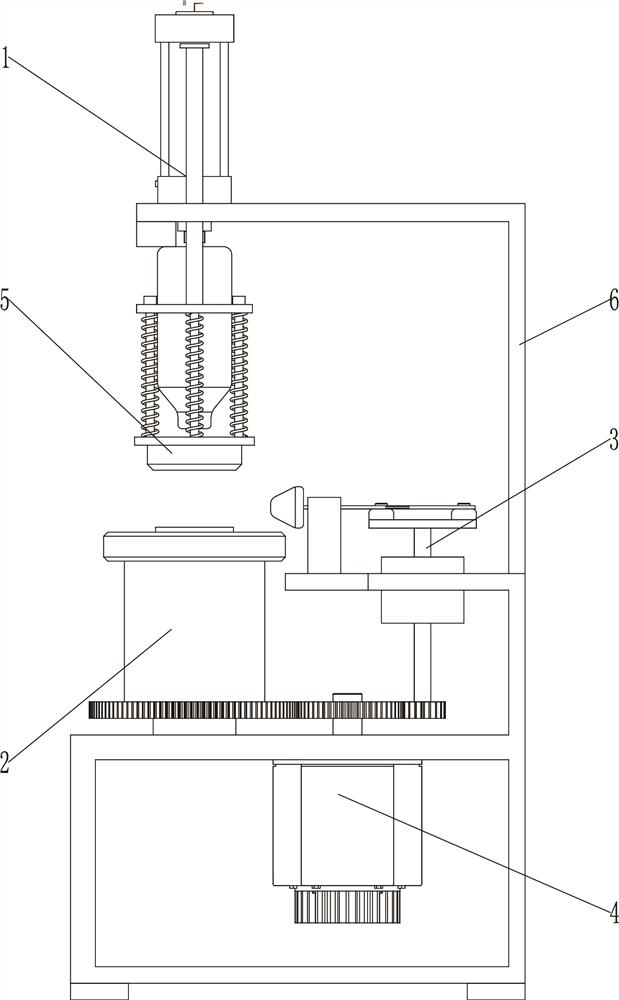

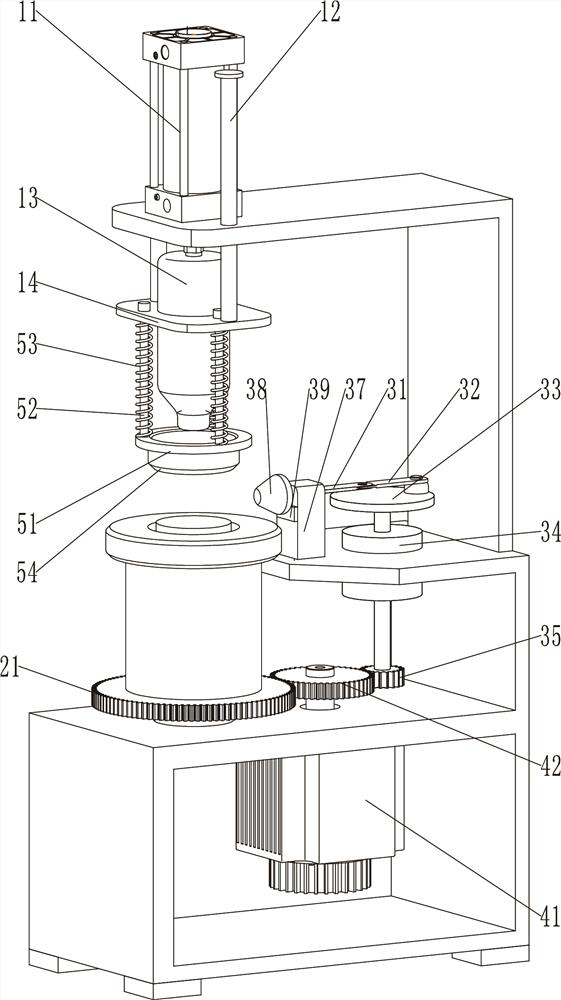

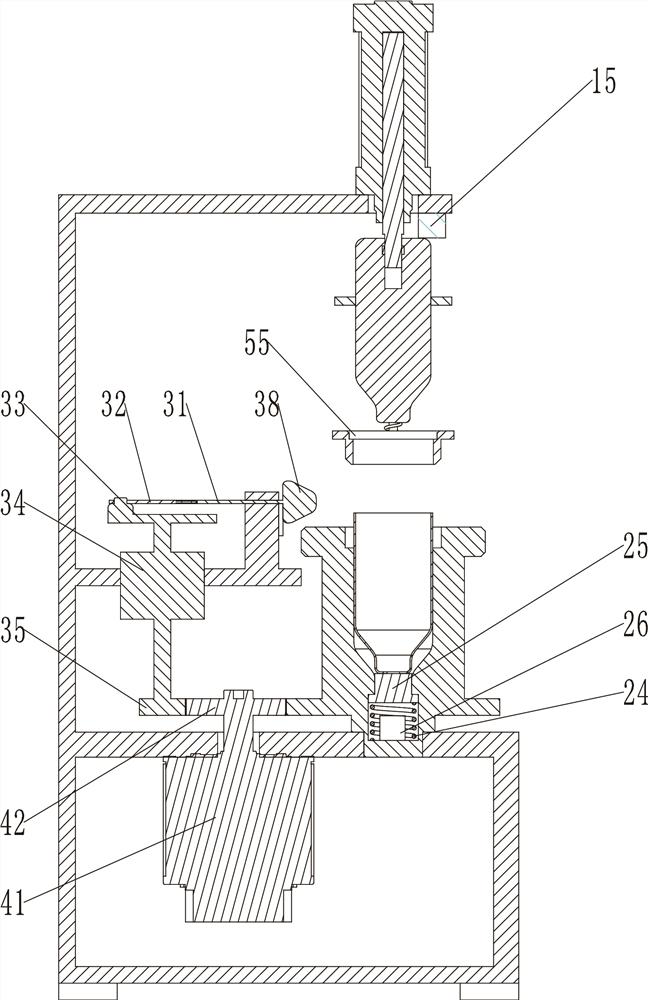

Manufacturing equipment for aluminum sports kettle

ActiveCN112916756ASolve the complex preparation processIncrease profit marginsHollow articlesMechanical engineeringIndustrial engineering

The invention discloses manufacturing equipment for an aluminum sports kettle. The manufacturing equipment comprises a stamping part, a forming clamping part, a closing-up part, a power part, a discharging part and a main body rack, the stamping part, the forming clamping part, the closing-up part and the power part are arranged on the main body rack, the discharging part is arranged on the stamping part, is connected with the stamping part and the discharging part in a matched mode, and is used for stamping an aluminum block into a bottomless bottle, the power part is arranged between the forming clamping part and the closing-up part, and provides power for the forming clamping part and the closing-up part, so that the bottle wall is flattened to be flat by an extrusion head arranged on the closing-up part while the forming clamping part rotates, and the bottom of an aluminum kettle is sealed. According to the manufacturing equipment for the aluminum sports kettle, the problem that an aluminum kettle manufacturing process is complex is effectively solved, the working efficiency is greatly improved, the repeated working time is saved, the equipment investment cost is reduced, and the profit rate of a factory is improved.

Owner:武义盛世工贸有限公司

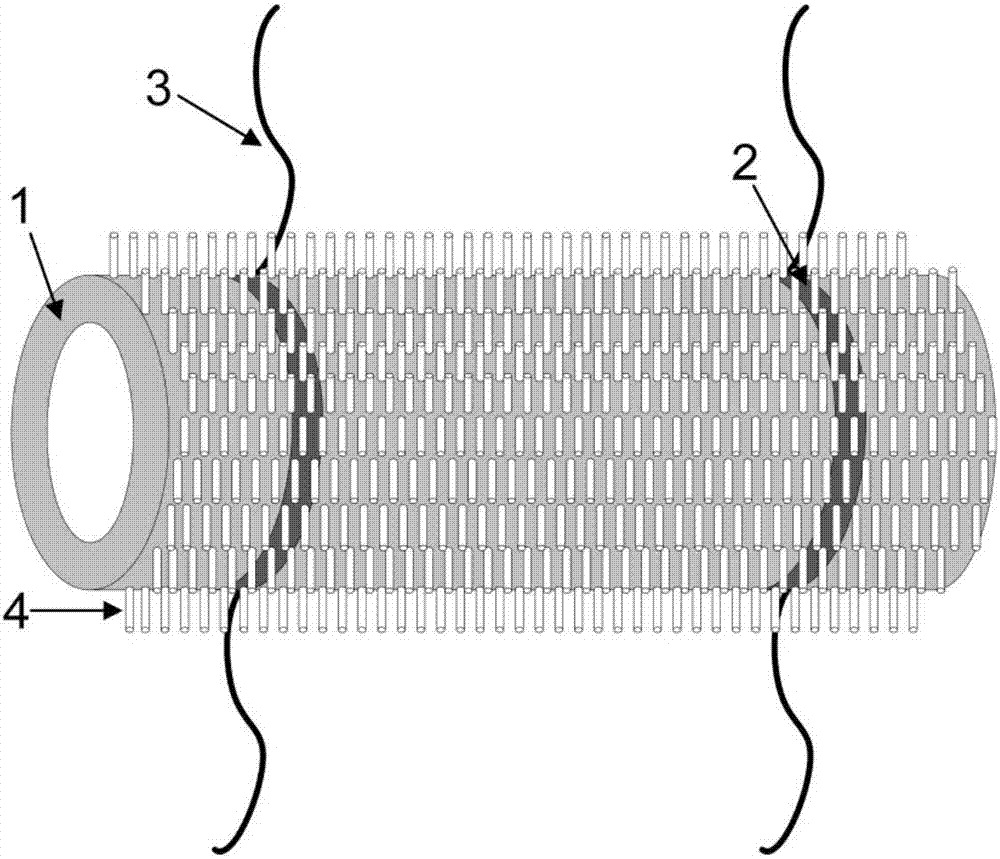

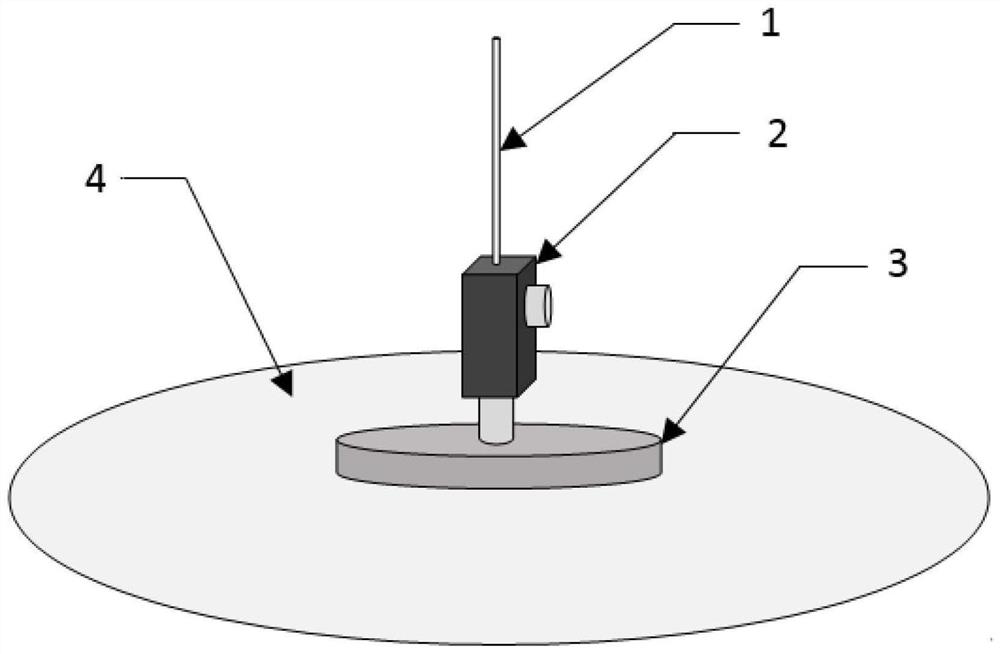

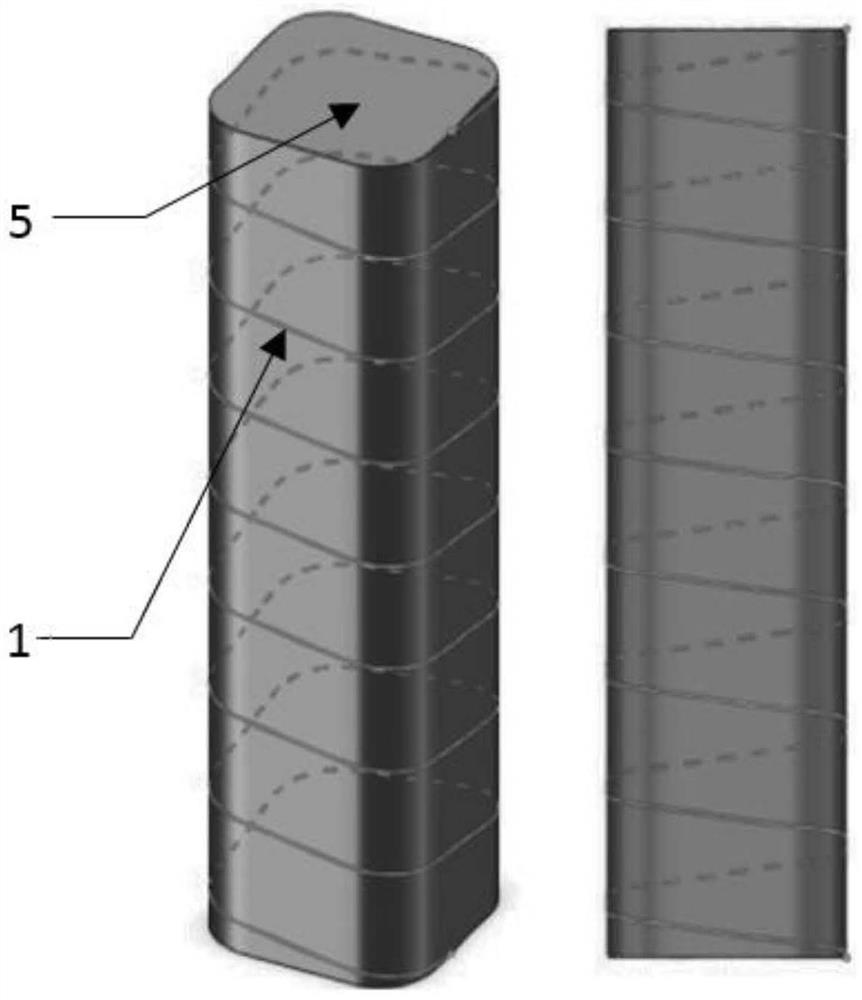

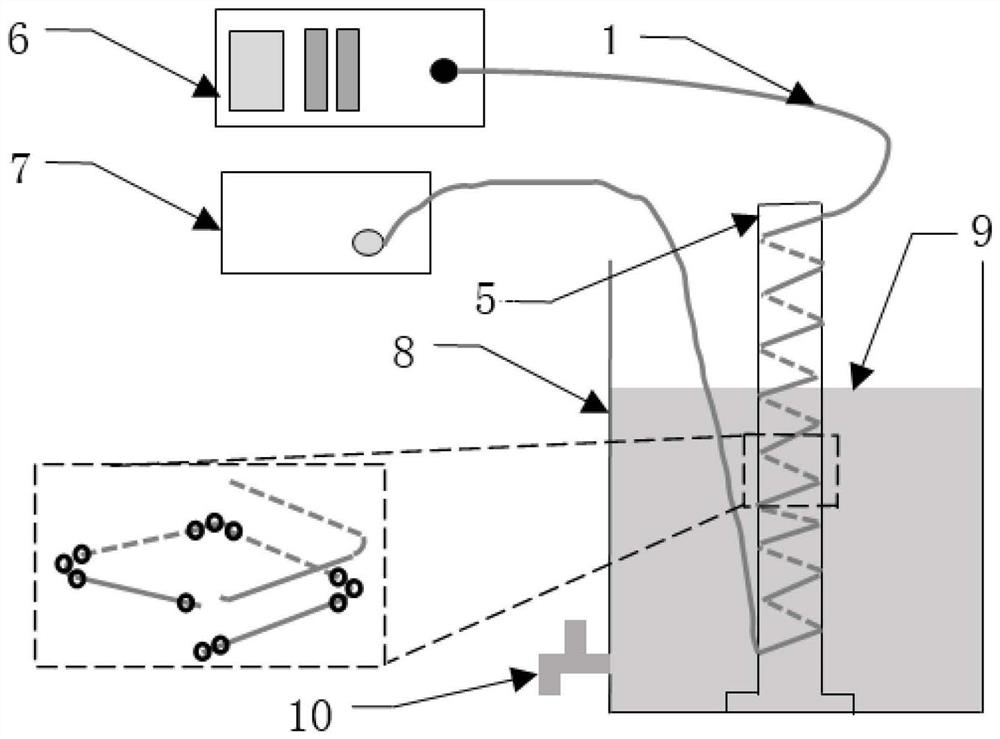

Liquid level sensor prepared based on plastic optical fiber macro-bending method

PendingCN113959527AImprove bending resistanceImprove insulation performanceMachines/enginesLevel indicatorsAdhesiveEngineering

The invention discloses a liquid level sensor prepared based on a plastic optical fiber macro-bending method, and relates to the field of plastic optical fibers and the technical field of liquid level sensing. The liquid level sensor is obtained by winding POF on the surface of a cylinder, and the cylinder is made of light modeling resin. The preparation method comprises the following steps: (1) preprocessing the POF end face to obtain a flat optical fiber end face; and (2) winding the POF on the surface of the cylinder according to a preset track, and fixing the POF through an adhesive. The method is simple to operate and high in measurement precision, and can adapt to the requirements of different resolutions by controlling the distance of each circle of optical fiber; the POF liquid level sensor has excellent electronic insulation and remote sensing performance, can perform safe measurement on flammable and explosive oil tanks, realizes point liquid level monitoring, and has the advantages of high sensitivity, quick response, electromagnetic interference resistance, small volume, light weight, corrosion resistance and the like.

Owner:NANCHANG UNIV

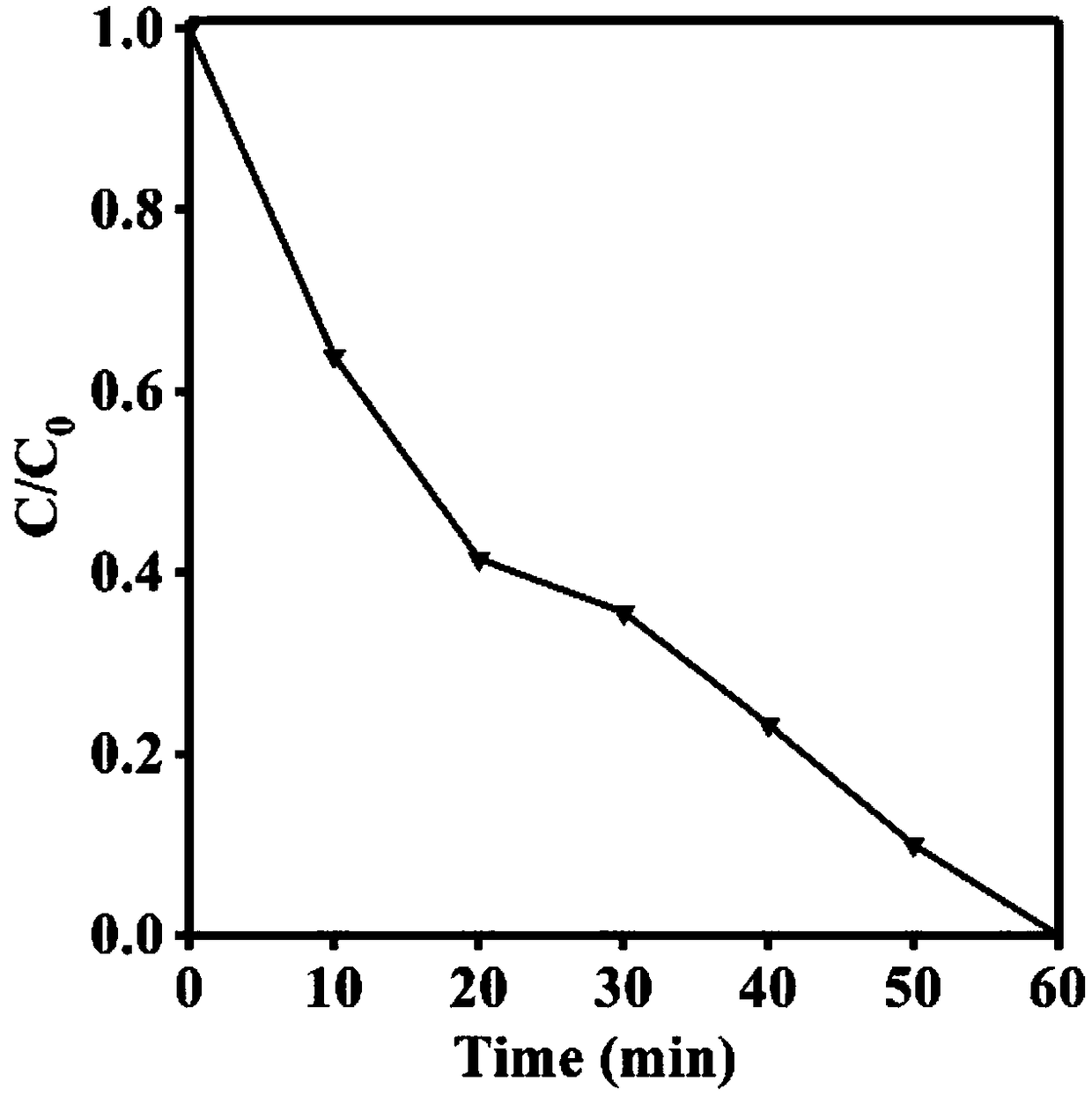

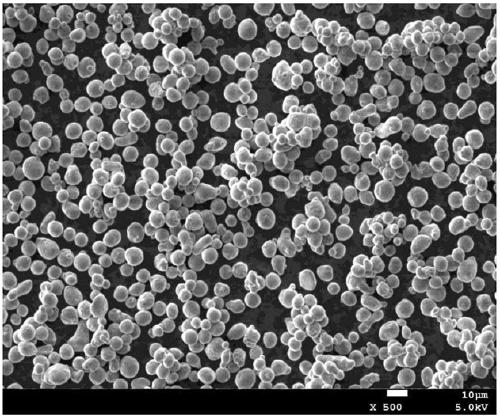

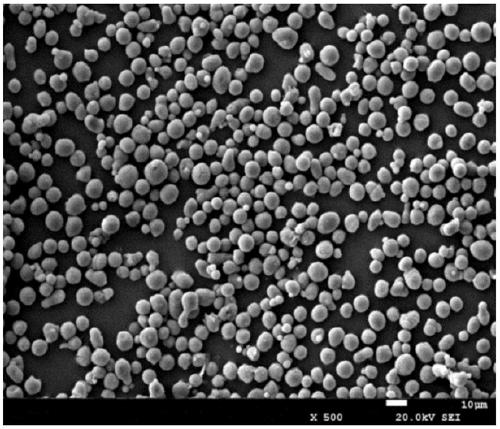

Silver rhodanide/polyacid nano composite material preparation method

ActiveCN108745379ASolve the complex preparation processComposition is easy to controlWater/sewage treatment by irradiationWater treatment compoundsMaterials preparationAlcohol

The invention belongs to the technical field of inorganic nanomaterial preparation and discloses a silver rhodanide / polyacid nano composite material preparation method. The method includes steps: adding thiocyanic acid or thiocyanate with polyacid or polyacid salt into water to form solution A; adding silver salt into water to form solution B; mixing the solution A with the solution B, performingreaction for 0.5-5h, and filtering to obtain a product; washing the product with water or ethyl alcohol, and drying to obtain a silver rhodanide / polyacid nano composite material. The silver rhodanide / polyacid nano composite material is prepared by one-step coprecipitation, controllability in composition and particle size is realized, and the problem of complexity of a composite material preparation process is solved; the preparation method and process are simple, convenient, environmentally harmless, suitable for large-scale industrial production and extensive in application prospect; the prepared silver rhodanide / polyacid nano composite material is excellent in performance and high in structural stability.

Owner:JINING UNIV

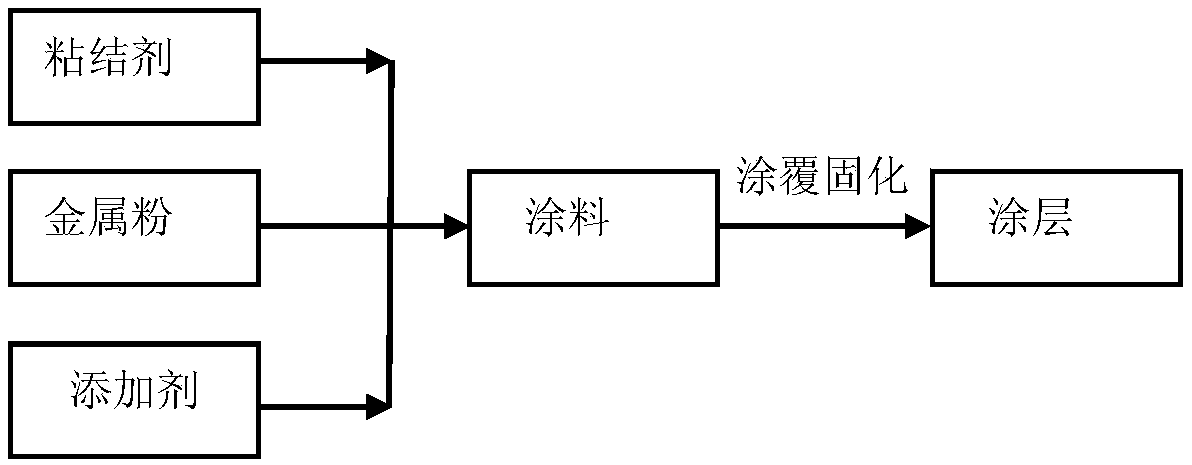

A kind of preparation method of modified metal powder

ActiveCN106424701BImprove corrosion resistanceImprove adhesionTransportation and packagingMetal-working apparatusO-Phosphoric AcidMetal powder

Owner:DONGFANG ELECTRIC (CHENGDU) HYDROGEN FUEL CELL TECH CO LTD

Hydrogel micro-fluidic chip and processing method thereof

InactiveCN102836751BAvoid damageConducive to true expressionLaboratory glasswaresPolyethylene glycolCell metabolite

The invention provides a hydrogel micro-fluidic chip, comprising a substrate layer, a chip layer and a gland layer, wherein the chip layer is formed by solidifying PEG (polyethylene glycol) base hydrogel pre-polymer and composed of an upper layer unit and a lower layer unit; a first layer unit comprises a micro-well array used for capturing cells and fixing and cultivating the captured cells; a second layer unit comprises a direct current channel used for pouring cell culture solution and rectangular grooves used for collecting and detecting cell metabolin; the micro-well array of a first layer chip unit is overlapped with the direct current channel area of a second layer chip unit; the rectangular grooves of the first layer chip unit and the second layer chip unit are overlapped; the chip layer is arranged between the substrate layer and the gland layer; and the gland layer is provided with a sample inlet and a sample outlet which are communicated with the direct current channel and the rectangular grooves. According to the invention, a processing method for the micro-fluidic chip is also provided; the hydrogel micro-fluidic chip is manufactured by poly(ethylene glycol) diacrylate (PEGDA), thus, a chip is manufactured more quickly and efficiently; and the processing method has practical importance at aspects of drug research and drug selection.

Owner:CHONGQING UNIV

Compressor system oil equalization control method and multi-compressor parallel system

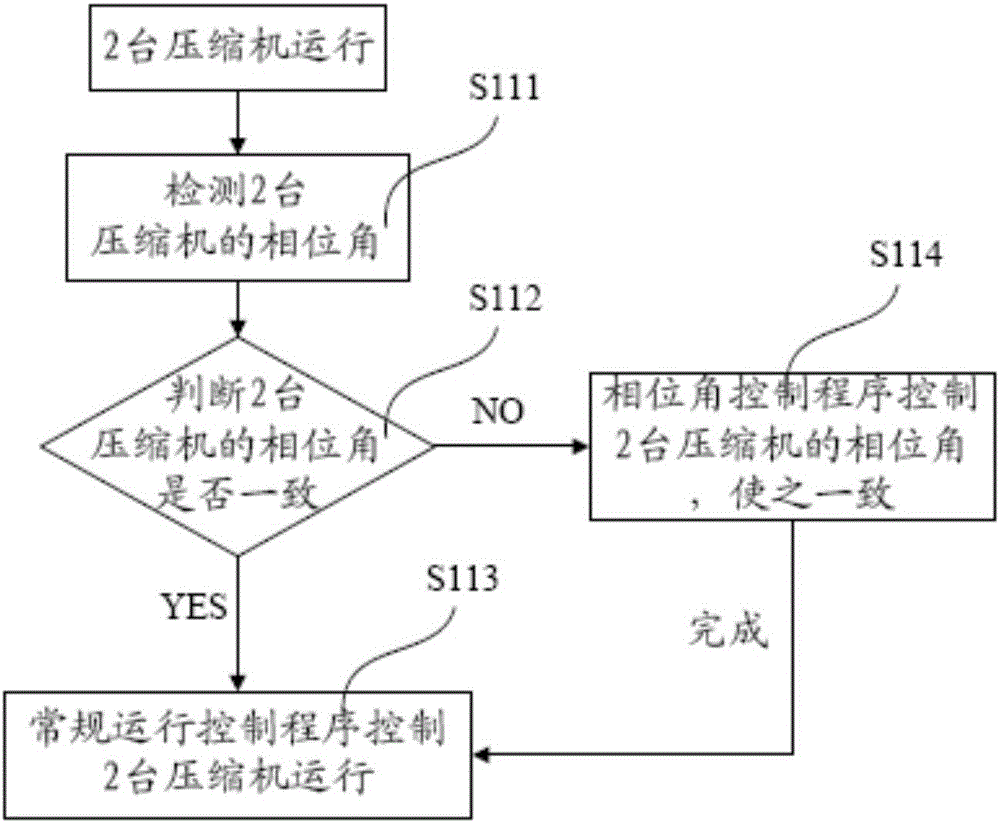

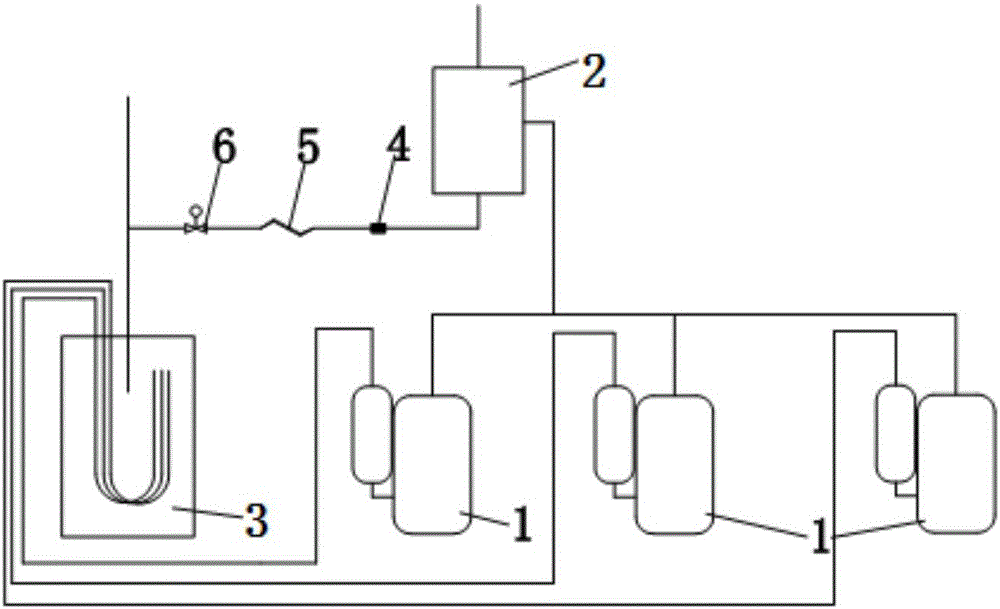

ActiveCN104048453BSolve the oil equalization problemNo damage to the compressor will occurCompressorCompression machines with non-reversible cycleManufacturing technologyControl engineering

The invention discloses an oil-equalizing control method for a compressor system and a multi-compressor parallel system. The method comprises the following steps: arranging N parallel rotor compressors; starting N1 compressors for simultaneously running; detecting phase angles of motor rotors of N1 compressors; judging if the phase angles of motor rotors of N1 compressors are consistent; if yes, running a conventional running control program for controlling the running of the N1 compressors; if not, adjusting the phase angles of motor rotors of N1 compressors and adopting the conventional running control program for controlling the running of the N1 compressors after the phase angles are consistent. According to the invention, the oil-equalizing problem between the compressors in the multi-compressor parallel system is solved; the phenomenon of compressor damage caused by long-term oil shortage of the compressors in the multi-compressor parallel system is avoided; the pipeline design is simplified; the problem of complex manufacturing technique caused by redundant pipelines is solved.

Owner:GREE ELECTRIC APPLIANCES INC

Single mold one-step forming system and single mold one-step forming method

InactiveCN102358027BReduce consumptionSolve the problem of complex manufacturing processMachine controlControl system

The present invention relates to the field of plastic forming and processing, specifically to a single mold one-step forming system and a single mold one-step forming method. The single mold one-step forming system of the present invention comprises: a host machine, wherein the host machine comprises a mold head; an auxiliary machine, wherein the auxiliary machine is positioned on the downstream of the host machine, comprises an auxiliary machine control system, a moveable frame and a drive system, wherein the moveable frame is provided with a lower mold and an upper mold, and can move along the guide rail of the auxiliary machine, the lower mold and the upper mold are provided for remaining upper and lower alignment. The single mold one-step forming method of the present invention comprises that: a prepared slice is guided and placed between the lower mold and the upper mold, wherein the upper mold and the lower mold remain the upper and lower alignment; the lower mold, the upper mold and the prepared slice move synchronously, the lower mold and the upper mold are closed and opened to enable the prepared slice to form the preset form. With the single mold one-step forming system and the single mold one-step forming method of the present invention, the problem of complex preparation process in the prior art can be solved, the occupied area and the equipment investment during the existing production process are substantially saved, the power consumption and the labor consumption are reduced.

Owner:程富保

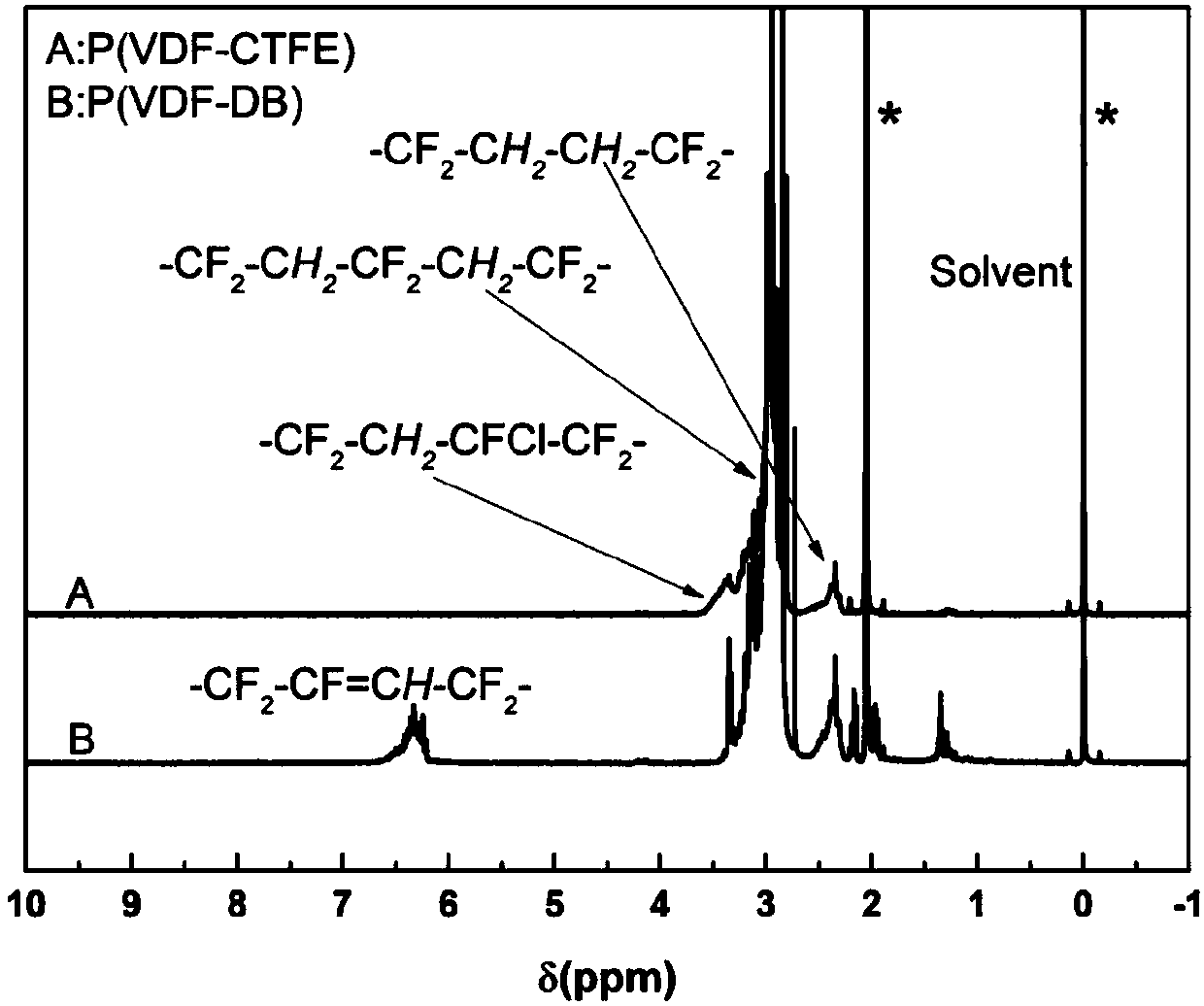

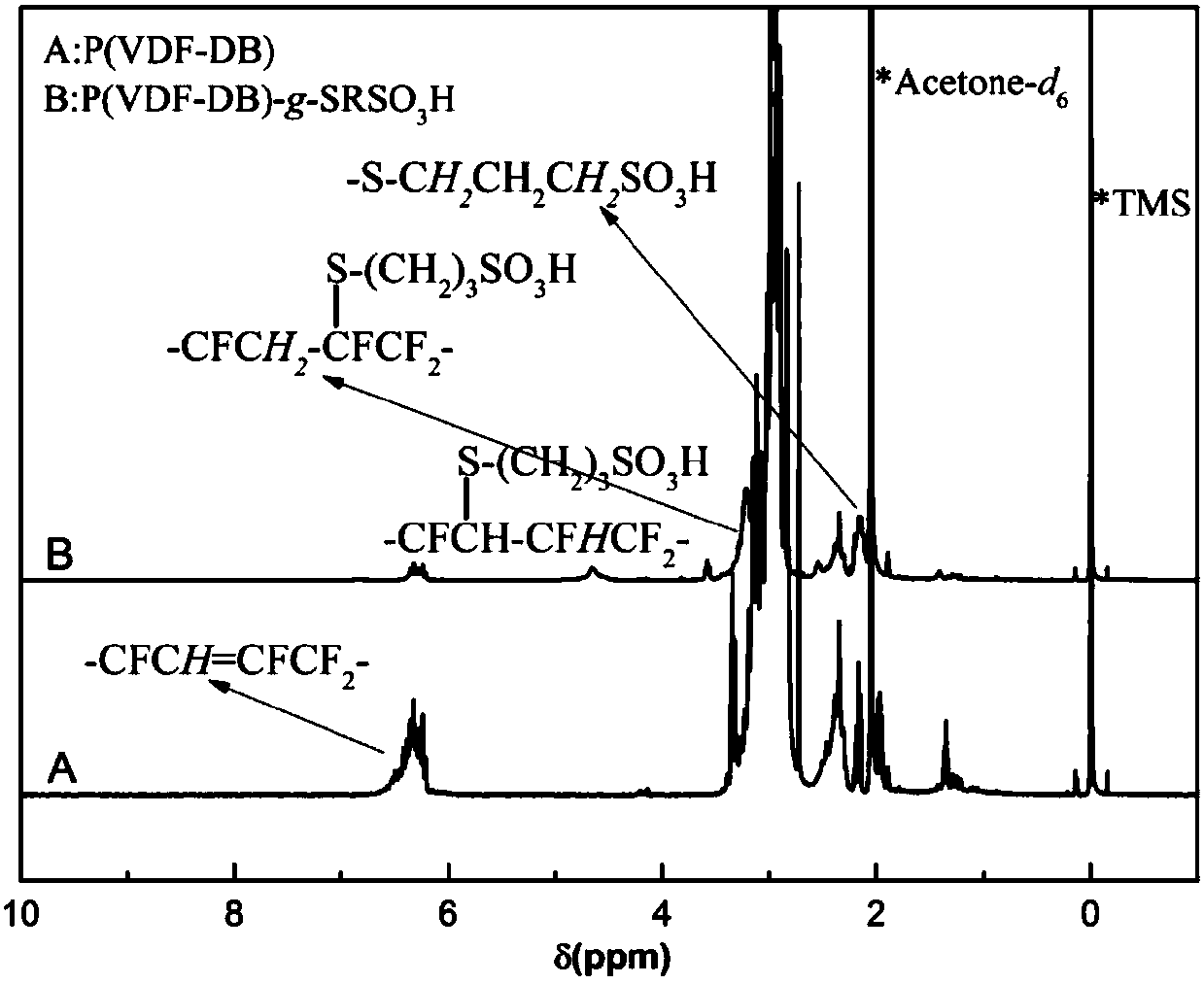

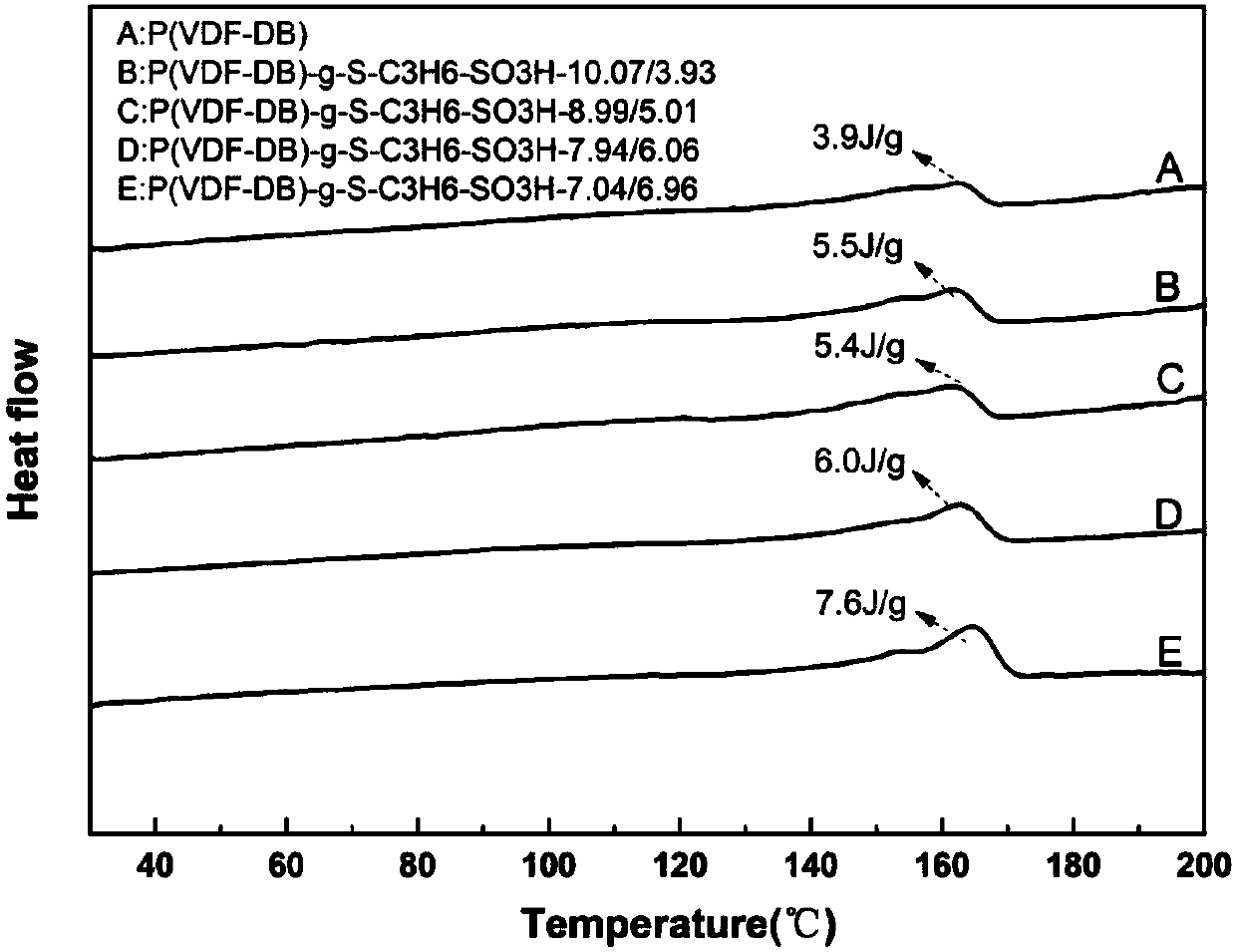

Method for preparing P(VDF-DB)-g-S-C3H6-SO3H proton exchange membrane material

The invention provides a method for preparing a P(VDF-DB)-g-S-C3H6-SO3H proton exchange membrane material. The method comprises the following steps: firstly, dissolving P(VDF-CTFE) and a catalyst intoa certain solvent; stirring and reacting for a certain time under a certain temperature condition; separating out a polymer P(VDF-DB) from de-ionized water; then, dissolving the P(VDF-DB), sodium thiosulfate and a catalyst into a certain solvent at the same time; after stirring and reacting for a certain time under a certain temperature condition, separating out a polymer in chloroform; decompressing and filtering to obtain a yellow polymer; sufficiently immersing the obtained yellow polymer by utilizing a hydrochloric acid solution (with the pH (Potential of Hydrogen) of 3); then decompressing and filtering and repeatedly immersing by utilizing methanol to remove unreacted organic matters and byproducts thereof; dissolving a washed product into acetone and sufficiently dissolving; then carrying out precipitation by utilizing n-hexane, and decompressing and filtering; finally, drying in vacuum until the weight is constant. The method provided by the invention has the advantages of simple technology, moderate conditions and easiness for obtaining the high-purity target product, and has a good industrial application prospect.

Owner:XI AN JIAOTONG UNIV

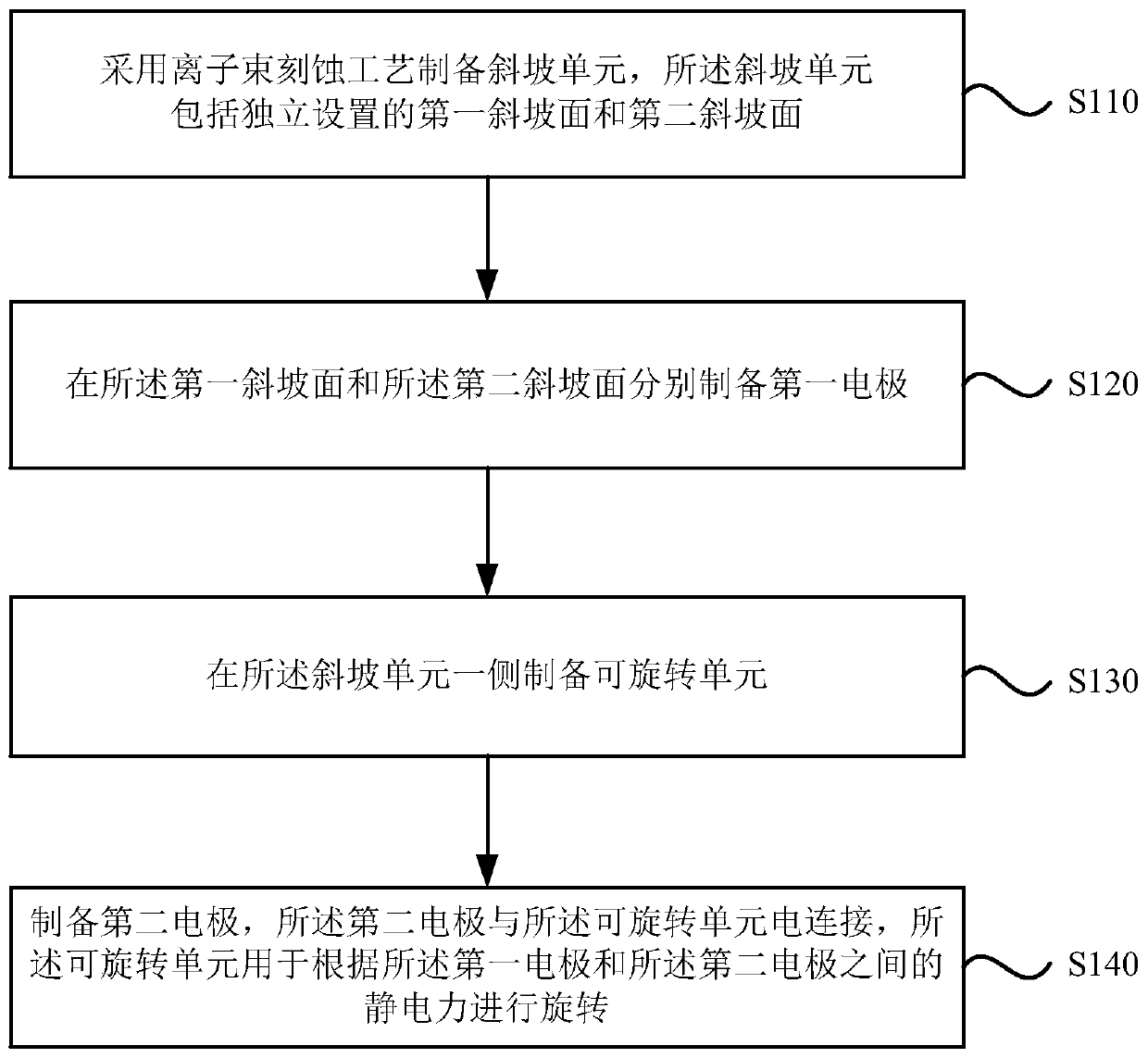

A kind of rotating structure and preparation method thereof

ActiveCN110217754BControllable Tilt AngleDecrease the tilt angleTelevision system detailsImpedence networksLithography processElectrical connection

Owner:SIWAVE INC

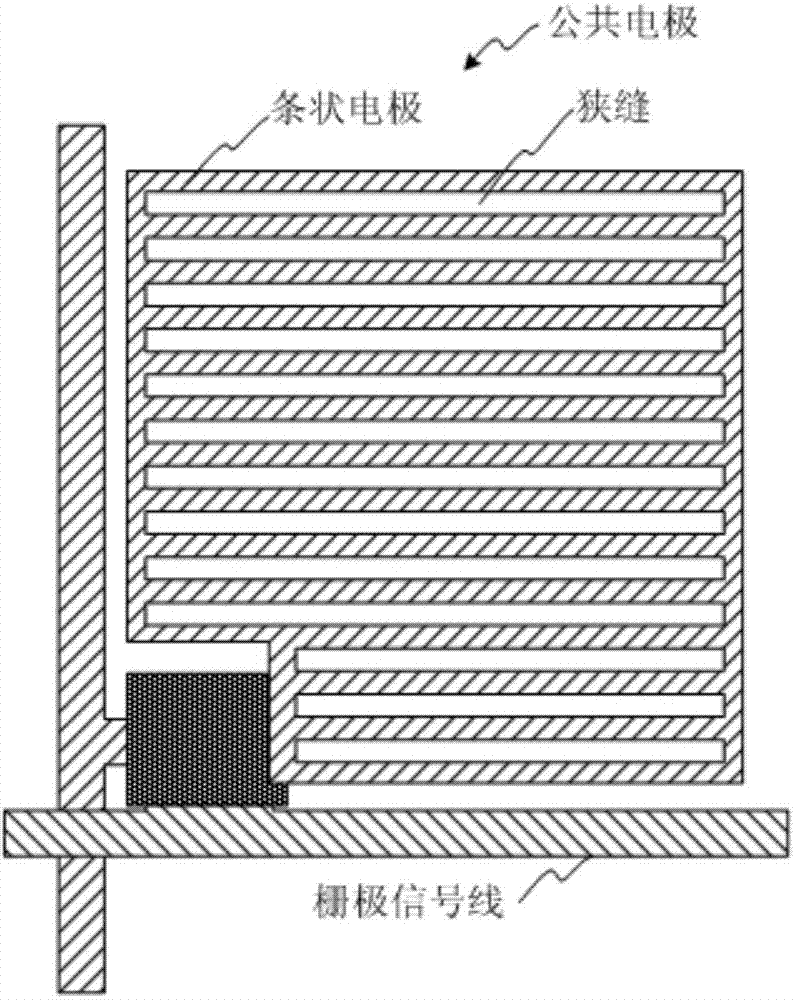

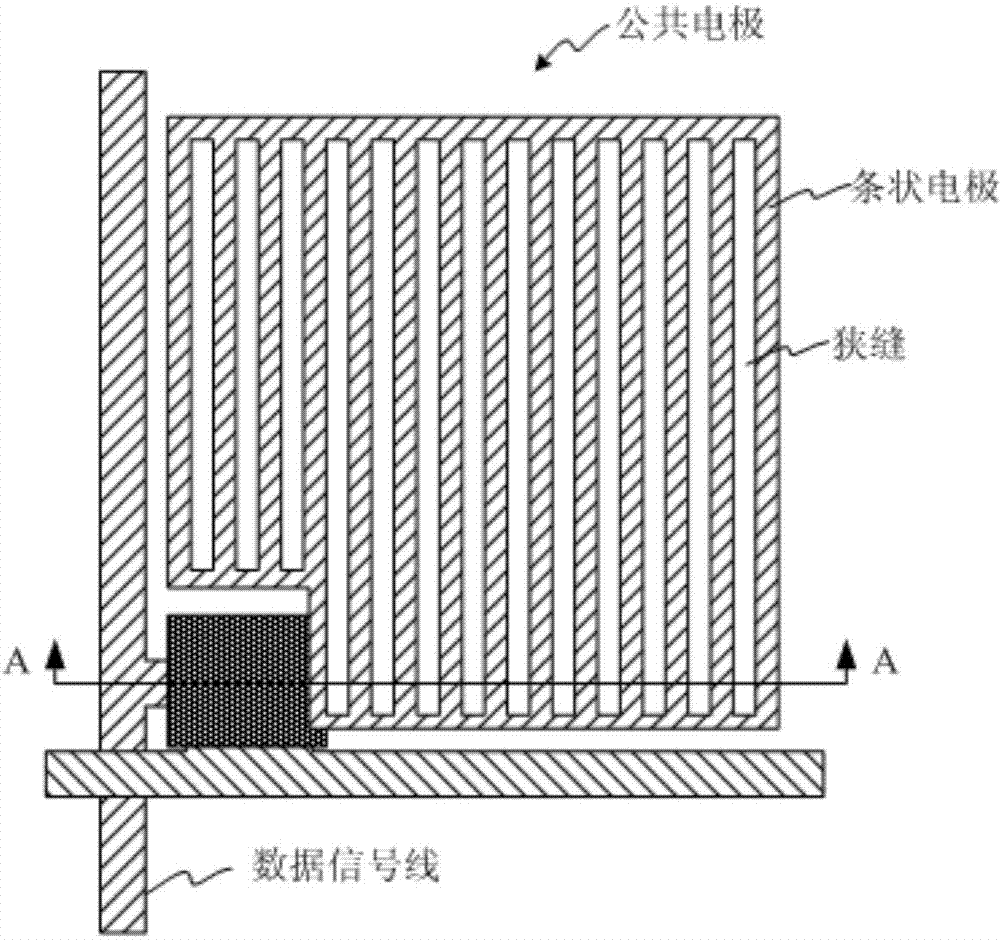

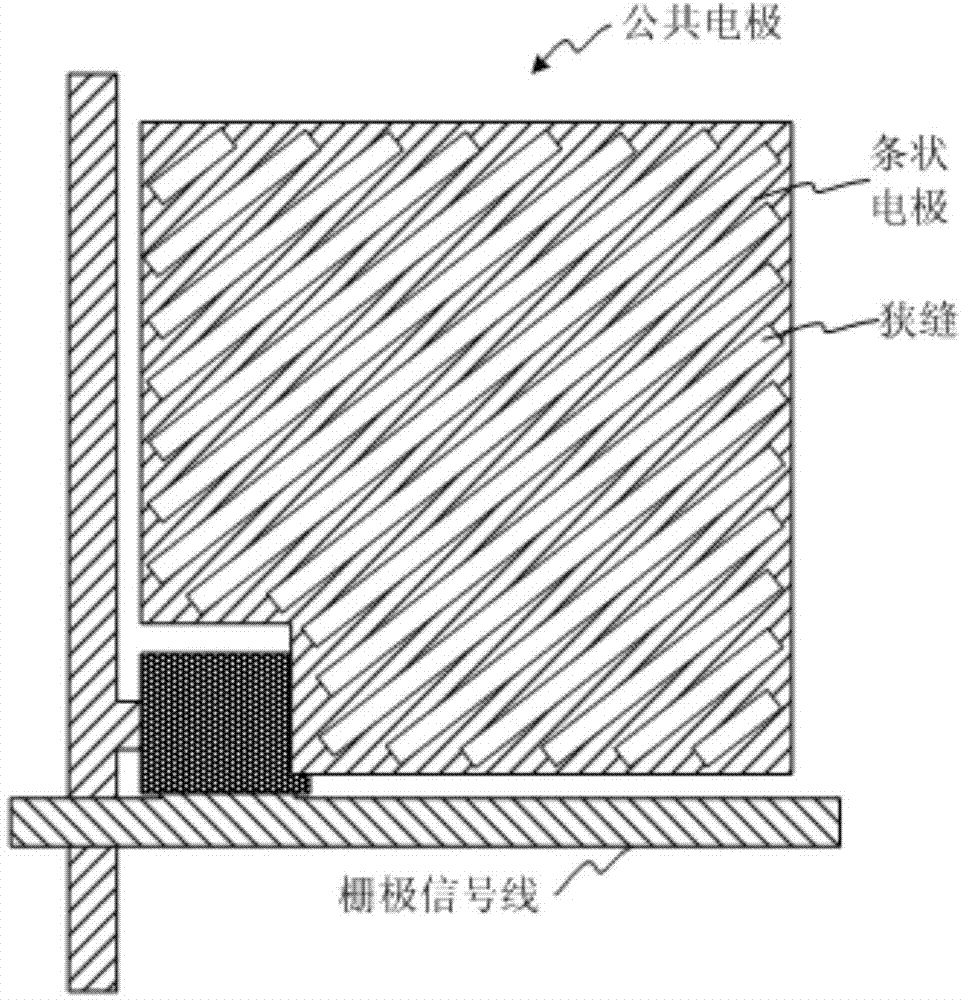

Thin film transistor array substrate, preparation method for same and display device of thin film transistor array substrate

InactiveCN103760721AAchieve semi-transparent and semi-reflective propertiesThe mask process does not need to increase theSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsDisplay device

The invention discloses a thin film transistor array substrate, a preparation method for the same and a display device of the thin film transistor array substrate. The problem that the manufacturing process of the existing thin film transistor array substrate is complicated is solved. According to an embodiment of the invention, the thin film transistor array substrate comprises a plurality of pixel units, wherein each pixel unit comprises a common electrode; patterns of the common electrodes are slit-shaped; each common electrode comprises a strip-shaped electrode and a slit; the strip-shaped electrode in each common electrode can reflect light rays emitted in the strip-shaped electrode; and the slit in each common electrode can transmit light rays emitted in the slit. By using the thin film transistor array substrate, the strip-shaped electrodes in the common electrodes can serve as reflecting areas of the array substrate, and the slits of the common electrodes can serve as transmitting areas of the array substrate, so that the semi-transmitting and semi-reflecting characteristic is realized. Because the slit-shaped common electrodes can be manufactured by using a mask process, the manufacturing process is simplified.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com