Patents

Literature

33results about How to "Arc smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

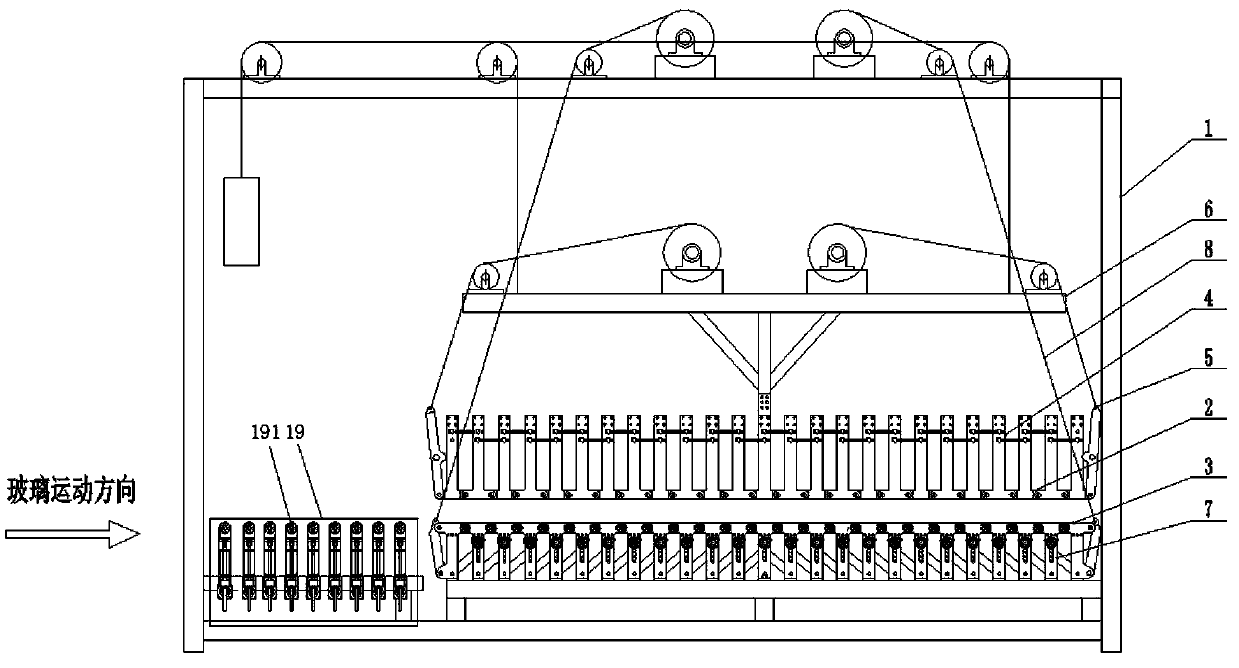

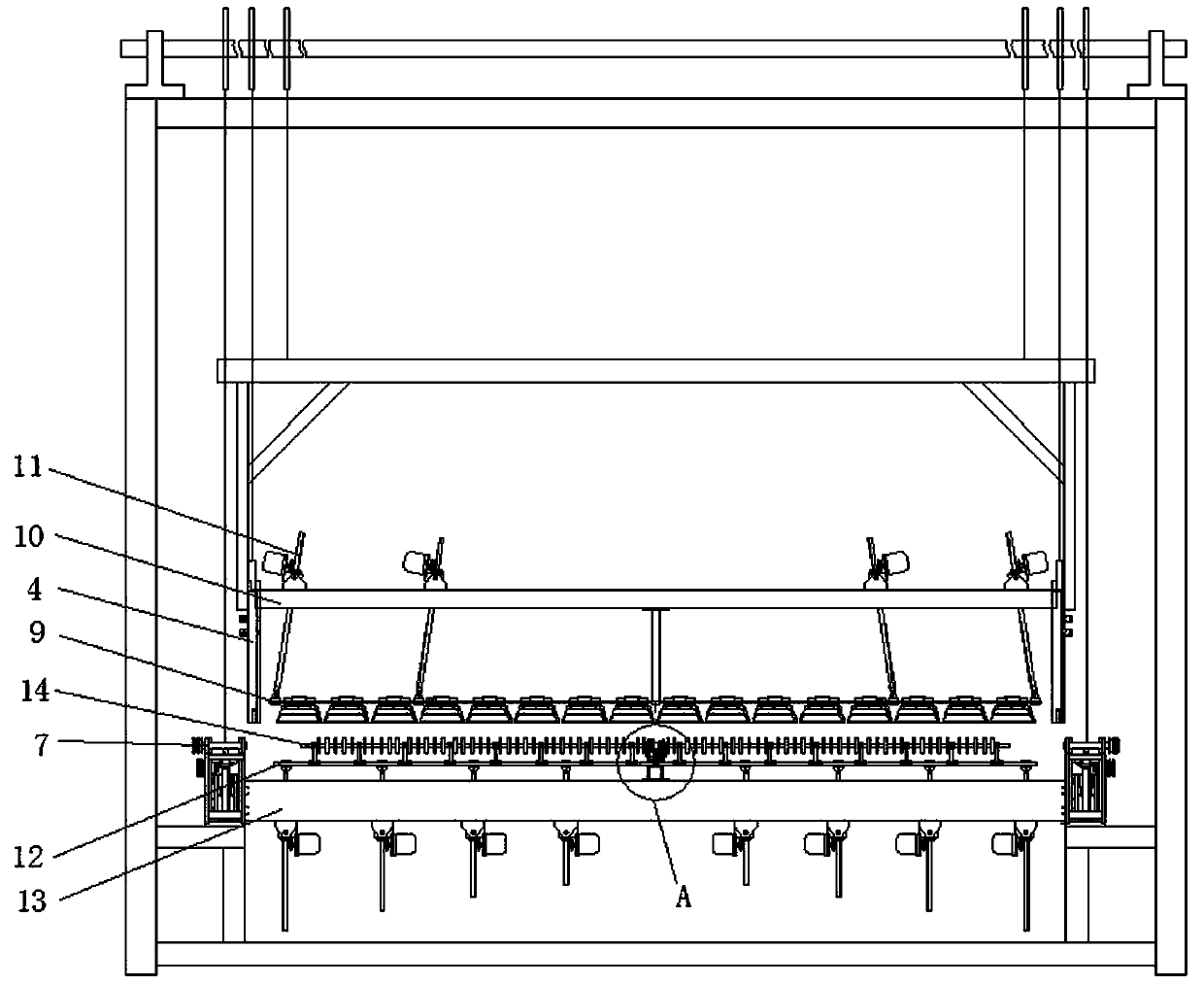

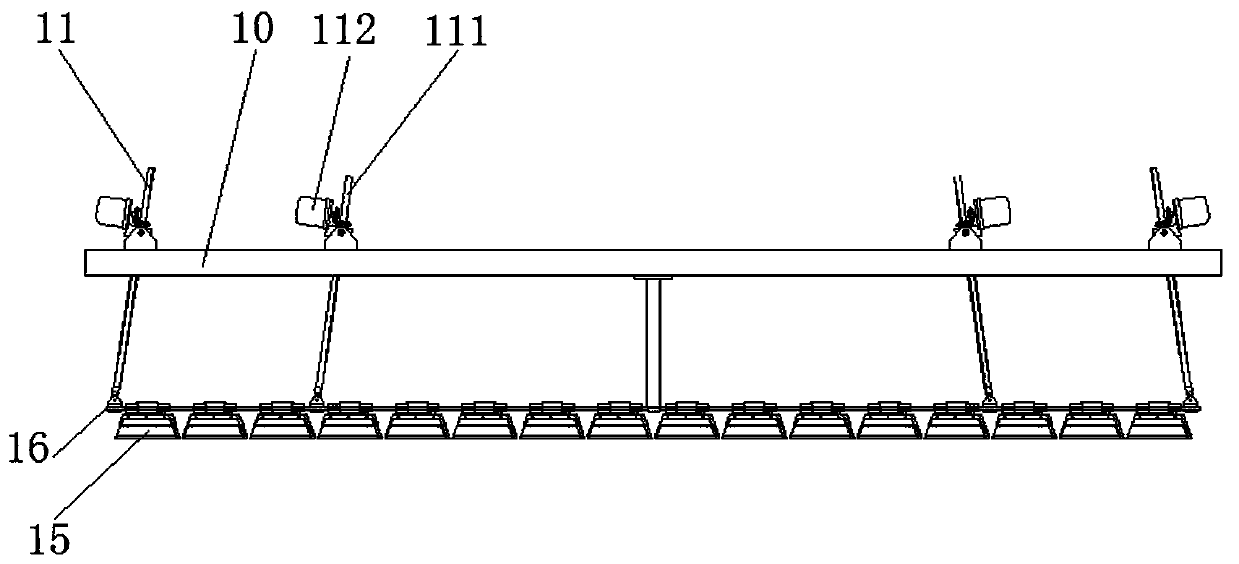

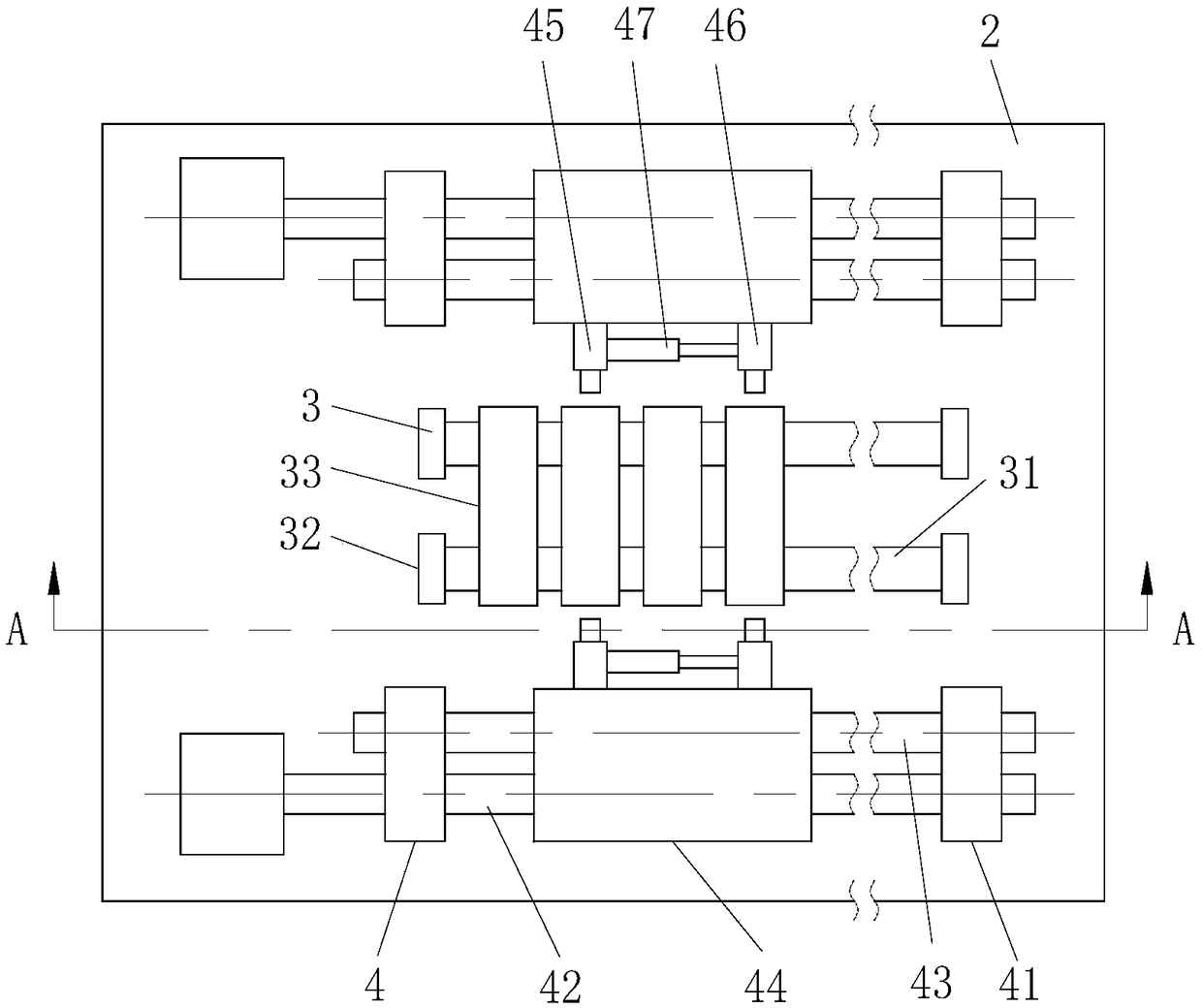

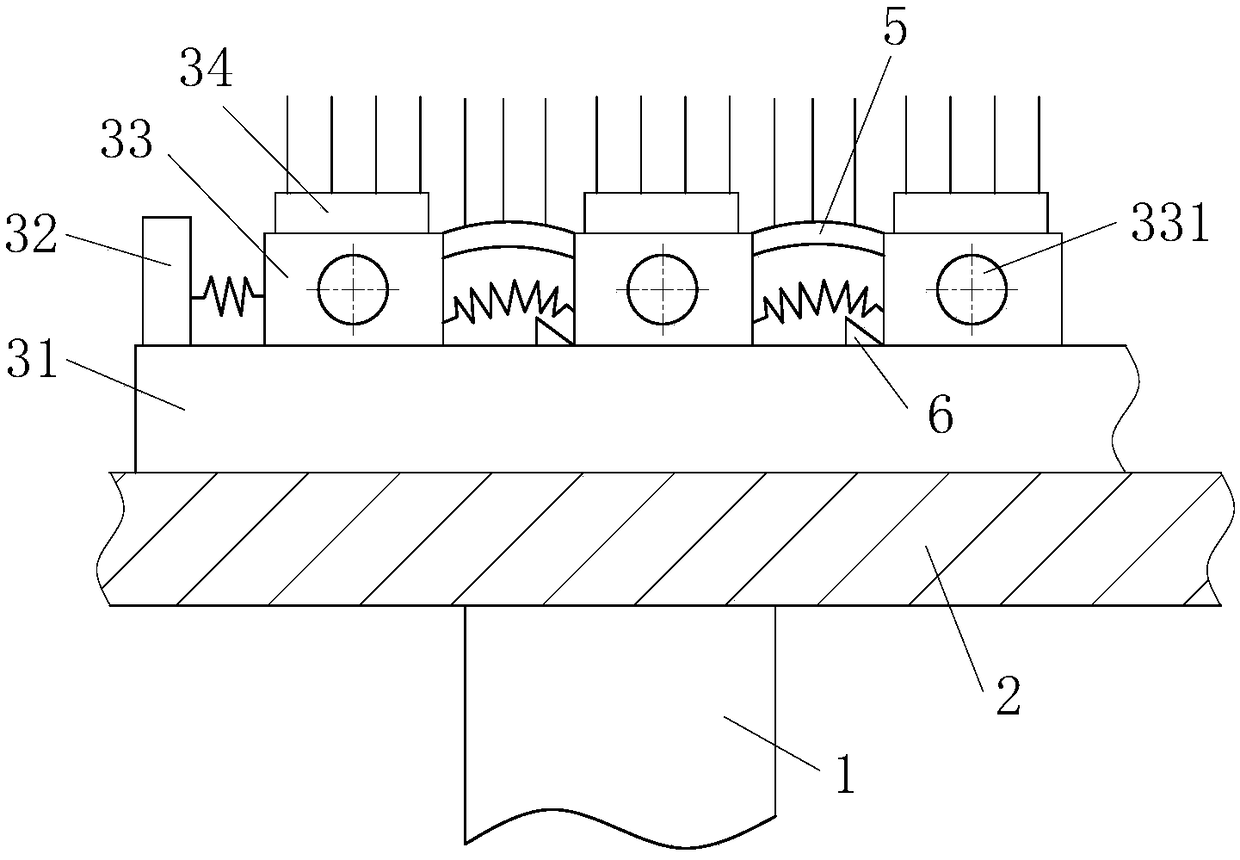

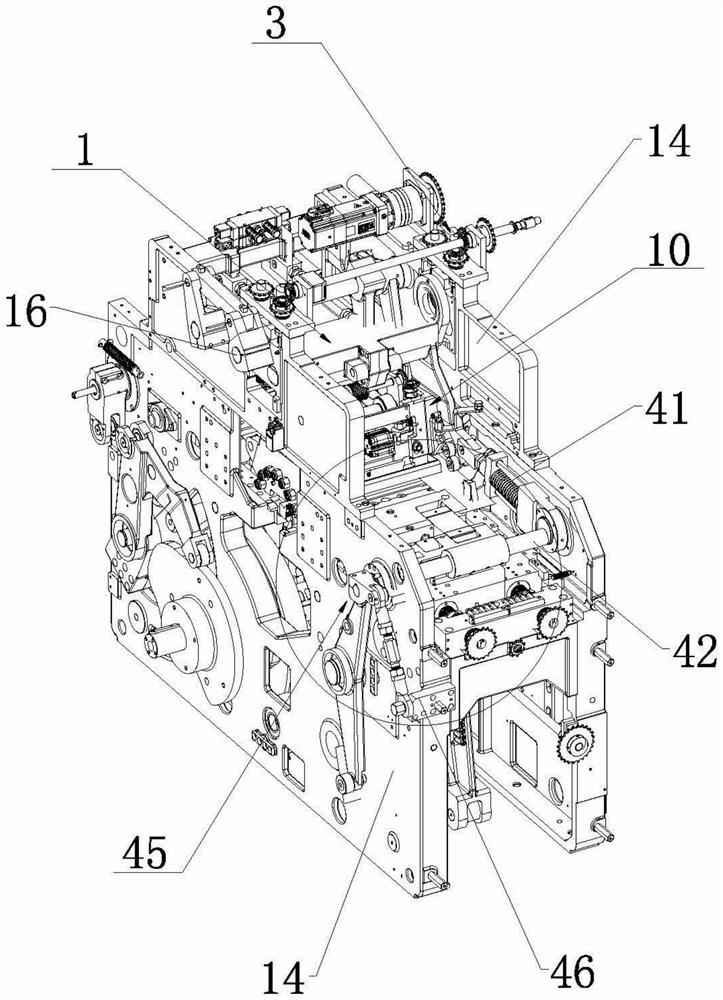

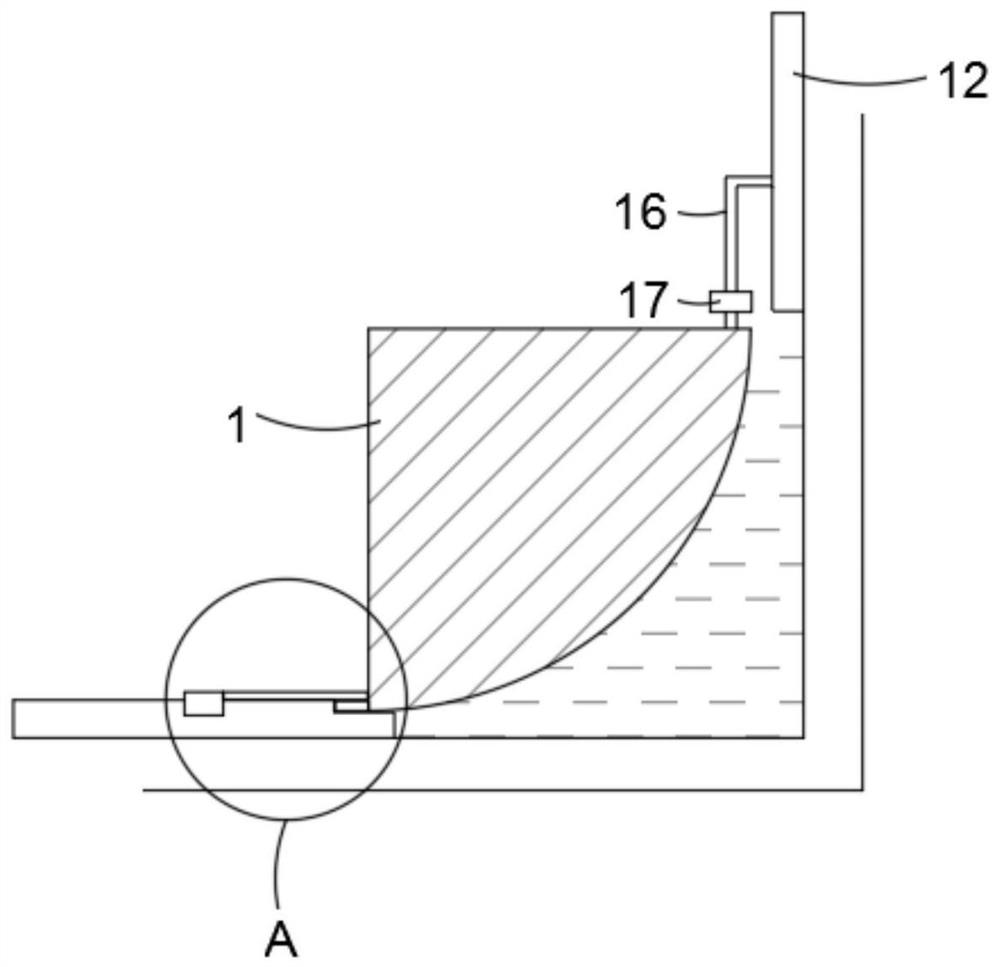

Bent toughened glass forming equipment and method

ActiveCN109748486AImprove general performanceQuick and easy molding adjustmentGlass transportation apparatusGlass reforming apparatusEngineeringToughened glass

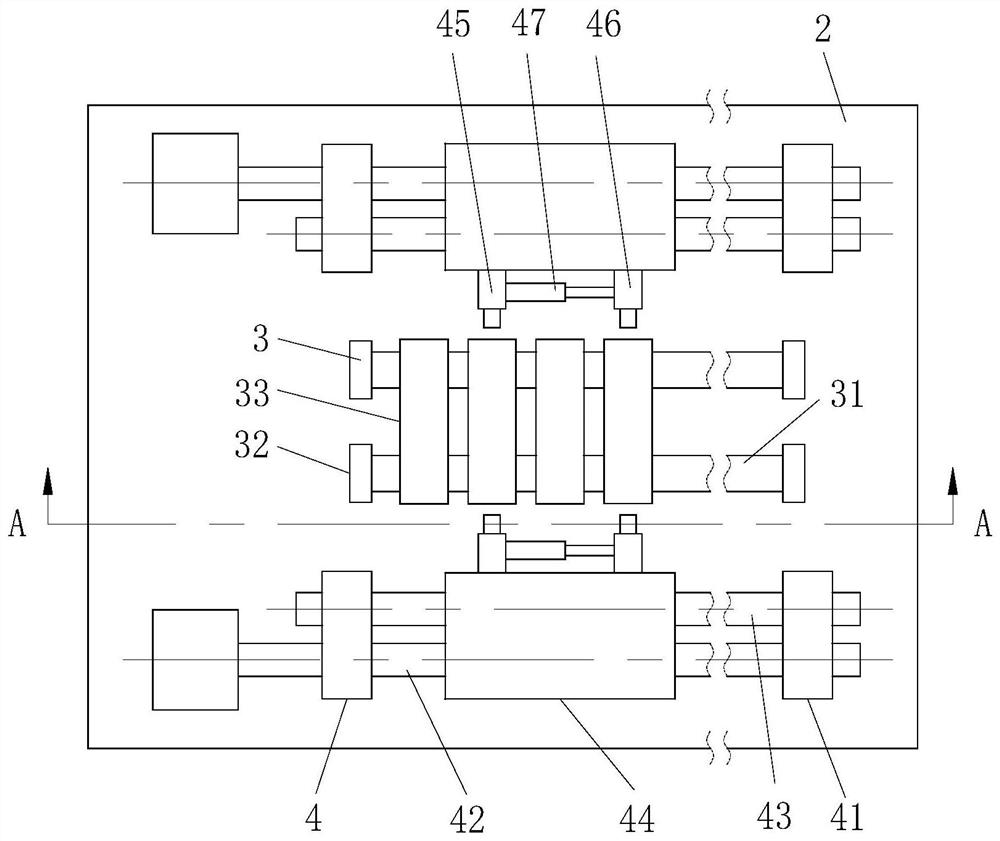

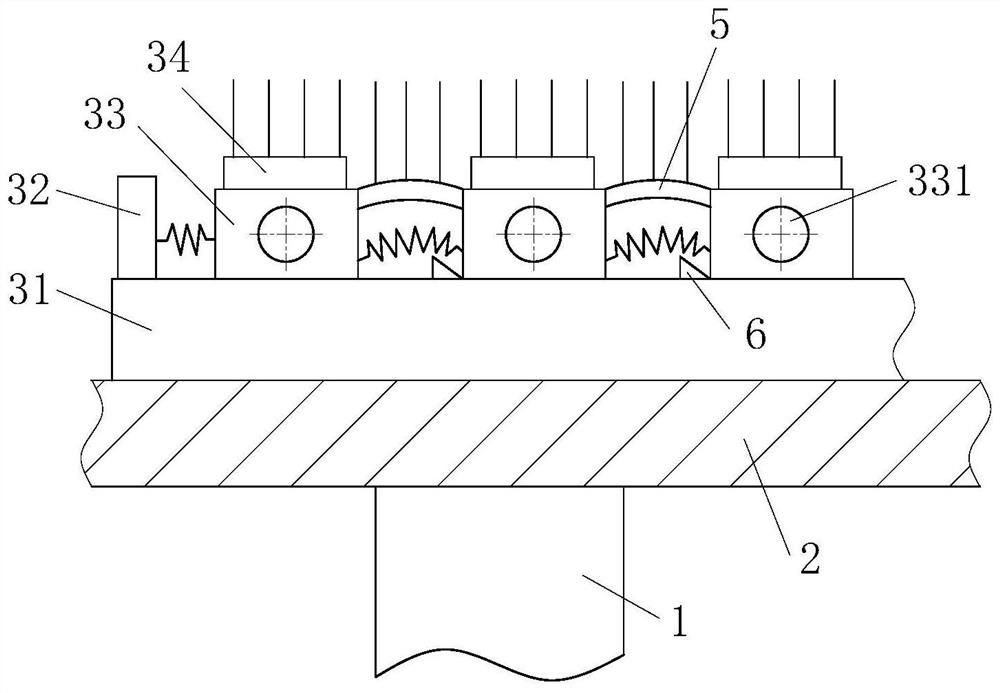

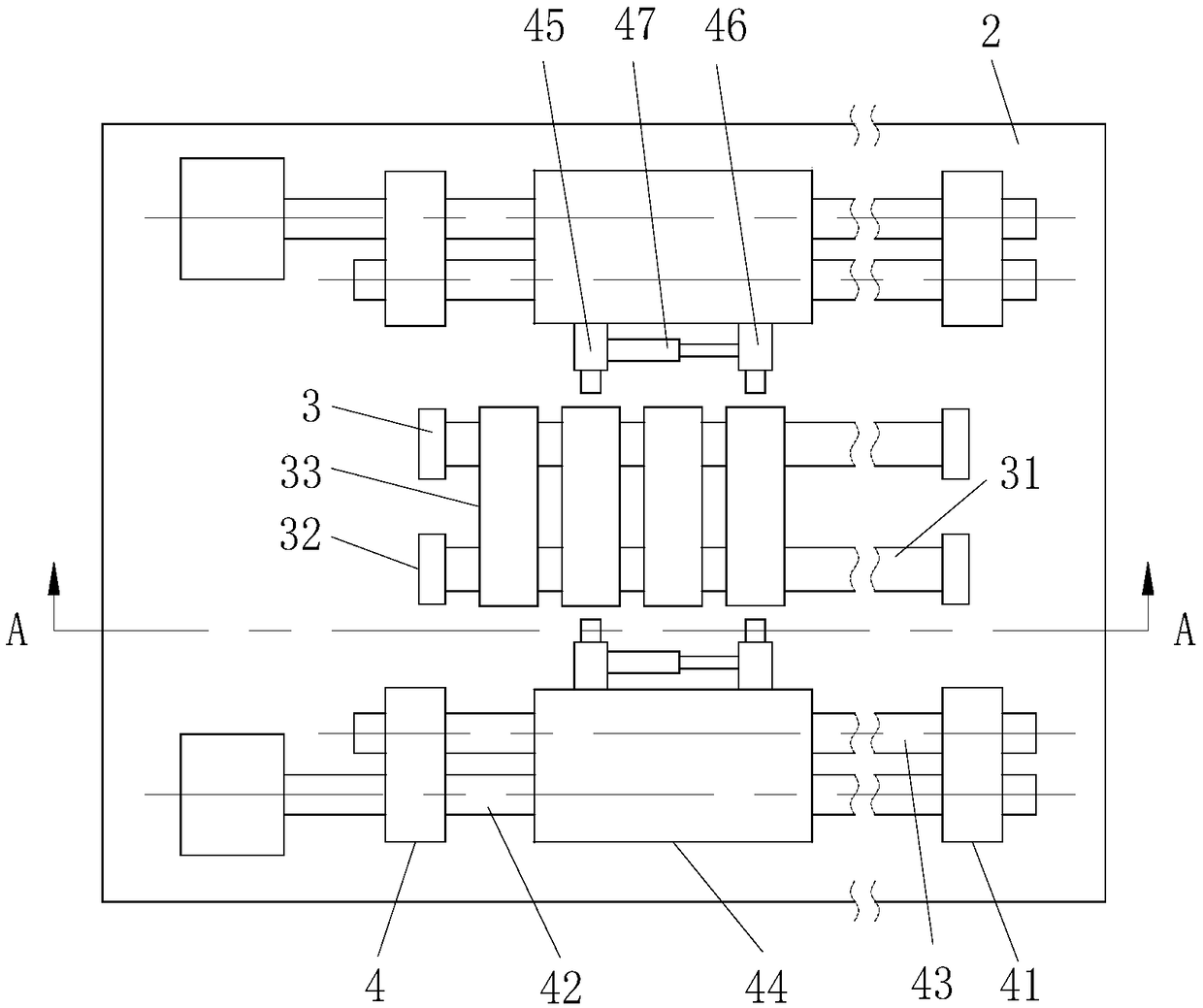

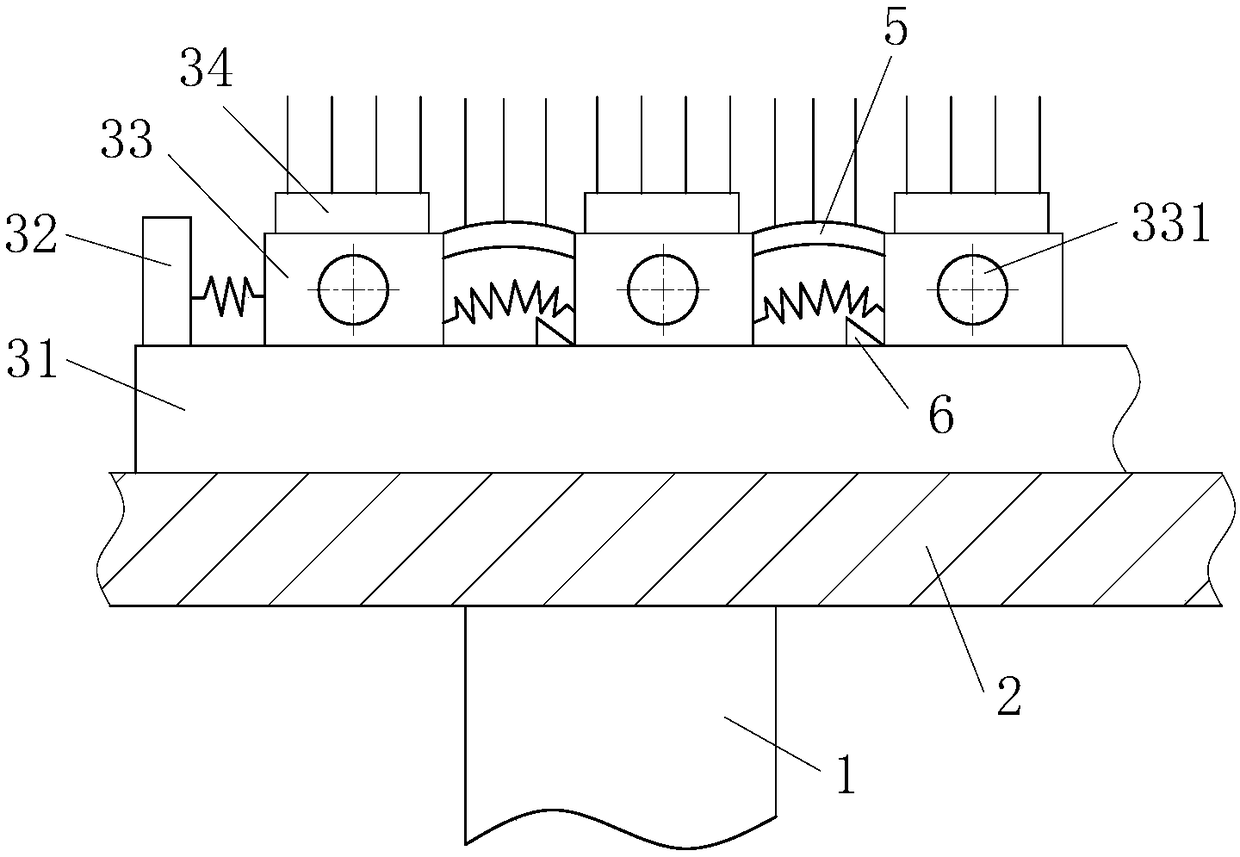

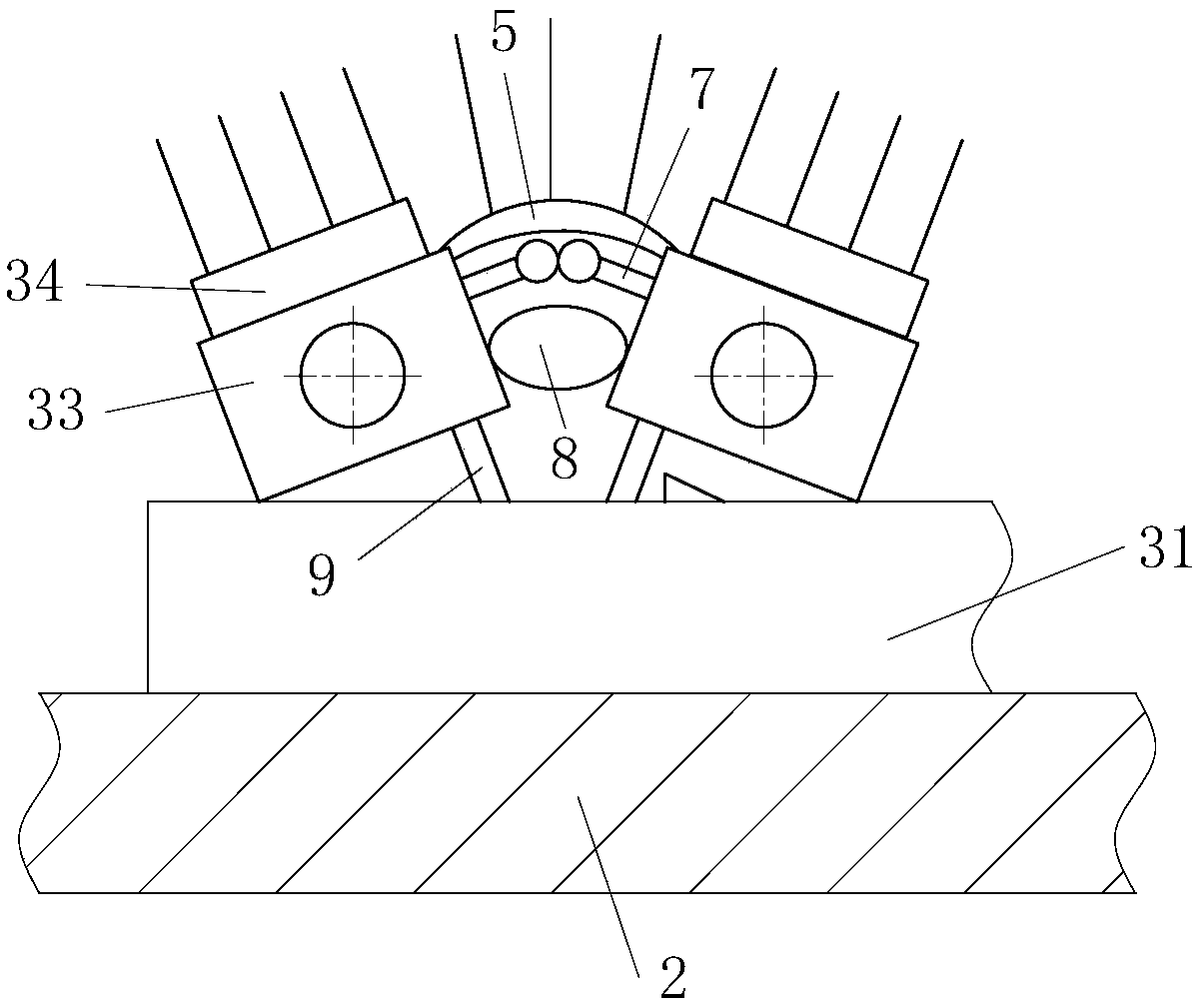

The invention discloses bent toughened glass forming equipment. The bent toughed glass forming equipment comprises a rack, an air grid system and a forming system, wherein the air grid system comprises a plurality of upper air grids and a plurality of lower air grids; the upper air grids are mounted on the upper portion of the rack through a hoisting mechanism; the lower air grids are mounted in the forming system on the lower portion of the rack; a gradual transition section is arranged on the inlet side of the forming system, so that a glass plate is gradually changed into an arc in the transverse direction, and the glass plate which has been gradually changed into the arc is fed into the forming system; the forming system comprises two longitudinal forming arc-changing mechanisms and aplurality of transverse forming arc-changing mechanisms arranged in the conveying direction of the glass plate; the longitudinal forming arc-changing mechanism longitudinally bends and forms the glassplate; and the transverse forming arc-changing mechanisms are connected with the longitudinal forming arc-changing mechanisms through lower support cross beams, and the glass plate is transversely bent and formed. The equipment and the forming method provided by the invention can be used for processing various bent toughened glass without manufacturing a special mold, and have the advantages of rapid and convenient forming adjustment, stability, reliability, difficulty in deformation and high production efficiency.

Owner:LUOYANG LANDGLASS TECH CO LTD

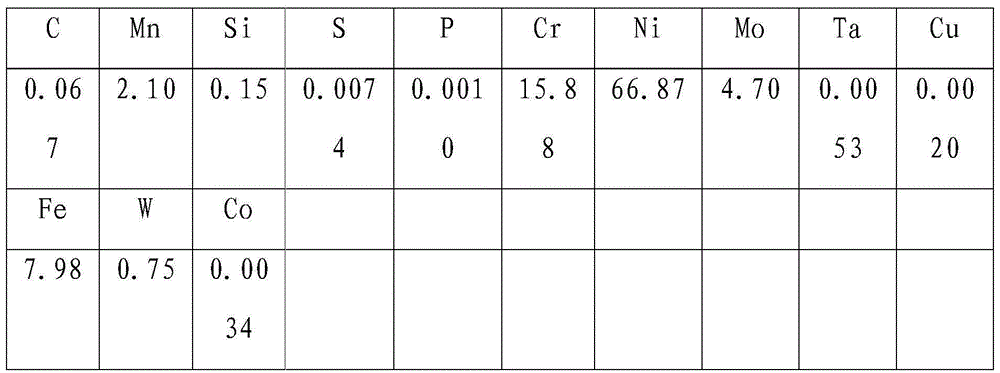

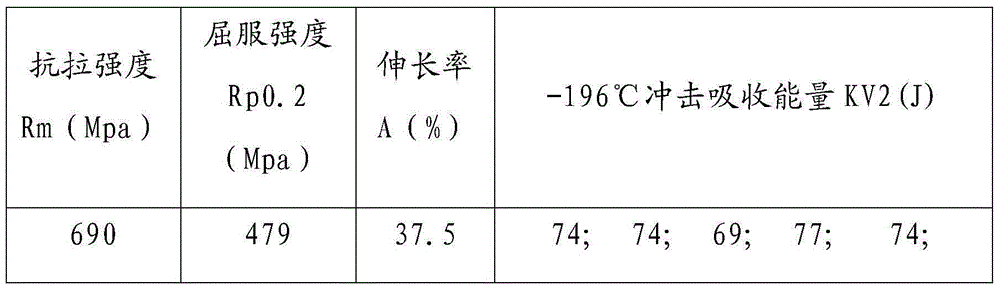

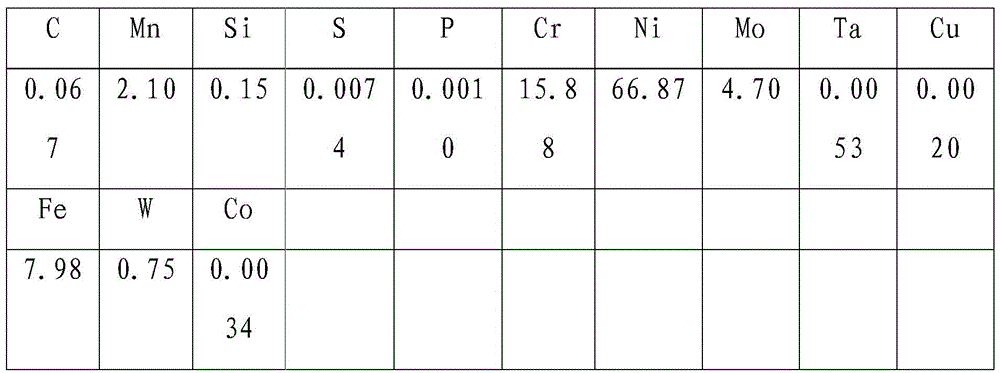

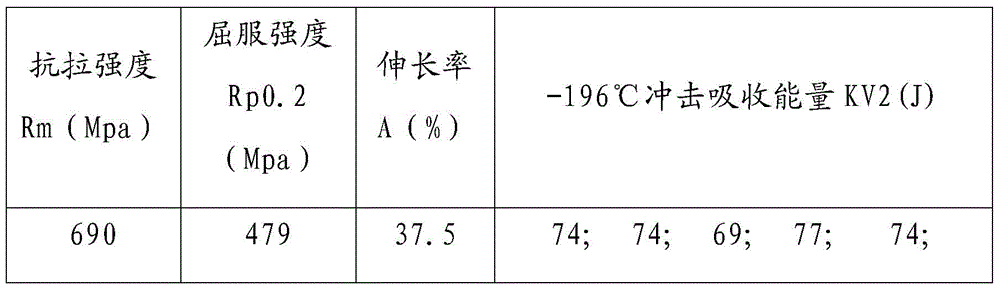

Nickel-based welding rod used for ultralow-temperature steel and preparation method of nickel-based welding rod

ActiveCN105081613AImprove performanceSimple welding processWelding/cutting media/materialsSoldering mediaHeat resistanceMass ratio

The invention belongs to the technical field of welding materials and particularly relates to a nickel-based welding rod used for ultralow-temperature steel and a preparation method of the nickel-based welding rod. The welding rod comprises a welding core wire, chemical powder and an adhesion agent; the mass ratio between the chemical powder and the welding rod is 25-27:100, and the mass ratio between the chemical powder and the adhesion agent is 100:25-30. When the welding rod prepared through the preparation method is welded, the electric arc is stable, the splatter is slight, the sediment separation is good, the form is beautiful, the welding can be conducted through alternate currents or direct currents, and the all-position operation performance is good. The nickel-based welding rod is mainly used for the nickel-based alloy welding with heat resistance and corrosion resistance requirements, and the nickel-based welding rod can also be used for the welding of some alloy hard to weld and dissimilar steel.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

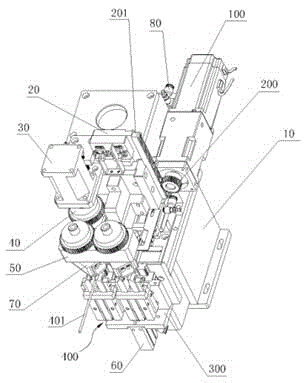

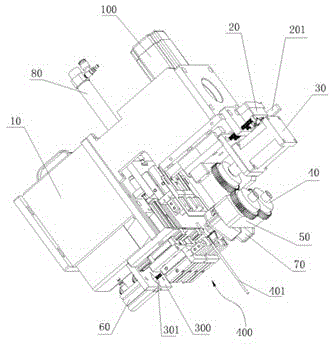

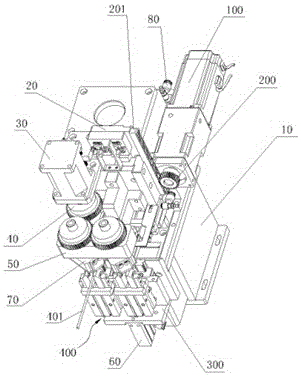

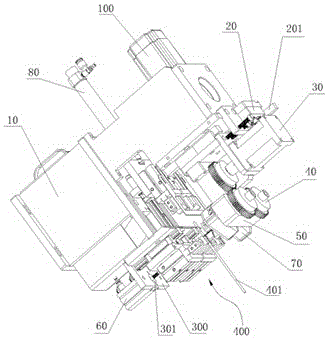

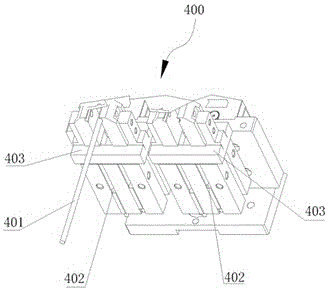

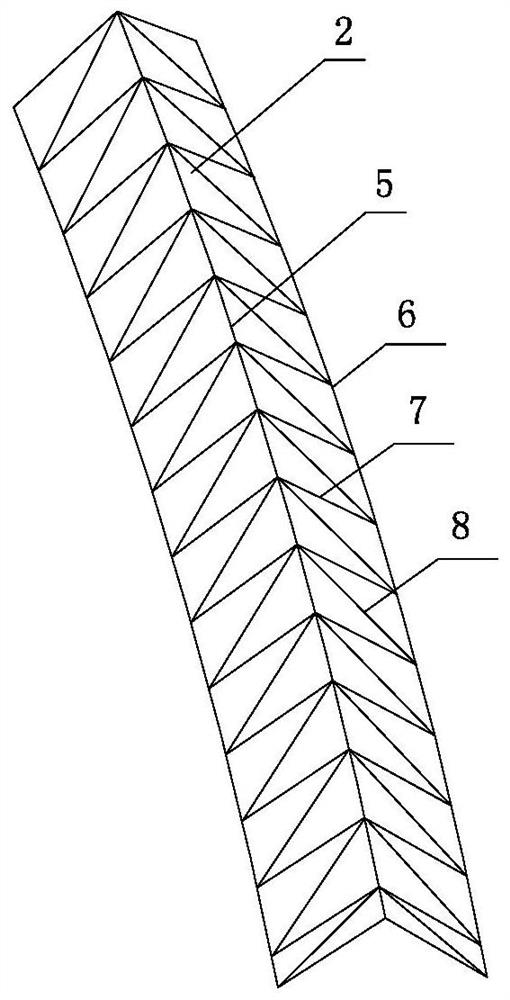

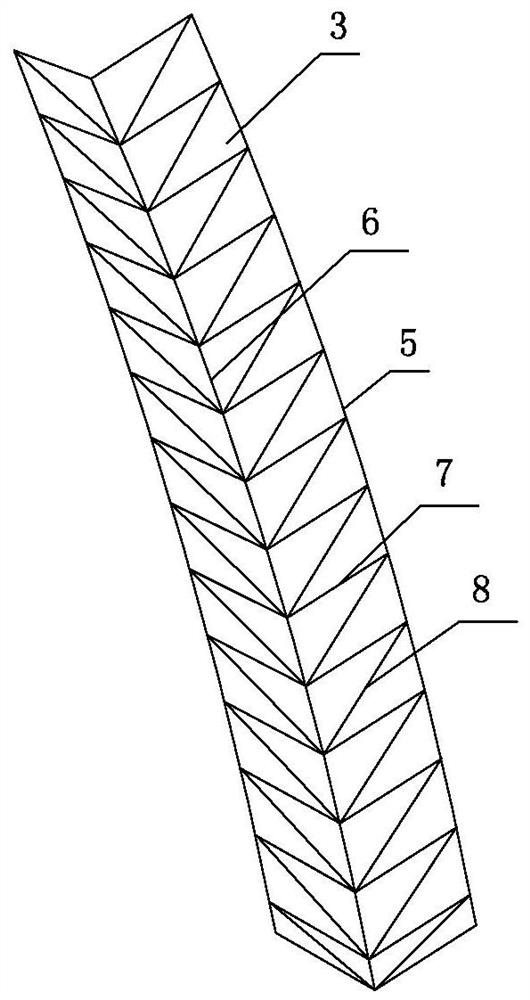

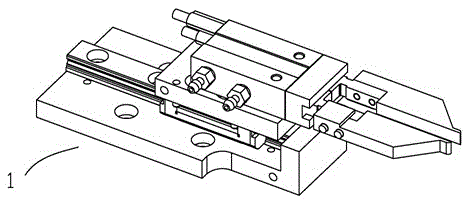

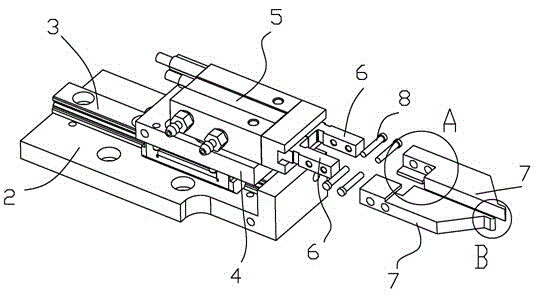

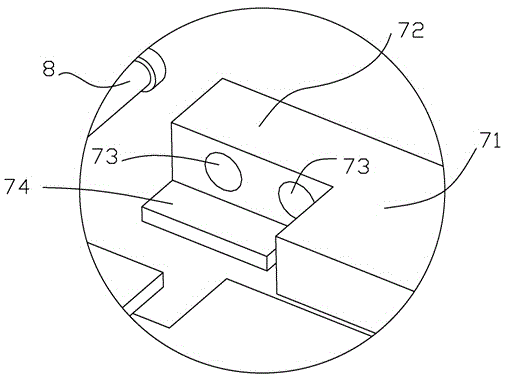

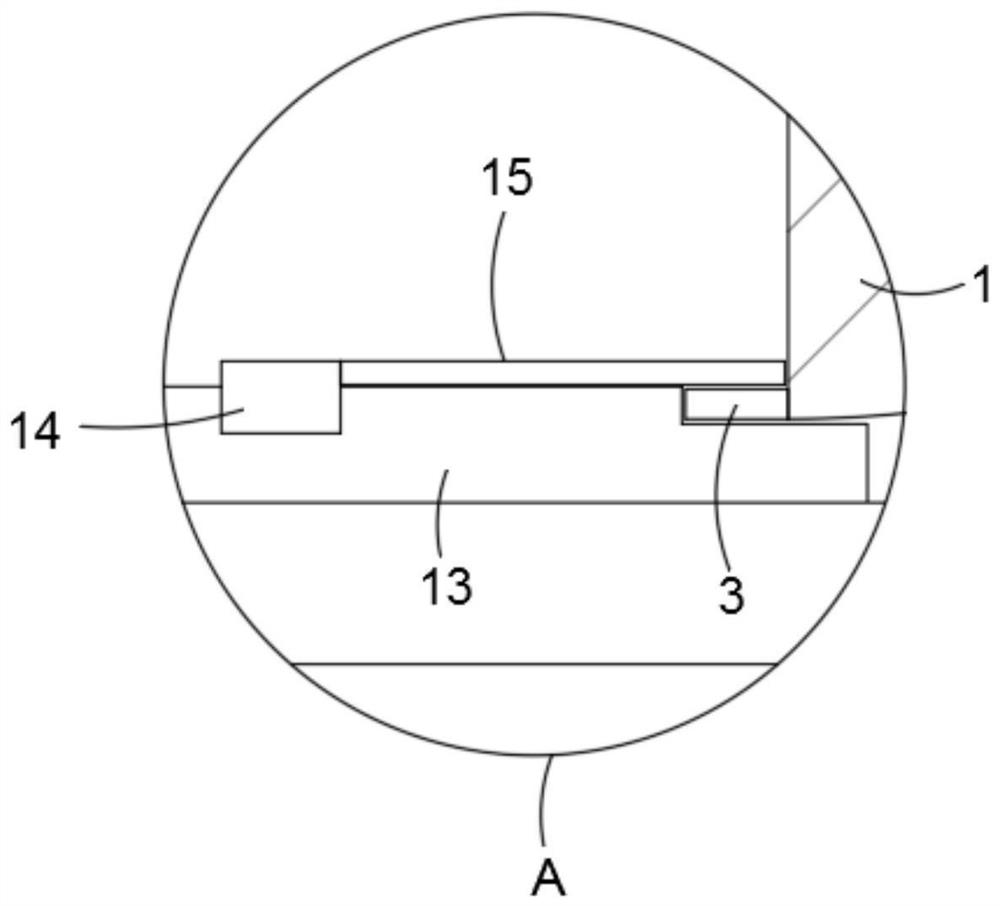

Steel pipe bending machine and forming process thereof

InactiveCN104475509AArc smoothClear arcShaping toolsMetal-working feeding devicesGear wheelEngineering

The invention discloses a steel pipe bending machine. The steel pipe bending machine comprises a base on which a cylinder is arranged; a gear which engages with a rack is arranged at the end part of the cylinder; the rack is fixedly arranged on a baffle on the base; a motor is arranged on the base; a transmission gear set is arranged at the lower end of the motor; a cushion block is arranged at the lower end of the transmission gear set; a pneumatic control switch is arranged at the lower part of the cushion block; a workbench is arranged at the front end part of the base; a lifting cylinder is arranged at the lower end of the workbench; a steel pipe bending die set is arranged on the workbench; the head part of the lifting cylinder passes through a through hole in the workbench and then is propped against the bottom part of a steel pipe bending die set; the steel pipe bending die set is of a concave-convex alternated shape. The invention also discloses a forming process of the steel pipe bending machine. With the adoption of the steel pipe bending machine and the forming process therefore, a steel pipe can be bent and formed at a time, and the situation that single surface of the bent steel pipe is incompletely processed can be avoided; in addition, the bent pipe has a smooth and clear circular arc, and the deformation of the steel pipe is reduced.

Owner:TAICANG XINBAOYI STEEL PIPE MFG

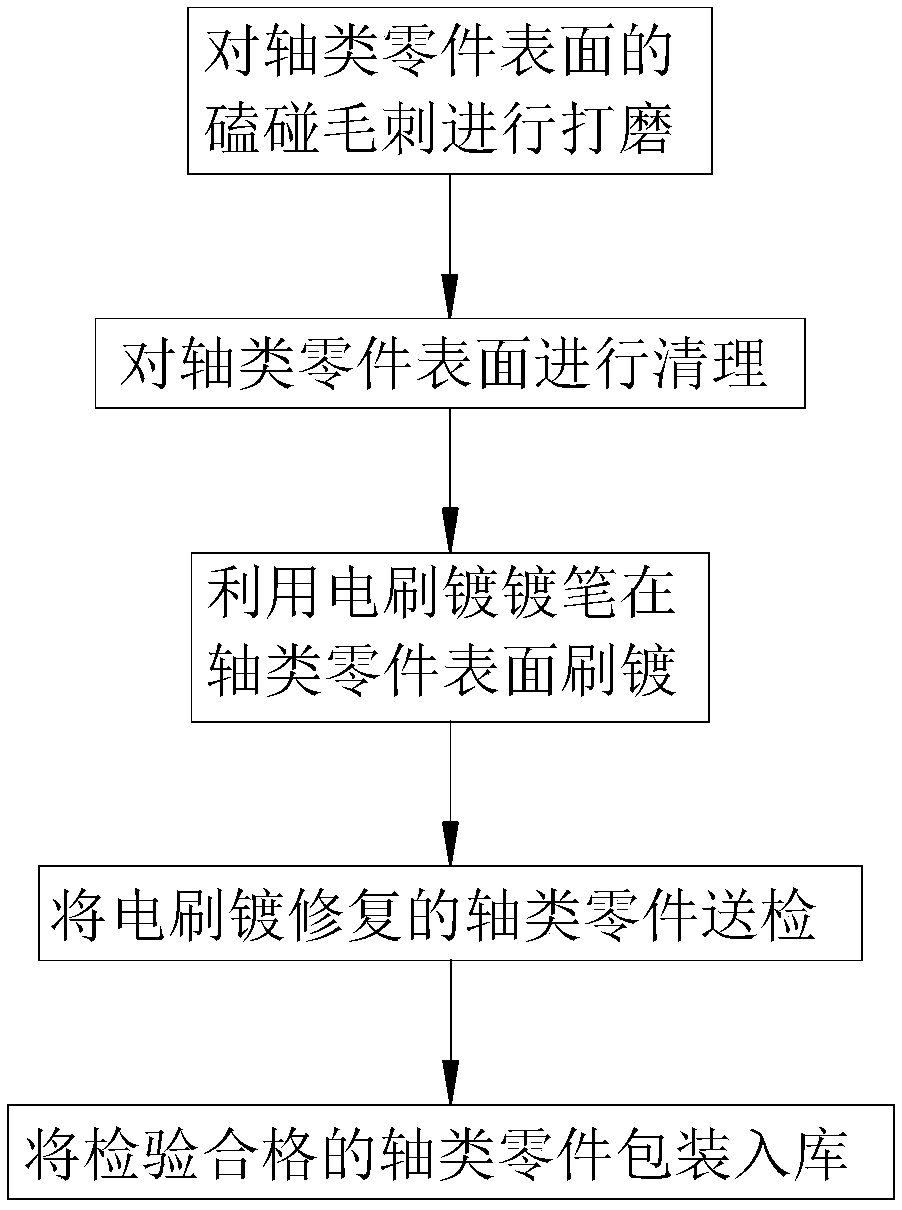

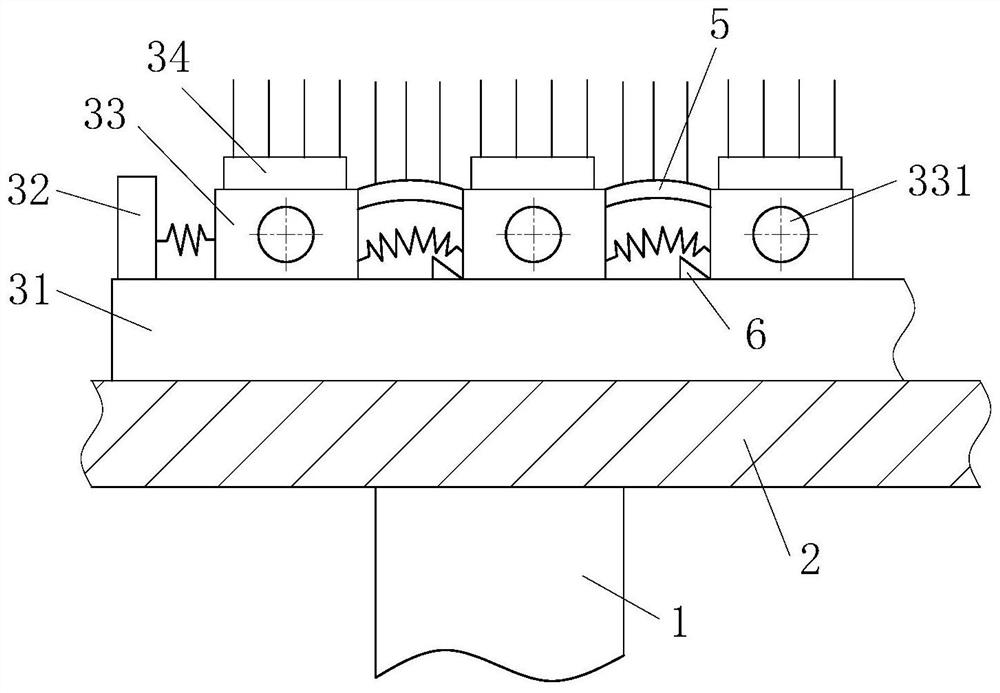

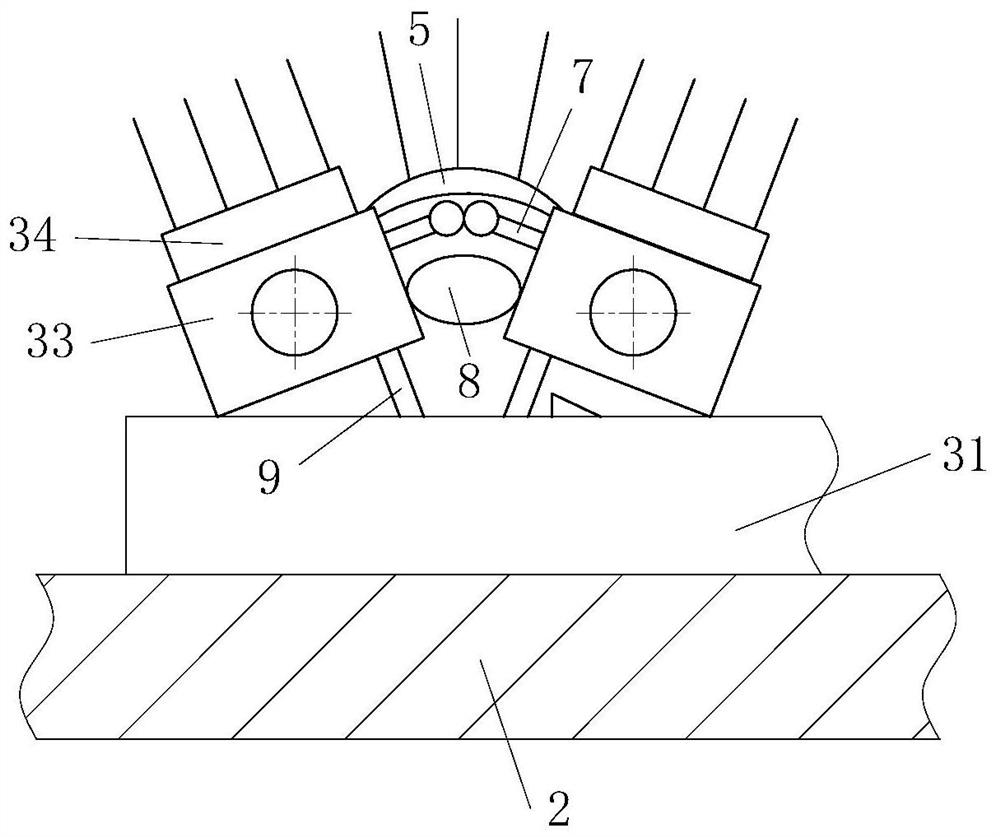

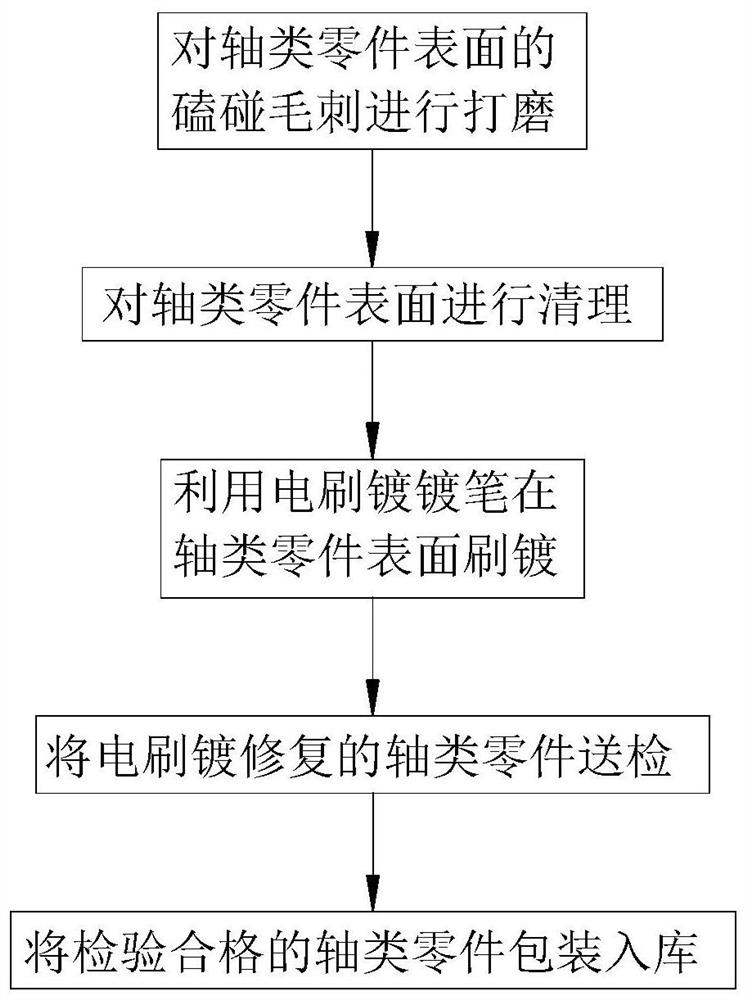

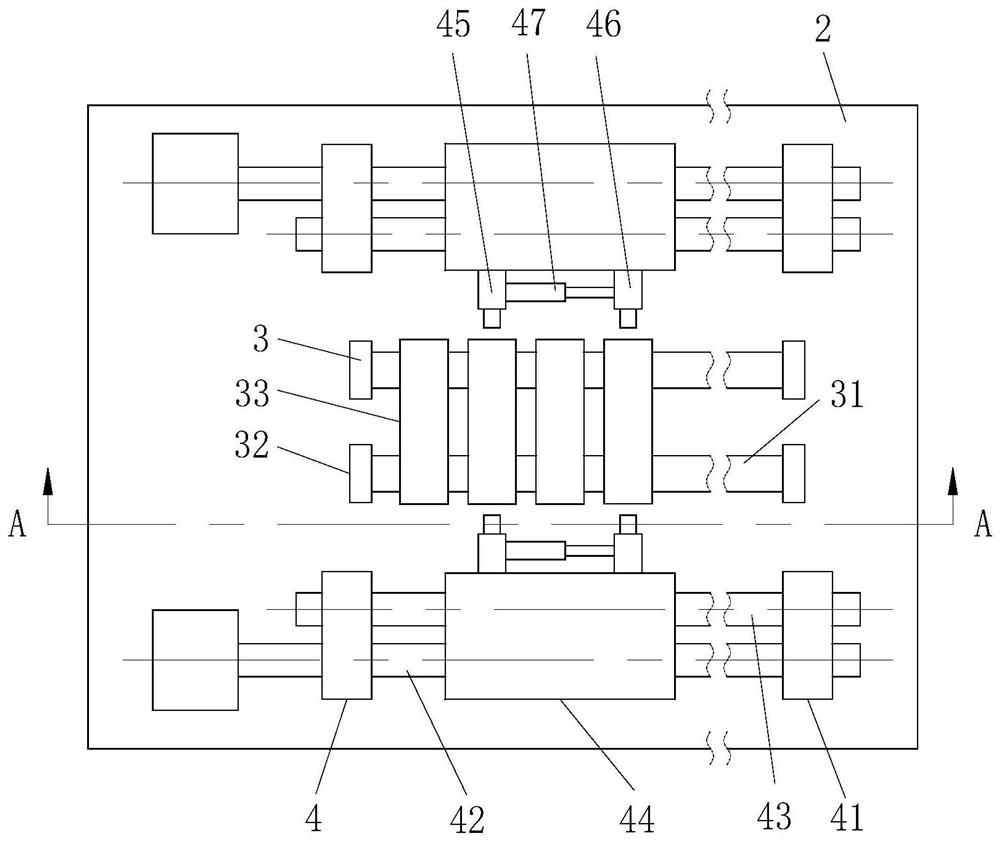

Shaft part damage repair method

ActiveCN108866589AImprove the efficiency of electroplating operationsUniform thicknessElectrolysis componentsMechanical componentsBiochemical engineering

The invention belongs to the technical field of mechanical part repair, and particularly relates to a shaft part damage repair method. According to the method, an electro brush-plating plating pen isused, wherein the electro brush-plating plating pen comprises a rod, a fixing board, an electroplating module and a clamping module; the electroplating module comprises installation boards, supportingboards, connected boards and positive boards; the two installation boards are arranged on the fixing board in parallel; the supporting boards are fixedly connected with end sockets of the installation boards; one set of connected boards are arranged between the two supporting boards, each two adjacent connected boards are connected through arc springs, the arc springs hog toward the outer side, and the connected boards can slide on the surfaces of the installation boards; the positive boards are fixedly connected with the upper parts of the connected boards; hair bundles are arranged on the positive boards; the clamping module is installed on the side edge of the electroplating module, and the clamping module is used for adjusting an interval between each two connected boards and making one set of connected boards form an arc surface. The shaft part damage repair method is suitable for electroplating work of shafts provided with arc ring grooves, and the electroplating work efficiencycan be improved.

Owner:宁波致泰精密轴业有限公司

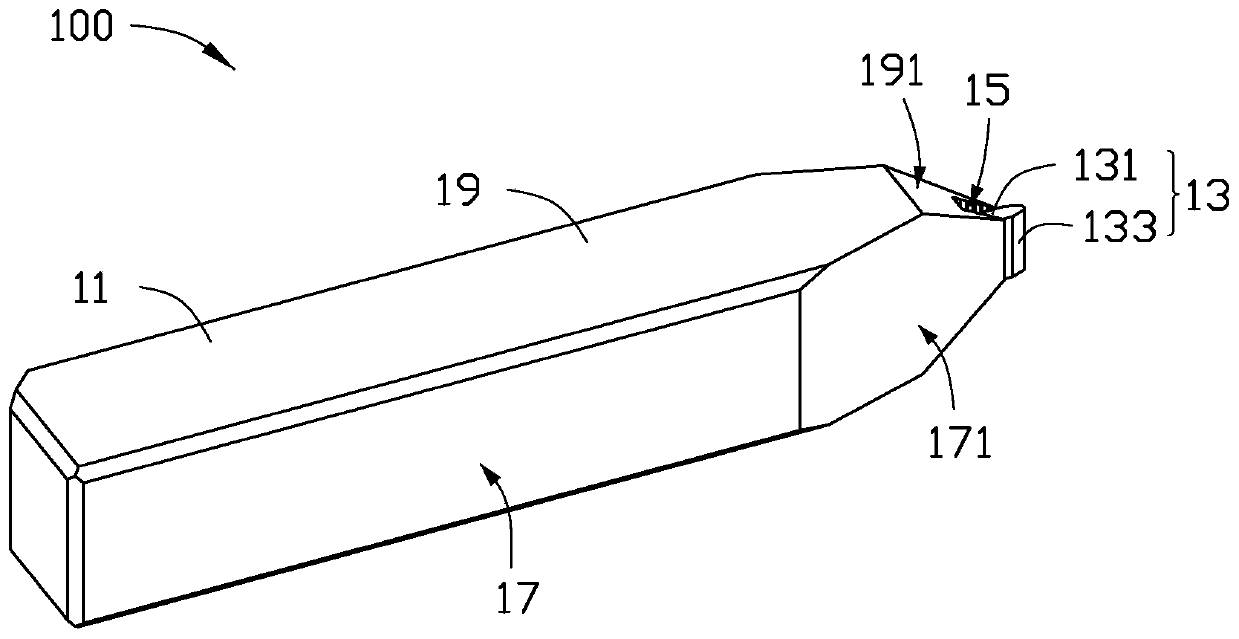

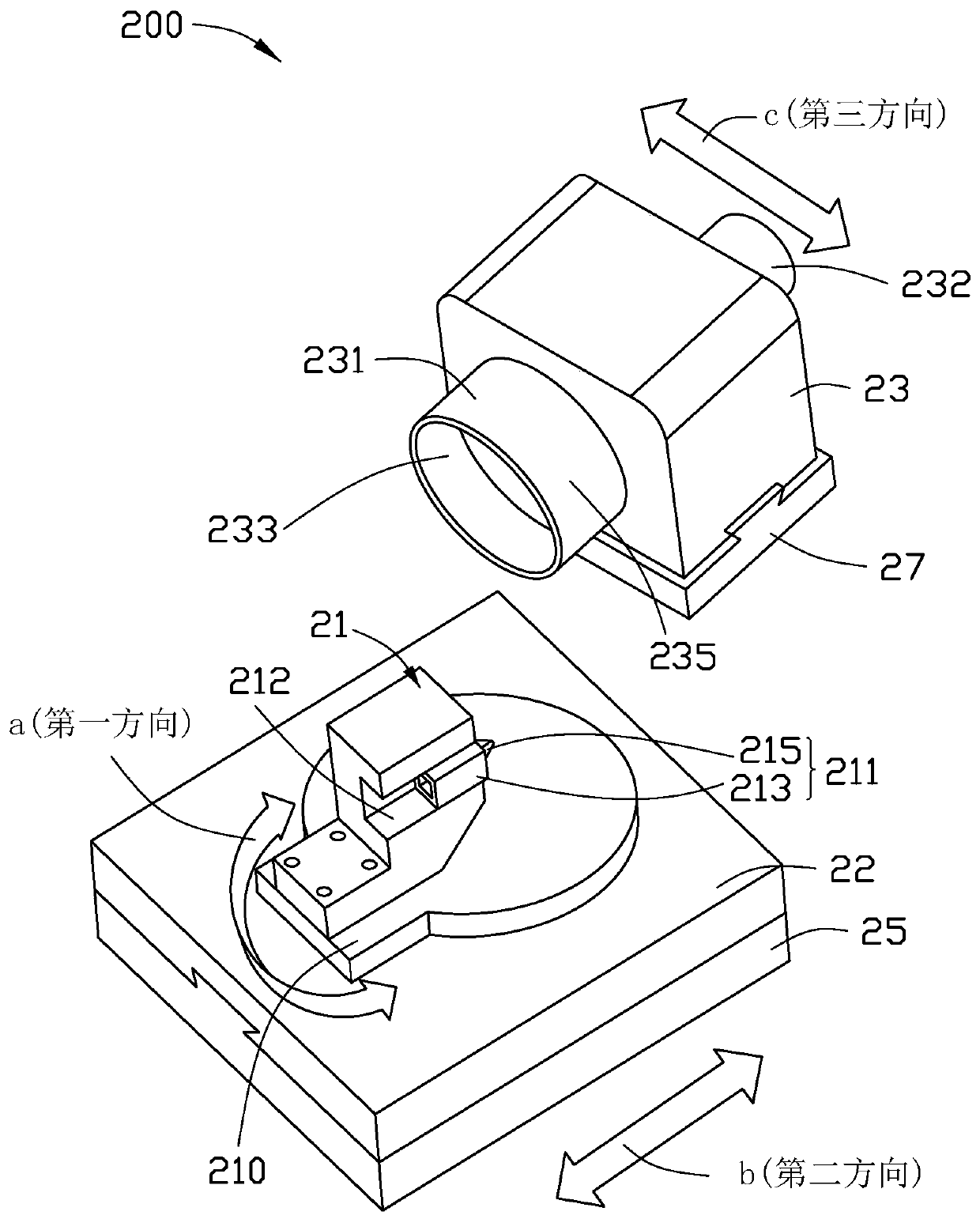

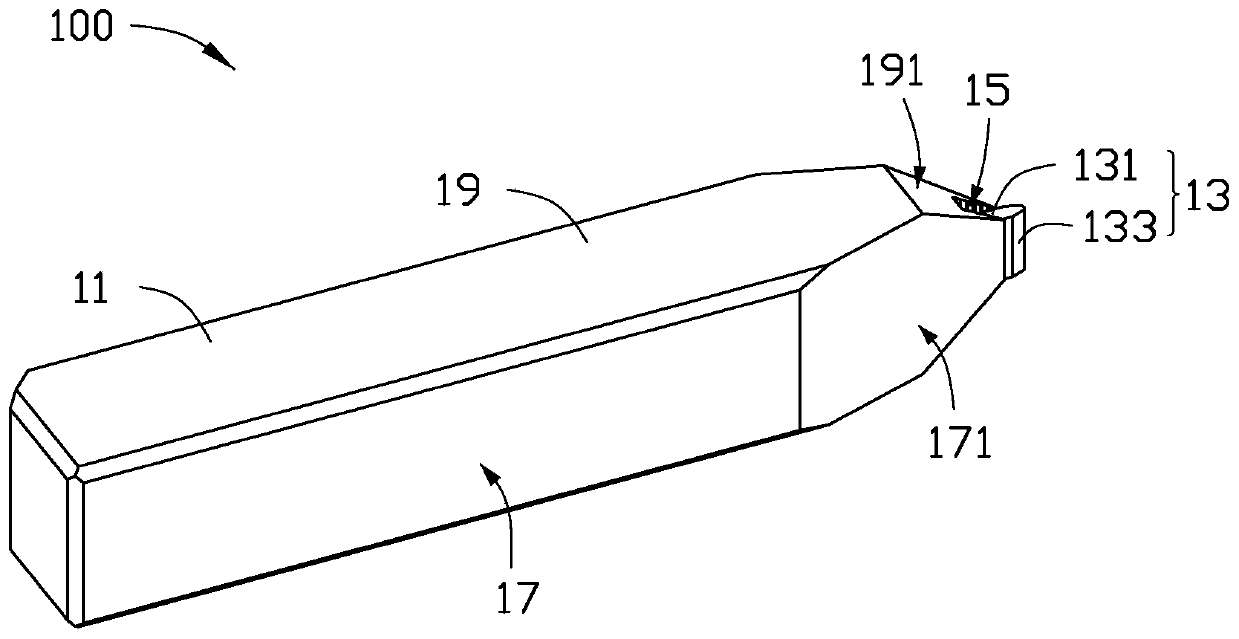

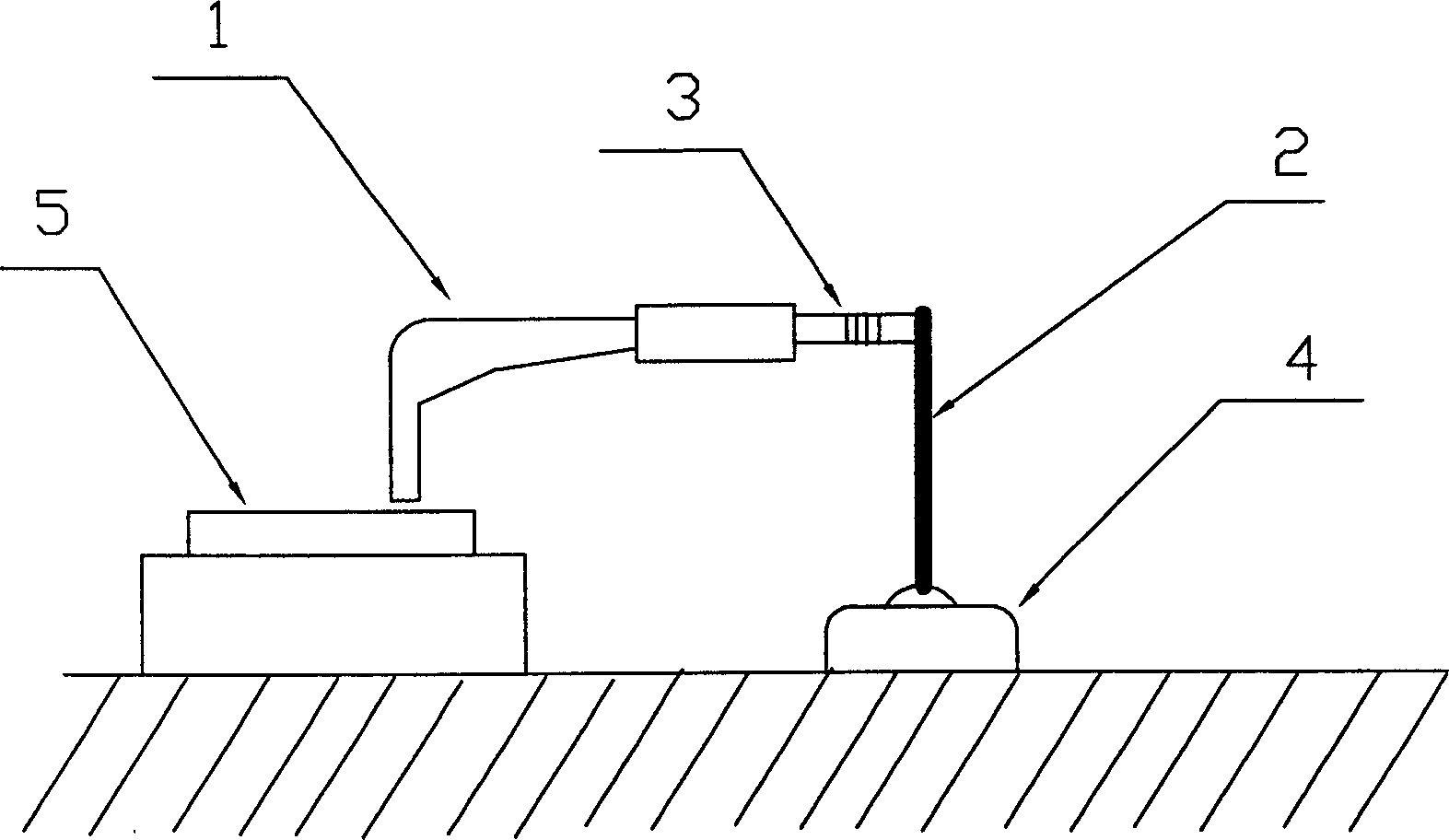

Grinding machine, diamond tool and machining method of diamond tool

A diamond tool is used for grinding a to-be-machined workpiece, and comprises a main body and a diamond particle fixed to one end of the main body; one end of the main body is provided with a concavegroove; the diamond particle comprises a fixing part and a grinding part formed by extending from the fixing part; the fixing part is stored and fixed to the concave groove; the grinding part is exposed out of the concave groove and used for grinding the to-be-machined workpiece, the profile arithmetical mean deviation Ra, the profile maximum height Ry and the microcosmic irregularity ten-point height Rz of the grinding part meet the relation that Ra is smaller than 0.124 [mu]m, Ry is smaller than 1.306 [mu]m, and Rz is smaller than 0.757 [mu]m. The invention further provides a grinding machine and a method for manufacturing the diamond tool. According to the diamond tool, the grinding machine and the method for manufacturing the diamond tool, flexible grinding is conducted through an airflotation shaft and an air flotation platform, thus, the obtained diamond tool meets the design requirements for the appearance and size and has the characteristics of being smooth in arc and free oflines, meanwhile, the machining yield reaches 99% or above, and one diamond tool can machine 600 to-be-machined workpieces.

Owner:JIZHUN PRECISION IND HUIZHOU

Circular cutter

InactiveCN1778509AArc smoothThe effect of cutting circle is goodGas flame welding apparatusSheet steelTorch

Owner:谢首海

Shoe tongue making process

ActiveCN107048595ARadian smoothStable and controllable qualityLeather sewingUpperEngineeringSewing machine

The invention discloses a shoe tongue making process. The shoe tongue making process comprises the steps of forming a wall groove in the thickness face of the top end of foam, wherein the distance between the wall groove and the outer surface of the foam is 2-3 mm; overlaying a tongue face with a tongue lining, and processing the top end of the tongue lining and the top end of the tongue face to form a joint portion; sewing the tongue lining and the tongue face together along the lower side of the joint portion; spraying glue onto the inner surface of the tongue face for enabling the tongue face to be attached to the foam, wherein the top end of the foam is located below a sewing thread by a distance of 2-3 mm; overturning the tongue lining to wrap the foam, guiding the joint portion into the wall groove by means of an auxiliary tool during overturning, and making the arc at the overturning position between the tongue lining and the top end of the foam smooth by means of an auxiliary tool; opening the lower end of the tongue lining, spraying glue onto the inner surface of the tongue lining and / or the back side, facing the tongue lining, of the foam, and laminating the tongue lining and the foam after glue spraying; and conducting sewing with a sewing machine along the lower-end arcs of the tongue lining and the tongue face, so as to form a closed sewn structure. By the adoption of the shoe tongue making process, the arc of the upper end of a shoe tongue can be smooth, and quality is stable and controllable due to the adoption of standard operation.

Owner:骆驼(福建)户外用品有限公司

A steel pipe bending machine and its forming process

InactiveCN104475509BArc smoothClear arcShaping toolsMetal-working feeding devicesGear wheelControl switch

Owner:TAICANG XINBAOYI STEEL PIPE MFG

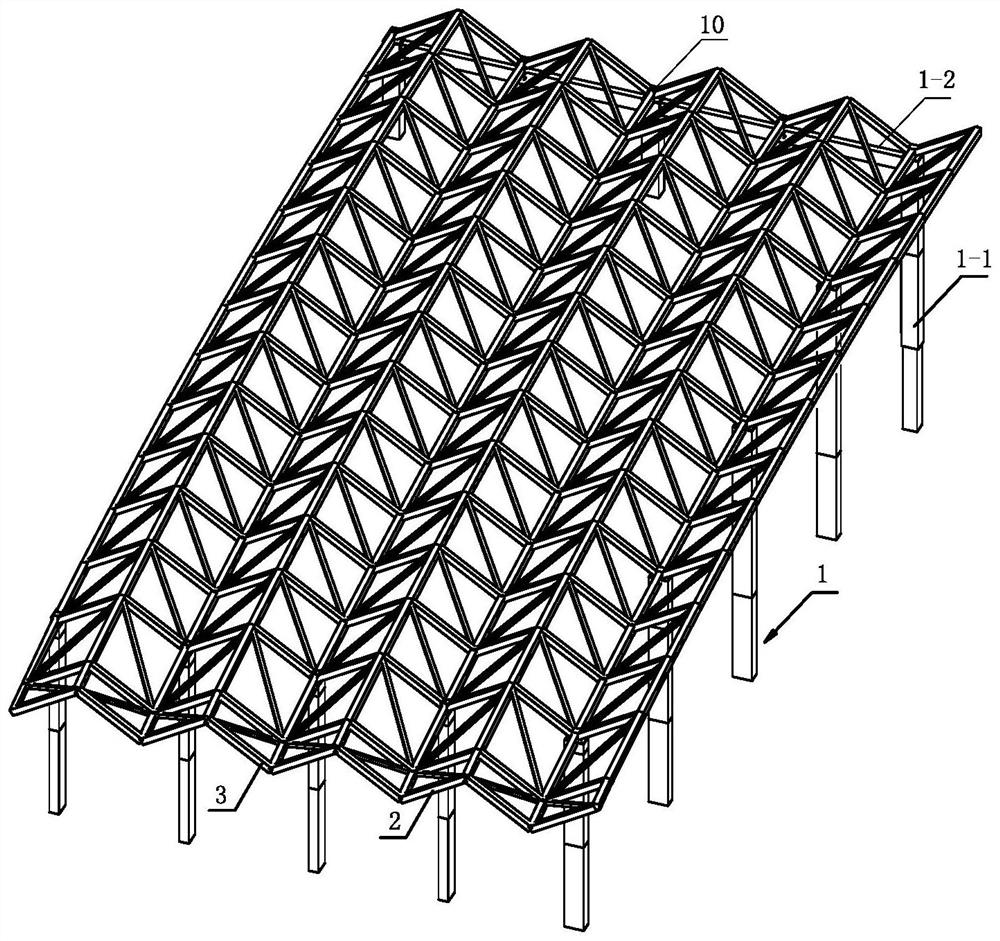

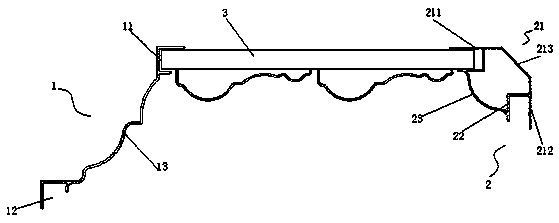

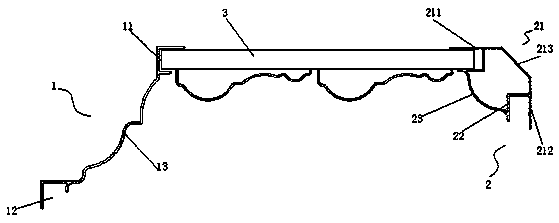

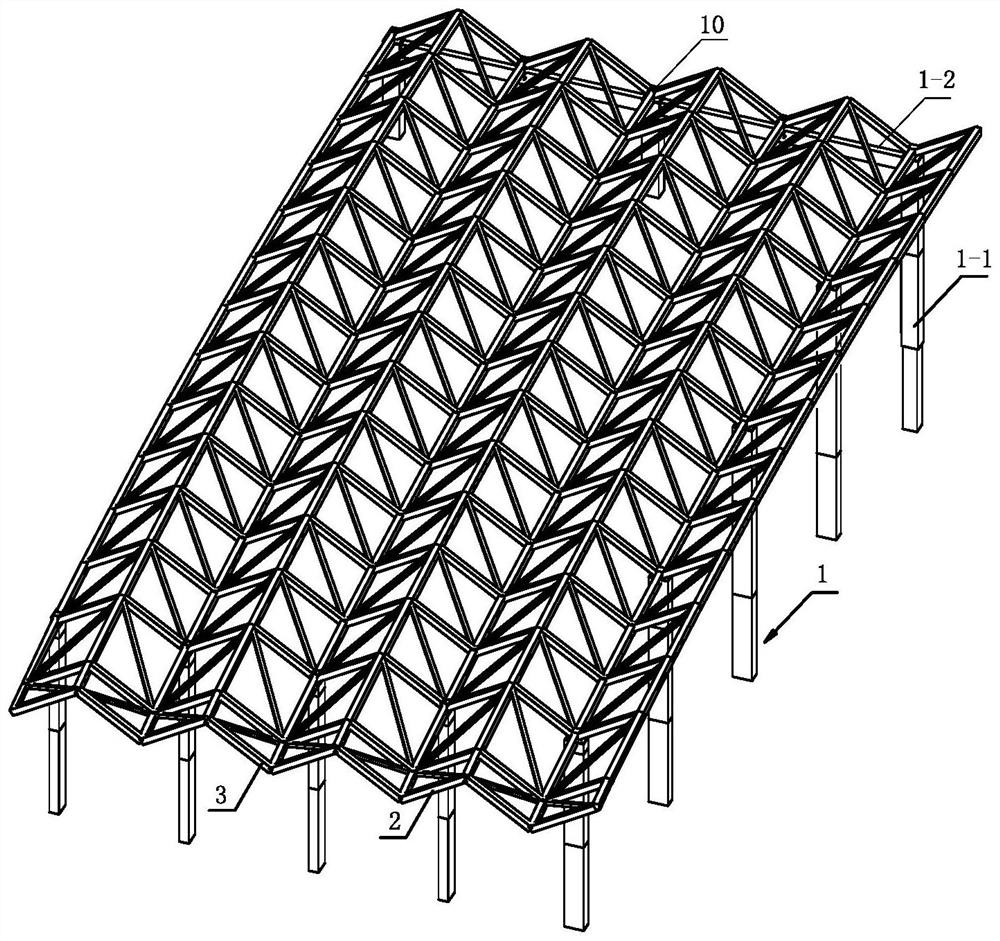

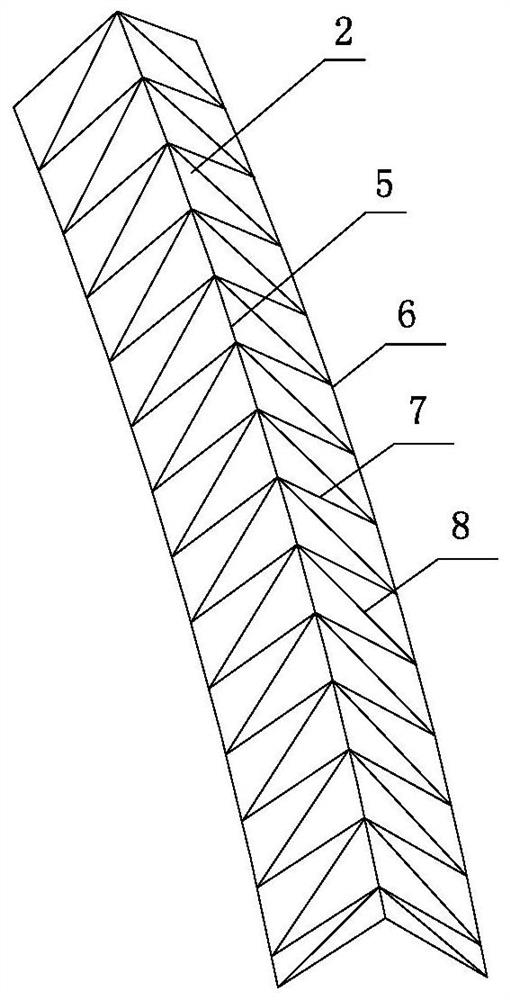

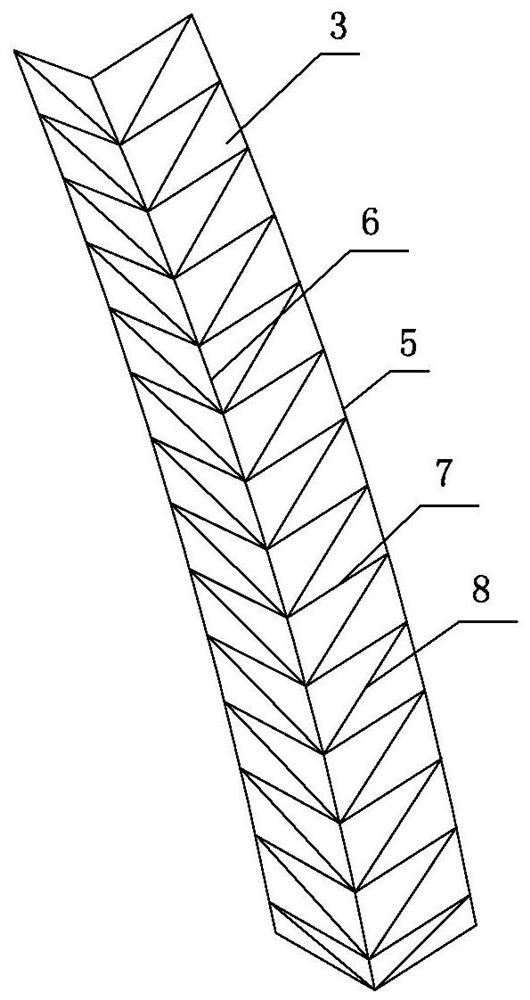

Construction method of large-span folded plate type steel roof truss

ActiveCN113152904AReduce installation deviationImprove efficiencyGeometric CADGirdersSteel frameLong span

The invention relates to a construction method of a large-span folded plate type steel roof truss. A roof truss support, a plurality of V-shaped steel frame units, a plurality of inverted-V-shaped steel frame units and an aerial scattered assembly unit form a whole roof steel frame in a folded plate shape. The construction method is characterized in that the V-shaped steel frame units and the inverted-V-shaped steel frame units are machined on the ground, the inverted-V-shaped steel frame units and the V-shaped steel frame units are integrally hoisted, and the aerial scattered assembly unit is hoisted; and an air assembly technology is carried out between the inverted-V-shaped steel frame unit and the V-shaped steel frame unit by utilizing the aerial scattered assembly unit. The construction method has the advantages that the technical problems of speed, precision, deformation and the like of ground assembly and aerial in-place measurement are solved, and the mounting precision, quality and safety of a steel structure and the project progress are effectively controlled. Roof steel frame hoisting units are reasonably divided, integral hoisting is adopted, high-altitude operation is reduced, the use efficiency, the safety coefficient, the construction quality and the construction efficiency of large hoisting machinery can be greatly improved, and the construction cost is reduced.

Owner:TIANJIN TIANYI CONSTR GRP

Combined internal corner plate for elevator interior decoration

The invention relates to a combined internal corner plate for elevator interior decoration. The combined internal corner plate is characterized by comprising a first internal corner plate, a second internal corner plate and a horizontal lifting plate; the first internal corner plate and the second internal corner plate are arranged at internal corners of the top end of the elevator car wall; the horizontal lifting plate is connected between the first internal corner plate and the second internal corner plate; the combined internal corner plate for decoration is convenient to install, labor-saving, time-saving, material-saving, and attractive and bright in decoration effects; the curved surface of a corner line is smooth, and the line is straight, which can effectively ensure that wrappingedges can be attached to corners straightly, and make the decorative corners have more three-dimensional aesthetic feeling; the color is rich, the color matching can be realized, the consistency of the elevator car wall surface and the side lines can be realized, and different colors can be matched to form contrast; corners of an elevator can be well protected; the environment-friendly performanceof a product is good, and used raw materials have no adverse effect on human body and on the environment, and the arc gentle right angles reduce damage caused by collision; and meanwhile, it can be ensured that the inner corners of the elevator is smoothly paved without interference with electronic equipment.

Owner:南通吉程机械有限公司

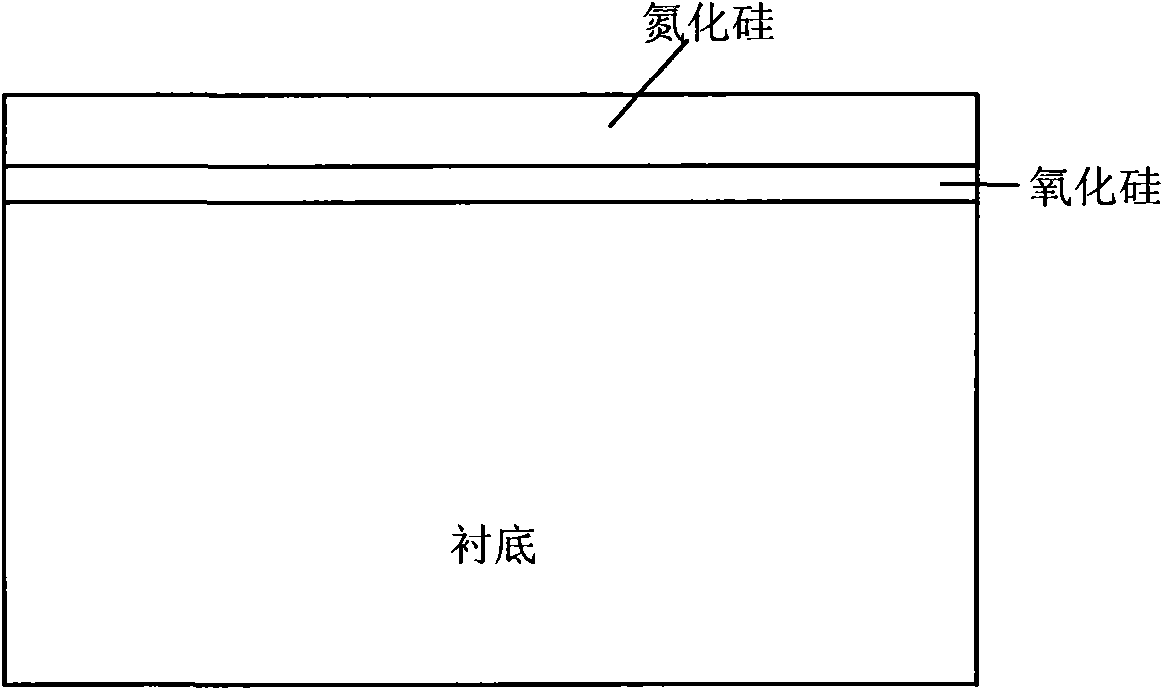

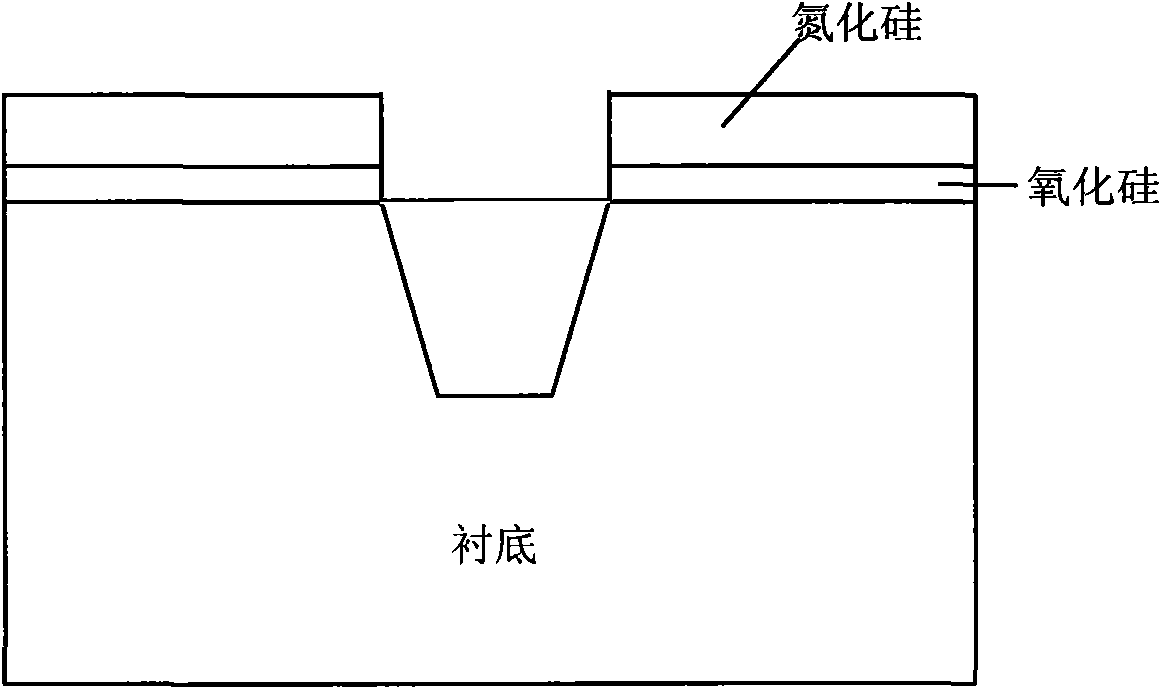

Preparation method of shallow trench isolation structure

ActiveCN101593717AAvoid makingAvoid formingSemiconductor/solid-state device manufacturingPhotosensitive material processingSilicon nitrideSilicon oxide

The invention discloses a preparation method of a shallow trench isolation structure, which comprises the following steps: forming a scalar silicon nitride appearance used as a mask for etching a shallow trench through three etching technologies, and realizing that a top angle is smoothed to prepare smoother silicon and silicon oxide interfaces by utilizing thinner silicon oxide with a poorer oxidation shielding property when the inner surface of a shallow trench is subsequently oxidized.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

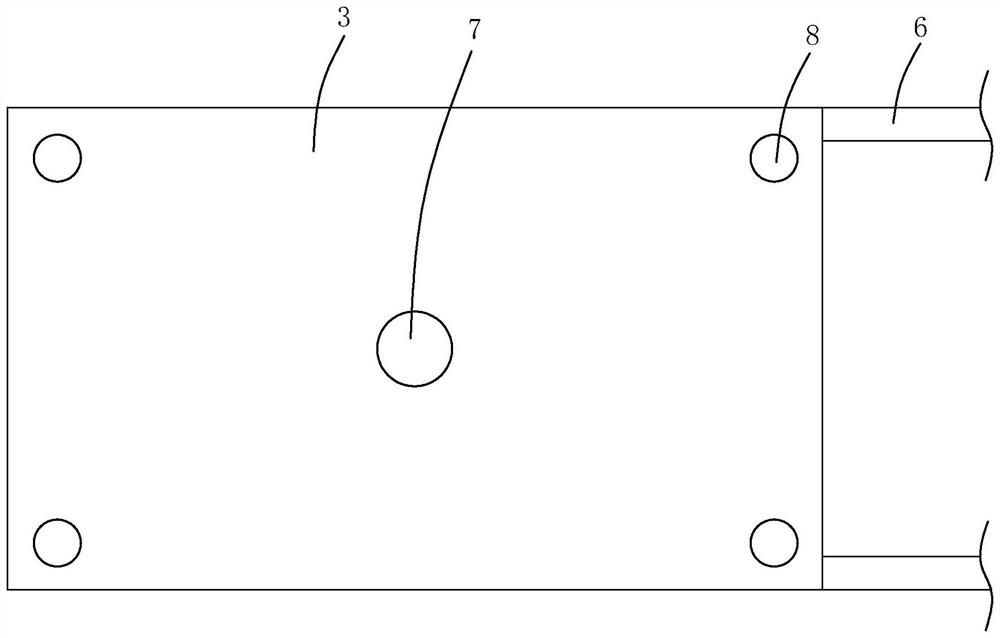

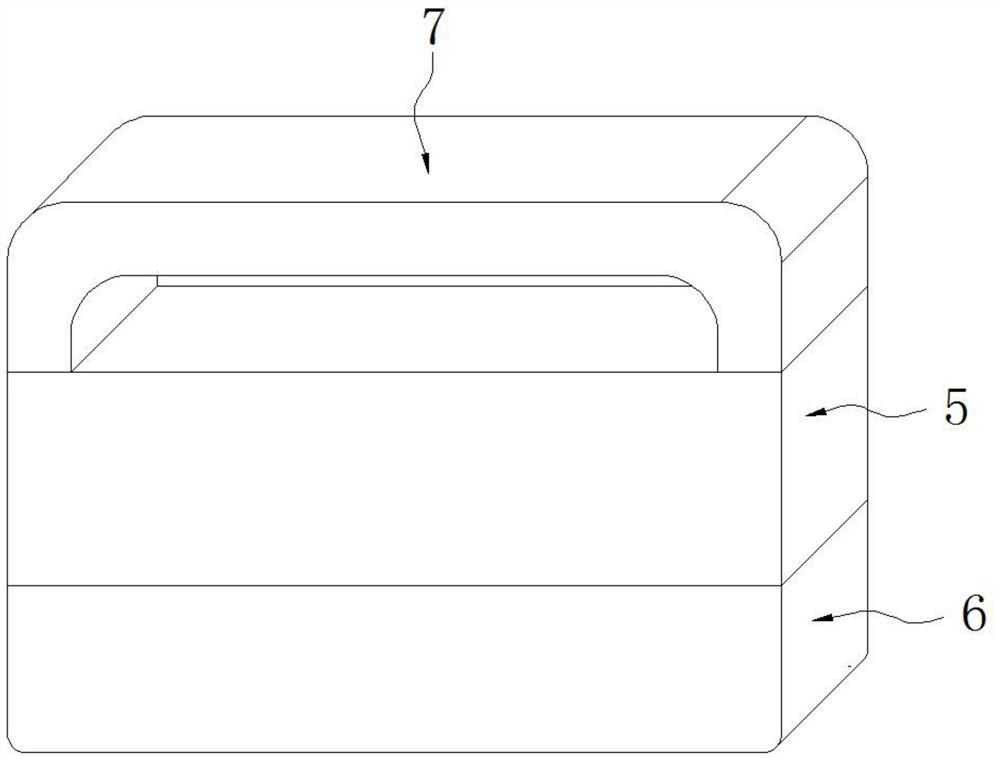

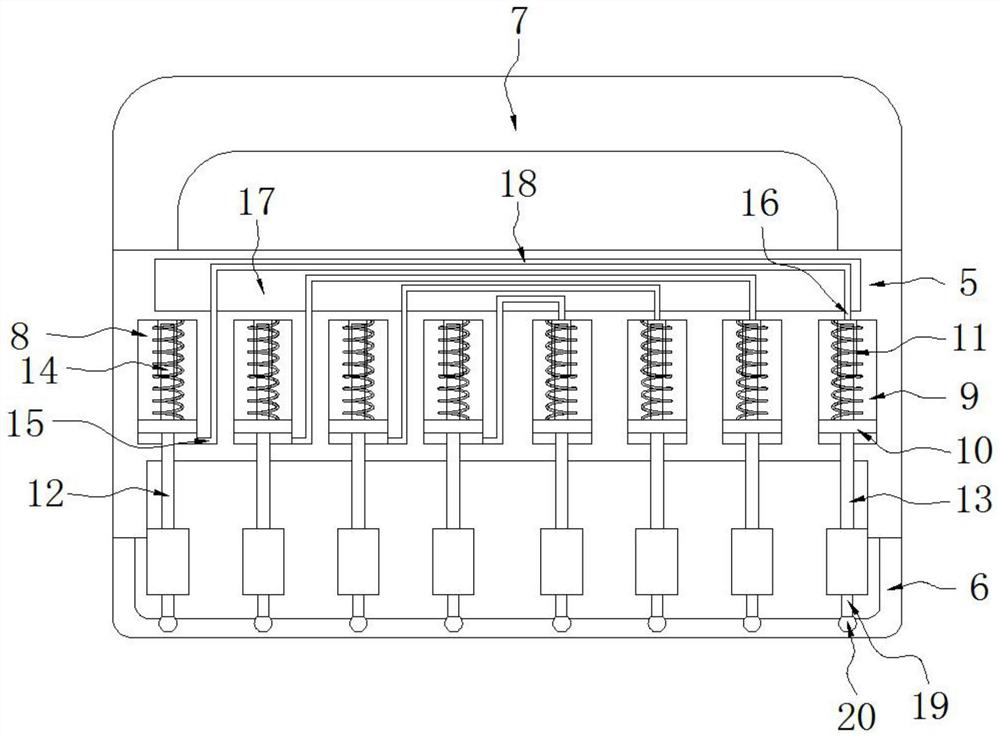

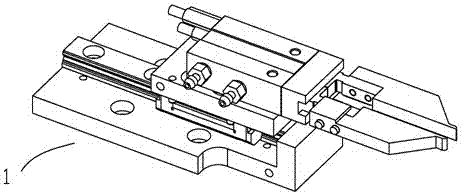

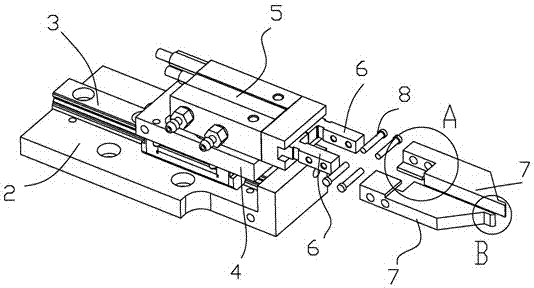

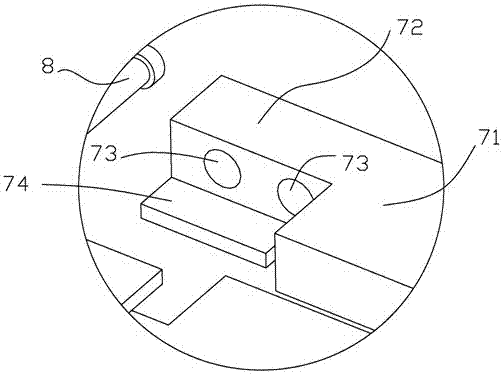

Metal reed one-time forming device used for patch panel

The invention discloses a metal reed one-time forming device used for a patch panel. The metal reed one-time forming device is characterized by comprising a fixed base plate which is horizontally arranged, a long-strip-shaped sliding transverse strip is arranged on the fixed base plate, a slidable cylinder base is arranged on the sliding transverse strip, a detachable double-head cylinder is arranged on the cylinder base, a pair of detachable side position supports are arranged at the heads of the double-head cylinder, and forming chucks are arranged on the heads of the side position supports respectively. After the double-head cylinder is started, the pair of side position supports synchronously move outwards, the forming chucks expand outwards at the same time, forming mold plates on the heads of the forming chucks directly act on a copper metal reed, and therefore the metal reed can be rapidly formed, forming is rapid, cambered surfaces are smooth, the electrical quality of the patch panel is greatly improved, and practicability is high.

Owner:重庆博视知识产权服务有限公司

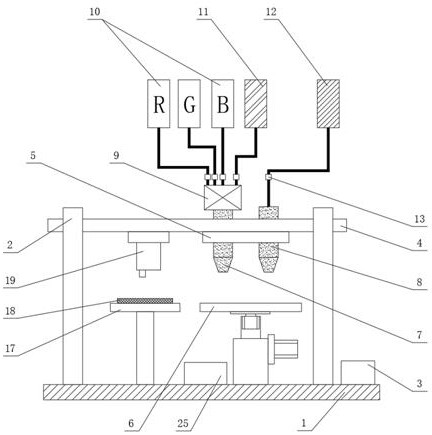

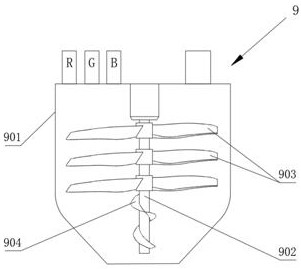

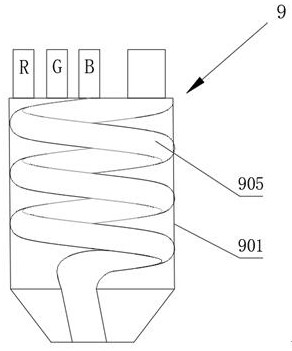

Novel color 3D printer

PendingCN112644015AGood chromaIncrease productivityManufacturing heating elementsManufacturing recyclingComputer printing3d printer

The invention relates to a novel color 3D printer, comprising a printer base, vertical supports arranged on the two sides of the base, a controller arranged on one side of the base, a transverse rod arranged at the upper ends of the supports and capable of horizontally moving front and back relative to the supports, and a spray head base arranged on the transverse rod and capable of horizontally moving relative to the length direction of the transverse rod. A printing platform is arranged on the base; a main spray head and an auxiliary spray head are fixedly arranged on the spray head base; a mixing unit is arranged at the feeding port end of the main spray head, and is connected with an RGB three-color feeding barrel and a first resin feeding barrel; the auxiliary spray head is connected with a second resin feeding barrel; resin in the first resin feeding barrel is thermosetting resin; and resin in the second resin feeding barrel is thermoplastic resin. According to the novel color 3D printer, the color mixing proportion of the RGB three-color feeding barrel is controlled through a switch, so that resin with the needed color can be obtained; and the thermoplastic resin sprayed by the auxiliary spray head serves as a removable supporting material, so that printing forming of an embedded non-supporting structure can be implemented.

Owner:厦门宽畅晖科技有限公司

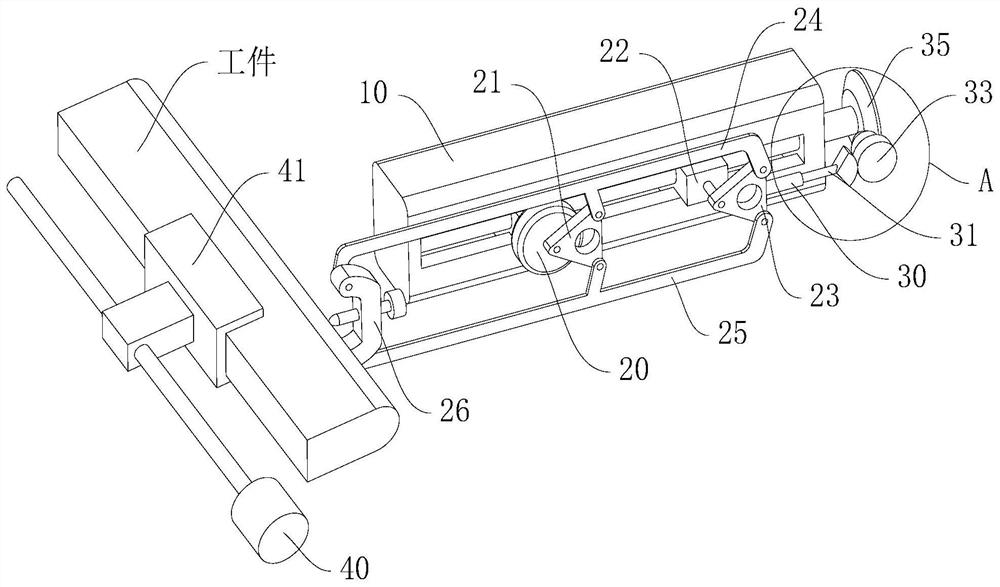

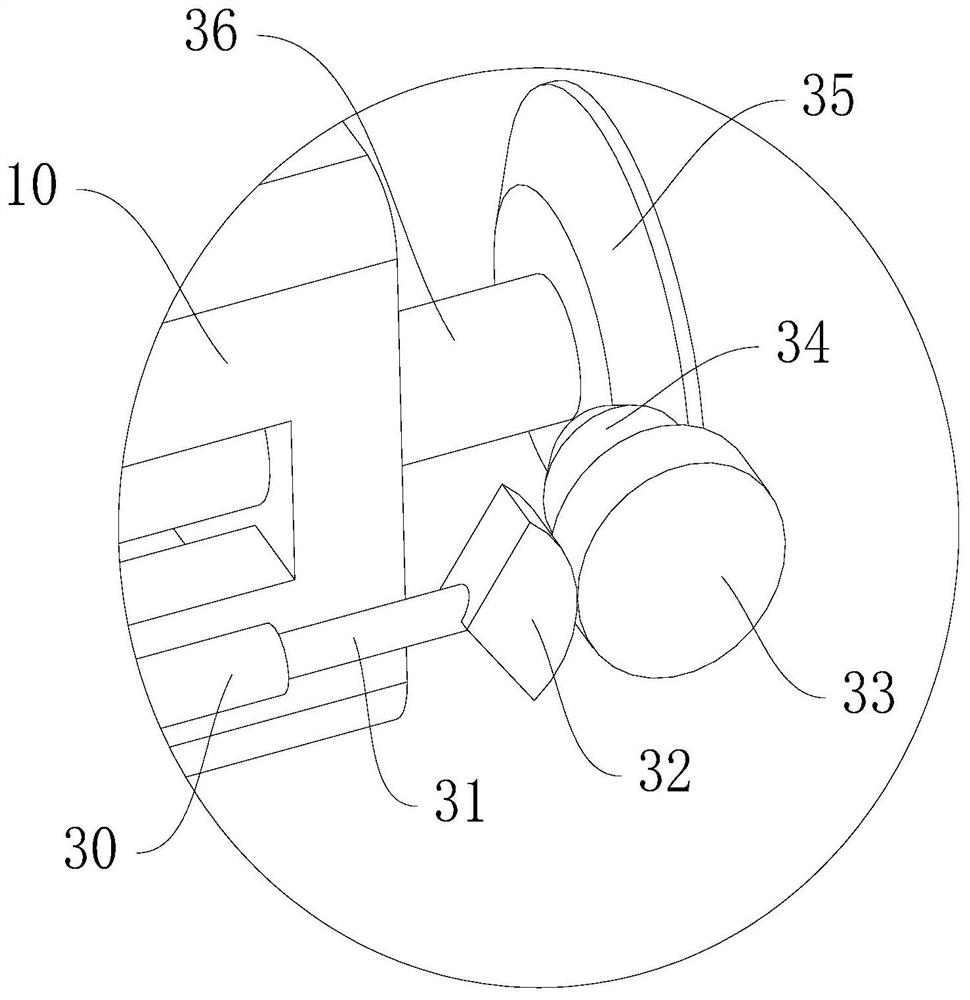

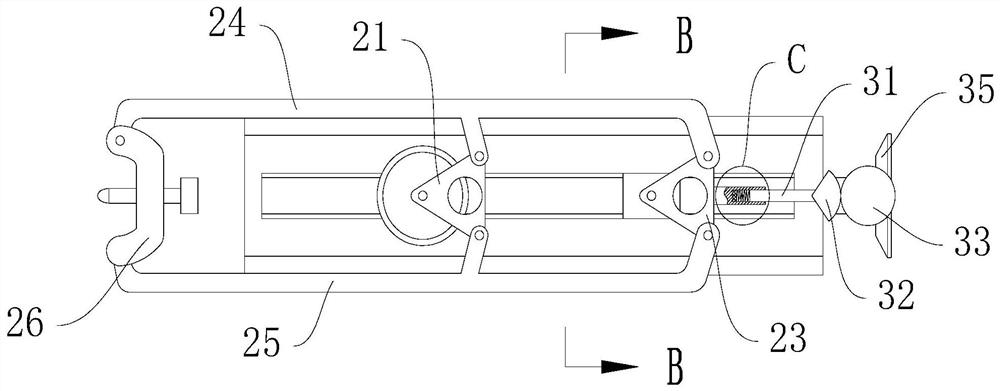

Straight workpiece arc angle cutting tool

ActiveCN112276245AImprove processing efficiencyImprove machining accuracyElectric machineryStructural engineering

The invention discloses a straight workpiece arc angle cutting tool, and belongs to the field of machining. The device comprises a driving mechanism and a grinding mechanism, wherein the driving mechanism comprises a driving motor, a driving lead screw and a clamping device; the grinding mechanism comprises a base, a grinding motor, a first rotating block, a second rotating block, a first overturning rod, a second overturning rod and a cutter rest, the cutter rest is used for installing a tool, the grinding motor is fixedly arranged on the base, the first rotating block is in transmission connection with the output end of the grinding motor, the second rotating block is rotationally arranged on the base, one end of the first overturning rod is hinged to the second rotating block, the otherend of the first overturning rod is hinged to the cutter rest, the middle of the first overturning rod is hinged to the first rotating block, one end of the second overturning rod is hinged to the second rotating block, the other end of the second overturning rod is hinged to the cutter rest, and the middle of the second overturning rod is hinged to the first rotating block. According to the straight workpiece arc angle cutting tool, the machining efficiency is improved, due to machining, the machining precision can be obviously improved, and the cut arc is regular and smooth.

Owner:JIANGSU SECURITY TECH CARRER ACADEMY

Construction method of large-span folded steel roof truss

ActiveCN113152904BReduce installation deviationImprove efficiencyGeometric CADGirdersSteel frameLong span

Owner:TIANJIN TIANYI CONSTR GRP

Arc-shaped rounding mechanism for rounding ridge part of book block

The invention relates to the technical field of book block back processing, in particular to an arc-shaped rounding mechanism for rounding a book block ridge, which comprises a rounding die for fitting a book block, and further comprises an arc-shaped driving mechanism for driving the rounding die to perform arc-shaped swing and a longitudinal driving mechanism for performing longitudinal motion; the rounding die comprises a die assembly and a guide mounting seat used for mounting the die assembly, the die assembly comprises an arc-shaped track and an arc-shaped friction surface which makes friction contact with the ridge part of the book block in an arc-shaped motion mode, and the guide mounting seat is provided with a guide moving part moving on the arc-shaped track; after the book block is in place, the whole circle mold descends as a whole, and the arc-shaped friction surface is attached to the ridge part of the book block, the mold assembly moves along the guide moving part through the arc-shaped track, so that the arc-shaped friction surface is attached to the ridge part to press and swing, the ridge part with radian is formed, due to surface contact movement, the contact range is larger, the formed arc surface is more uniform, and the service life of the whole circle mold is prolonged. The radian is smoother, and the quality is better.

Owner:东莞市浩信精密机械有限公司

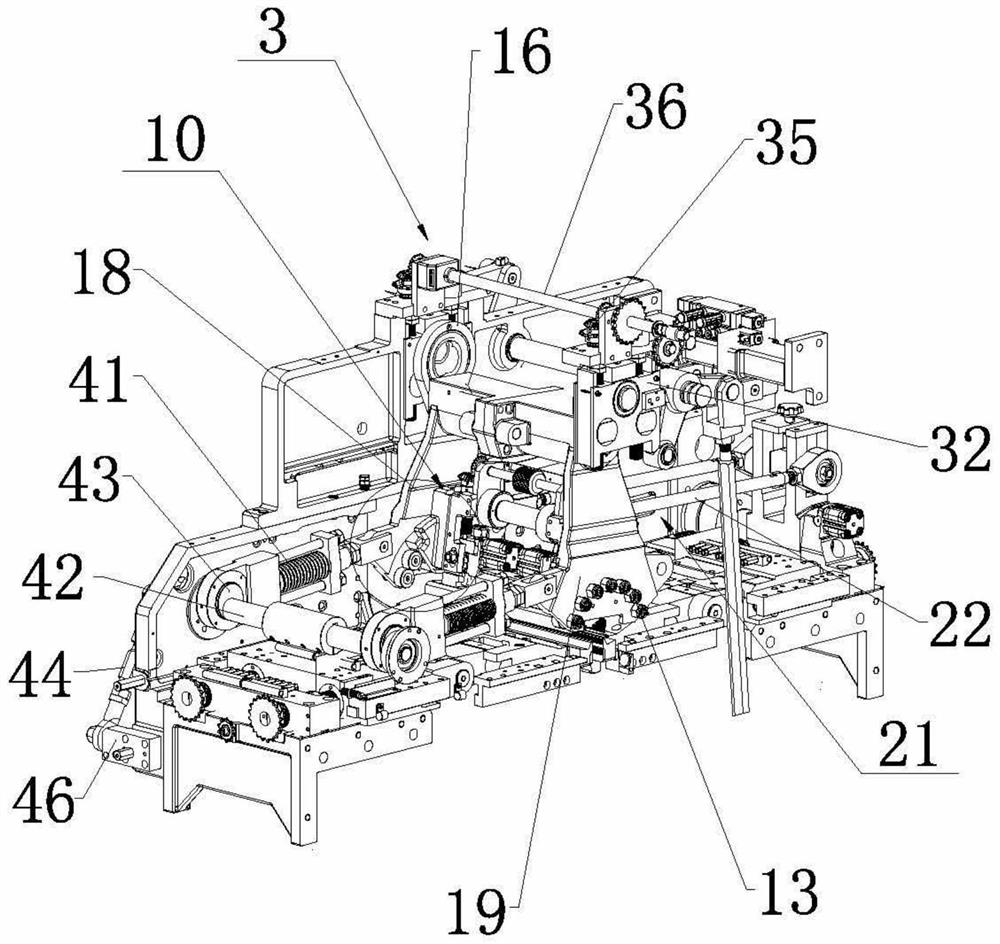

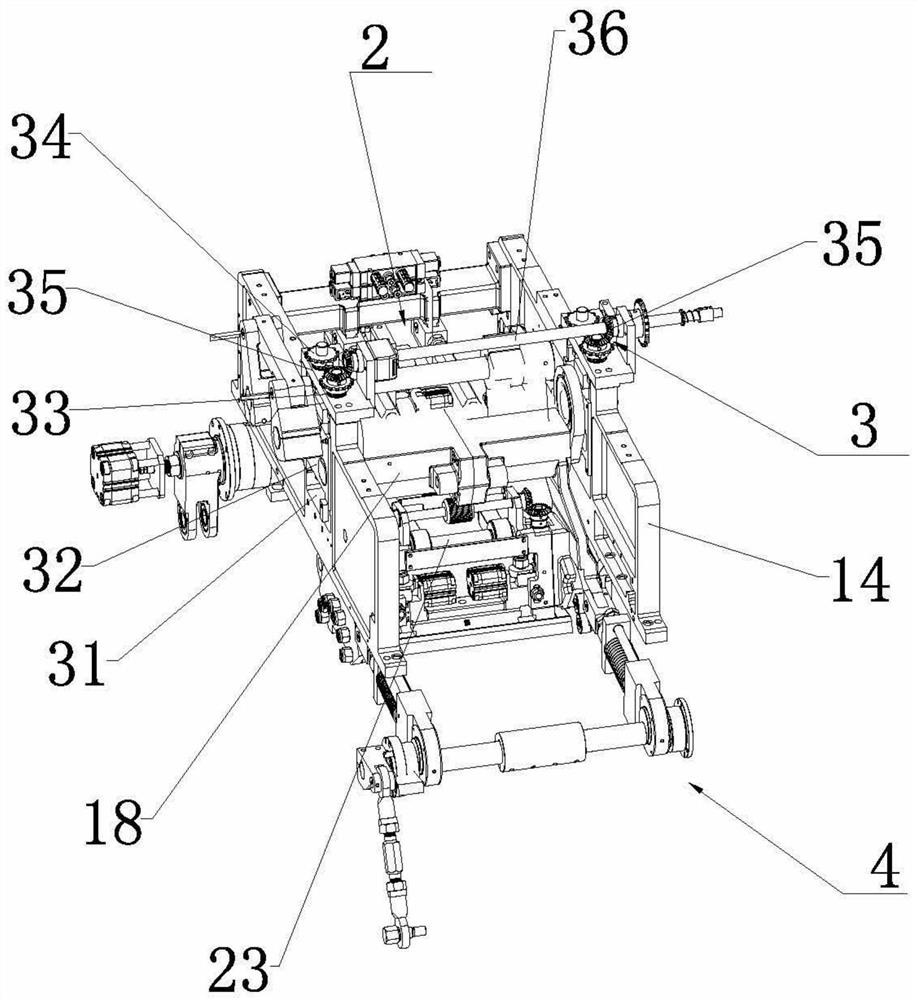

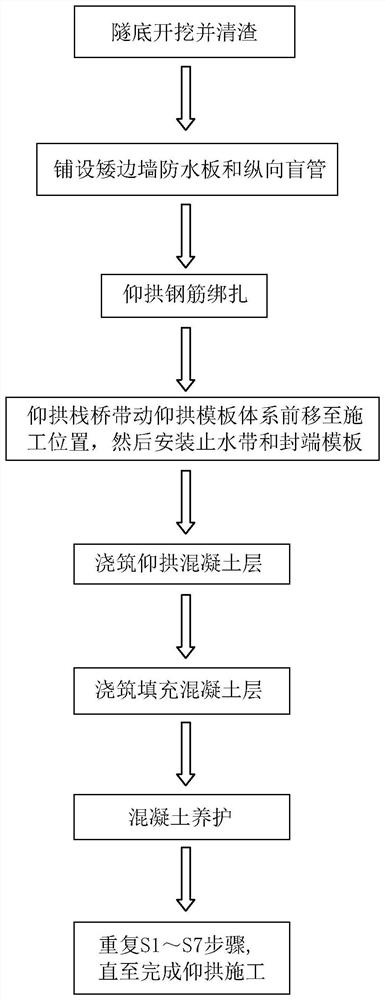

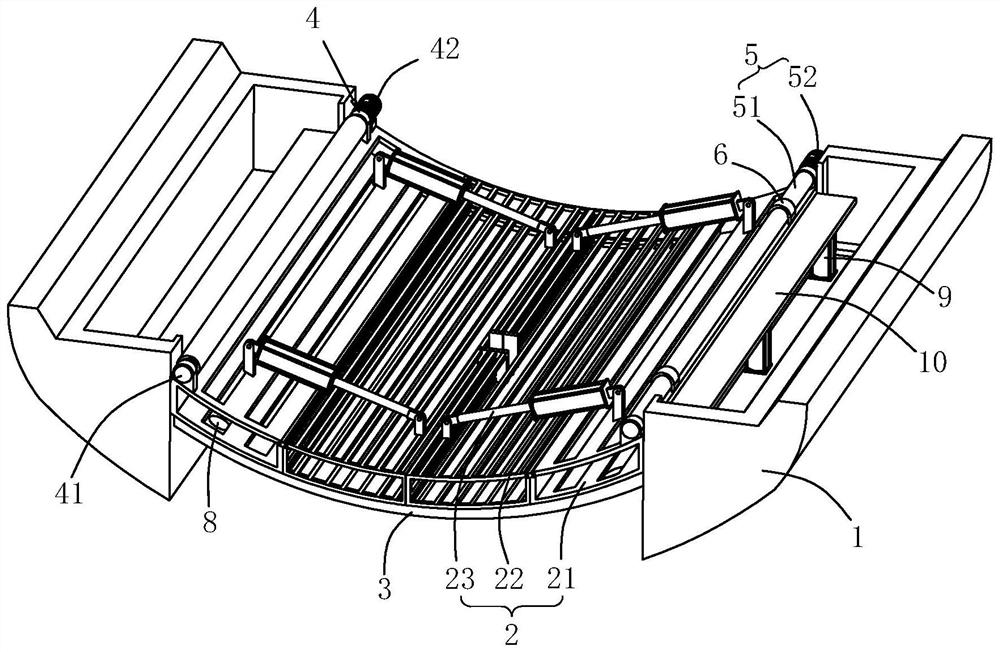

Rapid construction method adopting self-propelled inverted arch trestle

PendingCN114658446AStrongEasy to demouldUnderground chambersTunnel liningArchitectural engineeringRapid construction

The invention discloses a rapid construction method for a self-propelled inverted arch trestle, which comprises the following steps: when an inverted arch concrete layer is constructed and poured, drawing and pulling components arranged on an inverted arch template system are used for drawing and pulling a flexible sealing plate, so that the flexible sealing plate covers the top surface of an inverted arch; then concrete is poured into the space defined by the flexible sealing plate and the inverted arch formwork system through the pouring holes in the flexible sealing plate; the radian of the top surface of the formed inverted arch concrete layer meets the design requirement; after inverted arch concrete is formed, the flexible sealing plate is wound through the winding assembly arranged on the inverted arch formwork, automatic formwork removal is achieved, the construction efficiency is remarkably improved, and then the concrete is poured till the concrete reaches the designed elevation; and finally, concrete curing is conducted, and construction of a section of inverted arch structure is completed.

Owner:中铁广州工程局集团第三工程有限公司 +1

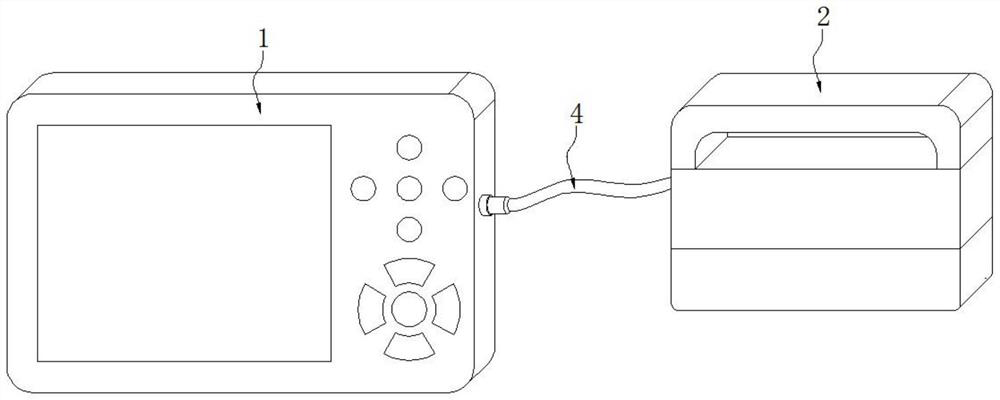

Pipeline defect ultrasonic detection device

ActiveCN114354747AAvoid detection impactHigh precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesSound waveSelf adaptive

A pipeline defect ultrasonic detection device provided by the present invention comprises an ultrasonic detection device main body, an auxiliary detection device and a detection head, the auxiliary detection device comprises a mounting seat and a rubber sheath, and the rubber sheath is fixedly mounted at the bottom of the mounting seat. The pipeline defect ultrasonic detection device is reasonable in design, a plurality of left convex linkage rods and a plurality of right convex linkage rods are mounted at the bottom of the mounting seat of the auxiliary detection device, the left convex linkage rods and the right convex linkage rods are connected with the left convex linkage rods and the right convex linkage rods, and the left convex linkage rods and the right convex linkage rods are connected with the left convex linkage rods and the right convex linkage rods through the left convex linkage rods and the right convex linkage rods. During detection, in the process that the auxiliary detection device is attached to the surface of a pipeline, the left convex linkage rods and the right convex linkage rods can be attached to the surface of the pipeline in a self-adaptive mode, and the rubber leather sheath is stretched and shaped at the same time, so that the detected position and the detection head are completely isolated from the outside, external sound waves are prevented from influencing detection, and the detection accuracy is improved.

Owner:湖北闪复管道科技有限公司

A kind of construction method of shaped roof arc concrete flooding

ActiveCN113047545BGuaranteed StrengthHigh strengthRoof drainageForms/shuttering/falseworksArchitectural engineeringStructural engineering

The invention discloses a construction method for stereotyped roof arc concrete flooding, comprising the following steps: S1: designing the size of the formwork according to the arc of the concrete, the formwork is made of 1.5mm thick 304 stainless steel, and the length of a single formwork is 2m; S2: Clean the roof and make grooves on the upper surface and the inner wall of the roof; S3: Fix the vertical board and the horizontal board in the two slots; S4: Connect the multi-section formwork, and insert the vertical board and the horizontal board after the connection is completed Fix between the boards; S5: Pour concrete slurry between the formwork and the wall, vibrate and compact; S6: After the concrete slurry is finalized, remove the formwork; the formwork is set in a long straight arc groove . The present invention replaces the traditional wooden formwork with a formwork made of stainless steel to increase the strength and smoothness and ensure the quality of the formed concrete. The formwork is detachable and assembleable, suitable for long-distance laying and transportation, realizes recycling, and ensures green construction.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

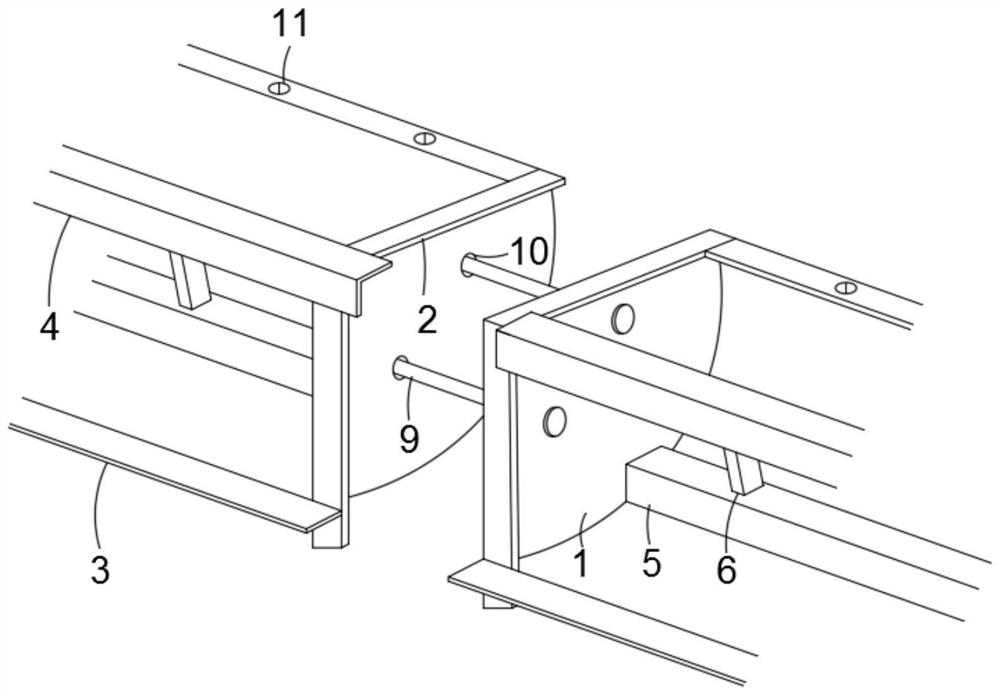

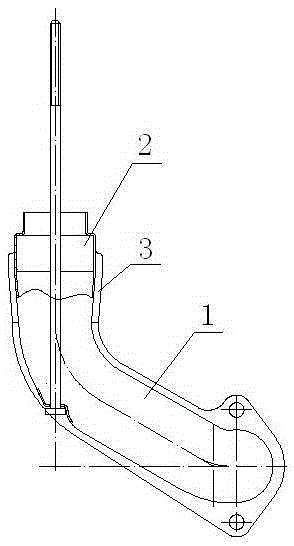

Air inlet tube for air cleaner and manufacturing technology for air inlet tube

InactiveCN103541840AFlat surfaceArc smoothCombustion-air/fuel-air treatmentMachines/enginesManufacturing technologyEngineering

The invention belongs to the field of diesel engine equipment and particularly relates to an air inlet tube for an air cleaner and a manufacturing technology for the air inlet tube. The air inlet tube comprises an air inlet elbow and a casing tube. The casing tube is arranged at an air inlet elbow and air cleaner connection end, the casing tube is integrated with the air inlet elbow, and the casing tube is a stamping tension portion of the air inlet elbow. The air inlet tube is smooth and flat in surface, smooth in arc, attractive and elegant, simple in production technology, capable of reducing the production cost and improving the work efficiency, convenient to mount and beneficial to environmental protection.

Owner:湖北省红安县滤通机械制品厂

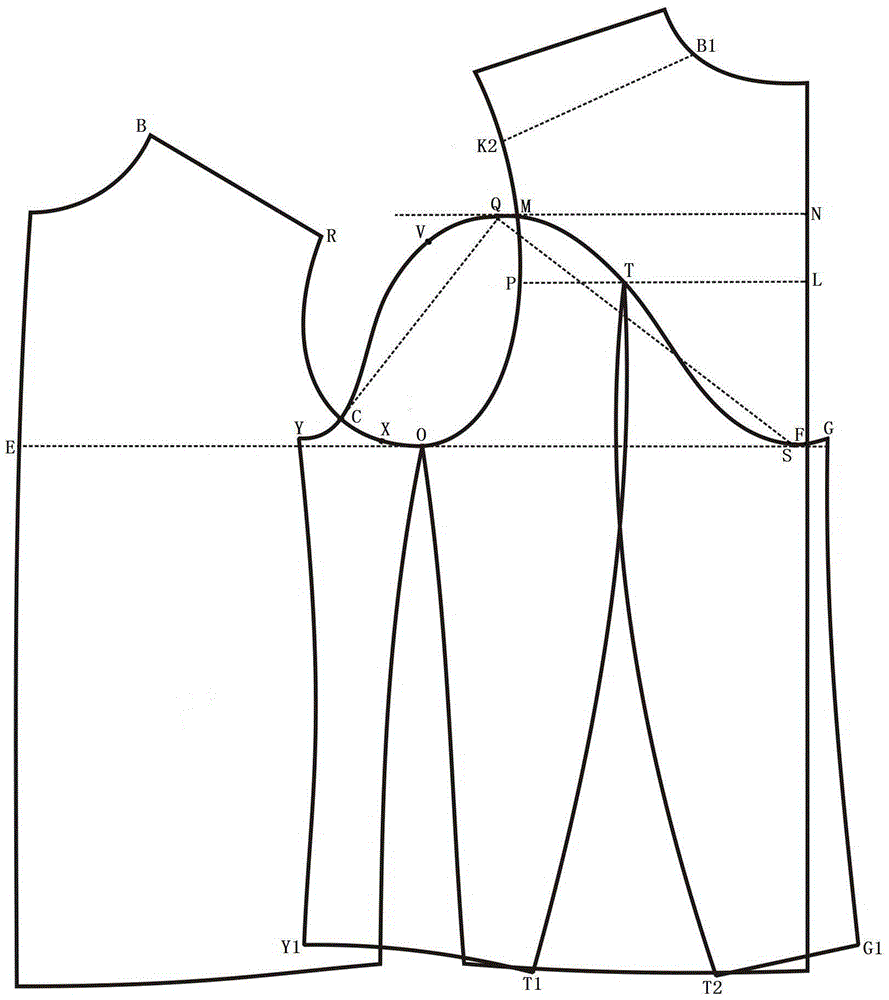

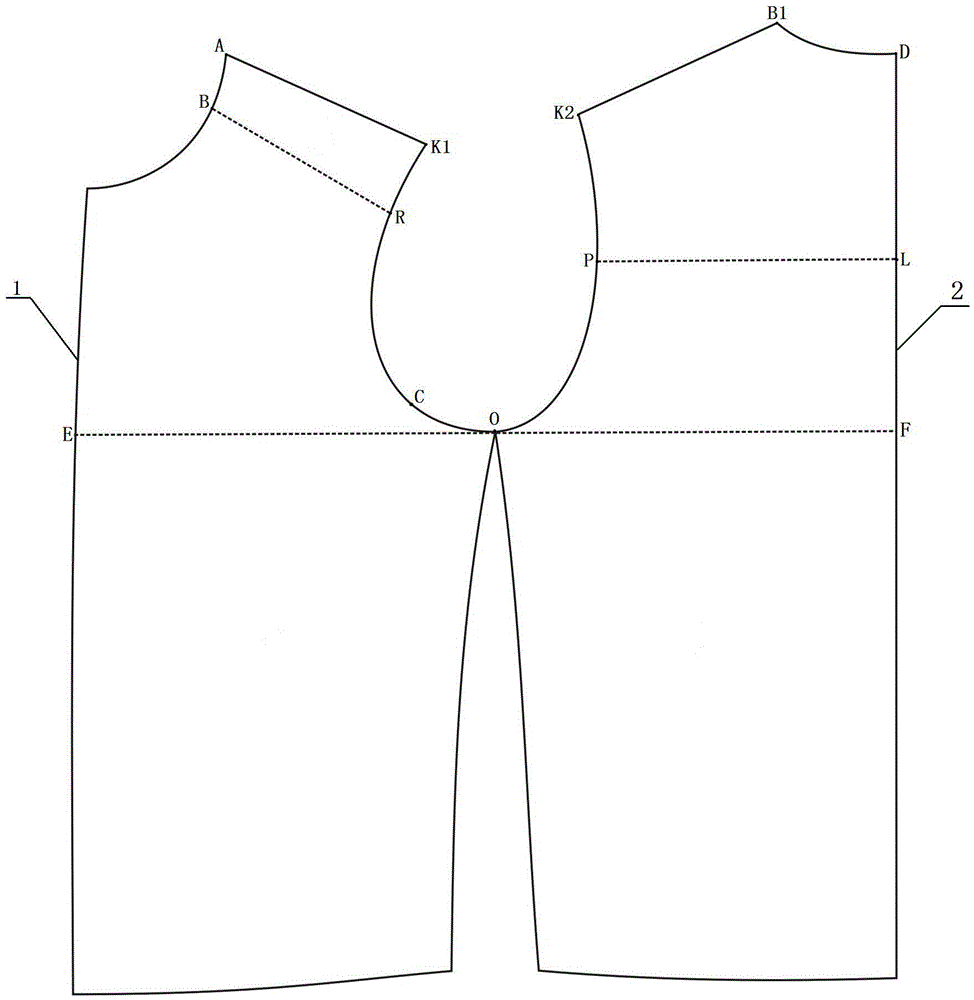

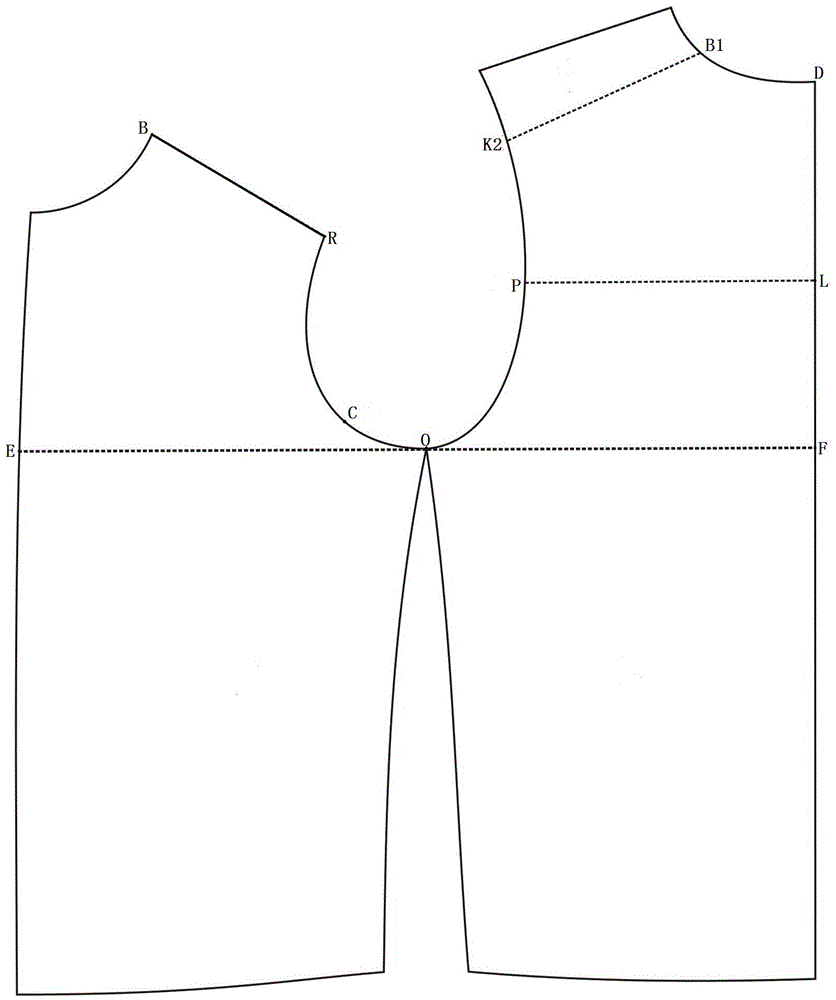

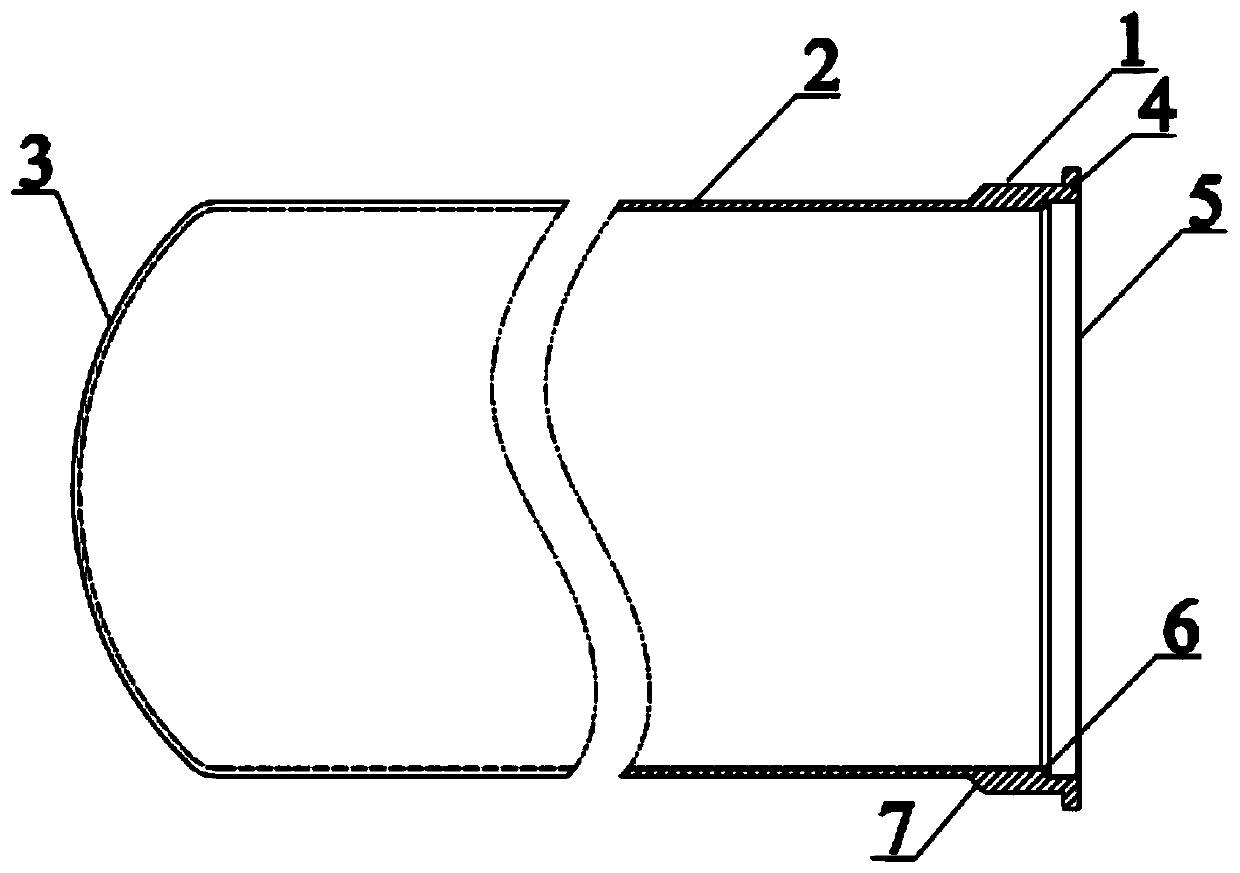

A kind of plate-making and sewing method of jacket clothing sleeve

Owner:JIHUA 3502 PROFESSIONAL GARMENT

Chemical vapor deposition (CVD) outer tube and processing technology thereof

PendingCN110977355AArc smoothLarge diameterCleaning using liquidsChemical vapor deposition coatingPhysical chemistryChemical vapor deposition

The invention discloses a chemical vapor deposition (CVD) outer tube and a processing technology thereof. The CVD outer tube comprises a quartz plate, a butt joint outer pipe, a top cover, a balance weight edge, an inner opening, a quartz sheet and an outer butt joint opening. The quartz plate and the butt joint outer pipe are welded into an integrated structure. The top cover is fixed to the front end of the butt joint outer pipe, the quartz plate is annular, the balance weight edge is fixedly arranged outside the quartz plate, the inner opening is formed in the quartz plate, the quartz sheetis fixed to the position, close to the inner opening, in the quartz plate, the quartz sheet is in lap joint with the inner inclined face of the quartz plate, and the quartz sheet and the quartz plateare welded and fixed.

Owner:北京凯德石英股份有限公司

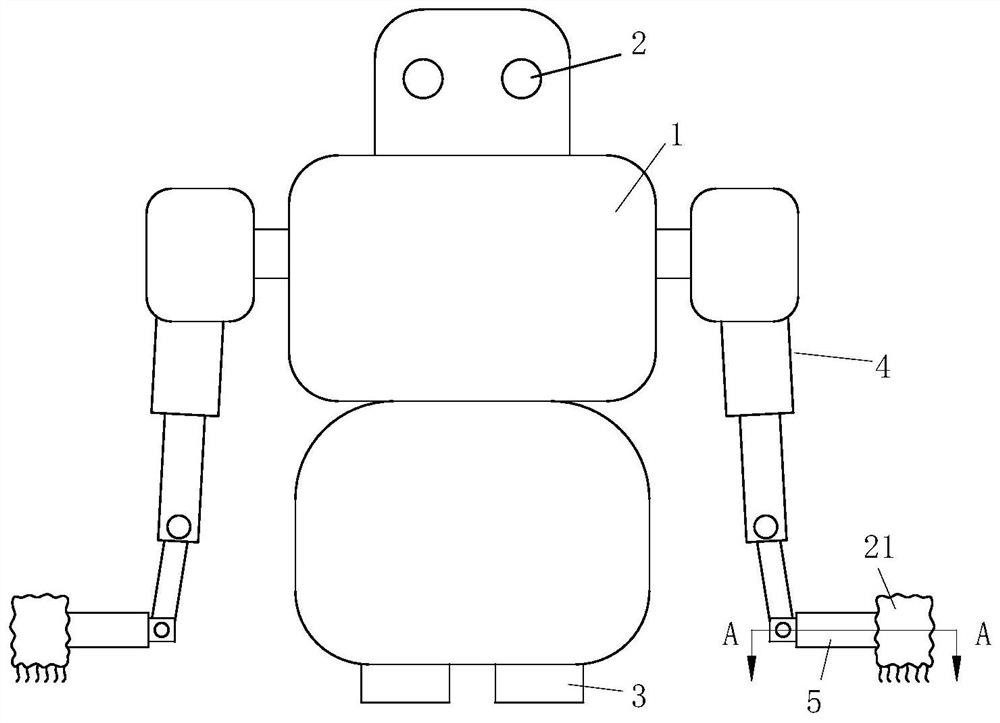

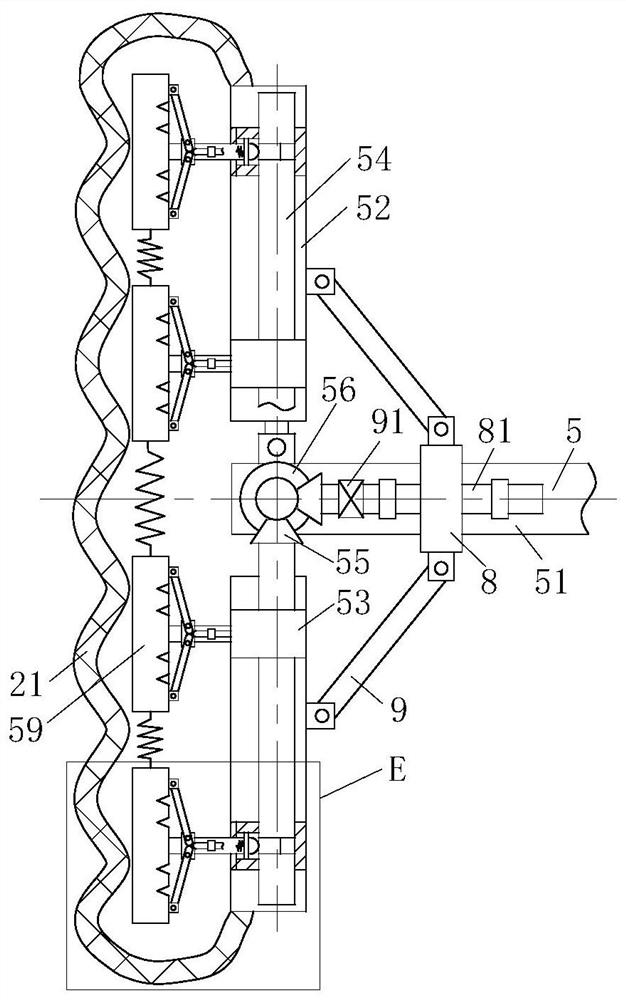

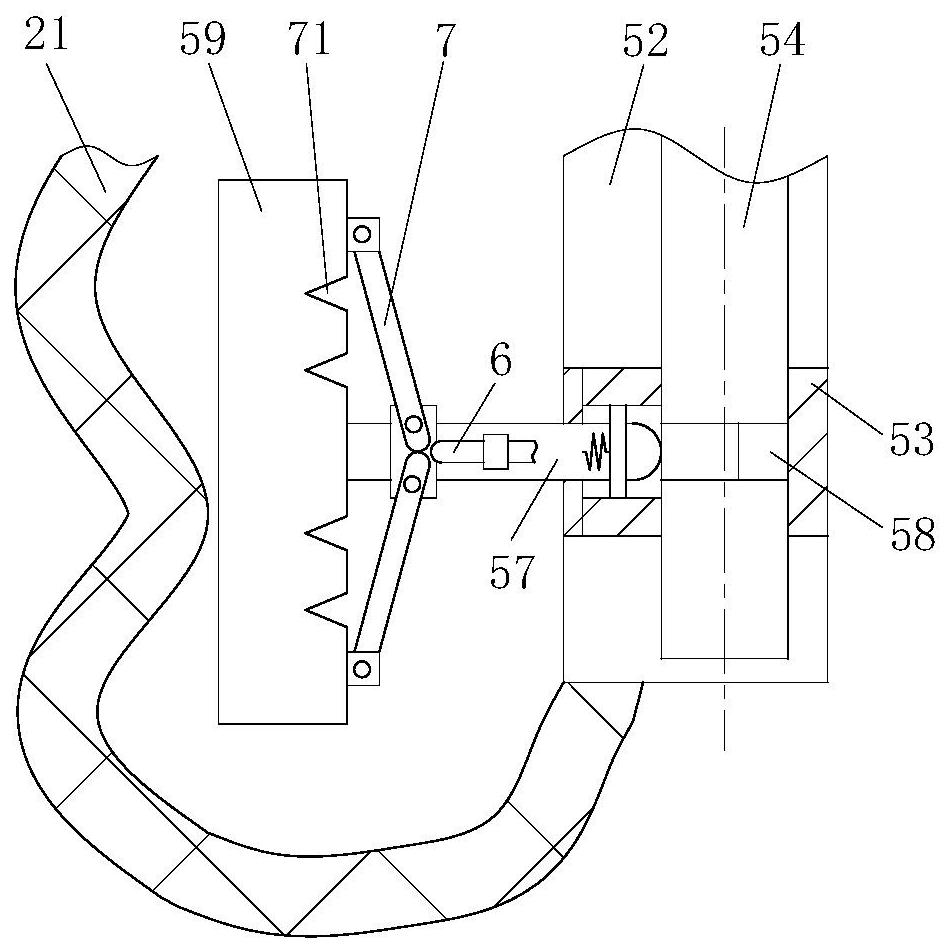

A profiling intelligent sweeping robot

InactiveCN108991995BImprove cleaning efficiencyArc smoothCarpet cleanersCleaning action controlElectric machineryControl arm

The invention relates to a profiling intelligent floor cleaning robot, and belongs to the technical field of floor cleaning devices. The robot comprises a robot body, visual sensors, road wheels, a controller, control arms and cleaning modules, the controller is arranged in the robot body, the visual sensors are arranged in the upper portion of the robot body, the road wheels are arranged in the bottom of the robot body, the control arms are arranged in the two sides of the robot body respectively, the end of each control arm is connected with the corresponding cleaning module, each cleaning module comprises a connection board, transverse plates, a support, crankshafts, a first bevel gear, a control motor, a driving bevel gear, a guide road, a shoe plate and an elastic sleeve, the transverse plates are arranged at the two sides of the end of the connection board respectively, and the support is arranged separately from the transverse plates; and the crankshafts are rotationally connected with the support, the guide rod is installed in one side of the support in a sliding way, the guide rod is arranged corresponding to an eccentric groove of the crankshaft, the end of the guide rodis fixedly connected with the shoe plate, the elastic sleeve wraps the shoe plate and the transverse plates, and the bottom of the elastic sleeve is provided with brushing hair. The profiling intelligent floor cleaning robot is especially suitable for cleaning the arc-shaped cleaning surface, and can improve the cleaning efficiency.

Owner:安徽普华灵动机器人科技有限公司

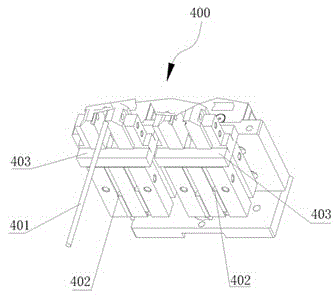

An electroplating brush pen

The invention belongs to the technical field of brush electroplating, and specifically relates to an electroplating brush pen. The electroplating brush pen comprises a rod body, a fixed plate, an electroplating module and a clamping module, wherein the electroplating module comprises installation plates, supporting plates, connecting plates and anode plates; two installation plates are parallellyarranged on the fixed plate; the end heads of the installation plates are fixedly connected with the supporting plates; a group of connecting plates are arranged between the two supporting plates; theconnecting plates are erected on the two installation plates; two adjacent connecting plates are connected through an arc-shaped spring; the arc-shaped springs are outwards arched; the connecting plates can slide on the surfaces of the installation plates; the connecting plates are fixedly connected with the anode plates; the anode plates are provided with hair bundles; the clamping module is arranged at the side edge of the electroplating module; the clamping module is used for regulating the space between the two connecting plates and enabling the group of connecting plates to form an arc-shaped surface. The electroplating brush pen disclosed by the invention is suitable for electroplating operation of an arc-shaped annular groove and an arc-shaped groove, and is capable of increasing the efficiency of the electroplating operation of the arc-shaped annular groove and the arc-shaped groove and ensuring the thickness uniformity of an electroplating layer.

Owner:嘉兴市金鹭喷织有限公司

A damage repair method for shaft parts

ActiveCN108866589BImprove the efficiency of electroplating operationsUniform thicknessElectrolysis componentsMechanical componentsEngineering

The invention belongs to the technical field of mechanical part repair, and particularly relates to a shaft part damage repair method. According to the method, an electro brush-plating plating pen isused, wherein the electro brush-plating plating pen comprises a rod, a fixing board, an electroplating module and a clamping module; the electroplating module comprises installation boards, supportingboards, connected boards and positive boards; the two installation boards are arranged on the fixing board in parallel; the supporting boards are fixedly connected with end sockets of the installation boards; one set of connected boards are arranged between the two supporting boards, each two adjacent connected boards are connected through arc springs, the arc springs hog toward the outer side, and the connected boards can slide on the surfaces of the installation boards; the positive boards are fixedly connected with the upper parts of the connected boards; hair bundles are arranged on the positive boards; the clamping module is installed on the side edge of the electroplating module, and the clamping module is used for adjusting an interval between each two connected boards and making one set of connected boards form an arc surface. The shaft part damage repair method is suitable for electroplating work of shafts provided with arc ring grooves, and the electroplating work efficiencycan be improved.

Owner:宁波致泰精密轴业有限公司

Electroplating brush pen

The invention belongs to the technical field of brush electroplating, and specifically relates to an electroplating brush pen. The electroplating brush pen comprises a rod body, a fixed plate, an electroplating module and a clamping module, wherein the electroplating module comprises installation plates, supporting plates, connecting plates and anode plates; two installation plates are parallellyarranged on the fixed plate; the end heads of the installation plates are fixedly connected with the supporting plates; a group of connecting plates are arranged between the two supporting plates; theconnecting plates are erected on the two installation plates; two adjacent connecting plates are connected through an arc-shaped spring; the arc-shaped springs are outwards arched; the connecting plates can slide on the surfaces of the installation plates; the connecting plates are fixedly connected with the anode plates; the anode plates are provided with hair bundles; the clamping module is arranged at the side edge of the electroplating module; the clamping module is used for regulating the space between the two connecting plates and enabling the group of connecting plates to form an arc-shaped surface. The electroplating brush pen disclosed by the invention is suitable for electroplating operation of an arc-shaped annular groove and an arc-shaped groove, and is capable of increasing the efficiency of the electroplating operation of the arc-shaped annular groove and the arc-shaped groove and ensuring the thickness uniformity of an electroplating layer.

Owner:嘉兴市金鹭喷织有限公司

One-time molding device for metal reeds used in plug-in boards

The invention discloses a metal reed one-time forming device used for a patch panel. The metal reed one-time forming device is characterized by comprising a fixed base plate which is horizontally arranged, a long-strip-shaped sliding transverse strip is arranged on the fixed base plate, a slidable cylinder base is arranged on the sliding transverse strip, a detachable double-head cylinder is arranged on the cylinder base, a pair of detachable side position supports are arranged at the heads of the double-head cylinder, and forming chucks are arranged on the heads of the side position supports respectively. After the double-head cylinder is started, the pair of side position supports synchronously move outwards, the forming chucks expand outwards at the same time, forming mold plates on the heads of the forming chucks directly act on a copper metal reed, and therefore the metal reed can be rapidly formed, forming is rapid, cambered surfaces are smooth, the electrical quality of the patch panel is greatly improved, and practicability is high.

Owner:重庆博视知识产权服务有限公司

A manufacturing process of an air filter intake pipe

InactiveCN103541840BFlat surfaceArc smoothCombustion-air/fuel-air treatmentMachines/enginesManufacturing technologyEngineering

The invention belongs to the field of diesel engine equipment and particularly relates to an air inlet tube for an air cleaner and a manufacturing technology for the air inlet tube. The air inlet tube comprises an air inlet elbow and a casing tube. The casing tube is arranged at an air inlet elbow and air cleaner connection end, the casing tube is integrated with the air inlet elbow, and the casing tube is a stamping tension portion of the air inlet elbow. The air inlet tube is smooth and flat in surface, smooth in arc, attractive and elegant, simple in production technology, capable of reducing the production cost and improving the work efficiency, convenient to mount and beneficial to environmental protection.

Owner:湖北省红安县滤通机械制品厂

A shoe tongue manufacturing process

ActiveCN107048595BArc smoothStable and controllable qualityLeather sewingUpperEngineeringSewing machine

The invention discloses a shoe tongue making process. The shoe tongue making process comprises the steps of forming a wall groove in the thickness face of the top end of foam, wherein the distance between the wall groove and the outer surface of the foam is 2-3 mm; overlaying a tongue face with a tongue lining, and processing the top end of the tongue lining and the top end of the tongue face to form a joint portion; sewing the tongue lining and the tongue face together along the lower side of the joint portion; spraying glue onto the inner surface of the tongue face for enabling the tongue face to be attached to the foam, wherein the top end of the foam is located below a sewing thread by a distance of 2-3 mm; overturning the tongue lining to wrap the foam, guiding the joint portion into the wall groove by means of an auxiliary tool during overturning, and making the arc at the overturning position between the tongue lining and the top end of the foam smooth by means of an auxiliary tool; opening the lower end of the tongue lining, spraying glue onto the inner surface of the tongue lining and / or the back side, facing the tongue lining, of the foam, and laminating the tongue lining and the foam after glue spraying; and conducting sewing with a sewing machine along the lower-end arcs of the tongue lining and the tongue face, so as to form a closed sewn structure. By the adoption of the shoe tongue making process, the arc of the upper end of a shoe tongue can be smooth, and quality is stable and controllable due to the adoption of standard operation.

Owner:肯拓(泉州)户外用品有限公司

A nickel-based electrode for ultra-low temperature steel and preparation method thereof

ActiveCN105081613BImprove plasticityImprove toughnessWelding/cutting media/materialsSoldering mediaMass ratioHeat resistance

The invention belongs to the technical field of welding materials and particularly relates to a nickel-based welding rod used for ultralow-temperature steel and a preparation method of the nickel-based welding rod. The welding rod comprises a welding core wire, chemical powder and an adhesion agent; the mass ratio between the chemical powder and the welding rod is 25-27:100, and the mass ratio between the chemical powder and the adhesion agent is 100:25-30. When the welding rod prepared through the preparation method is welded, the electric arc is stable, the splatter is slight, the sediment separation is good, the form is beautiful, the welding can be conducted through alternate currents or direct currents, and the all-position operation performance is good. The nickel-based welding rod is mainly used for the nickel-based alloy welding with heat resistance and corrosion resistance requirements, and the nickel-based welding rod can also be used for the welding of some alloy hard to weld and dissimilar steel.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com