Patents

Literature

38results about How to "No texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

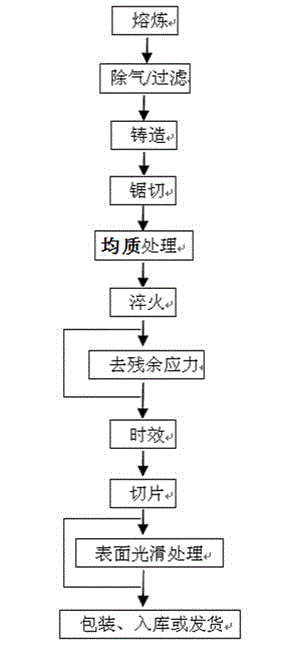

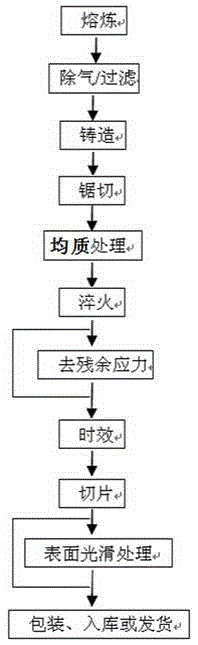

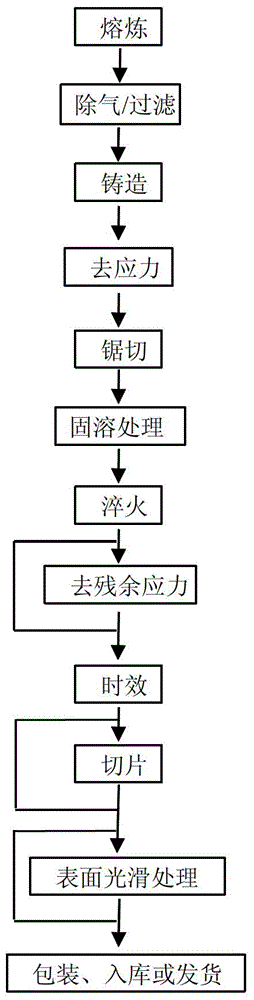

Processing method for aluminium alloy middle thick plate

The invention discloses a processing method for an aluminium alloy middle thick plate. The processing method comprises the following steps of smelting, degassing and filtering, casting, sawing, homogenizing, quenching, removing residual stress, carrying out aging treatment, cutting into slices and performing surface treatment to obtain the aluminium alloy middle thick plate. The aluminium alloy middle thick plate is uniform in structure, low in internal stress, high in size precision, high in strength and low in production cost, and has relatively good economic benefits and social benefits.

Owner:广西南南铝加工有限公司

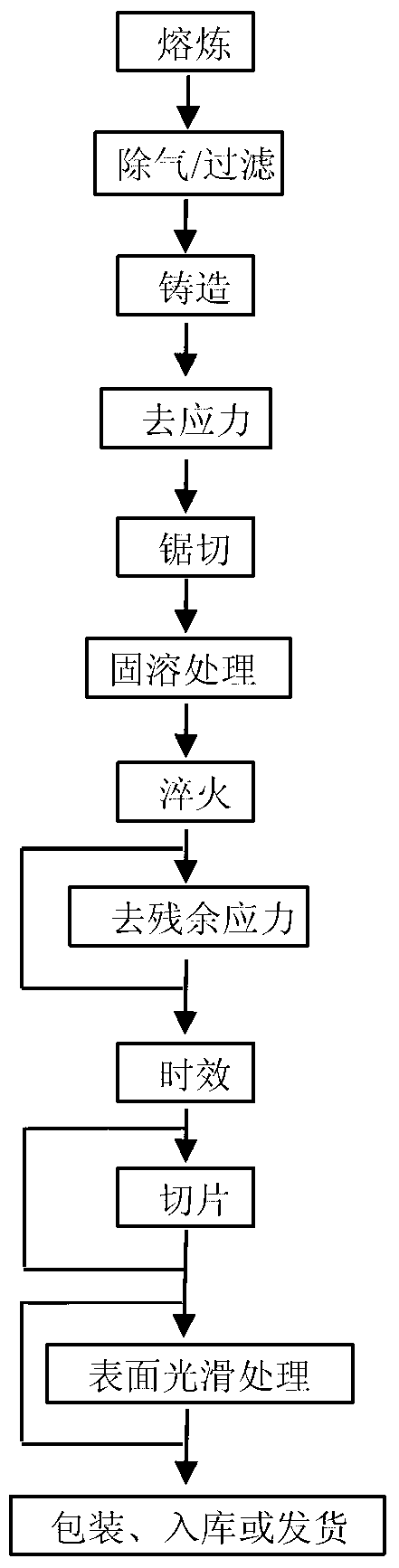

Aluminum alloy medium plate preparation method

The invention discloses an aluminum alloy medium plate preparation method. The aluminum alloy medium plate preparation method comprises the following steps of: smelting at 700-750 DEG C, degassing a melt by adopting a multistage degassing purification system, and filtering the melt by adopting a 300ppi-foamed ceramic filtration plate; casting the melt to obtain an aluminum alloy ingot blank, and carrying out stress-relieving treatment at 300-500 DEG C for more than or equal to 1 hour; controlling the temperature of a saw cutting aluminum alloy sheet at 350-500 DEG C, carrying out solution treatment for more than or equal to 0.5 hour, controlling the tensile deformation at 1%-4%, controlling the temperature of the aluminum alloy sheet at 50-300 DEG C, and carrying out aging treatment for 2-40 hours to obtain an aluminum alloy medium plate. Compared with the aluminum alloy medium plate prepared by a conventional hot-rolling method, the aluminum alloy medium plate prepared by the method has the advantages that the preparation working procedures are reduced, the production cycle is short, the cost is reduced, the plate has good quality and high strength and meets the market requirements, and the good economic benefits and social benefits are achieved.

Owner:广西南南铝加工有限公司

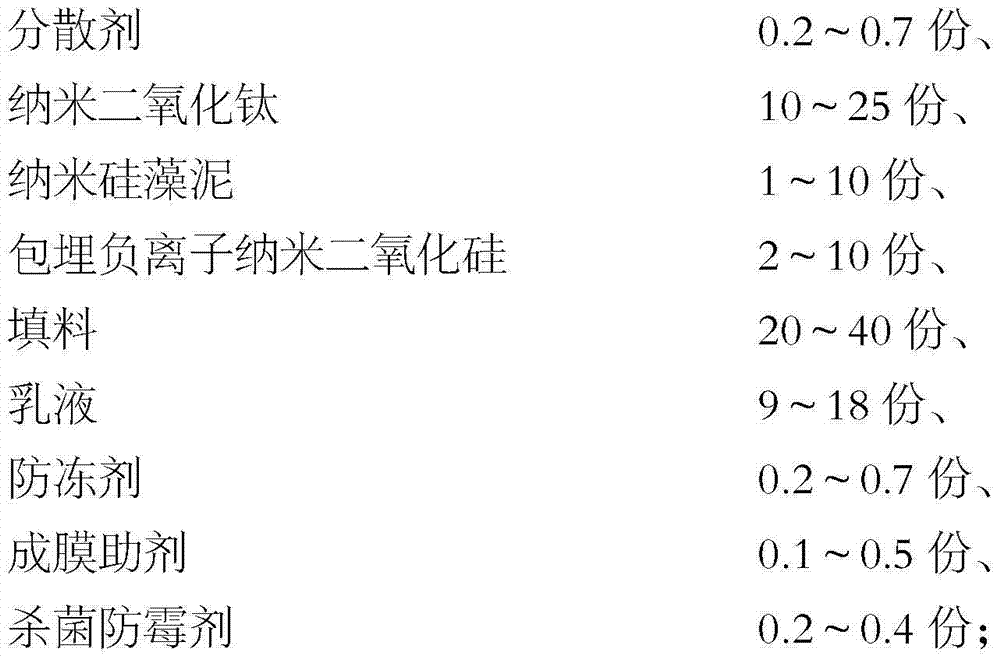

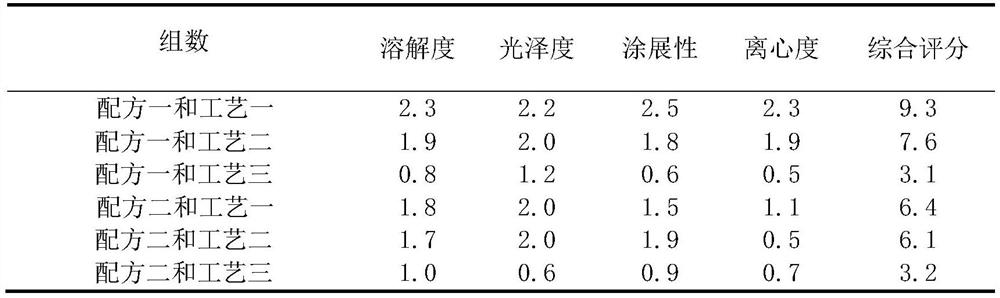

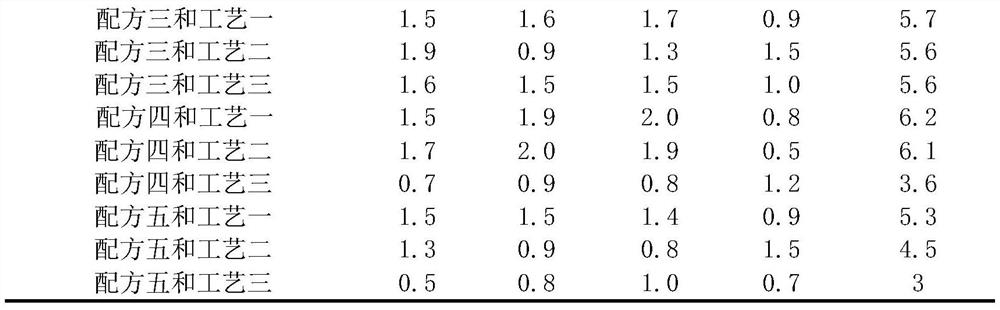

Special-effect heath indoor wall aqueous paint composition and preparation method thereof

The invention relates to a special-effect health indoor wall aqueous paint composition and a preparation method thereof, and belongs to the field of aqueous paint compositions for construction decoration. The paint composition is composed of the following raw materials in parts by weight: 20 to 30 parts of water, 0.2 to 0.5 part of thickening agent, 0.05 to 0.2 part of pH adjuster, 0.1 to 0.3 part of antifoaming agent, 0.1 to 0.4 part of wetting agent, 0.2 to 0.7 part of dispersant, 10 to 25 parts of nano titanium dioxide, 1 to 10 parts of nano diatom ooze, 2 to 10 parts of embedded anionic nano silicon dioxide, 20 to 40 parts of filling material, 9 to 18 parts of emulsion, 0.2 to 0.7 part of anti-freezing agent, 0.1 to 0.5 part of film-forming auxiliary agent, and 0.2 to 0.4 part of bactericidal mildew inhibitor. The paint composition can absorb the harmful components in air, is healthy and environment-friendly, and also has the advantages of excellent color retention, scrubbing resistance, water and alkali resistance, and proper softness of paint film.

Owner:SKSHU PAINT

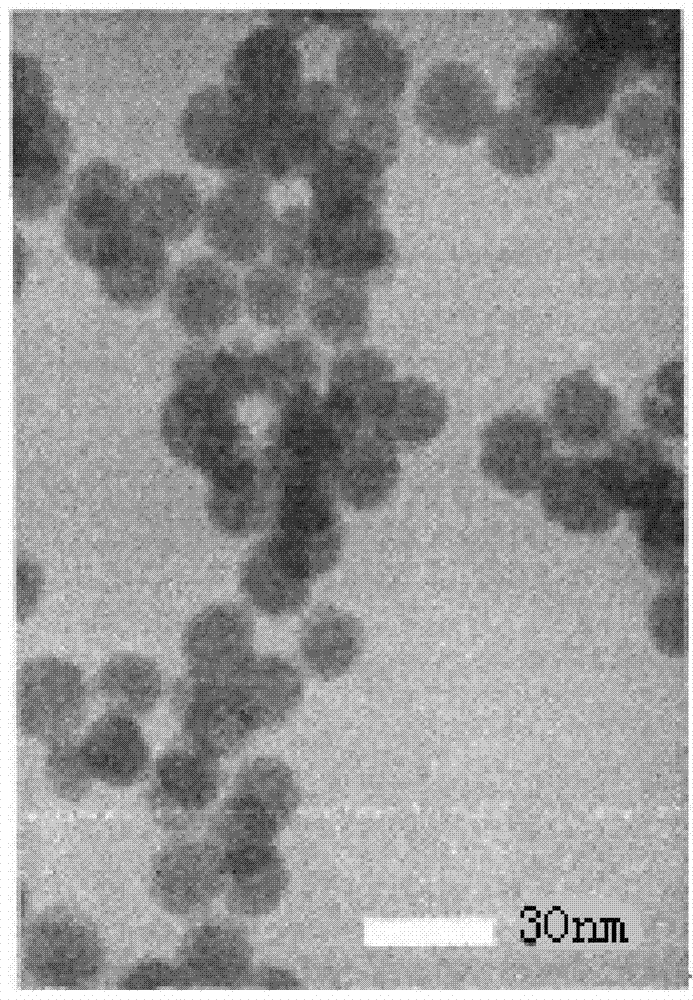

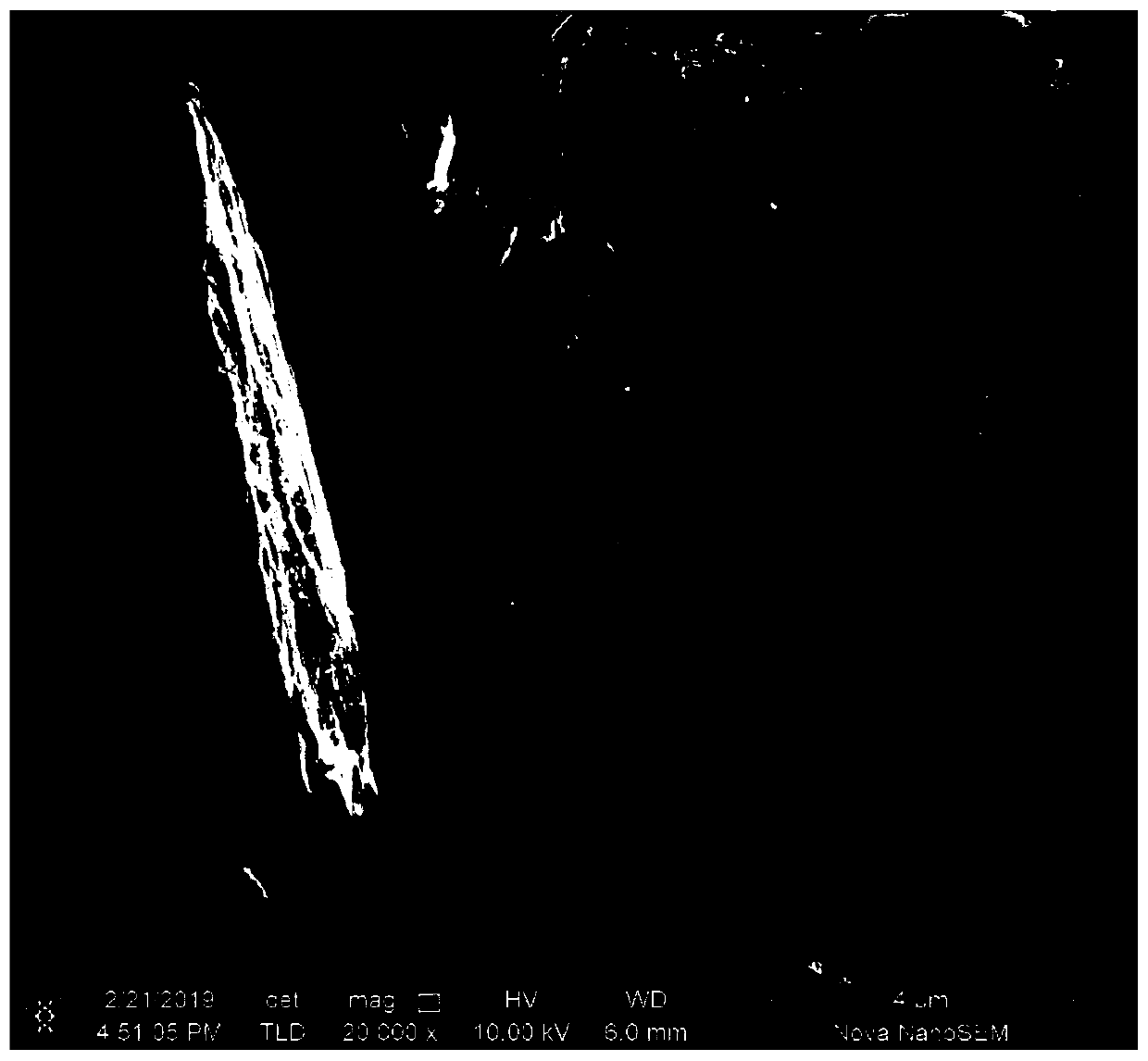

High-strength titanium alloy-graphene composite material and preparation method thereof

The invention provides a preparation method of a high-strength titanium alloy-graphene composite material. The preparation method comprises the following steps: (1) a proper amount of mixed powder consisting of titanium alloy powder and graphene, grinding balls and dispersing agents are put in a ball mill for low-temperature ball milling; and (2) the materials obtained in the step (1) are loaded in a cover for degassing insulation and hot isostatic pressing to finally obtain the high-strength titanium alloy-graphene composite material. Graphene-coated titanium alloy powder obtained through low-temperature ball milling can realize total compactness under special environment of high-temperature and high-pressure hot isostatic pressing; the prepared high-strength titanium alloy-graphene composite material is uniform in microscopic structure, fine in grain, free of texture and isotropic; meanwhile, the mechanical performances are excellent: the stretching strength can reach 1016 MPa, and the yield strength can reach 998 MPa; and the mechanical performances are far higher than the national standard (HB5432-1989) of titanium alloy forgings for aircrafts.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

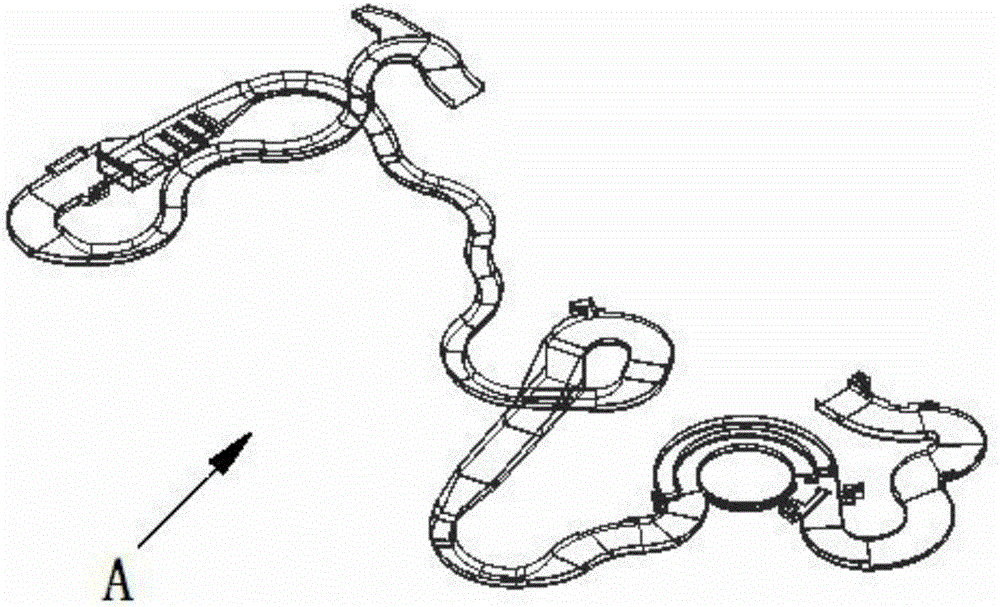

Method for constructing special-shaped solid concrete structure through wet sprayed concrete technique

The invention provides a method for constructing a special-shaped solid concrete structure through the wet sprayed concrete technique. The method comprises the following steps of constructing a special-shaped solid concrete structure building model; conducting batching on concrete materials, wherein dry mixed materials include cement, sand, stones, fiber, an anti-permeability agent and a water reducing agent; mixing the dry mixed materials with water; adding the mixed concrete into a spraying machine and spraying the mixed concrete onto the special-shaped solid concrete structure building model through an air pressure spraying system; trowelling and calendaring the concrete sprayed onto the building model when one-time spraying thickness reaches the design thickness of the concrete structure; and conducting maintenance on the concrete structure constructed through spraying. Through the method, the high-quality and high-precision special-shaped solid concrete structure can be obtained.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Environmental protection type printable top sheet of laminated molding card, preparation method and application

InactiveCN1727202AFlat surfaceHigh bonding strengthDuplicating/marking methodsEngineeringCompanion animal

An environment protection type printable surface film for certificate card is composed of a surficial protecting layer (polyethanediol tere-phthalate (PET) film) and a functional printing-adhering layer containing special osmotic cross-linking assistant. Its advantages are high adhesion and transparency, and high print clearness.

Owner:上海浮托实业有限公司

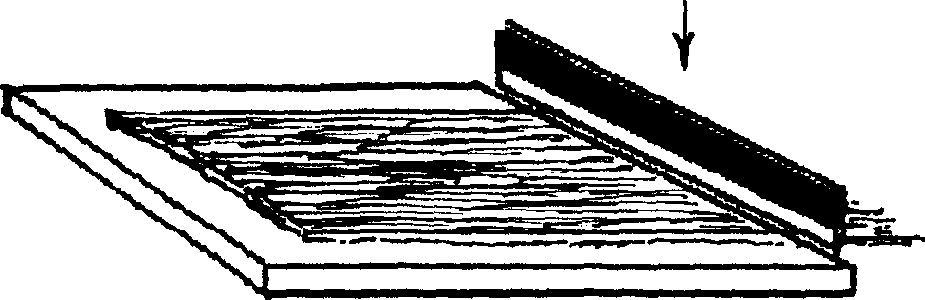

Reed plywood and its processing method

InactiveCN1552557ASimple processHigh strengthCane mechanical workingWood veneer joiningEngineeringWater soluble

A ply-reed used for building shuttering, non-bearing partition, packing material, or furniture is prepared from reed stalks through rolling for longitudinal breaking, cutting by needed size, automatically braiding reed curtain, immersing in water-soluble resin solution, removing excessive solution, baking, alternative laminating, and hot pressing.

Owner:褚宝顺

Positioning printing window curtain fabric with pencil drawing style and manufacturing method thereof

InactiveCN106283337AHigh weft weightNo textureCurtain accessoriesDyeing processDigital printingPolyester

The invention provides a positioning printing window curtain fabric with pencil drawing style and a manufacturing method thereof. The positioning printing window curtain fabric with pencil drawing style comprises a base cloth, wherein the base cloth is provided with at least one layer of fabric, and is formed by weaving warp yarns and weft yarns; each warp yarn is a 8.35tex interlaced yarn, and each weft yarn is a 33.4tex luster polyester drawn textured yarn; the arrangement ratio of weft yarns with different colors is 1 to 1; the base cloth is provided with a to-be-printed area and a printing-free area; the to-be-printed area adopts a five-satin weave, and the printing-free area adopts a honeycomb weave; a printing layer is attached to the to-be-printed area. The positioning print window curtain fabric has the advantages that by adopting weaving and printing integral technique, the digital jacquard weave technique and the precise positioning digital printing technique are organically combined, and the jacquard weave luster and obvious texture are realized by the precise mounting of printing patterns.

Owner:ZHEJIANG HEXIN TEXTILE

Preparation method for SBS (styrene-butadiene-styrene block copolymer) modified asphalt waterproof material

InactiveCN106751949ASimple processLess investmentBuilding insulationsBituminous waterproofingPhenyl Ethers

The invention discloses a preparation method for an SBS (styrene-butadiene-styrene block copolymer) modified asphalt waterproof material. The method comprises the following steps of step1): weighting matrix asphalt, high purity water, SBS, butadiene styrene rubber, N-Polyoxyethylated-N-octadecylamine, hydrochloric acid, methylbenzene, stearic trimethyl ammonium chloride, polyoxyethylene nonyl phenyl ether, sulphur, polyethylene resin, calcium oxide and carbon tetrafluoride; step2): adding the matrix asphalt into a reaction still provided with a stirrer and a thermometer, heating to 170 to 190 DEG C, adding the SBS, the butadiene styrene rubber, the N-Polyoxyethylated-N-octadecylamine, the hydrochloric acid, the methylbenzene, the stearic trimethyl ammonium chloride after melting, dehydration and filtering, stirring for 15 to 55min with the stirring speed of 800 to 1200r / min; step3): adding the high purity water while stirring, heating to 200 to 220 DEG C, adding residual raw materials for mixing 40 to 80min, then adding the components stirred in the step2) to obtain a mixture, adding the mixture into an emulsifying machine to perform emulsification, cooling to 30 to 40 DEG C and defoaming to obtain the SBS modified asphalt waterproof material. The method disclosed by the invention has the advantages that the process is simple, the equipment invest is small, the energy is saved and the consumption is reduced.

Owner:SUZHOU YUXI NEW MATERIAL TECH

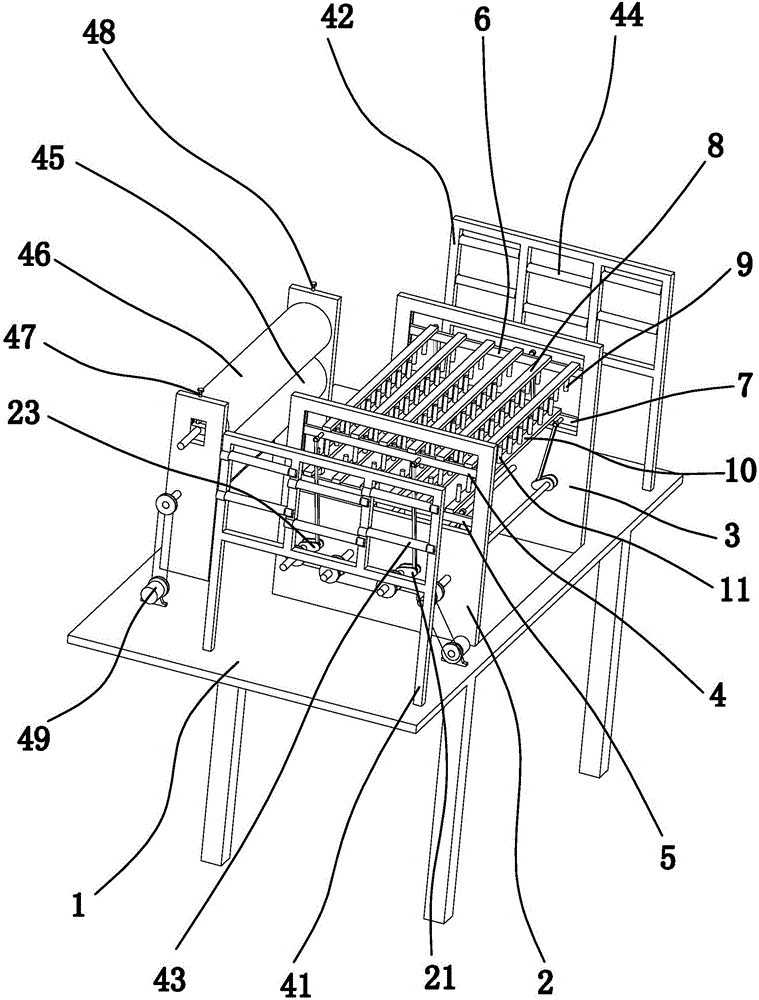

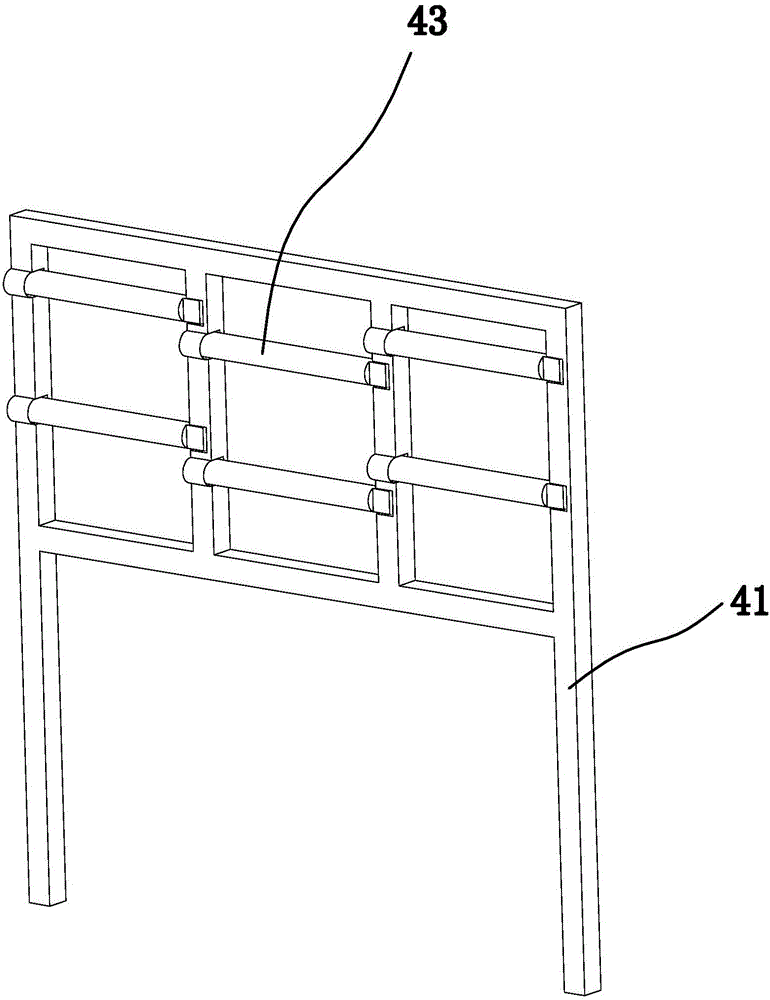

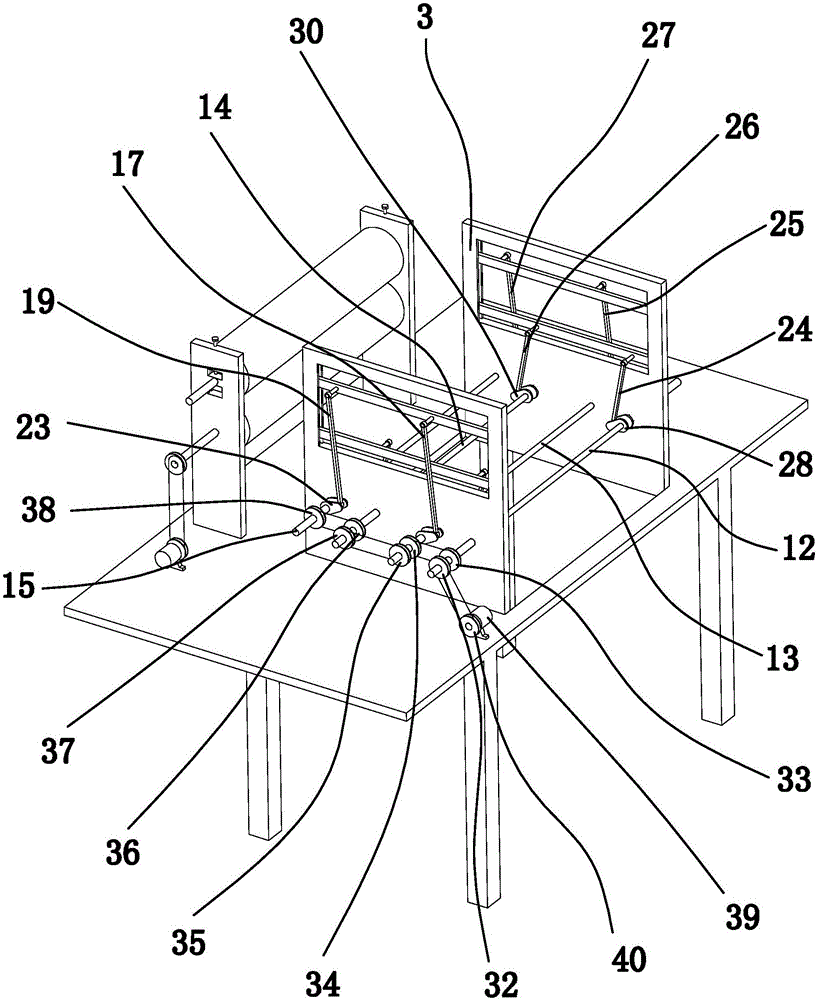

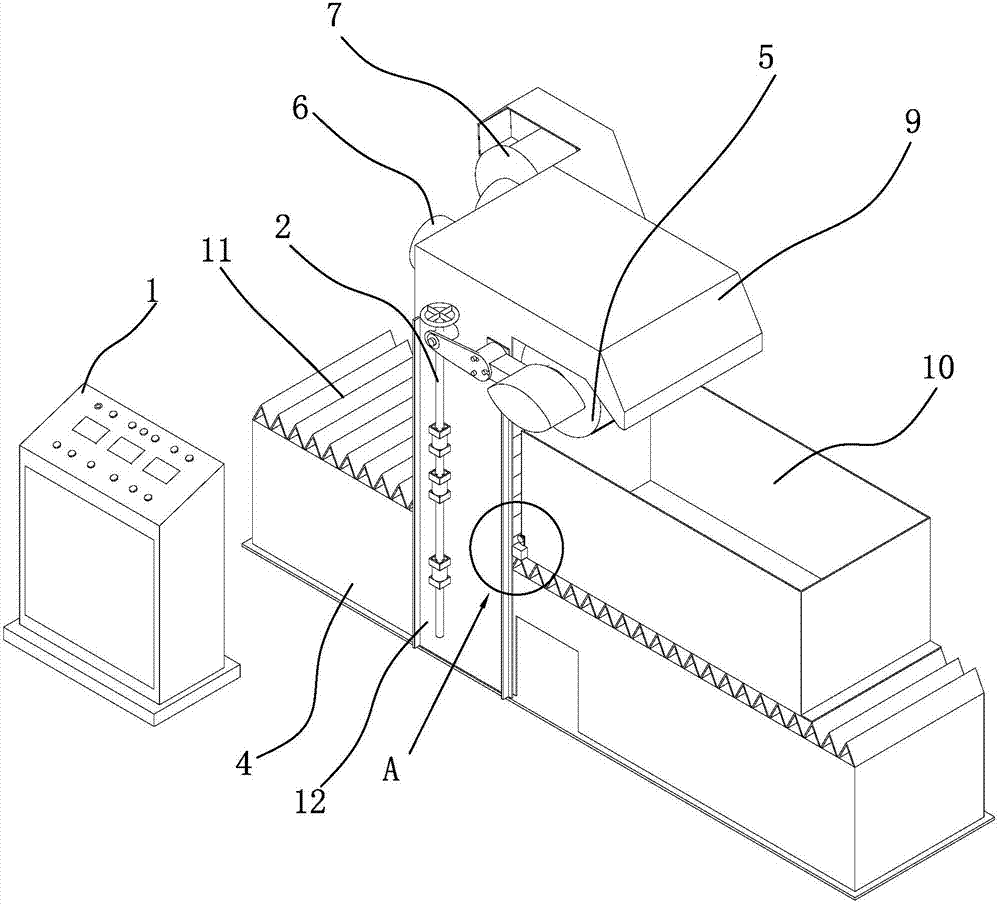

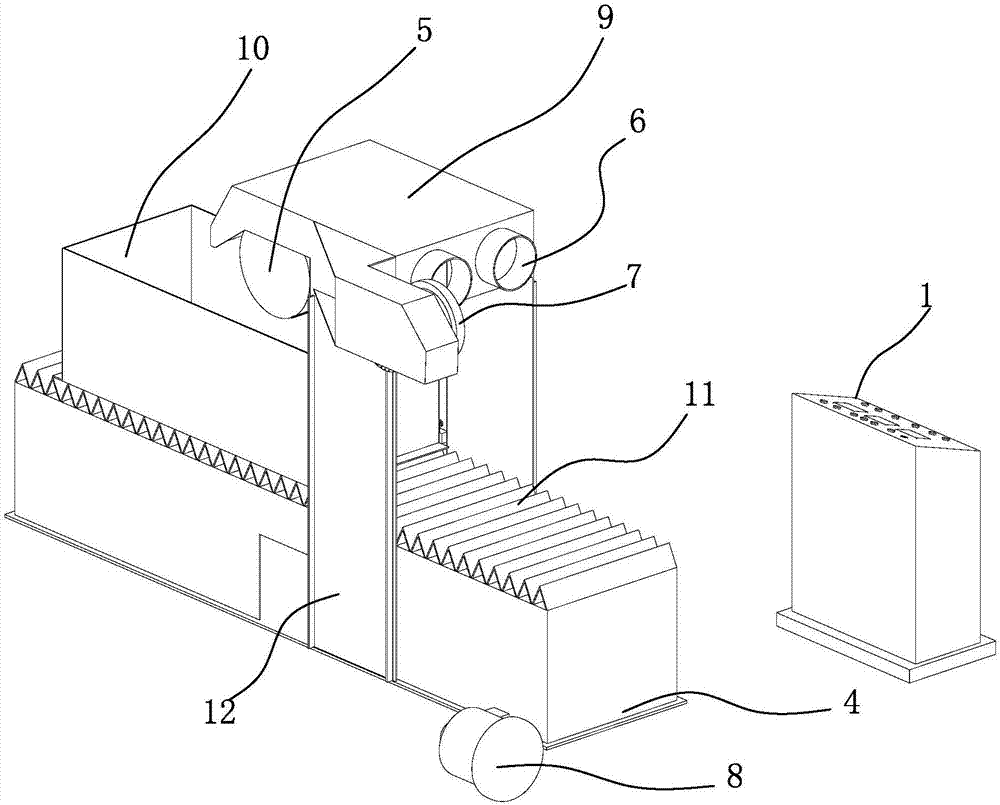

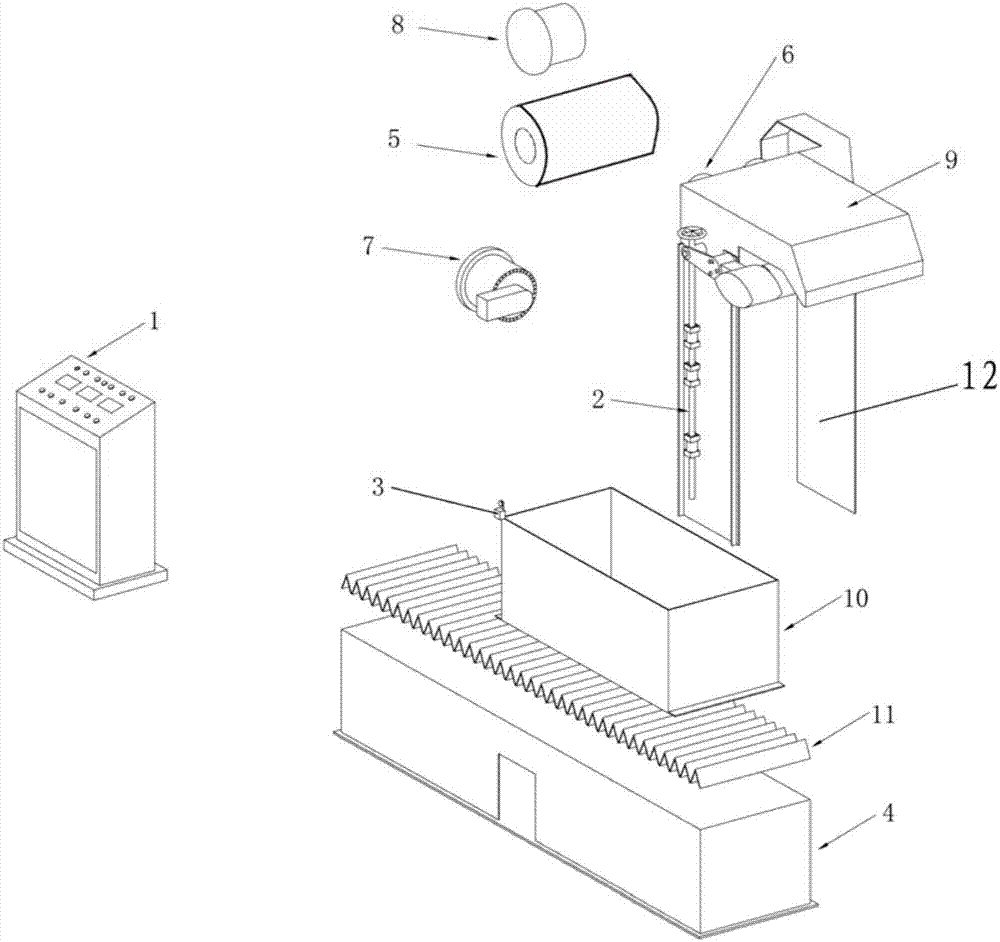

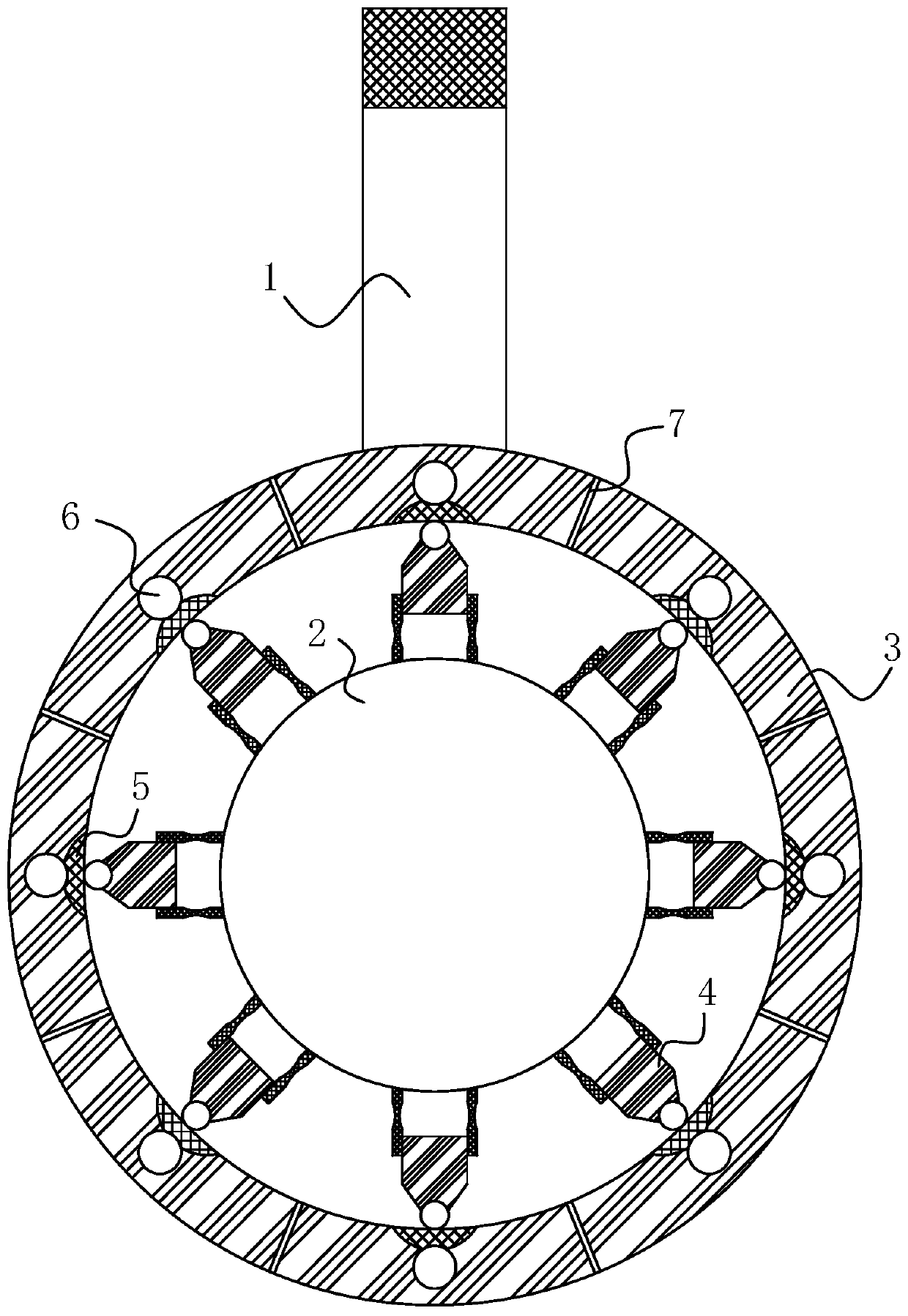

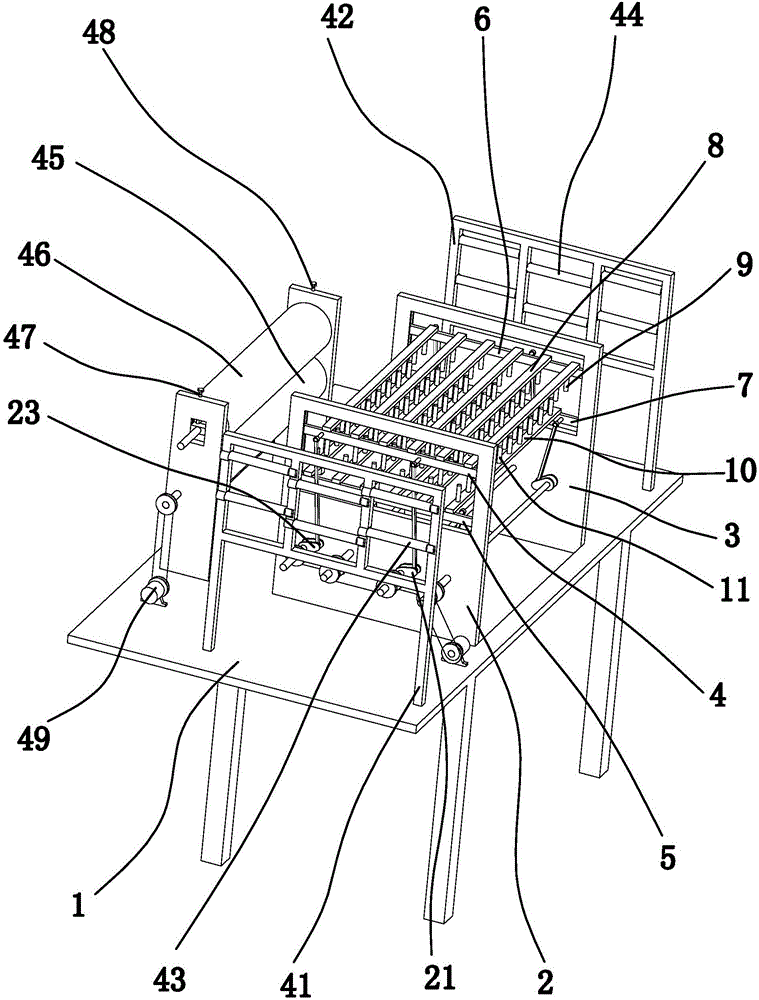

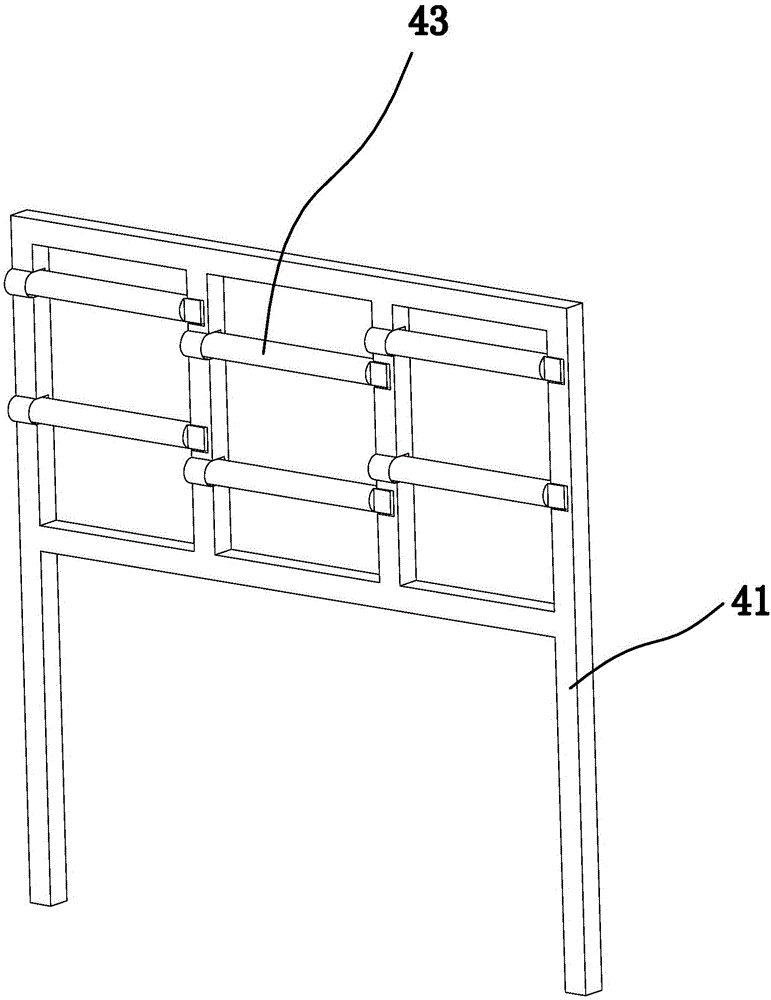

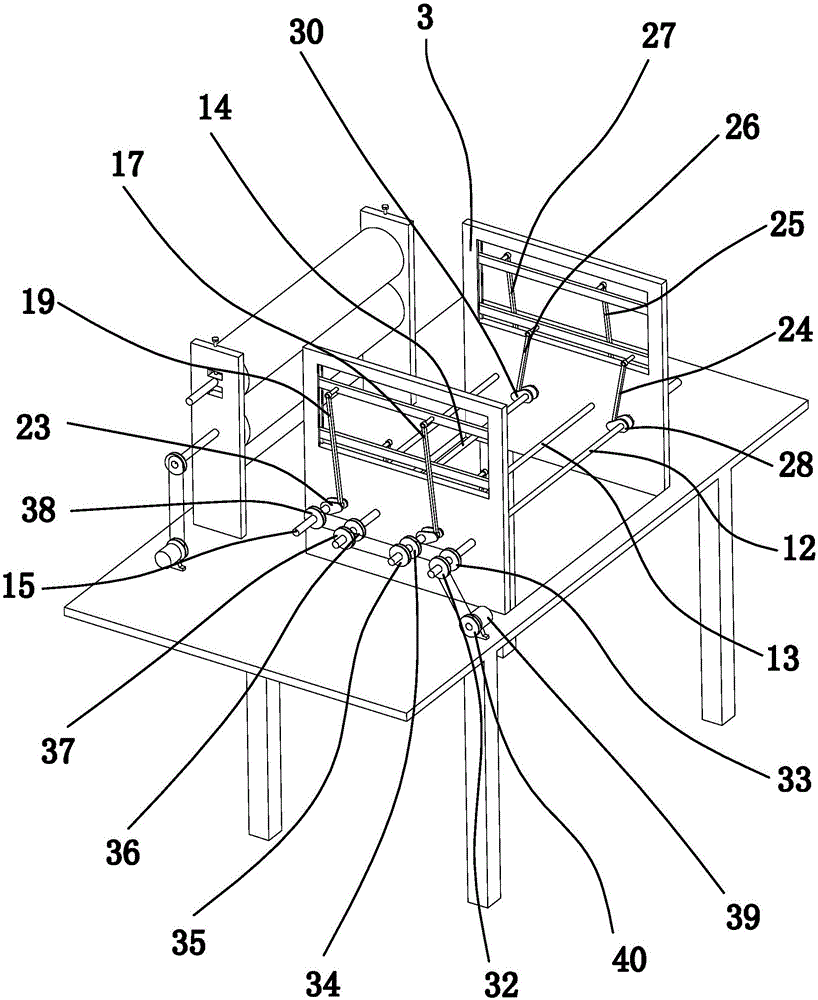

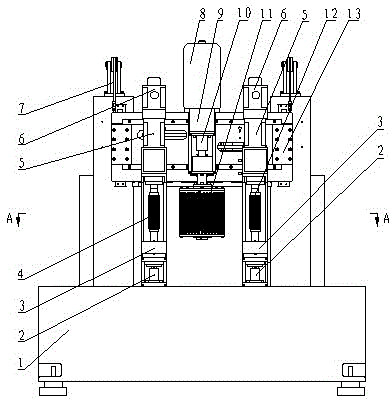

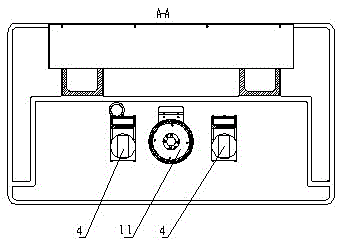

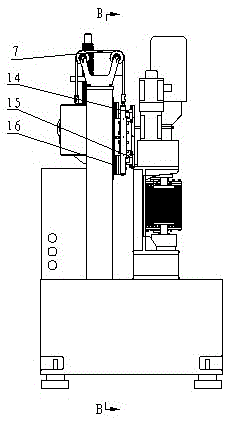

Automatic polishing device and operation method thereof

PendingCN107030585ANo textureIncrease productivityPolishing machinesGrinding feedersPolishingProcess engineering

The invention relates to an automatic polishing device and an operation method thereof. The device comprises a bracket, a processing box, a polishing structure and a conveying structure, wherein products are loaded in the processing box, and the polishing structure is positioned above the processing box; the processing box is positioned above the conveying structure; the polishing structure and the conveying structure are correspondingly connected to the bracket; when in polishing processing, the processing box is horizontally conveyed through the conveying structure, and then the products in the processing box are polished through the polishing structure. According to the automatic polishing device and the operation method thereof, batches of products are stored in the processing box; the processing box is pushed to move to be below polishing wheels through the conveying structure and a horizontal swinging structure; the polishing wheels are driven by the lifting structure to lift up or lift down to be in contact with the products, and thus the bathes of products can be polished, and the production efficiency is increased; in addition, each structure is controlled through a control box; the whole device is simple in structure; the polished surface is free from textures, and the surface is nice.

Owner:深圳市建美来展示制品有限公司

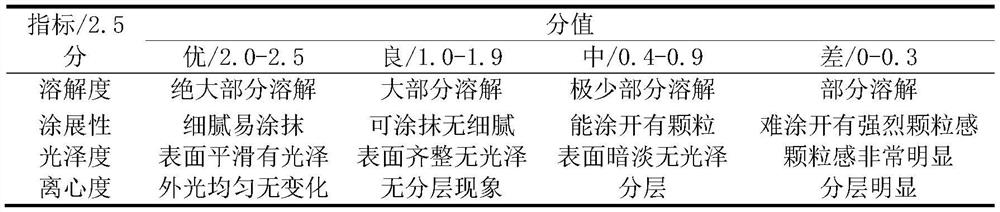

Moisturizing and repairing facial cream and preparation method thereof

ActiveCN112641657ASolve the complex preparation processNo textureCosmetic preparationsToilet preparationsGlycerolPantothenic acid

The invention relates to moisturizing and repairing facial cream and a preparation method thereof. The moisturizing and repairing facial cream is prepared from the following components in percentage by weight: 45-55% of water, 15-25% of caprylic / capric triglyceride, 5-8% of propylene glycol, 2.5-5.5% of cetostearyl oleate, 1.5-3% of sorbitan oleate, 1.5-3% of squalane, 1-3% of tocopheryl acetate, 5-9% of glycerol, 1-2% of avocado tree butter, 1-3% of urea, 0.5-1.5% of sodium hyaluronate, 0.1-0.5% of vitamin B3, 0.1-0.3% of acetyl chitin, 0.05-0.15% of calcium pantothenate, 0.04-0.10% of sodium citrate, 0.005-0.015% of adenosine, 0.005-0.013% of lactic acid and 0.001-0.006% of ceramide 3. The preparation method comprises the following steps of weighing different components to respectively prepare four different mixtures , combining the mixtures, uniformly stirring the mixtures by using a heat collection type magnetic stirrer, and obtaining the moisturizing and repairing facial cream. The moisturizing and repairing facial cream has the advantages of skin repairing, hydrating, moisturizing, whitening, wrinkle resisting and the like, and is simple in preparation process, low in equipment requirement and suitable for industrial production.

Owner:贵州大隆药业有限责任公司

Water-based paint for indoor wall surfaces

InactiveCN110746810AReduce the amount of solutionMeet brushing requirementsAntifouling/underwater paintsPaints with biocidesHazardous substanceNano titania

The invention belongs to the technical field of water-based paint for architectural decoration and particularly relates to water-based paint for indoor wall surfaces. The water-based paint comprises the following ingredients in parts by weight: 40 parts of water, 1 part of thickener, 0.5 part of pH adjuster, 0.5 part of antifoamer, 1 part of humectant, 0.9 part of dispersant, 30 parts of nano-titania, 20 parts of nano diatom ooze, 7 parts of anion embedded nano-silica, 50 parts of fillers, 15 parts of emulsion, 0.6 part of antifreezer, 0.5 part of film forming assistant and 2 parts of bactericidal mildew preventive. The water-based paint for the indoor wall surfaces, provided by the invention, can be used for effectively adsorbing formaldehyde released due to indoor fitment, organic aromatic hydrocarbon benzene solvents on sheets and substances harmful to human bodies such as amine substances; and through actions such as neutralization with harmful gases with positive charges and coating and settling of ions or particles of electrically-neutral harmful gases, the activity of the substances harmful to the human bodies is lost or lowered, and thus, a safe air quality environment fordwelling and living is provided.

Owner:高卫

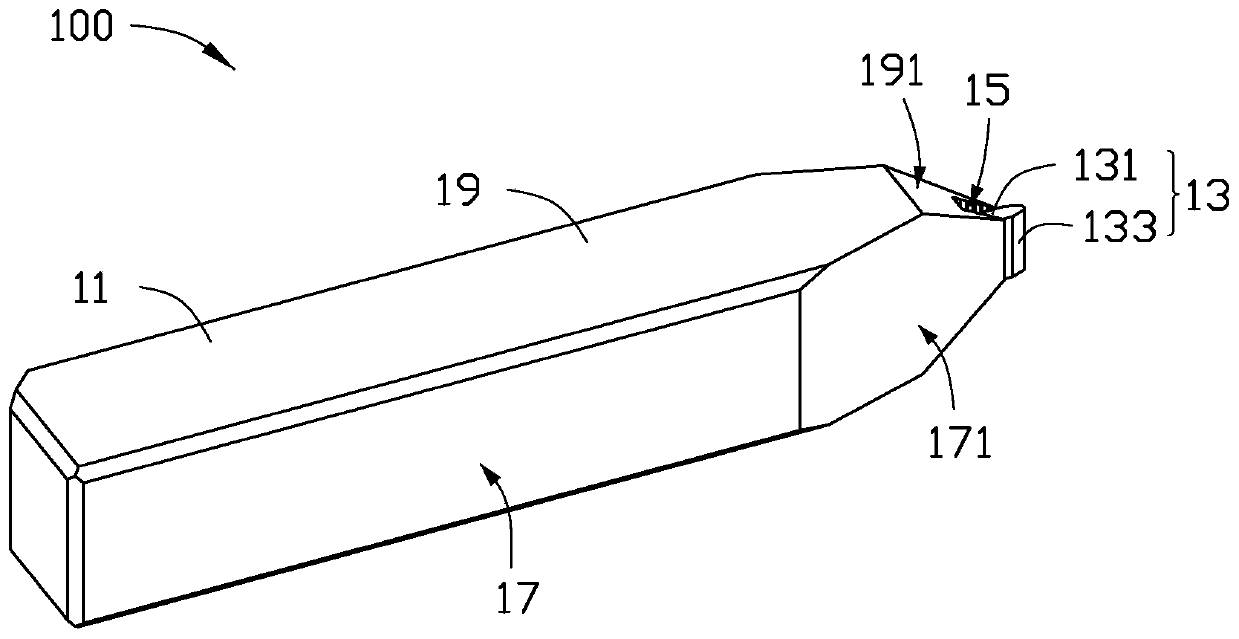

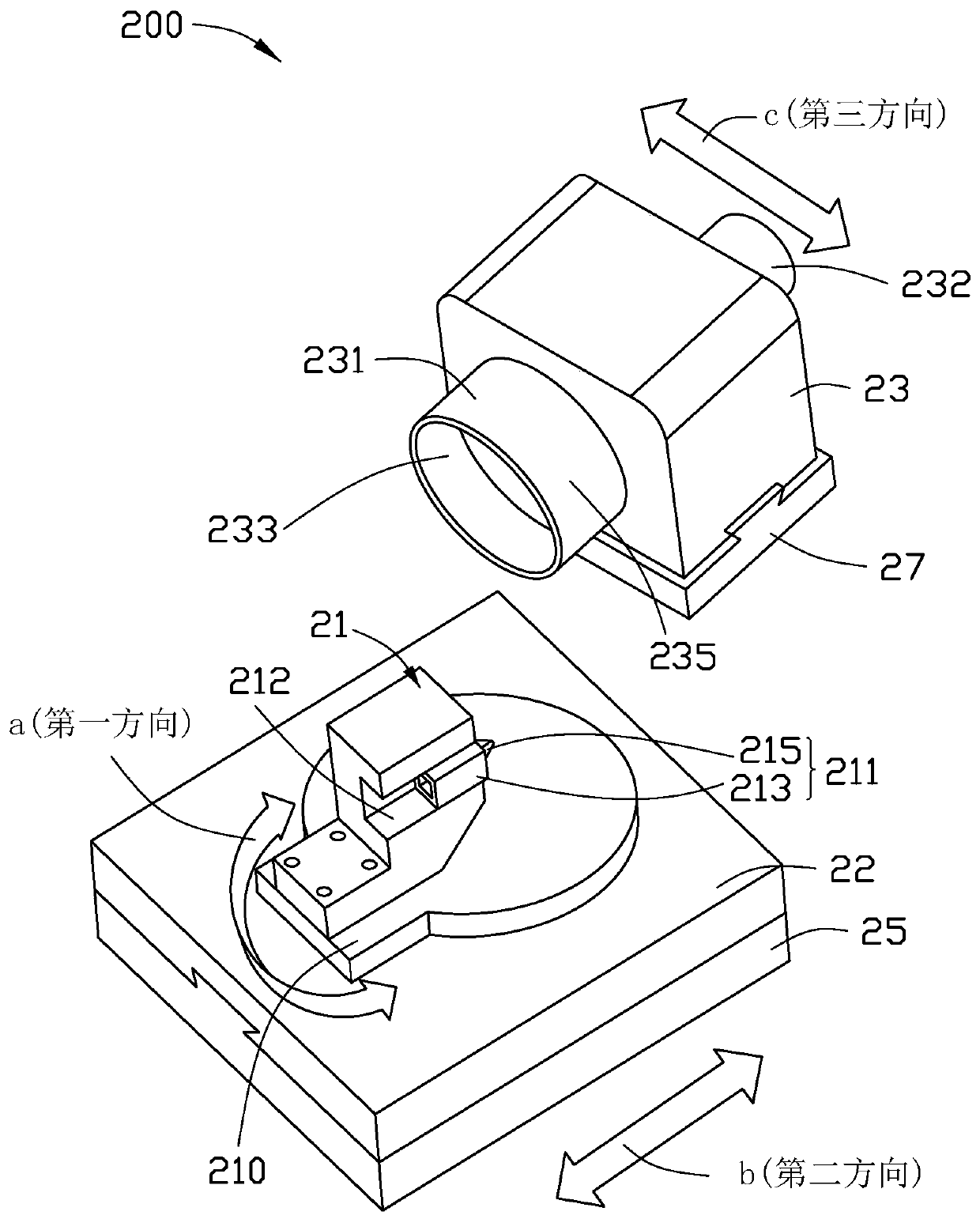

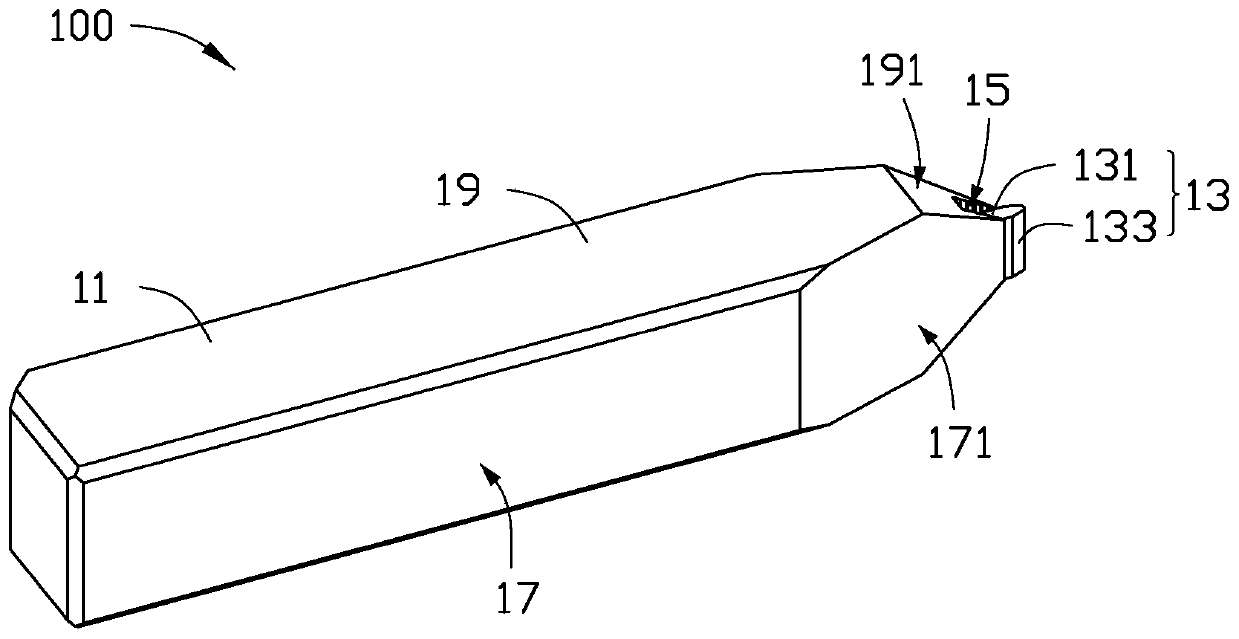

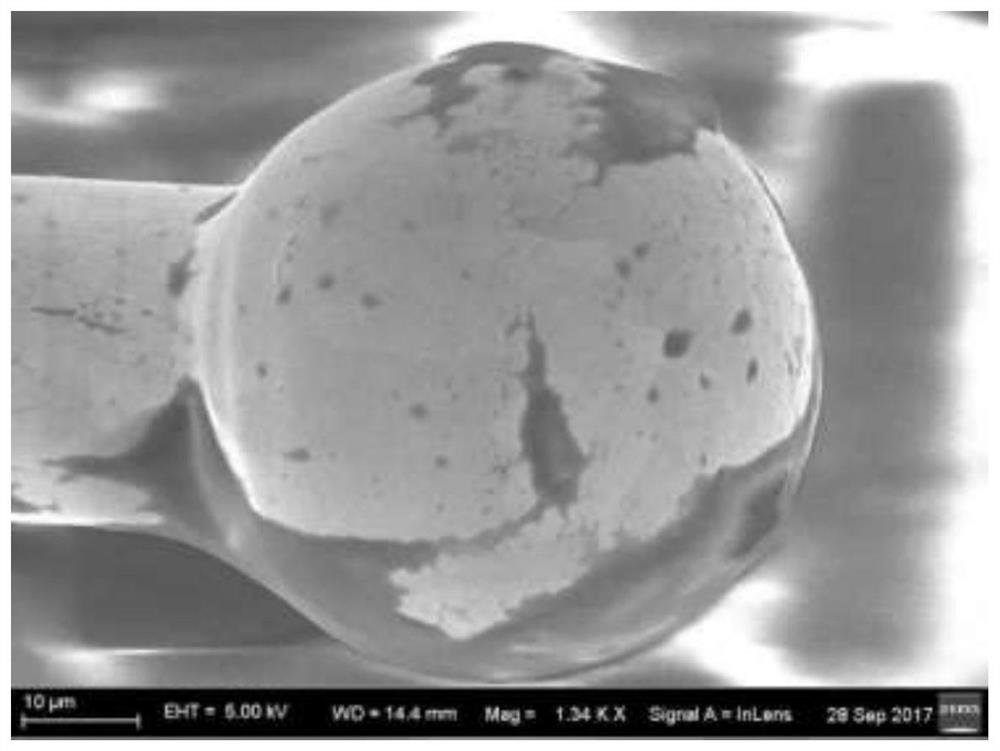

Grinding machine, diamond tool and machining method of diamond tool

A diamond tool is used for grinding a to-be-machined workpiece, and comprises a main body and a diamond particle fixed to one end of the main body; one end of the main body is provided with a concavegroove; the diamond particle comprises a fixing part and a grinding part formed by extending from the fixing part; the fixing part is stored and fixed to the concave groove; the grinding part is exposed out of the concave groove and used for grinding the to-be-machined workpiece, the profile arithmetical mean deviation Ra, the profile maximum height Ry and the microcosmic irregularity ten-point height Rz of the grinding part meet the relation that Ra is smaller than 0.124 [mu]m, Ry is smaller than 1.306 [mu]m, and Rz is smaller than 0.757 [mu]m. The invention further provides a grinding machine and a method for manufacturing the diamond tool. According to the diamond tool, the grinding machine and the method for manufacturing the diamond tool, flexible grinding is conducted through an airflotation shaft and an air flotation platform, thus, the obtained diamond tool meets the design requirements for the appearance and size and has the characteristics of being smooth in arc and free oflines, meanwhile, the machining yield reaches 99% or above, and one diamond tool can machine 600 to-be-machined workpieces.

Owner:JIZHUN PRECISION IND HUIZHOU

SBS (styrene butadiene styrene) asphalt modifier

InactiveCN106497107AImprove performanceChange structureBuilding insulationsPolyvinyl alcoholFlexural strength

The invention belongs to the field of asphalt materials, and particularly relates to a SBS (styrene butadiene styrene) asphalt modifier which comprises, by weight, 100 parts of SBS, 25-45 parts of chloroprene rubber, 4-8 parts of polyvinyl alcohol, 10-30 parts of stearic acid, 0.3-0.7 part of sodium hydroxide, 1-5 parts of dibutyl phthalate, 0.2-0.8 parts of sodium chloride, 10-20 parts of zinc oxide, 0.1-0.5 part of tetramethyl thiuram disulfide, 4-8 parts of light magnesium oxide, 1-5 parts of dioctyl phthalate and 5-10 parts of waste cooking oil. By the aid of the SBS asphalt modifier, base asphalt is good in toughness free from crack and breakage, caking property is 0.6-1MPa, the base asphalt endures high temperature ranging from 90 DEG C to 100 DEG C, flowing, foaming and sliding are omitted when the base asphalt is at the temperature of 100 DEG C for 5 h, impermeability is 0.1-0.2MPa, the base asphalt cannot be permeable for 30-60min, solid content is 52-58%, asphalt products are high in bending strength and compressive strength, and cobwebbing, cracking and tearing are omitted when the asphalt products are at the temperature of -10 DEG C.

Owner:SUZHOU YUXI NEW MATERIAL TECH

Preparation method of SBS asphalt stabilizer

InactiveCN106589987AEasy to prepareReduce manufacturing costBuilding insulationsNetwork structureUltimate tensile strength

The invention belongs to the technical field of asphalt modifiers and relates to a preparation method of a SBS asphalt stabilizer. The method comprises 1) preparation of activated calcium carbonate, and 2) preparation of the SBS asphalt stabilizer. The preparation method is simple, reduces a production cost and reduces labor intensity. The raw materials are used in a proportion to form a network structure of asphalt and SBS so that the storage stability between asphalt and SBS is improved and SBS-modified asphalt use performances are improved. In addition, through butyl titanate, the activated calcium carbonate in the SBS asphalt stabilizer is subjected to surface treatment so that the dispersibility and compatibility of the SBS asphalt stabilizer in the SBS-modified asphalt are improved.

Owner:SUZHOU YUXI NEW MATERIAL TECH

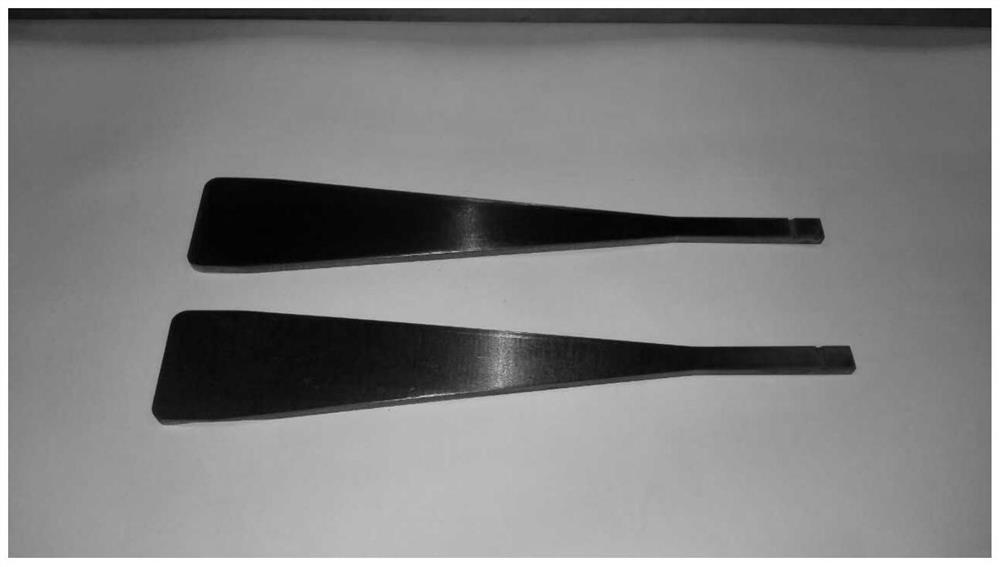

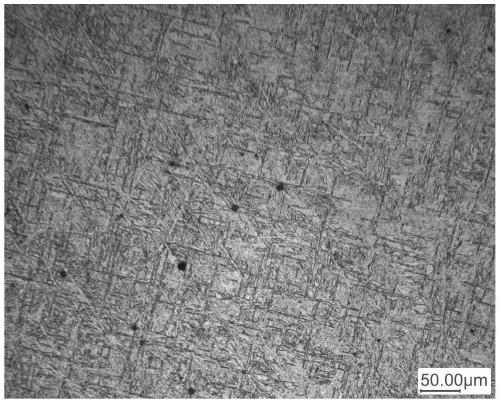

Method used for forming of thick plate blanks from high-temperature direct forging of TiAl alloy powder

The invention relates to a method used for forming of thick plate blanks from high-temperature direct forging of TiAl alloy powder, and belongs to the technical field of hot working of TiAl alloy. Themethod used for forming of the thick plate blanks from high-temperature direct forging of the TiAl alloy powder comprises the following steps: firstly, filling to-be-machined jackets with the alloy powder, sequentially conducting treatment of vacuumizing, heating and heat preservation, and vacuumizing to obtain powder ingot blanks, and conducting soldering and sealing on air vents; then placing the powder ingot blanks into a high-temperature furnace, conducting heating to elevate the temperature to 1400-1440 DEG C, and then conducting heat preservation; then conducting forging by adopting a forging machine in radial directions of the powder ingot blanks, and maintaining pressure for 20-30 s after forging is conducted, wherein under the binding action of an upper die and a lower die of theforging machine and the jackets, the alloy powder in the powder ingot blanks start to collide with each other, and is subjected to forming after being subjected to plastic deformation; and finally, placing the powder ingot blanks, subjected to forging and pressure maintaining, in air, conducting natural cooling until the temperature drops to a room temperature, and removing the jackets. Comparedwith a hot isostatic pressure technology, the method used for forming of the thick plate blanks from high-temperature direct forging of the TiAl alloy powder has the advantages that due to short heating time, few PPB particles participate, and the plastic deformation amount is large, so that original PPB networks are thoroughly destroyed, and adverse effects of PPB on the mechanical performance ofthe material (TiAl alloy powder) can be reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Manufacture method for positioned printing curtain fabric with pencil drawing style

InactiveCN106222842AHigh weft weightNo textureJacquardsMulti-ply fabricsImage processing softwareEngineering

The invention provides a manufacture method for a positioned printing curtain fabric with a pencil drawing style. The method comprises the steps that (1) a design diagram draft is scanned and input into image processing software; (3) a base fabric and a jacquard structure on the fabric are woven, sizing is conducted to the base fabric, a sizing agent is then dried, the base fabric is fixed on an accurate alignment digital printing machine, scanning and photography are conducted, an average returning standard is determined according to a photo obtained after the scanning, and a printing template is fabricated; (4) a printed layer and the printing template are compared and modified; and (5) ink-jet printing processing is conducted to areas on the base cloth in need of printing by the accurate alignment digital printing machine, so that the fabric which has features of jacquard and printing and has the pencil drawing style is obtained. By the method provided by the invention, gloss and textures of the jacquard become more striking.

Owner:ZHEJIANG HEXIN TEXTILE

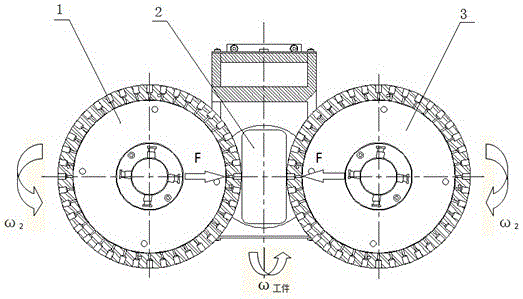

A polishing method for polygonal or curved workpieces

The invention discloses a polishing method for polygonal or curved workpieces. The polishing method is characterized by comprising the steps of utilizing a numerical control program of a computer to collect the load signal of a workpiece rotary servo motor, and respectively controlling the rotary speed omega of the workpiece and the polishing pressure F of a polishing wheel for the workpiece. The polishing method belongs to a continuous soft shape-following constant pressure variable speed control method and is suitable for the polishing of the polygonal or curved workpieces, the glass is uniform in polishing without lines and the polishing precision and polishing efficiency are improved.

Owner:YUHUAN CNC MACHINE TOOL

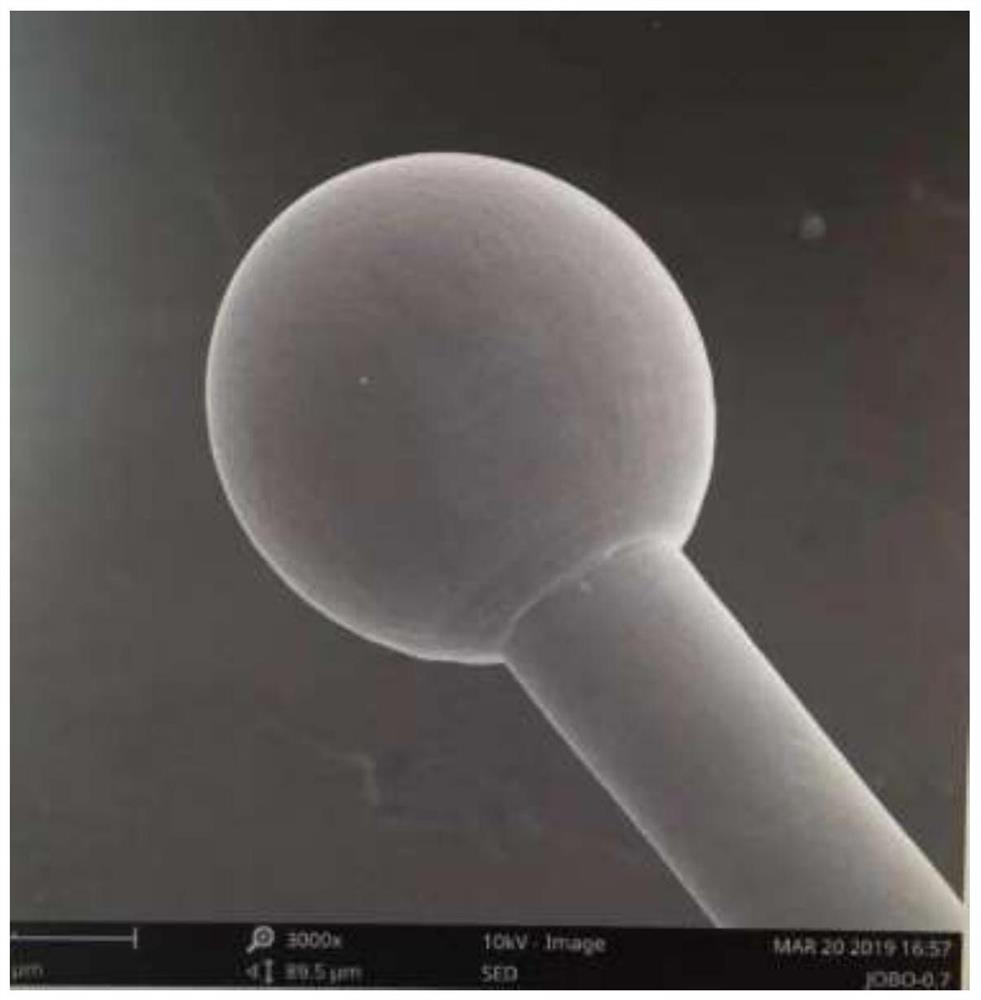

A kind of bonding silver wire material with high spheroidity and preparation method thereof

ActiveCN110699570BImprove ball formingHigh ballSemiconductor/solid-state device detailsSolid-state devicesIndiumCerium

The invention belongs to the technical field of bonding wire materials, and relates to a high spherical bonding silver wire material and a preparation method thereof. The composition of the material comprises silver 99%±0.2%, nickel 0.4%±0.04%, and cobalt 0.4% ±0.05%, calcium 0.01%±0.001%, copper 0.01%±0.001%, gold 0.03%±0.004%, palladium 0.03%±0.004%, lanthanum 0.01%±0.001% and lead 0.0025%±0.0005%, also including other trace amounts The elements include one or more of indium, cerium, yttrium, and selenium. The preparation method of the bonding silver wire material of the present invention makes each metal component melt and synthesizes separately by steps, so that the crystal grains of each component are fully matched during the synthesis process of the bonding silver wire material, and the spheroidization of the synthesized bonding silver wire is improved. , in order to improve the chemical stability and mechanical properties of the alloy wire material.

Owner:广东佳博电子科技有限公司

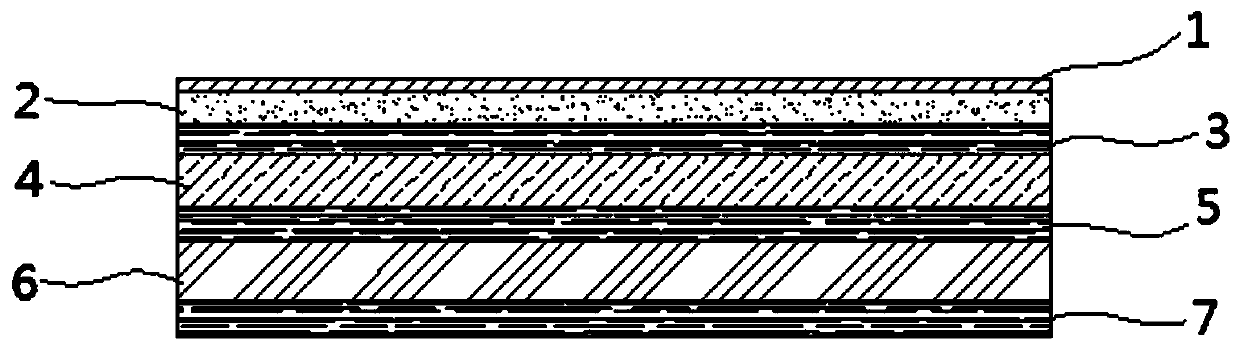

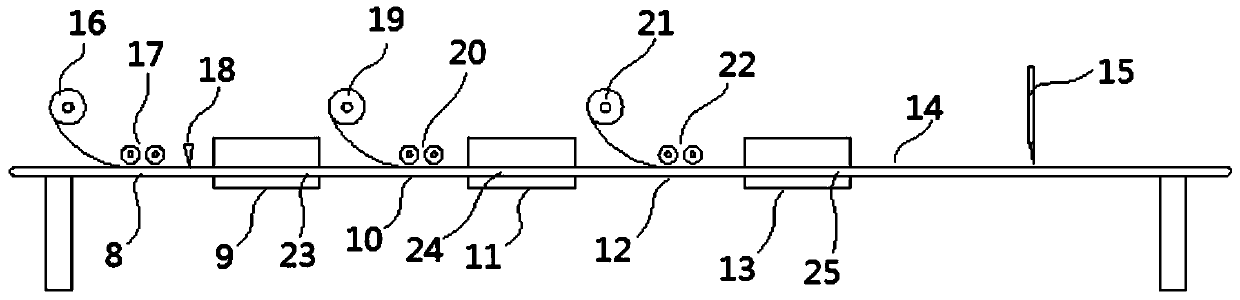

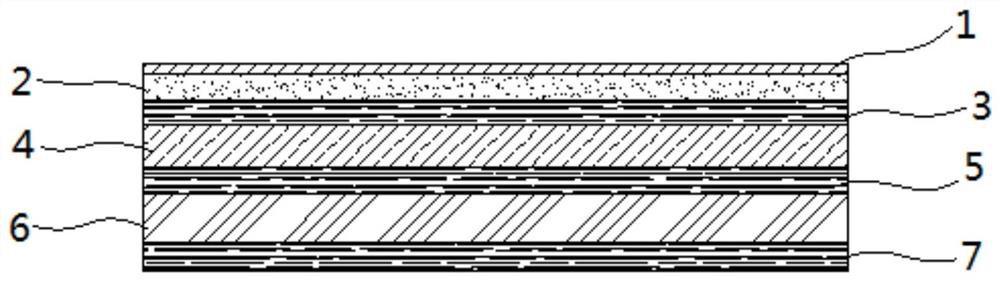

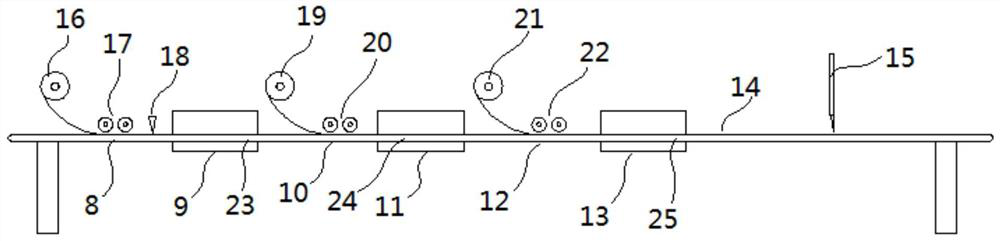

Mirror surface glass fiber reinforced plastic plate, preparation device and preparation method thereof

ActiveCN111086309AGood surface smoothnessSignificantly improved surface smoothnessSynthetic resin layered productsVehicle componentsGlass fiberShrinkage rate

The invention discloses a mirror surface glass fiber reinforced plastic plate, a preparation device and a preparation method thereof. The glass fiber reinforced plastic plate comprises a PET film layer, a zero-shrinkage gel coat layer, a first unsaturated resin layer, a glass fiber surfacing mat layer, a second unsaturated resin layer, a glass fiber chopped strand mat layer and a third unsaturatedresin layer which are sequentially connected from top to bottom. The preparation device comprises a first conveying belt, a first curing chamber, a second conveying belt, a second curing chamber, a third conveying belt, a third curing chamber, a fourth conveying belt and a cutting device which are connected in sequence, wherein a PET film unwinding device, a gel coat applying device and a scraperare sequentially arranged above the first conveying belt in the direction from the upstream to the downstream, a glass fiber surface mat unwinding device and a first gluing roller are sequentially arranged above the second conveying belt in the direction from upstream to downstream, and a glass fiber chopped strand mat unwinding device and a second gluing roller are sequentially arranged above the third conveying belt in the direction from upstream to downstream. The surface smoothness, the surface gloss and the mechanical property of the glass fiber reinforced plastic plate are remarkably improved, and the shrinkage rate of the gel coat is zero.

Owner:南京德嘉玻璃钢材料有限公司

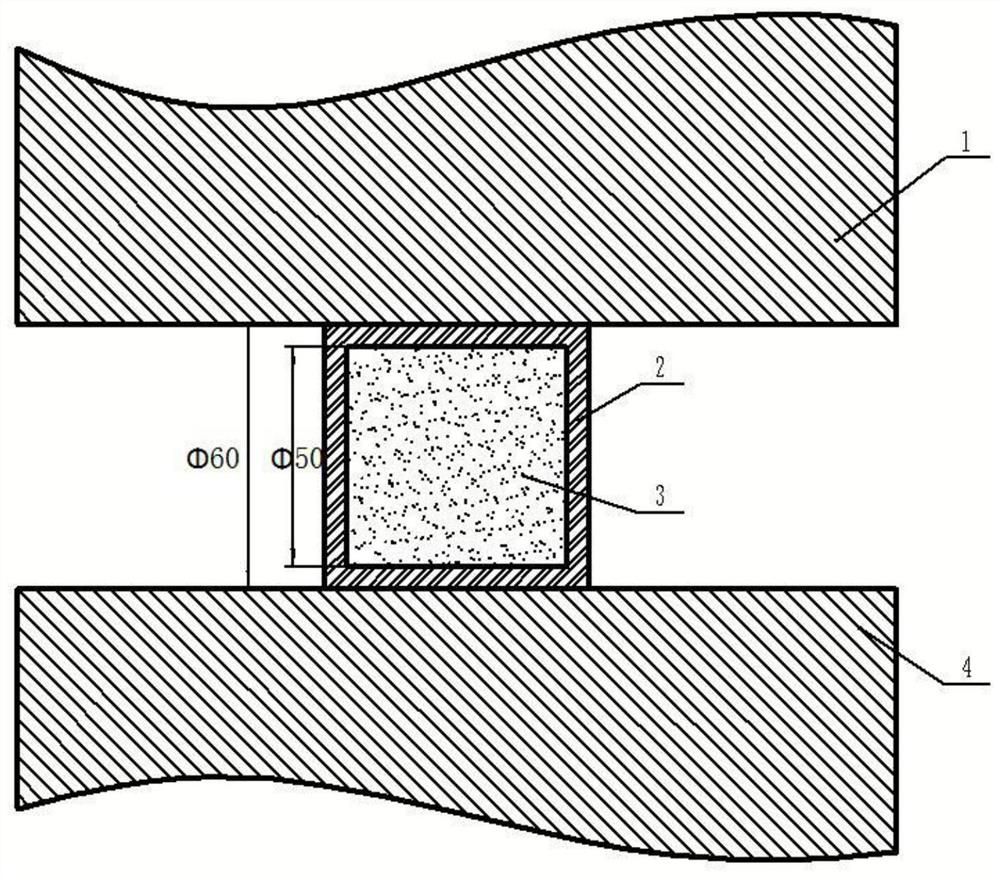

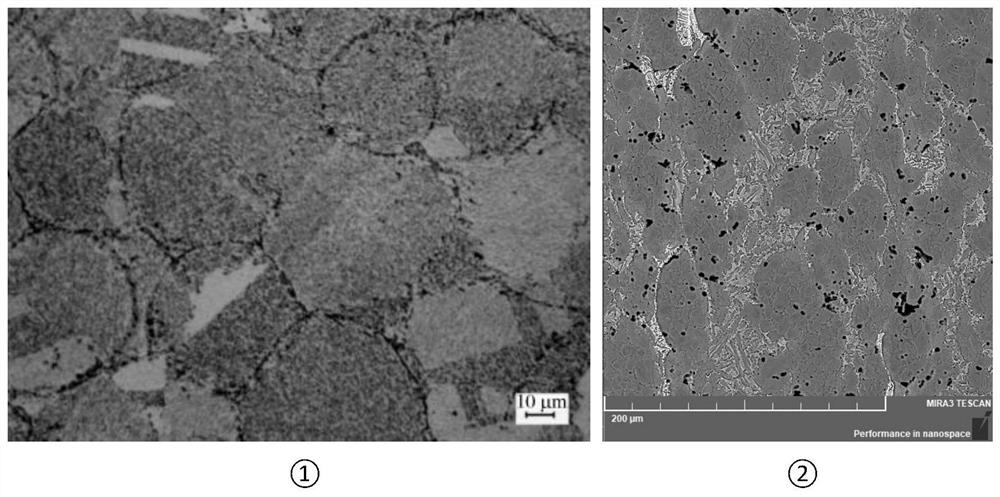

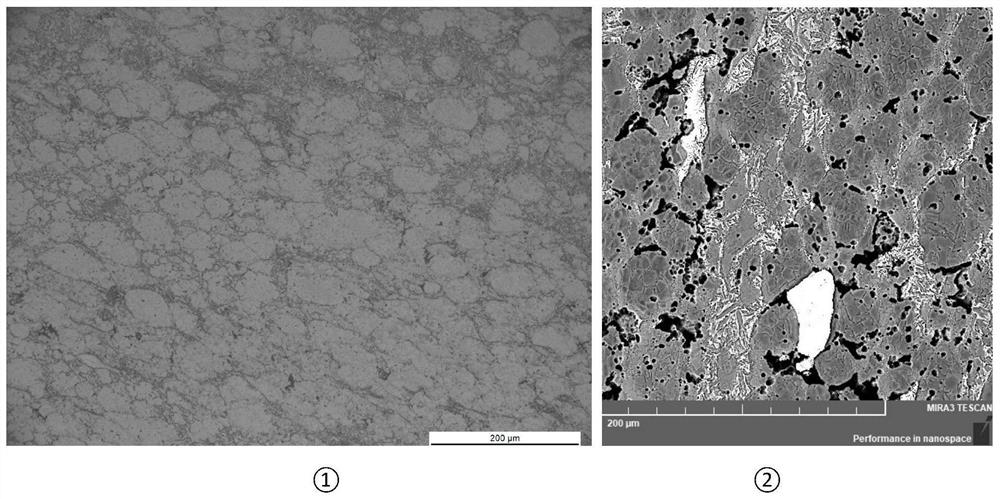

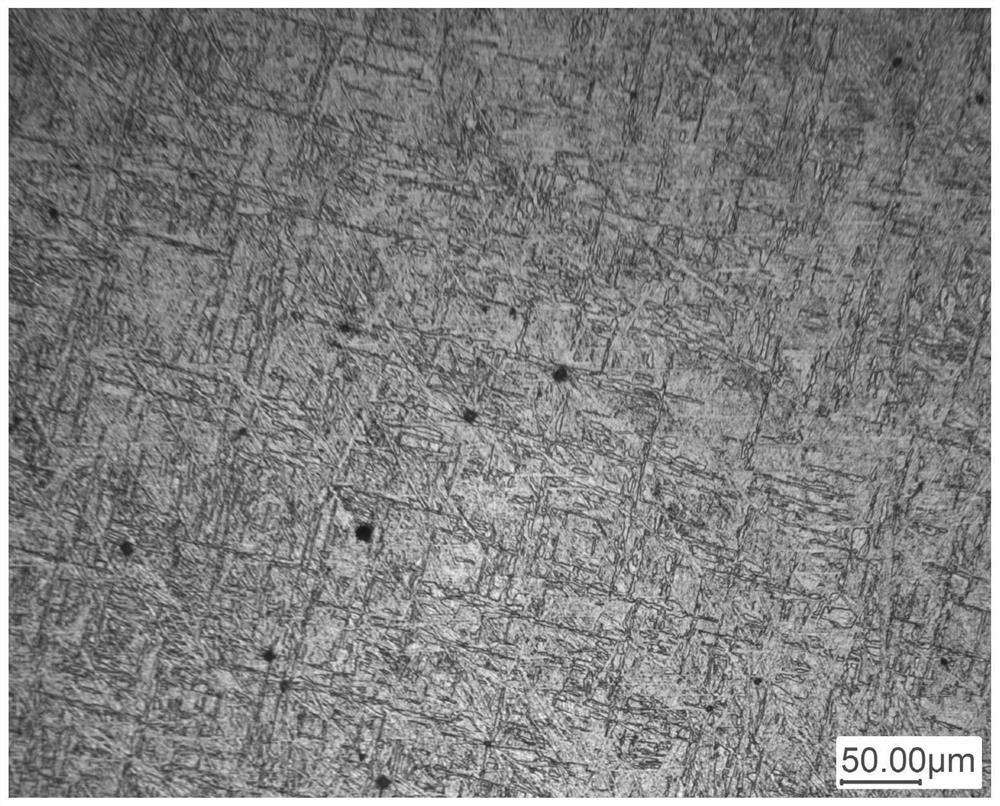

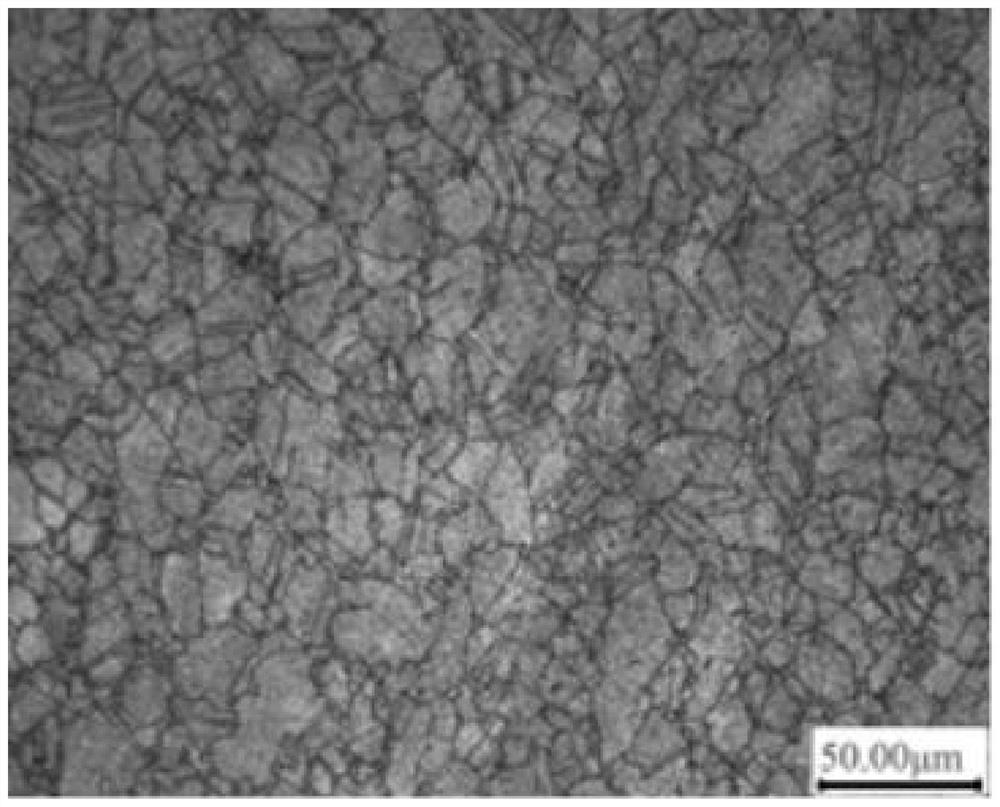

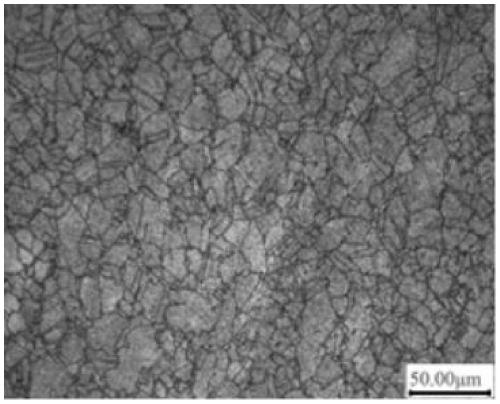

A kind of standard sample preparation method of residual stress deflection method calibration device

ActiveCN111551409BReduce residual stressUniform tissuePreparing sample for investigationElectrolysisInternal stress

The invention relates to the technical field of material analysis and testing, and provides a method for preparing a standard sample of a residual stress deflection method calibration device. In the present invention, by pressing the raw material powder and then sintering, the fine grain structure can be obtained, the internal stress caused by the uneven deformation between the large grains can be reduced, and then the remaining tiny margin is removed by electrolysis, which can avoid the introduction of large additional Proper annealing treatment of the sample after electrolysis can further reduce the internal stress of the sample, and finally obtain a high-precision standard sample for the calibration device of the residual stress deflection method. The residual stress of the standard sample prepared by the above method of the present invention is relatively small, and the residual stress is almost zero.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Standard sample preparation method of residual stress deflection method calibration device

ActiveCN111551409AReduce residual stressUniform tissuePreparing sample for investigationPhysicsStandard samples

The invention relates to the technical field of material analysis and testing, and provides a standard sample preparation method of a residual stress deflection method calibration device. Raw materialpowder is pressed and then sintered; fine grain structures can be obtained, the internal stress generated by uneven deformation between large crystalline grains is reduced, then residual tiny allowance is removed through electrolysis, introduction of large additional stress can be avoided, proper annealing treatment is conducted on the electrolyzed sample, the internal stress of the sample can befurther reduced, and finally the high-precision standard sample of the residual stress deflection method calibration device is obtained. The standard sample prepared by the method is relatively smallin residual stress, and the residual stress is almost zero.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A mirror glass steel plate, its preparation device and its preparation method

ActiveCN111086309BGood surface smoothnessSignificantly improved surface smoothnessSynthetic resin layered productsVehicle componentsGlass fiberShrinkage rate

The invention discloses a mirror glass steel plate, its preparation device and its preparation method. The glass steel plate comprises a PET film layer, a zero-shrinkage gel coat layer, a first unsaturated resin layer, and a glass fiber surface mat successively connected from top to bottom. Layer, second unsaturated resin layer, glass fiber chopped strand mat layer and third unsaturated resin layer. The preparation device comprises a first conveyor belt, a first curing chamber, a second conveyor belt, a second curing chamber, a third conveyor belt, a third curing chamber, a fourth conveyor belt and a cutting device connected in sequence; above the first conveyor belt A PET film unwinding device, a gel coat applicator and a scraper are arranged in sequence from upstream to downstream; a glass fiber surface mat unwinding device and a first sizing roller are arranged in sequence above the second conveyor belt from upstream to downstream ; Above the third conveyor belt, there are a glass fiber chopped strand unwinding device and a second sizing roller in sequence from upstream to downstream. The surface smoothness, surface gloss and mechanical properties of the above-mentioned FRP sheets are significantly improved; the shrinkage rate of the gel coat is zero.

Owner:南京德嘉玻璃钢材料有限公司

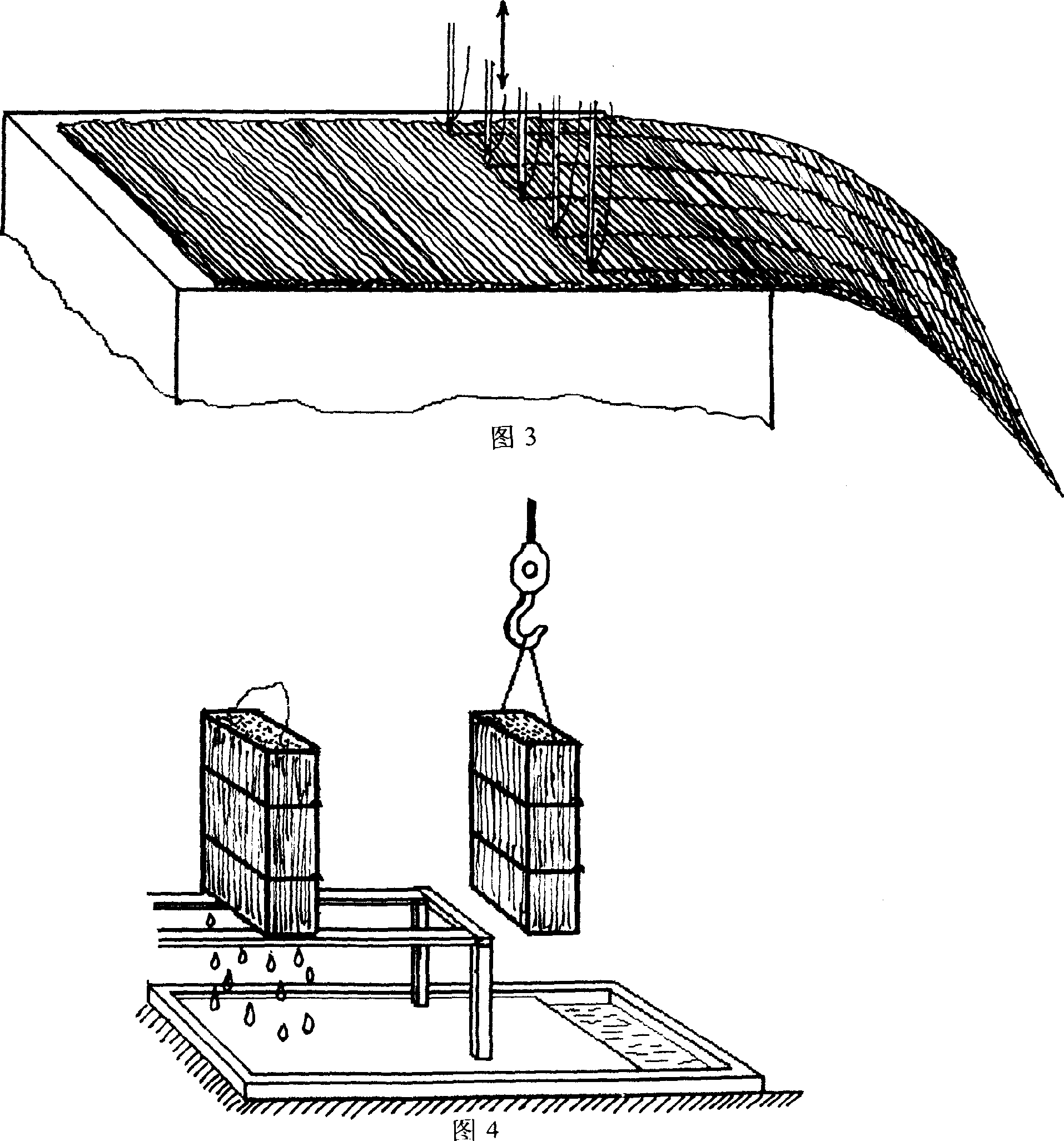

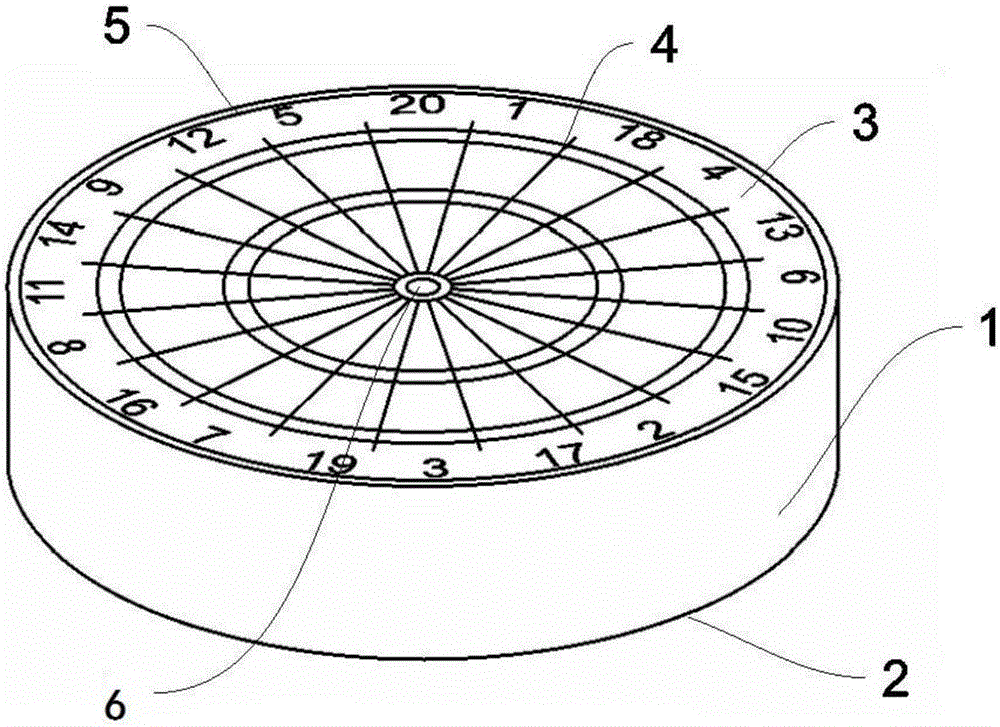

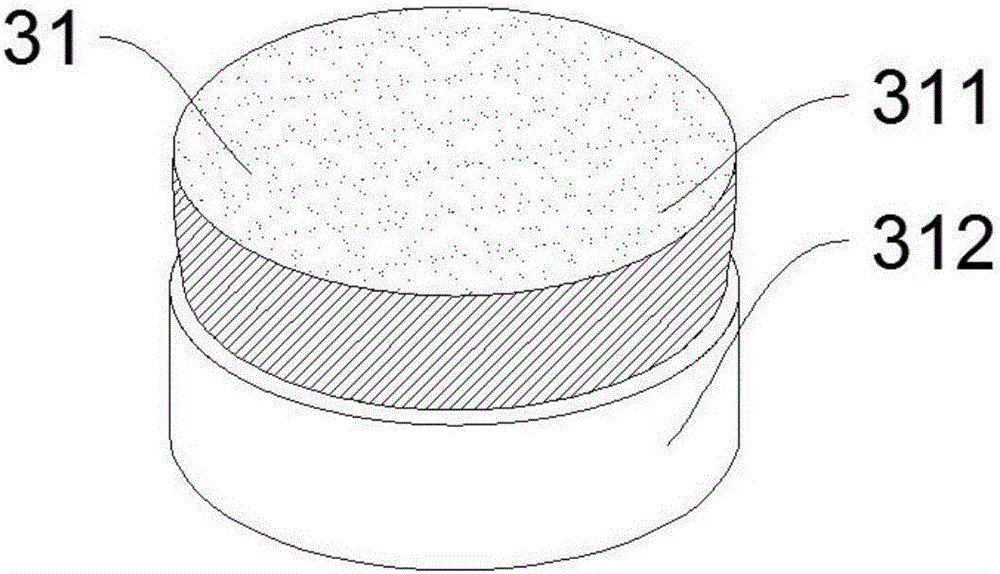

Grain-free tournament target

The invention belongs to the field of dart targets, and provides a grain-free dart target. The problems that dart falling is caused by adhesive tape or entanglements contained in a target body of an existing dart target, and the existing grain-free tournament target technology is complex are solved. Fiber bundles are fixed by entanglements, the entanglements are wound around the lower half portions of the fiber bundles, no entanglement is wound around the upper half portions of the fiber bundles, and therefore fiber cakes are formed. The surface of a fiber layer formed by pressing the above fiber cakes is free of gain, and the technology is simple.

Owner:王照

A multi-station vertical polishing machine

The invention discloses a multi-station vertical polisher comprising a frame, two workpiece clamping and rotation systems and a polishing wheel system. The polishing wheel system is disposed in the center of the frame. The workpiece clamping and rotation systems are arranged on two sides of a polishing wheel system and on the frame through horizontal guides on a support, and are connected with constant pressure drive systems respectively to move along horizontal guides. The support is disposed on vertical guides on the frame and connected with a lifting mechanism on the frame to move along the vertical guides. The multi-station vertical polisher can be controlled through a numerical control system, has the functions such as allowing rotation speed of a workpiece to change according to actual needs, presettable rotation speed of the polishing wheel, constant presettable polishing pressure and automatic abrasion compensation for abrasive material, and is available for polishing the periphery and surface of workpieces in various shapes.

Owner:YUHUAN CNC MACHINE TOOL

A kind of processing method of aluminum alloy medium and thick plate

The invention discloses a processing method of an aluminum alloy medium and thick plate, comprising the following steps: smelting, degassing and filtering, casting, sawing, homogenizing treatment, quenching, residual stress removal, aging treatment, slicing and surface treatment to obtain an aluminum alloy Plate. The aluminum alloy plate of the invention has uniform structure, low internal stress, high dimensional accuracy, high strength, low production cost and good economic and social benefits.

Owner:广西南南铝加工有限公司

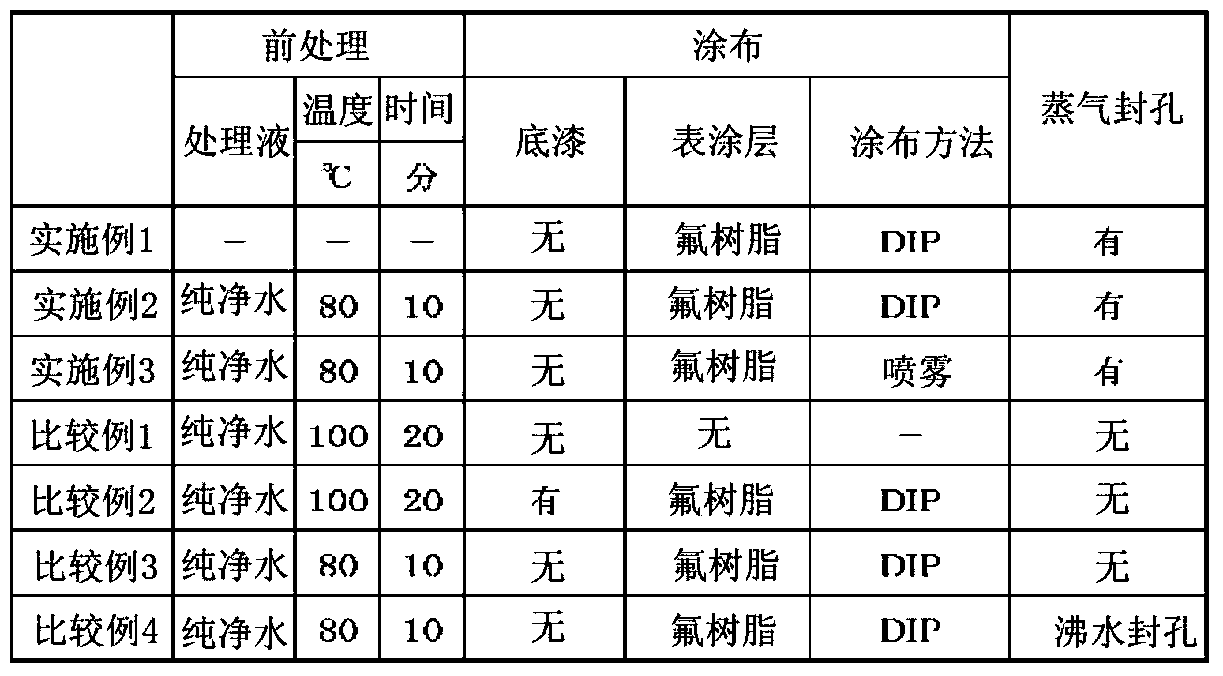

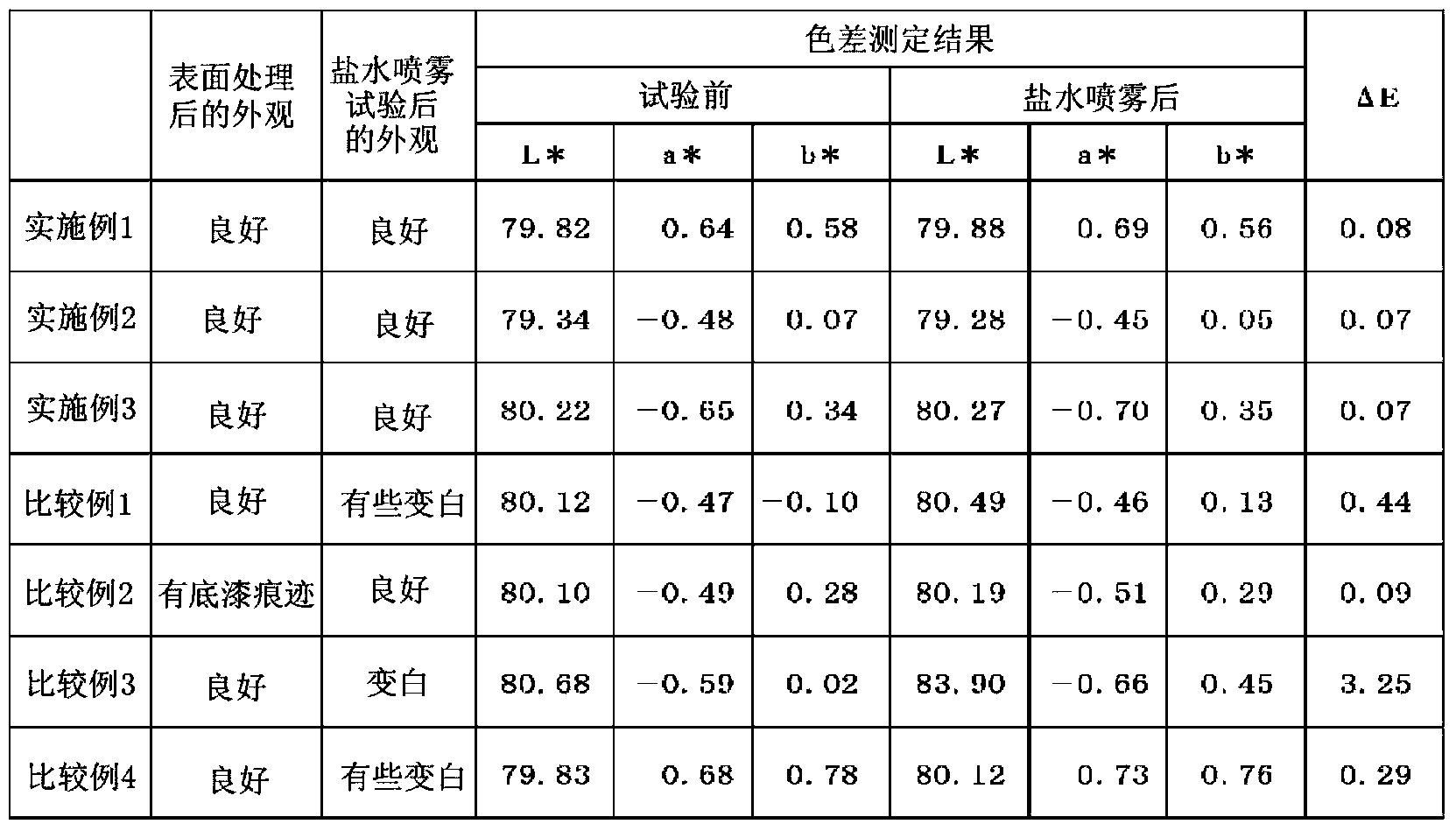

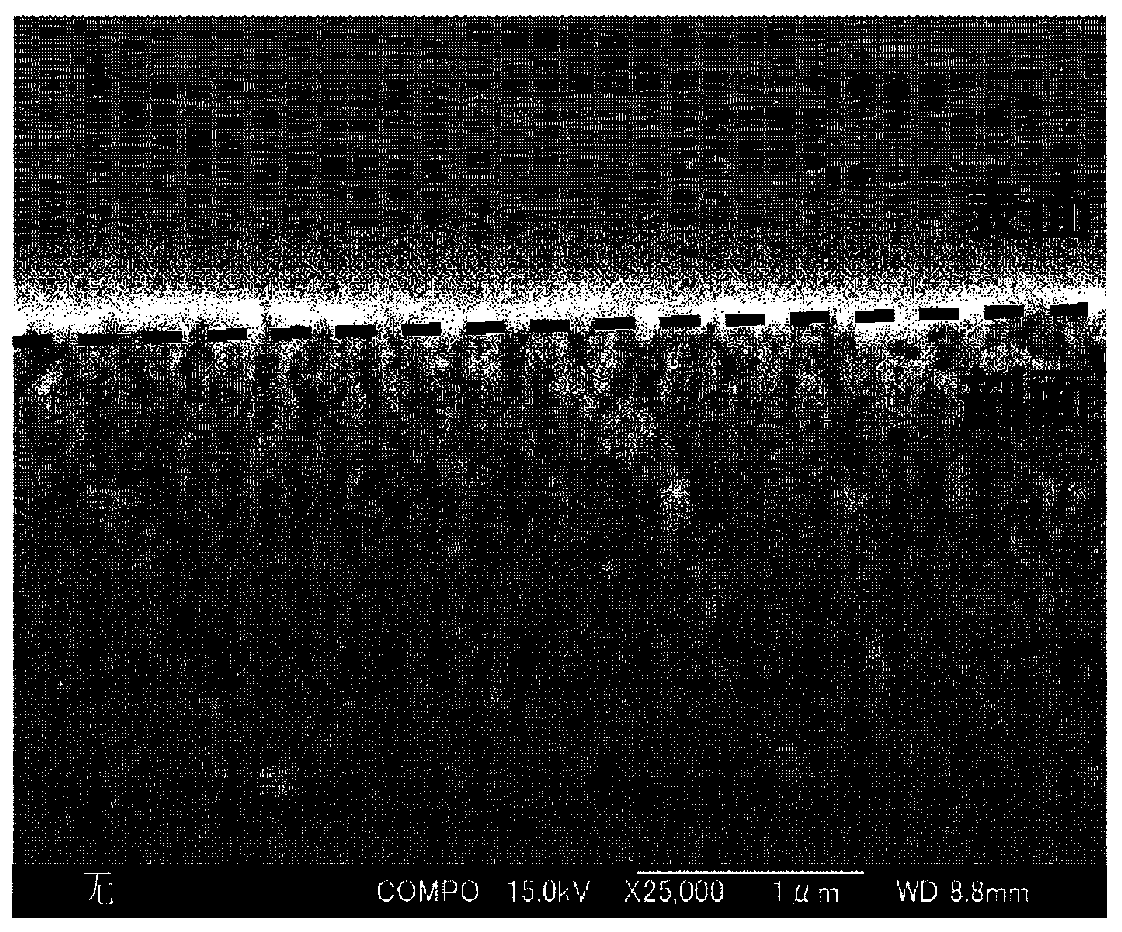

Surface treatment method for metal member and metal member obtained by same

[Problem] The purpose of the present invention is to provide a surface treatment method for a metal member which, while maintaining the metal texture of the surface of a metal member, improves surface characteristics of the metal member. Also provided is a metal member thus obtained. [Solution] The surface of an anodic oxide coating formed on a metal surface prior to sealing is brought into contact with a fluorine-based polymer solution, after which steam sealing is performed. Thus, the metal member obtained is characterized by having a fluorine-based polymer layer with a thickness of 100 nm or less, and a composite sealing treatment layer formed contiguously under the fluorine-based polymer layer and in which fluorine-based polymer has been filled into the pores of the anodic oxide coating.

Owner:AISIN KEIKINZOKU CO LTD

Aluminum alloy medium plate preparation method

The invention discloses an aluminum alloy medium plate preparation method. The aluminum alloy medium plate preparation method comprises the following steps of: smelting at 700-750 DEG C, degassing a melt by adopting a multistage degassing purification system, and filtering the melt by adopting a 300ppi-foamed ceramic filtration plate; casting the melt to obtain an aluminum alloy ingot blank, and carrying out stress-relieving treatment at 300-500 DEG C for more than or equal to 1 hour; controlling the temperature of a saw cutting aluminum alloy sheet at 350-500 DEG C, carrying out solution treatment for more than or equal to 0.5 hour, controlling the tensile deformation at 1%-4%, controlling the temperature of the aluminum alloy sheet at 50-300 DEG C, and carrying out aging treatment for 2-40 hours to obtain an aluminum alloy medium plate. Compared with the aluminum alloy medium plate prepared by a conventional hot-rolling method, the aluminum alloy medium plate prepared by the method has the advantages that the preparation working procedures are reduced, the production cycle is short, the cost is reduced, the plate has good quality and high strength and meets the market requirements, and the good economic benefits and social benefits are achieved.

Owner:广西南南铝加工有限公司

A kind of device and preparation method of embossed quartz stone pattern plate

ActiveCN108973492BExcellent adhesionEasy to cleanDecorative surface effectsEmbossing decorationsEngineeringQuartz

Owner:HENGYANG ATHENA QUARTZ STONE CO LTD

Environmental protection type printable top sheet of laminated molding card, preparation method and application

InactiveCN100354145CFlat surfaceHigh bonding strengthDuplicating/marking methodsEngineeringCompanion animal

An environment protection type printable surface film for certificate card is composed of a surficial protecting layer (polyethanediol tere-phthalate (PET) film) and a functional printing-adhering layer containing special osmotic cross-linking assistant. Its advantages are high adhesion and transparency, and high print clearness.

Owner:上海浮托实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com